Patents

Literature

43results about How to "Prevent shape deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

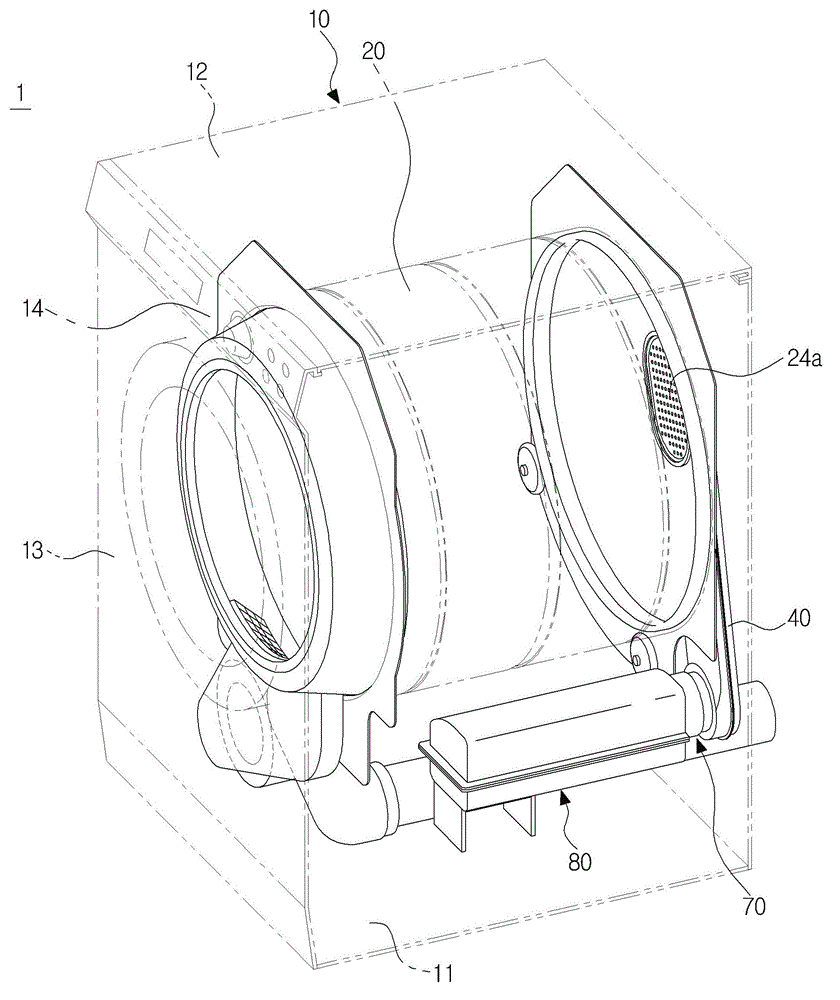

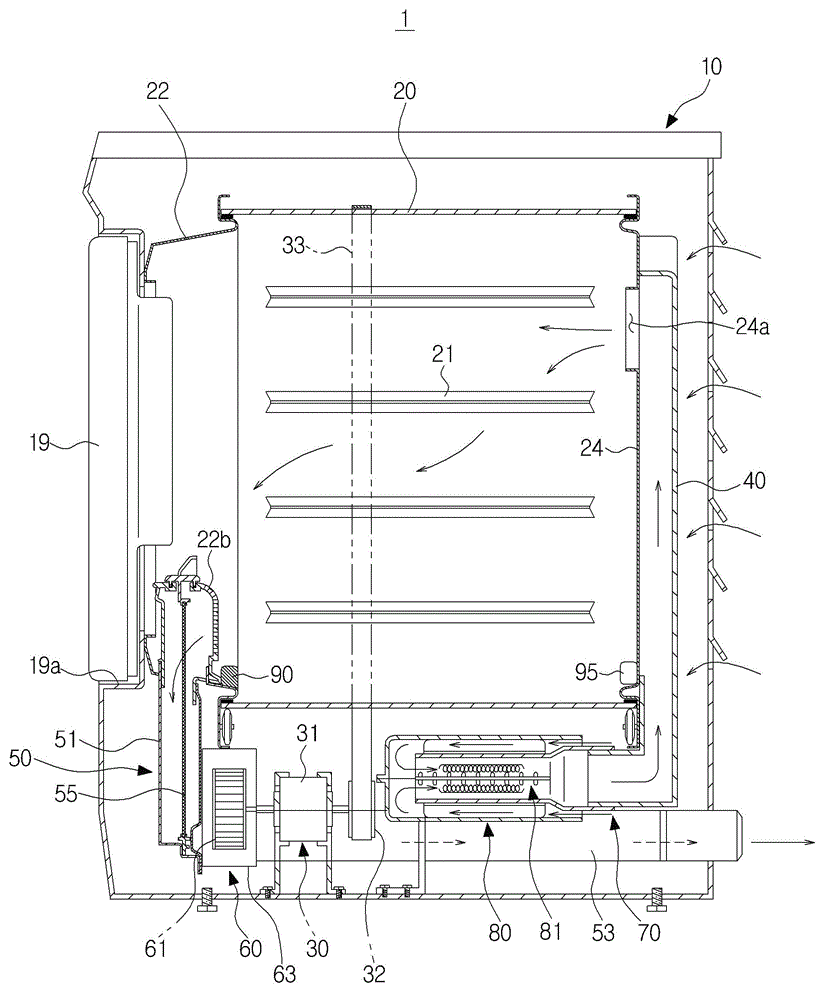

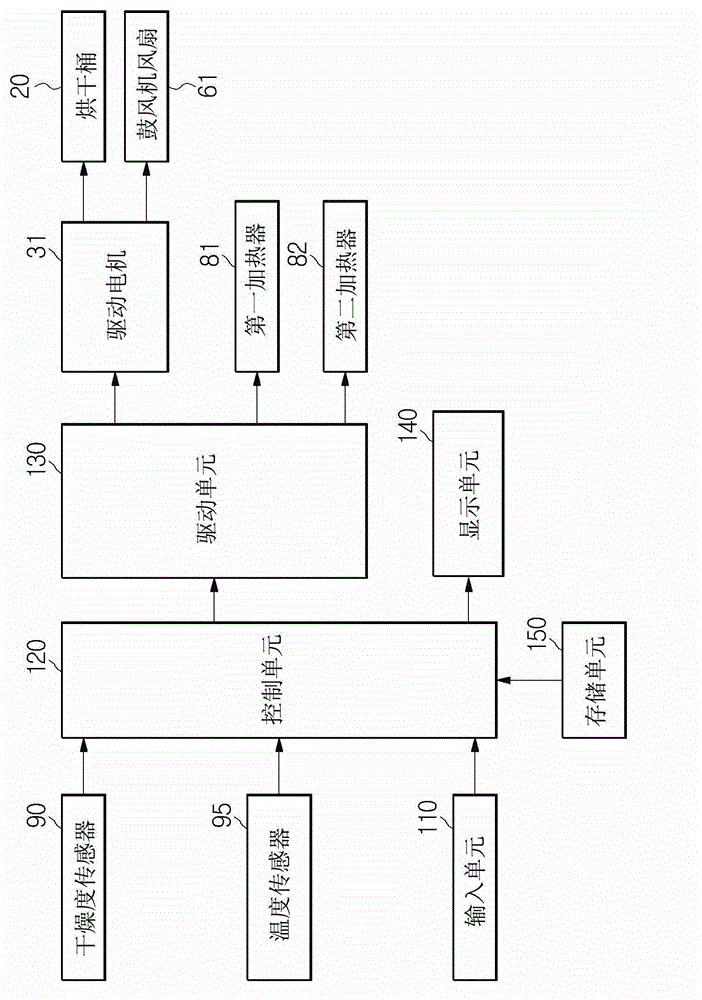

Clothes dryer and control method thereof

ActiveCN103184673APrevent shape deformationGood dryingTextiles and paperHeating arrangementEngineering

