Patents

Literature

49results about How to "Optimize process layout" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for polishing glass and polishing machine

InactiveCN102114607AEliminate mechanical positioning proceduresHigh positioning accuracyEdge grinding machinesDeflection angleNumerical control system

The invention discloses a method for polishing glass and a polishing machine. The polishing machine comprises a frame, a grinding operation platform arranged on the frame, a numerical control system, a grinding head controlled by a servo driving unit of the numerical control system, and an automatic imager controlled by the numerical control system, wherein a scanning head of the automatic imager is linked with the grinding head, and the data output end of the automatic imager is connected to the data input end of the numerical control system. By using the polishing machine, the deflection angle and position of a standard processing pattern of the numerical control system can be automatically adjusted according to a scanned pattern of the glass from the automatic imager, the glass blank can be directly and automatically ground without mechanically positioning the glass blank, and the finished glass product can be automatically detected, thereby realizing the full-automatic flow line production for grinding glass.

Owner:杭州富阳德迈机械有限公司

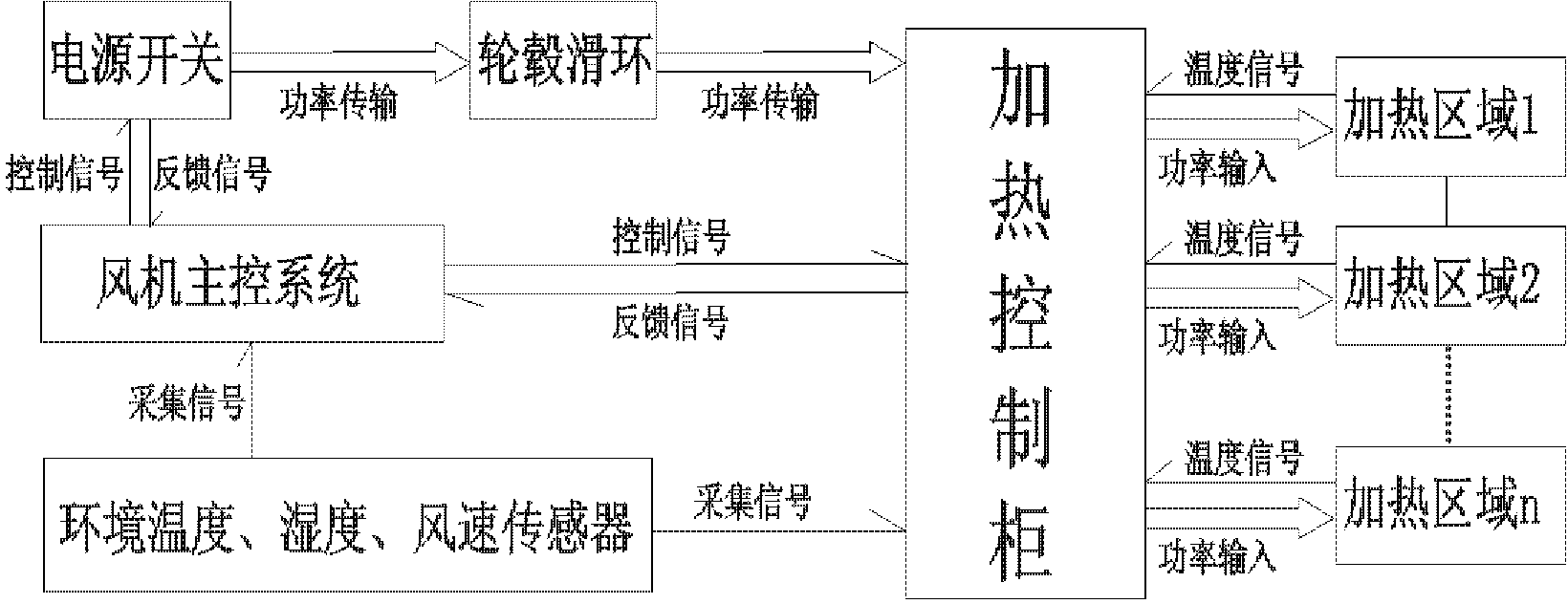

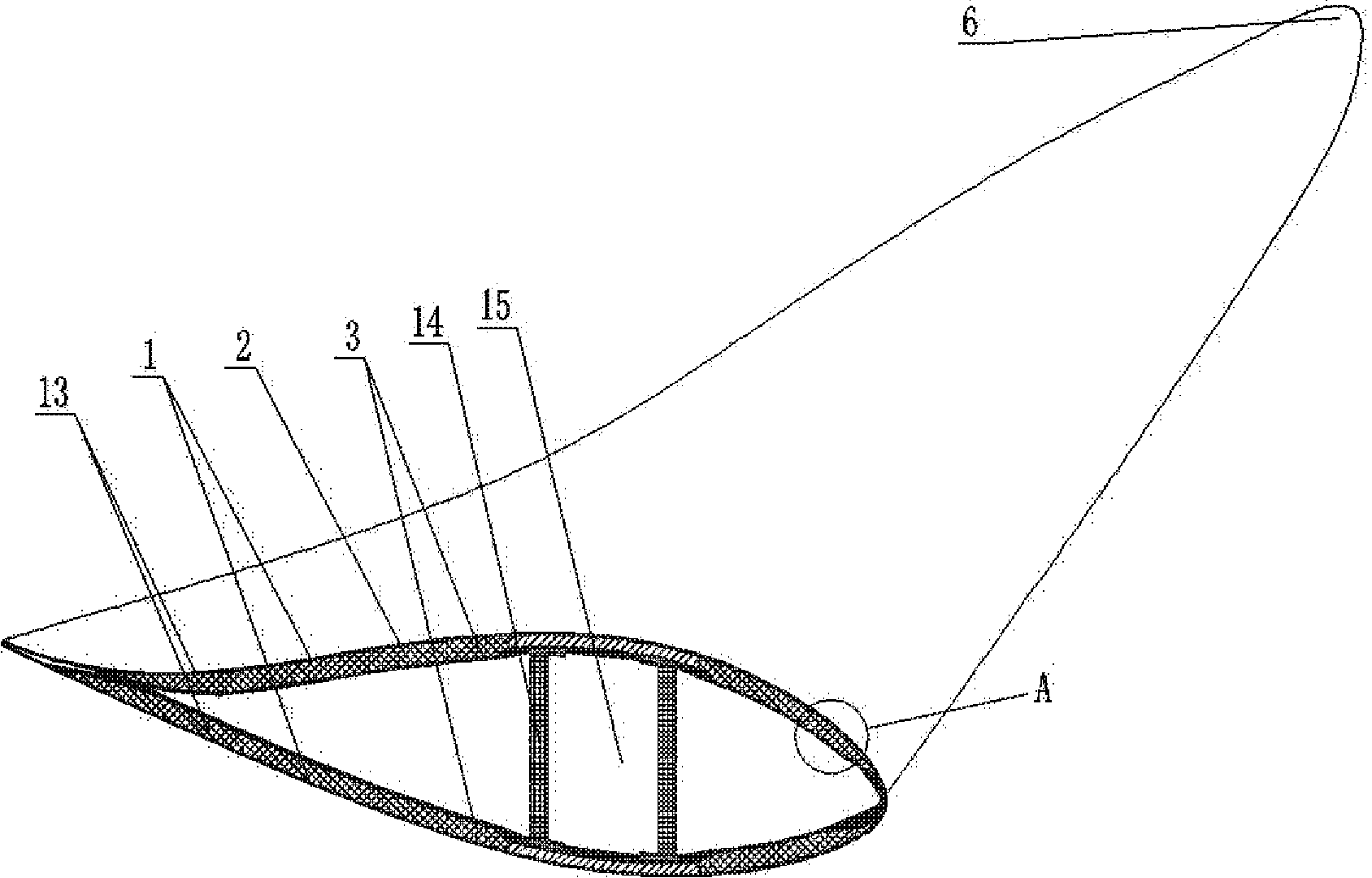

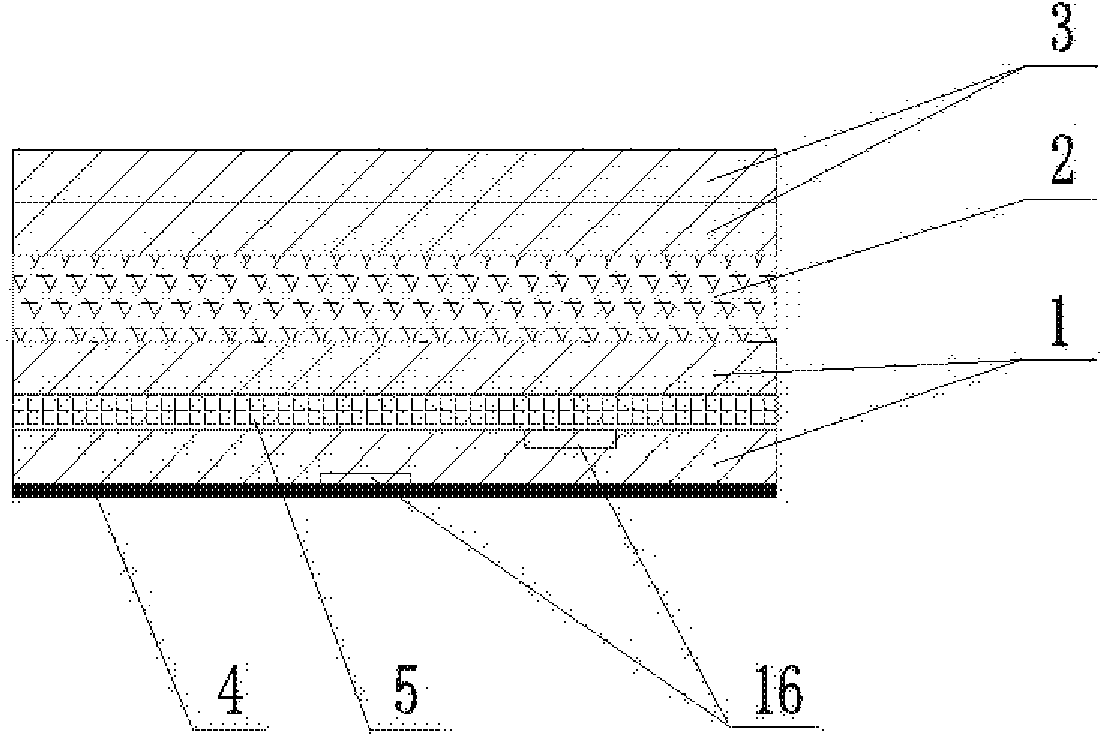

Anti-icing method of carbon crystal and wind power generator anti-icing system employing method

InactiveCN103291560AOptimize process layoutAnti-corrosionWind motor controlMachines/enginesManufacturing technologyClosed loop

The invention relates to an anti-icing method of a carbon crystal and a wind power generator anti-icing system employing the method. The method comprises the steps of printing the nanosized conductive carbon crystal on a carrier surface, preparing a thinner carbon crystal electric hot plate with two electrodes by a curing technology and a hot-pressing technology, taking one out of layers forming a blade as a heating layer, dividing the heating layer into a plurality of heating zones, arranging on-line temperature monitoring in each heating zone, performing temperature rising control with power units in corresponding zones in a heating control cabinet, and keeping the surface temperature of zones to be heated higher than and approximate to 0 DEG C. The anti-icing control system controls the heating zones in a simultaneous or alternant operation mode, and conducts on-line automatic ice prevention or ice melting. According to the method and the wind power generator anti-icing system, since the carbon crystal electric hot plate is adopted as an electric heating material of an anti-icing blade, the manufacturing technology is simple, and the heating is uniform and controllable; and since the surface adopts an on-line temperature monitoring closed-loop control mode, the anti-icing operation is stable, safe, and energy-saving.

Owner:XEMC NEW ENERGY

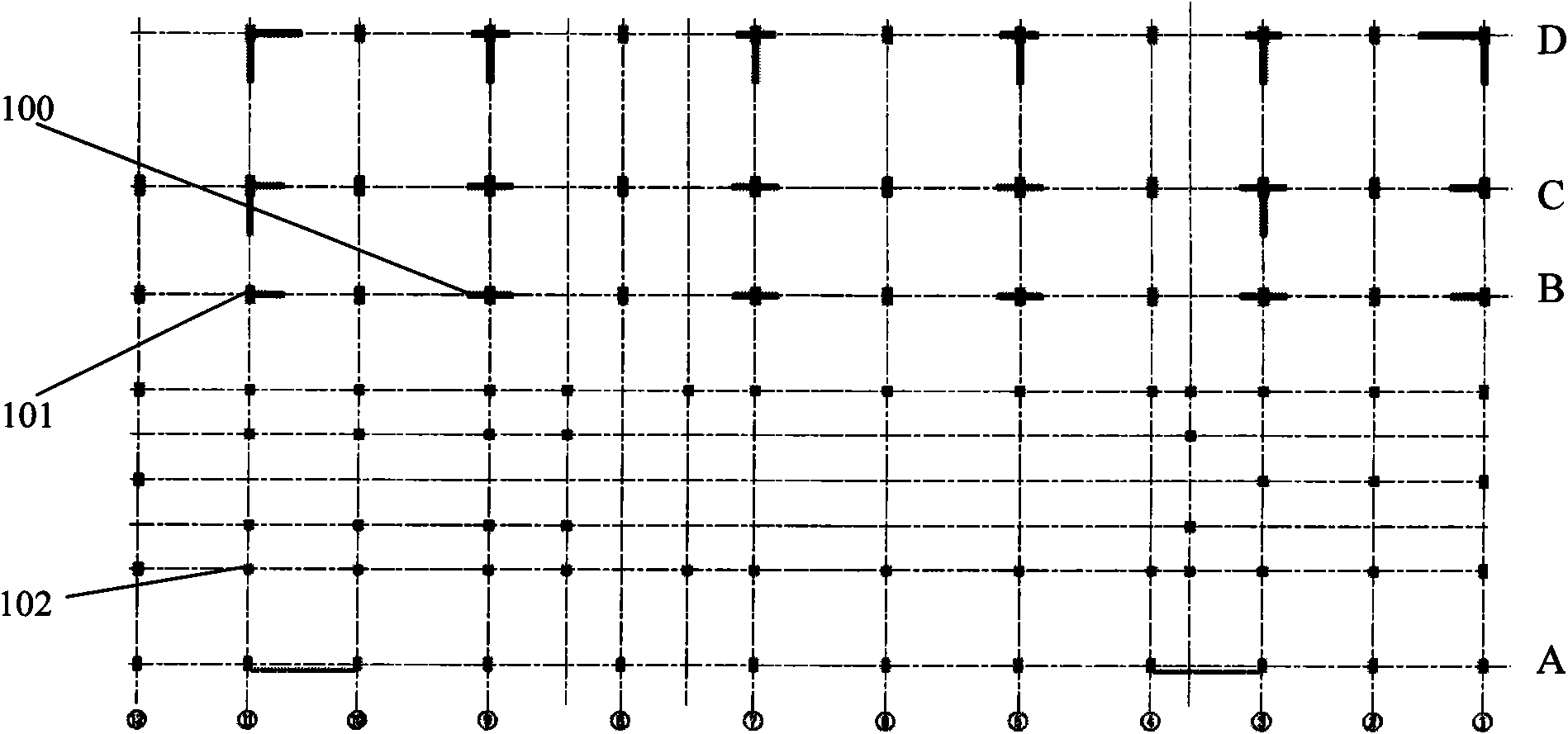

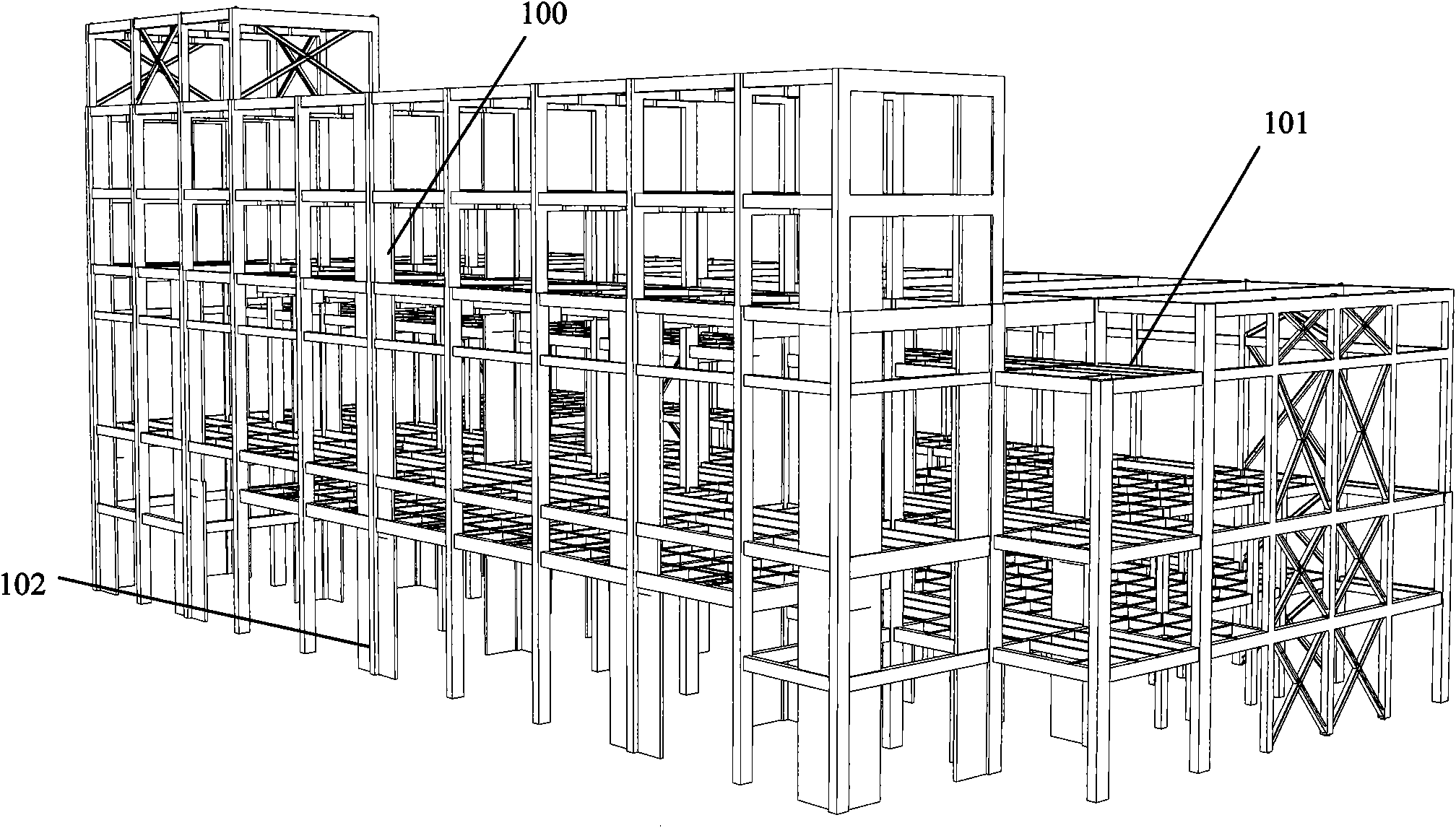

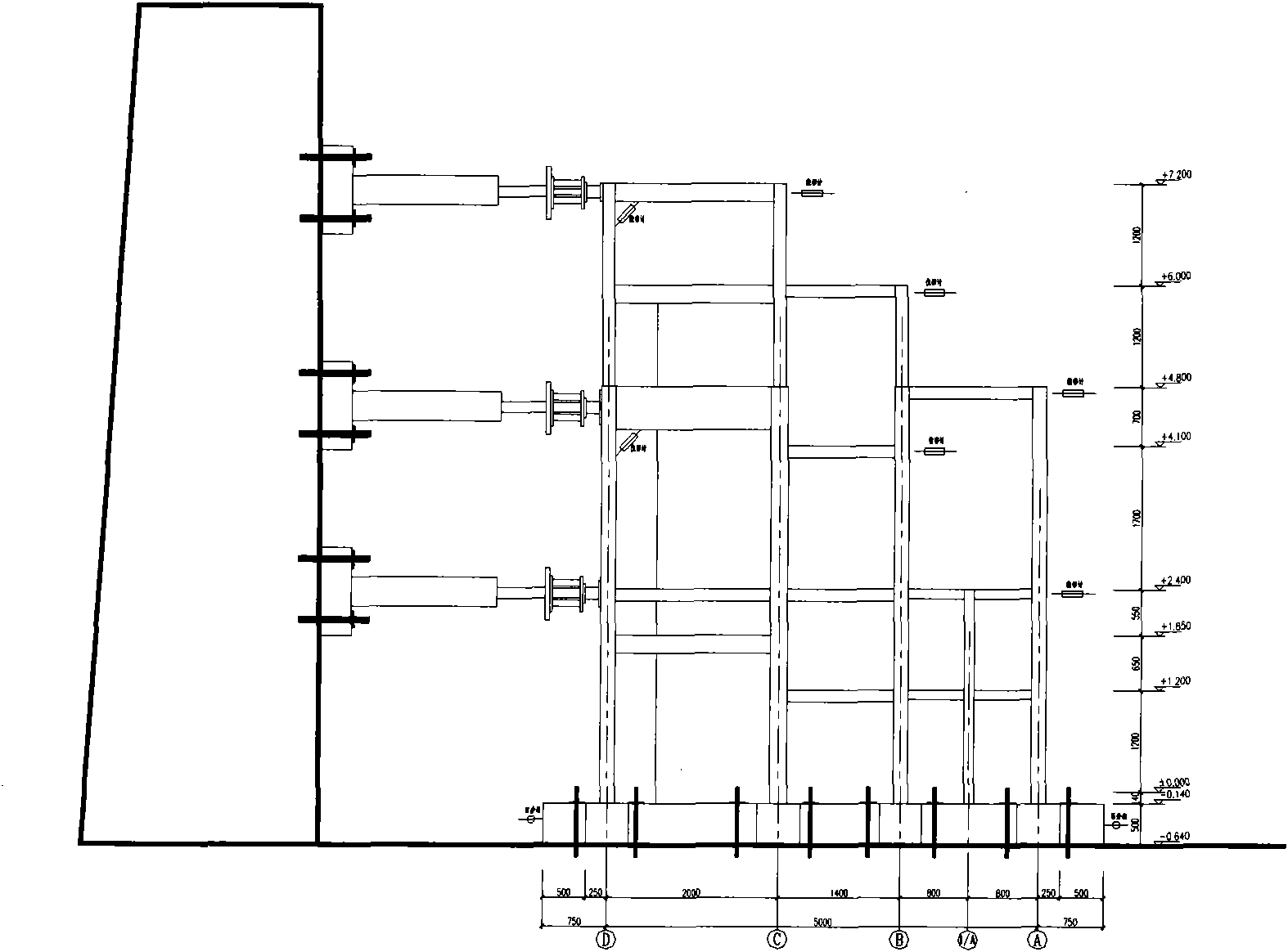

Main factory building structure system for large-scale thermal power plant

InactiveCN101566013ASmall sectionImprove seismic performanceBuilding constructionsIndustrial buildingsCoalReinforced concrete

The invention relates to a main factory building structure system for a large-scale thermal power plant, which comprises a framework part consisting of a coal bunker bay framework and a deaerator bay framework, and a framed bent part consisting of steam turbine hall framed bents, wherein the framework part adopts solid-web profiled bar concrete struts, and the framed bent part adopts reinforced concrete struts; and the profiled bar concrete struts in the framework part are provided with reinforced concrete short shear walls which are arranged at intervals along the transverse direction. The main factory building structure system has good shock resistance and can be arranged flexibly to satisfy various complex process conditions; and simultaneously, the application range of the structure system in designing the main factory building structure systems of thermal power plants which are at 7 and 8 degree areas, have machine sets of over 600 MW and are under the complex process conditions. Relative to the prior system, the main factory building structure system has good structural performance and comparatively low manufacturing cost, and has the advantages of better shock resistance, small column section, more convenient space for process layout, low post-maintenance cost and the like.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

