Patents

Literature

158results about How to "Good anti-icing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

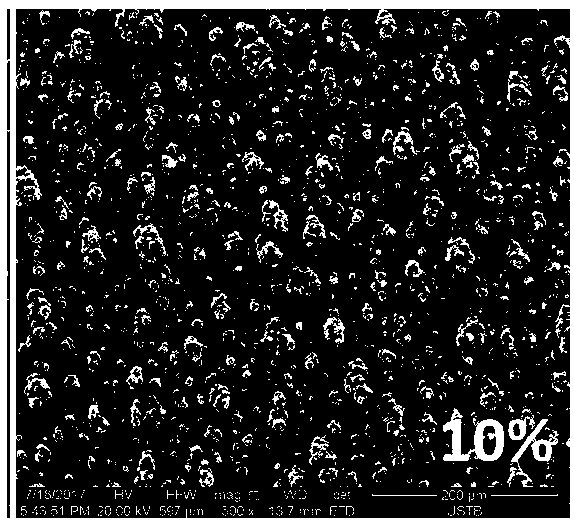

Super-hydrophobic ice-covering-proof coating having slowly-releasing function and preparation method thereof

ActiveCN102382536AExtensive sources of raw materialsWide variety of sourcesCoatingsNanoparticleWater contact

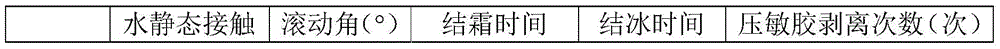

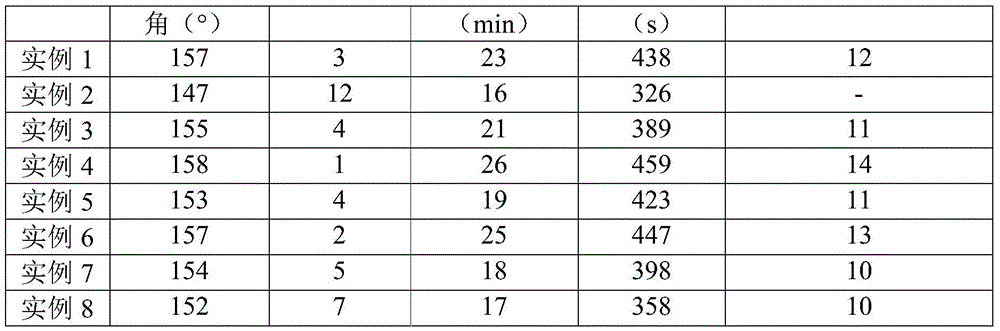

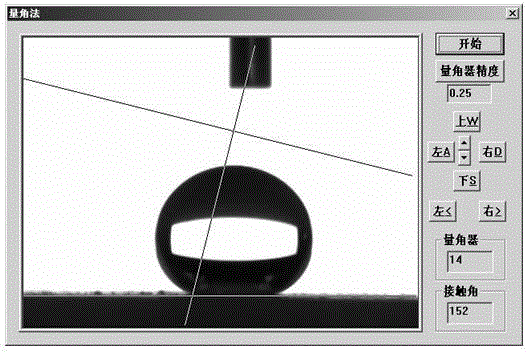

The invention discloses preparation of a super-hydrophobic ice-covering-proof coating having a slowly-releasing function. The ice-covering-proof coating consists of the following substances in parts by mass: 1.5-5 parts of inorganic hollow or porous nanoparticles for adsorbing small molecular anti-icing substances, 2-5 parts of fluorine-containing polymer and 1-15 parts of solvent. The super-hydrophobic ice-covering-proof coating having the slowly-releasing function can be obtained by uniformly mixing the three substances and coating the mixture onto the surface of a substrate. At the normal temperature, the water contact angle of the coating is greater than 150 degrees, and the rolling angle is smaller than 7 degrees. At 10 DEG C below zero, the low-temperature contact angle of water is greater than 140 degrees, and the rolling angle is smaller than 12 degrees. During testing of the ice cover at 10 DEG C below zero, the ice cover is lowered by over 70 percent, and is still higher than 50 percent after testing is performed circularly for ten times in comparison to a blank sample.

Owner:天津渤化讯创科技有限公司

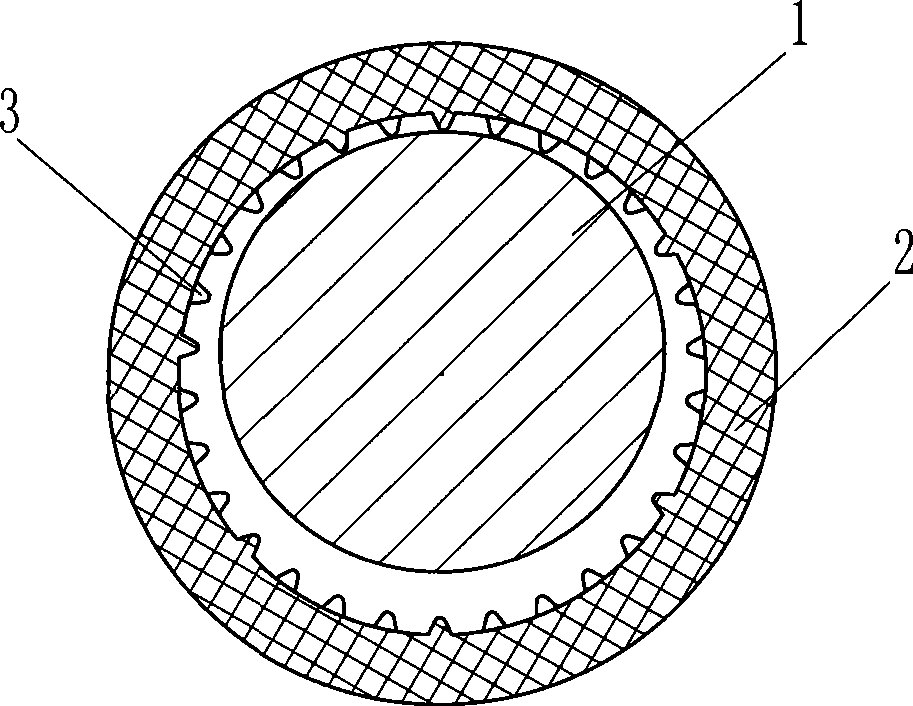

Polymer ice-coating-preventing coating containing modified nano particles and preparing method thereof

InactiveCN103483890ARaw materials are readily availableEasy to makePolyurea/polyurethane coatingsEpoxy resin coatingsPolymer scienceSilicone oil

The invention discloses a polymer ice-coating-preventing coating containing modified nano particles and a preparing method of the polymer ice-coating-preventing coating containing modified nano particles. The ice-coating-preventing coating comprises, by mass, 1-15% of silicone oil, 1-40% of modified nano particle with the particle diameter of 10-100nm, 15-75% of monomer or prepolymer used for bonding, 1-12% of hydrophobic resin, 1-30% of curing agent and 10-80% of thinning agent. The preparing method of the polymer ice-coating-preventing coating includes the steps that preparing of the modified nano particles is performed, preparing of the hydrophobic resin is performed, and the modified nano particles, the hydrophobic resin, the monomers or the prepolymers used for bonding, the curing agents, the thinning agent and silicone oil are evenly mixed to obtain the coating. The polymer ice-coating-preventing coating containing modified nano particles and the preparing method of the polymer ice-coating-preventing coating containing the modified nano particles have the advantages that raw materials for preparing the coating are easy to get, the process is simple, operation is convenient to carry out, a coating layer prepared by spraying the coating on a metal or glass substrate has a contact angle of 160 degrees in static water under a normal temperature and a low temperature, has a rolling angle of 4 degrees and has the good ice-coating-preventing effect.