Owner:SAMSUNG ELECTRONICS CO LTD

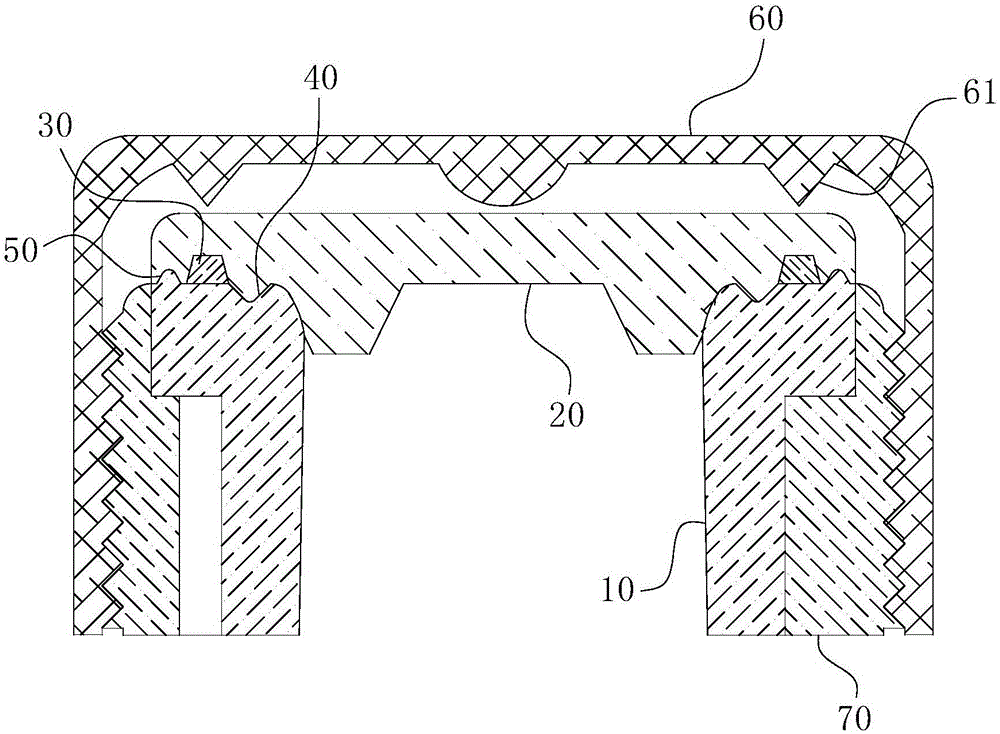

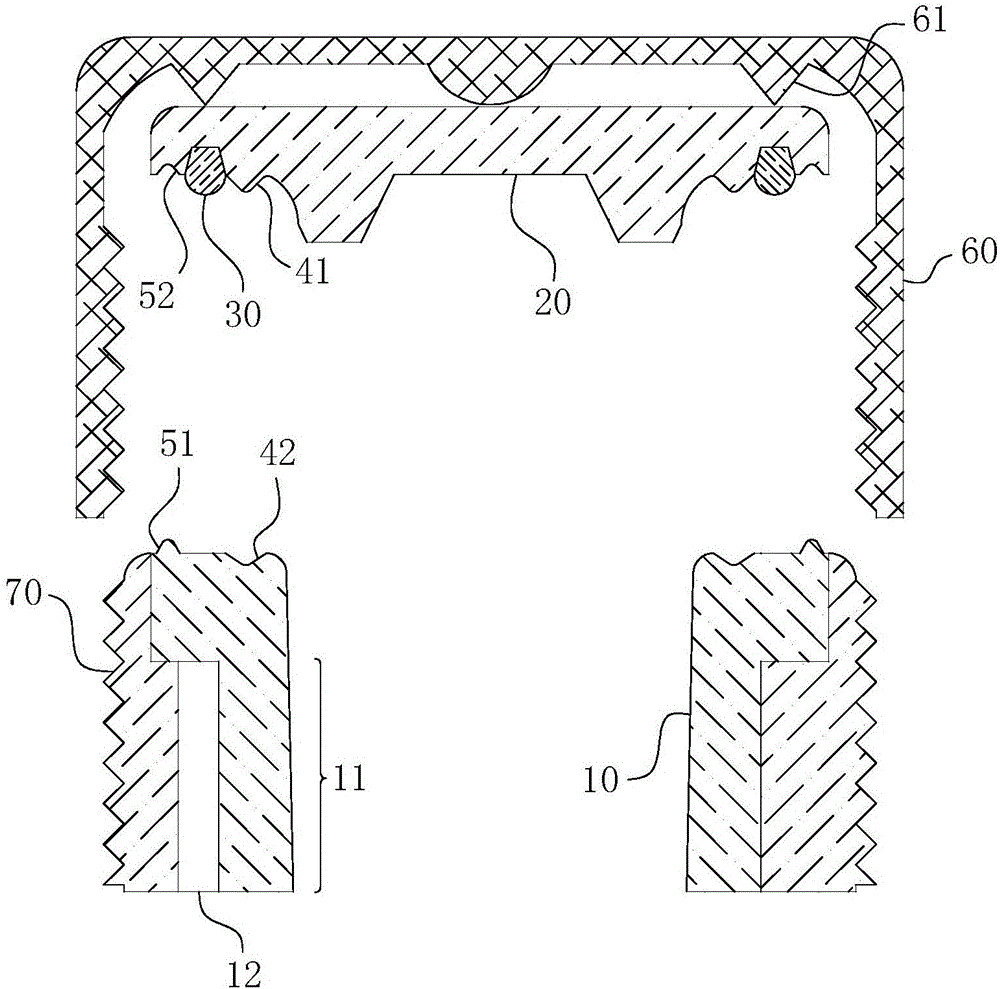

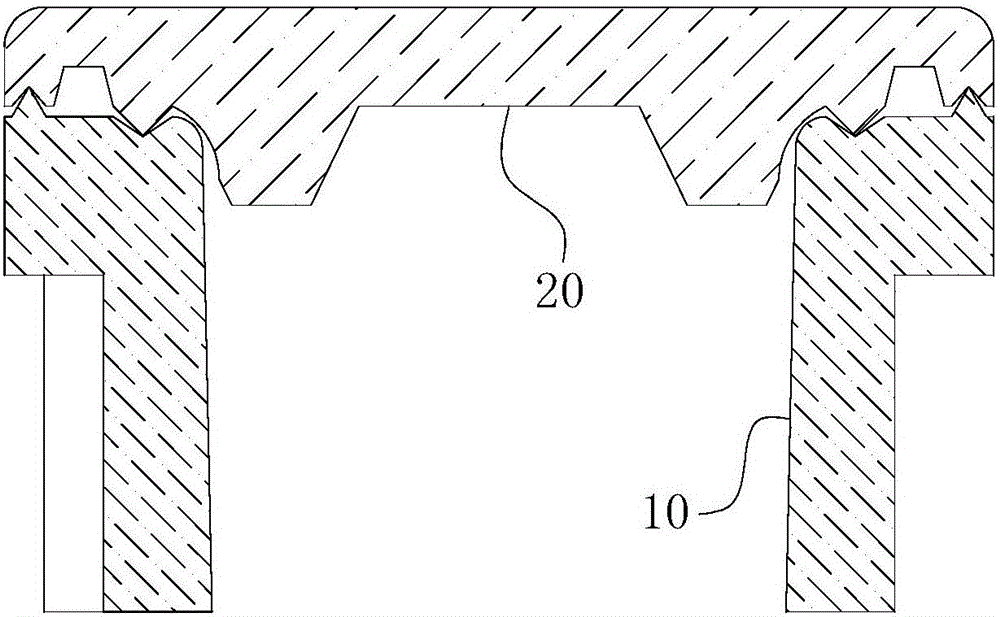

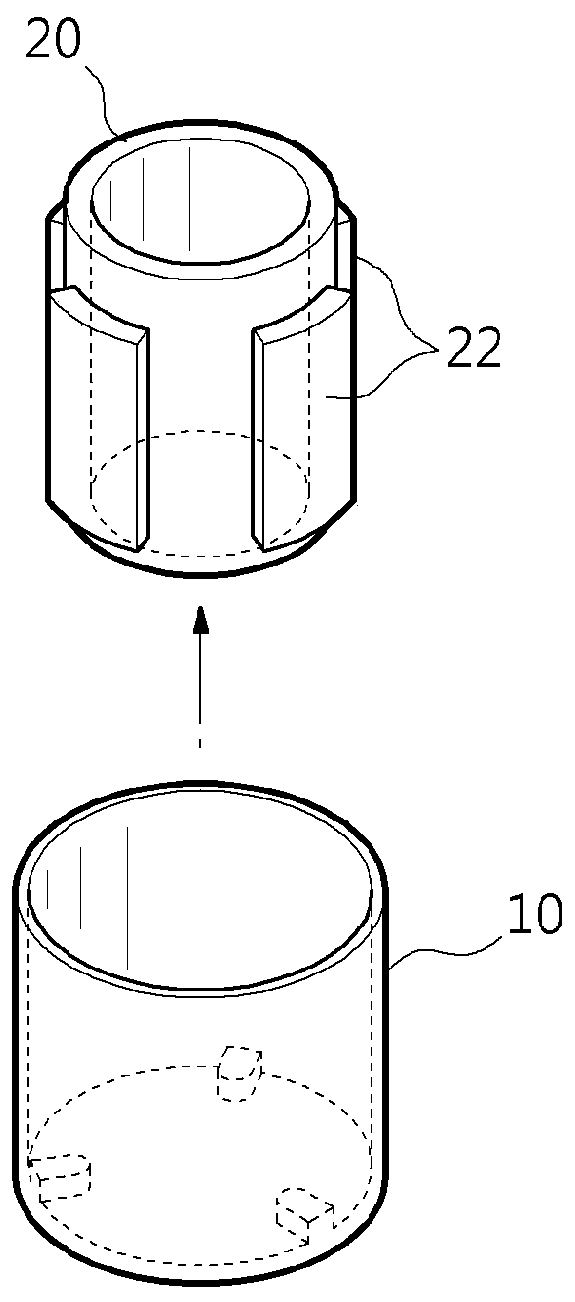

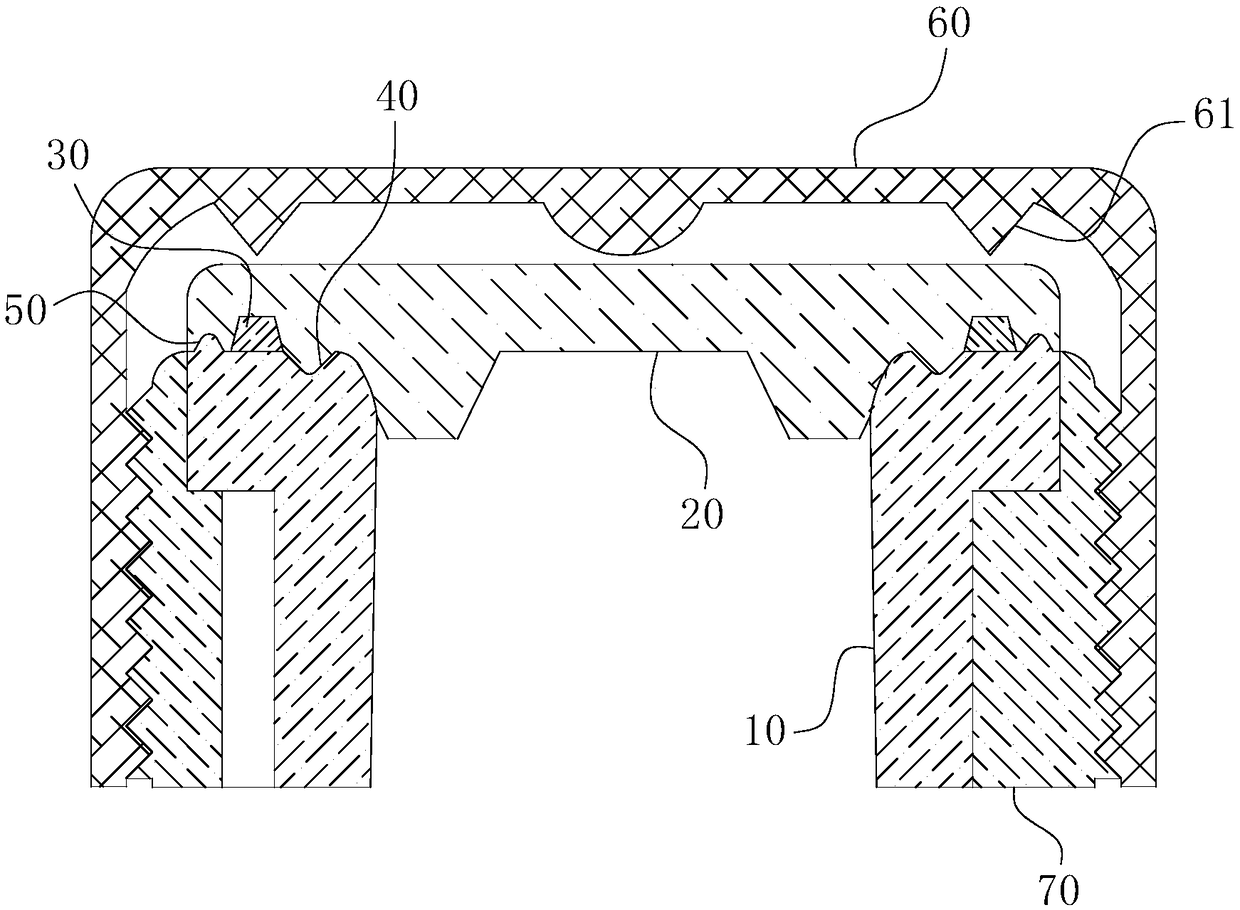

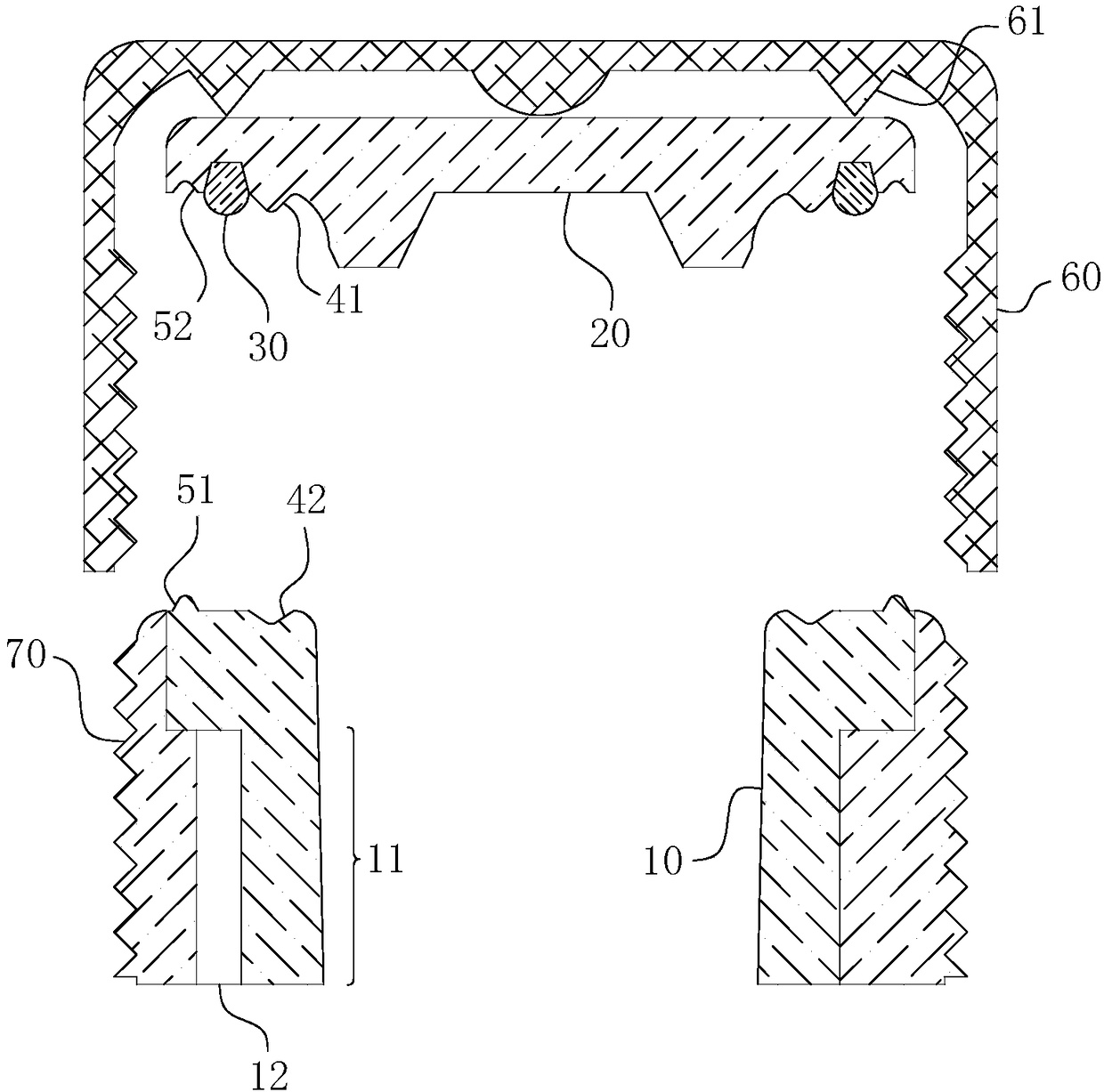

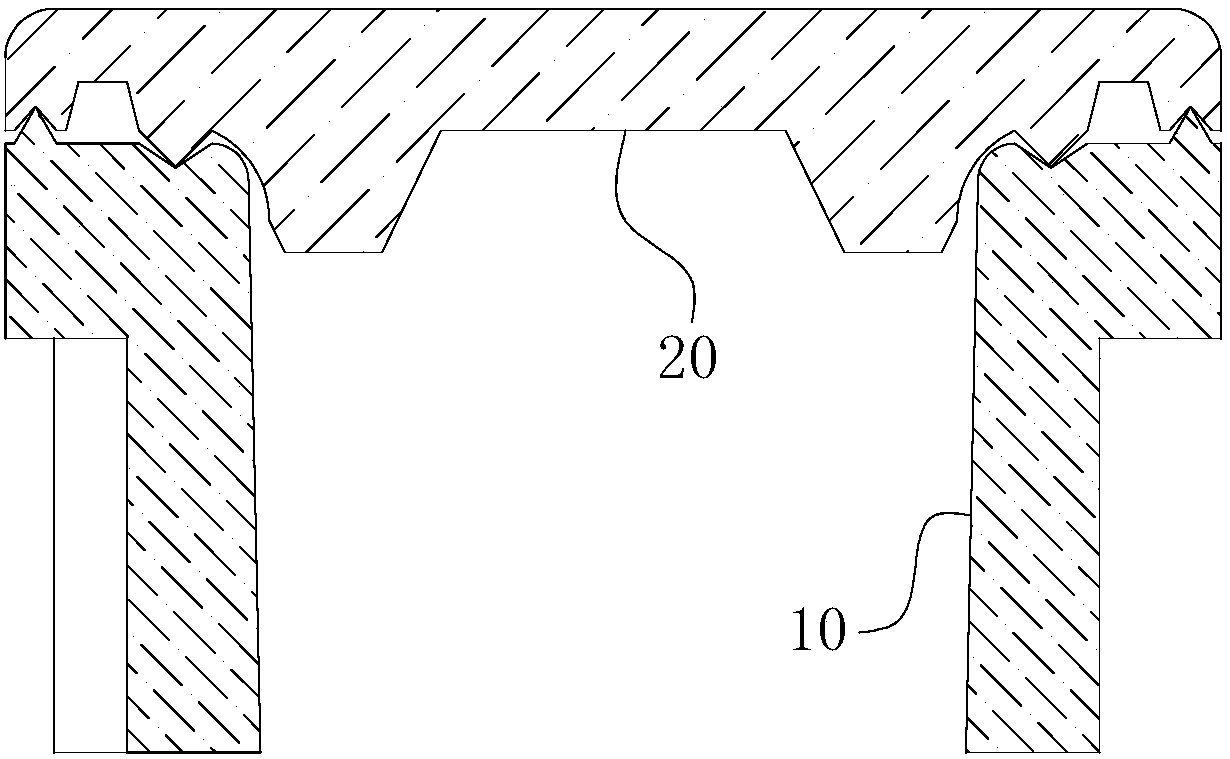

Ceramic vessel opening part sealing structure and preparation method thereof

The invention belongs to the technical field of storage sealing vessels, and particularly relates to a ceramic vessel opening part sealing structure and a preparation method thereof. The sealing structure comprises an opening part and a sealing cover. At least two sealing sections are arranged between the opening part and the sealing cover. The two sealing sections comprise a rubber sealing ring which is arranged on the upper surface of the opening part and / or the lower surface of the sealing cover and surrounds the axis of the opening part, and at least one circle of matting sealing ring which is located on the inner side of the rubber sealing ring and surrounds the axis of the opening part. By the adoption of the sealing structure, storage quality of reserved substances can be guaranteed while a normal packaging effect on the opening part by a traditional sealing cover is ensured. In the machining process, a carborundum grinding mode is used, and the top of an annular sealing ridge conducts rotating and grinding relative to the corresponding surface of the sealing cover or the opening part so that an annular sealing groove can be formed; and the top of an annular supporting ridge conducts rotating and grinding relative to the corresponding surface of the sealing cover or the opening part so that an annular supporting groove can be formed, and thus reliable machining of the structure can be guaranteed conveniently, rapidly and efficiently.