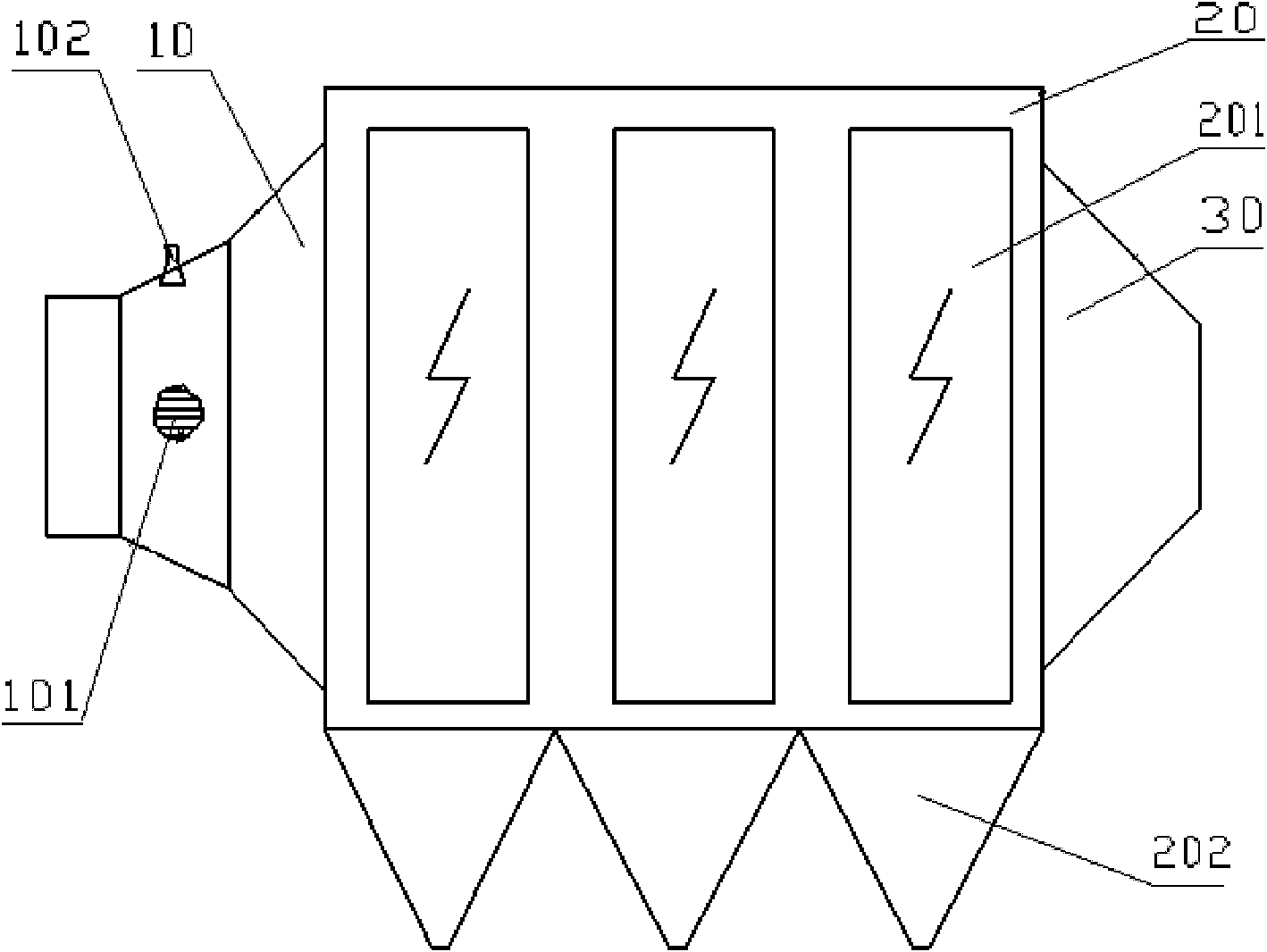

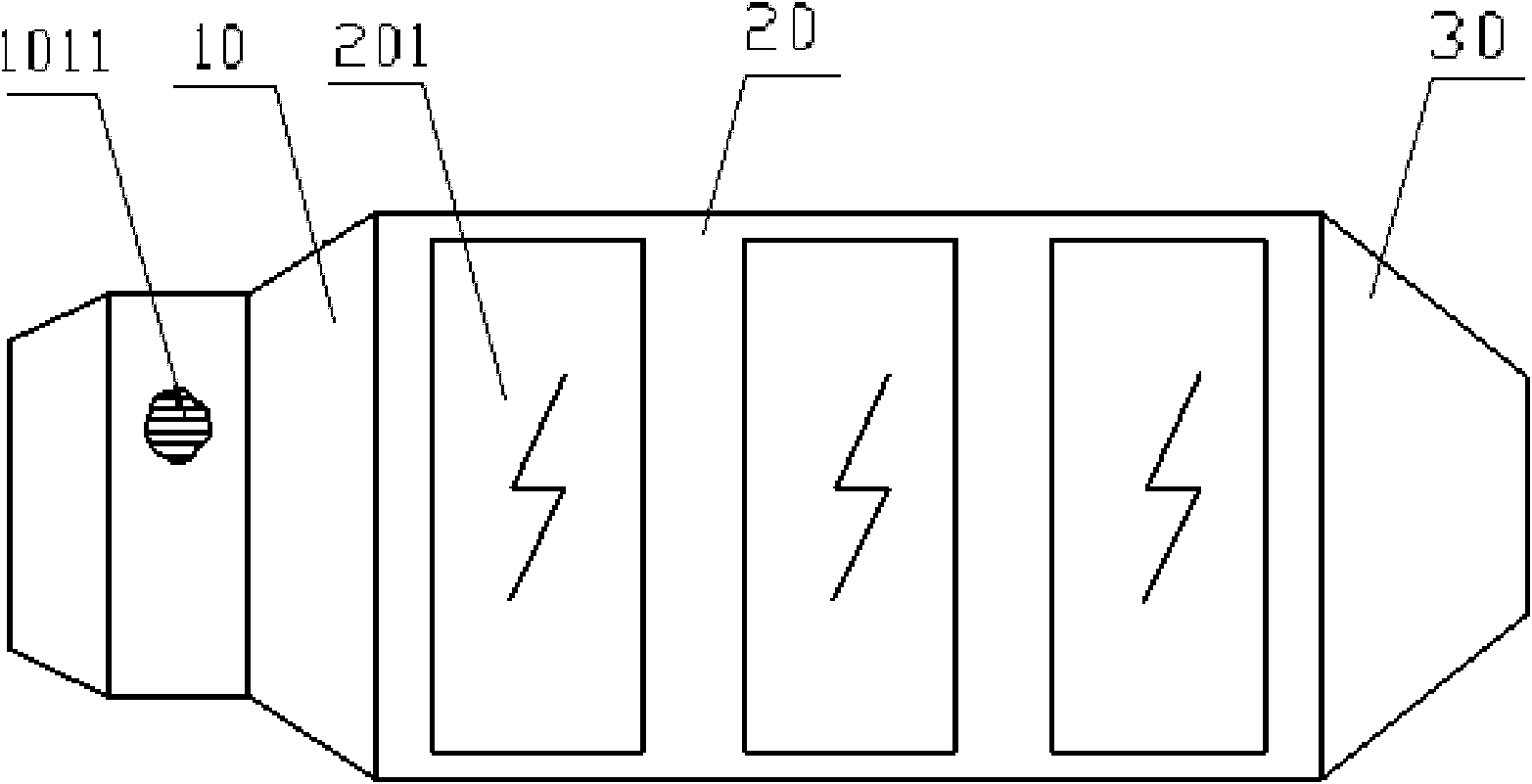

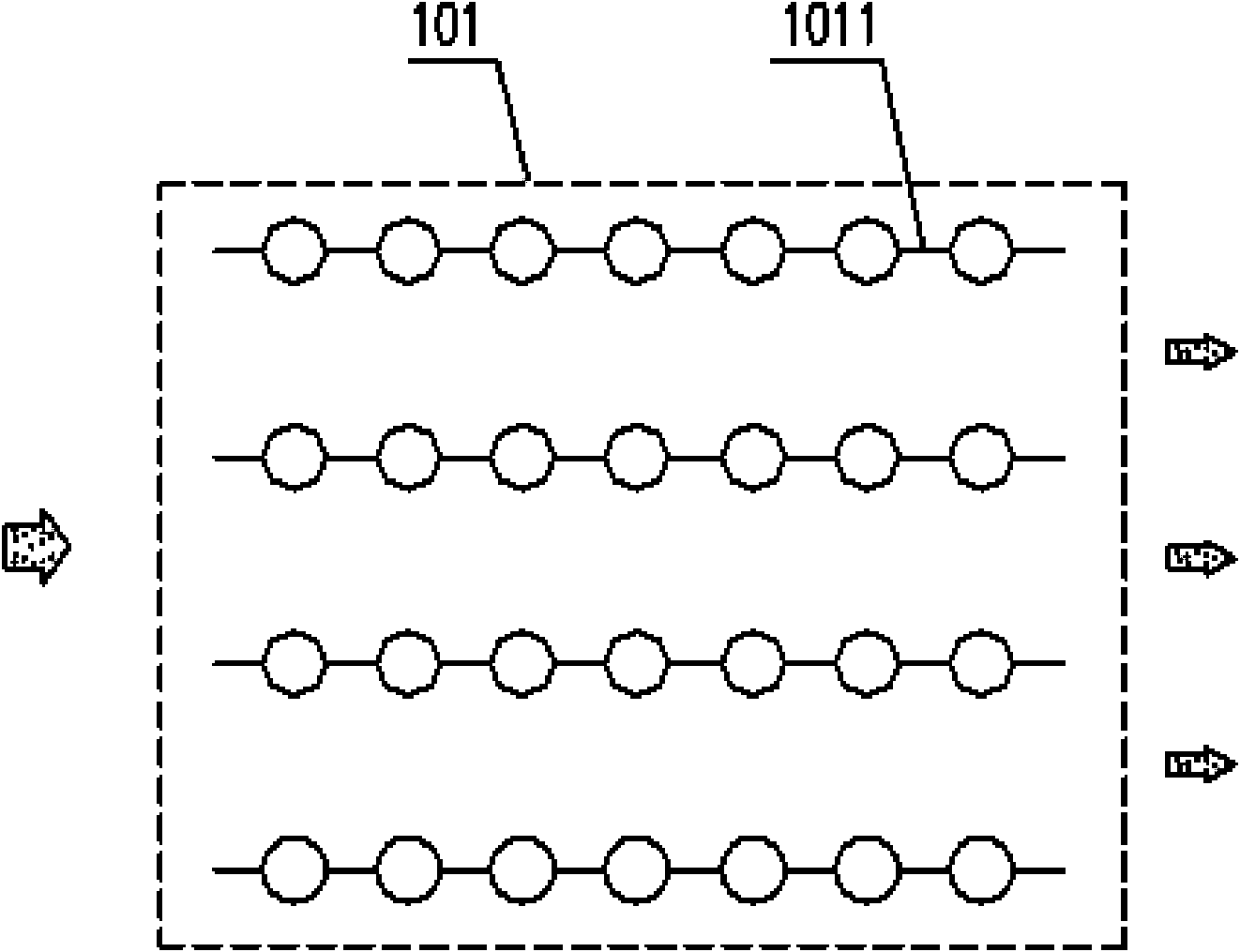

A flue gas dedusting system and its electric precipitator

ActiveCN102284361AImprove dust removal efficiencyCompact structureElectrostatic separationFlue gasProcess engineering

The invention discloses a flue gas electric dust remover. The flue gas electric dust remover comprises an inlet flue gas box, an outlet flue gas box, a high-pressure electrostatic dust collection electric field positioned between the inlet flue gas box and the outlet flue gas box, and a heat exchange device arranged in the inlet flue gas box. The flue gas electric dust remover can reduce the temperature of flue gas before the flue gas enters the high-pressure electrostatic dust collection electric field, so the volume flow rate of the flue gas to be treated which enters the electric field is reduced, and the flow velocity of the flue gas in a flue gas channel of the electric field is correspondingly reduced; meanwhile, the flue gas temperature is reduced, so the dust specific resistance of the flue gas is reduced, and the dust removal efficiency of the electric dust remover is improved; in addition, the heat exchange device is arranged at the inlet flue gas box, so the inner space of the inlet flue gas box on the conventional electric dust remover can be fully utilized, and additional occupied space is not increased while the dust removal efficiency is improved, namely the flue gas electric dust remover has the advantages of compact structure and contribution to system and process arrangement. The invention also discloses a flue gas dust removal system with the flue gas electric dust remover.