Owner:XI AN JIAOTONG UNIV +1

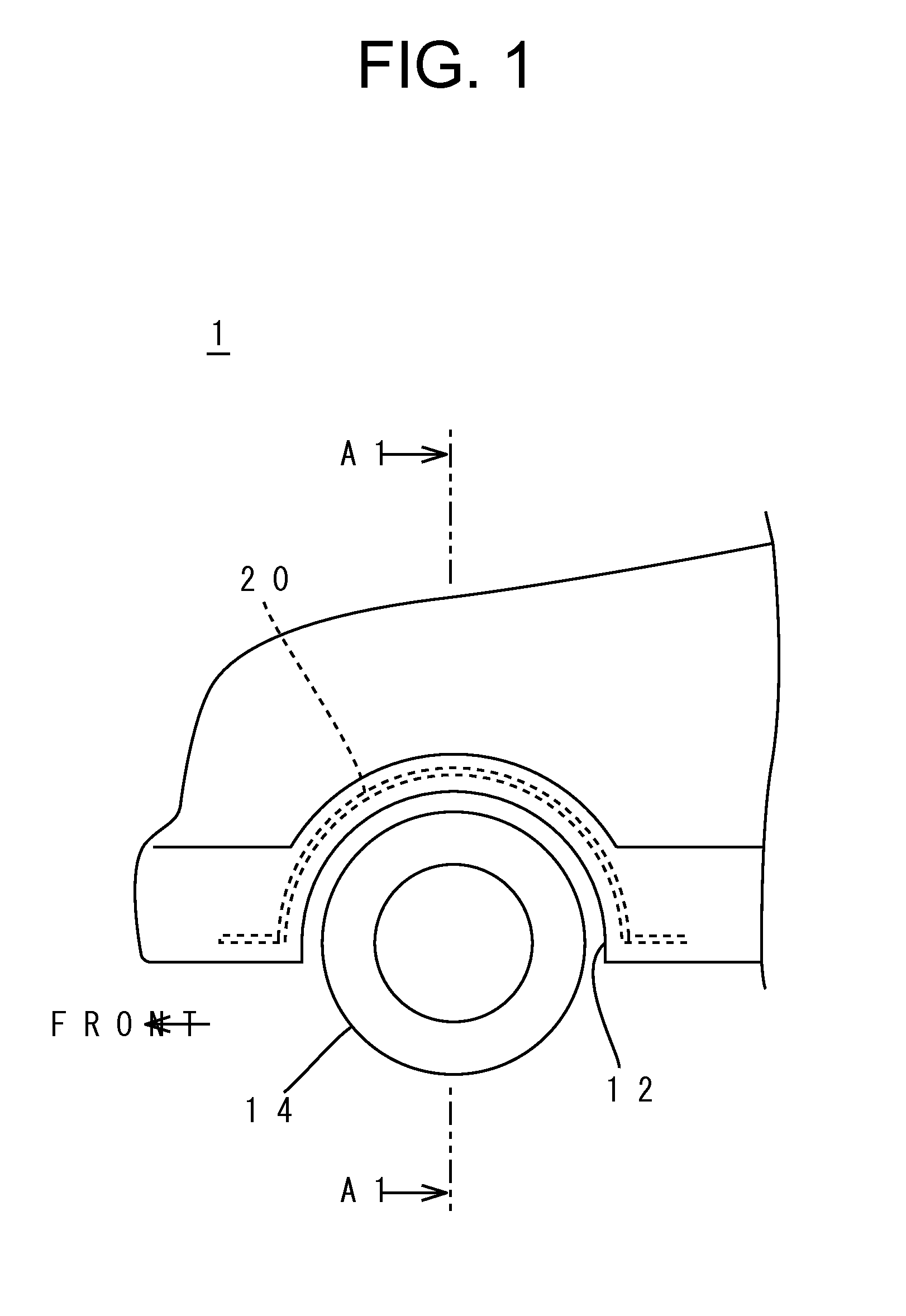

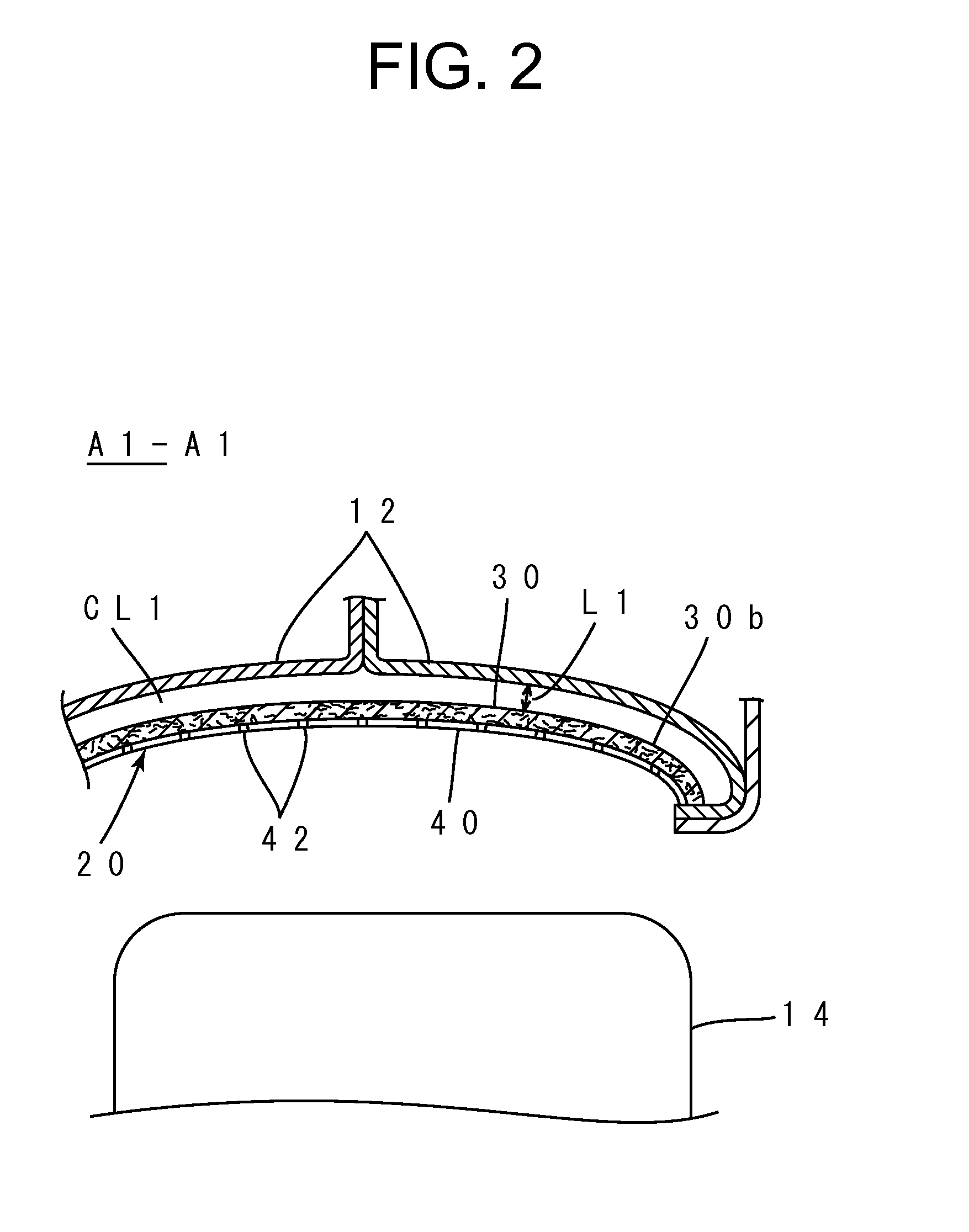

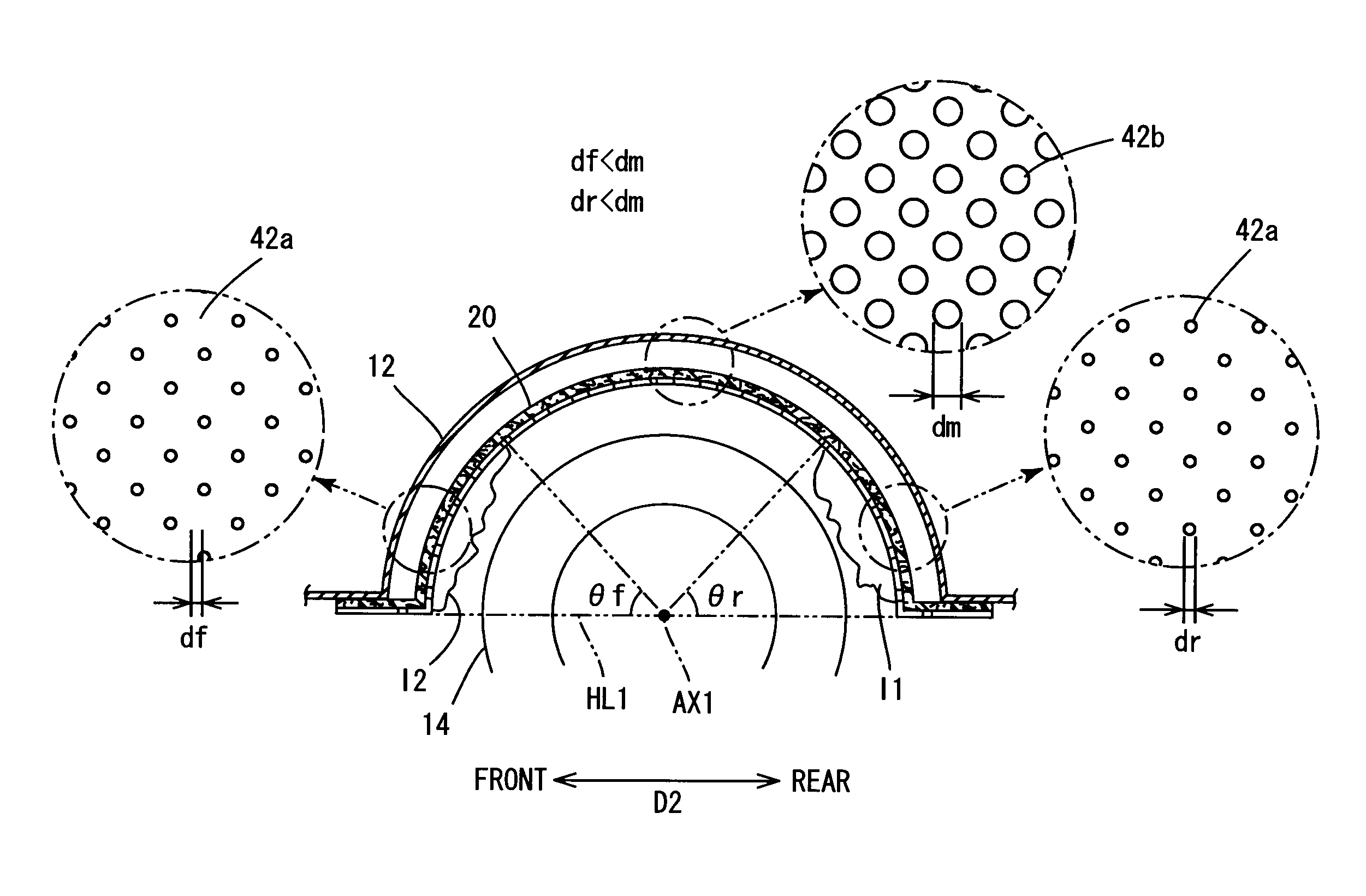

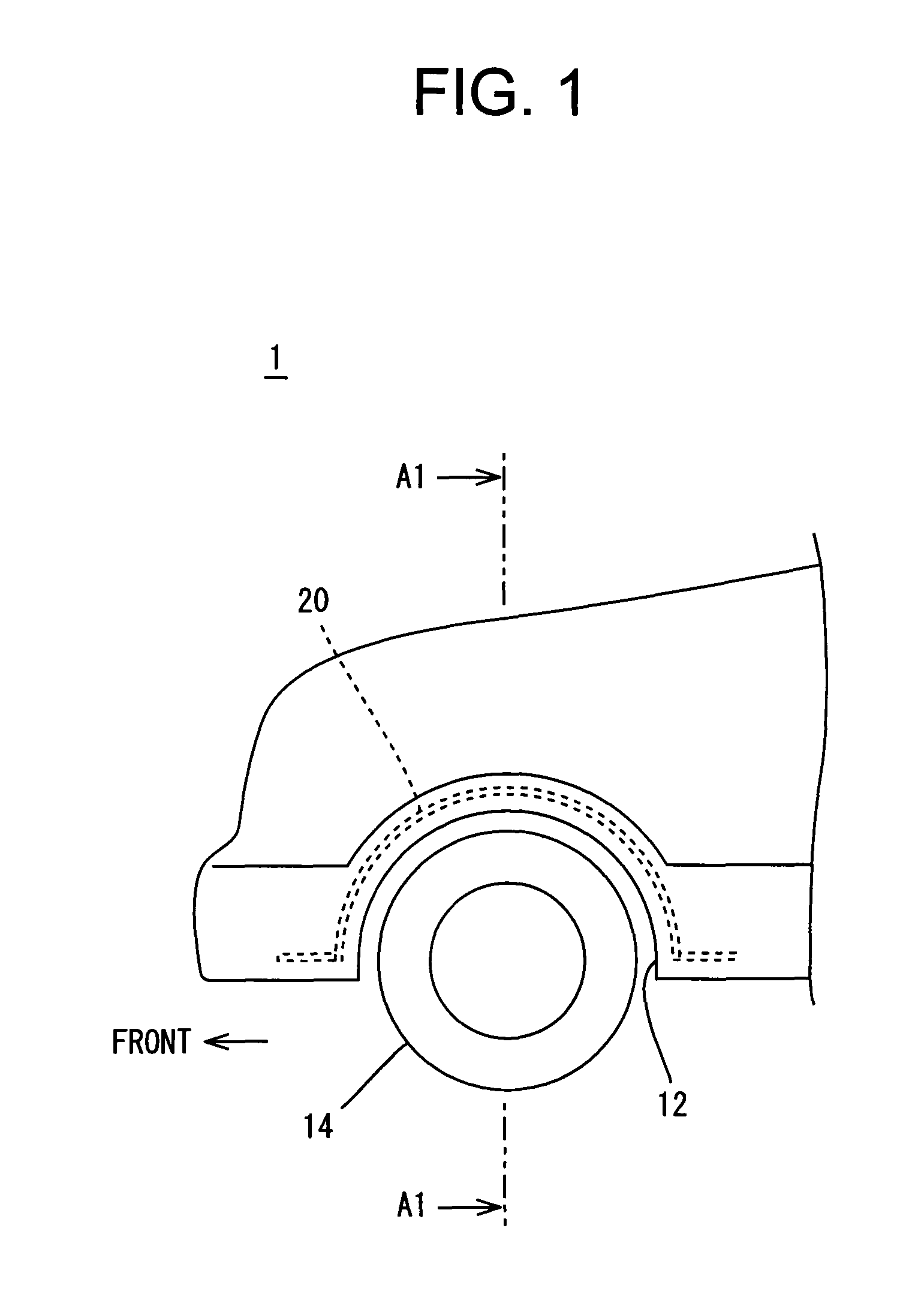

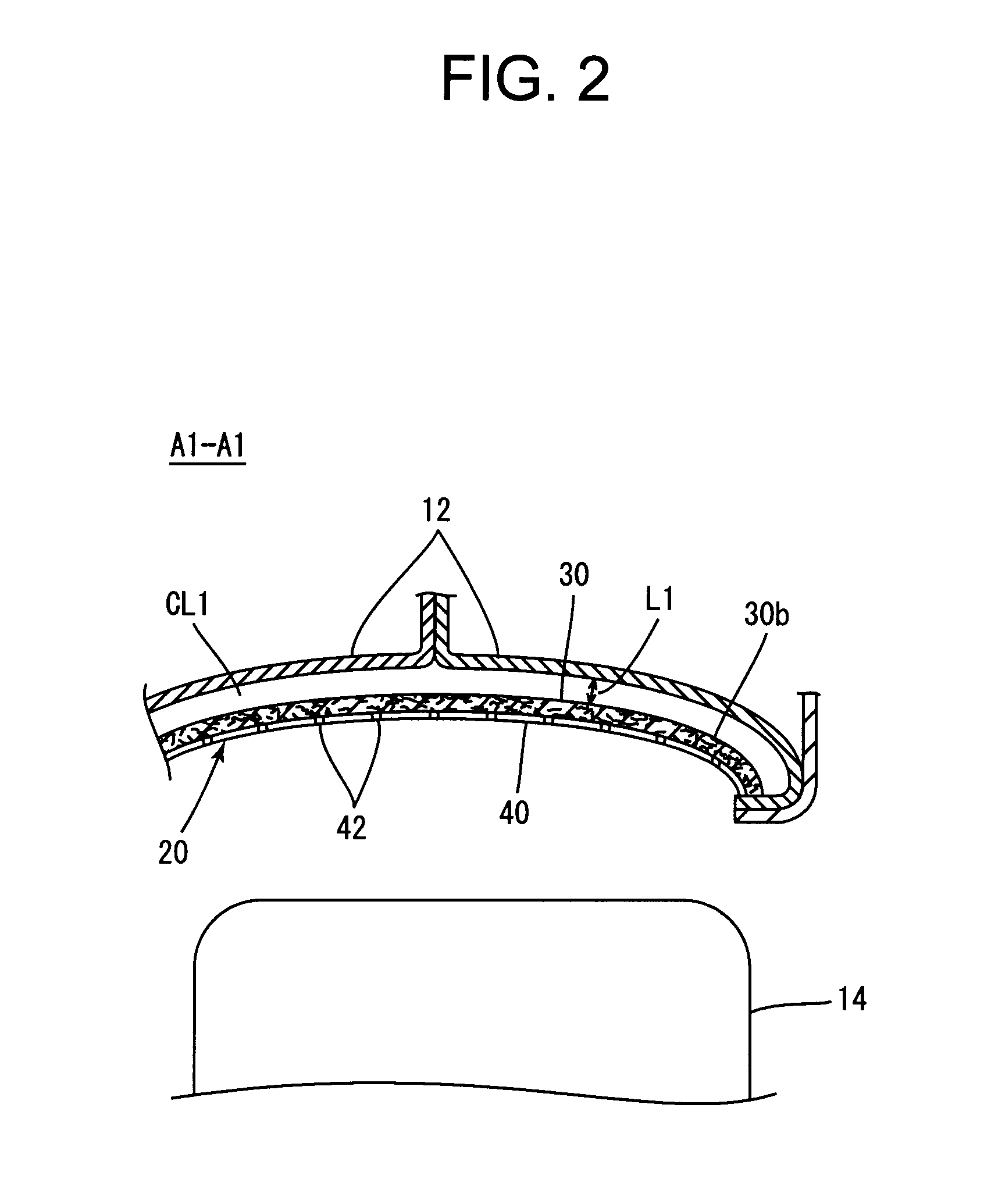

Fender liner and process for producing the same

InactiveUS20100078927A1Lower performance requirementsImprove antifouling performanceButtonsLamination ancillary operationsFiberEngineering

The present invention discloses a fender liner attached to a motor vehicle wheel house. The fender liner includes a breathable base material layer produced by forming a fiber assembly into a shape along the wheel house and a protective layer made of waterproof material. The protective layer is superimposed on a surface of the base material layer that is opposite to a side facing the wheel house. The protective layer is provided with a plurality of through-holes that allow air to flow through the protective layer to the surface of the base material layer on which the protective layer is superimposed.

Owner:HAYASHI TELEMPU CO LTD

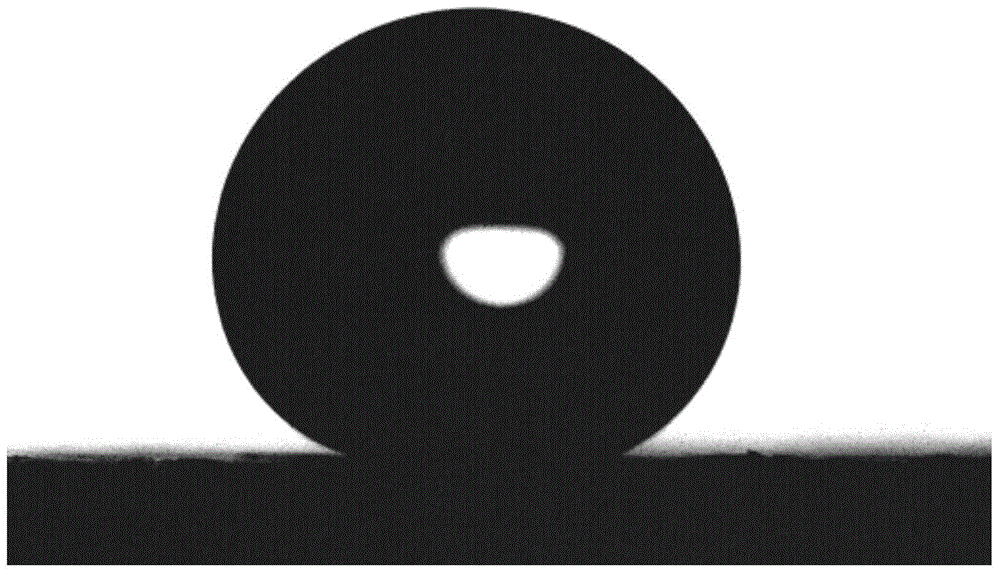

Preparation method of super-hydrophobic coating layer on aluminum surface

ActiveCN105521934AImprove hydrophobicityGood anti-fogPretreated surfacesLiquid/solution decomposition chemical coatingAcid etchingSilanes

The invention discloses a preparation method of a super-hydrophobic coating layer on an aluminum surface. The preparation method mainly comprises the following steps: (1) an aluminum piece is polished by an abrasive paper, is ultrasonically cleaned for 10 minutes by acetone and ethanol, is washed by distilled water to remove oil stains on the surface, and is dried in an oven; (2) the aluminum piece is dip in an acid etching agent for etching to obtain the aluminum surface with a micron rough structure; (3) the micron rough aluminum piece is dip in nanometer TiO2 particle solution, and is treated at high temperature to obtain the aluminum surface with a micron-nanometer composite rough structure; and (4) the aluminum surface with the micron-nanometer composite rough structure is treated by fluorine silane with low surface energy to obtain the aluminum surface with super-hydrophobic performance. The prepared super-hydrophobic aluminum piece is excellent in self-cleaning performance, fog resistance and ice covering resistance, and can be applied to field of ice covering prevention.

Owner:ZHEJIANG UNIV

Water-borne perfluoroalkyl fluorocarbon emulsion, water-borne cable anti-icing paint containing same and preparation method thereof

ActiveCN101798366AImprove stabilityIncrease crosslink densityAntifouling/underwater paintsPaints with biocidesCelluloseEmulsifying wax

The invention relates to a water-borne cable anti-icing paint containing water-borne perfluoroalkyl fluorocarbon emulsion, which comprises the following raw materials in percentage by weight: 58 to 62 percent of aqueous perfluoroalkyl fluorocarbon emulsion, 1.5 to 2.5 percent of water-borne polytetrafluoroethylene emulsifying wax, 15 to 20 percent of water-borne color paste, 0.1 to 0.5 percent of pH regulator, 1 to 2 percent of amino resin cross-linking agent or water-borne polyurethane cross-linking agent, 0.1 to 0.2 percent of antiseptic preservative, 1 to 1.2 percent of cellulose and the balance of deionized water, wherein the water-borne color paste is the mixture of the water-borne color paste with one color or the water-borne color paste with more than two colors. The water-borne cable anti-icing paint of the invention is big in water repellent angle, low in surface energy, excellent in water repellent and oil repellent properties, safe and environment-friendly, can firmly adhere to the surface of a cable in a low temperature and cold environment and is obvious in anti-icing function.

Owner:CHANGZHOU GUANGHUI CHEM

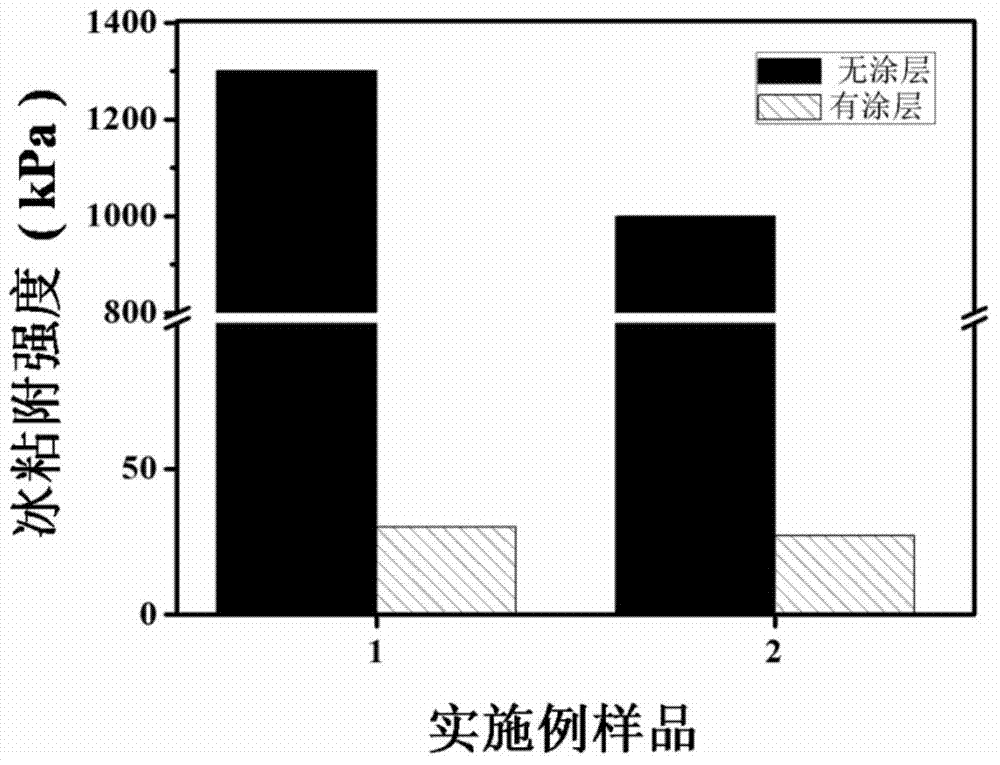

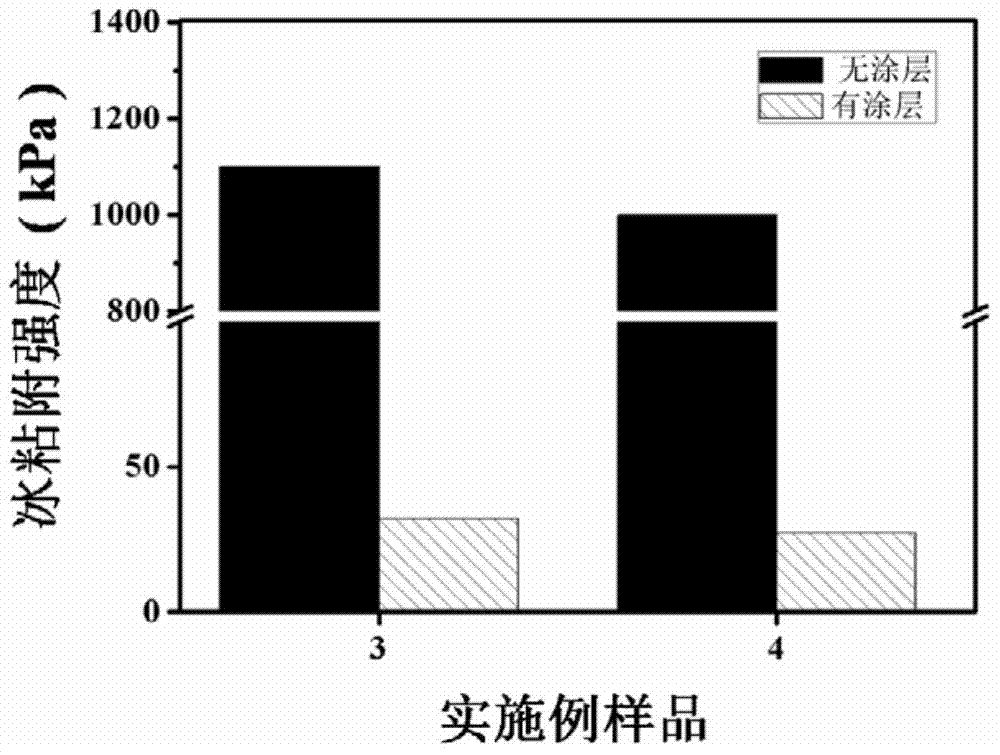

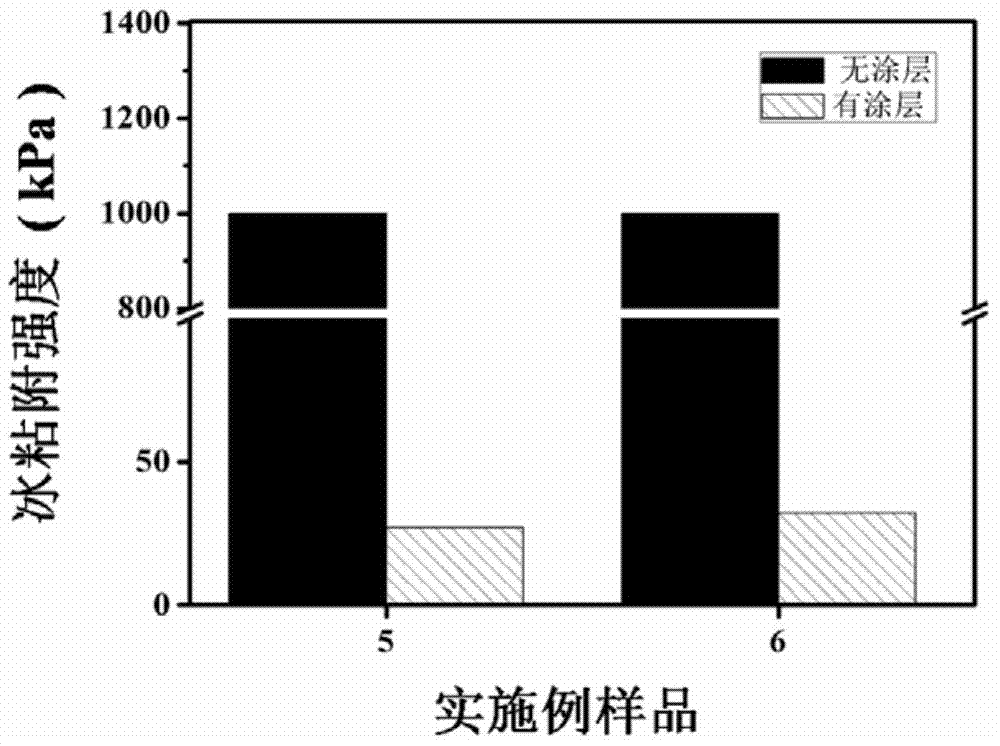

Two-component waterborne wear-resisting and low-ice-adhesion anti-icing coating and coating layer, and preparation methods and applications thereof

ActiveCN104762008ASimple preparation processEasy constructionOther chemical processesPolyurea/polyurethane coatingsCoated surfaceWear resistance

The invention provides preparation methods of a two-component waterborne wear-resisting and low-ice-adhesion anti-icing coating and a coating layer thereof. The two-component waterborne anti-icing coating is composed of a component A containing a core-shell structure polymer emulsion and inorganic nanoparticles and a component B containing a curing agent. An outer layer of the core-shell structure polymer emulsion in the component A of the anti-icing coating is a hydrophilic shell layer, so that polymer emulsion particles can be stably dispersed in water, and the advantages of being green and environmentally friendly are provided. The inorganic nano particles in the component A are rigid particles, can improve the mechanical properties of the anti-icing coating layer, endow the coating layer with excellent wear resistance and prolong the service life of the coating layer. After the coating is cured into a film, the hydrophilic shell layer of the polymer emulsion particles can absorb moisture, and thus a water lubricating layer is formed on the surface of the coating layer; when the coating layer surface is iced, due to the existence of the water lubricating layer, the acting force between ice and the coating layer is decreased, besides, the substrate surface roughness is also reduced, and the contact area between the ice and the substrate is decreased.