Owner:景德镇醉妙堂陶瓷有限公司

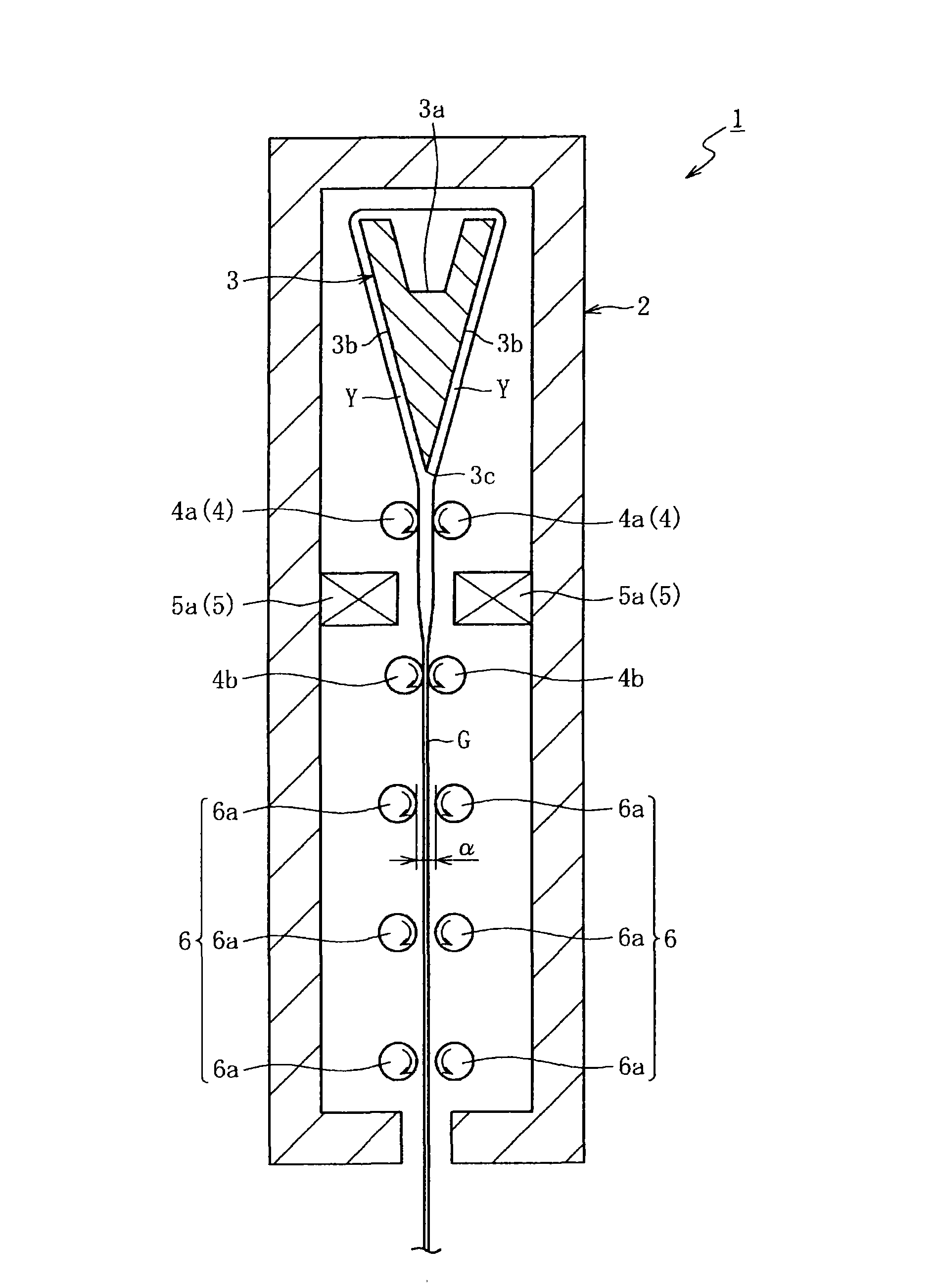

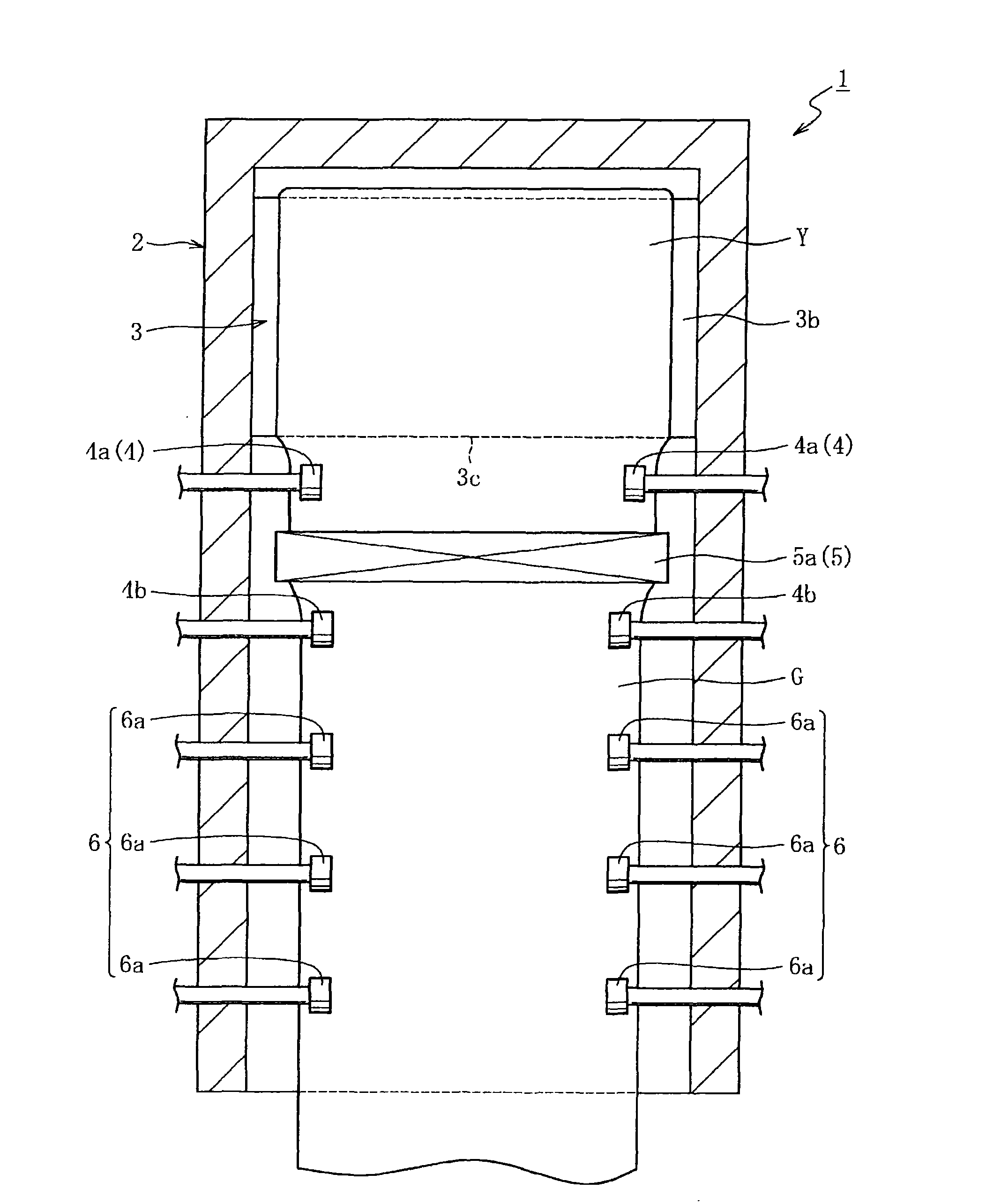

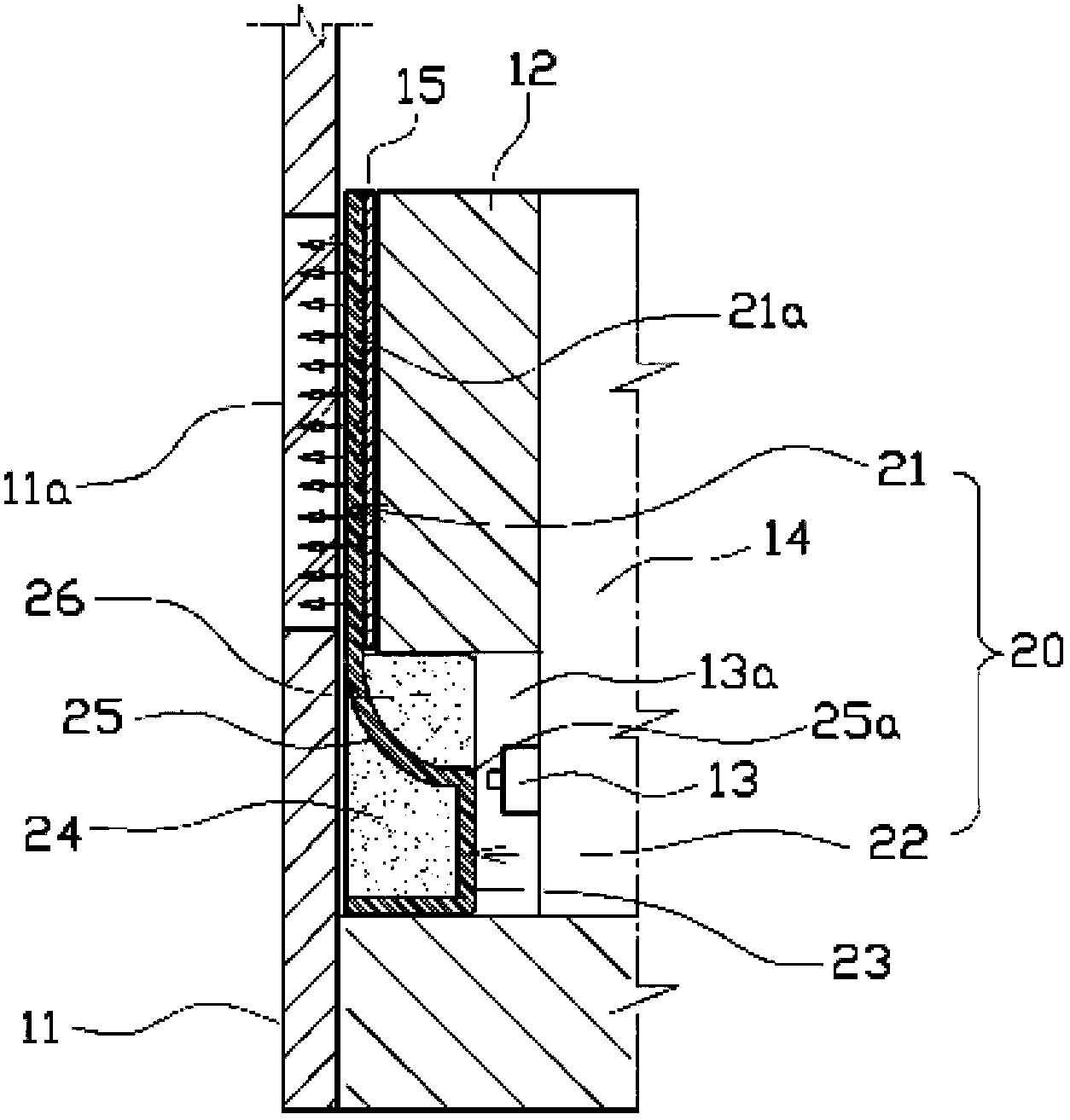

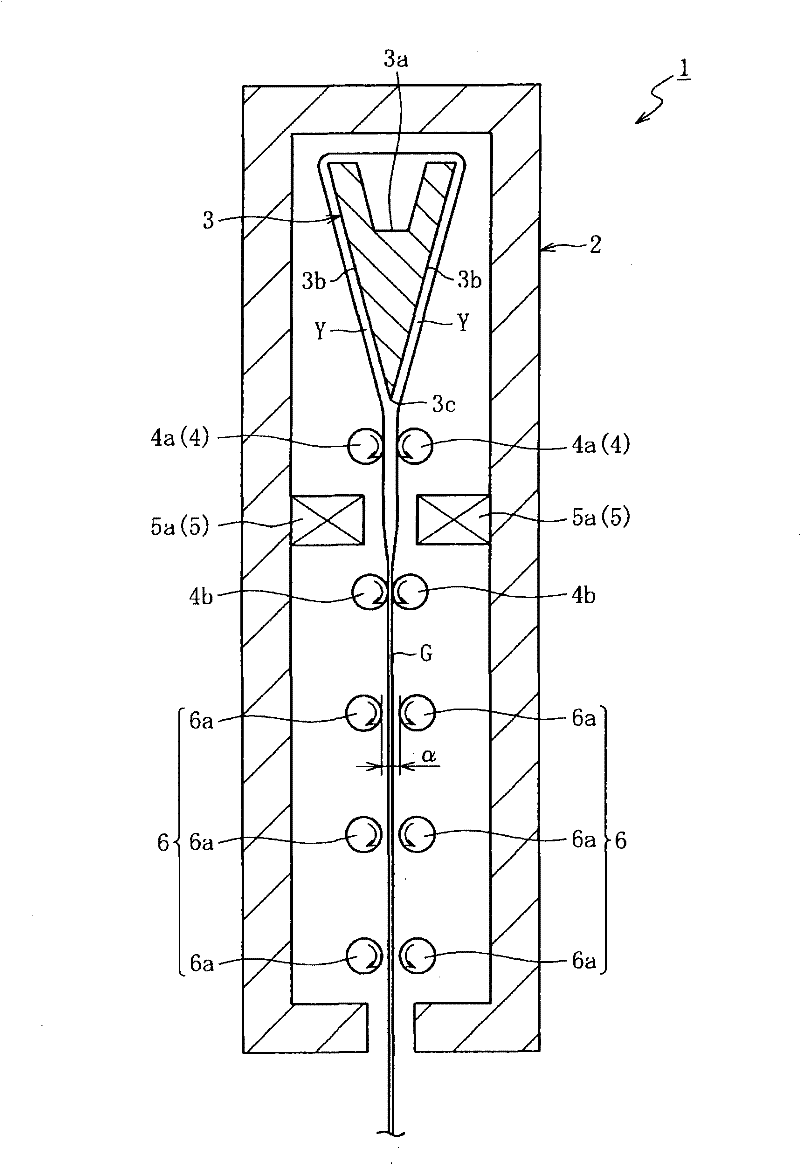

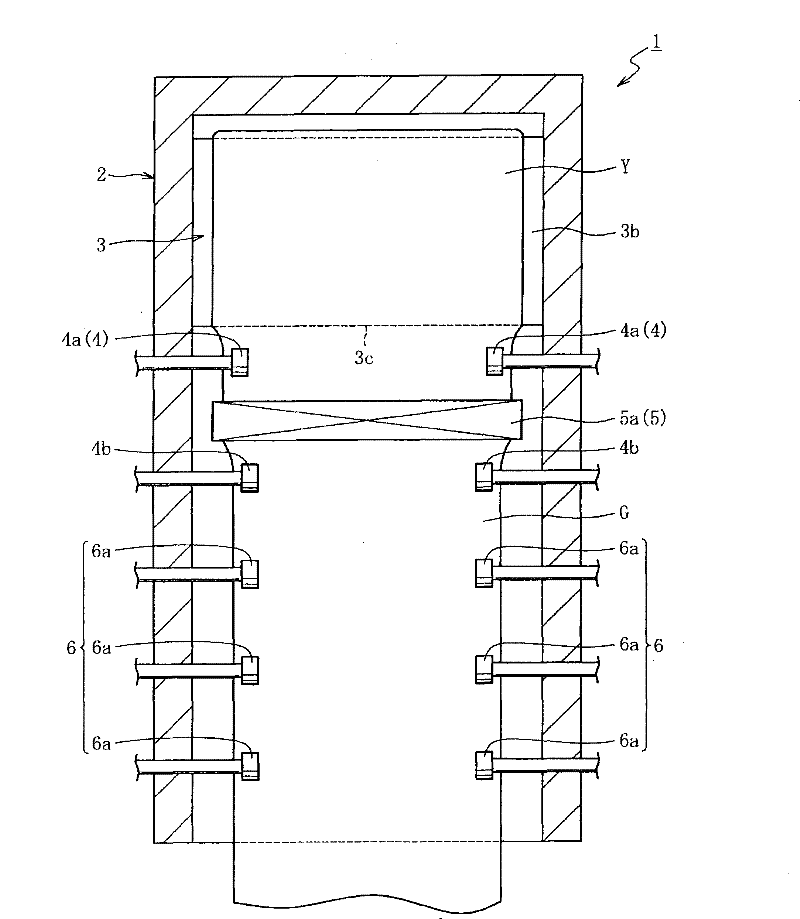

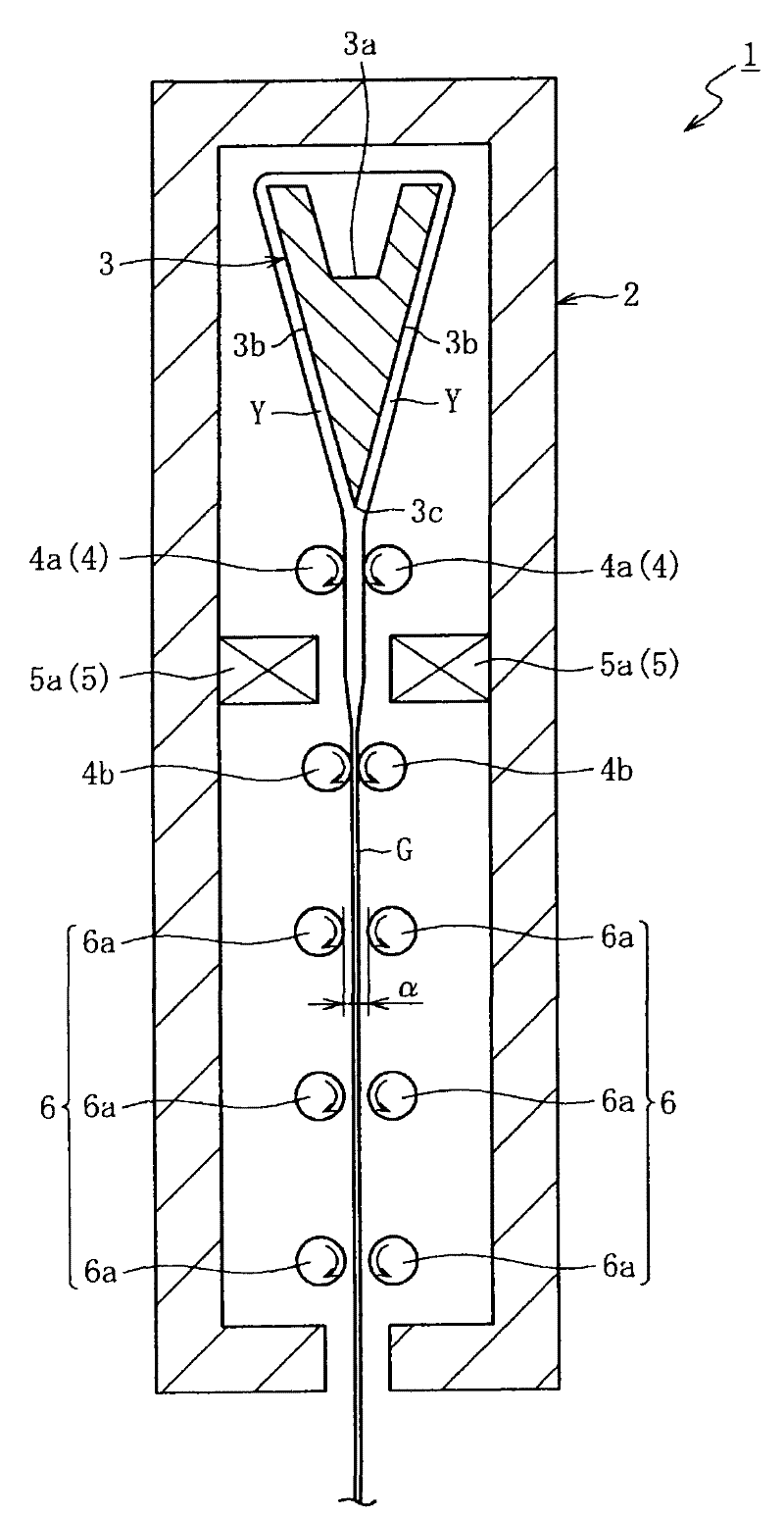

Glass ribbon producing apparatus and process for producing the same

ActiveCN101528618ARestriction disorderPrevent shape deformationGlass forming apparatusMolten glassElectrical and Electronics engineering

The invention provides a glass ribbon producing apparatus (1) adapted to feed molten glass (Y) to molding member (3) and to cause the molten glass (Y) to flow downward from the molding member (3) so as to form sheetlike glass ribbon (G), comprising guide means (6) disposed on a transport route for the glass ribbon (G) flowing downward, which guide means (6) has a gap of dimension larger than the sheet thickness at across-the-width both ends in the direction of thickness of the glass ribbon (G) and guides within the bound of the gap only the across-the-width both ends of the glass ribbon (G).

Owner:NIPPON ELECTRIC GLASS CO LTD

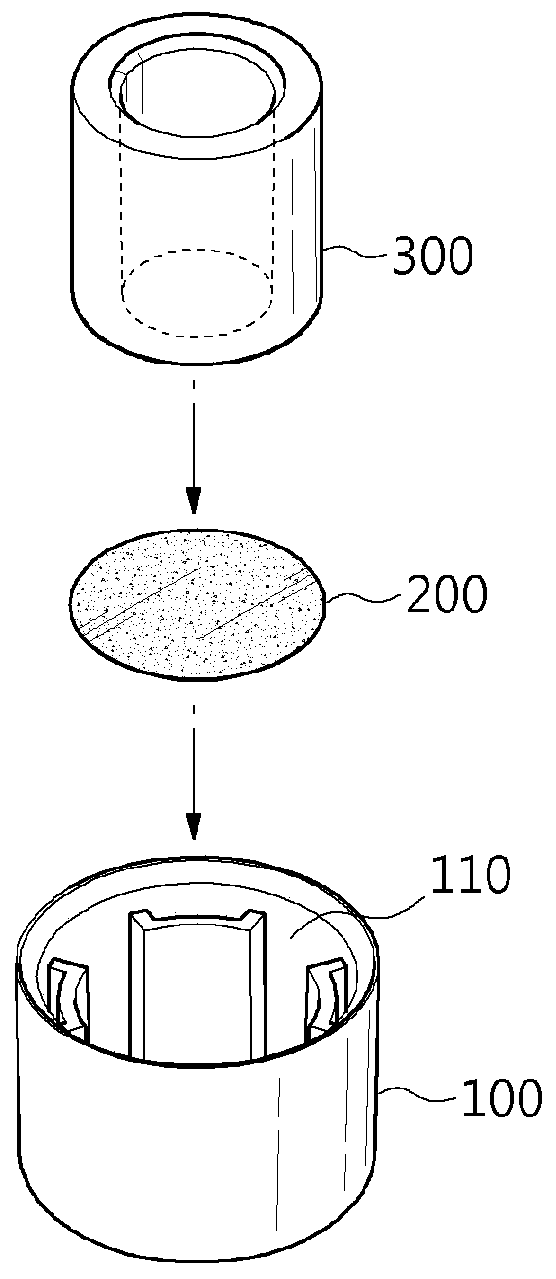

Cold pressing technology of solid-liquid hybrid electrolyte lithium storage battery

ActiveCN110048168APrevent shape deformationFully exhaustedFinal product manufactureLi-accumulatorsSolid-state batteryInner loop

The invention discloses a cold pressing technology of a solid-liquid hybrid electrolyte lithium storage battery, and relates to the field of solid state batteries. Through the key points of the technical scheme, the cold pressing technology comprises the following steps: step one, clamping a battery cell by using a cold pressing clamp; step two, cycling a saponification solution inside the cold pressing clamp; and step three, pressing the battery in stages. Pressing in stages while cooling is carried out by using the saponification solution in the cold pressing process is reached, so that gaspackaged in the battery in the formation process can be discharged in a gas bag, and rapid forming of the battery cell also can be realized while the quality of the battery cell is improved.

Owner:ZHEJIANG FUNLITHIUM NEW ENERGY TECH CO LTD

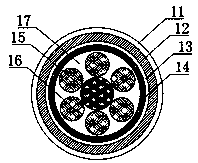

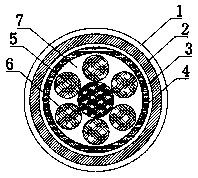

Heating cable and extrusion equipment thereof

ActiveCN107705893AGood flexibilityPrevent twistingClimate change adaptationFlexible cablesElectrical conductorFilling materials

The invention discloses a heating cable, and relates to special equipment or methods for manufacturing conductors or cables. The problems of the twisting and the bending of a cable, the non-rounding condition and the instable forming degree of the extruded cable, the loosening of a cable core, the reduced tensile strength and the shape deformation of the cable, due to the turnover of a special-shaped insulating wire core after the adoption of an existing cable extruding machine and the addition of heating and filling materials containing EPDM rubber 40 nm in grain diameter, can be solved. Theheating cable comprises an outer protective layer, an armor layer, an inner protective layer, an insulating layer and a conductor layer, wherein the above layers are sequentially wrapped from outsideto inside. Four to six anti-shielding layers are distributed on the outer ring of the conductor layer. The anti-shielding layers are located between the conductor layer and the insulating layer. Heating and filing materials are filled between the conductor layer and the insulating layer. According to the technical scheme of the invention, the twisting and the bending of the cable, caused by the turnover of the special-shaped insulating wire core, can be avoided. The invention further discloses equipment for machining and extruding the heating cable.