Owner:FUJIAN LONGKING

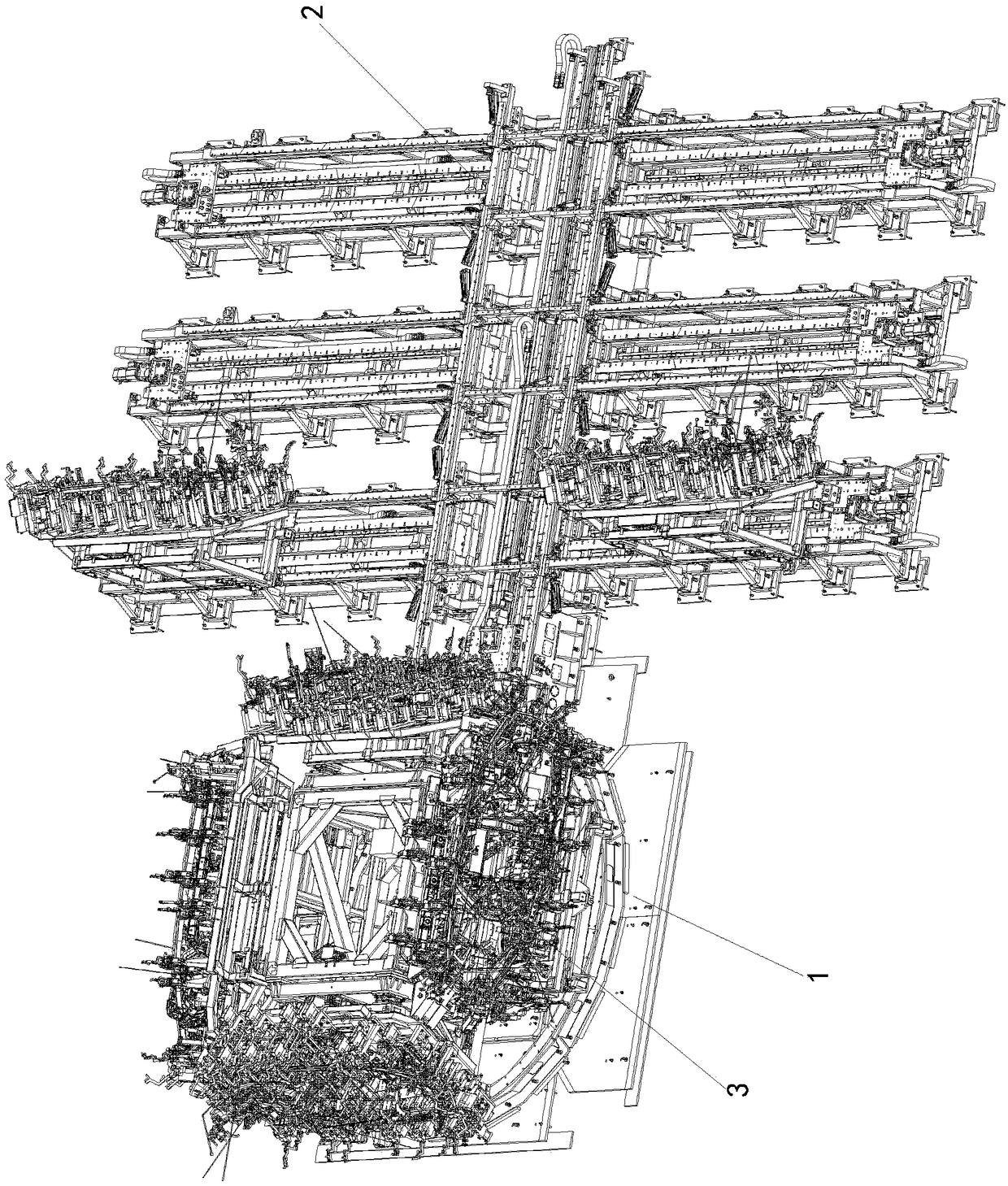

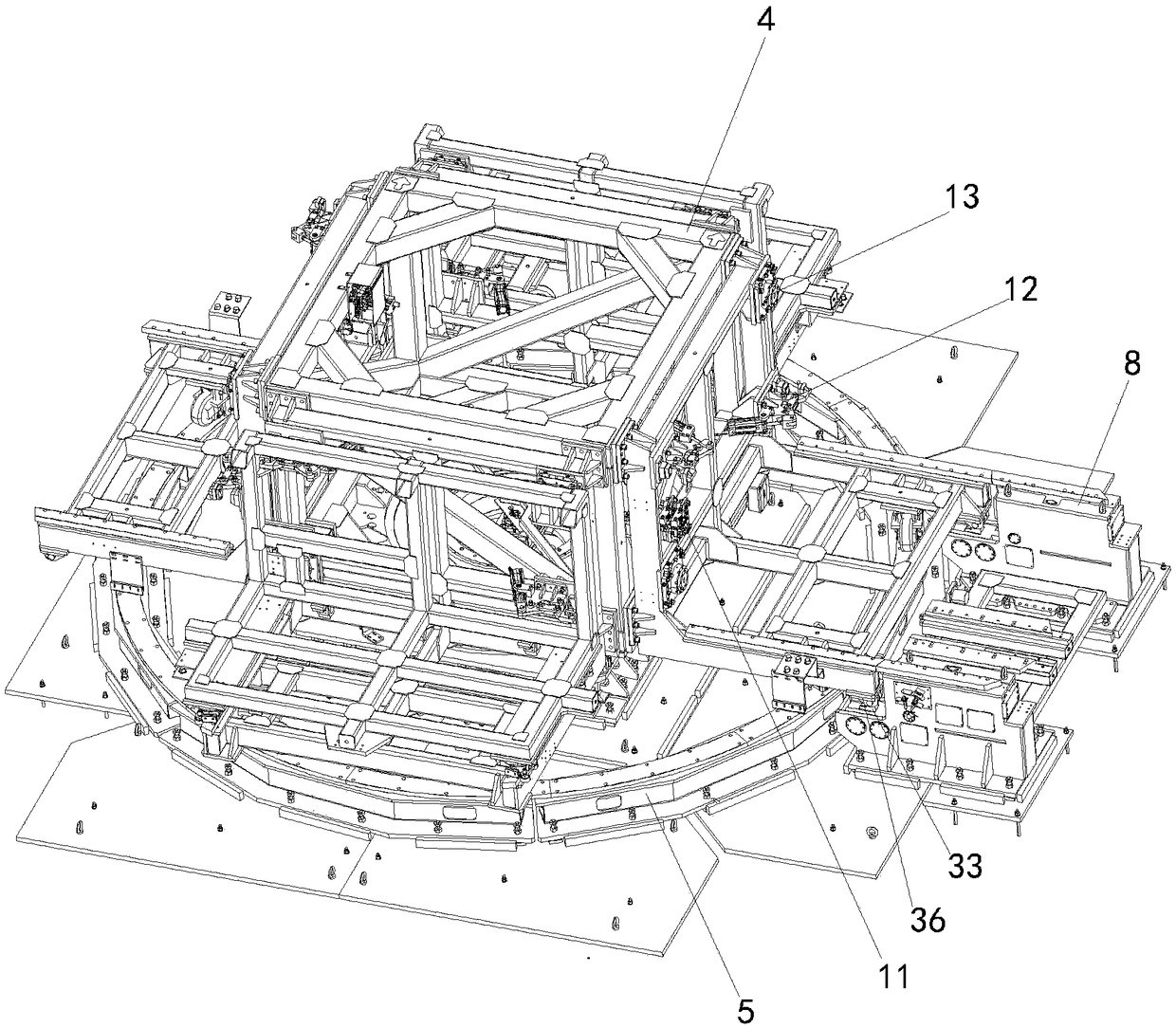

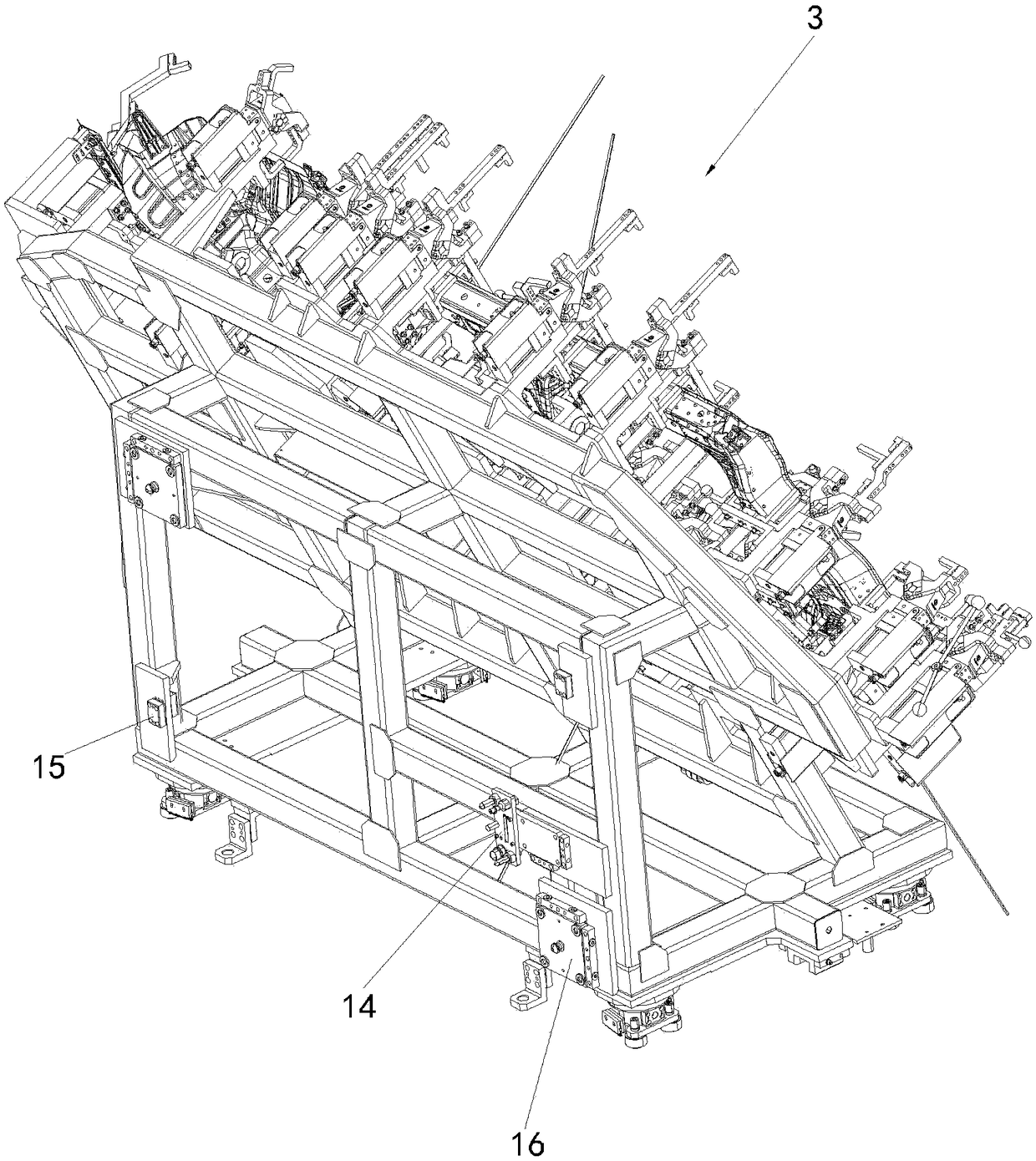

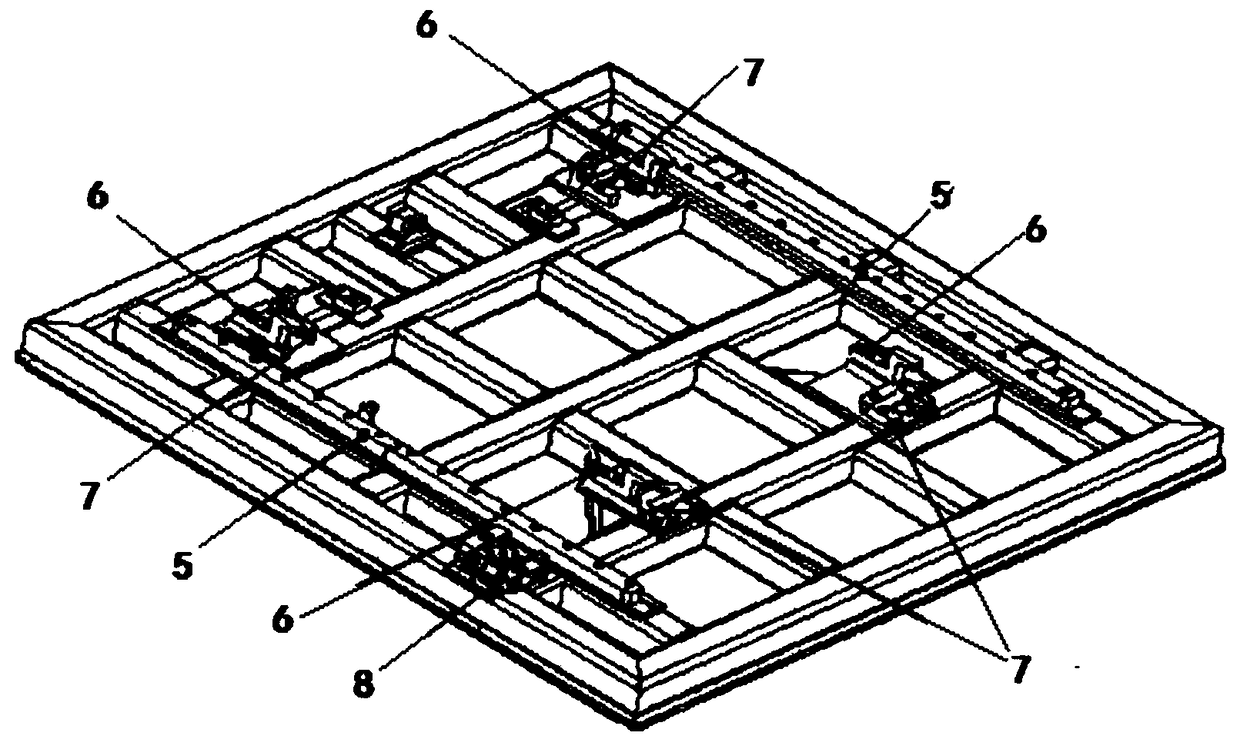

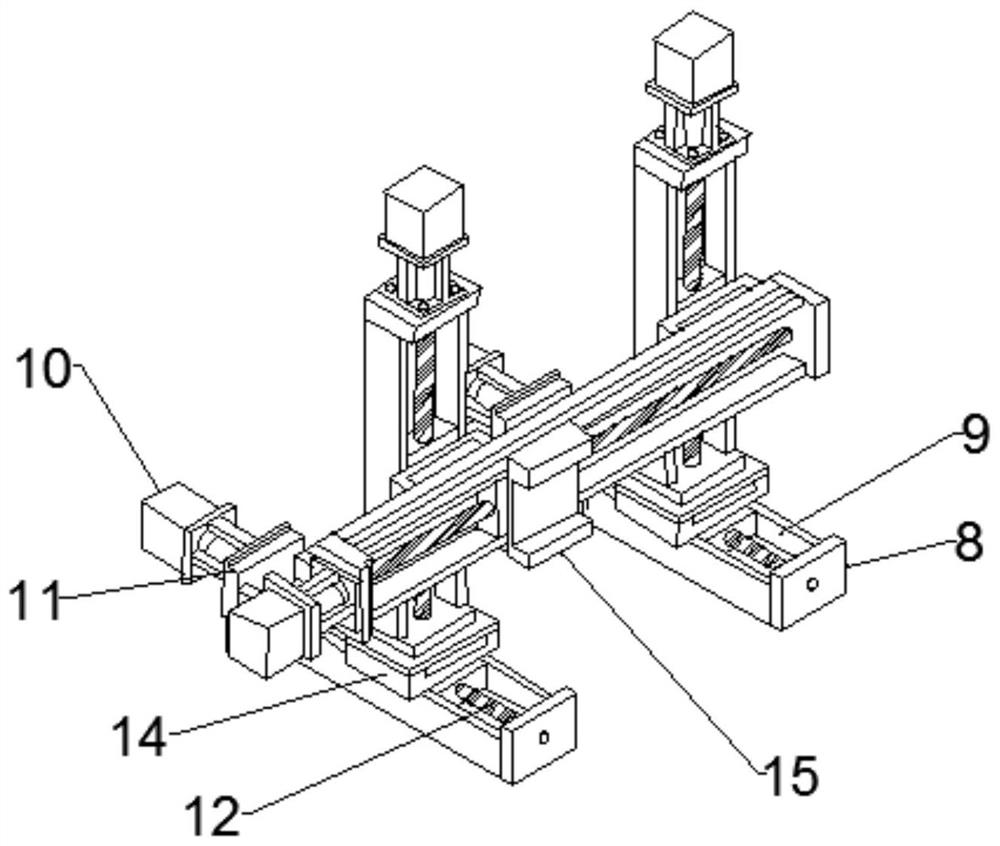

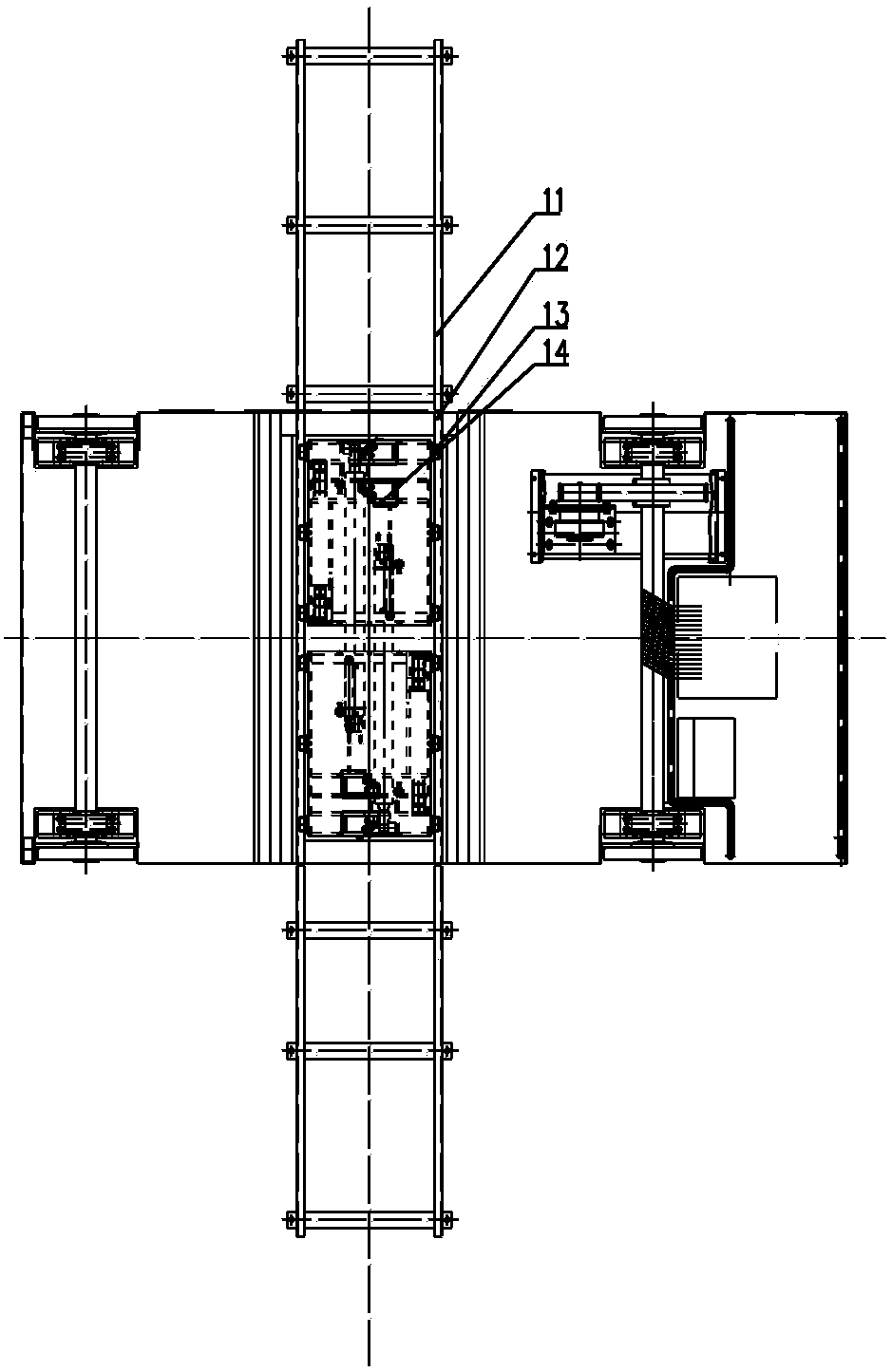

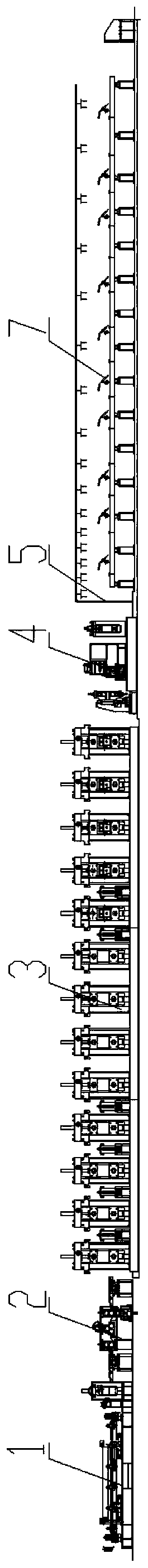

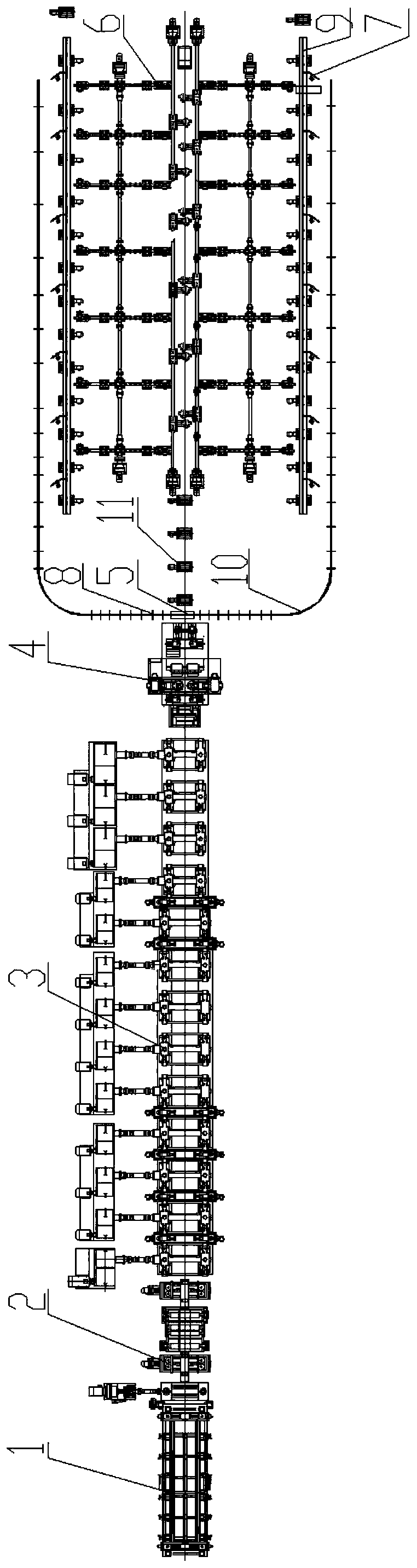

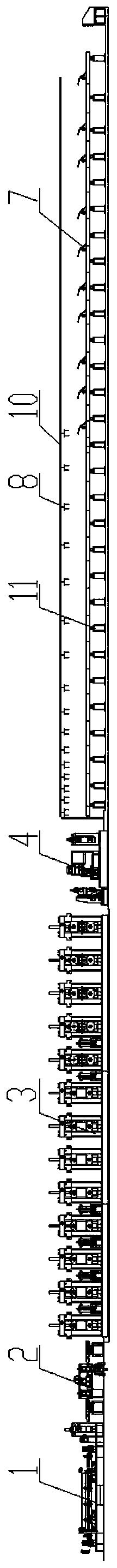

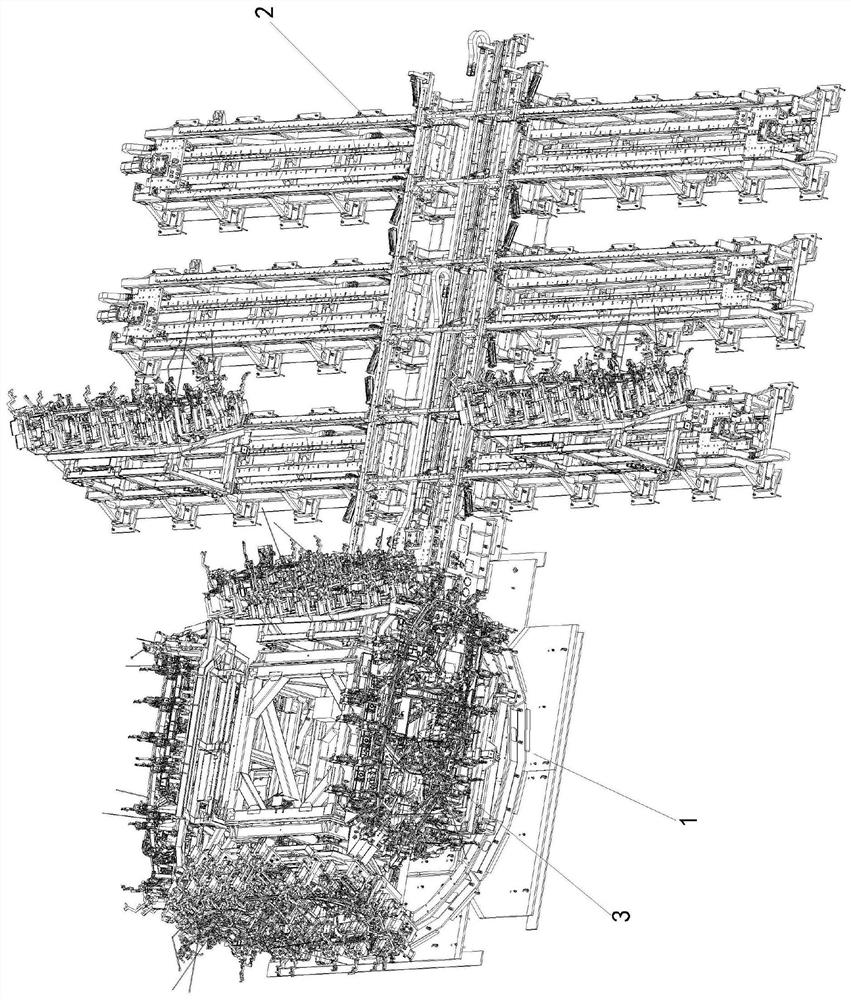

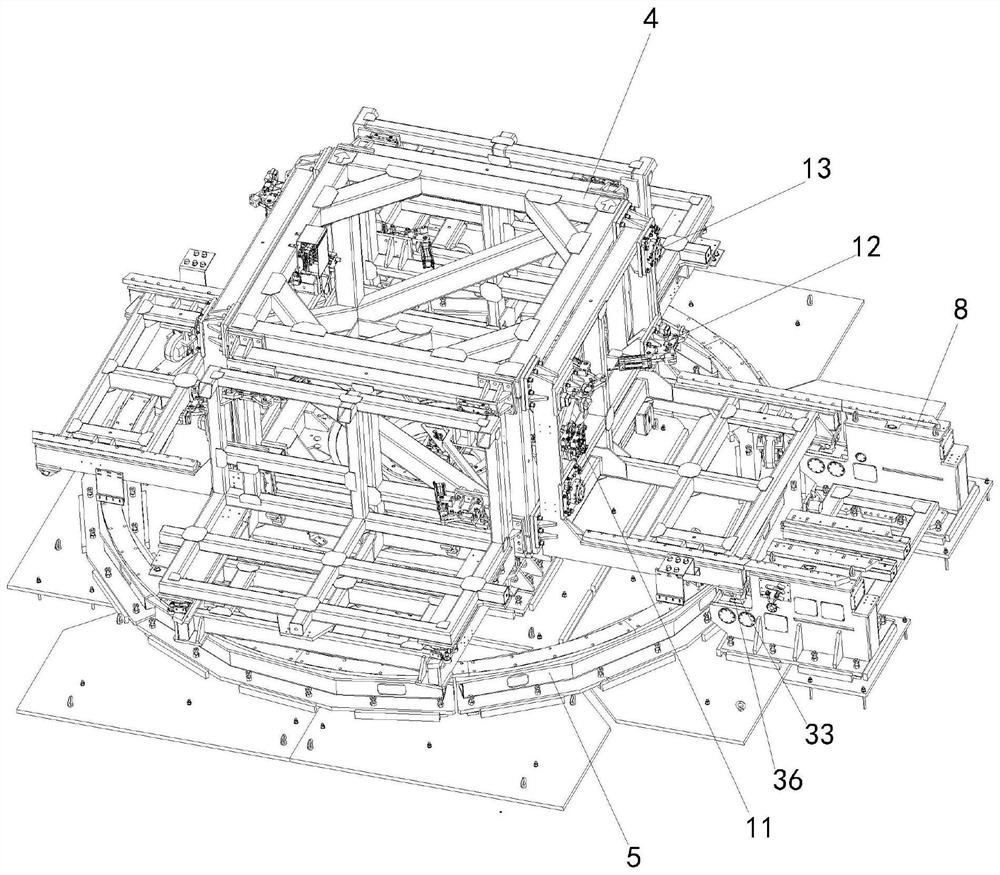

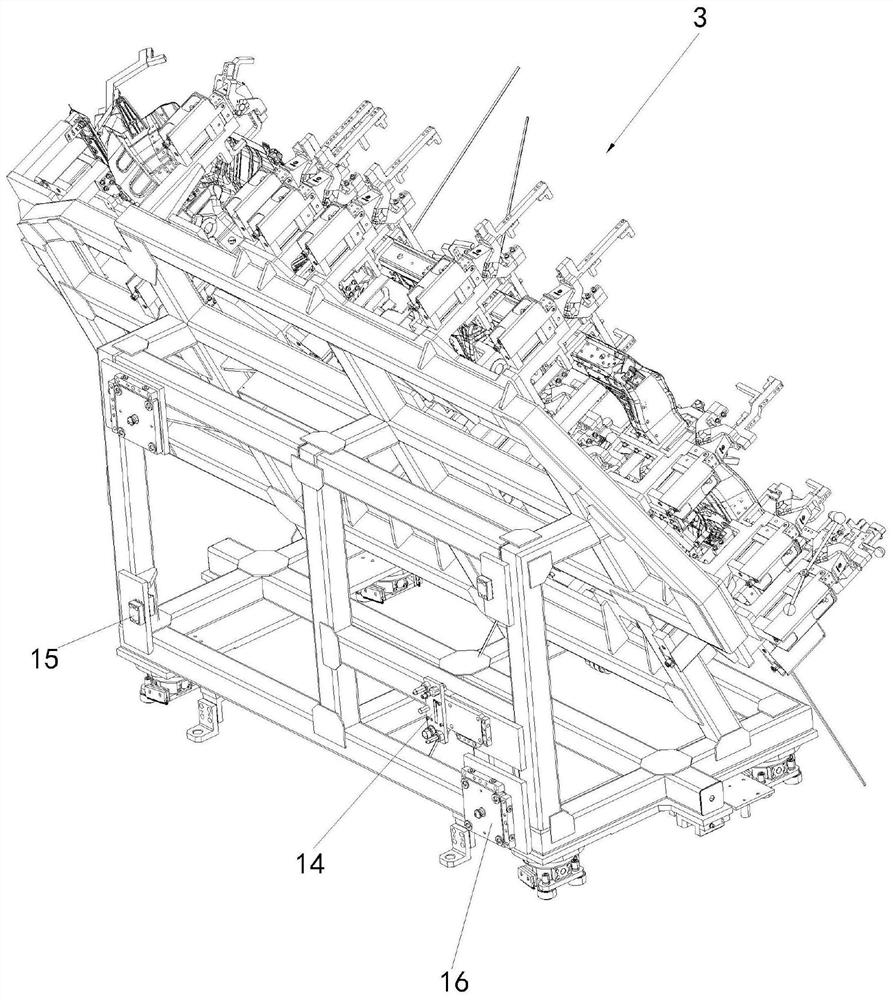

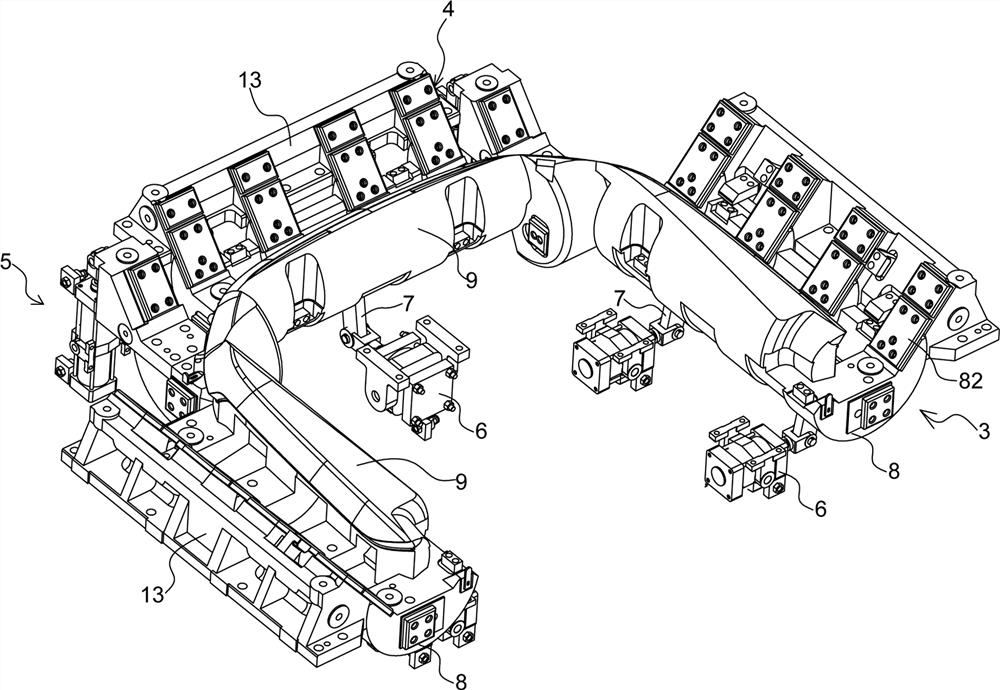

Multi-vehicle-type clamp switching warehouse system composed of tetrahedron rotary table and cross-shaped sliding table

ActiveCN108724049AReduce space footprintHigh degree of flexibilityWork holdersManufacturing efficiencyEngineering

The invention provides a multi-vehicle-type clamp switching warehouse system composed of a tetrahedron rotary table and a cross-shaped sliding table. Four side clamps are arranged on an upper tetrahedron frame of the tetrahedron rotary table in a center symmetry manner. A lower rotary table of the tetrahedron rotary table can rotate around the middle axis. Any side clamp can be switched to the butt joint position right opposite to a track butt joint device through rotation of the lower rotary table. A longitudinal sliding rail of the cross-shaped sliding table is in butt joint with a track ofthe track butt joint device, a plurality of transverse tracks are longitudinally arranged at intervals and are crossed with the longitudinal sliding rail in a cross manner, the various cross intersection positions on the cross-shaped sliding table are waiting positions, the side clamp located at the butt joint position is dragged by a traction trolley on the track butt joint device to run to one waiting position and is dragged by a traction trolley on the corresponding transverse track to run towards the left side or the right side to enter a warehouse. The multi-vehicle-type clamp switching warehouse system can meet the six-vehicle-type collineation production requirement, the equipment designing, machining, manufacturing, installing and maintaining difficulty is lowered, and the vehiclebody manufacturing efficiency is improved.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

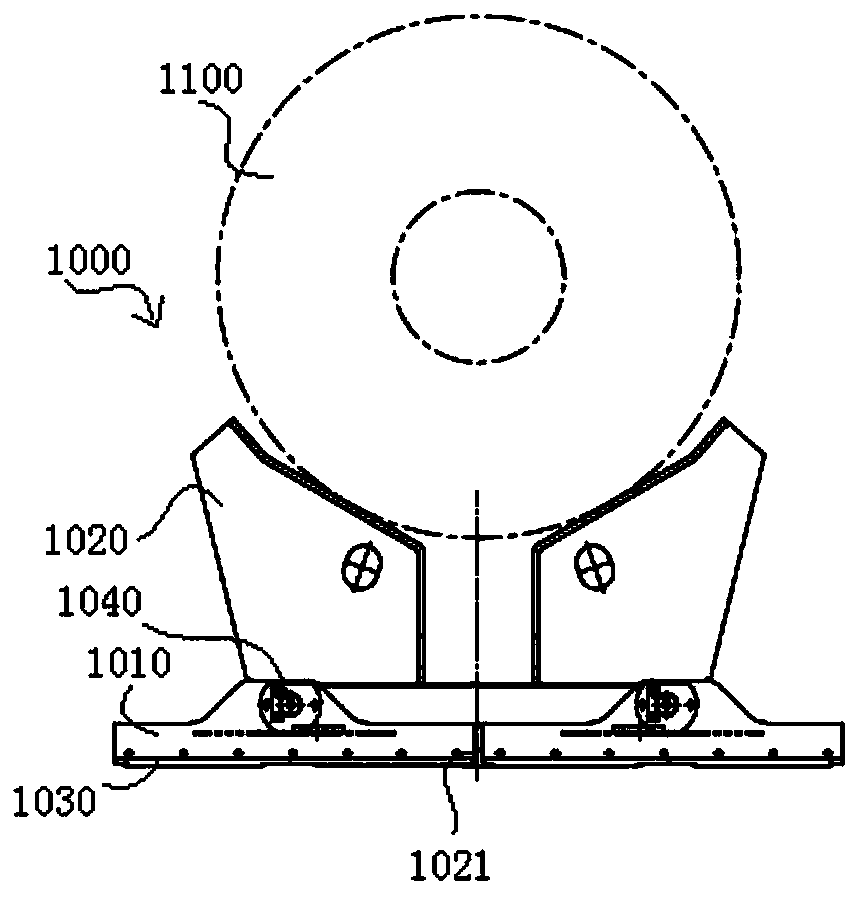

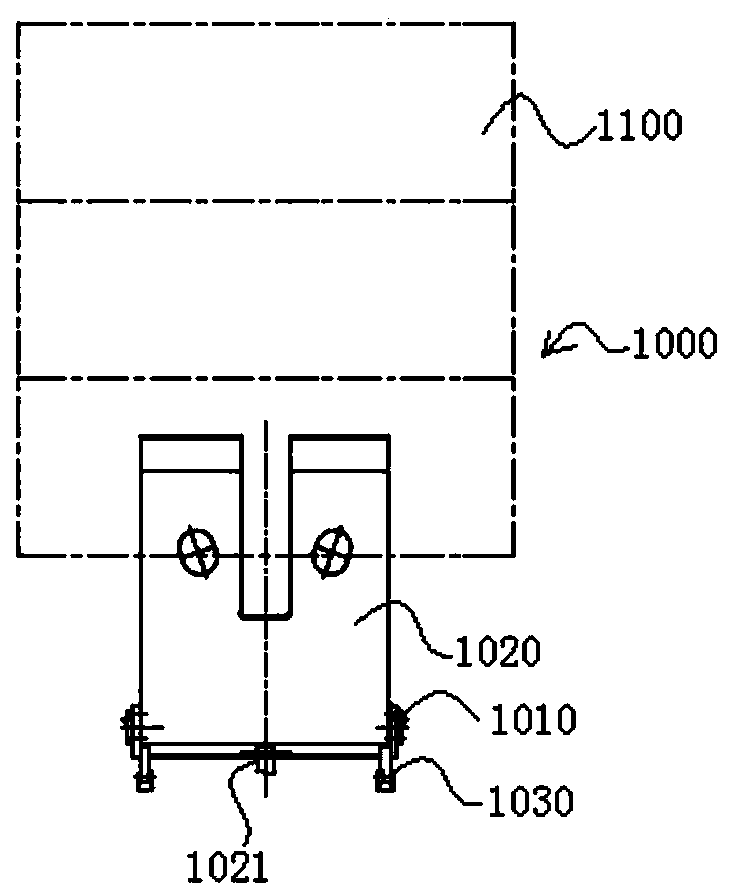

Efficient steel roll transportation system

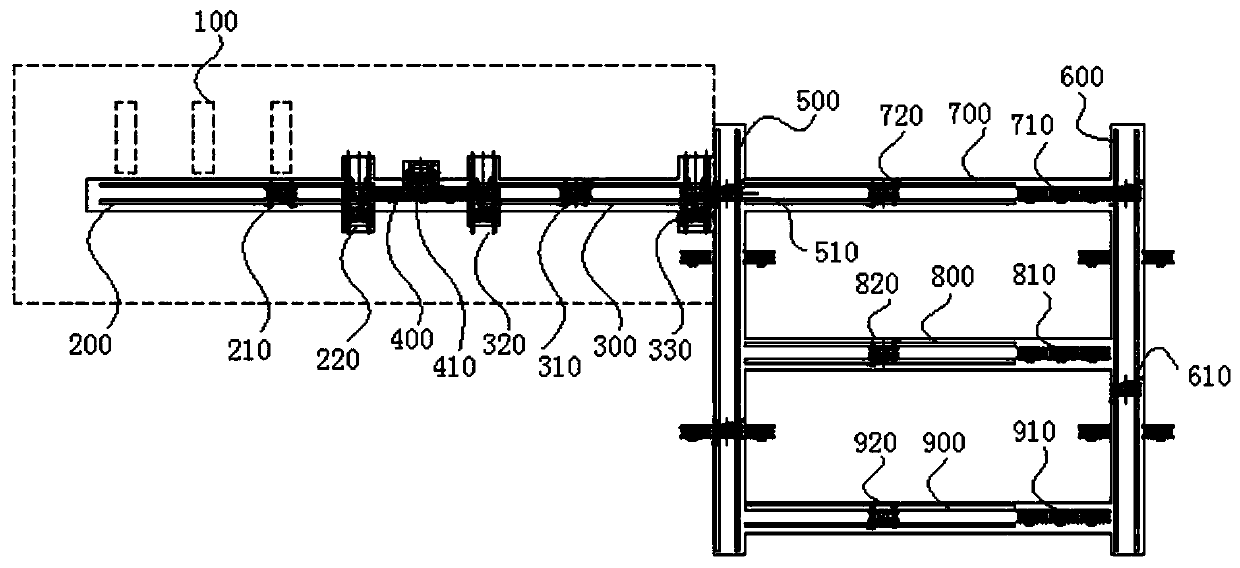

PendingCN110342169ASolve the problem of wide base widthReduce typesControl devices for conveyorsStorage devicesControl systemStructural engineering

The invention discloses an efficient steel roll transportation system. A steel roll bearing device, a conveying track, a circulation track, a transverse moving conveying device, a rapid conveying trolley and a PLC control system are included. The circulation start end of the circulation track communicates with the tail end of the conveying track. The circulation track comprises a first vertical track and a second vertical track which are arranged in parallel. Each of the first vertical track and the second vertical track is provided with at least one circulation trolley capable of moving up and down on each of the first vertical track and the second vertical track. A plurality of transverse tracks horizontally arranged in parallel are arranged between the first vertical track and the second vertical track and provided with unloading trolleys capable of moving front and back along the transverse tracks. The equipment base occupied width is small, the depth is small, construction difficulty is low, and economical efficiency is higher.

