Preparing method for aluminum surface super-hydrophobic coating with micro-nano composite structure

A technology of micro-nano composite structure and super-hydrophobic coating, which is applied in the direction of surface-coating liquid devices, coatings, special surfaces, etc., which can solve the problem of affecting the heating effect of air conditioners, reducing the heat exchange efficiency of condensers, and ventilation of heat sinks Channel blockage and other problems, to achieve the effect of excellent hydrophobicity, anti-icing performance, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0029] 1. Ultrasonic clean the aluminum sheet with acetone and toluene for 10 minutes, then wash it with distilled water to remove the oil on the surface of the aluminum sheet, and dry it in an oven at 100°C.

[0030] 2. Put the clean aluminum sheet into 3mol / L hydrochloric acid solution and etch it for 20min at room temperature, then take out the aluminum sheet and wash it with a large amount of distilled water to stop the reaction. Dry in an oven after ultrasonic cleaning.

[0031] 3. Immerse the aluminum sheet obtained in step 2 into 15nm, 1wt% nano-SiO 2 in the ethanol solution for 2 minutes, take it out and react in the muffle furnace at 300°C for 3 hours, and the nano-SiO 2 grafted onto aluminum surfaces.

[0032] 4. Spray fluorine-silicon modified polyester resin on the aluminum sheet in step 3, and cure at 150°C for 3 hours to obtain a super-hydrophobic coating.

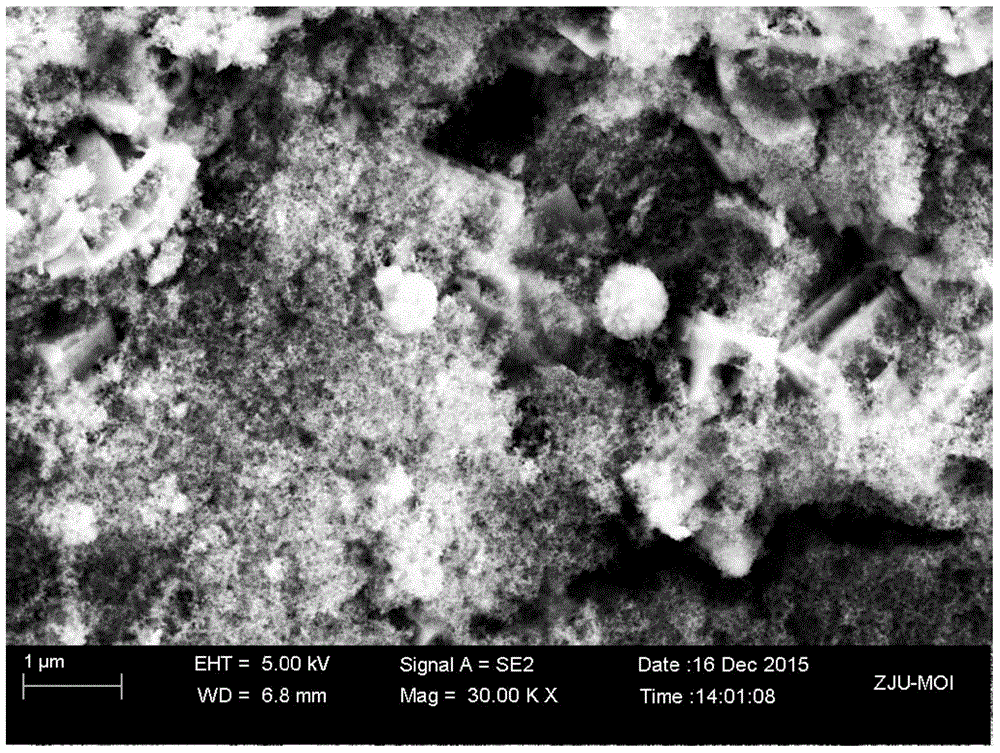

[0033] The obtained superhydrophobic aluminum surface was scanned by SEM as figure 1 As shown, the sur...

example 2

[0035] 1. Ultrasonic clean the aluminum sheet with acetone and toluene for 10 minutes, then wash it with distilled water to remove the oil on the surface of the aluminum sheet, and dry it in an oven at 100°C.

[0036] 2. Put the clean aluminum sheet into 3mol / L hydrochloric acid solution and etch it for 20min at room temperature, then take out the aluminum sheet and wash it with a large amount of distilled water to stop the reaction. Dry in an oven after ultrasonic cleaning.

[0037] 3. Spray fluorine-silicon modified polyester resin on the aluminum sheet in step 3, and cure at 150° C. for 3 hours to obtain a super-hydrophobic coating.