Owner:CHINA SCI INTELFUSION INT TECH (BEIJING) CO LTD

Anti-icing coating for ultra-high voltage power transmission line and preparation method thereof

The invention discloses an anti-icing coating for an ultra-high voltage power transmission line. The coating includes the following raw materials by weight: 50-60 parts of silicon fluorine resin, 6-10 parts of diamond like carbon, 2-3 parts of carbon nanotube, 5-8 parts of nano TiO2, 8-12 parts of nano SiO2, 0.3-1 part of a dispersant, 0.5-1 part of an antifoaming agent, 0.3-1 part of a leveling agent, 1-3 parts of an anticorrosive and bactericidal agent, and 20-30 parts of a solvent. The anti-icing coating for ultra-high voltage power transmission line has contact angle with water reaching 135-165 DEG C, also has good heating effect, the average temperature rise of 9.5-16 DEG C, very high hardness, excellent adhesion performance, acid and alkali resistance and wear resistance.

Owner:STATE GRID HENAN ELECTRIC ZHOUKOU POWER SUPPLY

Super-hydrophobic and anti-icing transparent coating and preparation method thereof

The invention discloses a super-hydrophobic and anti-icing transparent coating. The super-hydrophobic and anti-icing transparent coating is prepared by mixing super-hydrophobic inorganic nanoparticles, fluoroalkyl silane, fluorocarbon varnish, curing agents and organic diluents. A preparation method of the super-hydrophobic and anti-icing transparent coating comprises the following steps: adding a silane coupling agent into an organic solvent, uniformly mixing and then adding deionized water, uniformly dispersing the inorganic nanoparticles into the organic solvent containing the silane coupling agent through ultrasonic wave or a mechanical stirring method and dispersing for 2-4 hours; carrying out suction filtration, washing, drying, grinding via a mortar to obtain super-hydrophobic and anti-icing inorganic nanoparticle fillers; adding transparent fluorocarbon varnish into corresponding mass of fluoroalkyl silane, uniformly mixing at normal temperature, then uniformly dispersing the prepared super-hydrophobic and anti-icing inorganic nanoparticle fillers into the commercial fluorocarbon varnish by mechanically stirring, finally uniformly mixing the composition with the curing agents and the diluents, wherein the curing agents account for 0-10% of the total mass, and the diluents account for 8-18% of the total mass; and preparing the super-hydrophobic and anti-icing transparent coating. The coating has the advantages of strong binding force, super-hydrophobic property, anti-icing property and self-cleaning property.

Owner:LIAONING NORMAL UNIVERSITY

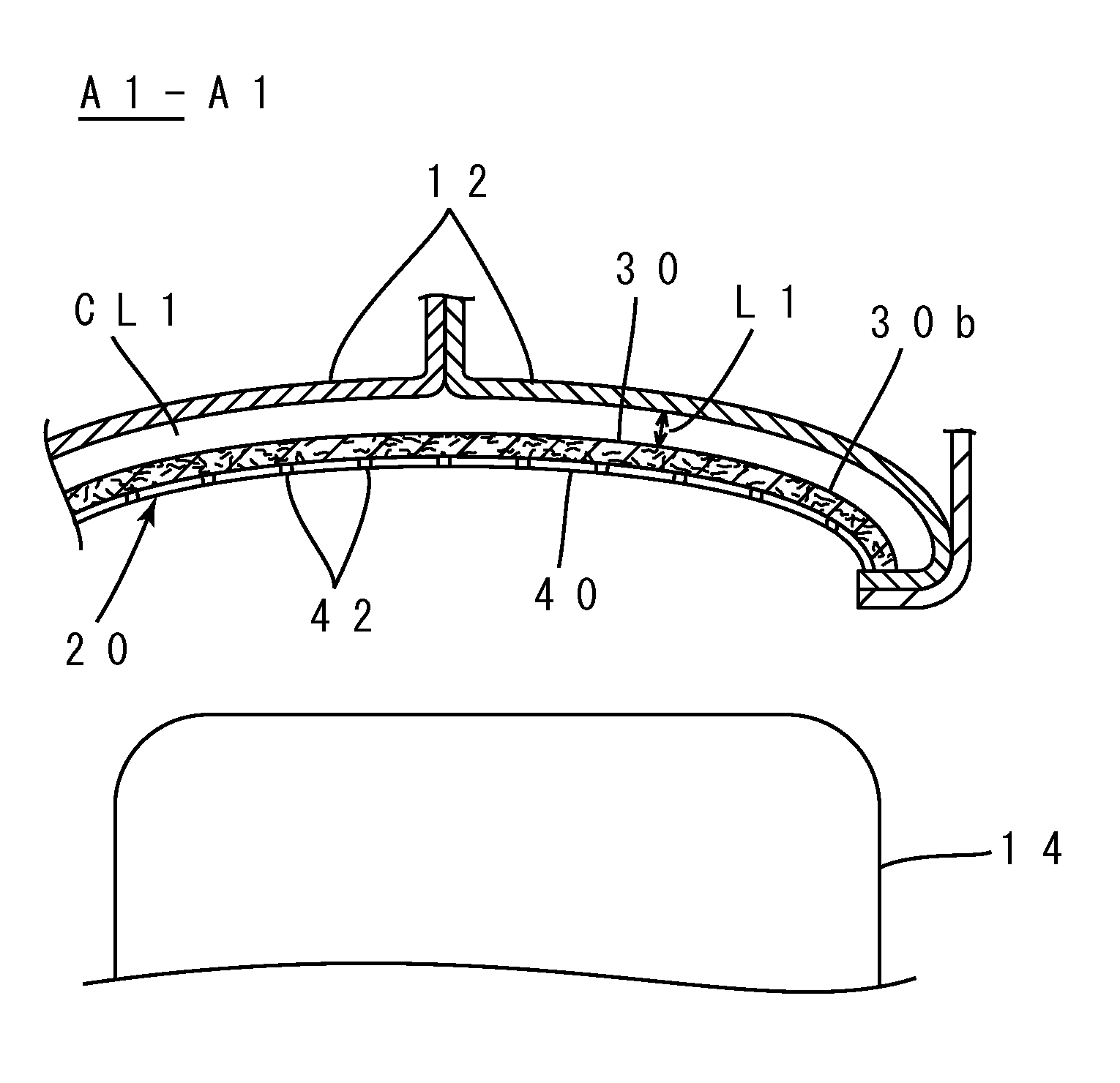

Fender liner and process for producing the same

InactiveUS8167335B2Lower performance requirementsImprove antifouling performanceButtonsLamination ancillary operationsFiberEngineering

The present invention discloses a fender liner attached to a motor vehicle wheel house. The fender liner includes a breathable base material layer produced by forming a fiber assembly into a shape along the wheel house and a protective layer made of waterproof material. The protective layer is superimposed on a surface of the base material layer that is opposite to a side facing the wheel house. The protective layer is provided with a plurality of through-holes that allow air to flow through the protective layer to the surface of the base material layer on which the protective layer is superimposed.

Owner:HAYASHI TELEMPU CO LTD

Polymer-thickened non-Newton aircraft deicing/anti-icing liquid

InactiveCN101831275ANo refreezingAvoid refreezingOther chemical processesTime rangeApparent viscosity

The invention provides a polymer-thickened non-Newton aircraft deicing / anti-icing liquid, comprising the following components based on weight percentages: 45%-65% of freezing point depressant, 0.05%-5% of thickening agent, 0.05%-5% of neutralizing agent, 0.05%-5% of viscosity control agent, 0.05%-5% of corrosion inhibitor, 0.05%-5% of surfactant, and the balance liquid. The preparation method of the invention comprises: sequentially adding the freezing point depressant, the thickening agent, the neutralizing agent, the viscosity control agent, the corrosion inhibitor and the surfactant to solvent, respectively stirring and dissolving to obtain the product. The polymer-thickened non-Newton aircraft deicing / anti-icing liquid has the characteristics of high apparent viscosity, slowly reduced viscosity after shearing treatment, excellent anti-icing property and good dynamic performance. After anti-icing treatment via the product, the outer surface of an aircraft can not be refrozen and frosted within a very long time range, thus effectively avoiding a refreezing phenomenon of the aircraft during the delay period in an airport, and guaranteeing normal flight of the aircraft under an ice and snow weather.

Owner:SHANXI GAOKE PHYSICAL & CHEM TECH

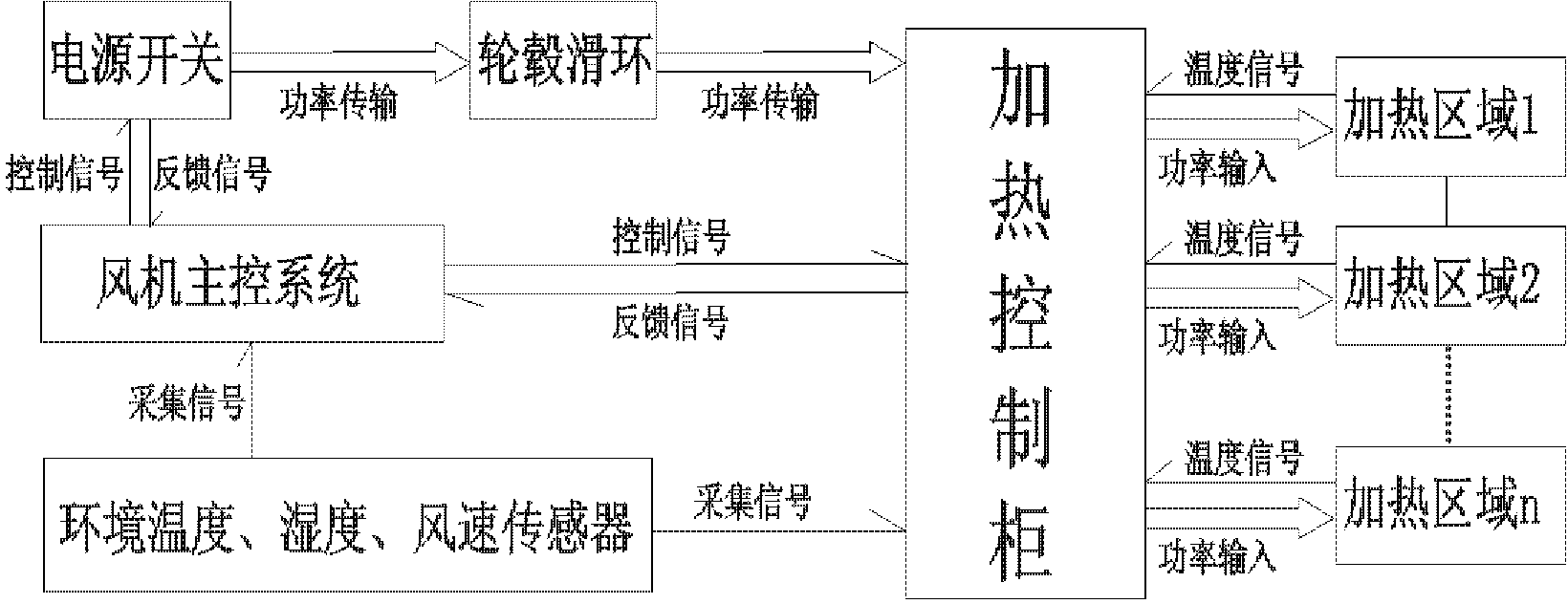

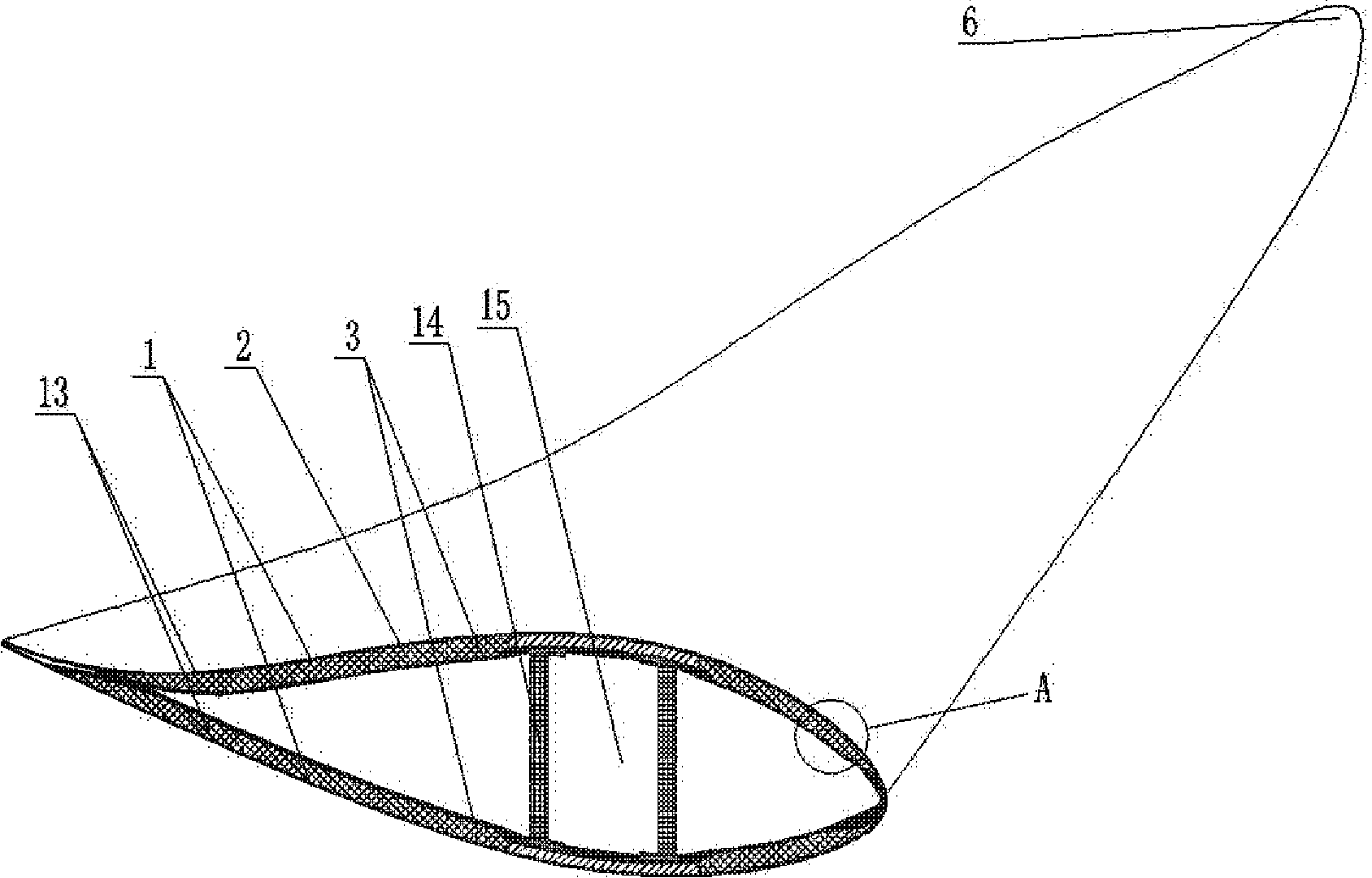

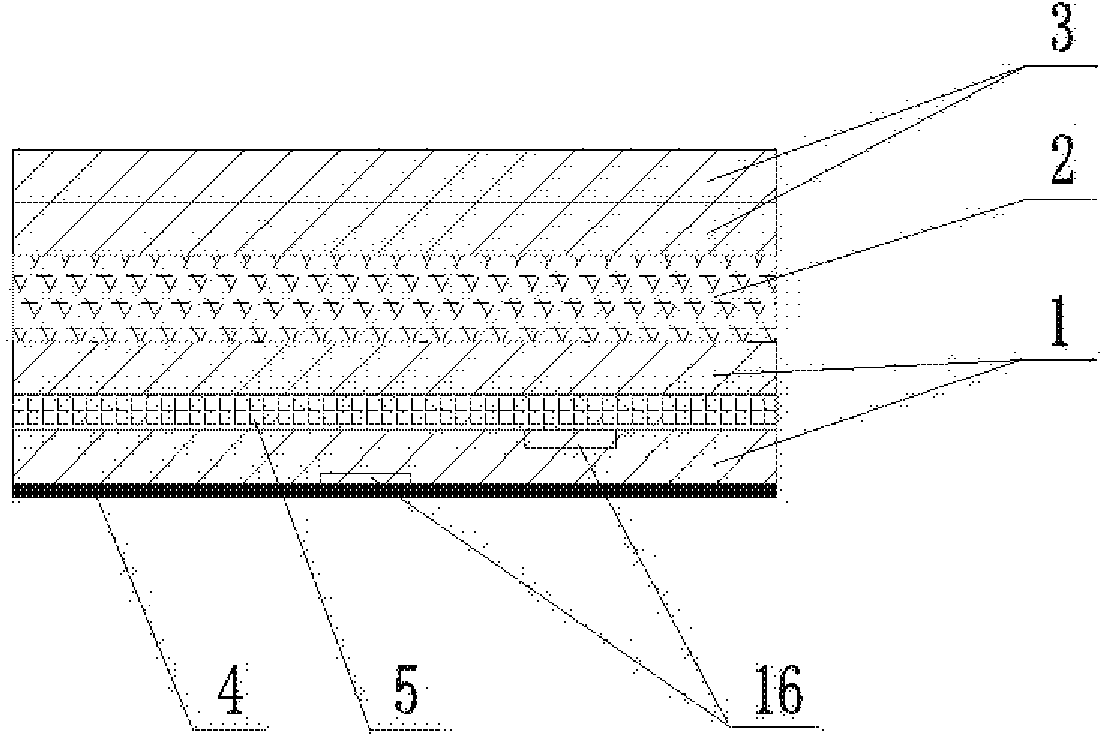

Anti-icing method of carbon crystal and wind power generator anti-icing system employing method

InactiveCN103291560AOptimize process layoutAnti-corrosionWind motor controlMachines/enginesManufacturing technologyClosed loop

The invention relates to an anti-icing method of a carbon crystal and a wind power generator anti-icing system employing the method. The method comprises the steps of printing the nanosized conductive carbon crystal on a carrier surface, preparing a thinner carbon crystal electric hot plate with two electrodes by a curing technology and a hot-pressing technology, taking one out of layers forming a blade as a heating layer, dividing the heating layer into a plurality of heating zones, arranging on-line temperature monitoring in each heating zone, performing temperature rising control with power units in corresponding zones in a heating control cabinet, and keeping the surface temperature of zones to be heated higher than and approximate to 0 DEG C. The anti-icing control system controls the heating zones in a simultaneous or alternant operation mode, and conducts on-line automatic ice prevention or ice melting. According to the method and the wind power generator anti-icing system, since the carbon crystal electric hot plate is adopted as an electric heating material of an anti-icing blade, the manufacturing technology is simple, and the heating is uniform and controllable; and since the surface adopts an on-line temperature monitoring closed-loop control mode, the anti-icing operation is stable, safe, and energy-saving.