Owner:欧耐特线缆集团有限公司

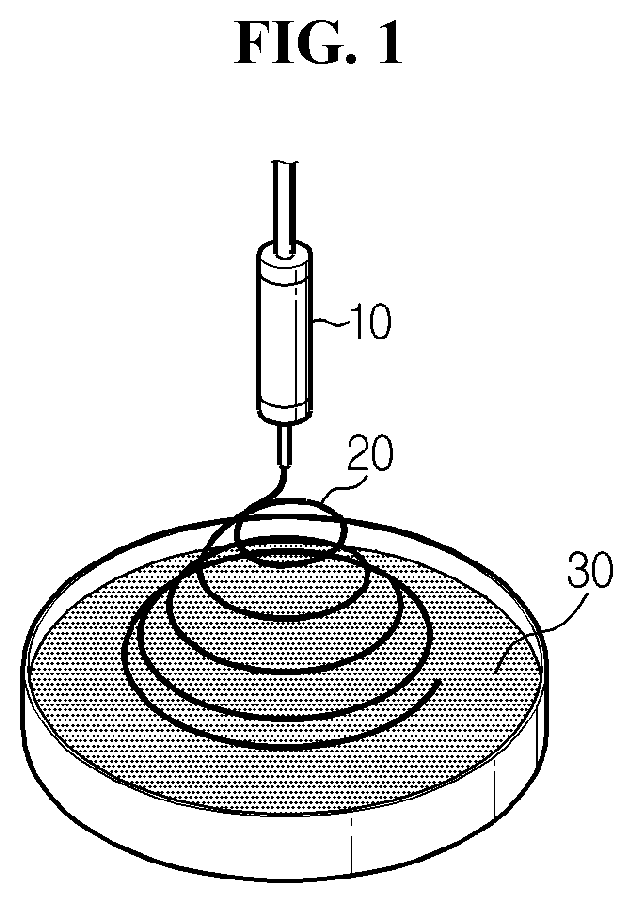

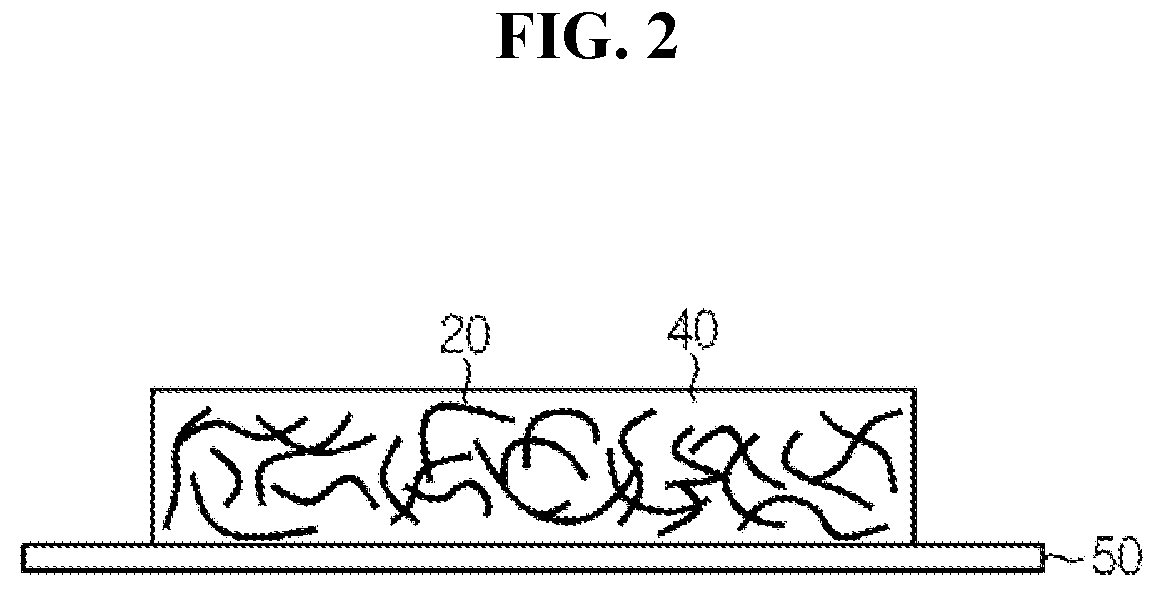

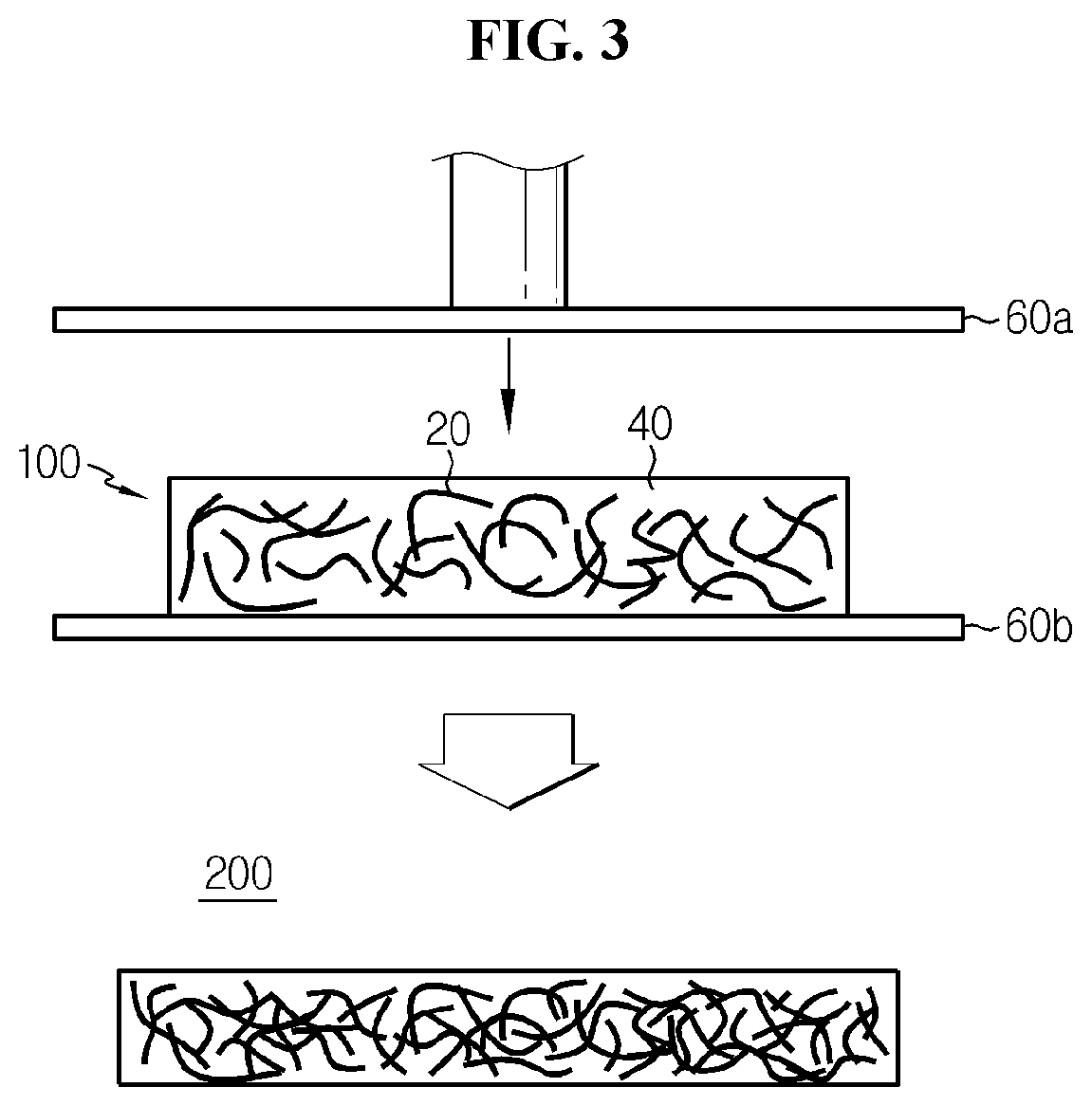

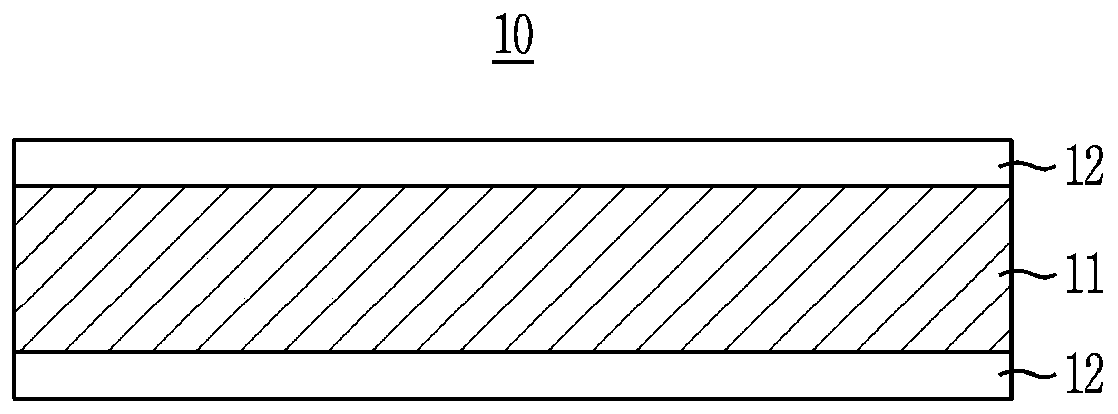

Method for manufacturing solid electrolyte membrane for all solid type battery and solid electrolyte membrane manufactured by the method

ActiveUS20190372149A1Increase durability and flexibilityPrevent shape deformationSolid electrolytesCell seperators/membranes/diaphragms/spacersElectrolytePolymer

A solid electrolyte membrane and method of preparing, including a plurality of polymer filaments arranged crossed as a 3-dimensional structure in the form of a net of nonwoven fabric-like shape, and a plurality of inorganic solid electrolytes inserted and uniformly distributed in the structure. By this structural feature, a large amount of solid electrolyte particles are uniformly distributed and filled in the electrolyte membrane, contact between the particles is good, and ionic conduction paths are sufficiently provided. Additionally, the durability of the solid electrolyte membrane is improved by the 3-dimensional structure, and the flexibility and strength increase. The nonwoven fabric composite solid electrolyte membrane has an effect in preventing inorganic solid electrolyte particle from being disconnected therefrom.