Owner:SHANGHAI MEISHAN IND CIVIL ENG DESIGN & RES INST CO LTD

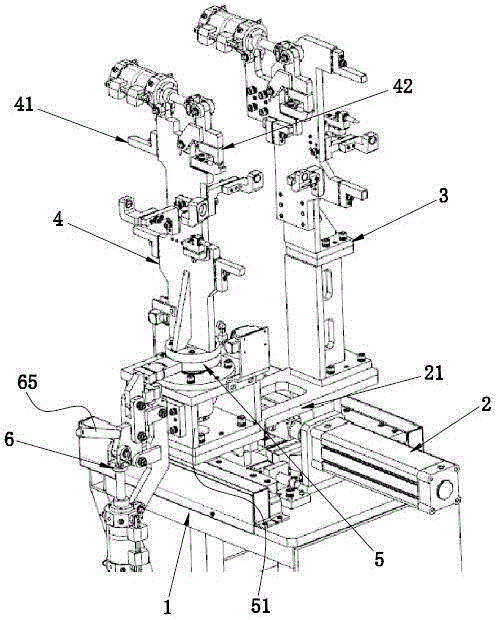

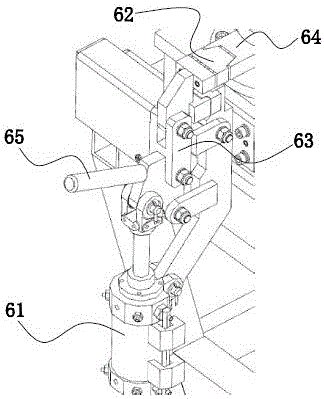

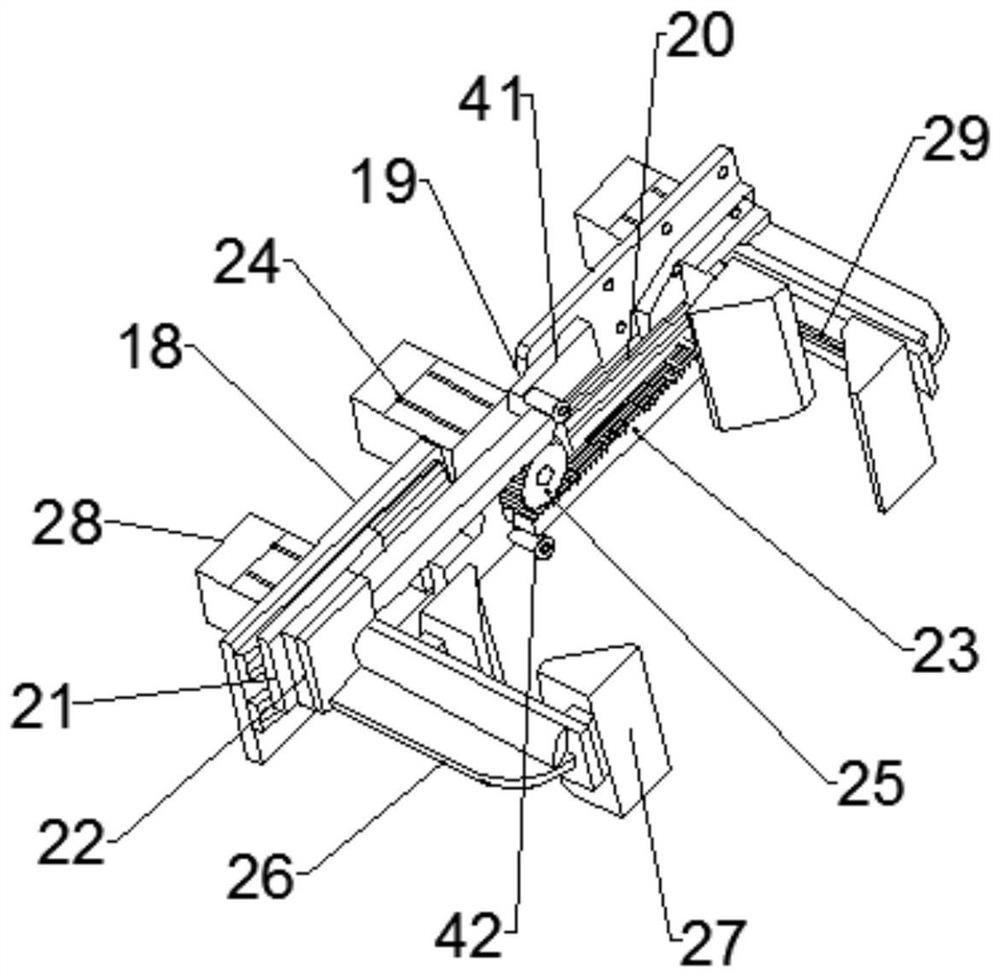

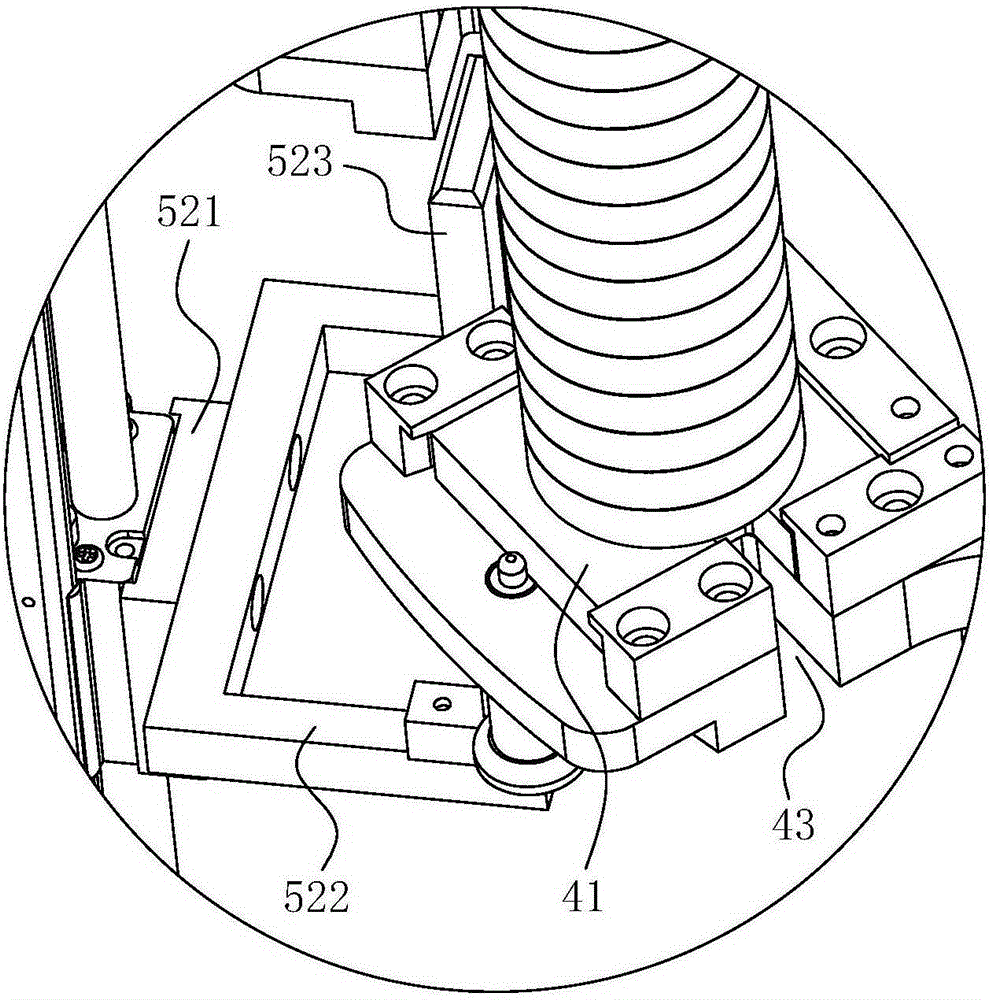

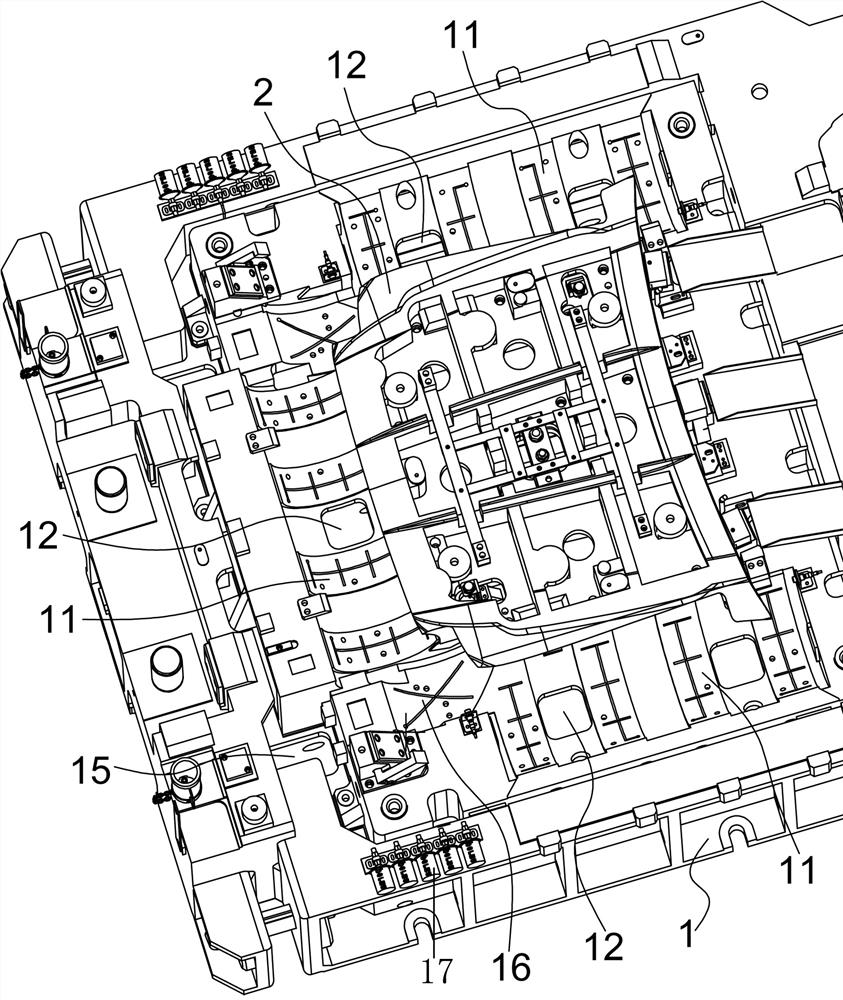

Front wheel cover outer plate reinforcing plate flexible positioning device

ActiveCN106216923AEasy to switchOptimize process layoutWelding/cutting auxillary devicesAuxillary welding devicesLocking mechanismEngineering

The invention provides a front wheel cover outer plate reinforcing plate flexible positioning device. The device comprises a bracket, a translation mechanism and a positioning mechanism; the translation mechanism is mounted on the bracket; the positioning mechanism is arranged on the translation mechanism, and includes a first positioning mechanism and a second positioning mechanism; positioning units are respectively arranged at the upper ends of the first positioning mechanism and the second positioning mechanism; a rotating mechanism and a locking mechanism are arranged at the lower end of the second positioning mechanism; and the second positioning mechanism includes a first positioning unit, and a second positioning unit arranged in the opposite direction of the first positioning unit. As the second positioning mechanism is provided with the rotating mechanism, and is provided with the first positioning unit and the second positioning units with opposite directions, different positioning units can be replaced according to different vehicle types, each set of positioning tools can adapt to two vehicle types, the tool switching is simpler, and the process layout is facilitated.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

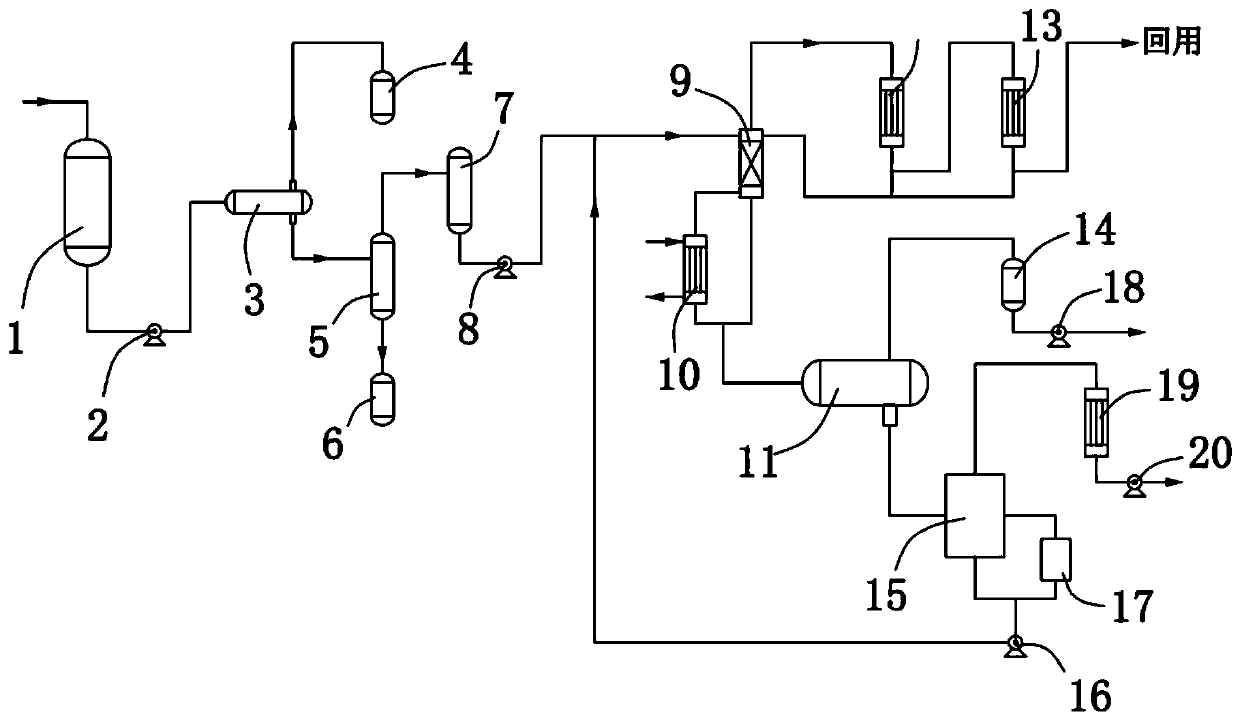

Organosilicone waste acid contained tributylamine, siloxane and aluminum chloride recycling technology

ActiveCN110272348AImprove recycling efficiencySimple processSilicon organic compoundsAmino compound purification/separationReboilerEvaporation

The invention relates to the technical field of environment-friendly industry waste acid recycling, in particular to an organosilicone waste acid contained tributylamine, siloxane and aluminum chloride recycling technology. The technology comprises the steps of acid and oil separation, aluminum chloride film separation, hydrochloric acid salting analysis, tributylamine and salt separation and salt evaporation and concentration. Equipment of the technology comprises a waste hydrochloric acid groove, a waste acid feeding pump, an acid and water separator, a siloxane recycling tank, a film filter, an aluminum chloride collecting tank, a hydrochloric acid tundish, a hydrochloric acid entrance pump, an analysis tower, a first reboiler, a two-phase separator, a primary condenser, a secondary cooler, a tributylamine recycling tank, an evaporator, a calcium chloride recycling pump, a second reboiler, a tributylamine recycling pump, a wastewater condensation groove and a wastewater pump; the organosilicone waste acid contained tributylamine, siloxane and aluminum chloride recycling technology has the advantages of lowering the treatment operation cost, meanwhile, recycling lost catalysts, siloxane, aluminum chloride and other substances, and improving economic benefits of an enterprise.