Owner:XEMC NEW ENERGY

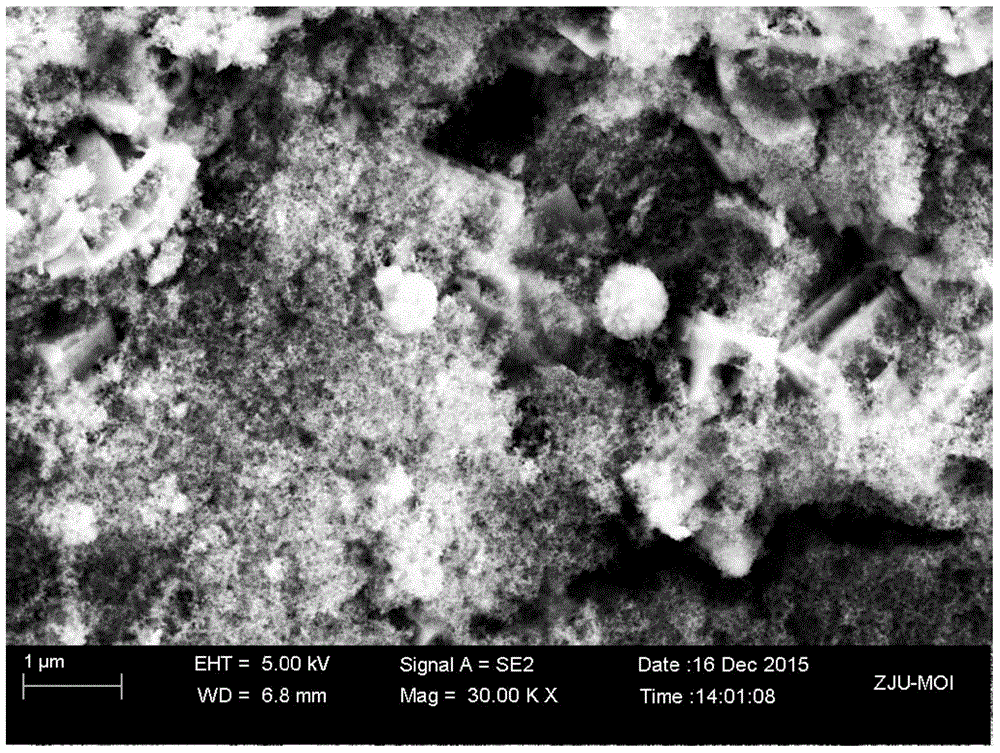

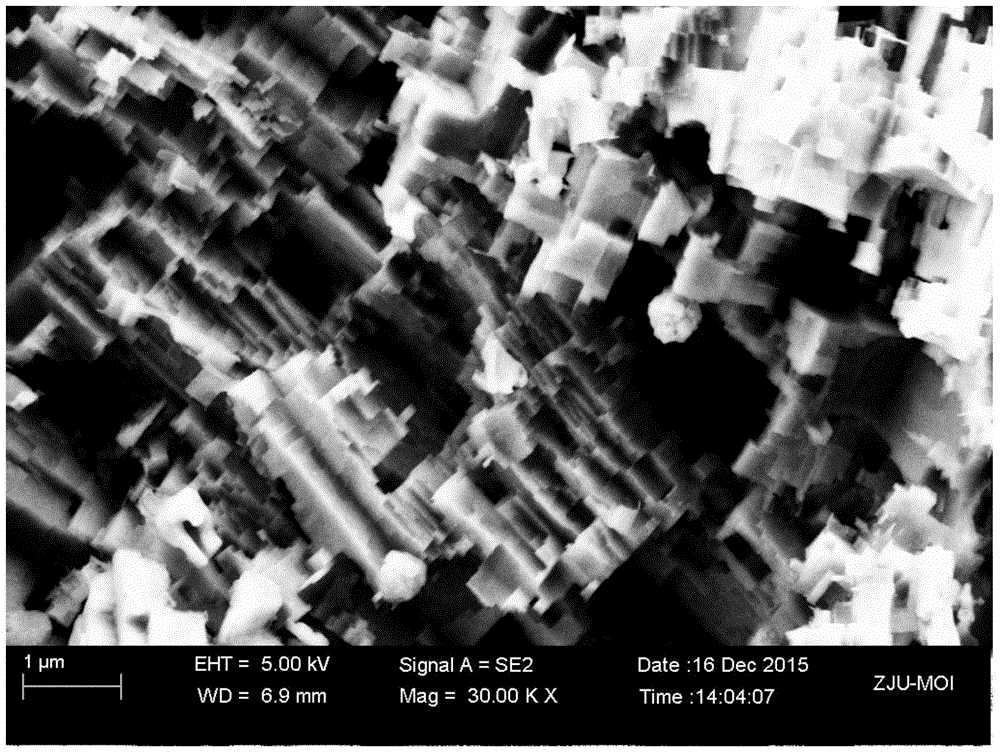

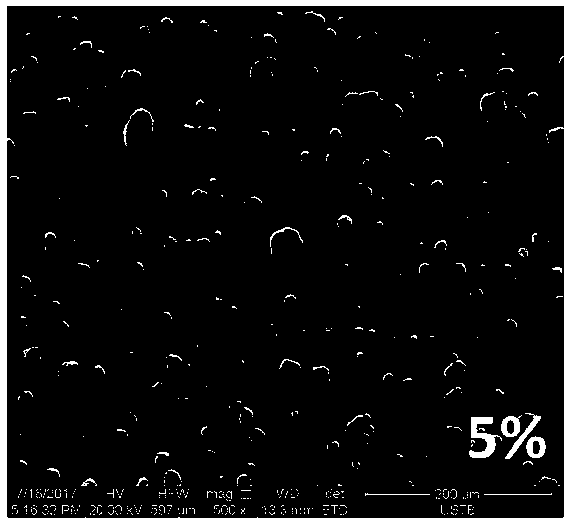

Preparing method for aluminum surface super-hydrophobic coating with micro-nano composite structure

InactiveCN105689236AImprove hydrophobicityGood anti-fogPretreated surfacesSpecial surfacesAcid etchingMicro nano

The invention discloses a preparing method for an aluminum surface super-hydrophobic coating with a micro-nano composite structure. The method mainly comprises the steps that firstly, an aluminum sheet is ultrasonically cleaned for 10 min through acetone and methylbenzene and then flushed thoroughly through distilled water, and the aluminum sheet is dried in an oven at the temperature being 100 DEG C; secondly, the cleaned and dried aluminum sheet is immersed in an acid etching agent to be etched, and an aluminum surface with a micron rough structure is obtained; thirdly, after the etched aluminum sheet is ultrasonically cleaned thoroughly, the aluminum sheet is immersed in a nano particle solution, and after the aluminum sheet is treated at the high temperature, an aluminum surface with a micro-nano composite rough structure is obtained; and fourthly, after low-surface-energy fluorosilicone modified polyester resin is sprayed to the aluminum surface with the micro-nano composite rough structure, an aluminum surface with super-hydrophobic performance can be obtained. The super-hydrophobic aluminum sheet prepared through the preparing method has the superior icing preventing performance and very good mechanical strength and can be applied to an air conditioner heat exchange sheet, and frosting and icing of the heat exchange sheet are effectively restrained.

Owner:ZHEJIANG UNIV

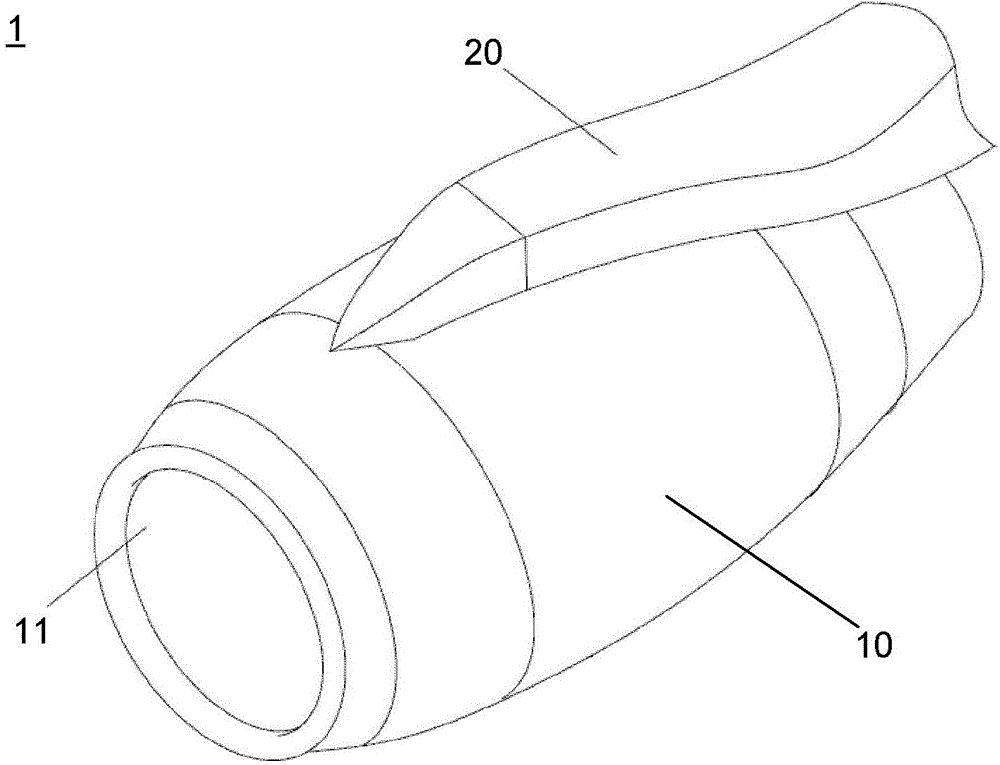

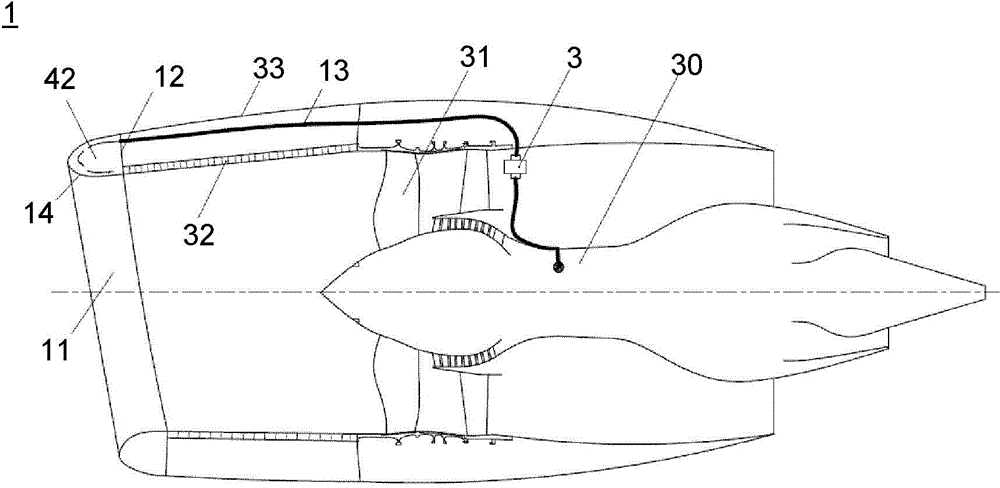

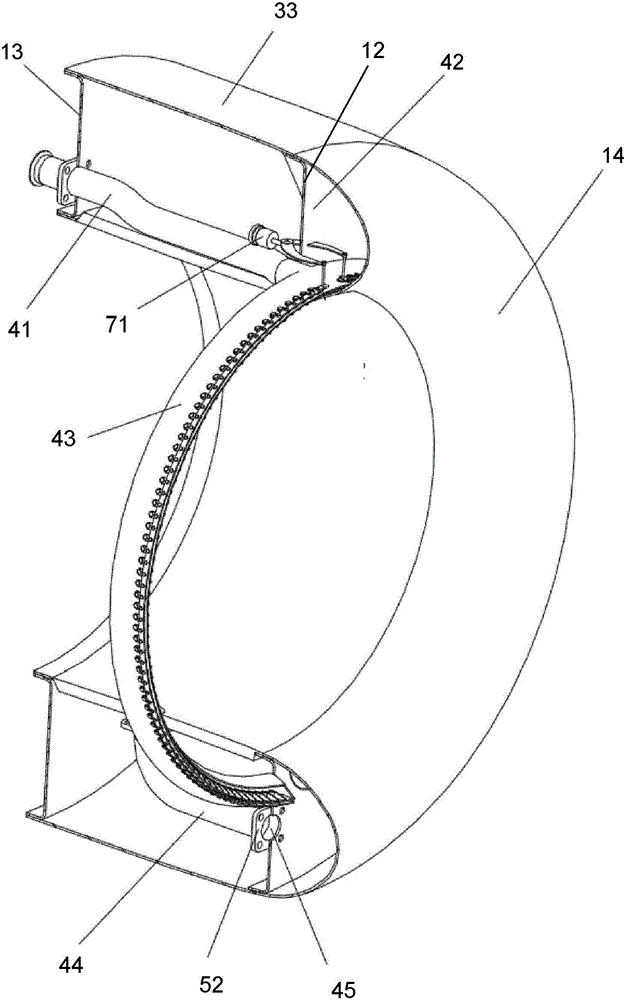

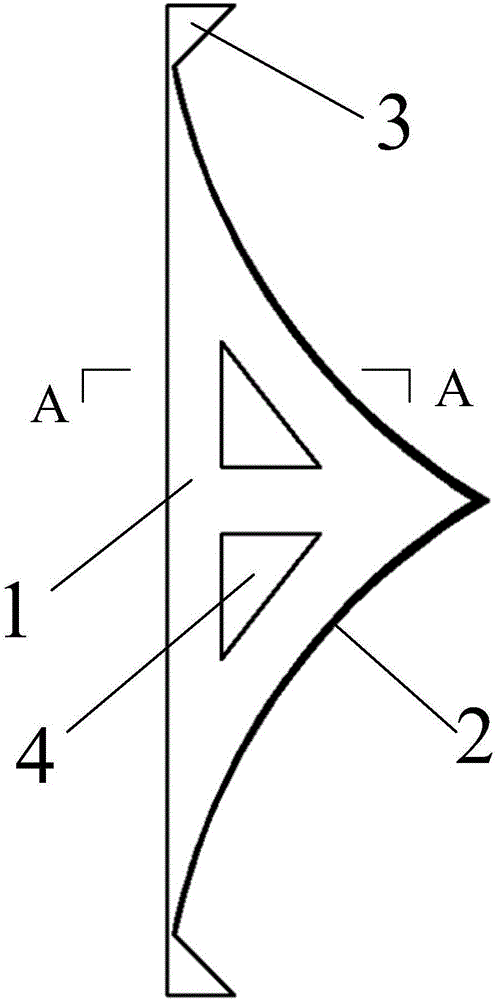

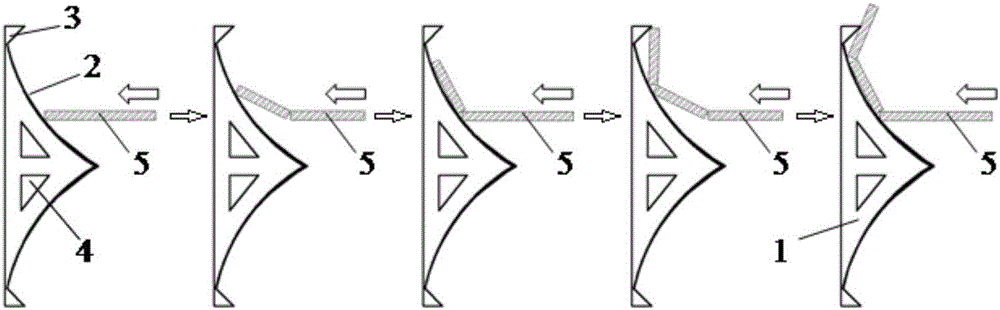

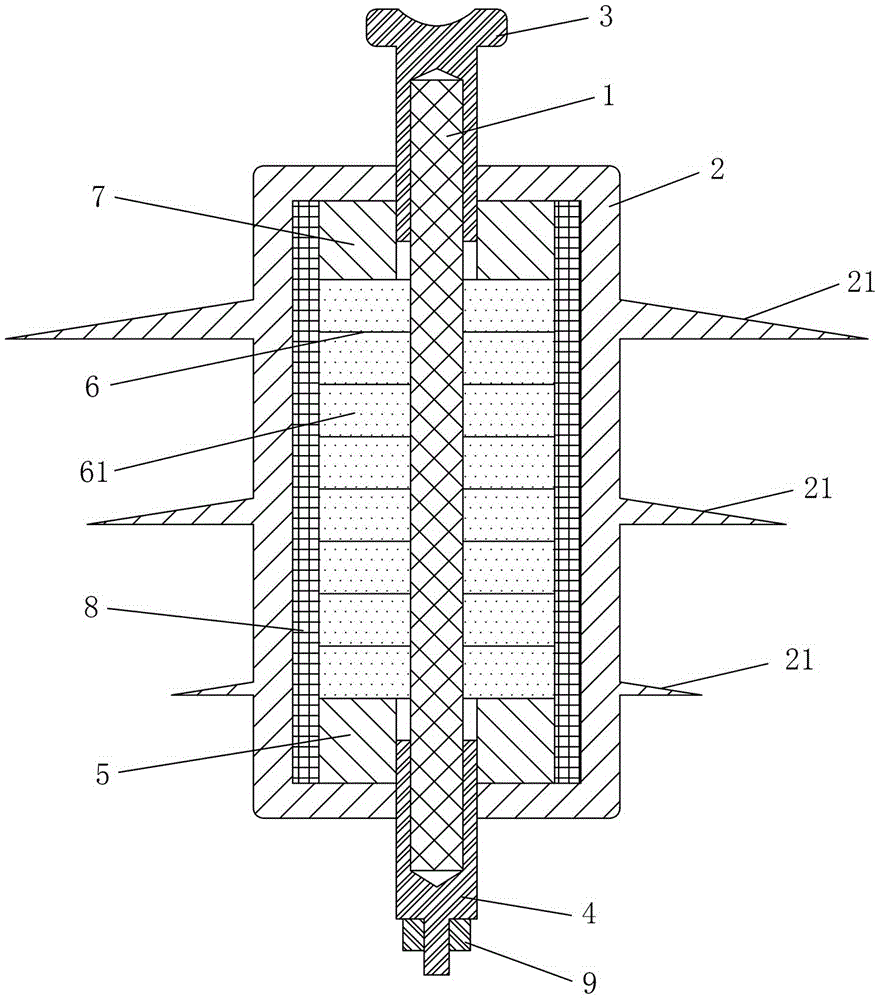

Engine gas inlet duct anti-icing system

ActiveCN104929778AControl flowGood anti-icing effectGas turbine plantsJet propulsion plantsEngineeringStreamflow