Owner:LG ENERGY SOLUTION LTD

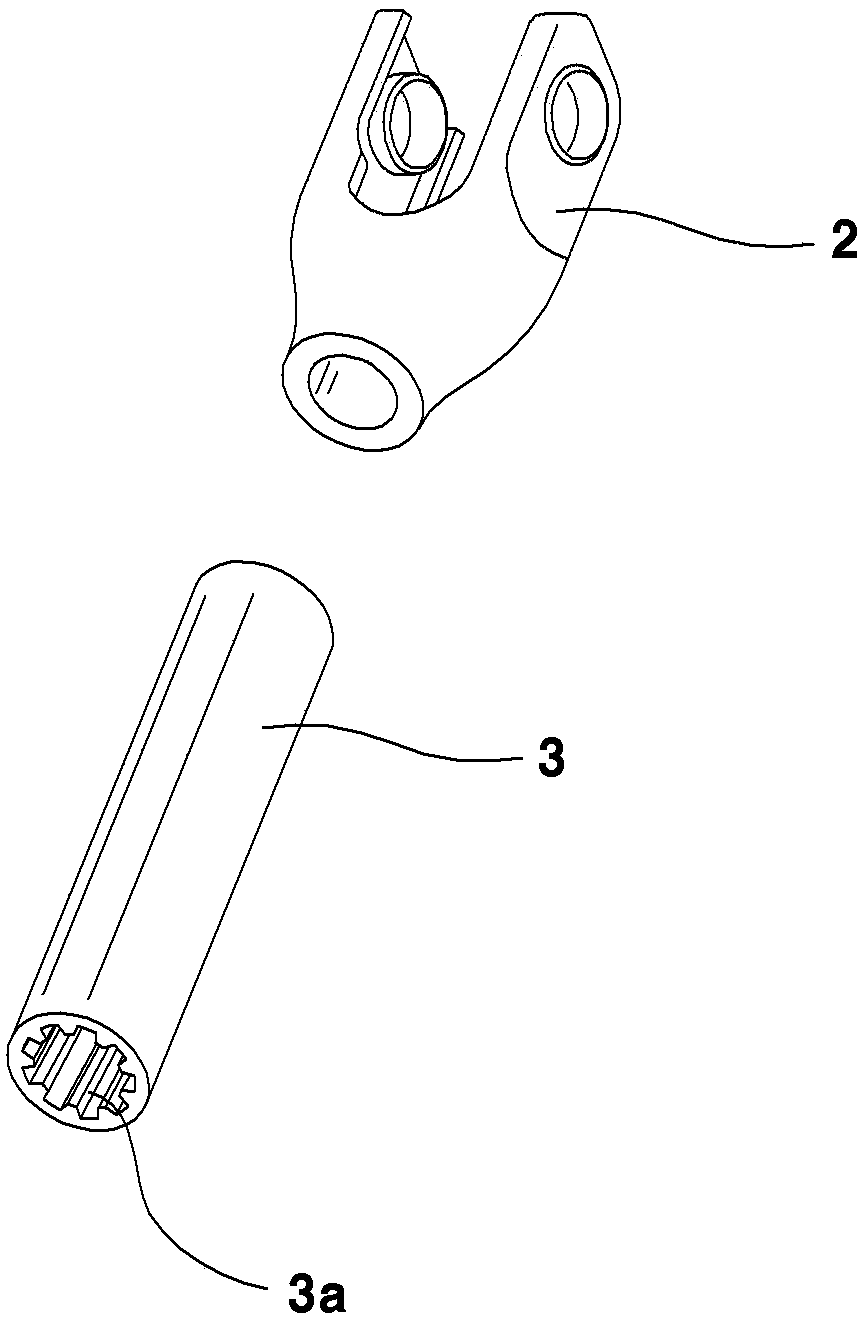

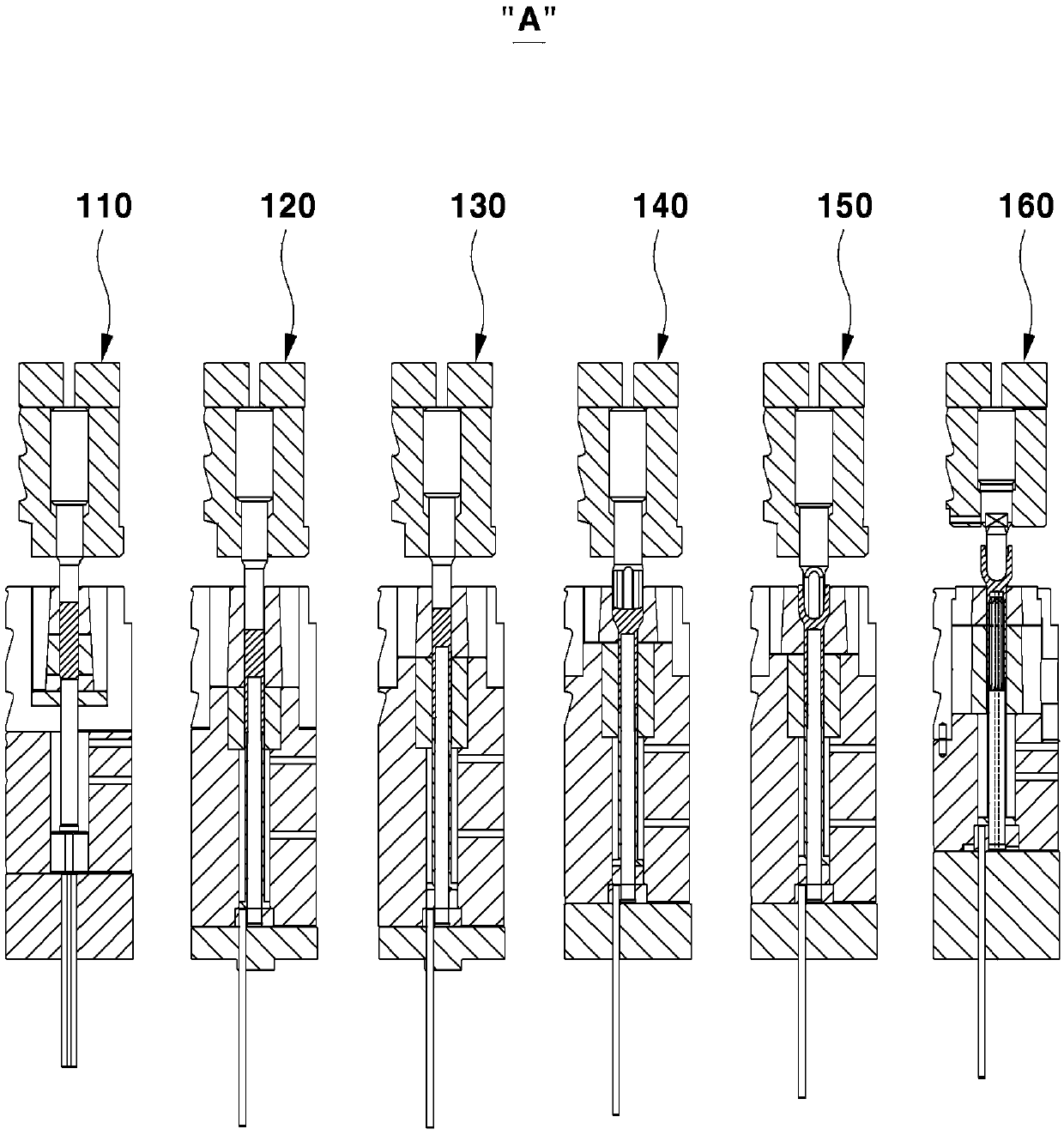

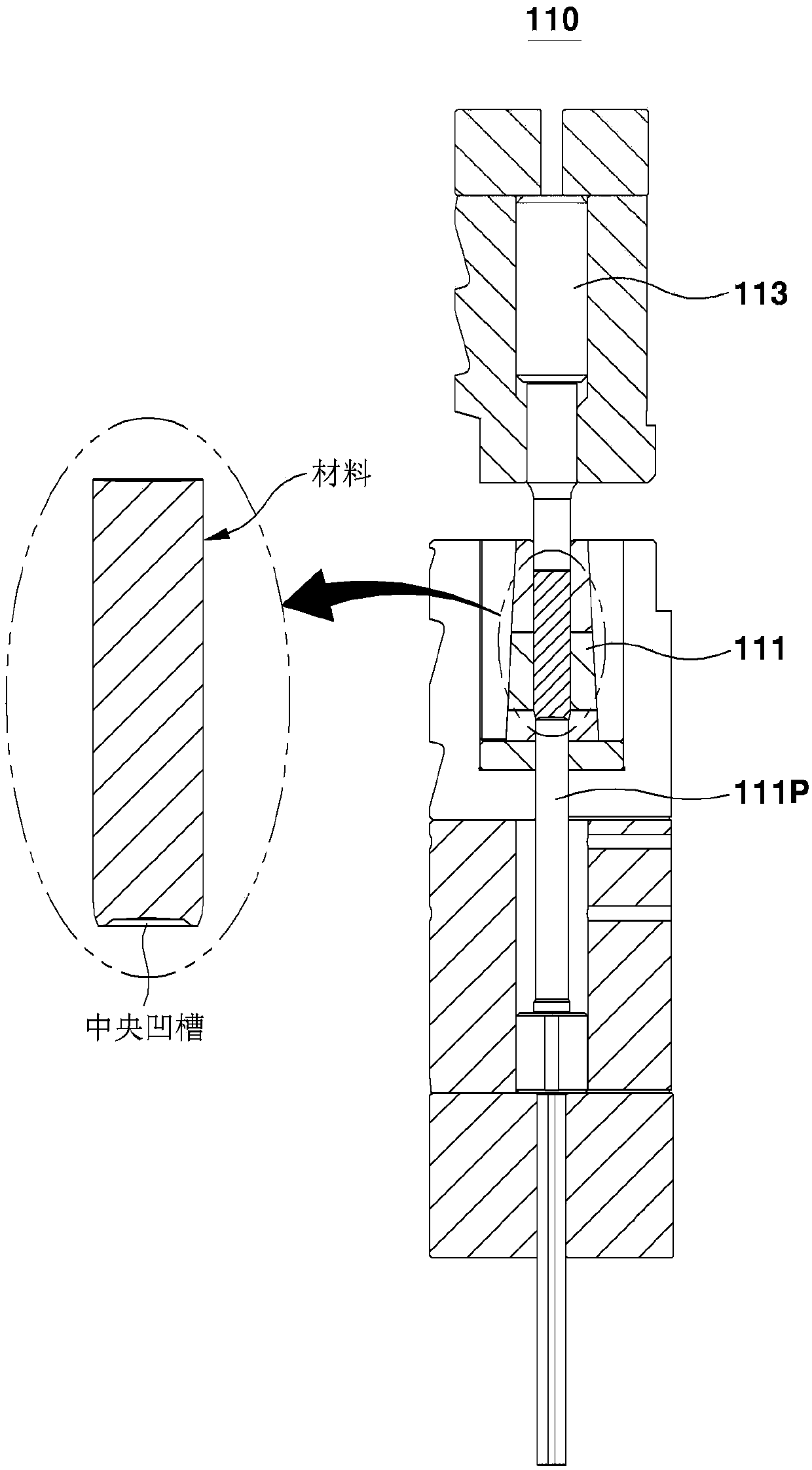

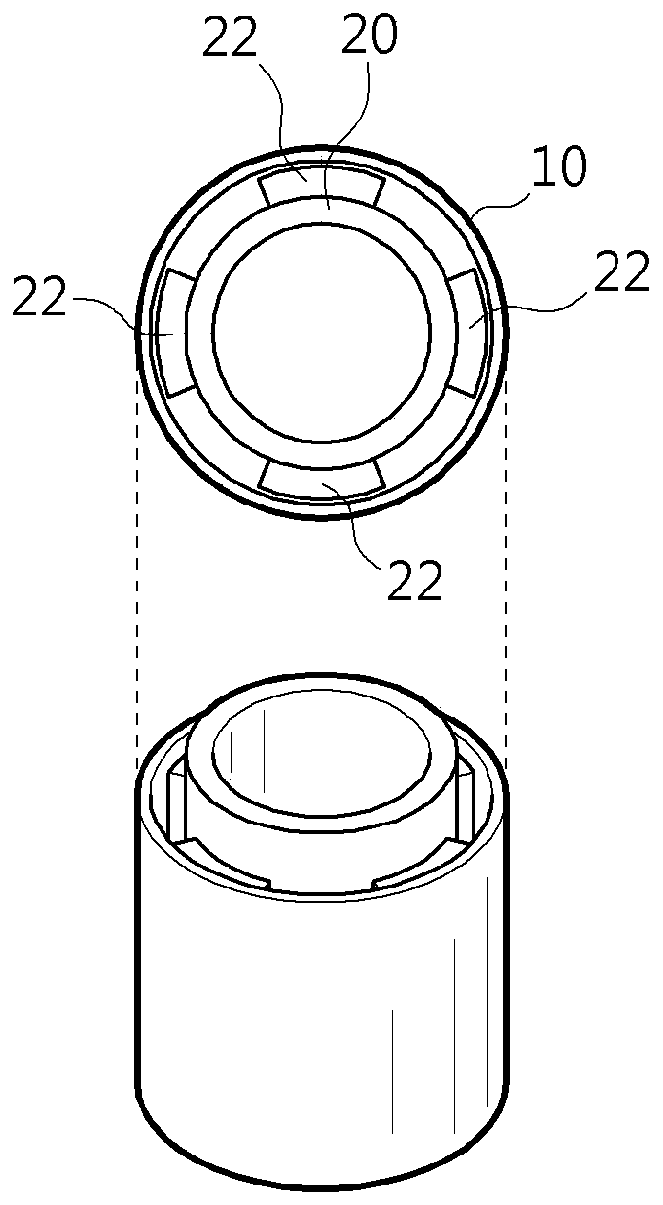

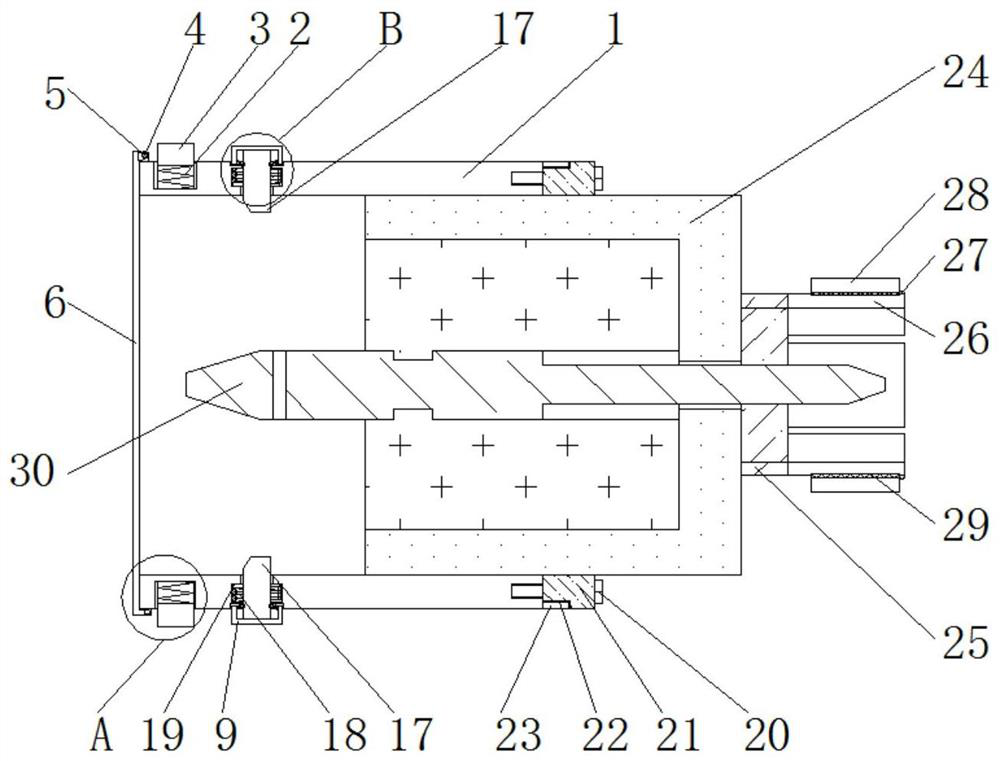

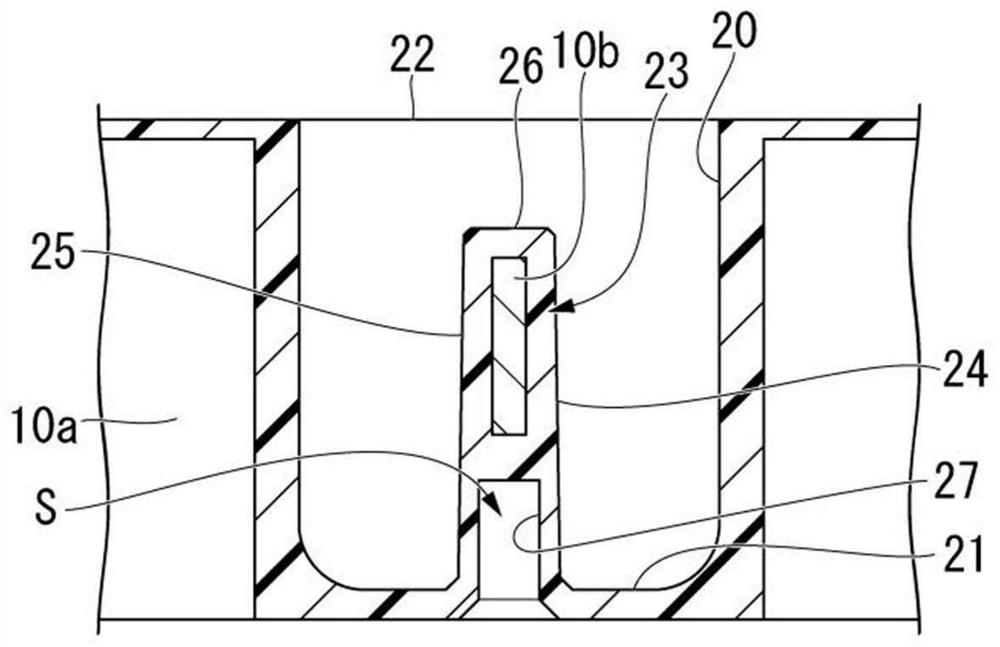

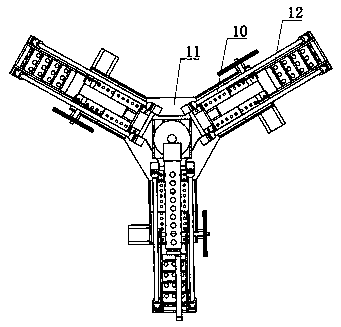

Apparatus for manufacturing tube yoke

ActiveCN107708889AFast preparationPrevent shape deformationForging/hammering/pressing machinesForging press detailsEngineeringMechanical engineering

The present invention relates to an apparatus for manufacturing a tube yoke, capable of rapidly manufacturing a tube yoke provided with a spline on a tube part through a forging step while preventingdistortion involving a twisted shape of the spline. To this end, the apparatus for manufacturing the tube yoke, according to the present invention, comprises a plurality of molds for molding the tubeyoke formed so as to mold the tube yoke by injecting a material into dies and pressing with a punch to form the tube yoke comprising the tube part and a yoke part, wherein the apparatus for manufacturing the tube yoke further comprises a spline forging mold equipped with a mold pin, which is provided with a spline part on the outer circumferential surface thereof, for forming the spline on the inside of the tube part by being inserted into the tube part.

Owner:SUNGJIN FO MA INC

Cap-type vent

ActiveCN110249174AReduce shockIncrease stiffnessLighting and heating apparatusOptical signallingAir cycle

Owner:AMOGREENTECH CO LTD

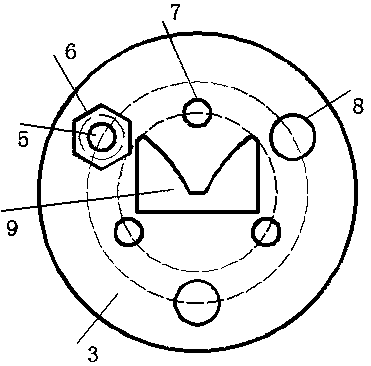

Radio frequency coaxial connector with self-locking structure

PendingCN112152011AQuick installation and fixingWith self-locking structureEngagement/disengagement of coupling partsCouplings bases/casesRadio frequencyEngineering

The invention discloses a radio frequency coaxial connector with a self-locking structure. The radio frequency coaxial connector comprises a shaft body, a bolt, a connecting body and an inner conductor. A damping spring is connected to the interior of the shaft body, an elastic block is fixedly connected to one end of the damping spring, a positioning block is arranged on one side of the elastic block, and a rotating shaft is movably connected to the interior of the positioning block; and the surface of the rotating shaft is movably connected with a cover plate, and one side of the cover plateis fixedly connected with a butt joint. According to the radio frequency coaxial connector with the self-locking structure, when a corresponding device is installed, the installation block is extruded to move towards one end of the fixing spring, and after the corresponding device is installed, the installation block returns to the original position through the elasticity of the fixing spring sothat the corresponding device is self-locked and fixed, and then the pressing block is pressed; and the pressing block drives the end, close to the pressing block, of the adjusting rod to move downwards, the other end of the pressing block is lifted upwards through an adjusting shaft, the installation block moves upwards, and then the corresponding device is taken out.

