The connection method of continuous hot bending forming and closed welding process

A welding station and process technology, which is applied in the field of connection between continuous hot bending forming and closed welding process, can solve the problems such as difficulty in ensuring the shape of closed welding section, online closed welding of difficult high temperature components, and matching of forming speed of difficult hot bending machines, etc. Achieve the effects of improving production efficiency and welding quality, improving production efficiency, and ensuring the shape of the closed welding section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

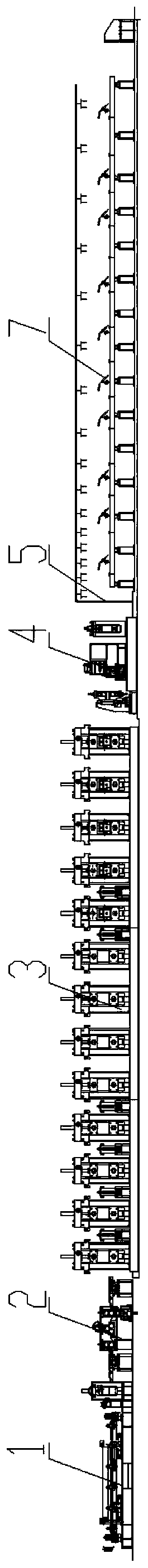

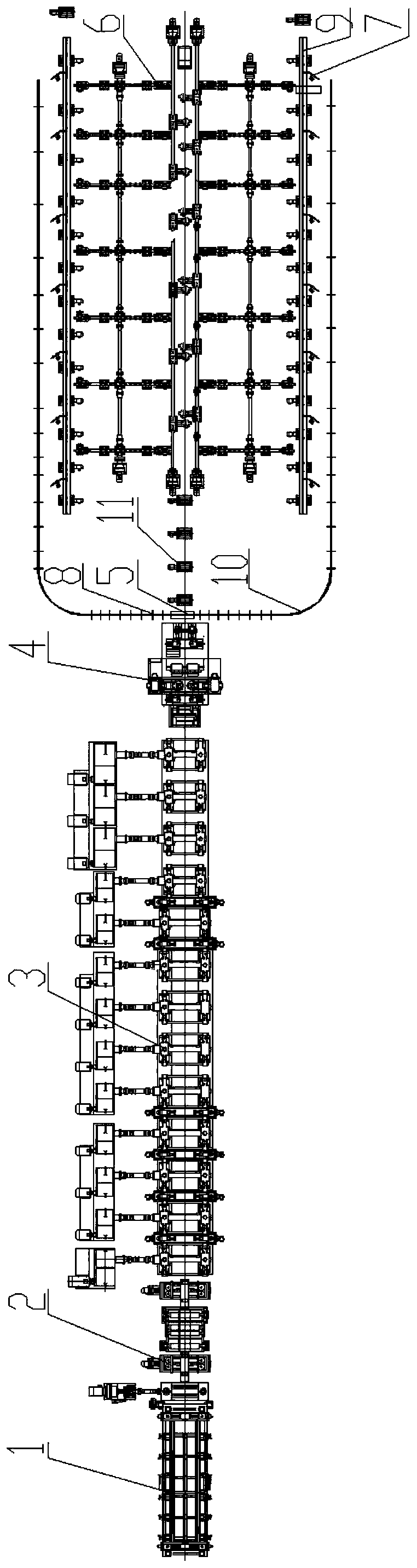

[0030] Such as figure 1 , 2 As shown, the feeding roller table 1, the centering device 2, the forming unit 3, the squeeze roller 4, the quick clamping device 5 that can release the clamp, the transfer device 6 and the welding equipment 7 are arranged in order along the component production direction, The raw steel plate is hoisted to the feeding roller table, enters the forming unit after the centering device, and then squeezed by the squeeze roller to form a closed steel member 9. When the head of the closed steel component exits the squeeze roller, during the operation of the component, the quick clamping device 5 quickly releases a set of clamps to clamp the high temperature component. As the closed steel component continues to be extruded, it will release after a certain distance. The second set, the third set...the Nth set of clamps clamp the high temperature components, and after each clamp 8 clamps and locks the high temperature components, the power source is quickly cut...

Embodiment 2

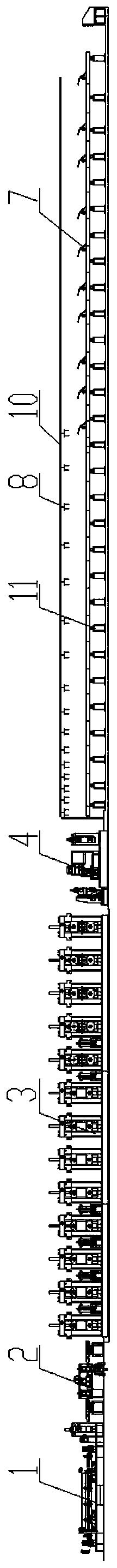

[0032] Such as image 3 , 4 As shown, the feeding roller table 1, the centering device 2, the forming unit 3, the squeeze roller 4, the quick clamping device 5 that can release the clamp, the transfer device 6 and the welding equipment 7 are arranged in order along the component production direction. The steel plate is hoisted to the feeding roller table, enters the forming unit after the centering device, and then squeezed by the squeeze roller to form a closed steel component. When the tail of the high-temperature component is completely out of the squeeze roller and stops, the quick clamping device 5 releases several sets of clamps 8 along the length of the component at the same time to clamp the high-temperature component. After the molded component is completely clamped, the power source is quickly cut off , And then the closed steel component with the clamp is restarted and transported to the transfer device, and then transferred to the welding station through the transfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com