An engine gas inlet duct anti-icing system comprises a heat exchange passage, a gas guiding pipe, an annular gas distribution pipe and a gas exhausting pipe. The annular gas distribution pipe is arranged in the heat exchange passage, an opening hole is formed in the annular gas distribution pipe, and one end, close to an inlet of a gas inlet duct, of the gas guiding pipe is connected with the opening hole. The annular gas distribution pipe has a throat and a lip mouth; the lip mouth extends along the inlet direction of the gas inlet duct; an adjustable guide vane grid is arranged on the lip mouth, a certain angle is formed between the adjustable guide vane grid and the middle face of the gas inlet duct, and the angle of the guide vane grid is adjusted by a driving mechanism. The engine gas inlet duct anti-icing system can control the flow rate and the flow direction of hot air aiming at different anti-icing conditions, so that a best anti-icing effect can be realized under different anti-icing conditions and different gas inlet duct positions.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

Deicing and anti-icing liquid for airplane

ActiveCN102732217AAvoid secondary freezingSecondary icing reductionOther chemical processesPotassium hydroxideEthylene glycol toxicity

The invention discloses deicing and anti-icing liquid for an airplane. The deicing and anti-icing liquid comprises the following components by weight: 30-50% of propylene glycol, 25-52% of diethylene glycol, 0.15-8% of methylbenzotriazole, 0.8-8% of triethanolamine, 0.02-2% of polyoxyethylene lauryl (9) ether, 0.01-3% of linear alcohol (16-18) polyoxyethylene (35) ether, 1-3% of potassium hydroxide and 16-25% of deionized water, wherein a pH is 8.6-9.0+ / -0.5, and a freezing point is not more than -25 DEG C. The invention aims at the requirement that a water atomizing tolerance test for hard water stability and hot stability of the deicing and anti-icing liquid of the airplane lasts for 3 minutes, provides a new design project on selection of a freezing point decreasing agent, a corrosion inhibitor, an impregnating agent and an inhibitor, and adopts an organic freezing point decreasing agent, an organic corrosion inhibitor, an organic impregnating agent and an organic inhibitor, so that the deicing and anti-icing liquid is more environment-friendly and the anti-icing performance is more excellent.

Owner:西安高科理化技术有限责任公司

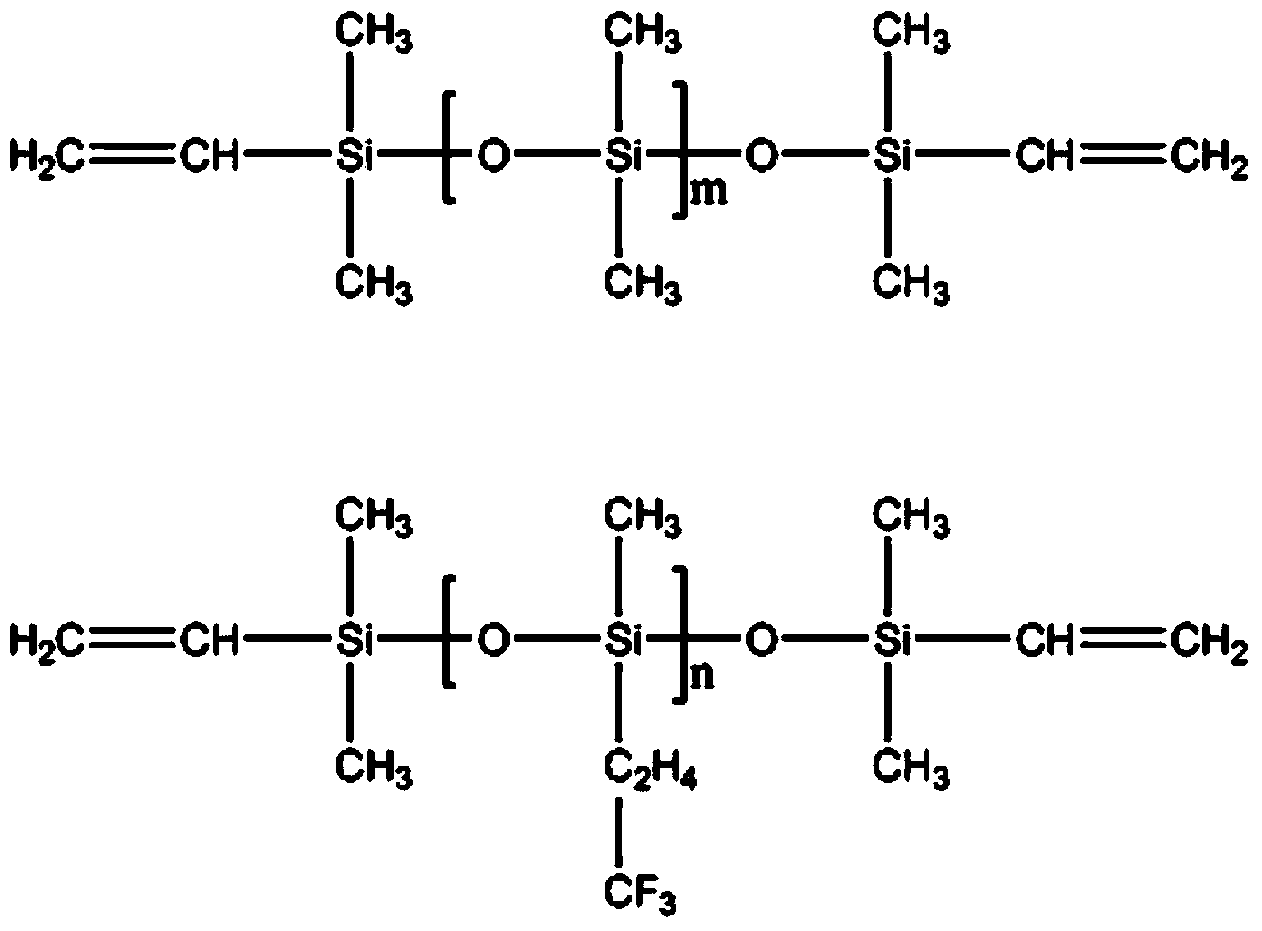

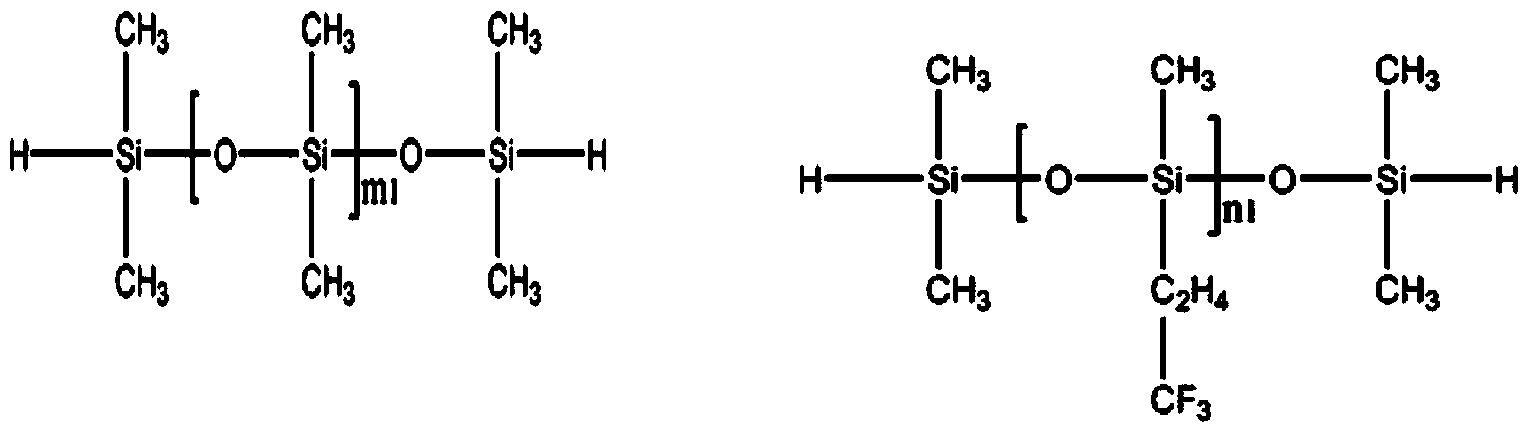

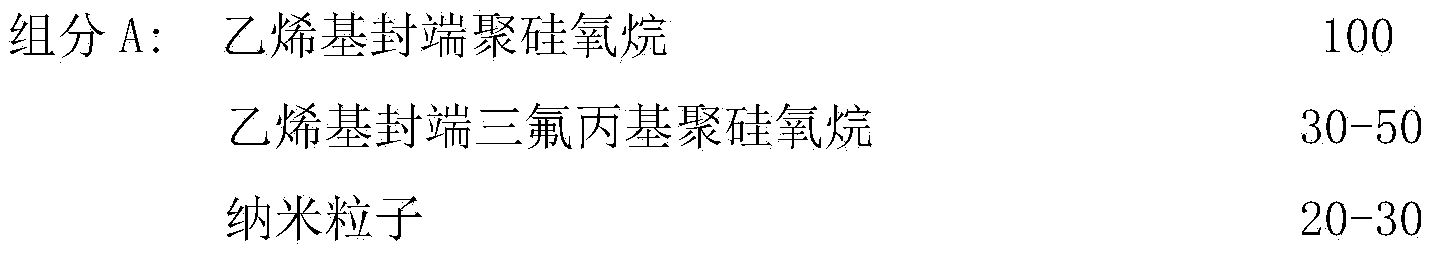

Addition fluorinated silicone rubber nano antifreezing adhesive paint and preparation method thereof

InactiveCN103725199ADoes not affect the anti-icing effectGood anti-icing effectCoatingsPolymer scienceSilanes

The invention discloses addition fluorinated silicone rubber nano antifreezing adhesive paint and a preparation method thereof, belongs to the field of organic fluorinated silicon polymer materials, and overcomes the problems of the prior art that the coating curing temperature is high and the anti-icing effect is poor. The addition fluorinated silicone rubber nano antifreezing adhesive paint consists of a component A and a component B, wherein the component A comprises the following ingredients in parts by weight: 100 parts of vinyl-terminated polysiloxane, 30 to 50 parts of vinyl-terminated trifluoropropyl polysiloxane, 20 to 30 parts of nano particles and 20 to 30 parts of solvent; the component comprises the following ingredients in parts by weight: 9 to 12 parts of end hydrogen-containing silicone oil, 9 to 10 parts of end hydrogen-containing fluorine silicone oil, 20 to 30 parts of solvent, 0.0074 to 0.012 part of Karstedt catalyst, 0.05 to 1 part of defoaming agent and 1 to 2 parts of dispersing agent. The preparation method comprises the following steps of (1) uniformly mixing the ingredients according to the weight parts to obtain the component A, ball-milling the component A, and uniformly mixing the ingredients according to the weight parts to obtain the component B; (2) uniformly mixing the component A and the component B, uniformly smearing onto the surface of the workpiece which is coated with silane undercoat, and then curing the workpiece at room temperature. By adopting the paint, the anti-icing effect is good.

Owner:JILIN UNIV

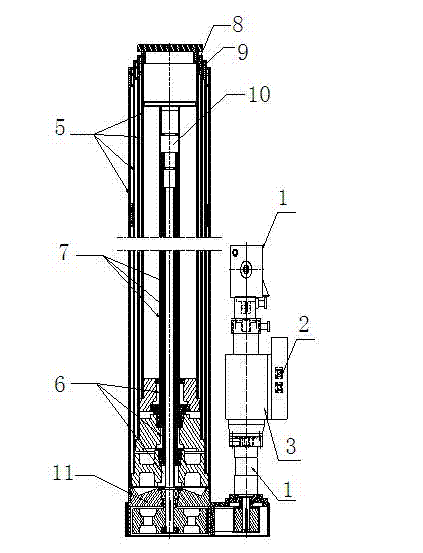

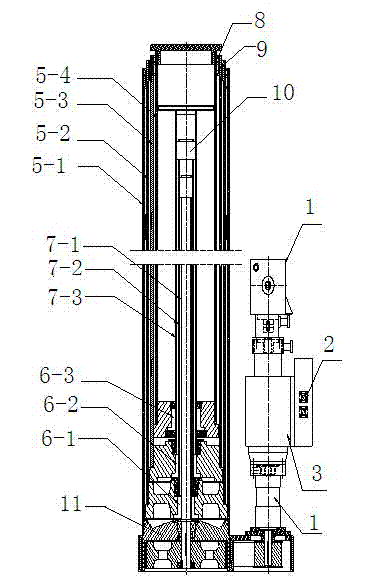

Electric lifting rod

InactiveCN102951573AImprove carrying capacityImprove waterproof performanceLifting devicesClassical mechanicsElectric machinery

The invention relates to an electric lifting rod, which comprises a driving device and a lifting device, wherein the driving device comprises a driving motor, a reduction box and a hand-cranking box; the lifting device comprises a base, casing pipes and a transmission structure; and the casing pipes and the transmission structure are both connected to the base. The electric lifting rod is characterized in that the transmission structure is set into a rolling spiral transmission structure, and the transmission structure comprises lead screws and nuts cooperatively and fixedly connected with the lead screws. The relative displacement of the casing pipes of the electric lifting rod disclosed by the invention is lead screw and nut transmission, other transmission modes, such as steel wire ropes, are omitted, and the electric lifting rod has the advantages of big load bearing capability, high reliability and safety, simple transmission structure and convenience in disassembling and maintaining, and multi-section lead screws are in invaginating transmission.

Owner:南京俊东机电设备有限公司

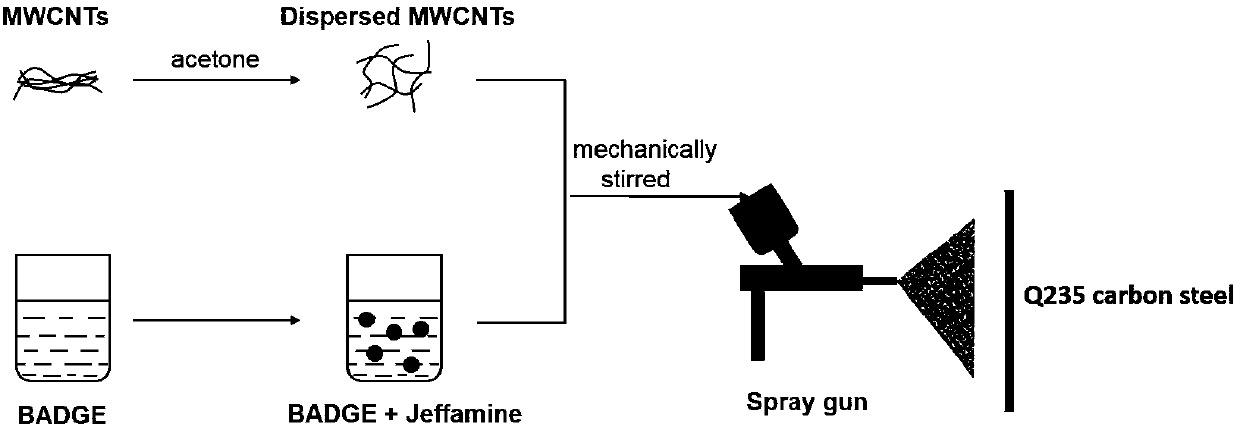

Super-hydrophobic surface coating and preparation method thereof

InactiveCN108047884AImprove production efficiencyGood self-cleaningEpoxy resin coatingsElectrically-conductive paintsEpoxyCarbon nanotube

The invention relates to a super-hydrophobic surface coating and a preparation method thereof, and belongs to the field of polymer coating materials. The super-hydrophobic surface coating is obtainedby spraying a super-hydrophobic solution containing epoxy resin, an epoxy curing agent, an epoxy solvent and carbon nanotubes on a substrate material. The super-hydrophobic surface coating has the advantages that materials are easy to obtain, self-cleaning is achieved, and icing is prevented, the preparation technology is simple, and large scale production and application are facilitated.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of super-hydrophobic aluminum surface with freezing prevention performance

InactiveCN107899921AEasy to roll offSimple configurationPretreated surfacesCoatingsWater bathsMegasonic cleaning

The invention discloses a preparation method of a super-hydrophobic aluminum surface with a freezing prevention performance. The method comprises the following steps: firstly, an abrasive paper is used for polishing a pure aluminum surface to remove oil stains and an oxide layer on an aluminum base surface; then, hydrochloric acid solution is adopted to etch the aluminum base surface to etch out arough structure on the aluminum surface; and finally, stearic acid anhydrous ethanol solution is used for processing to reduce the aluminum base surface energy to obtain the super-hydrophobic aluminum surface. Reagents adopted by the preparation method are common reagents and easy to prepare; such laboratory common devices as ultrasonic cleaners, electronic scales, drying boxes, water bath stirrers and the like are only needed; the method is simple and feasible; the production cost is greatly reduced; the average contact angle of the prepared aluminum base surface is more than 150 degrees; the surface adhesion is weak; water drops are easy to roll down from the surface; the excellent freezing prevention performance is achieved; and the unexpected technical effects are achieved.