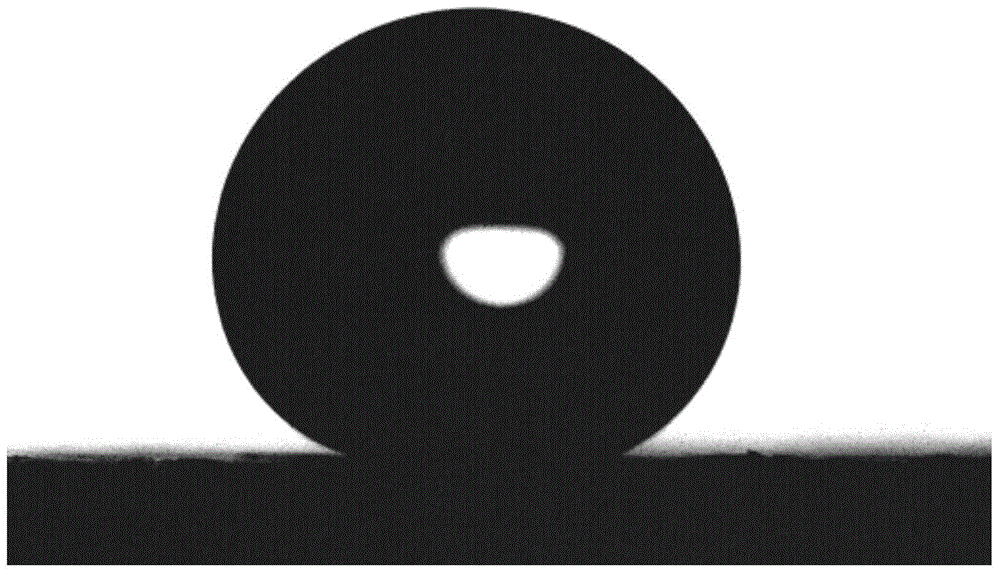

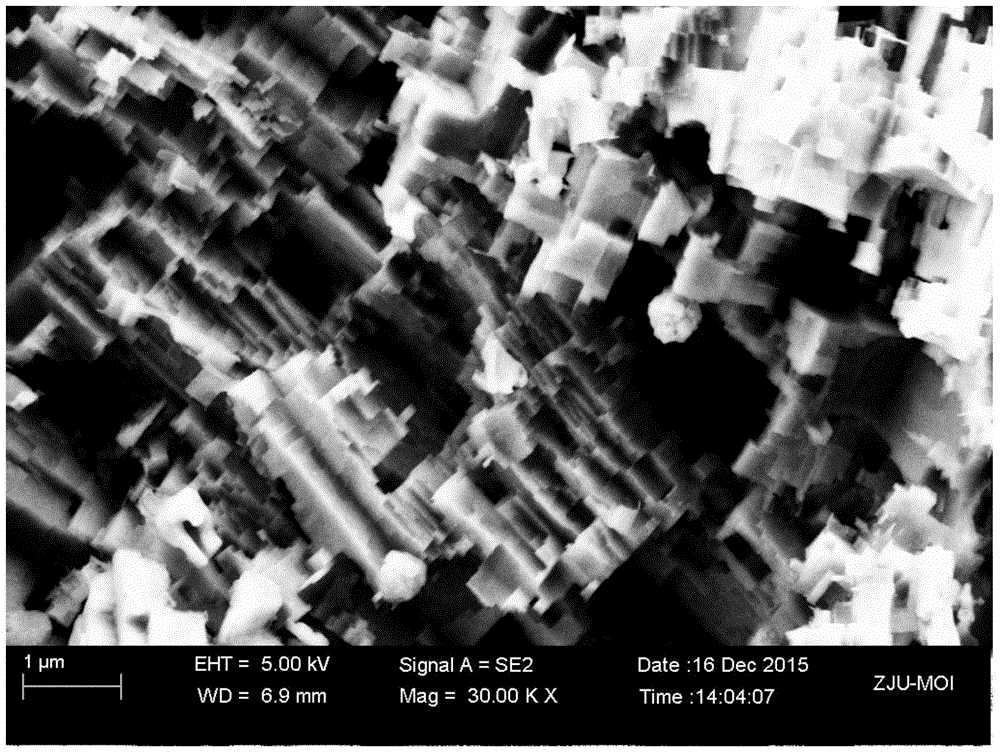

[0038] The obtained superhydrophobic aluminum surface was scanned by SEM as image 3 As shown, the surface structure consists of 1-2 μm step-like structures. It is subjected to a contact angle test, and an anti-frost and anti-icing test. The contact angle test was performed on it ( Figure 4 ), and the anti-frost and anti-icing test, the r...

example 3

[0040] 1. Ultrasonic clean the aluminum sheet with acetone and toluene for 10 minutes, then wash it with distilled water to remove the oil on the surface of the aluminum sheet, and dry it in an oven at 100°C.

[0041] 2. Put the clean aluminum sheet into a mixed solution of 0.5 mol / L hydrochloric acid and 0.5 mol / L oxalic acid solution, etch at room temperature for 15 hours, then take out the aluminum sheet and wash it with a large amount of distilled water to stop the reaction. Dry in an oven after ultrasonic cleaning.

[0042] 3. Immerse the aluminum sheet obtained in step 2 into 15nm, 0.5wt% nano-SiO 2 in n-hexane solution for 10min, take it out and react in muffle furnace at 300°C for 6h, the nano-SiO 2 grafted onto aluminum surfaces.

[0043] 4. Spray fluorine-silicon modified polyester resin on the aluminum sheet in step 3, and cure at 150°C for 3 hours to obtain a super-hydrophobic coating.

[0044] The contact angle test and the anti-frost and anti-icing test were c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com