Owner:南京蓝胜环保科技有限公司

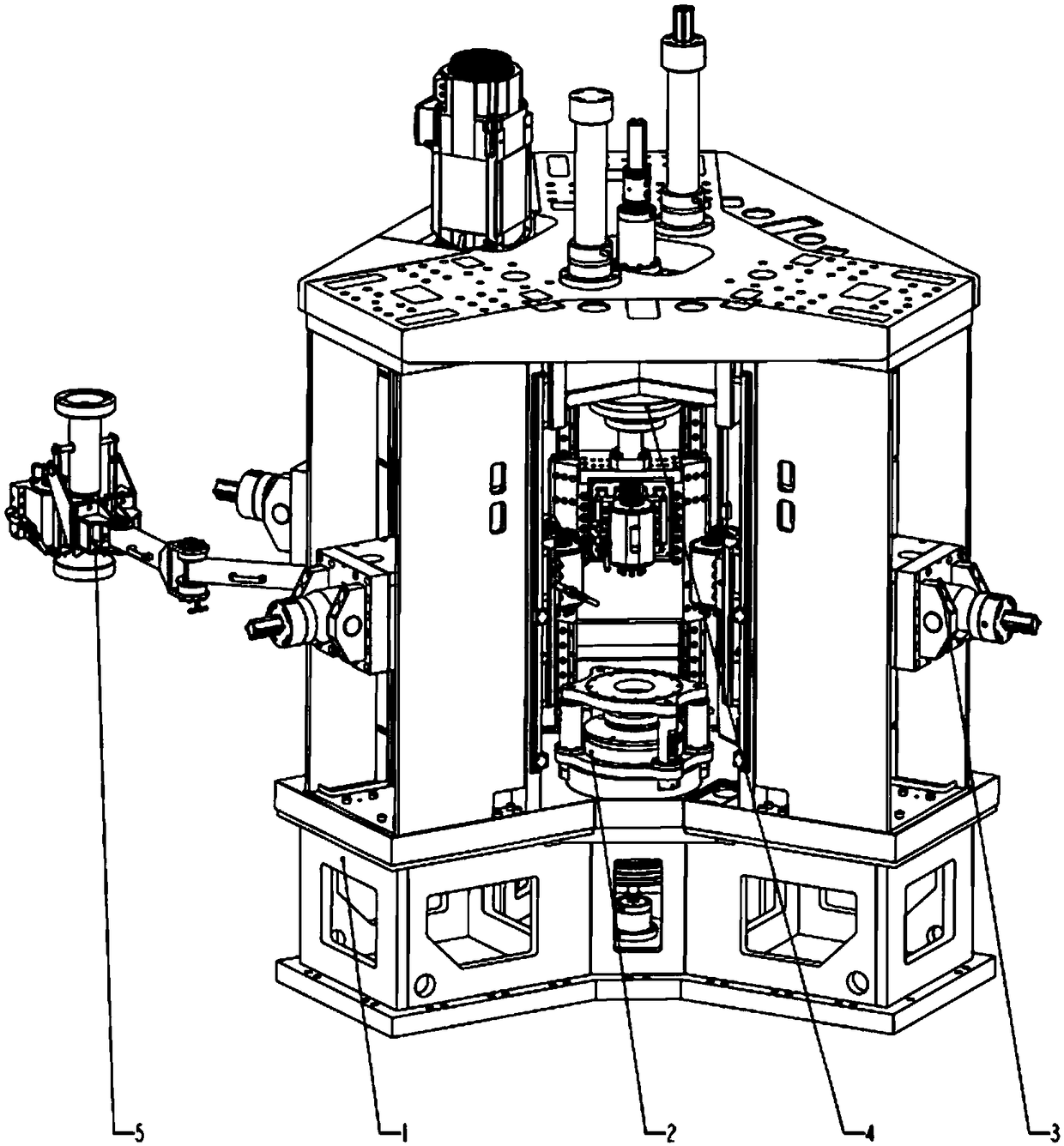

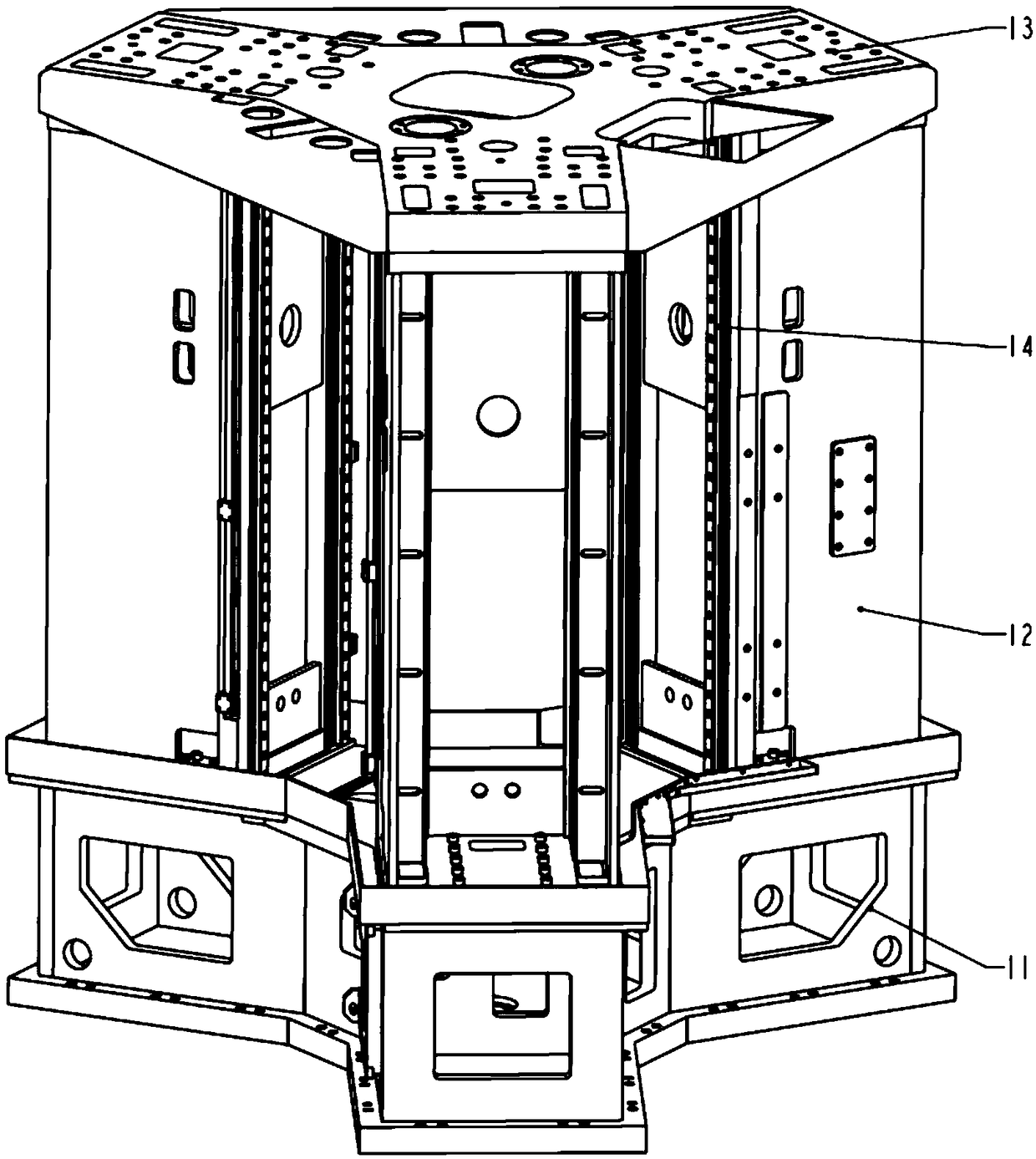

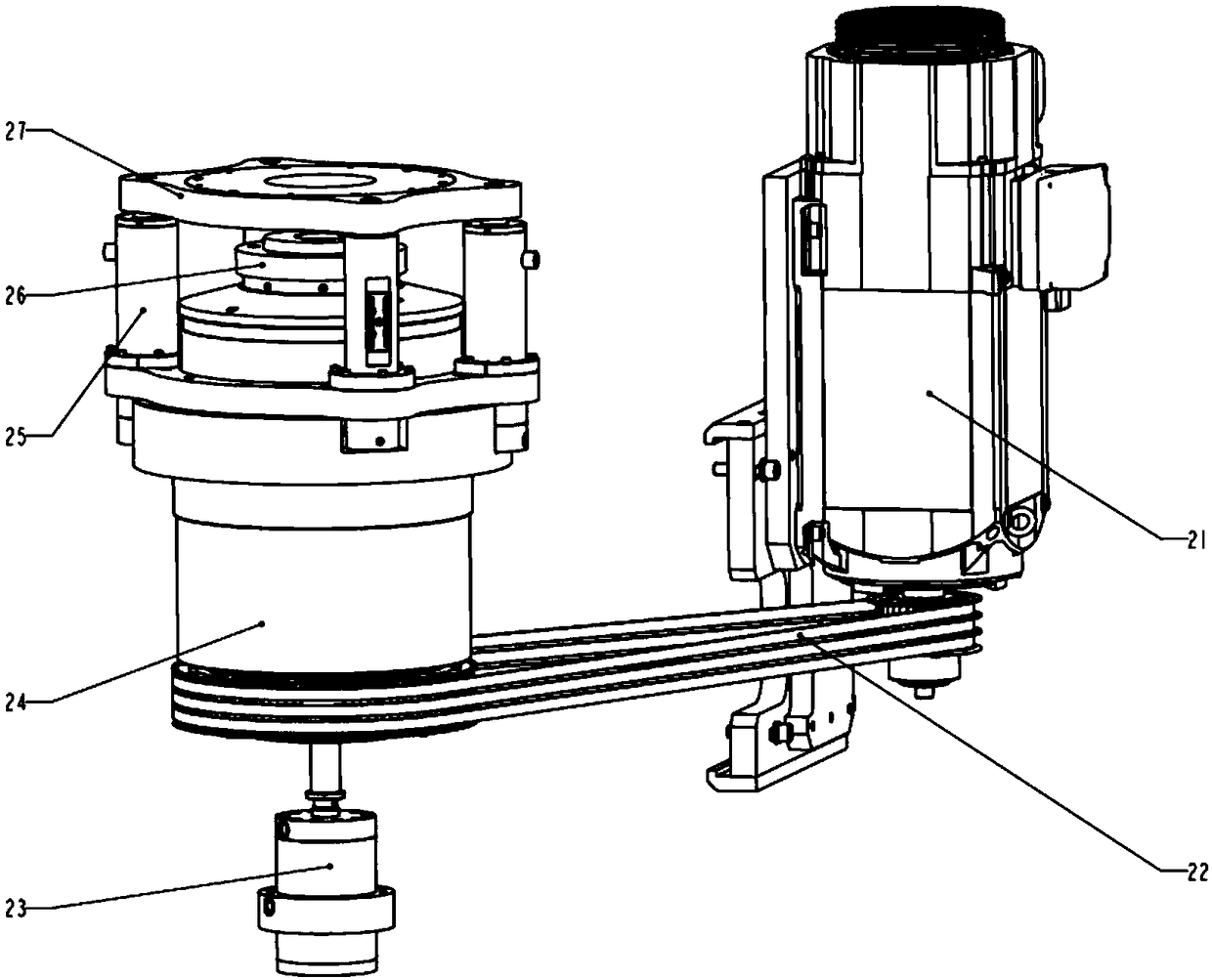

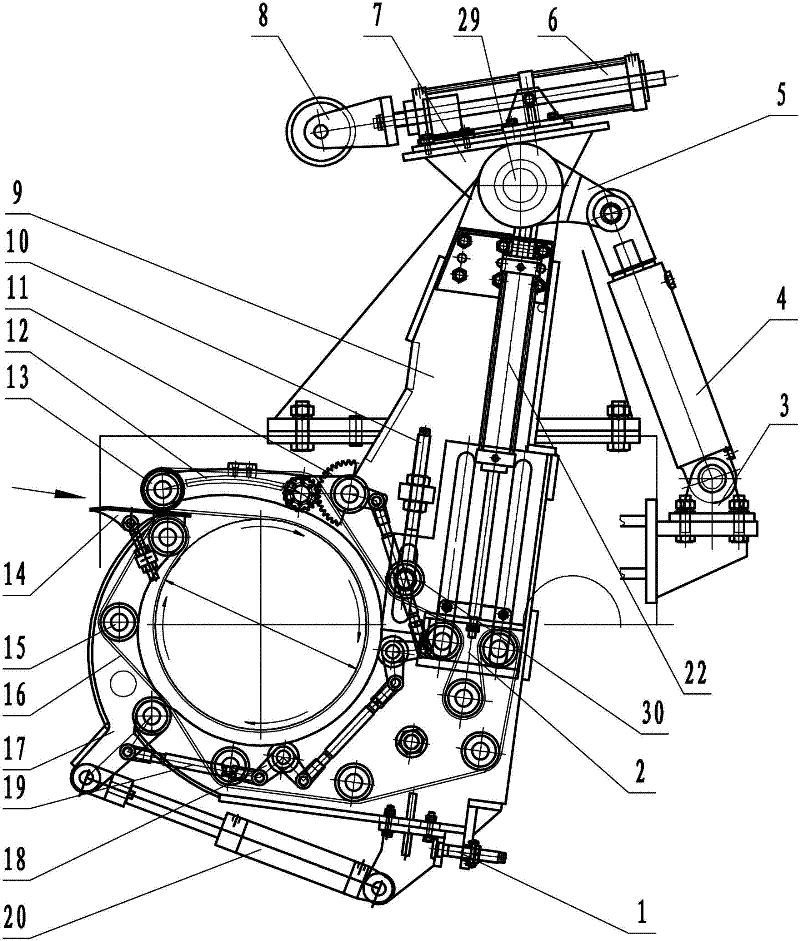

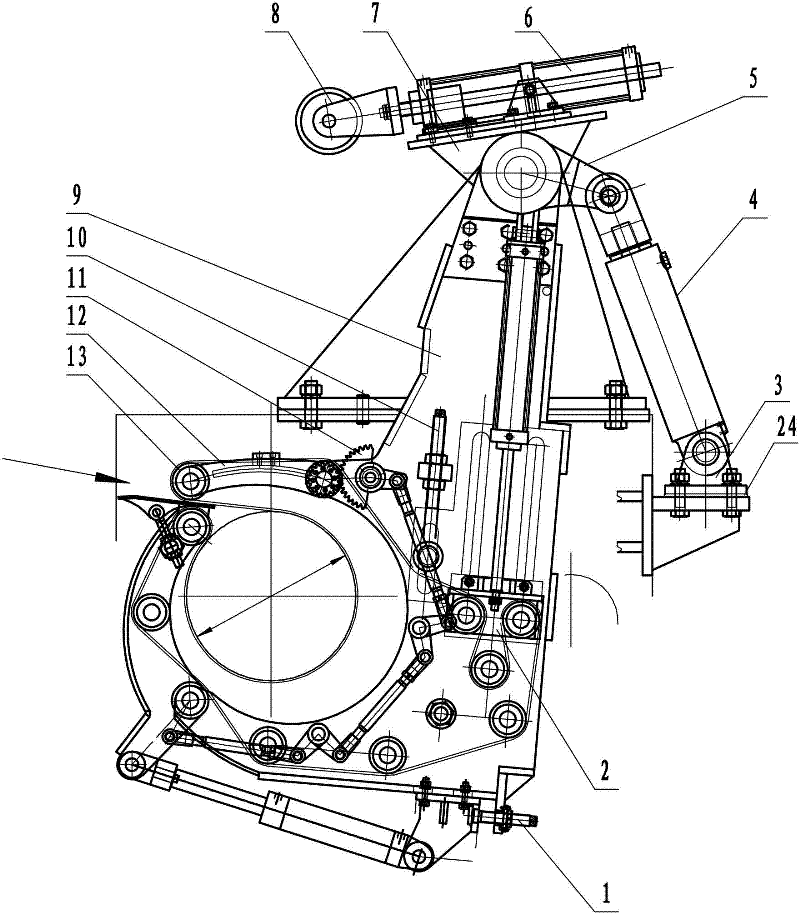

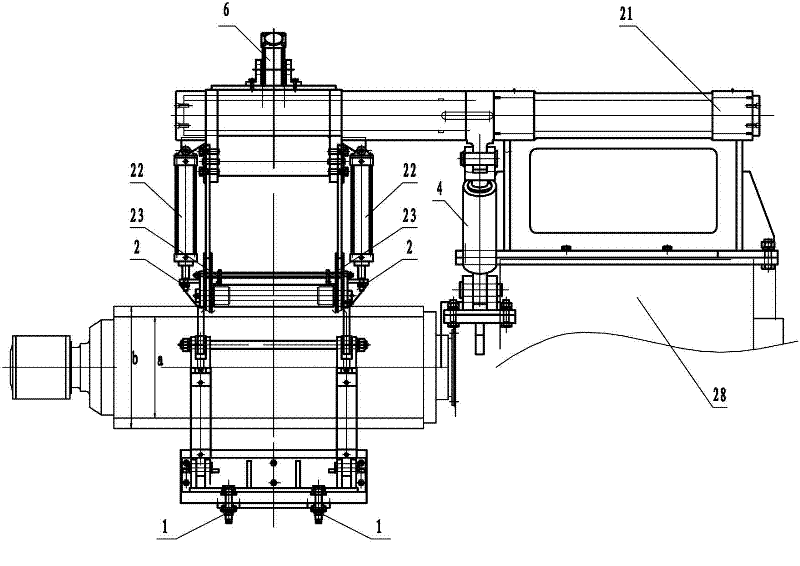

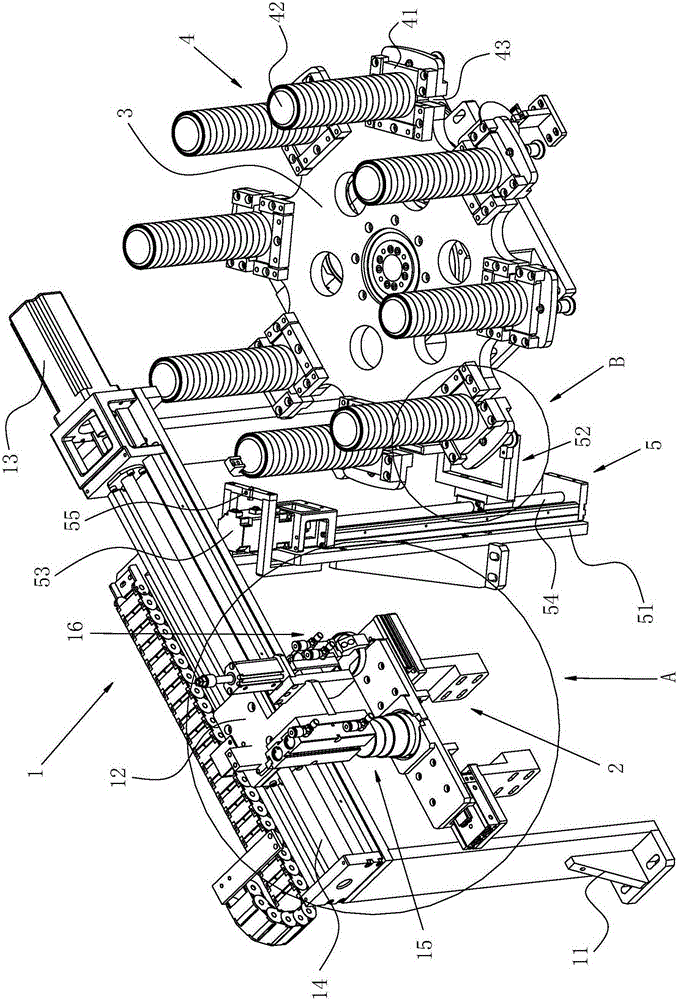

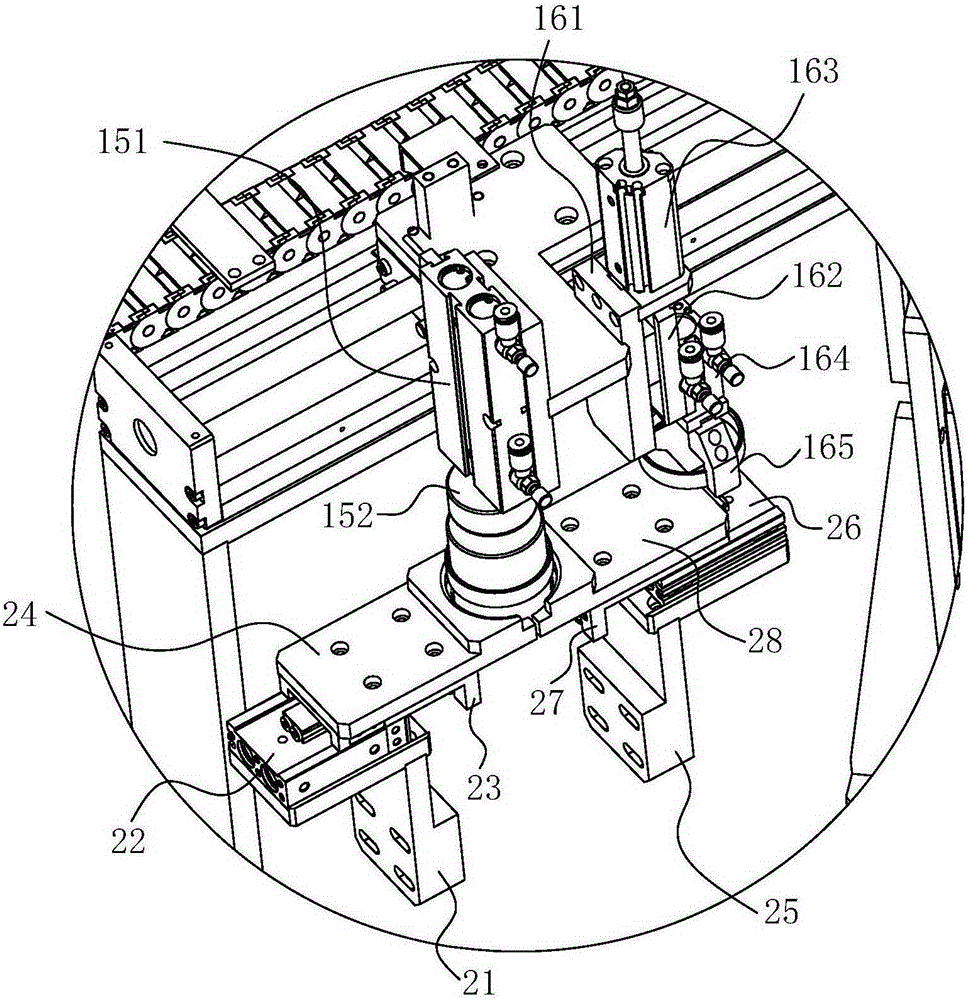

Vertical spinning machine

The invention relates to a vertical spinning machine comprising a machine body component, a main shaft component, a spinning wheel component, a tail jack component and a mechanical arm component as well as electronic control, hydraulic, lubrication, cooling and protection systems; the spinning wheel component of the vertical spinning machine is composed of three groups of spinning wheels distributed by 120 DEG, and a group of auxiliary spinning wheels; and each group of spinning wheels can achieve axial and radial servo feed motion alone. According to the vertical spinning machine stated in the invention, new technological methods, such as stagger spinning, local thickening and splitting, can be achieved, and the process flow is simplified; and the processing efficiency is improved, and the manufacturing cost is saved. The batch production of automobile clutch shell parts can be achieved, and the defects of existing equipment for producing such parts in China are overcome; and the gapbetween the automobile manufacturing field and foreign technical level is narrowed.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

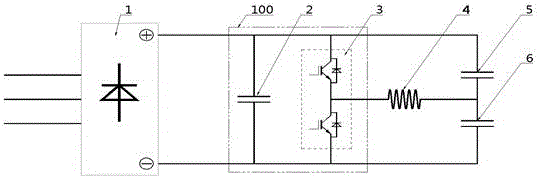

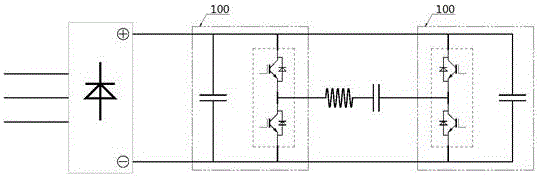

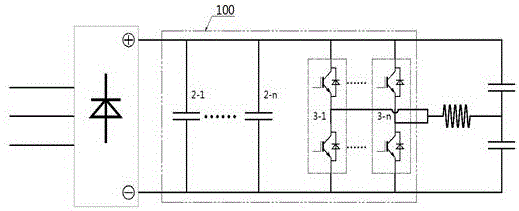

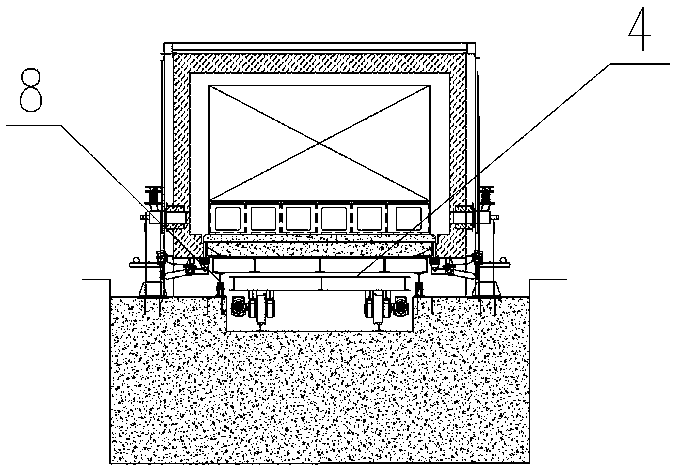

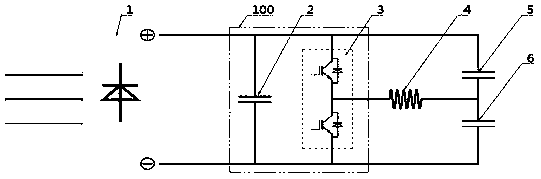

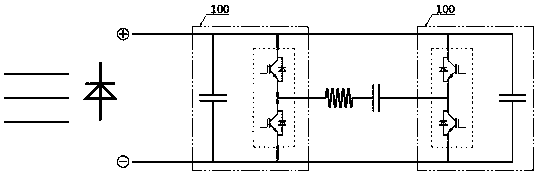

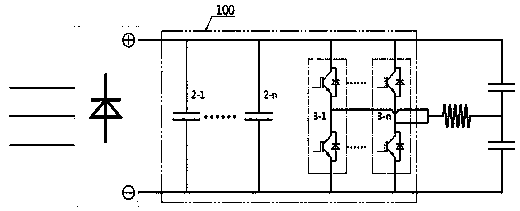

IGBT variable-frequency power source for energy-saving intermediate-frequency smelting furnace

ActiveCN105763073AImprove capacity utilizationIncrease operating powerConversion constructional detailsAc-ac conversionCapacitanceThermodynamics

The invention relates to an IGBT variable-frequency power source for an energy-saving intermediate-frequency smelting furnace. The IGBT variable-frequency power source comprises a power source cabinet, a diode rectifier bridge, filter capacitors, IGBT modules, an induction coil and a resonance capacitor. In the power source cabinet, the filter capacitors, water cooling boxes, the IGBT modules, a connecting copper bar and a current transformer are installed in a square box in an integrated mode to form a structural unit entity. The filter capacitors are arranged in through space above a separation plate of the box, the water cooling boxes for mounting of the IGBT modules are arranged in through space below the separation plate, and the common connecting copper bar is fixed to an insulation supporting block at the top of the box. The IGBT modules and the filter capacitors are composed of more than two entities. Through optimization of the process layout, currents flowing through an IGBT device are even and consistent, and the capacity utilization rate of the IGBT device and the running power of the IGBT induction heating power source are increased; the application range of the IGBT induction heating technology is widened, so that the energy saving and environment friendliness advantages of IGBT induction heating equipment are further achieved.

Owner:株洲弗拉德科技有限公司

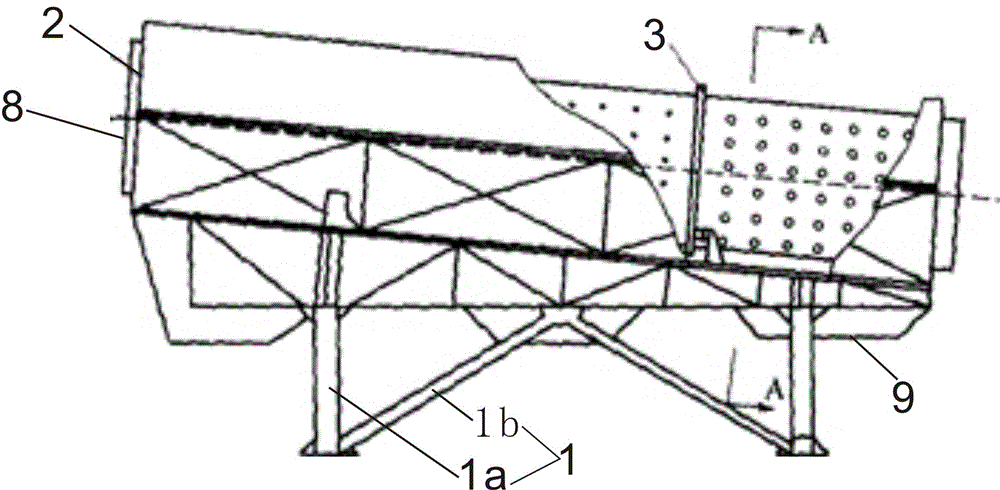

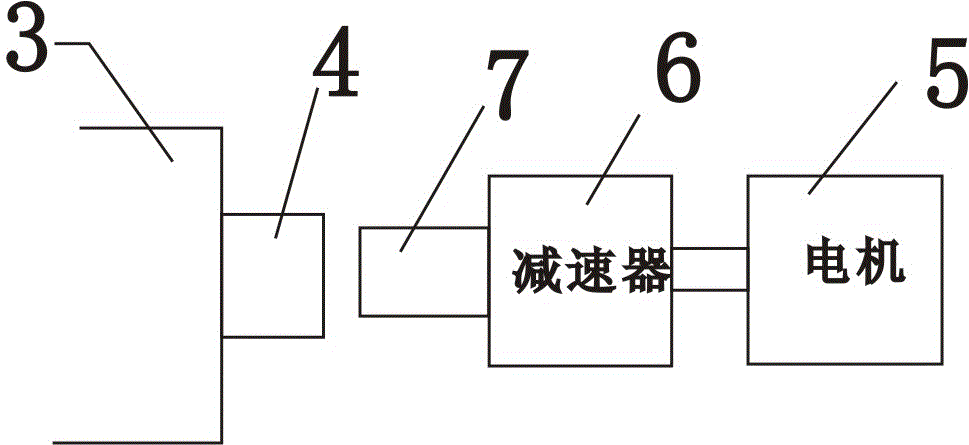

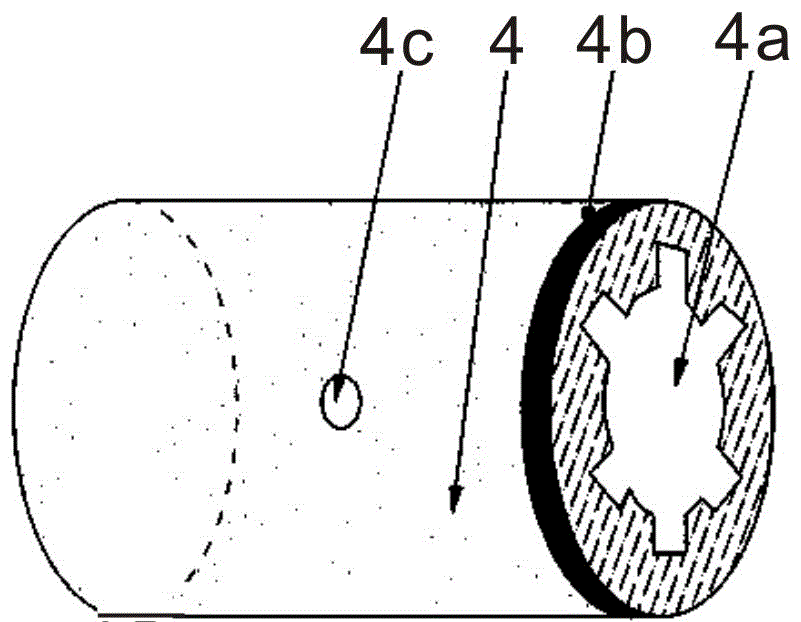

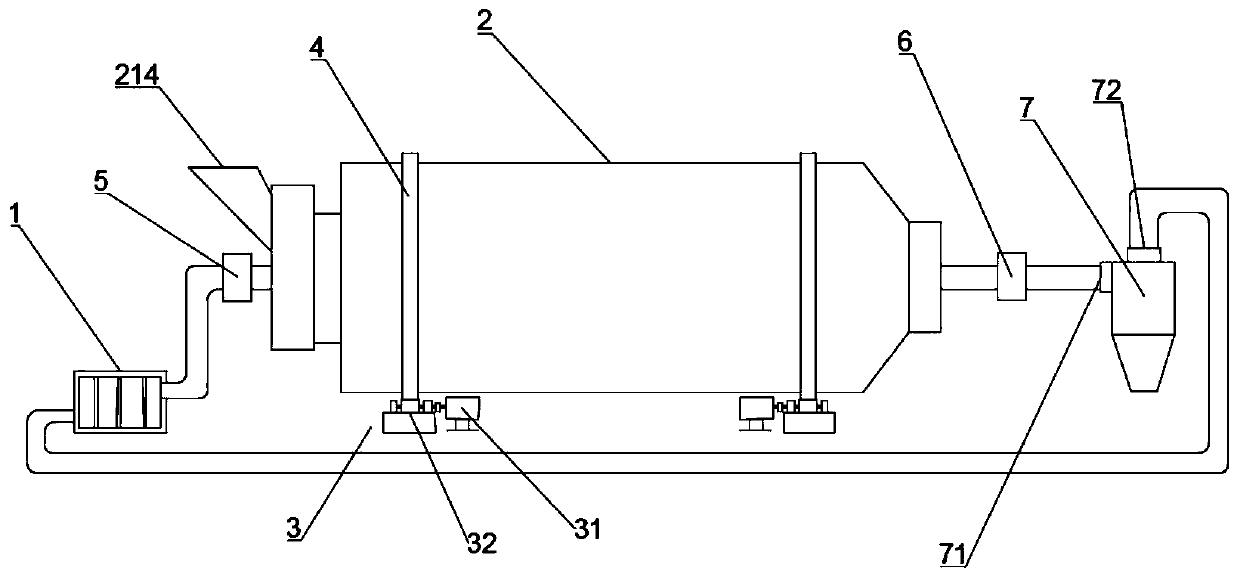

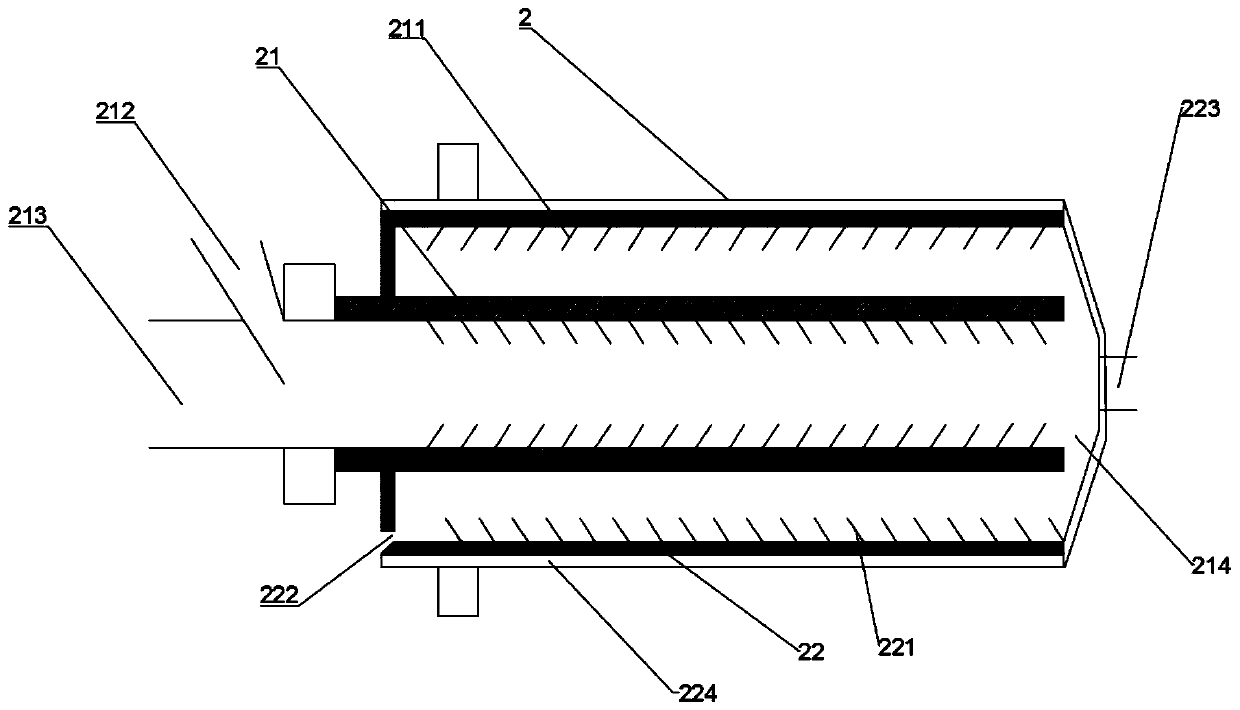

Drum screen

The invention discloses a drum screen. The drum screen is characterized in that the drum screen comprises a rack system, a drum shell, a drum screen body and a motor; the drum shell is obliquely fixed to a rack at a certain angle on the whole, the drum screen body is arranged in the drum shell on the whole and made of stainless steel, and a plurality of sieve meshes are formed in the drum screen body; and a coupling piece A is fixed to the rotating end of the drum screen body, the transmission end of the motor is connected with a speed reducer, and the output end of the speed reducer is connected with a coupling piece B. The drum screen is mainly composed of a drum device, the speed reducer, the motor, an intra-screen cleaning device, bottom supports, a sealing cover, a discharging port, a feeding port and the like. A spline type coupling special for the drum screen is composed of the coupling piece A and the coupling piece B, the structure is simple, and manufacturing and mounting are convenient; and the connecting strength is high, and normal operation of the drum screen is guaranteed.