Owner:镇江市滨江电子有限公司

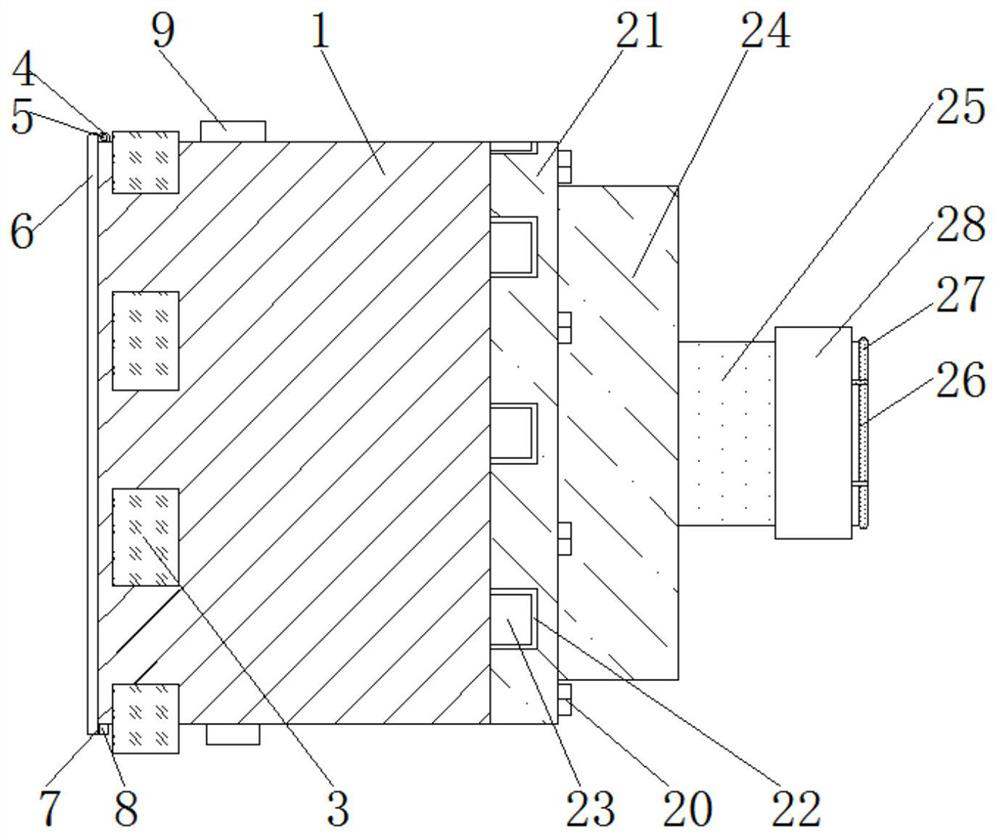

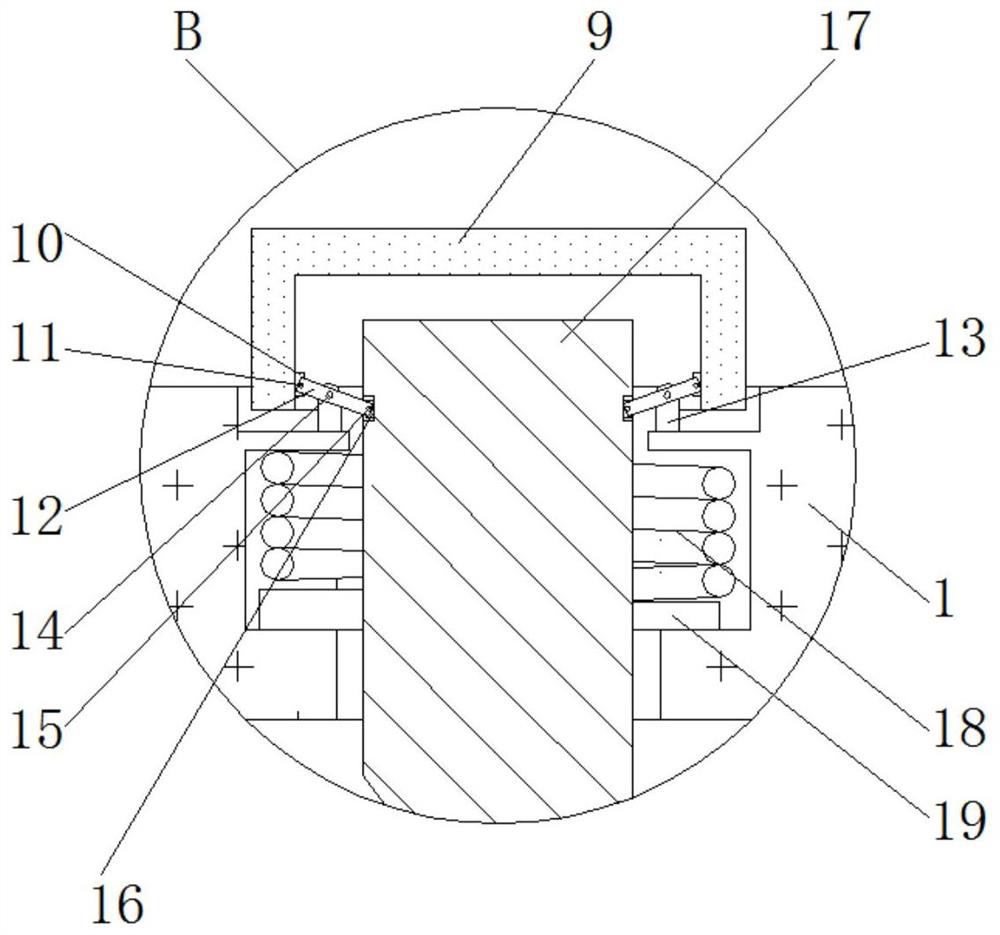

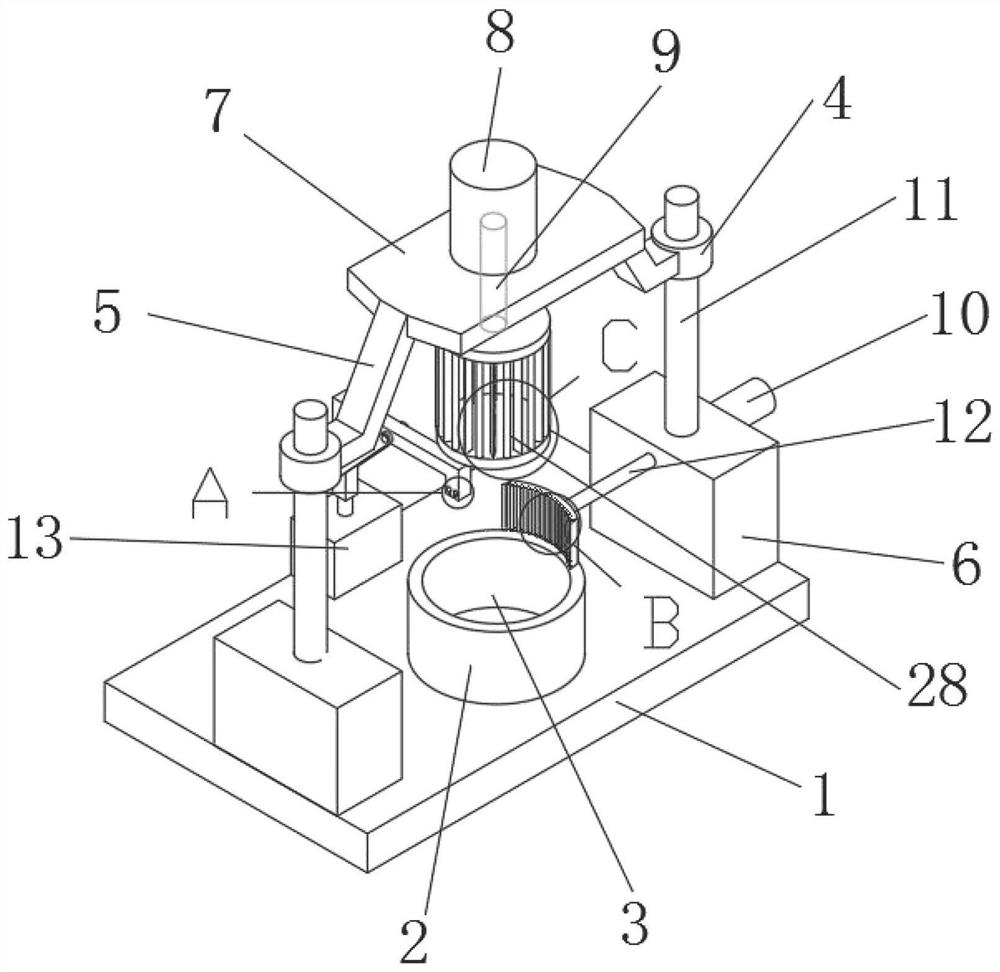

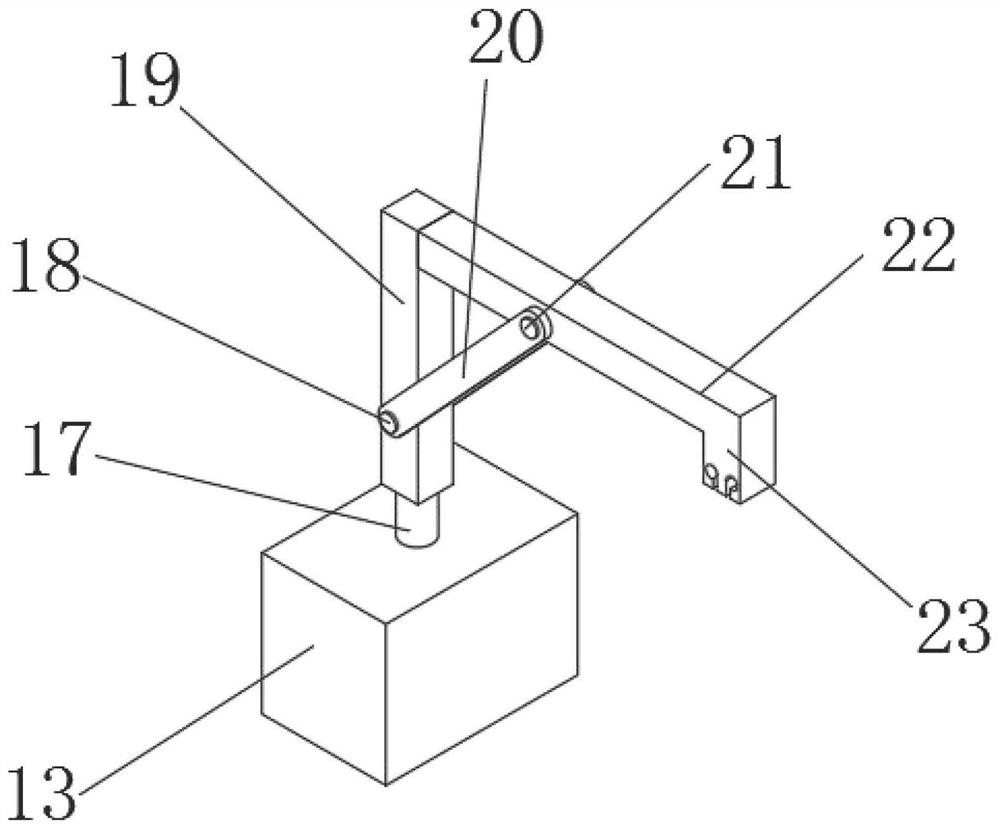

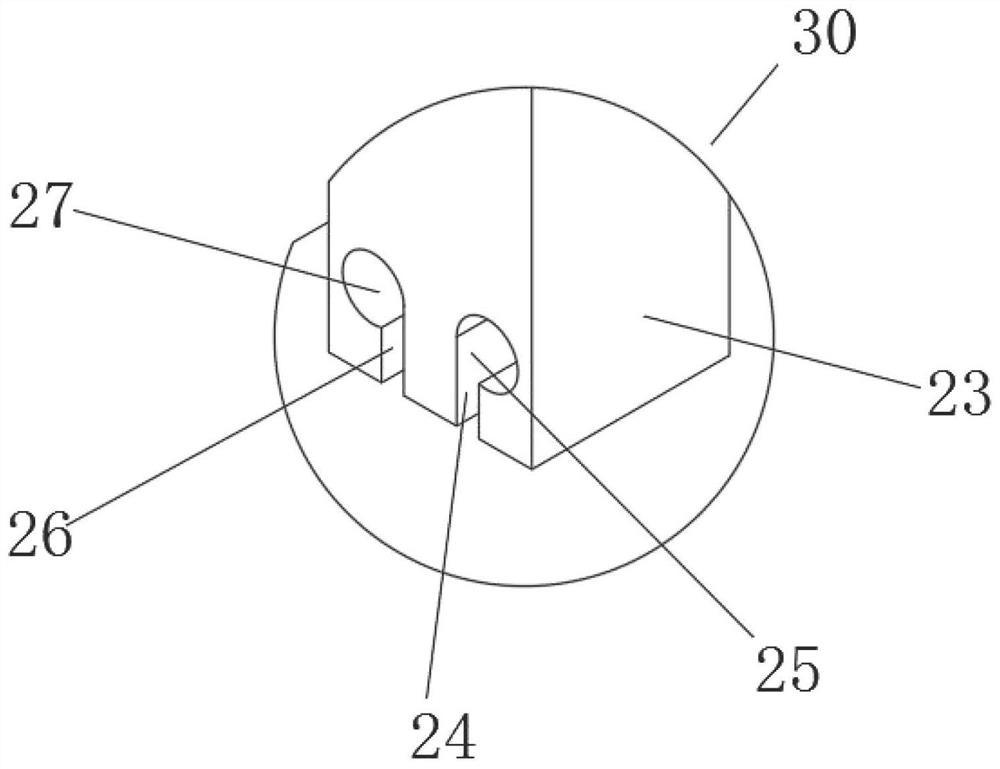

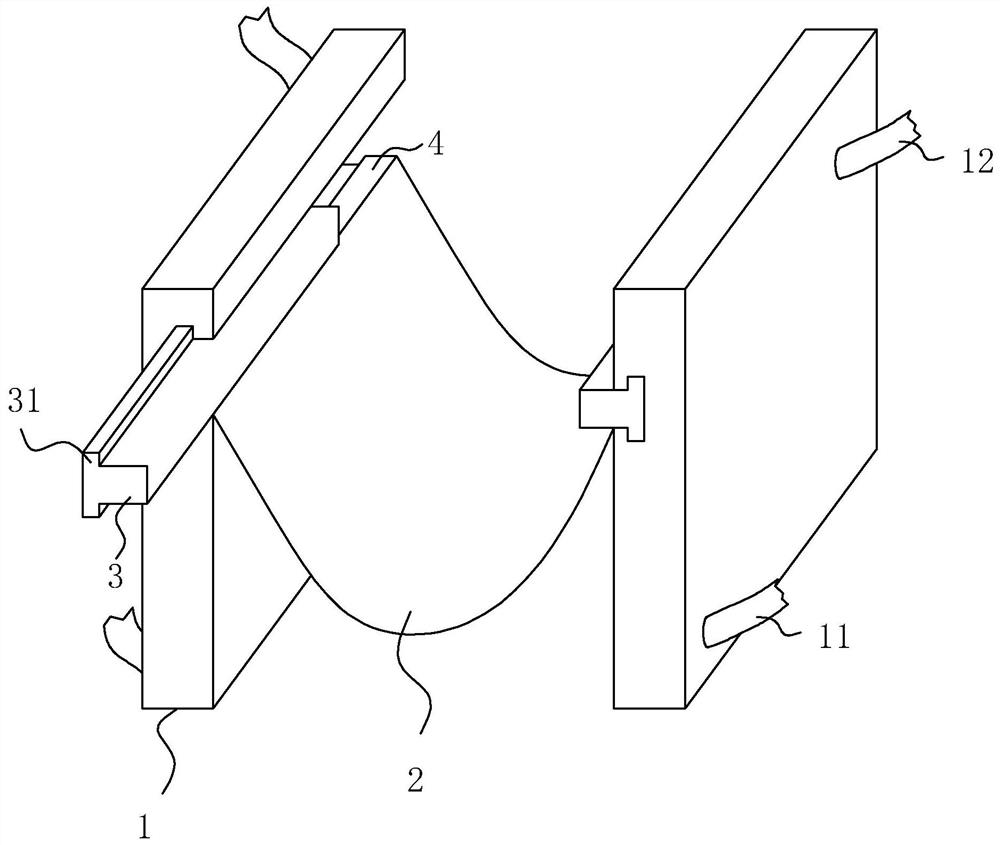

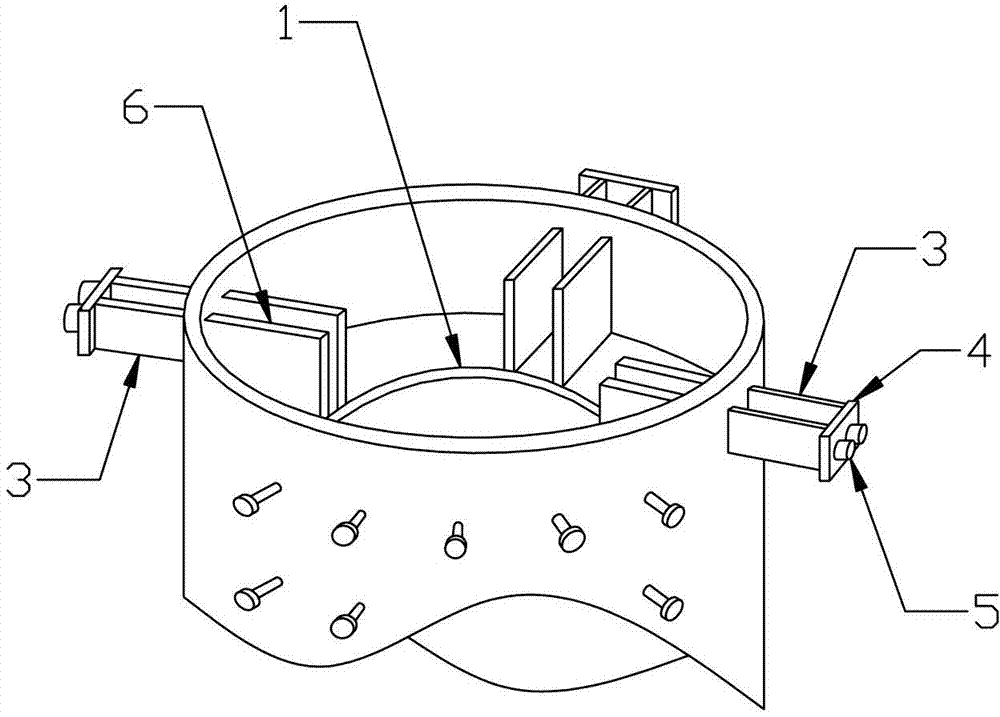

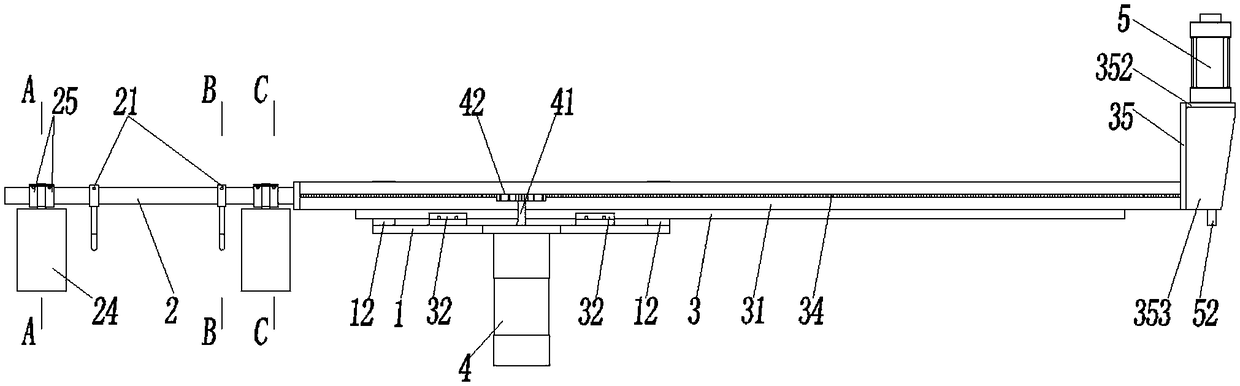

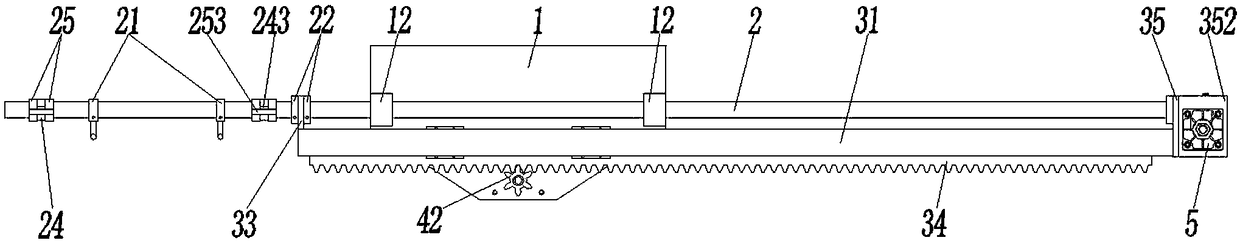

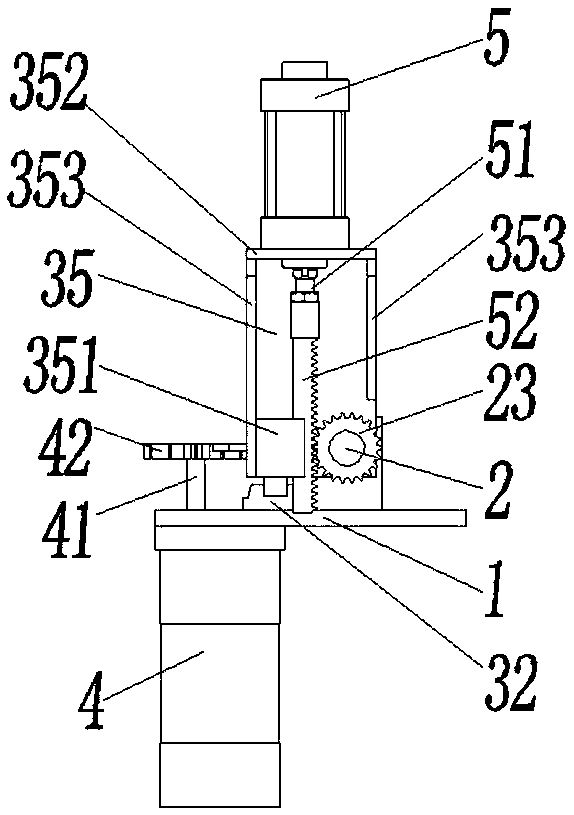

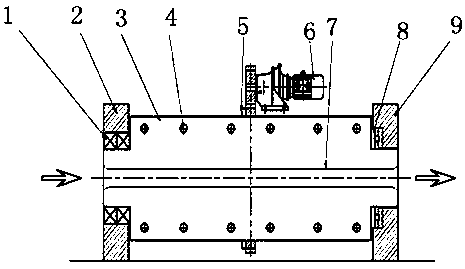

Curling equipment for intelligent manufacturing of metal sheets

ActiveCN112642902APrevent shape deformationBeautiful appearanceShaping toolsStructural engineeringMetal sheet

The invention discloses curling equipment for intelligent manufacturing of metal sheets. The curling equipment comprises a base 1, a mold block 2 is fixedly connected to the middle of the top of the base 1, a barrel carrying groove 3 is formed in the middle of the mold block 2, the top of the outer ring of a vertical rod 11 is sleeved with a fixing block 4, first supporting rods 5 are arranged on the opposite faces of the fixing block 4, and a top plate 7 is arranged between the first supporting rods 5; a first driving mechanism 10 is fixedly connected to the right side of a right side base 6, a pushing rod 12 is fixedly connected to the left side of the first driving mechanism 10, an outer wall rounding mechanism 30 is fixedly connected to the left side of the pushing rod 12, an inner wall rounding mechanism 28 is fixedly connected to the bottom of a rotating shaft 9, and a second driving mechanism 13 is fixedly connected to the back of the middle of the top of the base 1; and a lifting rod 17 is fixedly connected to the middle of the top of the second driving mechanism 13, a vertical rod 19 is installed on an outer ring of the lifting rod 17 in a sleeve manner, a longitudinal supporting rod 22 is fixedly connected to the top of the front face of the vertical rod 19, and a hemming mechanism 30 is fixedly connected to the bottom of the longitudinal supporting rod 22.

Owner:SHANDONG HONGXING NEW MATERIAL TECH CO LTD

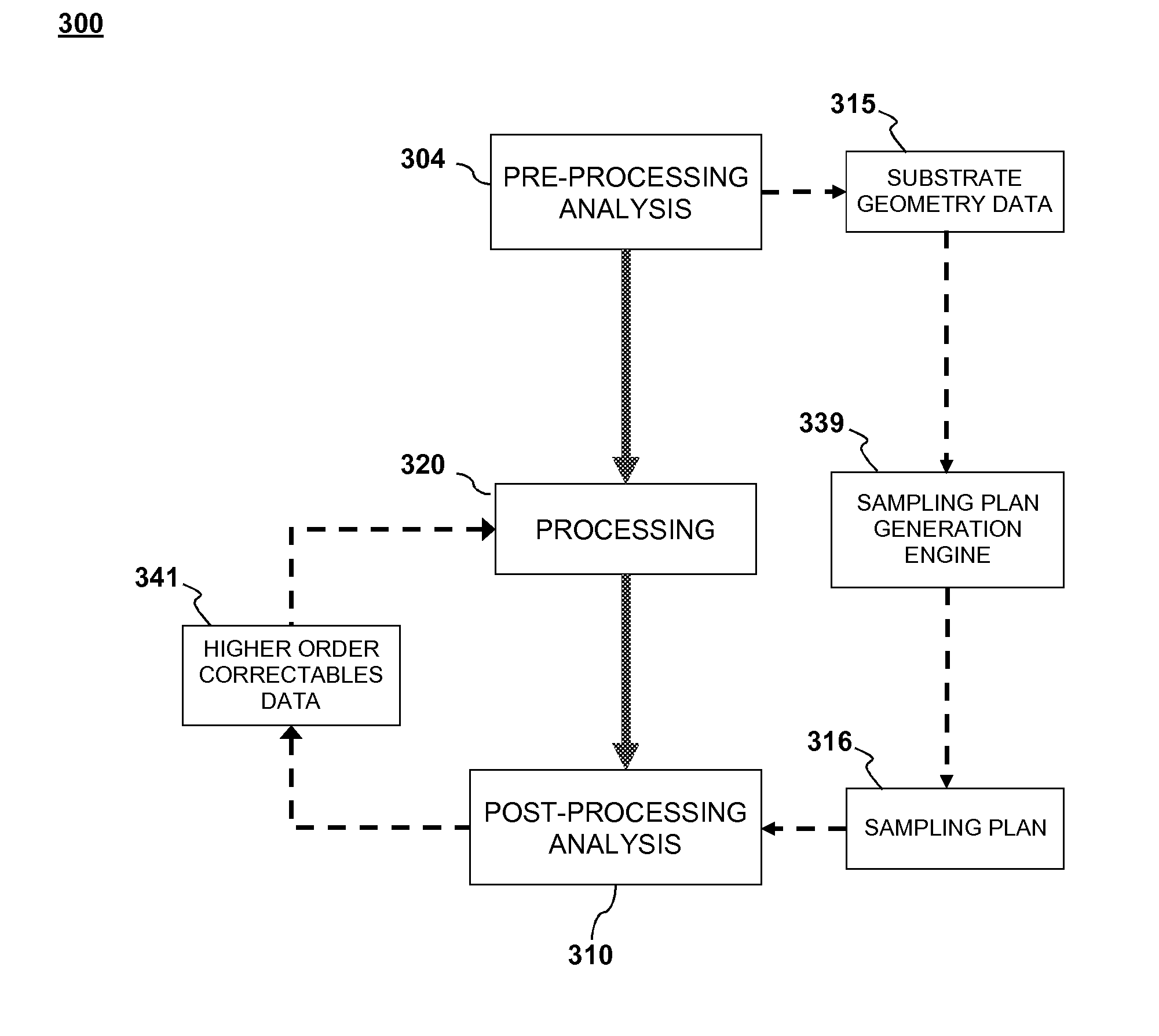

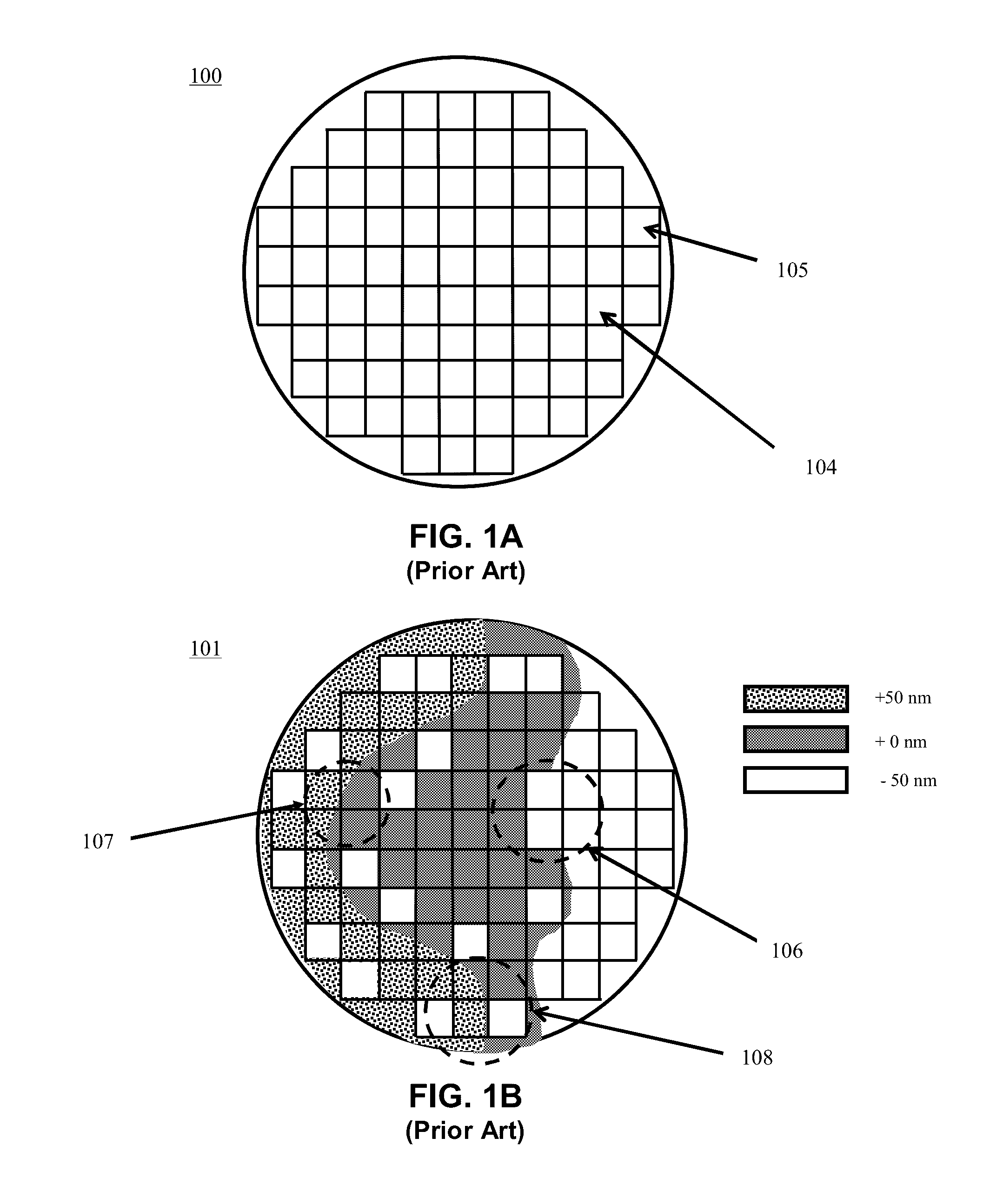

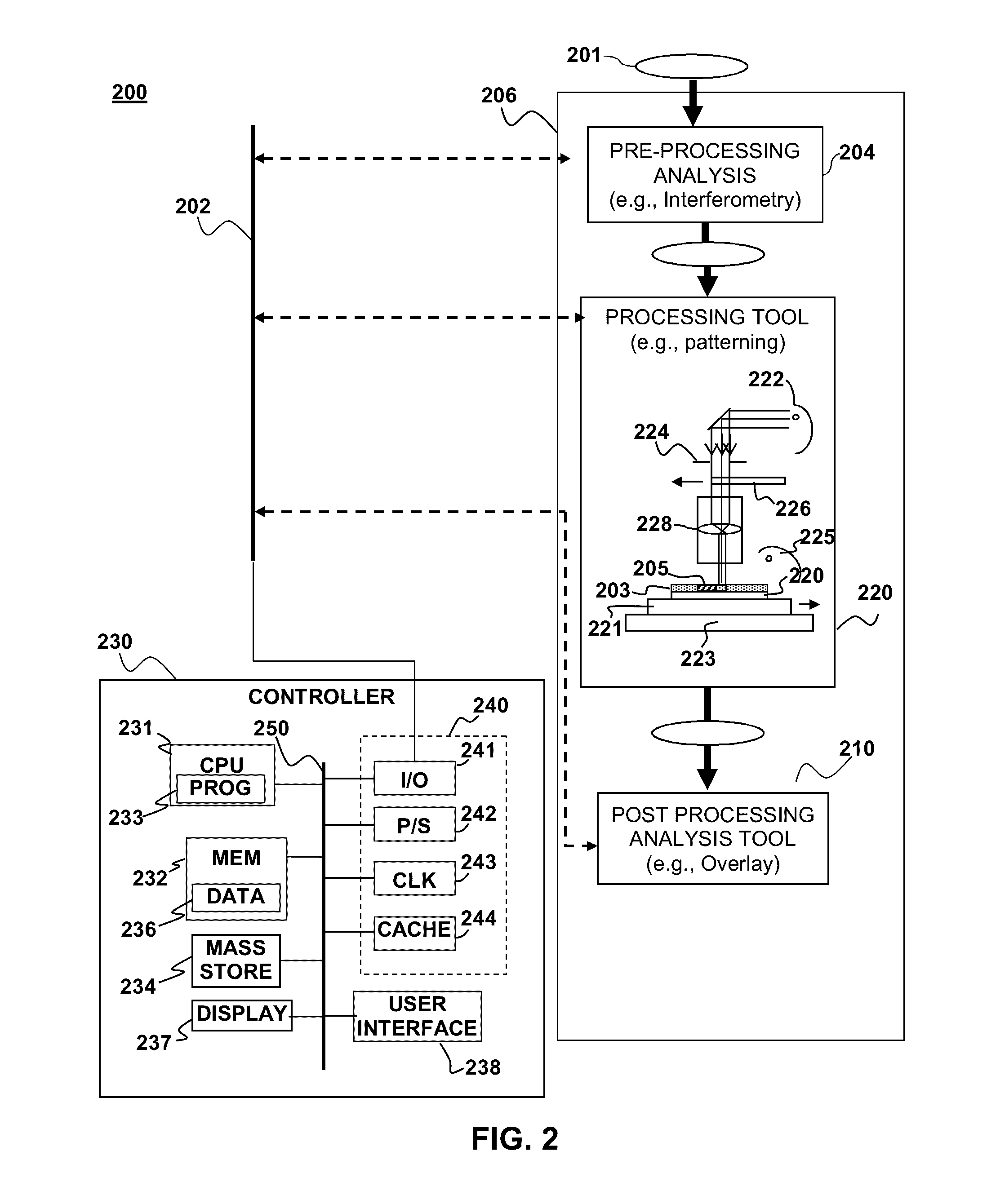

Method and device for using substrate geometry to determine optimum substrate analysis sampling