Owner:JIANGSU UNIV OF TECH

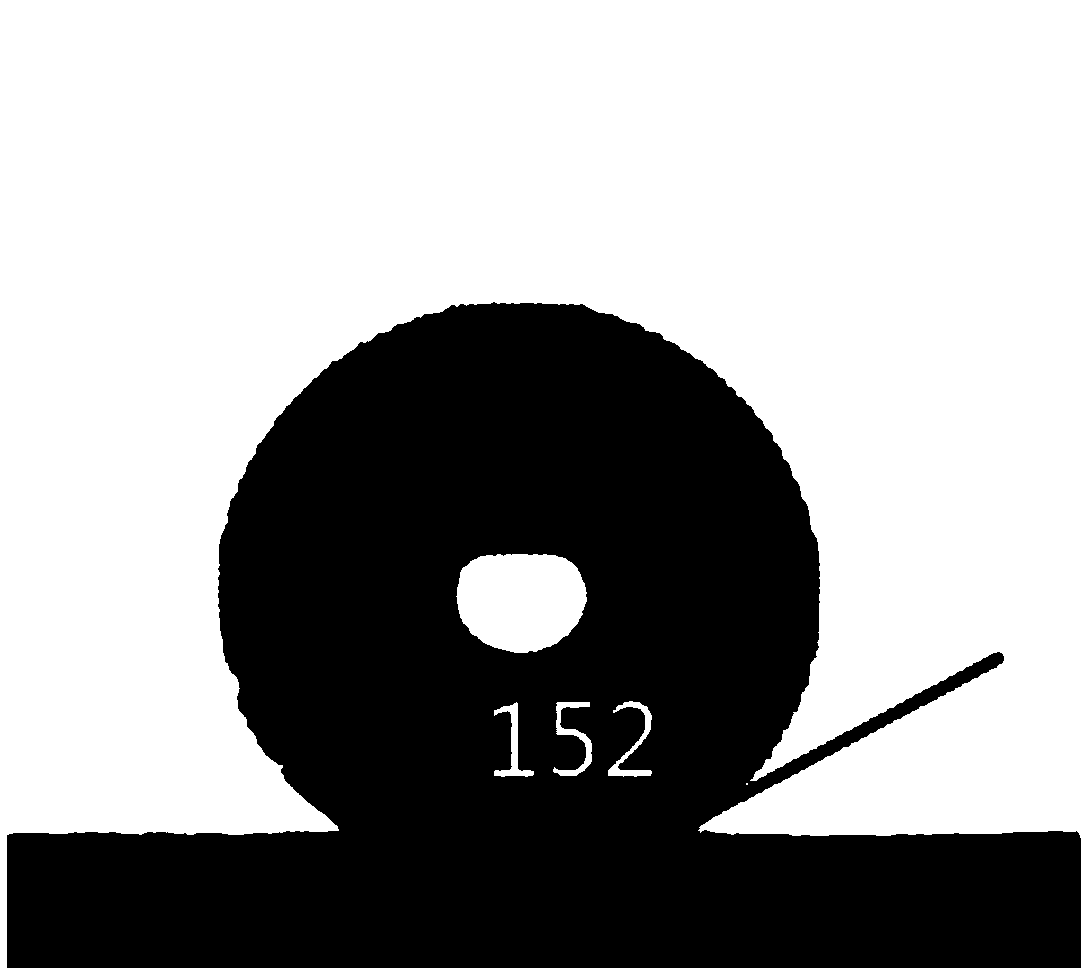

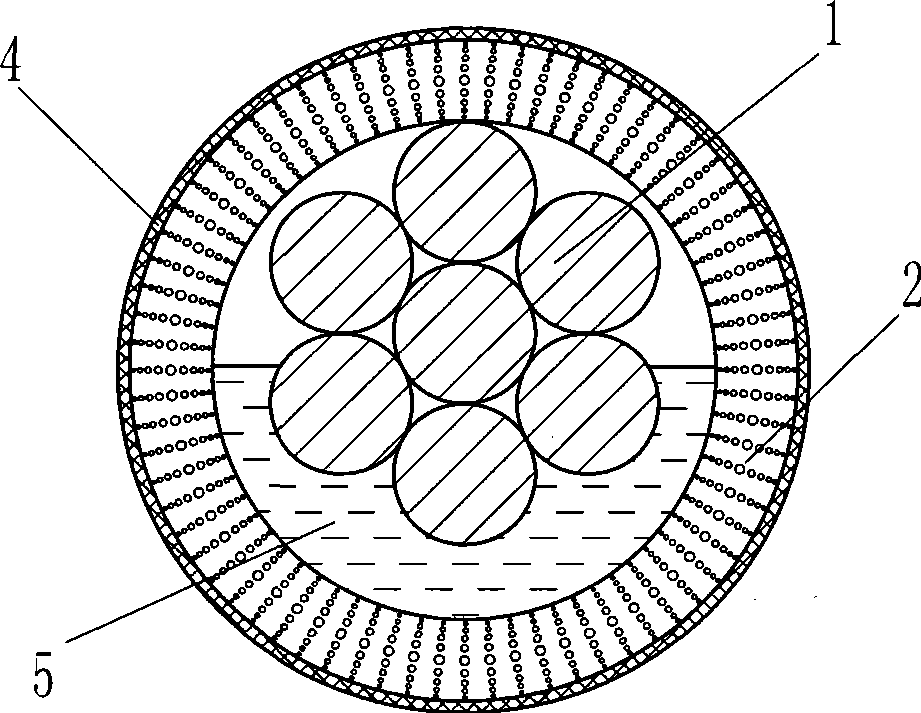

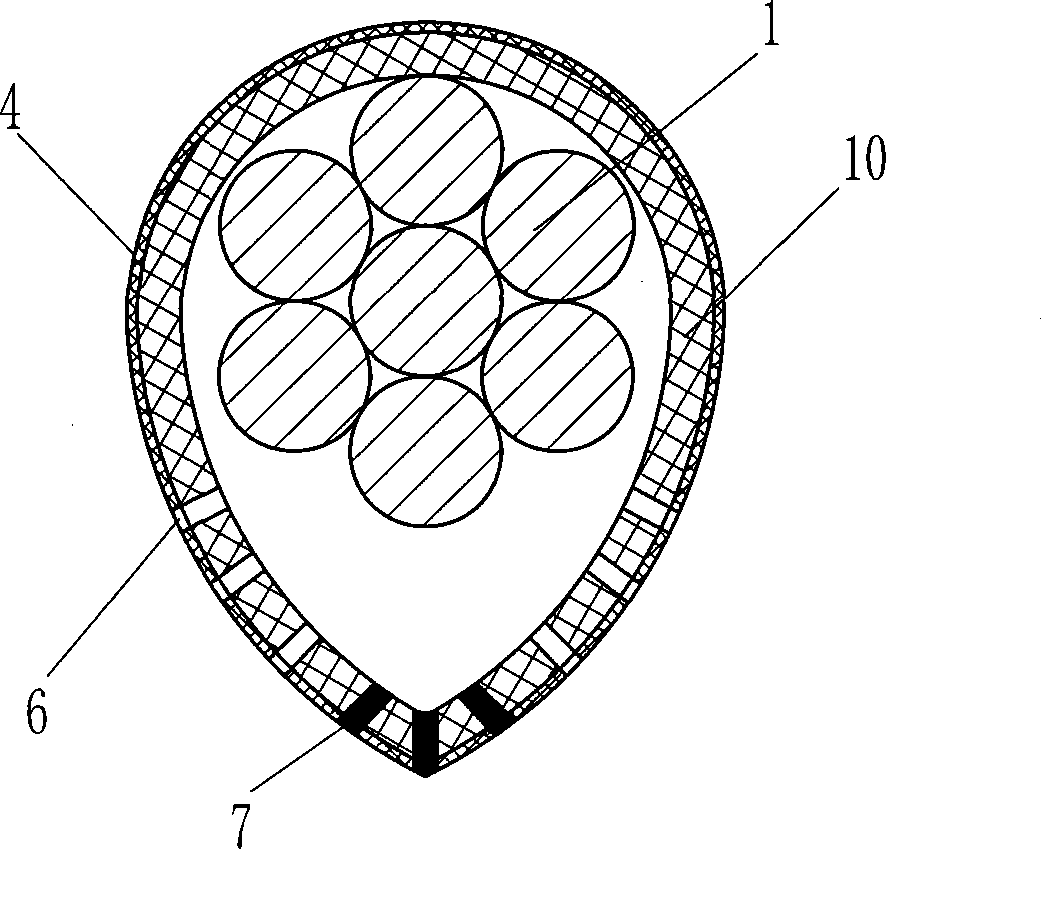

Ice coagulation preventing cable and auxiliary equipment

ActiveCN101504877AReduce gallopingImproved collision angleOverhead installationInsulated cablesEngineeringBottle

The invention relates to an anti-icing cable applicable to ice rain atrocious weather and matched auxiliary facilities with anti-icing property. The anti-icing cable of the invention is characterized in that the cable is sleeved with an anti-icing sleeve, a clearance is reserved between the inner surface of the anti-icing sleeve and the surface of the cable, and the anti-icing sleeve can rotate relative to the cable. An insulating bottle for field power transmission is characterized in that the easy-icing surface of the insulating bottle is provided with the anti-icing sleeve. An anti-icing field metal tower body is characterized in that the surface of an easy-icing part of the tower body is provided with an anti-icing element. A method for arranging the anti-icing sleeve or the anti-icing element on the easy-icing part of the cable, the insulating bottle or the tower body effectively prevents the surface from icing, greatly reduces the heat exchange with the outside, and effectively prevents the icing phenomenon caused by heat absorption after rainwater is directly contacted with the cable, the insulating bottle or the tower body.

Owner:尹学军

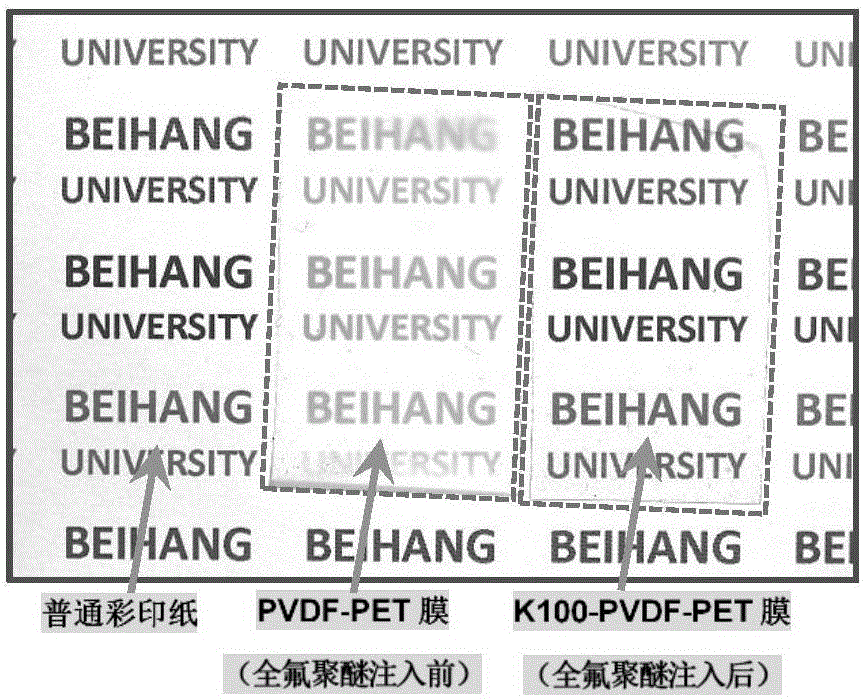

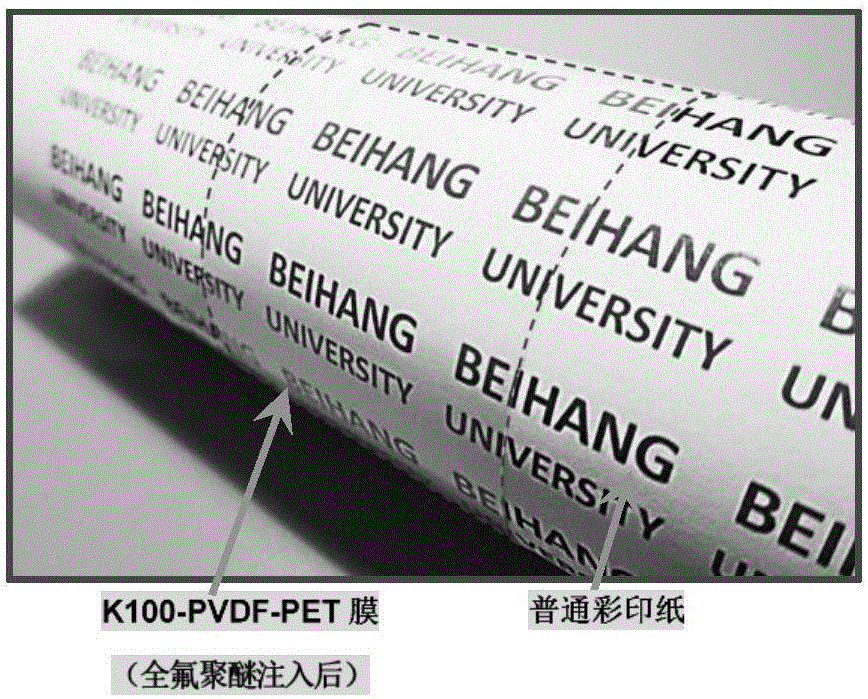

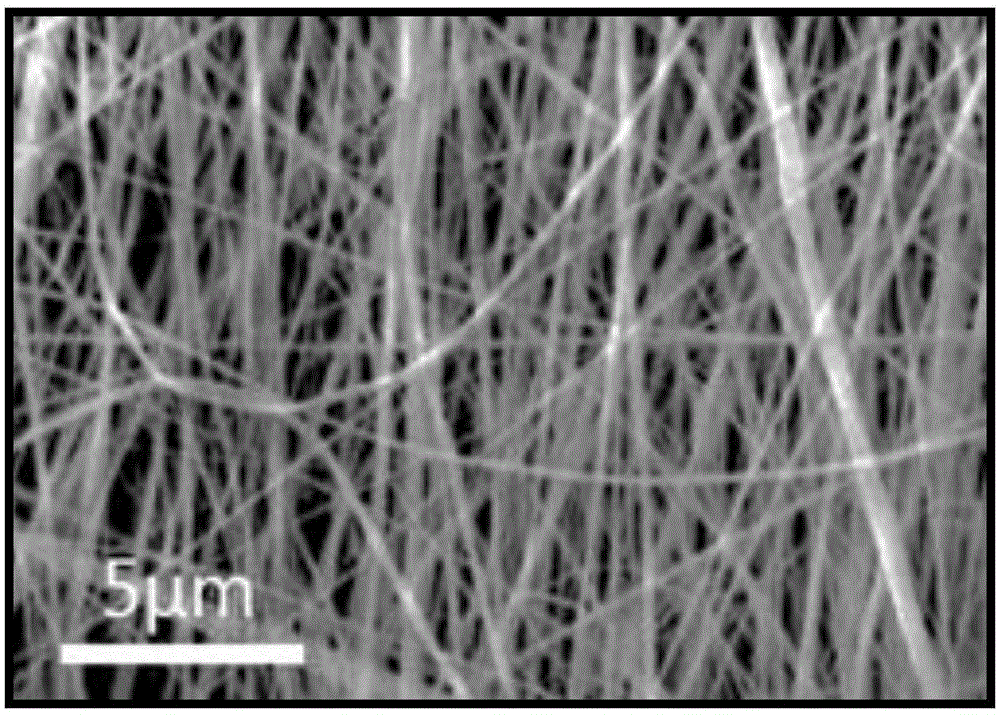

Method for preparing perfluor liquid injection type transparent flexible anti-icing thin film through electrostatic spinning

ActiveCN105063894AEasy to fixEasy to operateFilament/thread formingNon-woven fabricsAlcoholNanofiber

The invention provides a method for preparing a perfluor liquid injection type transparent flexible anti-icing thin film through electrostatic spinning and belongs to the field of interface chemistry. An electrospinning film is prepared on the surface of aluminum foil through the electrospinning technology; the electrospinning film on the surface of the aluminum foil is transferred to the surface of a propping material through alcohol soaking, hot pressing and drying processes, and a porous electrostatic spinning nanofiber film is prepared; perfluor liquid is added to the surface of the porous electrostatic spinning nanofiber membrane dropwise, and the perfluor liquid injection type transparent flexible anti-icing thin film is obtained. The visible light transmittance of the prepared transparent flexible anti-icing thin film is more than 80%, the contact angles between water drops and the surface of the flexible anti-icing thin film are 113 degrees, and the rolling angles are 3 degrees. Most of the regions of the surface of the transparent flexible anti-icing thin film are frostless after 60 min under the condition of the -5 DEG C temperature and the 50% humidity, and the drop setting time is obviously prolonged compared with a traditional hydrophobic film.

Owner:BEIHANG UNIV

Nano-composite superhydrophobic icing-proof coating material and preparation method thereof

ActiveCN103819995AExcellent performancePersistent low surface energyCoatingsSurface energyDichloromethane

The invention discloses a nano-composite superhydrophobic icing-proof coating material. The nano-composite superhydrophobic icing-proof coating material comprises the following components in percentage by mass: 5-50% of fluorine-containing acrylate copolymer-modified inorganic nanoparticles and 50-95% of an organic solvent. A preparation method for the nano-composite superhydrophobic icing-proof coating material comprises the following steps: uniformly mixing nano-SiO2, methylbenzene and 3-aminopropyl triethoxysilane, and performing refluxing reaction in an oil bath to obtain amino-modified SiO2-NH2 inorganic nanoparticles; uniformly mixing the SiO2-NH2, dichloromethane, triethylamine and 2-bromoisobutyryl bromide, and reacting in an ice-water bath to obtain 2-bromoisobutyryl bromide-grafted nanoparticle SiO2-NH-Br; uniformly mixing the SiO2-NH-Br, an acrylate monomer, fluorine-containing acrylate, CuX, methylbenzene and a ligand, deoxidizing, precipitating, performing centrifugal separation, and dissolving a product into the organic solvent to obtain the nano-composite superhydrophobic icing-proof coating material. The nano-composite superhydrophobic icing-proof coating material has excellent performance, lasting low surface energy and superhydrophobicity, and good icing-proof performance and has the effect of prolonging the icing time, and can be widely used for prevention and control of icing on the surfaces of communication lines, fan blades, airport facilities, airplane wings and the like.