Owner:曾凤林

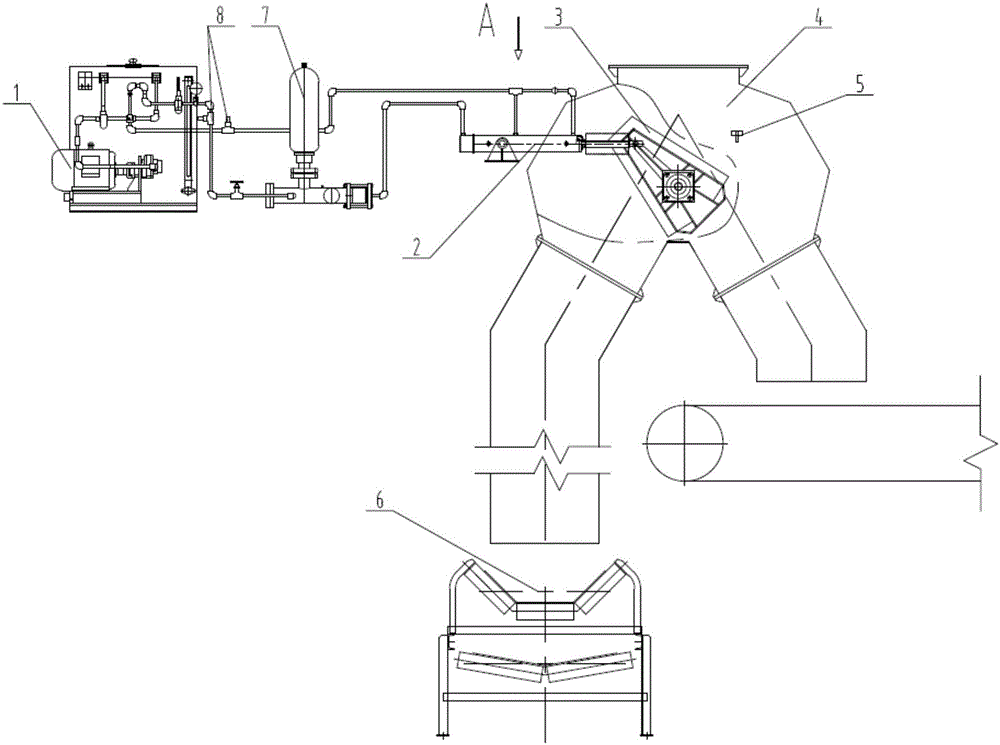

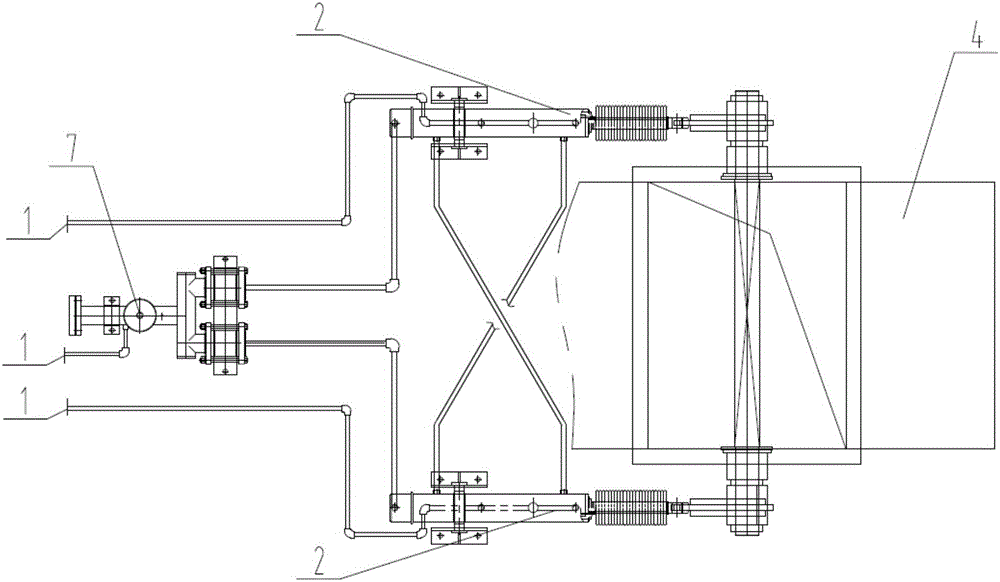

Automatically-controlled hydraulic material dividing device

ActiveCN106081587ARelieve pressureReduce energy consumptionConveyorsConveyor partsAutomatic controlDevice form

An automatically-controlled hydraulic material dividing device comprises a hydraulic device, transmission devices, a material flow divider, a three-way body, limit switches, a weighing adhesive tape machine, an impact stabilizer and a locking adjusting valve; the material flow divider is of a trapezoid-like box structure and is connected with the transmission devices through rotation shafts, hydraulic cylinders located on the two sides of the three-way body serve as the main structures of the transmission devices, the hydraulic device and the transmission devices form a closed loop through oil pipes, the position can be adjusted according to the on-site actual work condition, the impact stabilizer and the locking adjusting valve are arranged on the oil way between the hydraulic device and the transmission devices, the weighing adhesive tape machine is located on the lower portion of the whole device, and the limit switches are welded to the external extreme positions of the two sides of the three-way body. According to the automatically-controlled hydraulic material dividing device, material flow dividing is automatically controlled and adjusted through the hydraulic device, the technological process that materials are directly conveyed into a workshop or a boiler is achieved, the pressure of the material site storage quantity is reduced, system energy consumption is reduced, the working efficiency is improved, and the automatically-controlled hydraulic material dividing device is applied to the technical field of bulk material conveying systems in the industries of ports, coal, electric power, metallurgy, mines and the like.

Owner:NORTHERN HEAVY IND GRP CO LTD

Closed multifunctional reducing wrapper

The invention provides a closed multifunctional reducing wrapper. The closed multifunctional reducing wrapper comprises a supporting base, wherein a large bent hook is connected with the supporting base through a rotating shaft; the large bent hook is provided with an upper pressing arm and a lower pressing arm; the lower pressing arm is connected with a pressing cylinder; the lower pressing arm is connected with the upper pressing arm through an amplification mechanism; wrapping adhesive tape devices are arranged in the large bent hook, the upper pressing arm and the lower pressing arm and two-wheel tension mechanisms and adhesive tape error correction mechanisms are arranged in the wrapping adhesive tape devices; one end of a beam position cylinder is connected with the rotating shaft through a crank, and the other end of the beam position cylinder is connected with a beam position cylinder support; and the pressing cylinder, the amplification mechanism, the tension adjustment cylinders in the two-wheel tension mechanisms and the adhesive tape error correction mechanisms are in a double-side symmetric distribution. The closed multifunctional reducing wrapper can be conveniently applicable for working situations of different winding drum diameters after being adjusted simply; due to the stacking of the upper pressing arm and the lower pressing arm, a 360-degree wrap angle of a wrapping adhesive tape on a winding drum can be realized, so the wrapping forces of the winding drums having different diameters cannot be influenced; therefore, slipping of the closed multifunctional reducing wrapper due to an undersized wrap angle during wrapping of the wrapping drums having smaller diameters can be avoided; and the appearance of a tape volume can be guaranteed.

Owner:OUDA YICHANG ELECTROMECHANICAL EQUIP

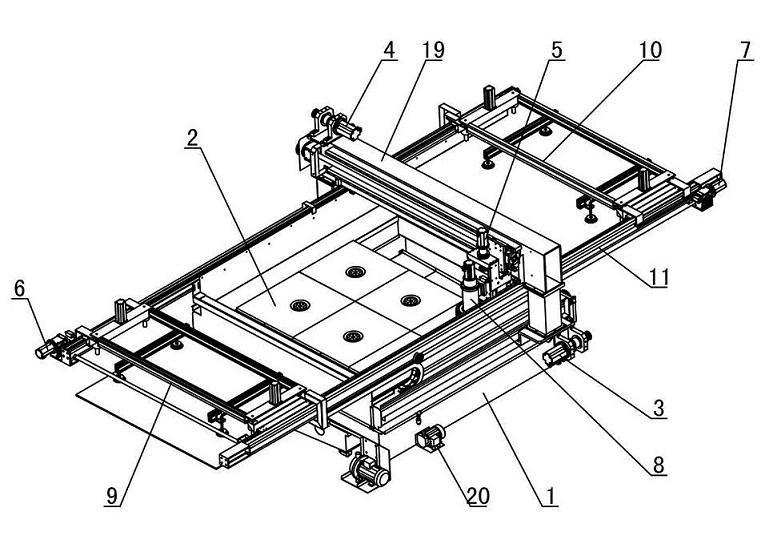

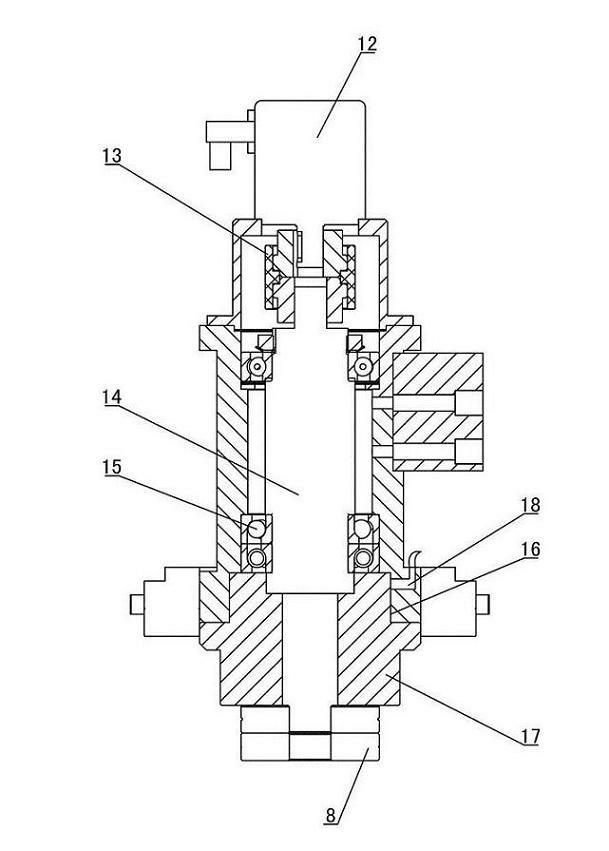

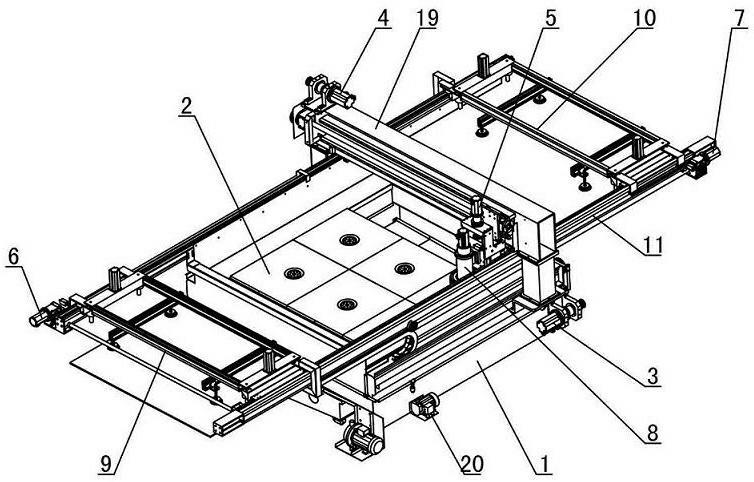

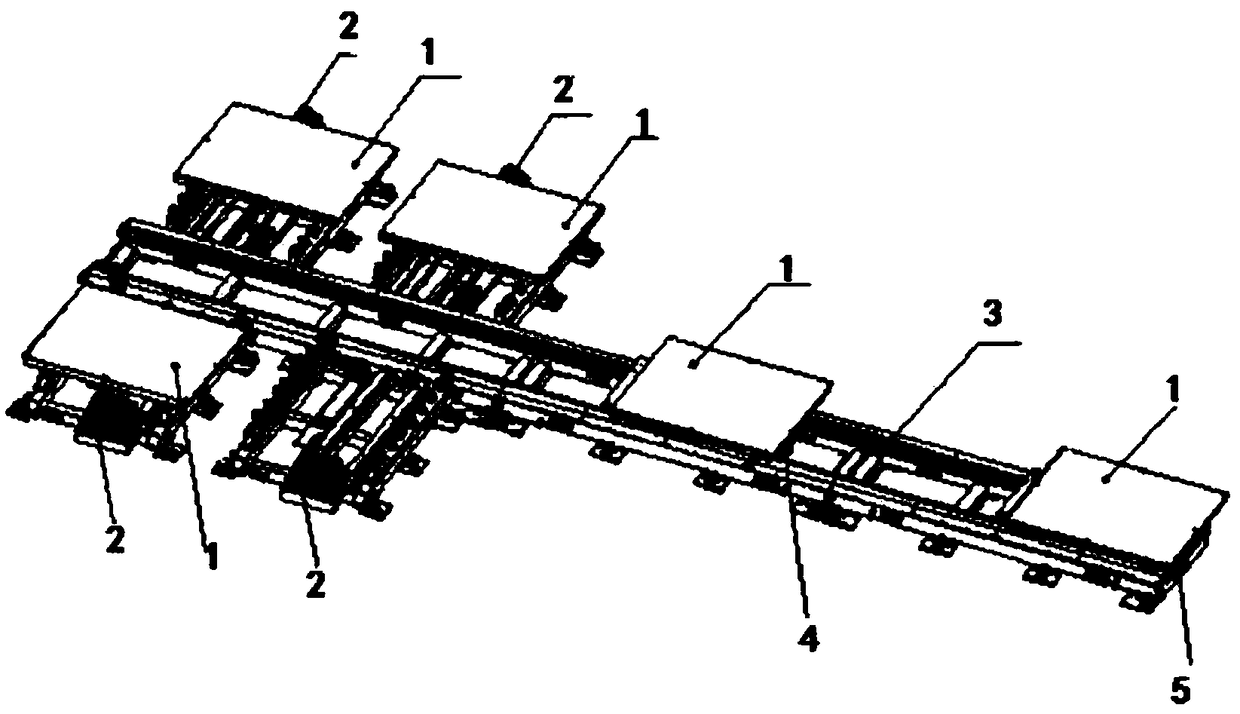

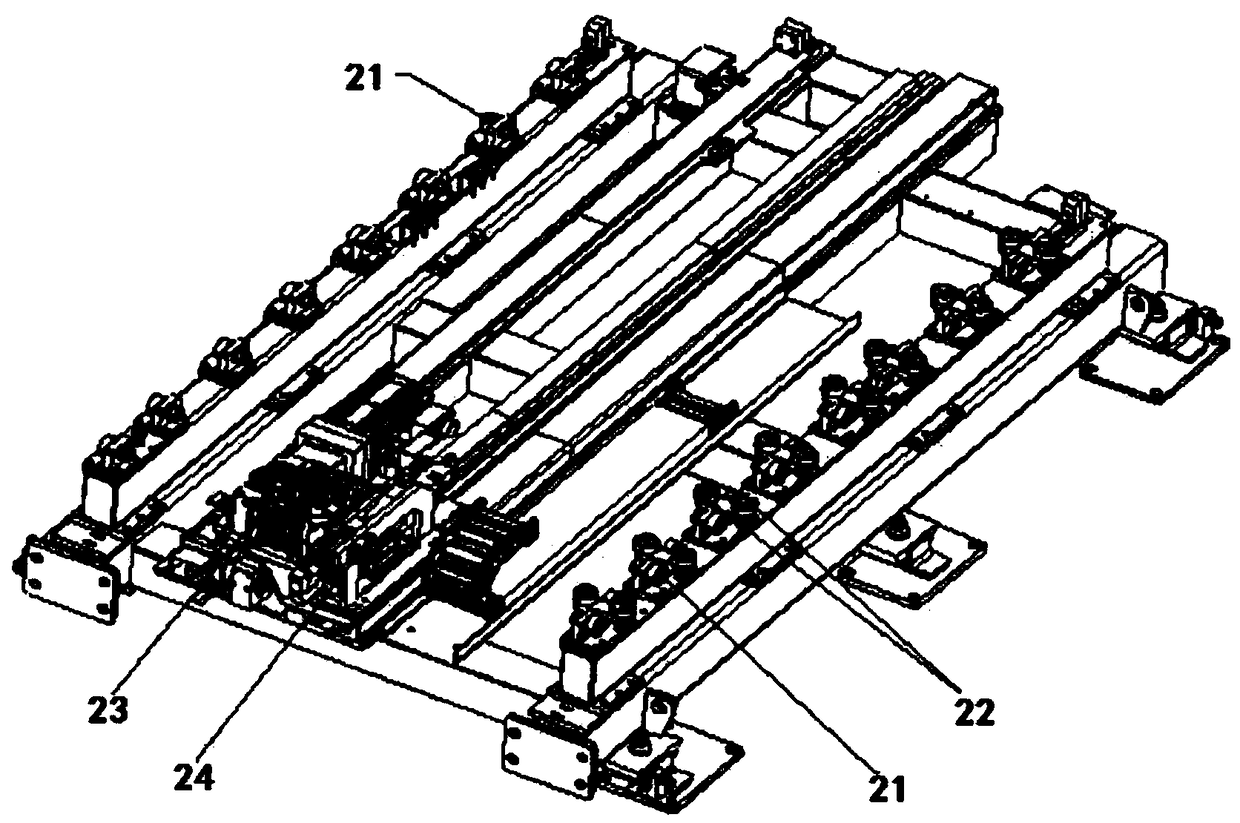

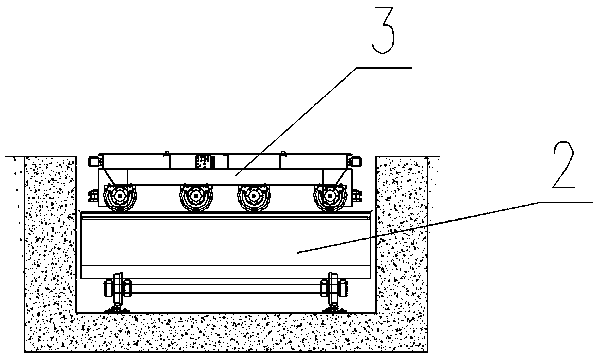

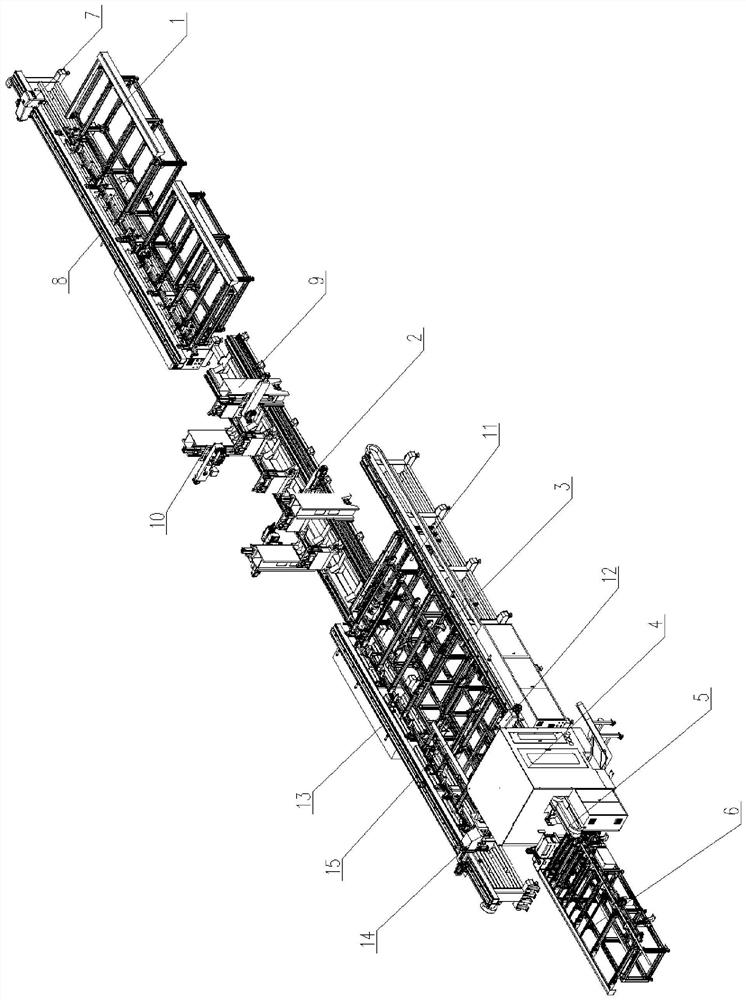

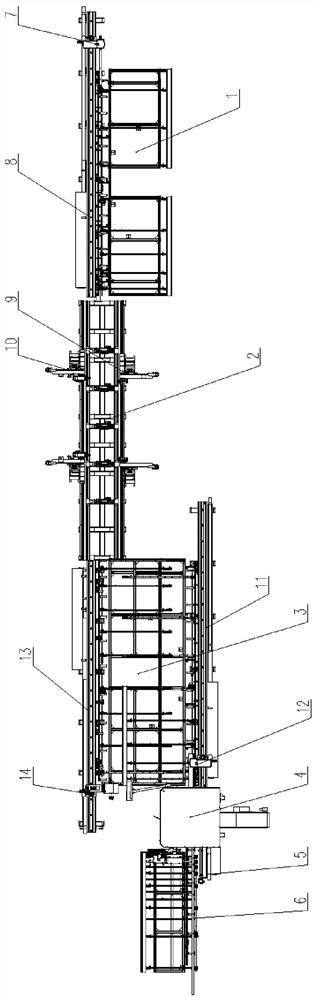

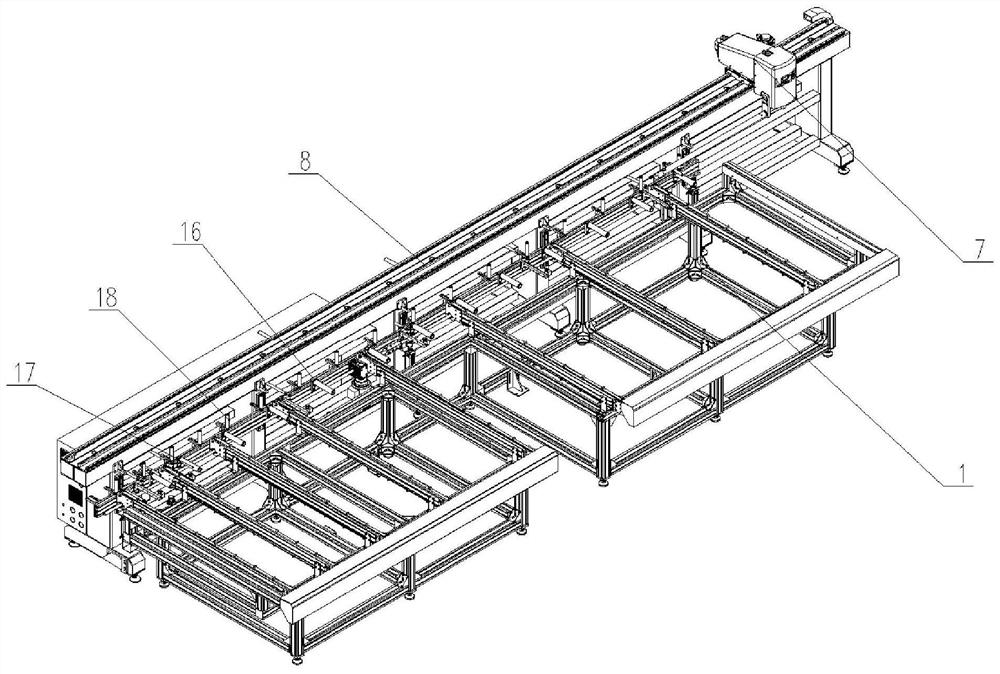

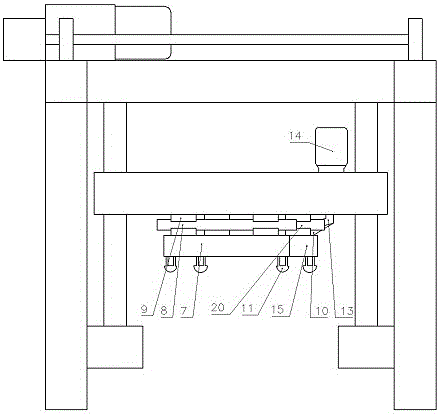

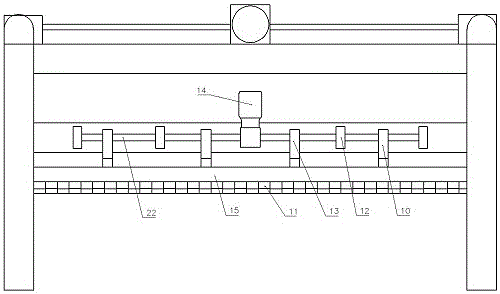

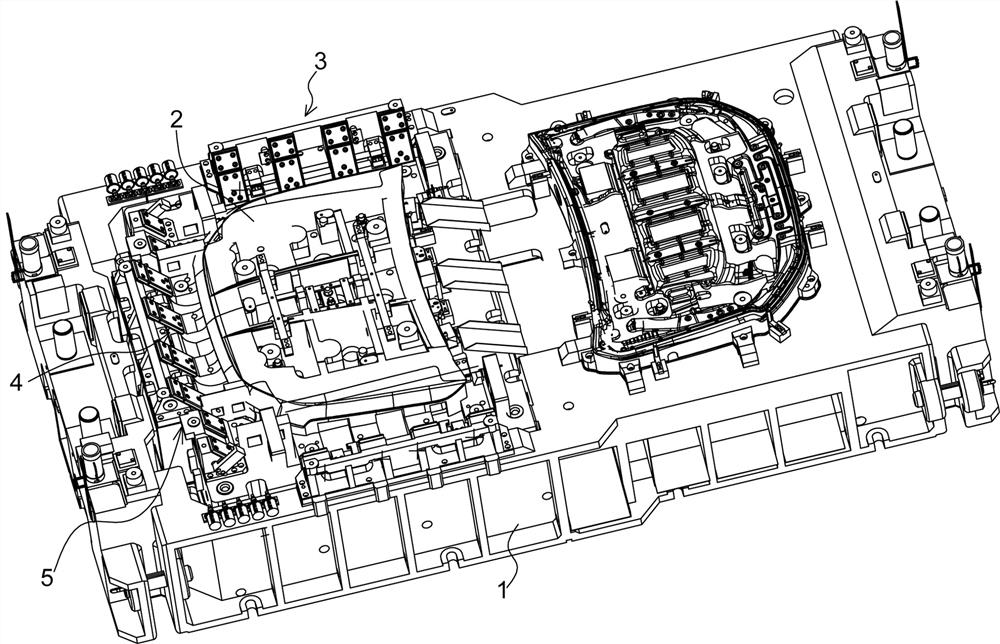

Multi-vehicle-type white body collinear flexible welding device

InactiveCN108637514ASolve technical problems such as lack of flexibilitySimple mechanical structureWelding/cutting auxillary devicesAuxillary welding devicesProduction lineProduction rate

The invention discloses a multi-vehicle-type white body collinear flexible welding device. The multi-vehicle-type white body collinear flexible welding device comprises a positioning clamp platform, storage mechanisms, a sliding supporting mechanism and a sliding positioning table, the sliding positioning table is installed on the sliding supporting mechanism in a sliding mode, the storage mechanisms are connected with the sliding supporting mechanism and distributed on the two sides of the sliding supporting mechanism, and the positioning clamp platform is arranged on the sliding positioningtable and slides between the sliding positioning table and the storage mechanisms. The multi-vehicle-type storage mechanisms are arranged, colinearity is achieved in a rapid switching mode, the devicehas the characteristics that the mechanical structure is simple, the automation degree is high, conveying and positioning are accurate and reliable and the productivity is greatly improved, and the technical problem that vehicle white body welding production lines are short of flexibility is solved.

