Offshore large-diameter pile foundation with ice-resistant structure

A pile foundation and large-diameter technology, applied in the field of marine engineering, can solve problems such as difficult construction, large vertebral volume, and large engineering volume, and achieve good ice-breaking effect and small edge contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

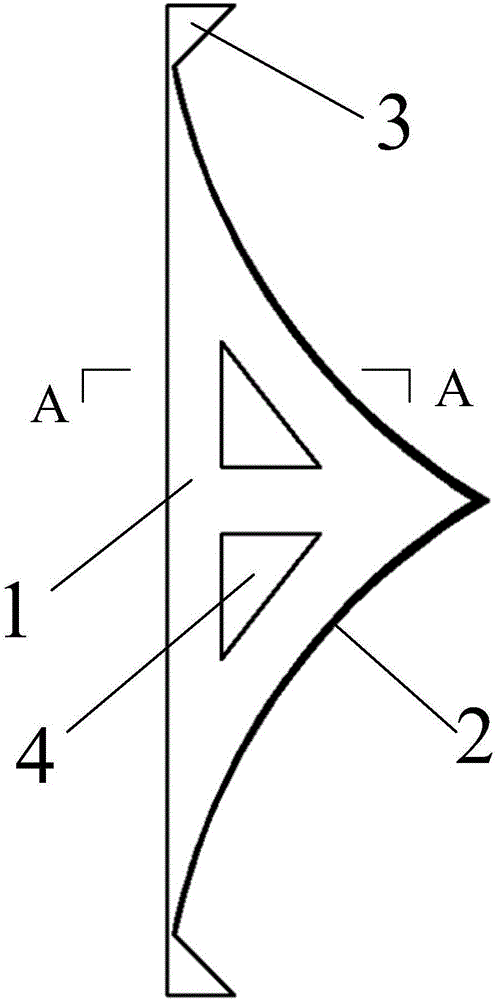

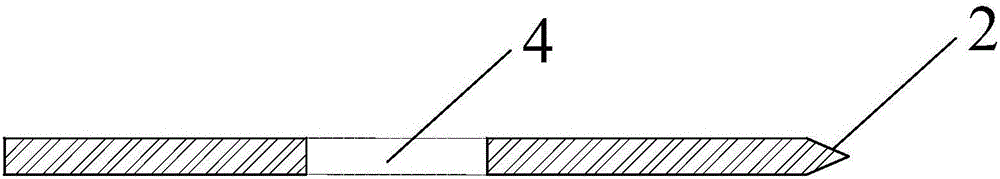

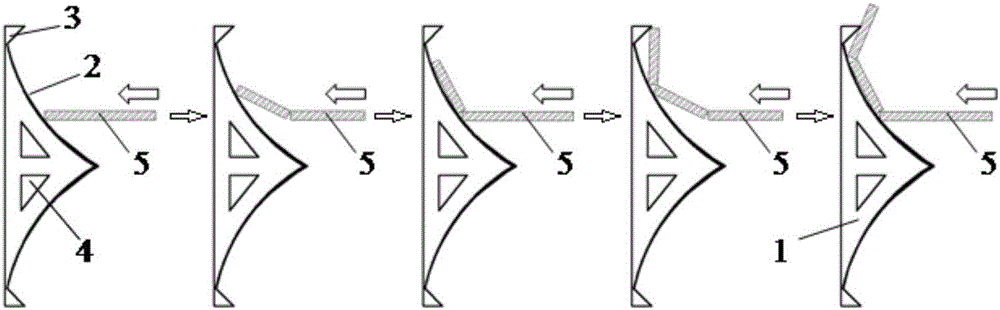

[0025] See attached picture:

[0026] The offshore large-diameter pile foundation with an ice-resistant structure is formed by welding a certain number of ice-resistant standard parts 1 symmetrically and evenly around the steel pile foundation. The ice-resistant standard parts welded around the steel pile foundation are provided with a main stiffened plate 7 and two upper and lower secondary stiffened plates 8 to improve the lateral stiffness of the ice-resistant standard parts. The ice-resistant standard parts 1 are evenly distributed around the pile foundation in an axisymmetric state, and the ice-breaking blades 2 face radially outward, thereby forming an ice-resistant structure.

[0027] The anti-ice standard part 1 has a symmetrical structure up and down, and two curved ice-breaking blades 2 concave inward are arranged symmetrically on the outside. The ice-breaking blades 2 are in the shape of a cutting edge. , the stress concentration on the contact surface makes the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com