Owner:ZHEJIANG UNIV

High-performance wind-power generating facility coating prepared by taking organic fluorinated silicone modified elastic polyurethane-urea resin as substrate

InactiveCN101665655AHigh tensile strengthHigh resistivityPolyurea/polyurethane coatingsUreaWeather resistance

The invention discloses high-performance wind-power generating facility coating prepared by taking organic fluorinated silicone modified elastic polyurethane-urea resin as substrate. The high-performance wind-power generating facility coating is prepared from component A and component B according to proportion. The wind-power generating facility coating has toughness, attrition resistance, high elasticity, excellent mechanical property, yellowing resistance, good colour retention, high ultraviolet resistance, high weather resistance, favorable and excellent electrical insulation, chemical stability, moisture resistance and freeze resistance. In addition, the wind-power generating facility coating has high performance and moderate cost and can strongly protect the wind-power generating facility, reduce the maintenance frequency and lower the purchasing cost of the wind-power generating facility, thereby having extremely high implementation value and social and economic benefit.

Owner:西北永新涂料有限公司 +1

Offshore large-diameter pile foundation with ice-resistant structure

InactiveCN106120832ASmall cutting edge contact areaGood ice breaking effectArtificial islandsUnderwater structuresSea iceMarine engineering

The present invention discloses an offshore large-diameter pile foundation with an ice-resistant structure. The offshore large-diameter pile foundation with the ice-resistant structure comprises a plurality of ice-resistant standard parts that are welded in a circle symmetrically and uniformly around the pile foundation made of steel. A primary stiffened plate and upper and lower secondary stiffened plates are arranged through the plurality of ice-resistant standard parts. The plurality of ice-resistant standard parts, the primary stiffened plate, and the upper and lower secondary stiffened plates are connected and fixed to form the ice-resistant structure. The ice-resistant standard parts provided by the present invention are each provided with icebreaking blades, such that concentrated stress is produced on sea ice, and the sea ice thus is easy to break; the icebreaking blades are each in an inwardly recessed arc shape, which is also conducive to breaking sea ice; ice blocking lugs force sea ice to turn over and fall off, and prevent the sea ice from contacting with the pile foundation; moreover, the ice-resistant standard parts are distributed axisymmetrically around the pile foundation, and can resist the effect of sea ice in any direction.

Owner:HEFEI UNIV

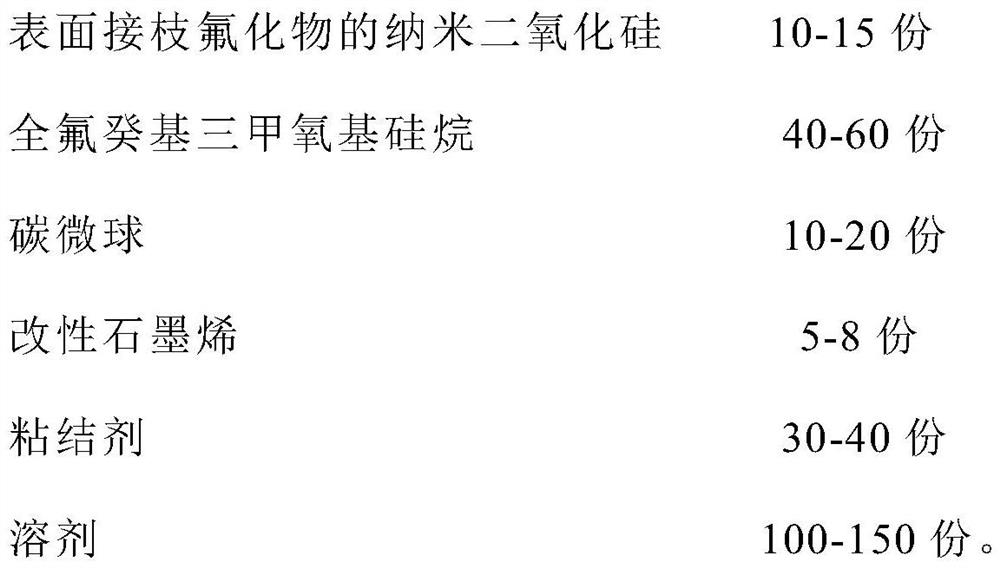

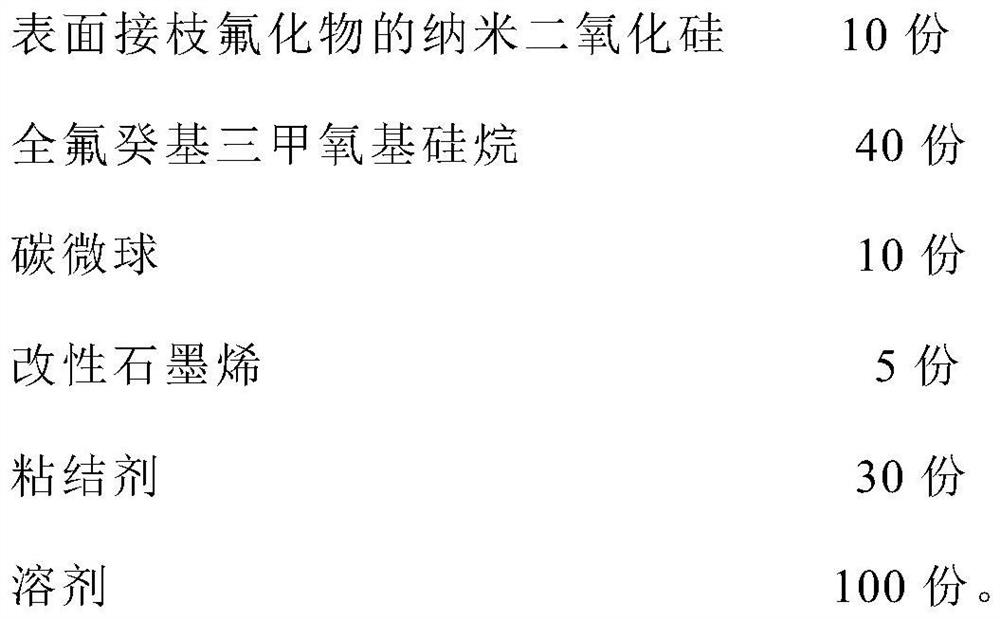

Super-hydrophobic anti-fouling anti-icing water-based paint

InactiveCN112724830AImprove anti-icing performanceImprove hydrophobicityAntifouling/underwater paintsOther chemical processesMicro nanoCoated surface

The invention relates to the technical field of material surface engineering, in particular to a super-hydrophobic anti-fouling anti-icing water-based paint which comprises the following components in parts by weight: 10-15 parts of fluoride-grafted nano silicon dioxide on the surface, 40-60 parts of perfluorodecyltrimethoxysilane, 10-20 parts of carbon microspheres, 5-8 parts of modified graphene, 30-40 parts of binder and 100-150 parts of solvent. According to the super-hydrophobic anti-fouling anti-icing water-based paint, the super-hydrophobic material and the near-infrared photothermal material are added, so that the super-hydrophobic anti-fouling anti-icing water-based paint has the dual effects of super-hydrophobicity and photothermal deicing, and the near-infrared photothermal material is modified graphene which is a compound of graphene and CdS; and the super-hydrophobic material is very beneficial to formation of a rough micro-nano structure on the surface of the coating, so that the coating can obtain a larger static contact angle and a smaller rolling angle, the icing time of water drops on the surface of the coating is further prolonged, and a better anti-icing effect is achieved.

Owner:广东绿色大地化工有限公司

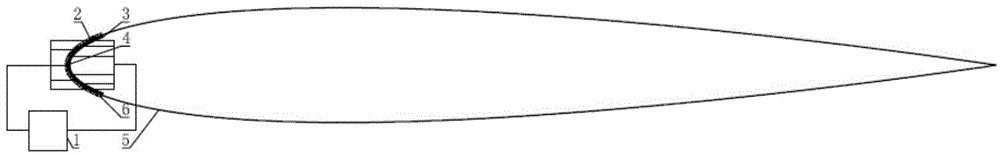

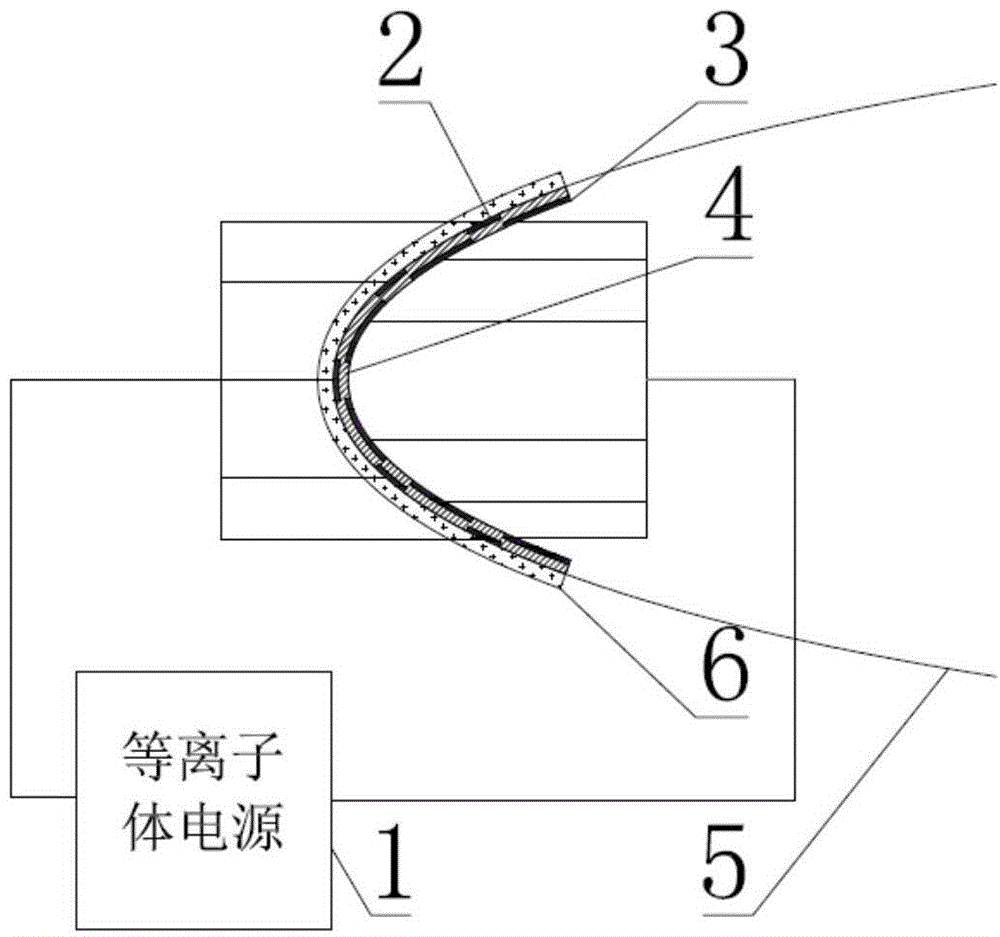

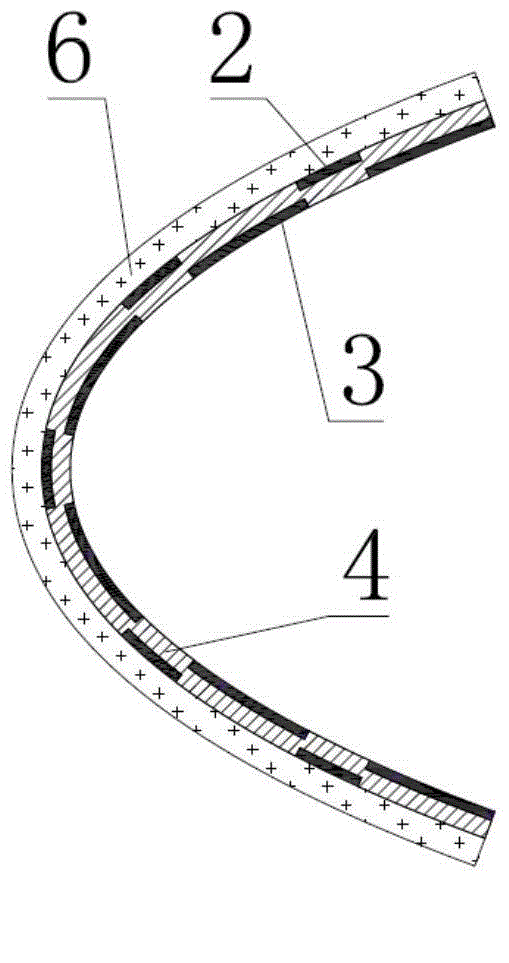

Dielectric barrier discharge plasma anti-icing device and method

InactiveCN104875894ASimple structureIncrease the electric field strengthDe-icing equipmentsInsulation layerAdhesive belt

The invention discloses a dielectric barrier discharge plasma anti-icing device and method. A plurality of layers of polyimide adhesive tape are overlapped and pasted to serve as an insulation layer. Upper electrodes and lower electrodes are pasted along the two side faces of the insulation layer in a staggered mode. The upper electrodes are connected in parallel to be connected with a positive electrode of a plasma power source. The lower electrodes are connected in parallel to be connected with a negative electrode of the plasma power source. The insulation layer is fixed into a groove in the surface of an aircraft skin, and efficient anti-icing of the surface of an aircraft is achieved. Due to the fact that the thickness of the electrodes and the thickness of the insulation layer are very small, the effect of the electrodes and the insulation layer on the aerodynamic performance of the aircraft can be ignored. The dielectric barrier discharge plasma anti-icing device is simple in structure, and the electrodes can be flexibly distributed according to the different geometrical shapes of the frozen positions of the aircraft. When the voltage of the plasma power source is adjusted to 70 V and the current strength ranges from 1.5 A to 2.5 A, the voltage actually loaded to the electrodes can reach 10 KV or more, the responding time is short, the anti-icing effect is good, the implement method is convenient to implement and easy to achieve and has good application prospects, and no pollution exists.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