Owner:ANHUI CHANGFENG YANGZI MOTOR MFG +1

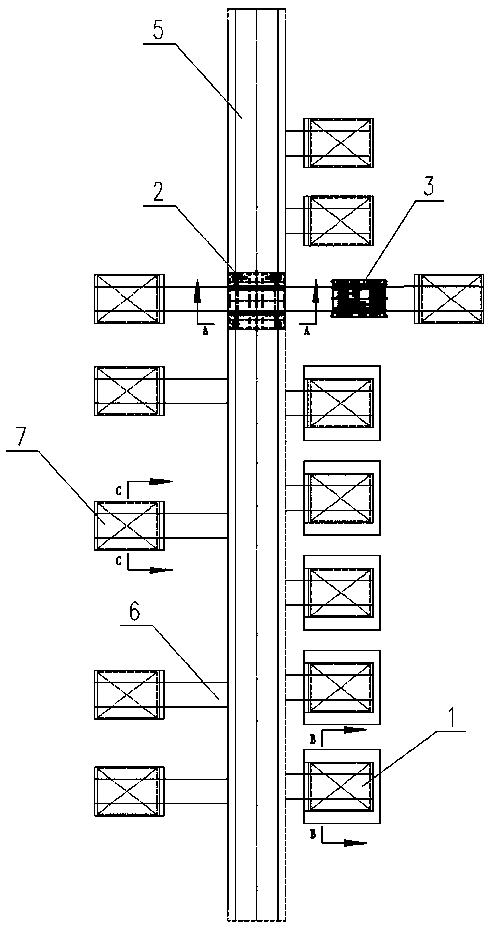

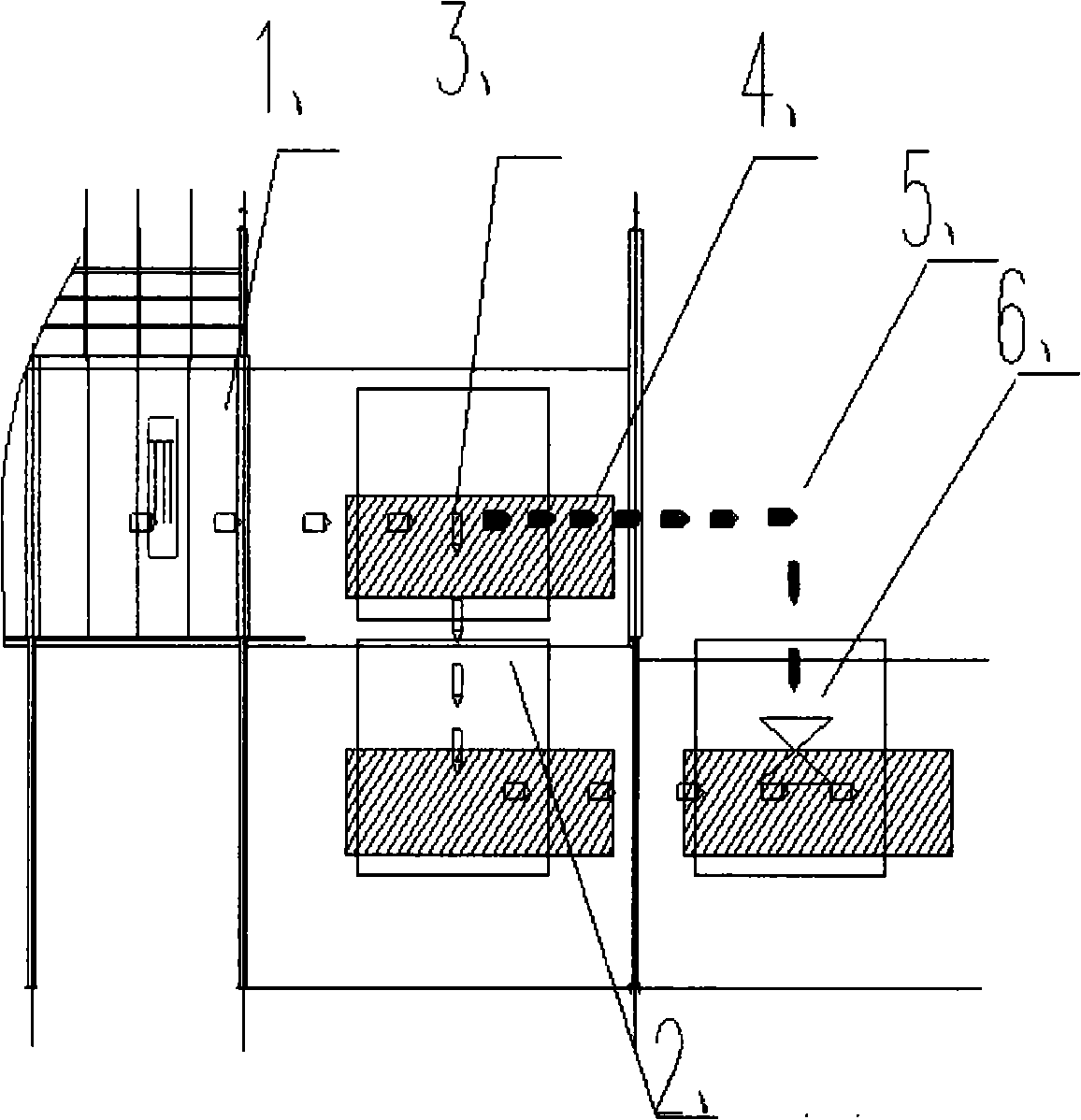

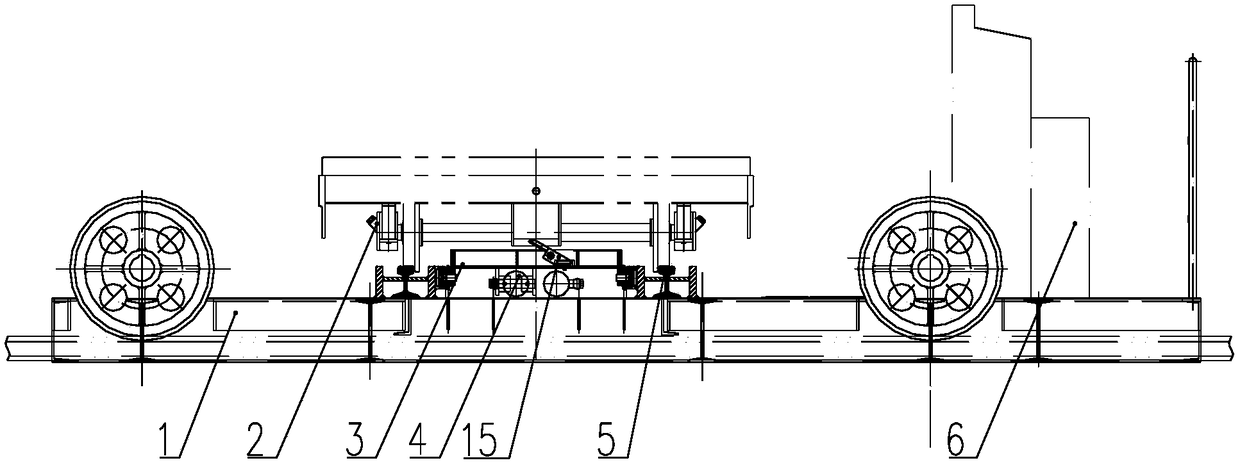

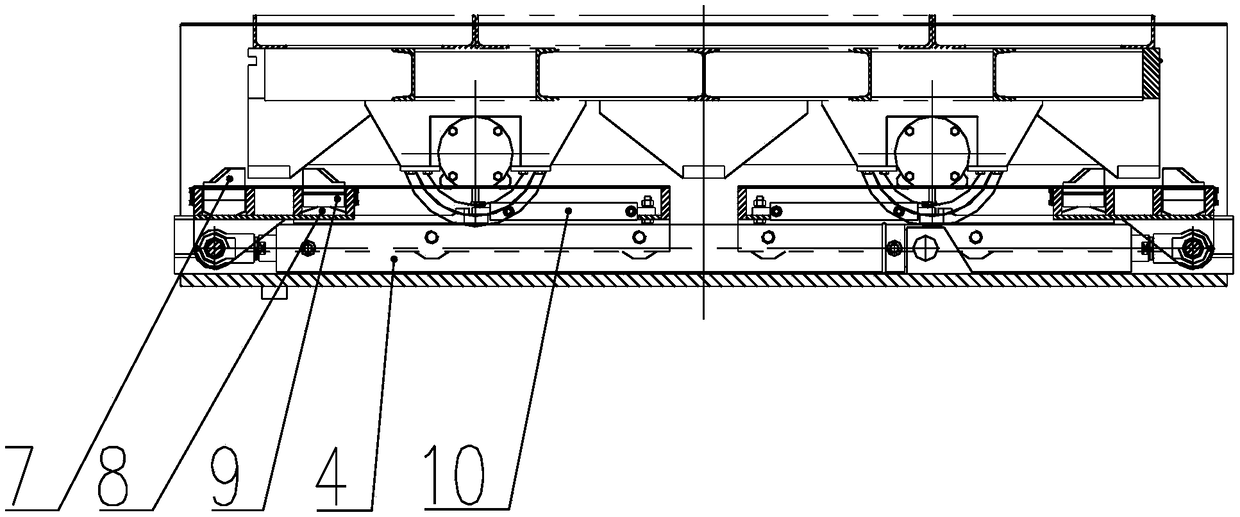

Automatic trolley transferring line used for casting heat treatment furnace group workshop and transferring method

InactiveCN107904384AOptimize process layoutRealize loading and transshipmentFurnace typesHeat treatment furnacesEconomic benefitsHeat treated

The invention discloses an automatic trolley running line for a workshop of a group of casting heat treatment furnaces, comprising a heat treatment furnace and a trolley, the trolley includes a mother car and a sub-car for loading trays, and the top of the sub-car is equipped with a With the jacking mechanism and positioning mechanism matched with the tray, the sub-cars are superimposed on the mother car and run back and forth along the main track along the main track or independently along the secondary track. The main track is one, so There are multiple auxiliary tracks, all of which are perpendicular to the main track, and the starting end of each auxiliary track is connected to the main track, and the end is connected to the heat treatment furnace or the transfer position, and the heat treatment furnace and the transfer position are equipped with trays A support frame; meanwhile, a trolley running method using the above running line is disclosed. The invention optimizes the technological layout of the workshop, realizes intelligent logistics transportation in the heat treatment workshop, and has good economic benefits.

Owner:SIPPR ENG GROUP

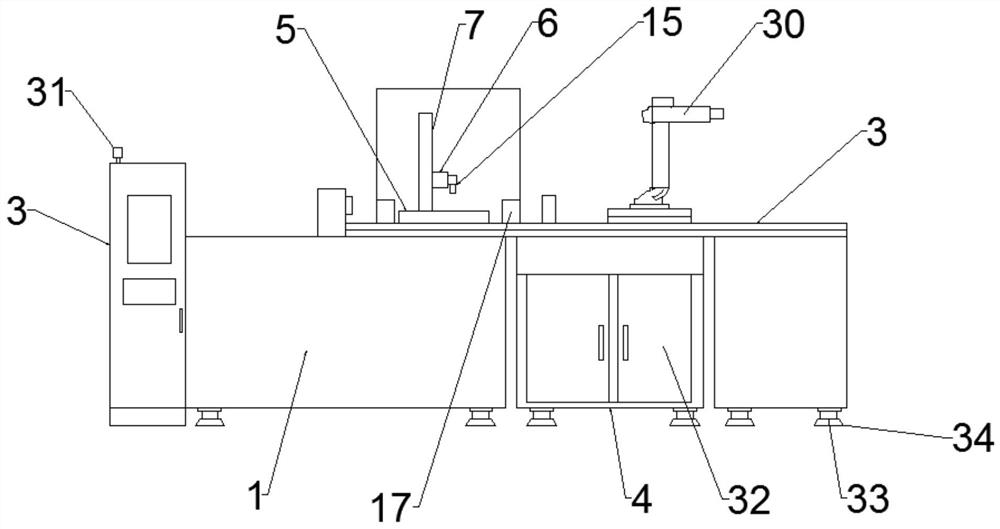

Multi-axis numerical control linkage welding production line and control method thereof

InactiveCN112025154ARealize clamping and fixingCompact structureWelding/cutting auxillary devicesAuxillary welding devicesNumerical controlBall screw

The invention discloses a multi-axis numerical control linkage welding production line. The multi-axis numerical control linkage welding production line comprises a supporting table, a numerical control box is arranged at one end of the supporting table, a ball screw conveying line is arranged in the middle of the upper end of the supporting table, a Z-axis transmission mechanism, an X-axis transmission mechanism and a Y-axis transmission mechanism are arranged at one end of the ball screw conveying line, each of the Z-axis transmission mechanism, the Y-axis transmission mechanism and the X-axis transmission mechanism comprises a connecting frame, a first groove, an adjusting motor, a fixing block, a rotating lead screw, an adjusting block and a bearing plate, a clamping and positioning mechanism is arranged at the upper end of each sliding block, a carrying robot arm is arranged at the end, close to a tool cabinet, of the ball screw conveying line, and a stacking machine matched withthe carrying robot arm is arranged on the side edge of the tool cabinet. The multi-axis numerical control linkage welding production line has the beneficial effects that automation is achieved, the production efficiency is greatly improved, the manual labor amount is reduced, the consistency of the production efficiency and the welding quality is improved, and the labor cost is saved.

Owner:杭州焊林科技有限公司

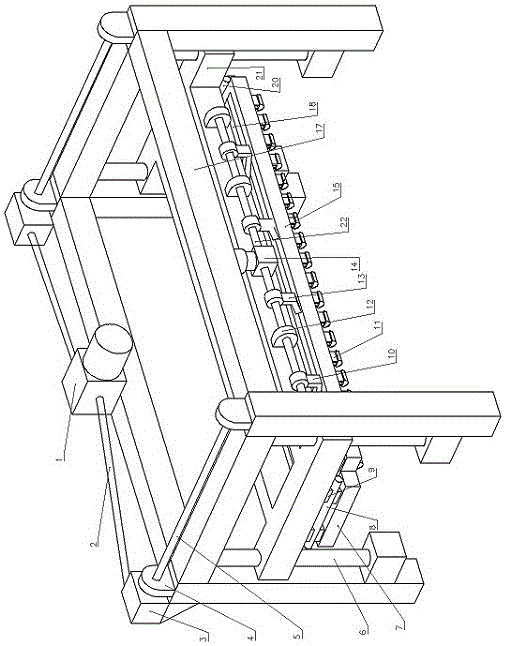

Door and window machining production line and machining technology

PendingCN113857862AWith automatic feedingWide range of processingOther manufacturing equipments/toolsPositioning apparatusProduction lineMachining process

The invention provides a door and window machining production line and a machining technology. The door and window machining production line is sequentially provided with a feeding area, a machining area, a buffer area, a cutting center area and a discharging area in the feeding direction, wherein the machining area is provided with a door and window machining center; the door and window machining center comprises a machining base; horizontal guide rails are arranged at the front end and the rear end of the machining base; at least two sets of machining machine heads are arranged on the machining base in the feeding direction; each set of machining machine heads comprises two machining machine heads; the two machining machine heads in each set of machining machine heads are oppositely arranged; and the cutting center area is provided with a saw cutting center and a milling center. The door and window machining production line and the machining technology have the beneficial effects that when a to-be-machined profile is machined, hole groove machining is conducted firstly, then cutting-off, end face milling and other machining are conducted, when the to-be-machined profile is subjected to hole groove machining, the two machining machine heads are adopted for machining the to-be-machined profile at the same time, and the machining efficiency is greatly improved.

Owner:SHANDONG LEDE CNC MACHINERY

Frame type swinging cutting machine

InactiveCN106346599ASimple structureOptimize process layoutCeramic shaping apparatusEngineeringWire drawing

The invention relates to manufacturing of aerated concrete production equipment, and provides a cutting machine frame type swinging cutting mechanism. The cutting machine frame type swinging cutting mechanism comprises a machine body, wherein cross beams are arranged at the two sides of the machine body; a swinging frame is arranged inside the machine body; a lifting speed reducing machine is arranged in the middle part of the cross beam formed in one side of the machine body; speed reducing machines in transmission connection with the lifting speed reducing machine are respectively arranged at the front side and the back side of the machine body; a swinging motor is connected with a transverse swinging shaft; the swinging shaft is connected with an inner side swinging frame and an outer side swinging frame through an inner side swinging arm and an outer side swinging arm; the inner side swinging frame and the outer side swinging frame forwards and backwards swing through being driven by the swinging shaft; a plurality of wire drawing tiles are respectively arranged under the inner side swinging frame and the outer side swinging frame. The cutting frame type swinging cutting machine has the advantages that the optimization of the process layout of the frame type swinging cutting on a green body is realized; the structure of a cutting machine is simplified; the reliability is improved; mechanisms of each part independently work; the connection structure is clear; the later-stage maintenance is simple.

Owner:山东阳光众泰机械工程有限公司

Copper ring unloading and recycling system

ActiveCN105355959AEasy to operateIncrease productivityFinal product manufacturePrimary cellsMetallurgyTransfer operation

The invention discloses a copper ring unloading and recycling system including a copper ring unloading device for dismounting copper rings and a copper ring recycling device for storing the copper rings; the copper ring unloading device includes a copper ring unloading clamping assembly for fixing the copper rings and a copper ring unloading compound mechanical hand; the copper ring unloading clamping assembly is mounted on a battery conveying line; the copper ring unloading compound mechanical hand includes an unloading extrusion jig and a copper ring transfer jig which are arranged side by side; the copper ring recycling device includes a plurality of copper ring storage molds for storing the copper rings and a copper ring supporting assembly for selectively supporting the copper rings, and the copper ring supporting assembly is located below the copper ring unloading compound mechanical hand. On one hand, the copper ring unloading and recycling system realizes automatic dismounting and recycling of the copper rings and improves the battery production efficiency and reliability, on the other hand, by arranging the copper ring unloading compound mechanical hand provided with the unloading extrusion jig and the copper ring transfer jig, the dismounting operation and the clamping transfer operation of the copper rings are achieved, a device structure is more compact, and process layout is facilitated.

Owner:HUIZHOU JINYUAN PRECISION AUTOMATION EQUIP

A kind of igbt frequency conversion power supply for intermediate frequency melting furnace

ActiveCN105763073BImprove capacity utilizationIncrease operating powerConversion constructional detailsAc-ac conversionCapacitanceIntermediate frequency

Owner:株洲弗拉德科技有限公司

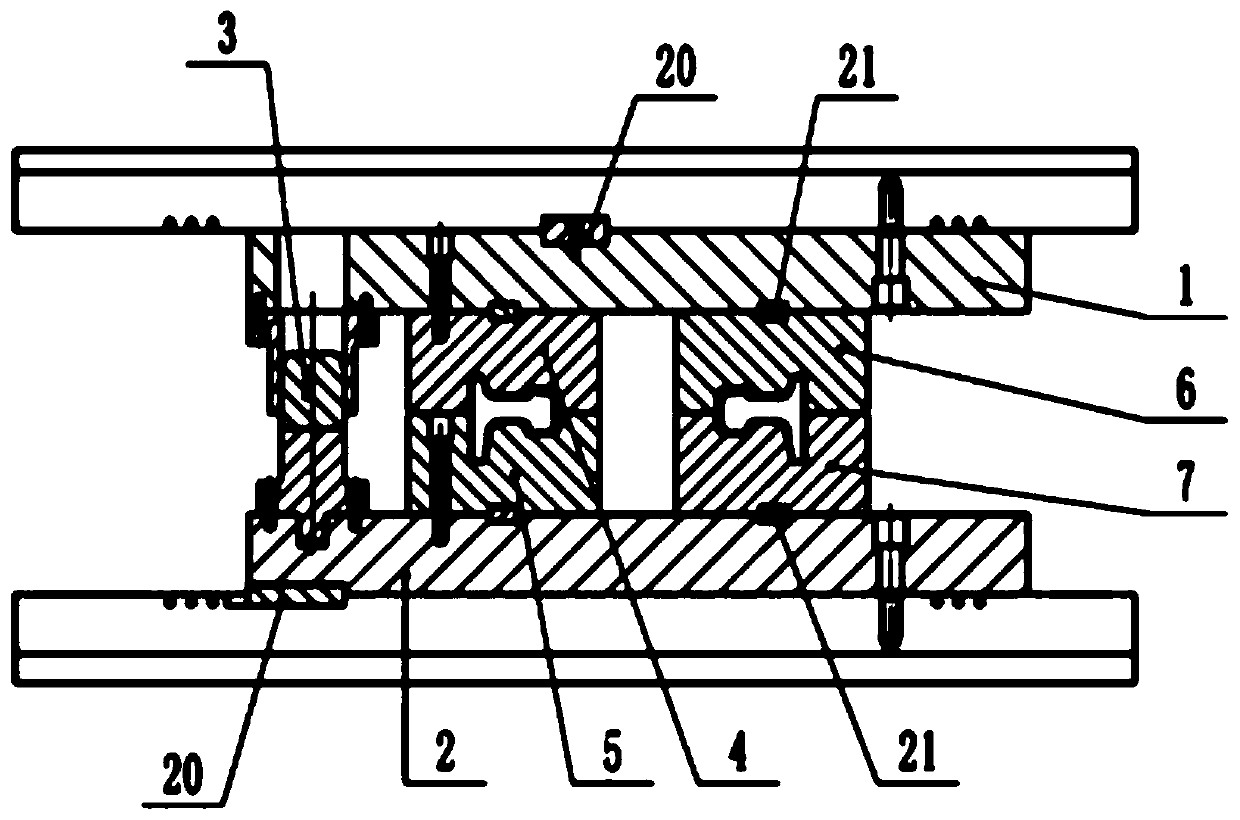

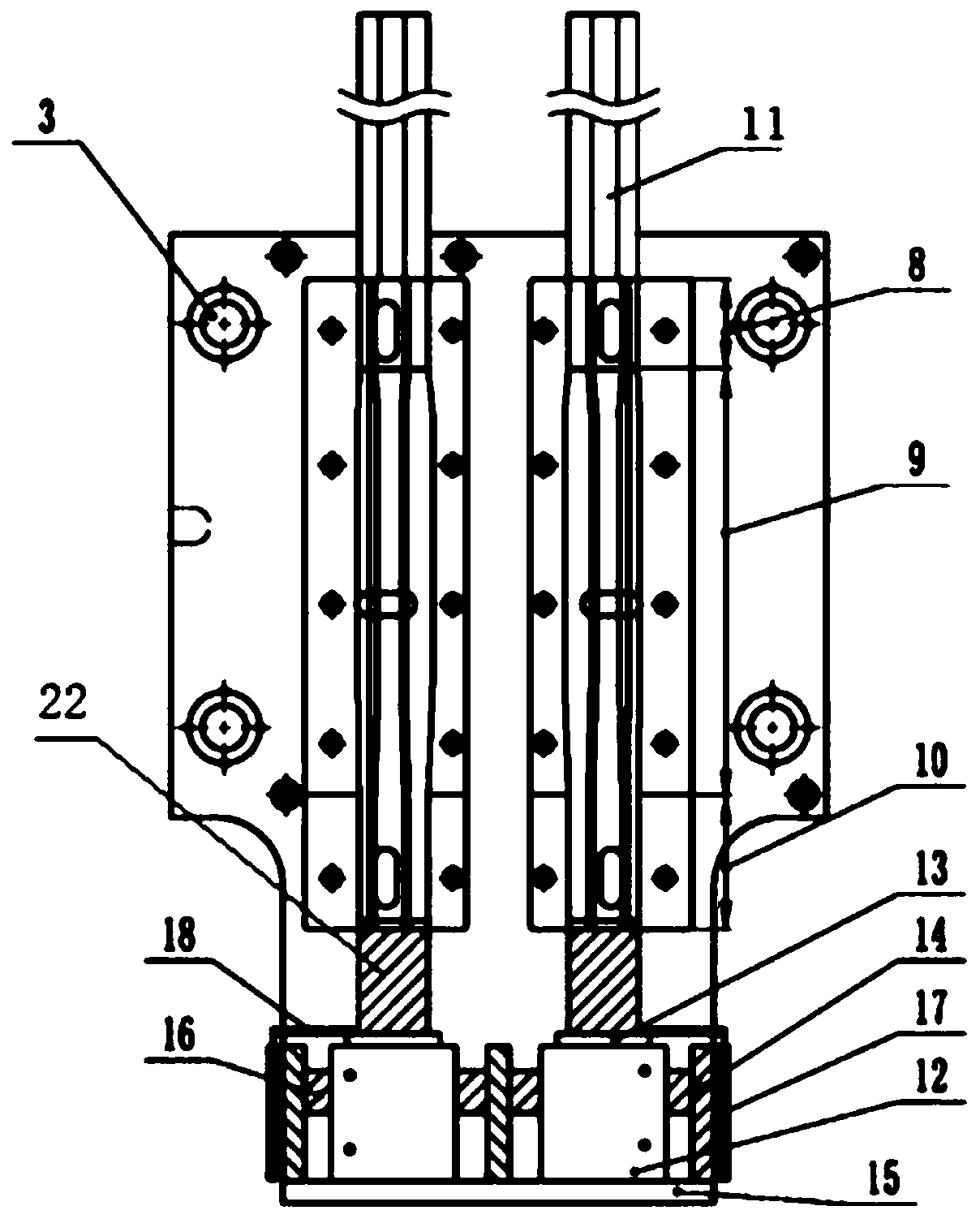

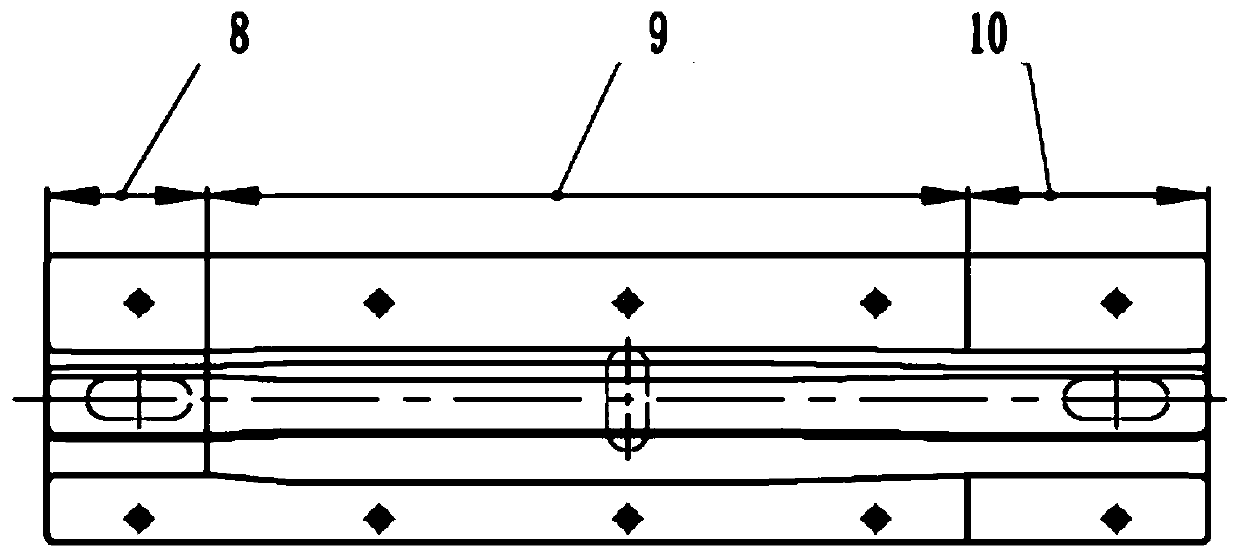

Upsetting device for steel rail with asymmetric section

PendingCN109877266APrecise control of upsetting amountMeet the requirements of process designRailway componentsForging/hammering/pressing machinesStructural engineeringProcess design