ActiveUS9588441B2Improve chip yieldHigh yieldSemiconductor/solid-state device manufacturingElectric controllersSubject matterEngineering

A method and apparatus for process control in the processing of a substrate is disclosed in the present invention. Embodiments of the present invention utilize a first analysis tool to determine changes in a substrate's geometry. The substrate geometry data is used to generate sampling plan that will be used to check areas of the substrate that are likely to have errors after processing. The sampling plan is fed forwards to a second analysis tool that samples the substrate after it has been processed. It is emphasized that this abstract is provided to comply with the rules requiring an abstract that will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:KLA CORP

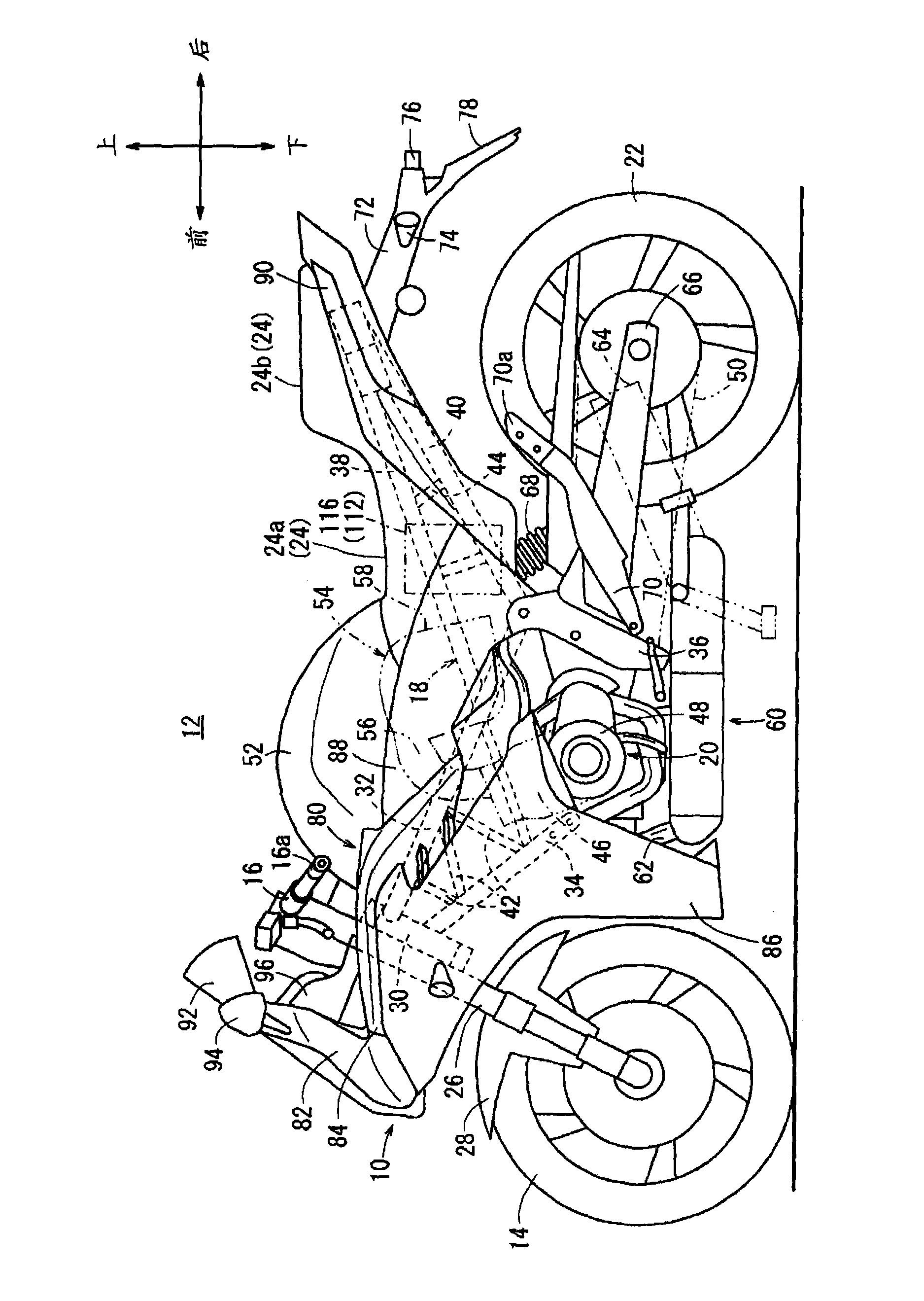

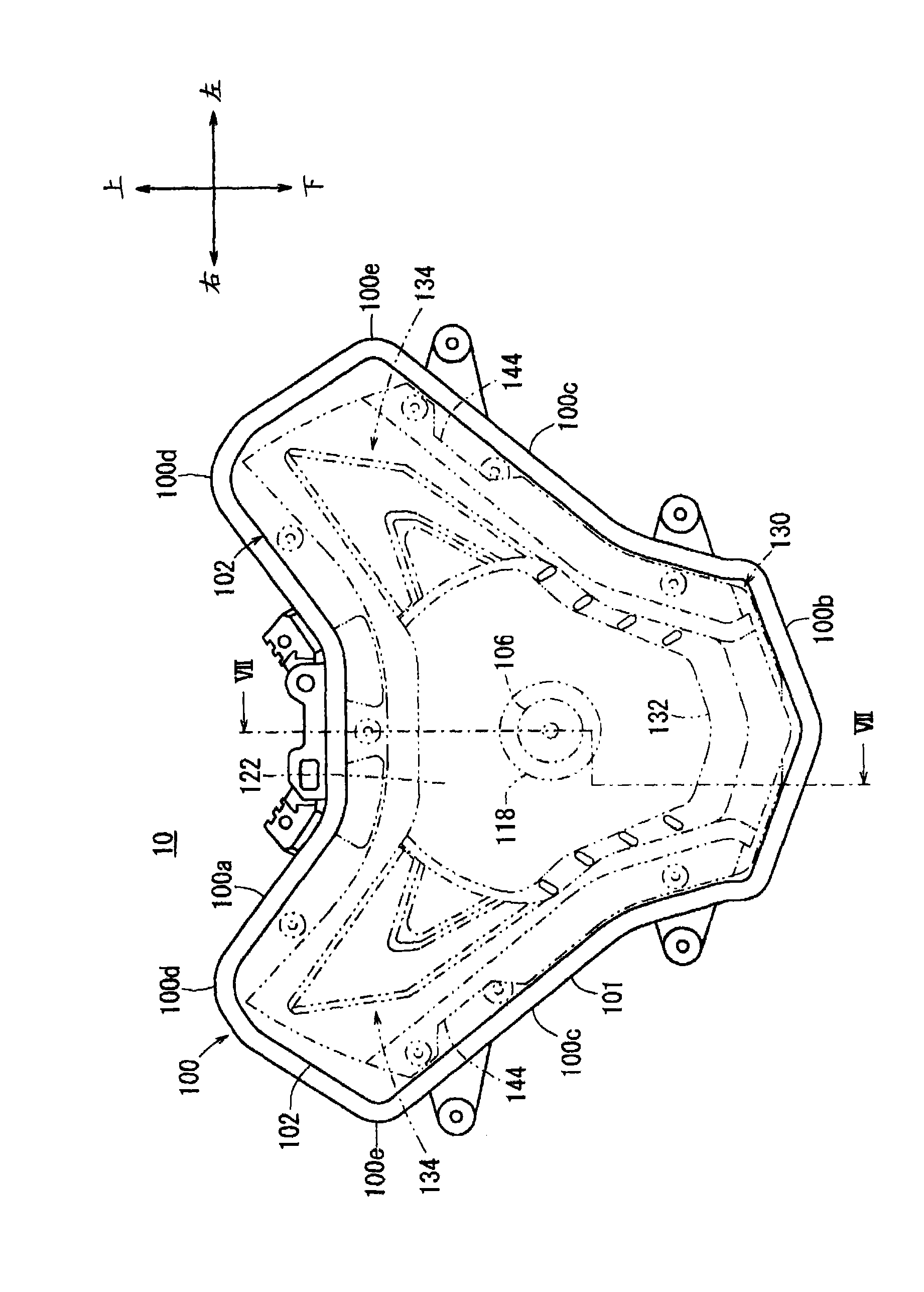

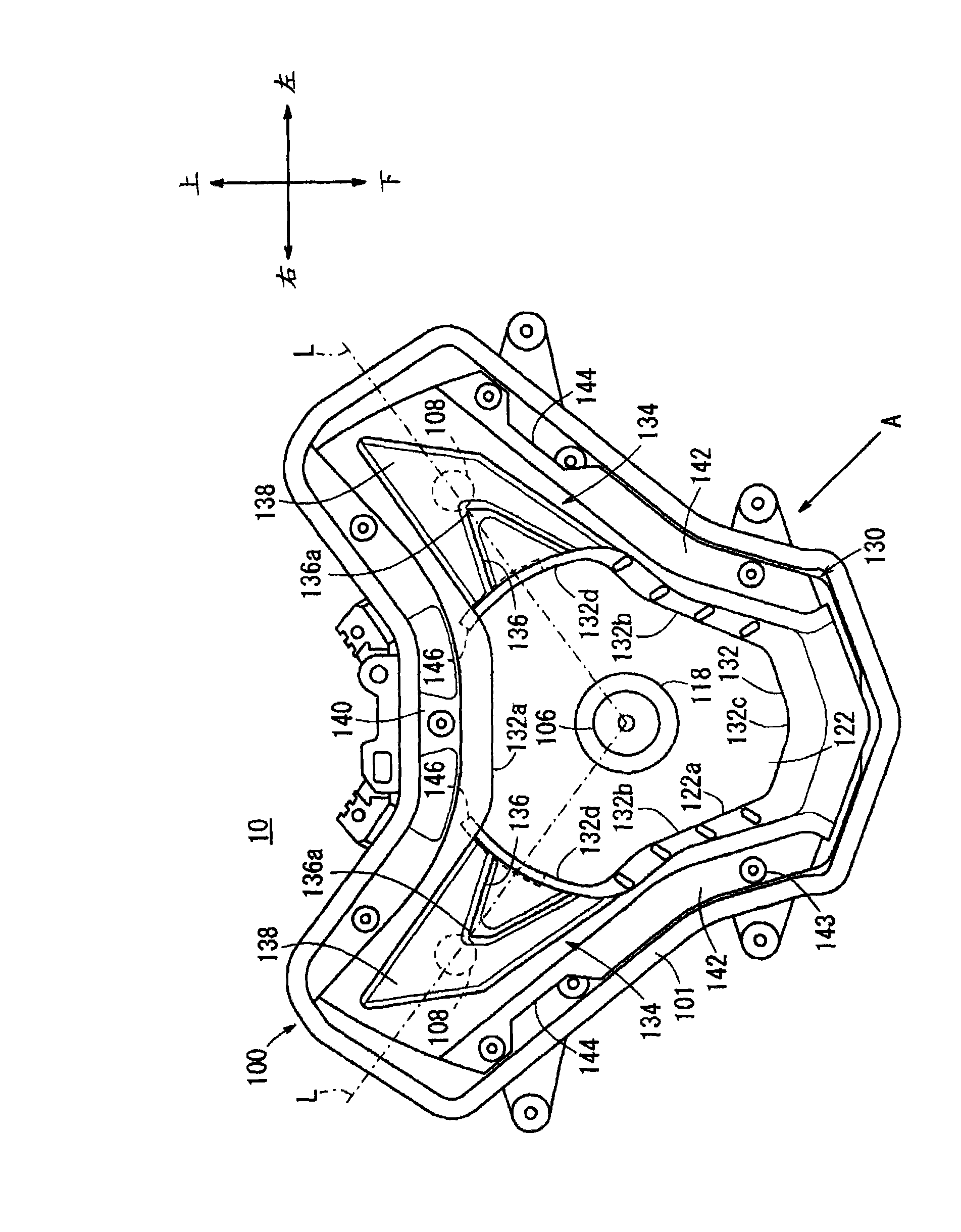

Headlamp device

ActiveCN102679251APrevent shape deformationSuppress fogVehicle headlampsOptical signalInterior spaceConvection

The invention provides a headlamp device, which obviates fogging on a lens by accelerate releasing of heat from within an internal space of the headlamp device. The headlamp device (10) includes a headlight bulb (106) and position light bulbs (108). In addition, the headlamp device (10) has an intermediate member (130) between the lens (102) and a reflector (122) by which light from the headlight bulb (106) is reflected. The intermediate member (130) is provided with cutouts (144) through which a gas present on the lens (102) side relative to the intermediate member (130) can flow to the base member (100) side relative to the intermediate member (130). Thus convection of the gas takes place easily, whereby release of heat from within the internal space (114) is accelerated.

Owner:HONDA MOTOR CO LTD

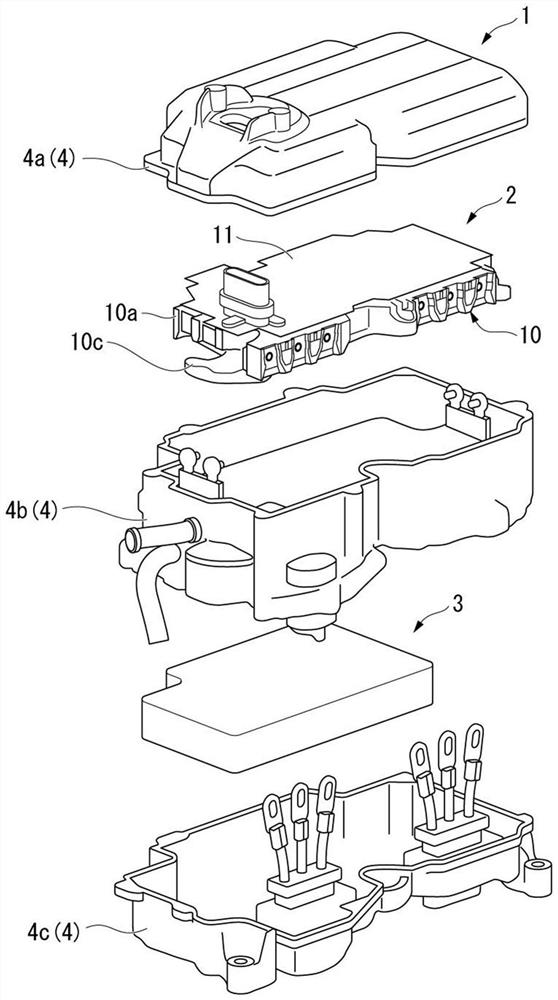

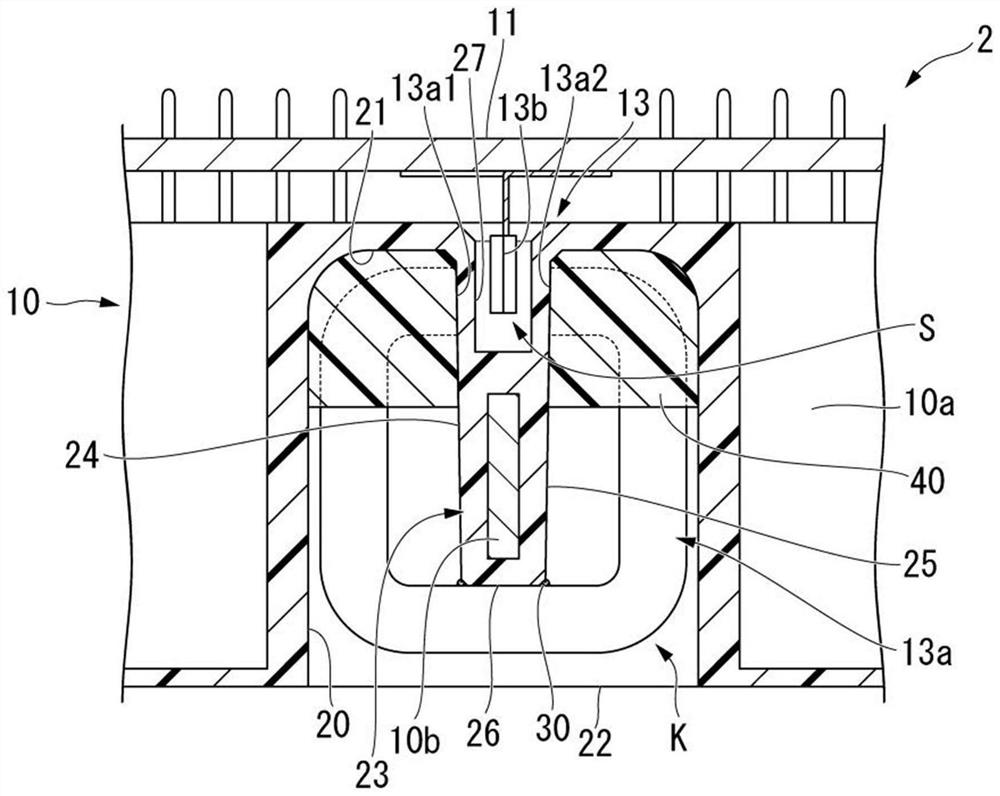

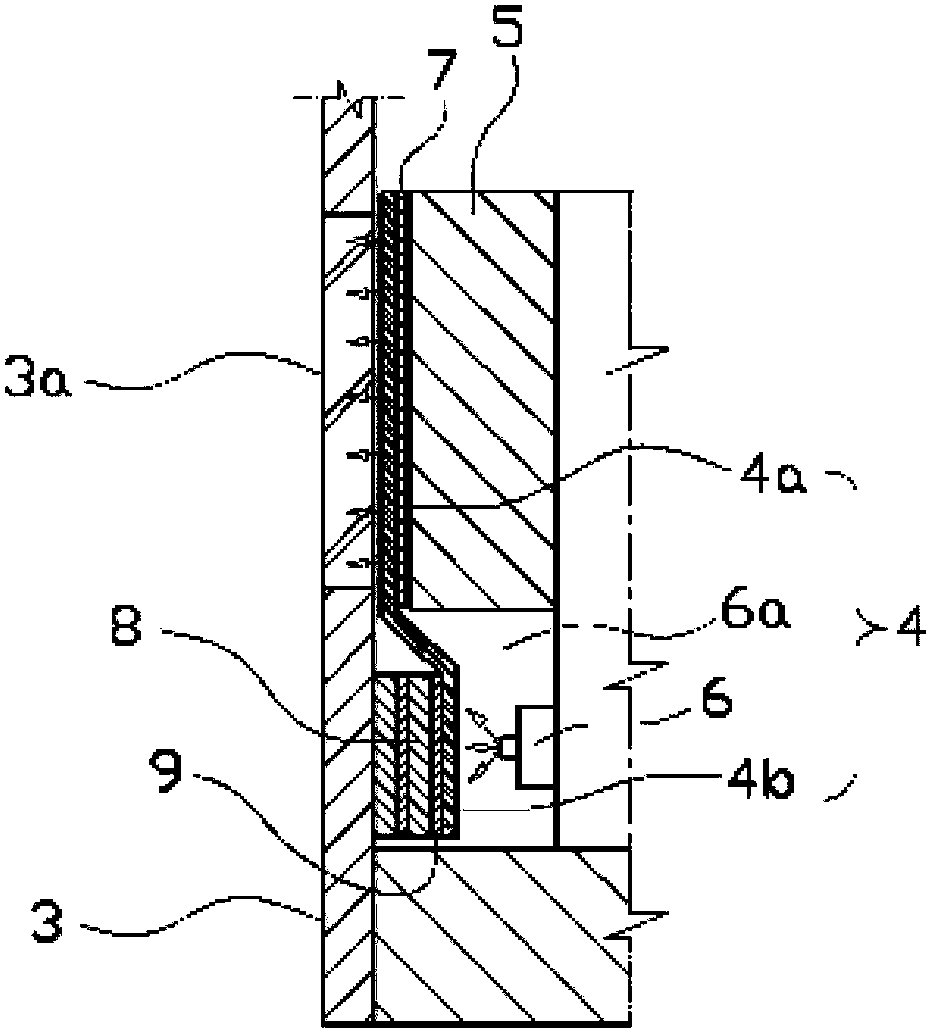

Power conversion device

PendingCN112311201APrevent shape deformationPrevent unexpected changes in detection characteristicsDc-ac conversion without reversalCurrent transducerStructural engineering

The invention relates to a power conversion device. This power conversion device is provided with a bus bar through which a current flows, a current sensor having a magnetic core surrounding the bus bar, and a power module case having an accommodating recess for accommodating the magnetic core, and is also provided with an embedded fixture. And an embedding fixture that embeds a portion of the housing recess and fixes the magnetic core to the power module case in a state in which a portion of the magnetic core is exposed.