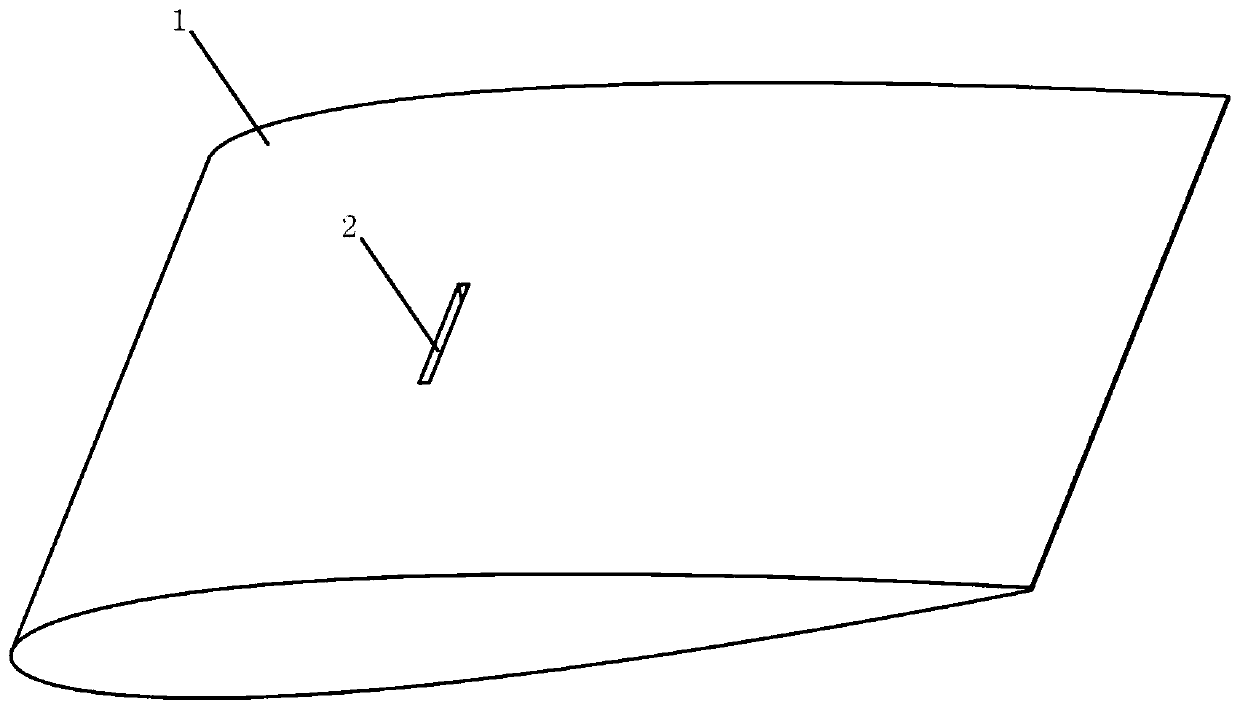

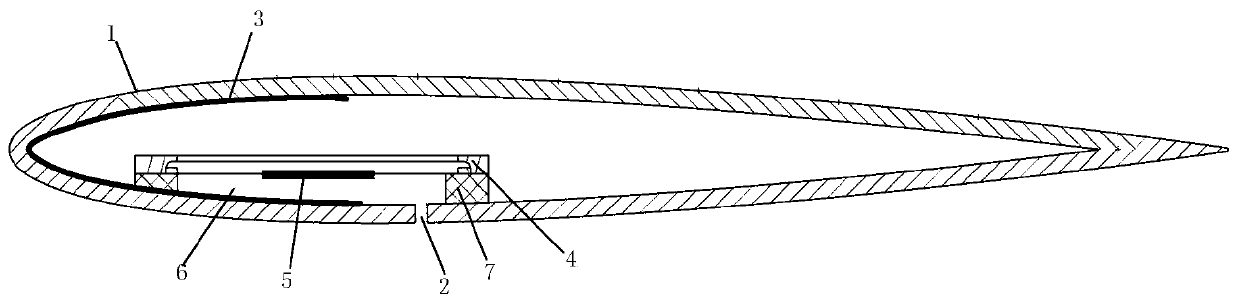

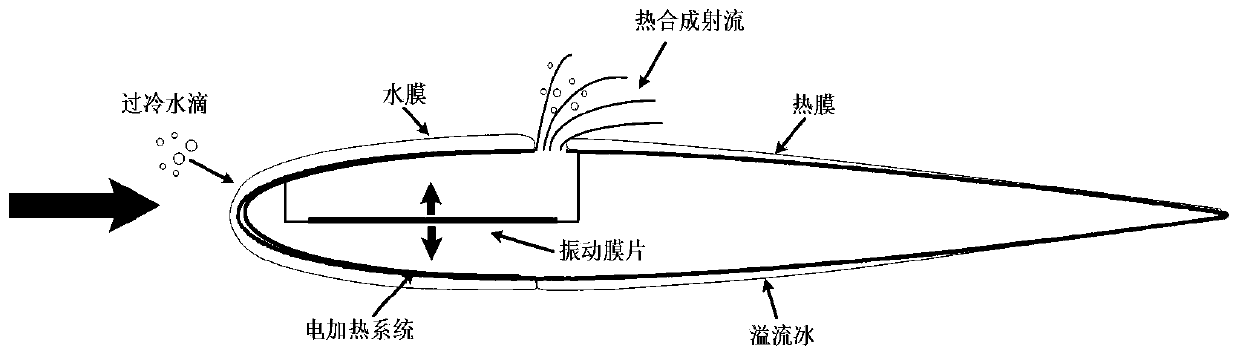

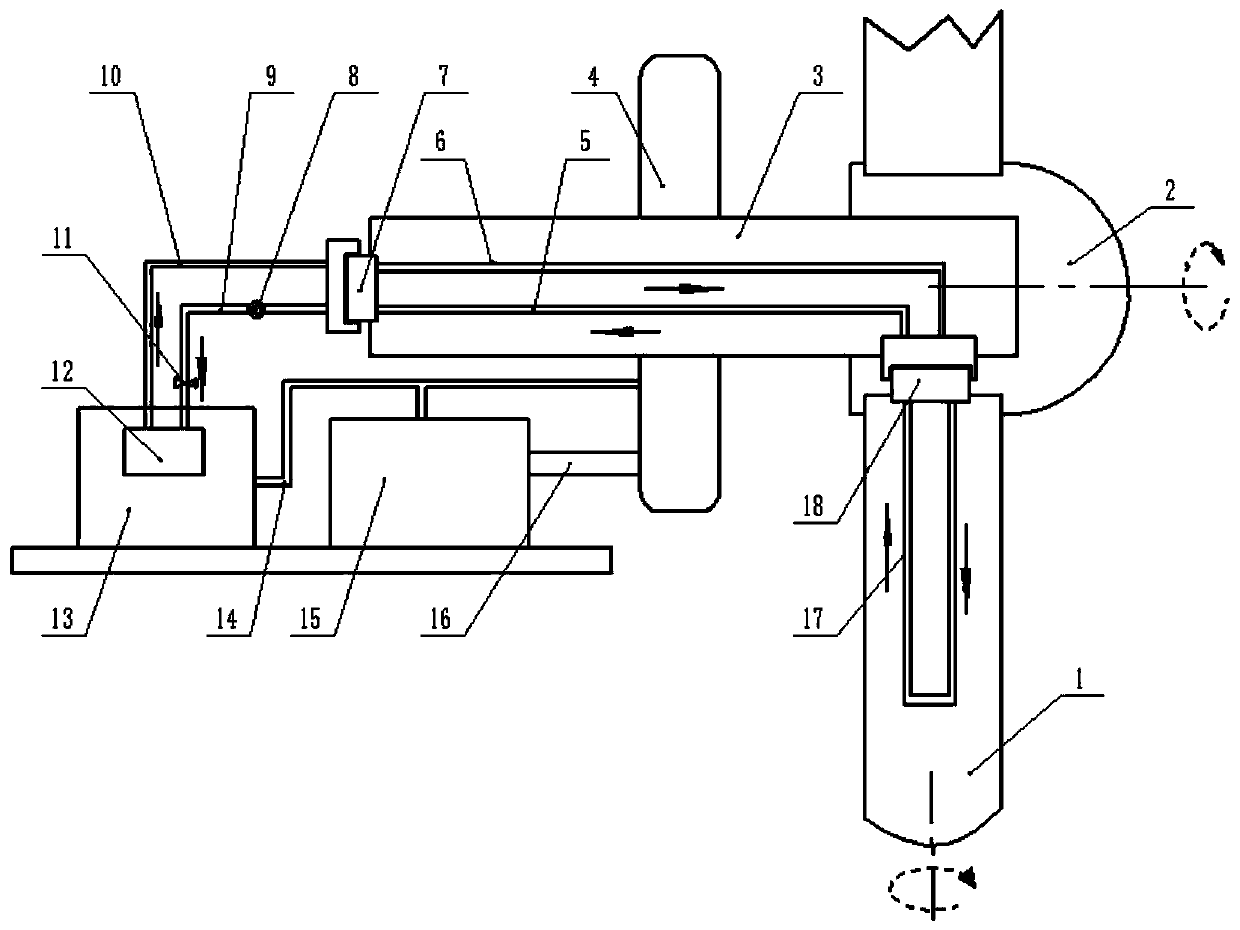

Ice prevention and removal system for wing

PendingCN110834734ATo achieve the purpose of full coverage anti-icingImprove aerodynamic performanceDe-icing equipmentsWingsLeading edgeEngineering

The invention discloses an ice prevention and removal system for a wing. The system comprises a wing, wherein an electric heating system is distributed in the leading edge skin of the wing. The systemalso comprises a synthetic jet exciter distributed in the wing, wherein the synthetic jet outlet of the synthetic jet exciter is positioned on the surface of the wing and is positioned on the rear side of the ice prevention area of the electric heating system; and after a synthetic jet in the synthetic jet exciter is injected from the synthetic jet outlet, the synthetic jet mutually acts with water drops on the surface of the wing so as to change the movement trajectory of each water drop. By use of the ice prevention and removal system, the leading edge surface of the wing is heated throughthe electric heating system, so that the leading edge of the wing is kept in a certain temperature range. When cold water drops knock on the leading edge of the wing, since a surface temperature is high, water drops are not iced on the leading edge of the wing but flow form one layer of water film, and the water film flows to the back of the wing. When the water film flows to the synthetic jet outlet, due to the function of the synthetic jet, the water film changes an original movement locus so as to be far away from the rear surface of the wing, the formation of overflowing ice is avoided, and the aerodynamic performance and the safety performance of the wing are improved.

Owner:中国人民解放军63831部队

Wind turbine blade ice prevention and removal mechanism

InactiveCN109751205ALow costImprove utilization efficiencyMachines/enginesWind energy generationThermal energyTurbine blade

Disclosed is a wind turbine blade ice prevention and removal mechanism belonging to ice prevention and removal technology. A hub is provided with a blade through a rotary joint B. A condenser is installed in the blade. Two ends of the condenser are respectively connected with the rotary joint B. A rotary joint A is installed on the rear end portion of a main shaft. A steam transfer pipe B and a liquid return pipe A are arranged in a shaft cavity of the main shaft. Two ends of the steam transfer pipe B are connected with the rotary joint A and the rotary joint B correspondingly. Two ends of theliquid return pipe A are connected with the rotary joint B and the rotary joint A correspondingly. A gear transmission box and a generator communicate with a heat accumulator through heat transfer pipes. An evaporator is installed in the heat accumulator. Two ends of the steam transfer pipe A are connected to the evaporator and the rotary joint A correspondingly. Two ends of a liquid return pipeB are connected to the rotary joint A and the evaporator correspondingly. A liquid pump and a valve are installed on the liquid return pipe B. The wind turbine blade ice prevention and removal mechanism uses waste heat energy generated by a wind turbine to carry out blade ice prevention and removal, thereby saving energy and being low in operation cost and good in operation effect.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Anti-thunder and anti-icing pin type composite insulator for 10 kV transmission line

InactiveCN104952561AImprove lightning protectionGood anti-icing effectPin insulatorsComposite insulatorsMetal

The invention discloses an anti-thunder and anti-icing pin type composite insulator for a 10 kV transmission line. The composite insulator comprises a mandrel, a composite insulator assembly, an insulating shed housing, a trunking fitting and a steel leg fitting, wherein the composite insulator assembly comprises a lower conductive heel block, a metal oxide resistor disc group and an upper conductive heel block which are sequentially arranged on the mandrel in a sleeving manner and are tightly attached; the composite insulator assembly is wrapped with the insulating shed housing; an insulating layer is arranged between the composite insulator assembly and the insulating shed housing; the trunking fitting penetrates through the insulating shed housing and is in threaded connection with the upper conductive heel block; the steel leg fitting penetrates through the insulating shed housing and is in threaded connection with the lower conductive heel block; two ends of the mandrel are connected with the trunking fitting and the steel leg fitting respectively. The anti-thunder and anti-icing pin type composite insulator for the 10 kV transmission line has the advantages of good anti-thunder and anti-icing effects, simplicity and convenience in installation, long service life, facilitation of reconstruction of a conventional electric transmission line and the like.

Owner:STATE GRID CORP OF CHINA +2

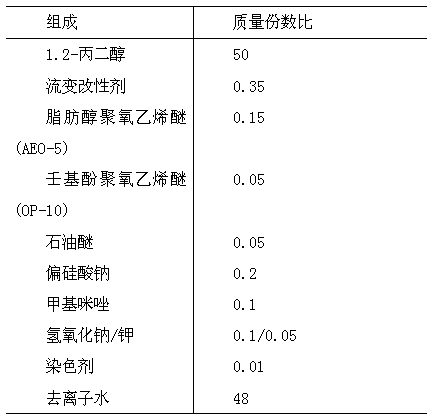

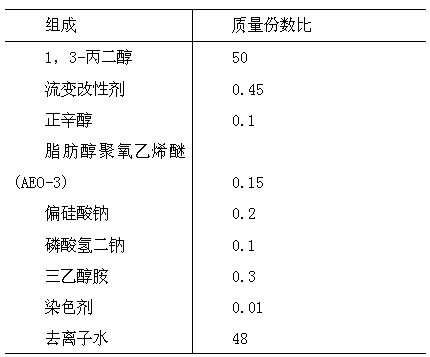

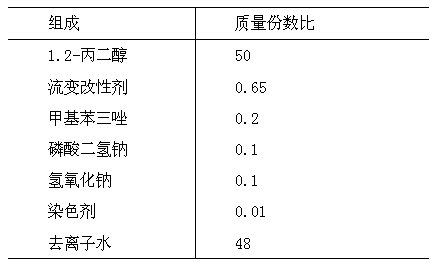

Non-Newtonian fuselage deicing and anti-icing fluid and preparation method thereof

ActiveCN103059813AExcellent shear recovery abilityLong anti-icing timeOther chemical processesPhysical chemistryRheopecty

The invention relates to a deicing and anti-icing fluid, particularly a non-Newtonian fuselage deicing and anti-icing fluid and a preparation method thereof. The non-Newtonian fuselage deicing and anti-icing fluid can reduce adhesion of ice on the object surface to eliminate and prevent icing on the aircraft fuselage surface, and has superlong anti-icing retention time. The non-Newtonian fuselage deicing and anti-icing fluid comprises the following components in parts by mass: 40-60 parts of freezing-point depressant, 0.05-1.2 parts of rheologic modifier, 0.01-0.3 part of anti-icing compounding agent, 0.01-3 parts of pH regulator, 0.01-3 parts of corrosion inhibitor, 0.01-0.5 part of staining agent and 40-60 parts of deionized water. The invention is based on the low-temperature rheologic research, especially aims at the low-temperature operating environment and characteristics of the deicing and anti-icing fluid, and determines the distribution and arrangement of the main chain and branch chain of the rheologic modifier as well as the preparation and acquisition method of the low-temperature conformation. By combining the anti-icing compounding agent, corrosion inhibitor and other assistants in the formula, the prepared deicing and anti-icing fluid has the characteristics of excellent shearing restorability, excellent ice adhesion inhibition capacity at 0 to -20 DEG C, and long anti-icing time.

Owner:成都民航六维航化有限责任公司

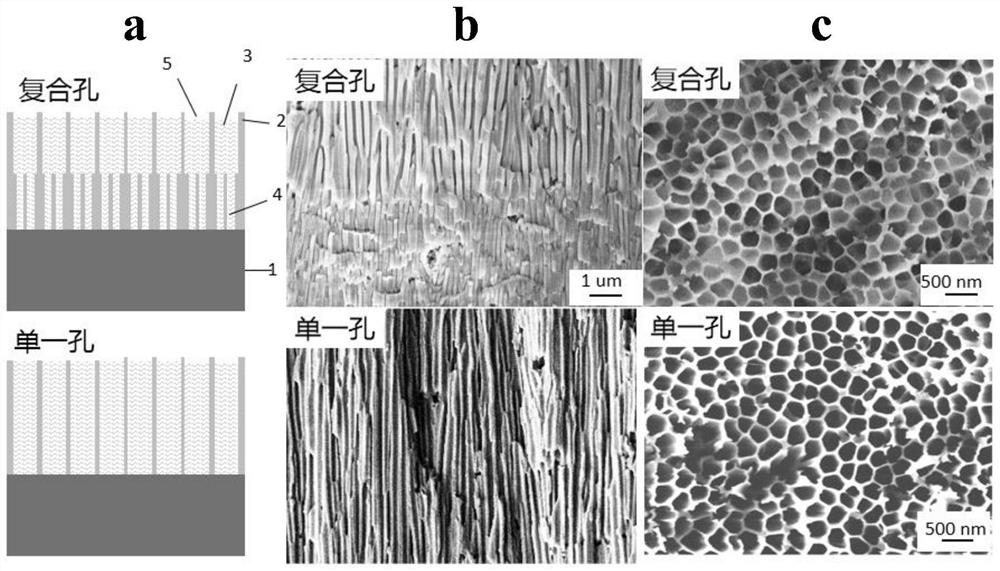

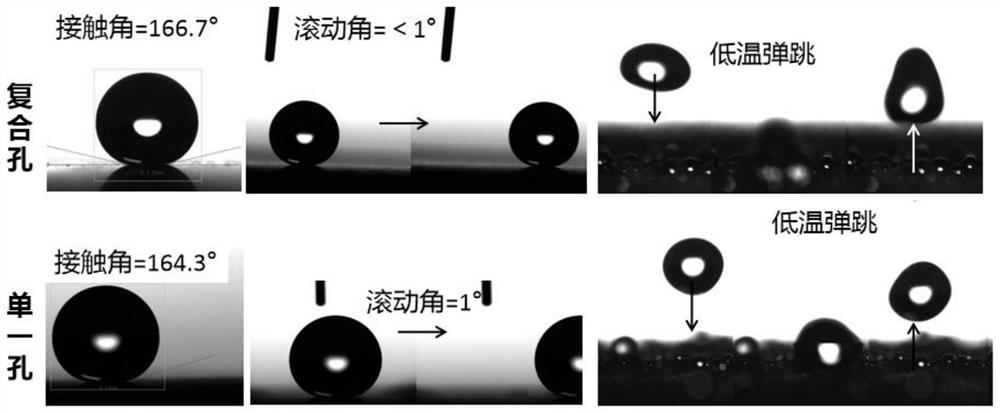

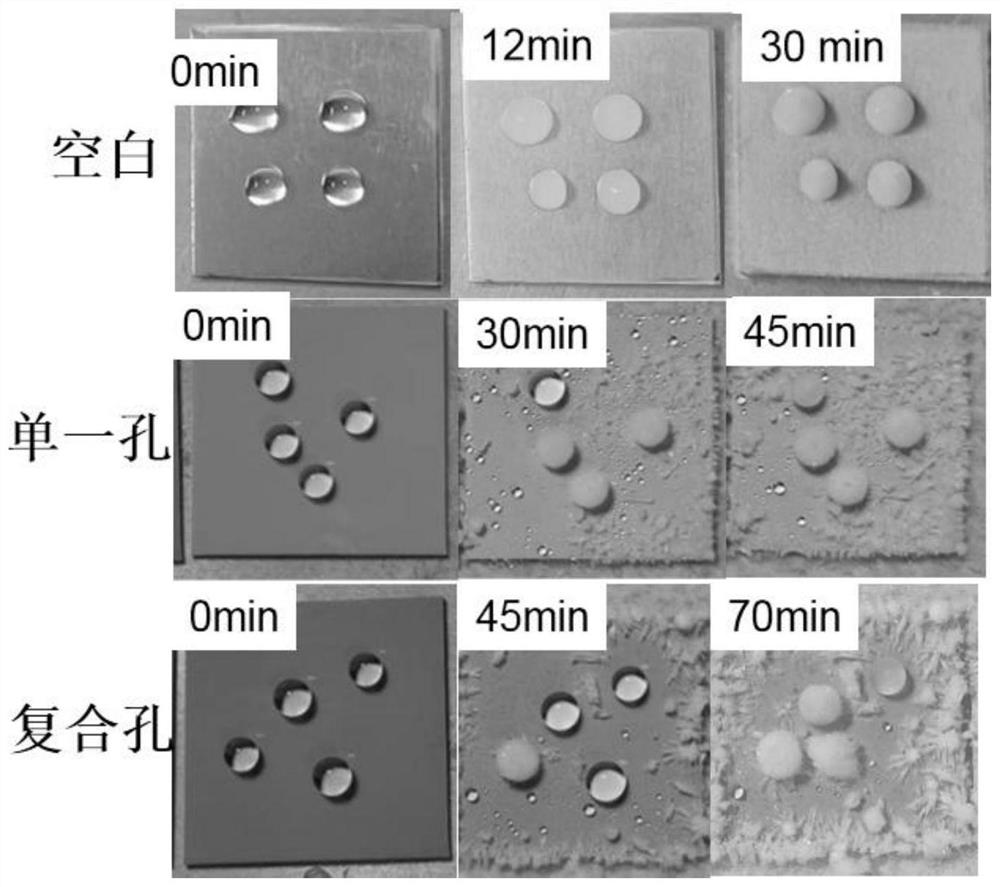

Self-repairing anti-icing aluminum stranded wire with composite holes and preparation method of self-repairing anti-icing aluminum stranded wire

InactiveCN113450945AExtend the life of anti-icingRaise the ratioAnodisationNon-insulated conductorsStructural engineeringAluminium matrix

The invention relates to a self-repairing anti-icing aluminum stranded wire with composite holes and a preparation method of the self-repairing anti-icing aluminum stranded wire, and belongs to the technical field of anti-icing material preparation. According to the self-repairing anti-icing aluminum stranded wire with the composite holes provided by the invention, the uniform porous aluminum oxide film grows on the surface of the aluminum substrate to form small-aperture inner layer holes (for storing a repairing agent for a long time) and large-aperture outer layer holes (for improving the anti-icing performance by increasing the air cushion proportion), the anti-icing aluminum wire with lasting and excellent anti-icing self-repairing performance is prepared by optimizing the aperture and thickness of the large holes (outer holes) and the small holes (inner holes) and filling a low-surface-energy repairing agent in the holes under the action of air pressure, capillary force and surface energy. The anti-icing performance of the aluminum stranded wire in practical application and self-repairing of the anti-icing performance after the aluminum stranded wire is damaged are improved, so that the anti-icing service life of the aluminum stranded wire is prolonged, and the lasting anti-icing performance of the aluminum stranded wire is improved. According to the self-repairing anti-icing aluminum stranded wire with the composite holes, repeated self-repairing of the anti-icing performance is achieved, and meanwhile, the hardness and the abrasion resistance of the film layer are improved.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com