The invention discloses an upsetting device for a steel rail with a symmetric section. Upper and lower moulding boards are connected through a guide device; two upper moulds and two lower moulds are arranged between the upper and lower moulding boards; the two upper moulds are fixedly arranged on the lower end surface of the upper moulding board, the two lower moulds are fixedly arranged on the upper end surface of the lower moulding board, and the two upper moulds are separately positioned right on the two lower moulds; the two upper moulds and the two lower moulds are closed to separately form two mould cavities; each mould cavity sequentially consists of a clamping mould cavity section, an upsetting mould cavity section and a guide mould cavity section, wherein the clamping mould cavity section, the upsetting mould cavity section and the guide mould cavity section are separately in a close-fit state, an clearance fit state and a sliding fit state with a to-be-upset steel rail; twoupsetting oil cylinders are fixedly arranged on the lower moulding boards; and piston rods of the two upsetting oil cylinders are separately opposite to the two guide mould cavity sections. Integral upsetting for different product types of the steel rail with the symmetric section is accomplished through a set of tool moulds; and meanwhile, a ball grid digital display system is utilized to precisely control steel rail upsetting amount, so that process design requirements are met.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

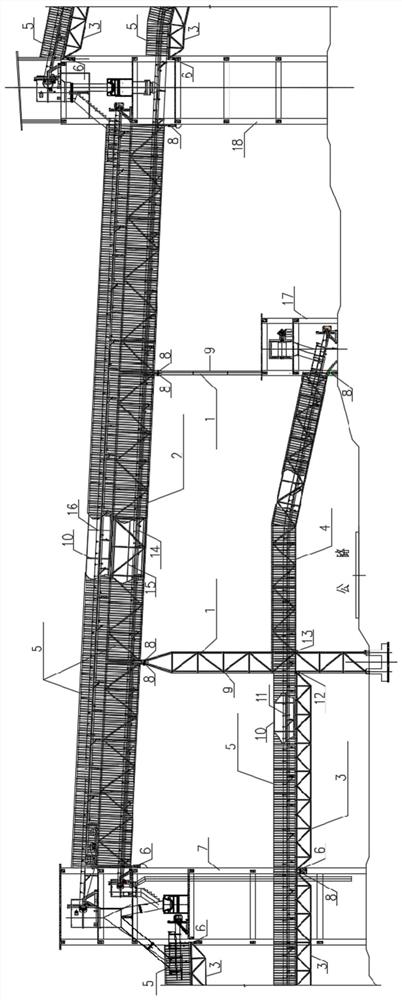

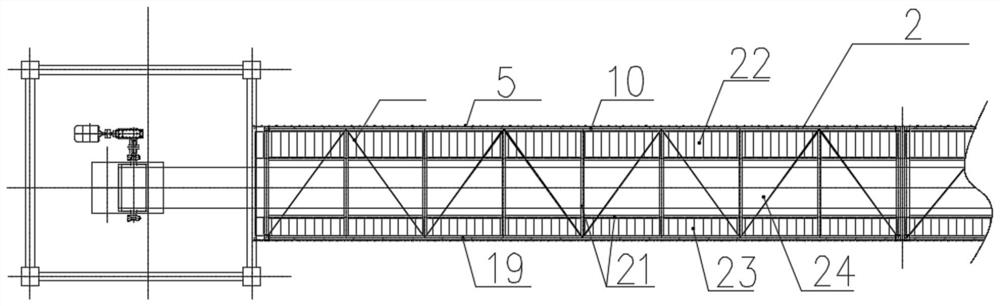

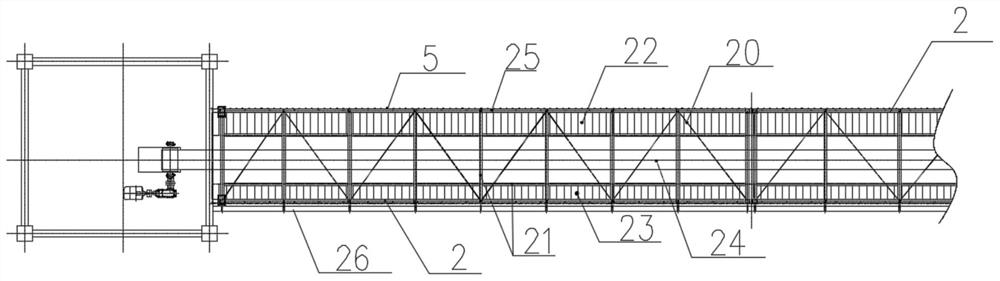

Multi-layer overhead closed conveying gallery steel pipe truss combination system

ActiveCN113636361AReduce occupancyReduce in quantityConveyorsSupporting framesEngineeringIntegrated design

The invention discloses a multi-layer overhead closed conveying gallery steel pipe truss combination system, and belongs to the technical field of assembly type steel structures. The multi-layer overhead closed conveying gallery steel pipe truss combination system involves a plurality of transfer stations and a plurality of conveying galleries, wherein the conveying galleries are arranged between the transfer stations, and the conveying galleries running in the same transportation direction are arranged in the same vertical surface direction, and are formed into a three-dimensional overall structure in spatial arrangement; the conveying galleries on the same vertical surface share a common stand column support, the stand column support is provided with a penetrating channel, the two ends of the penetrating channel are connected with the corresponding conveying galleries into a whole, and the stand column support can be supported on the roof or the ground of the transfer stations; and the conveying galleries located on the same vertical surface are arranged to be any one or two or more combinations of single-layer conveying galleries and double-layer conveying galleries. A plurality of belts running in the same direction are arranged on the same vertical surface in a conveying mode, and meanwhile a conveying structure is subjected to three-dimensional integrated design, so that multiple purposes of a structural unit are achieved, and the effect that the single structural unit can support a plurality of belt conveyor conveying devices is achieved.

Owner:成都建筑材料工业设计研究院有限公司

Rotatable hanging device and technique for vehicle painting production line

InactiveCN101279311AEasy to operateSimple process layoutLiquid surface applicatorsCoatingsManufacturing efficiencyBatch production

The invention discloses a rotary hanging device used for automobile coating production line which comprises a bottom plate at the rotary hanging position of a lower piece as well as a rising section and a descending section of a hanger of the rotary hanging of the lower piece; a pre-descending section is added on the transverse position between the rising section and the descending section. The technical scheme provided by the invention can be adopted to effectively solve the technical problems of wasting a large amount of time caused by a stepping manufacture technique, being incapable of adapting to the requirements of batch production line and seriously restricting manufacture efficiency in the automobile coating manufacture technique; simultaneously the rotary hanging device of the invention has the advantages of easy operation, simple and convenient technique arrangement, low cost and reliable operation.

Owner:CHERY AUTOMOBILE CO LTD

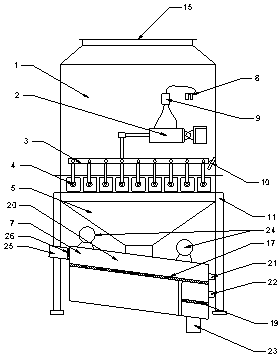

Compound fertilizer particle cooling and screening equipment

InactiveCN110404760AGood cooling and screening effectLow costSievingGas current separationScreening effectCooling effect

The invention discloses a compound fertilizer particle cooling and screening equipment. The equipment comprises a cooler, a buffer hopper, a screening device and a rack, wherein the cooler is positioned at the upper end of the rack, the buffer hopper is arranged at the lower end of the cooler, an outlet of the buffer hopper is connected with an inlet of the screening device, two sides of the screening device are fixedly connected with the rack through springs, a cooler feeding hole is formed in the top of the cooler, a cooler air outlet is formed in the upper part of the side face of the cooler, a turnover plate is arranged at the lower part of the cooler, a cylinder and a swing arm are arranged above one side of the turnover plate, and the cylinder is connected with the turnover plate through the swing arm. According to the equipment, the cooling and screening effects are good, the cost is low, the cooling and screening can be completed at the same time, the process arrangement is facilitated, the occupied area is small, fertilizer particles can be bounced by a screen to a certain height under the action of a vibration pump, so that the fertilizer particles are relatively dispersed rather than formed into a stock pile, the cooling effect is good, mechanical stirring is not needed in a cooling and screening process, and the breakage rate of the fertilizer particles can be reduced.

Owner:安徽中农大丰化肥有限公司

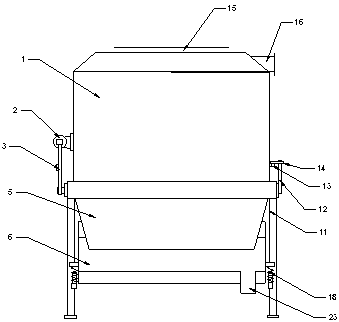

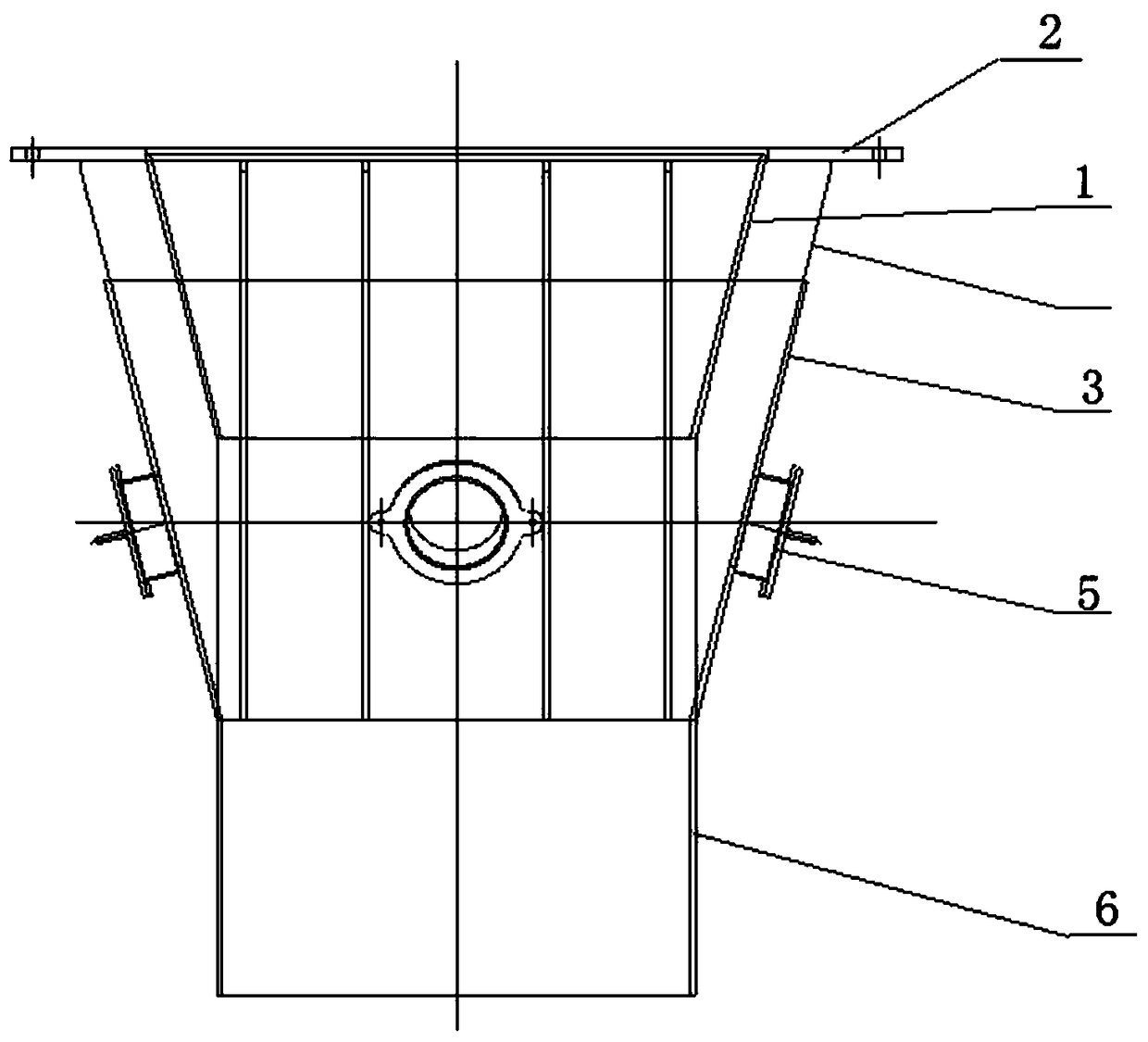

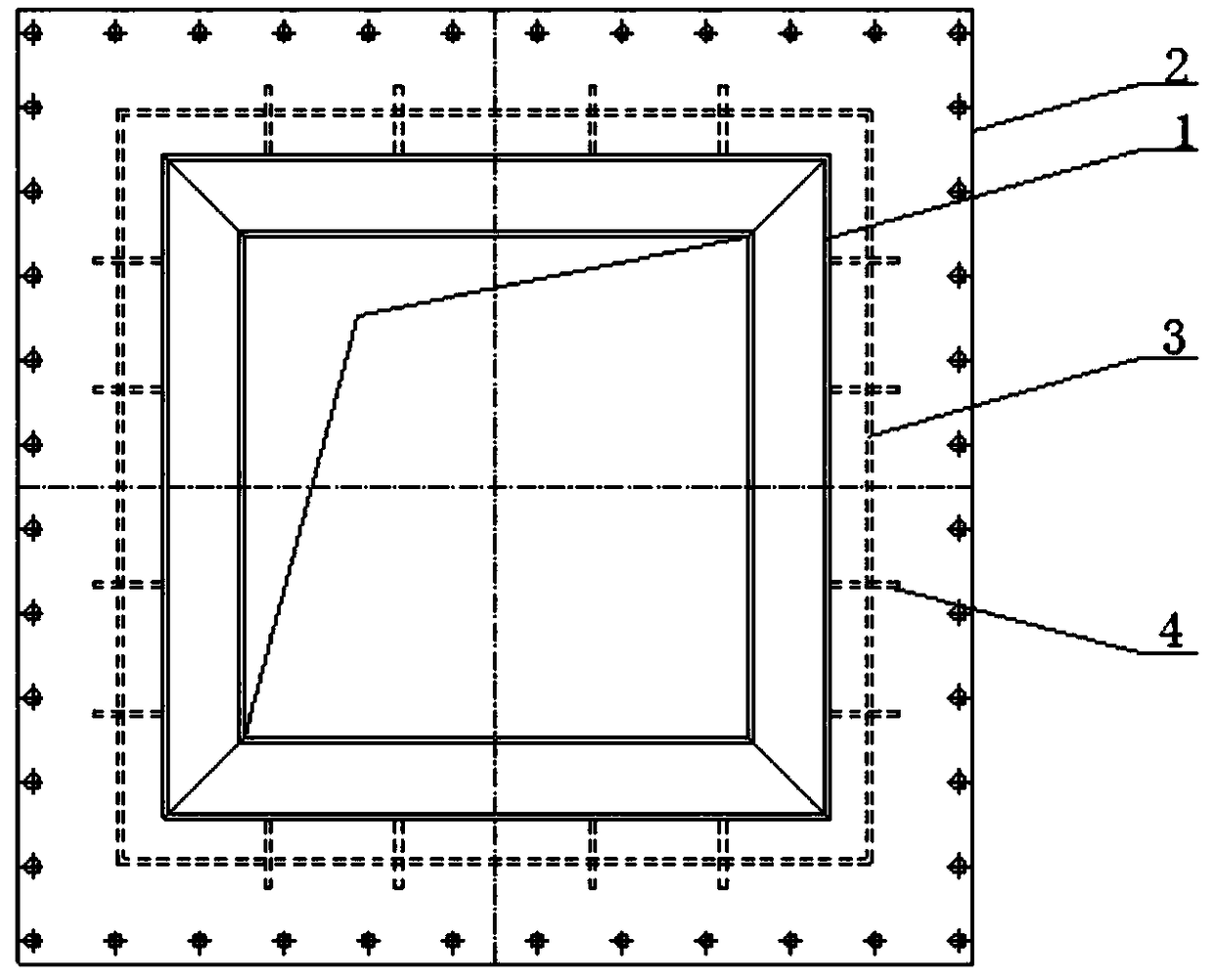

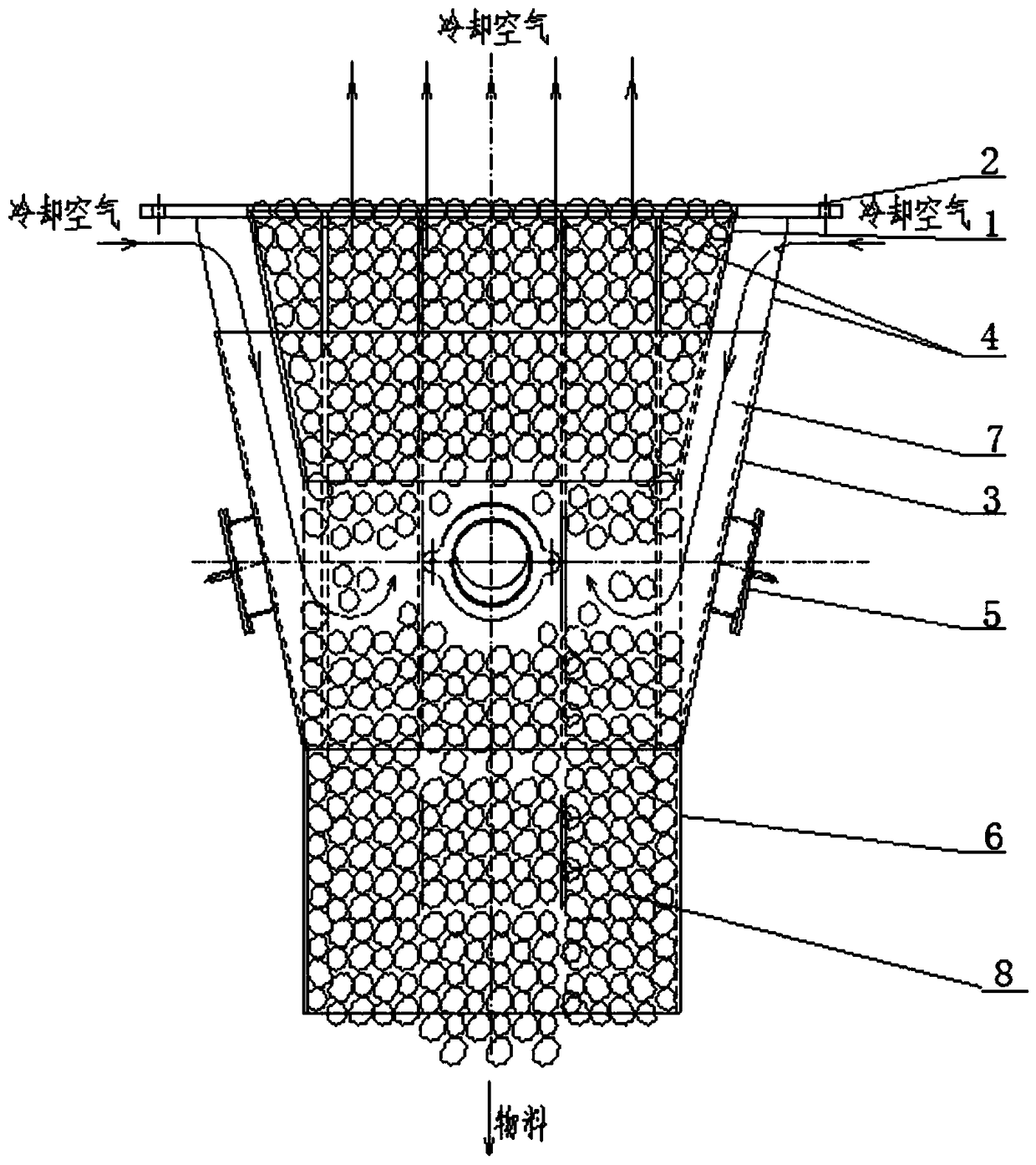

Double-horn-mouth type vertical kiln lower discharging hopper structure and work method thereof

PendingCN109307427ACompact structureOptimize process layoutCharge manipulationFurnace coolingArchitectural engineeringKiln

The invention relates to a double-horn-mouth type vertical kiln lower discharging hopper structure and a work method thereof. The discharging hopper structure comprises an inner surrounding groove, anouter surrounding groove, strengthening rib plates and a straight pipe section. The inner surrounding groove and the outer surrounding groove are fixedly connected through the multiple strengtheningrib plates. Each of the inner surrounding groove and the outer surrounding groove is provided with a horn mouth structure with a large upper part and a small lower part, and a cooling air channel is formed between the inner surrounding groove and the outer surrounding groove. The top of the inner surrounding groove is higher than the top of the outer surrounding groove, and a top annular air inletis formed in the top of the cooling air channel. The bottom of the inner surrounding groove is higher than the top of the outer surrounding groove. A bottom annular air inlet is formed in the bottomof the cooling air channel. The bottom of the outer surrounding groove is connected with the straight pipe section. In the double-horn-mouth type vertical kiln lower discharging hopper structure and the work method thereof, cooling air enters a kiln through the cooling air channel composed of the inner surrounding groove and the outer surrounding groove, it is guaranteed that the roasted materialscan be sufficiently cooled and cannot easily block a cooling air inlet, and the materials cannot leak to other worktable tops except a discharging hopper. The discharging hopper structure is simple,and manufacturing, installing and maintaining are convenient.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Staged roller biomass dryer

InactiveCN110411171AReduce dry spaceReduce empty capacityDrying gas arrangementsDrying chambers/containersPulp and paper industryAir blower

The invention relates to a staged roller biomass dryer. The staged roller biomass dryer comprises a heat source, a drying cylinder and a power device; a wheel belt is arranged on the outer side wall of the drying cylinder; the power device comprises a motor and a support wheel; the support wheel is tightly contacted with the wheel belt; the drying cylinder is divided into an inner cylinder and anouter cylinder; the inner cylinder is embedded in the outer cylinder; a first spiral shoveling plate and a second spiral shoveling plate are arranged on the inner side walls of the inner cylinder andthe outer cylinder, and are opposite in spiral direction; a feed hopper and an intake port are arranged at one end of the inner cylinder, and a blanking port is formed in the other end; a discharge port is formed in the bottom of the end, near the feed hopper, of the outer cylinder, and an exhaust port is formed in the other end; an air blower is arranged between the heat source and the intake port; and an induced draft fan is arranged at the external of the exhaust port. The dryer shortens the length by at least one half compared with a common dryer to facilitate the process arrangement, reduces the construction area of factory buildings, saves the engineering investment, and is more suitable for existing factory transformation process arrangement.

Owner:ANHUI HUANTAI BIO ENERGY TECH DEV

Inclined block type push head car pusher for electric trailer for transferring refractory kiln cars and usage method

ActiveCN108068840AReduce contact areaIncrease contact areaTrain hauling devicesCharge manipulationElectricityEngineering

The invention relates to an inclined block type push head car pusher for an electric trailer for transferring refractory kiln cars and a usage method. The inclined block type push head car pusher includes a hydraulic car pusher, a car pusher oil cylinder and a car pusher guide track. The hydraulic car pusher includes a car pusher frame, a reversing oil cylinder, inclined block type push heads anda reversing convex block. The two inclined block type push heads are symmetrically disposed on the car pusher frame, and the inclined block type push heads are hinged to the car pusher frame and are naturally in a vertical state under the action of gravity. Under the state, the inclined block type push heads are attached to the contact inclined plane of the car pusher and the bottom surface of thecar pusher. One end of the reversing oil cylinder is fixed to the car pusher frame, the other end of the reversing oil cylinder is connected with the reversing convex block, and when the reversing convex block extends into the bottom of the inclined block type push head, the inclined block type push head is pushed towards one side. The inclined block type push head car pusher can push dozens of full-load kiln cars to move on a track; and the inclined block type push head car pusher is simple in structure and convenient to maintain and has a large thrust. The inclined block type push head carpusher can be favorable for process arrangement and investment reduction of a refractory factory.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

The connection method of continuous hot bending forming and closed welding process

The invention discloses a linking method for continuous hot bending forming and closing welding work procedures, that is, a device capable of releasing a clamping hoop is arranged at the outlet end ofa continuous hot bending unit, so that the clamping hoop is used for performing clamping shape determining on a closing type steel component after being formed through the continuous hot bending unit, and then the closing type steel component subjected to clamping shape determining through the clamping hoop is conveyed to a welding station to be subjected to closing welding. The method can effectively solve the component shape deforming problem caused by the factors of the internal heat stress generated due to the temperature drop of the component and the self hot bending springback, and therefore the purpose of guaranteeing the closing welding end face shape is achieved. Flexible linking between the continuous hot bending unit and the welding station is further achieved, so that a wholeproduction line can be continuously arranged, athe production line is more continuous and compact, and the production efficiency and the welding quality can be improved easily.

Owner:CISDI RES & DEV CO LTD

A Multi-vehicle Fixture Switching Library System Consisting of Tetrahedral Turntable and Cross Slide

ActiveCN108724049BOptimize process layoutImprove production efficiencyWork holdersStructural engineeringMachining

The invention provides a multi-vehicle-type clamp switching warehouse system composed of a tetrahedron rotary table and a cross-shaped sliding table. Four side clamps are arranged on an upper tetrahedron frame of the tetrahedron rotary table in a center symmetry manner. A lower rotary table of the tetrahedron rotary table can rotate around the middle axis. Any side clamp can be switched to the butt joint position right opposite to a track butt joint device through rotation of the lower rotary table. A longitudinal sliding rail of the cross-shaped sliding table is in butt joint with a track ofthe track butt joint device, a plurality of transverse tracks are longitudinally arranged at intervals and are crossed with the longitudinal sliding rail in a cross manner, the various cross intersection positions on the cross-shaped sliding table are waiting positions, the side clamp located at the butt joint position is dragged by a traction trolley on the track butt joint device to run to one waiting position and is dragged by a traction trolley on the corresponding transverse track to run towards the left side or the right side to enter a warehouse. The multi-vehicle-type clamp switching warehouse system can meet the six-vehicle-type collineation production requirement, the equipment designing, machining, manufacturing, installing and maintaining difficulty is lowered, and the vehiclebody manufacturing efficiency is improved.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

A new type of linked rotary wedge

ActiveCN111468616BOptimize process layoutReduce development costsShaping toolsVehicle componentsClassical mechanicsStructural engineering

The present invention relates to the technical field of flanging of the engine cover outer plate, in particular to a novel linkage rotating wedge, comprising a wedge base, a punch provided with an engine cover outer plate on the upper surface of the wedge base, and a punch of the punch There are two side flanging mechanisms on both sides, the front end of the punch is provided with a middle mesh side flanging mechanism, and there are two lamp mouth corner turning mechanisms between the side flanging mechanism and the middle mesh side flanging mechanism. Edge mechanism; when working, after the side flange mechanism of the center grid and the two lamp mouth corner flange mechanisms rotate clockwise for 25° at the same time, the two side flange mechanisms rotate clockwise for 15°. The present invention can realize side flanging in three directions in one station, and can optimize two-step flanging into one-step flanging in the process of stamping process layout, optimize process arrangement, and save development cost.

Owner:JIANGLING MOTORS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com