Manufacturing equipment and method of long screw rod

A technology for manufacturing equipment and long screws, which is applied in the field of variable cross-section FRP pultrusion forming equipment. It can solve the problems of poor mechanical processing performance, not too long length, and difficult deformation of composite materials, so as to achieve rapid curing, improve the pass rate, and withstand stress. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

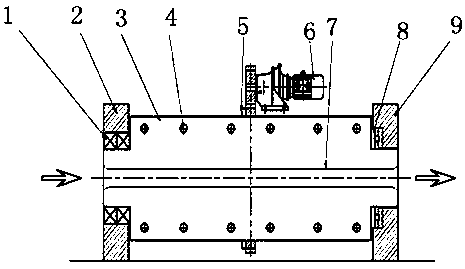

[0030] Such as figure 1 Shown, a kind of manufacturing equipment of long screw rod, comprises rear support frame 2, mold body 3, screw thread 7, front bracket 9, it is characterized in that: the two ends of described mold body 3 pass through rear support frame 2 and front support respectively Frame 9, and can carry out self-rotation, and described thread line 7 is positioned at the inner surface of mold cavity 10 that passes through the center axis inside mold body 3, and the workpiece to be processed enters the device in the direction of the arrow in the figure, and the rotation of the mold body makes the to-be-processed The processing part is used for the processing of the screw, and the device is released from the other end to complete the processing.

[0031] A number of heating tubes are arranged on the mold body, and the heating tubes are connected to the conductive ring of the heating tube located on the outer circumference of the mold body. The conductive ring of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com