Owner:HITACHI ASTEMO LTD

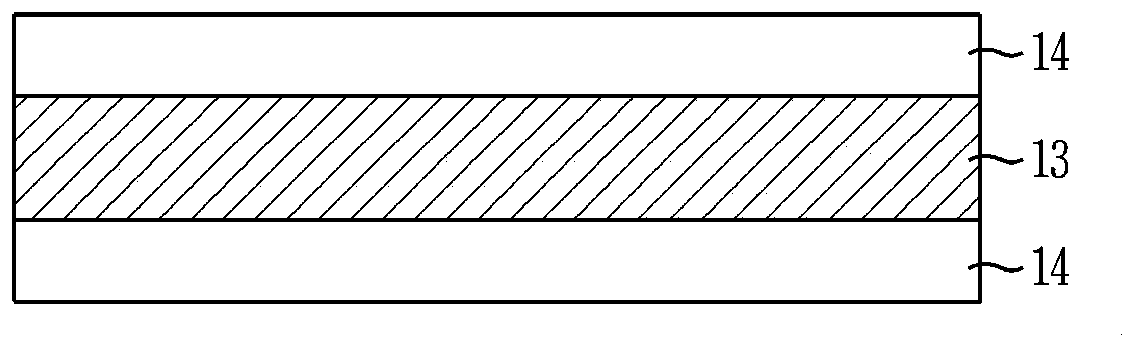

Ion exchange membrane, manufacturing method therefor, and energy storage device comprising same

ActiveCN110462906AImprove ionic conductivityGood chemical stabilitySolid electrolytesFinal product manufactureElectrical conductorChemical physics

The present invention relates to an ion exchange membrane, a manufacturing method therefor, and an energy storage device comprising the same. The ion exchange membrane comprises: a porous support including a plurality of pores; and an ion conductor filling the pores of the porous support, wherein the porous support includes a micropore having a size of 31 to 1000 Mum. In addition, the ion exchangemembrane has high charge / discharge cycle durability, high ion conductivity, and excellent chemical and thermal stability, and thus can achieve a high energy efficiency when applied to an energy storage device, such as a vanadium redox flow cell.

Owner:KOLON IND INC

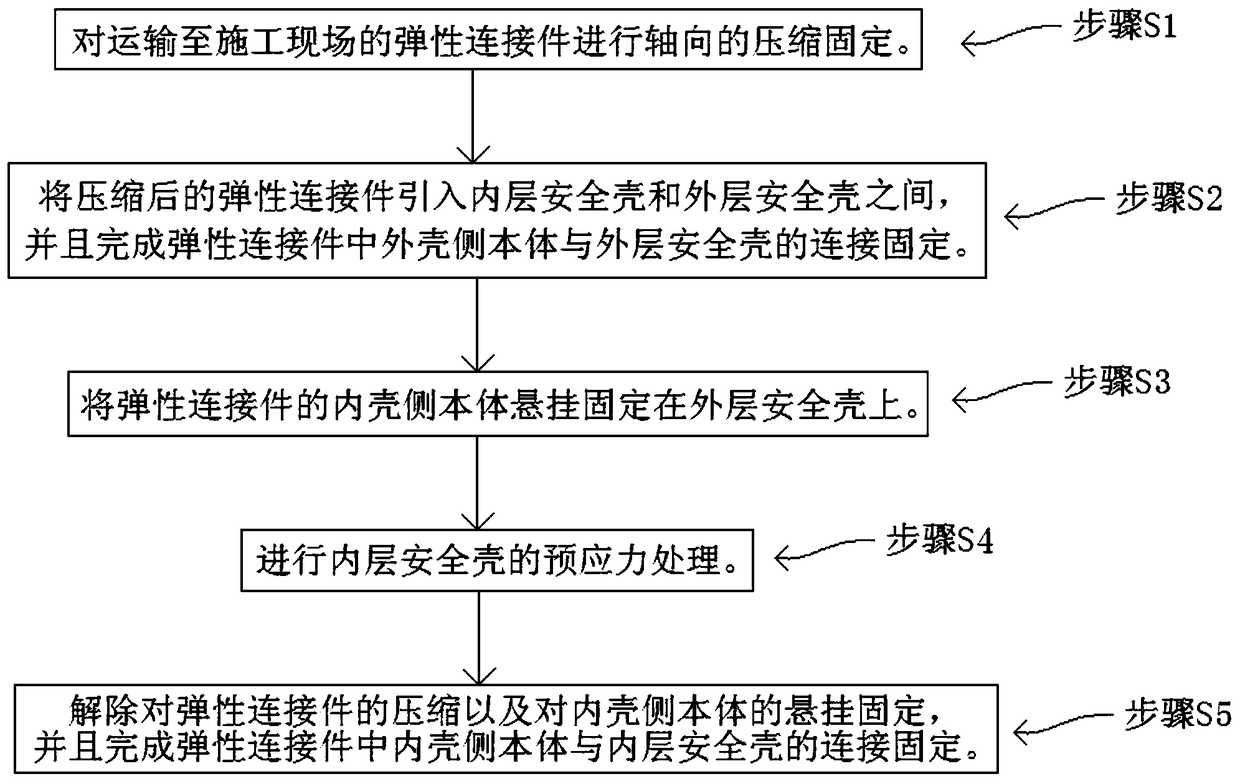

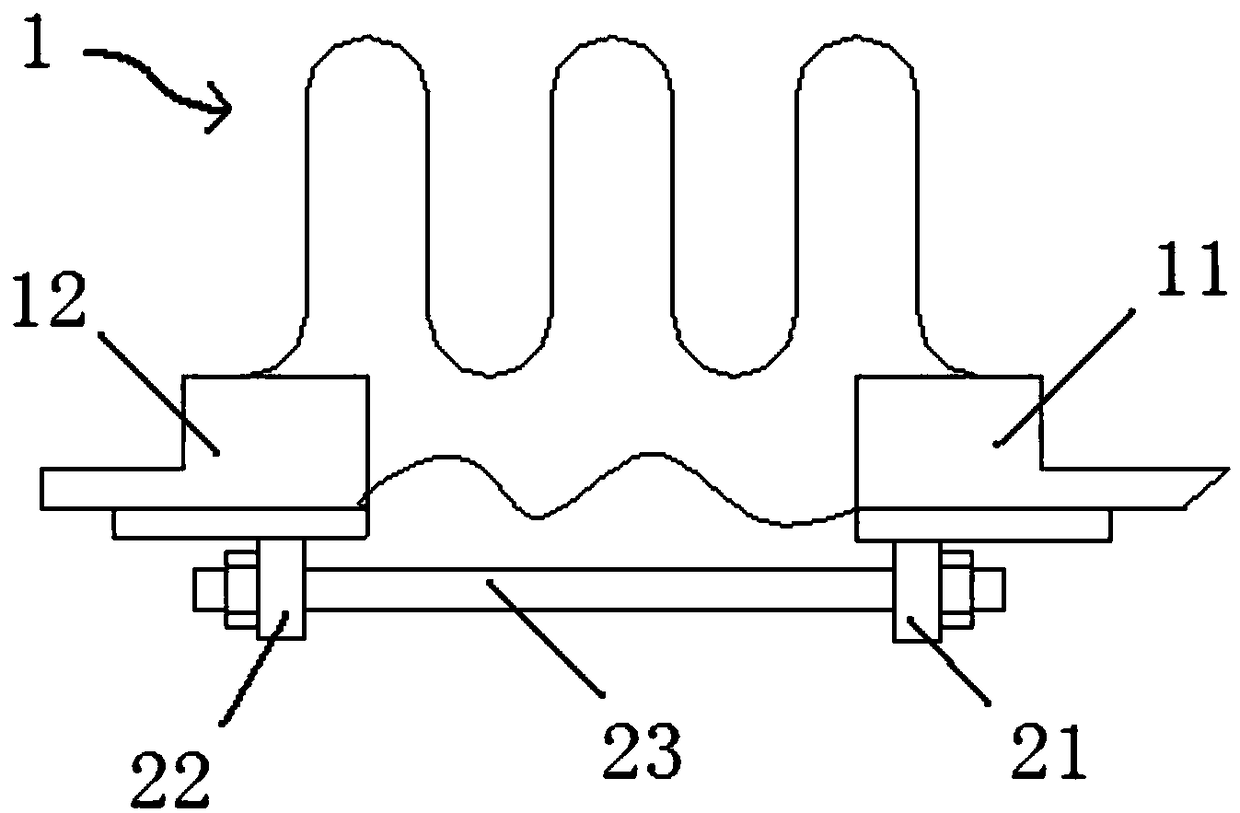

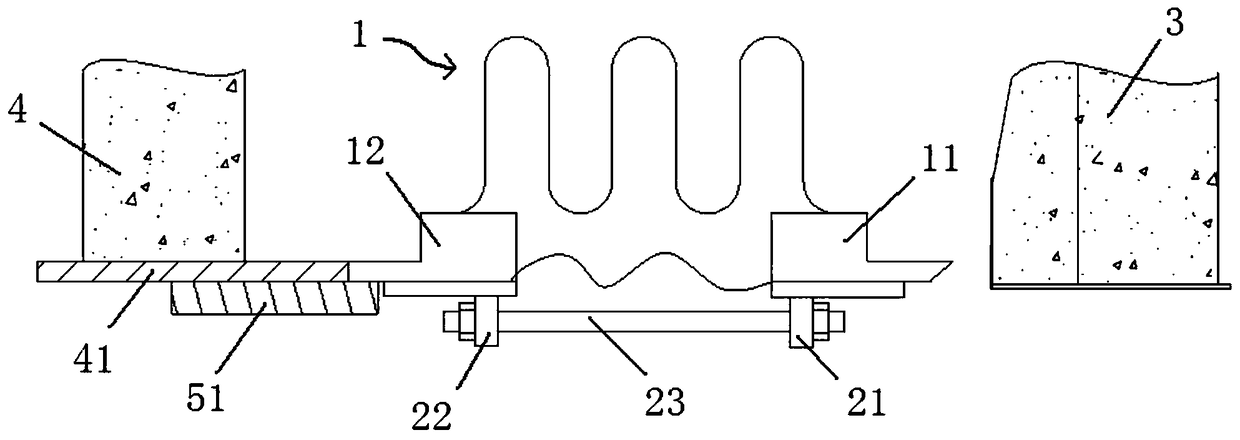

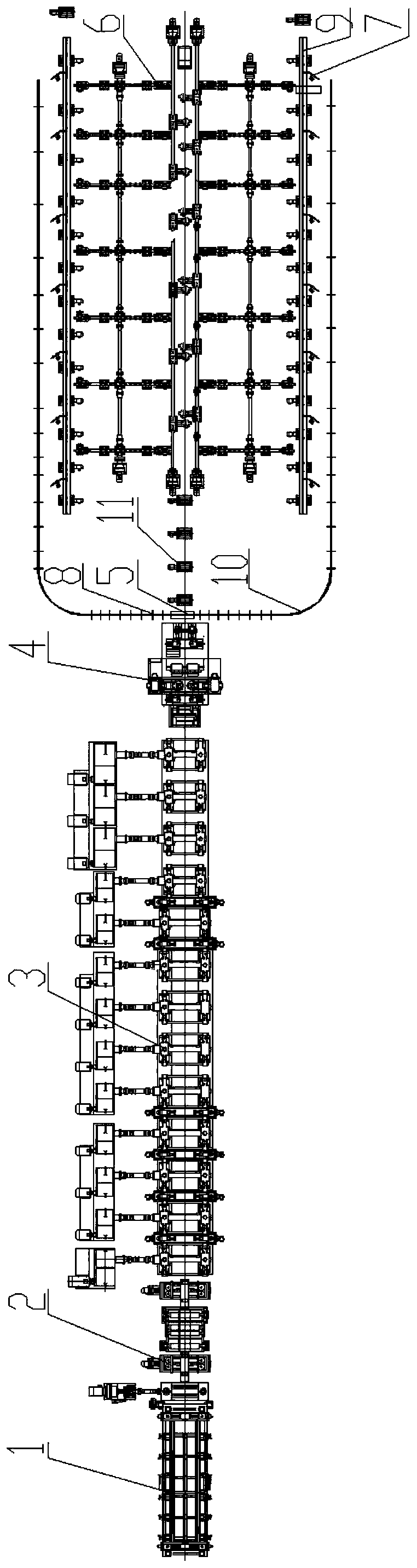

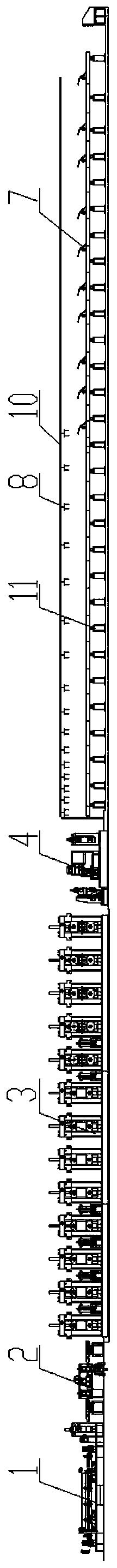

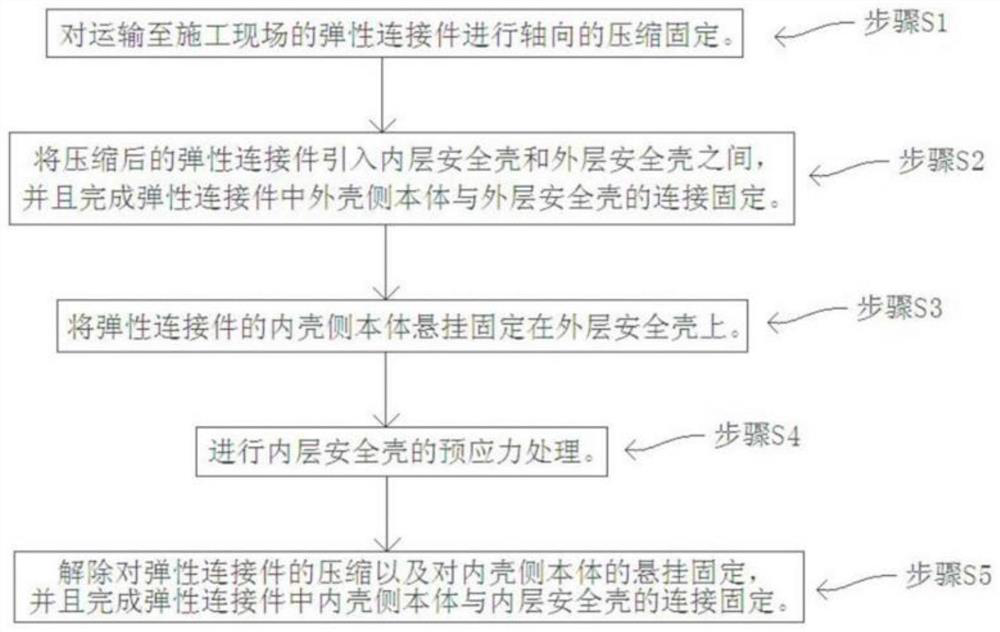

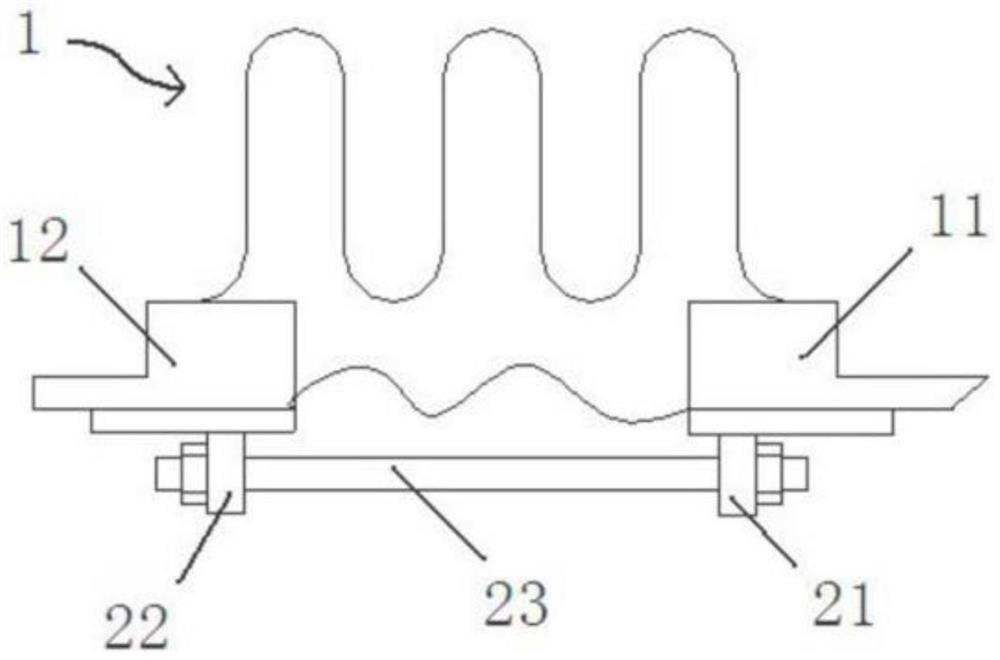

Method of installing elastic connecting pipe of gate of nuclear power plant equipment

ActiveCN109192334AThe introduction was smooth and fastChange the installation processNuclear energy generationContainmentEngineeringPre embedding

The invention belongs to the technical field of installation of nuclear power plant equipment. In order to successfully complete the installation of an elastic connecting piece of an equipment gate and ensure the successful construction progress of an entire safety shell, the invention discloses a method of installing the elastic connecting pipe of the gate of nuclear power plant equipment. The installation method comprises the following steps: step 1. axially compressing and fixing the elastic connecting piece; and step 2. introducing the elastic connecting piece and completing the connectionand fixation between the elastic connecting piece and an outer casing penetration shell ring after completing the installation of the outer casing penetration shell ring and before carrying out the inner casing prestressing force operation; step 3. temporarily connecting an inner casing side body in the elastic connecting piece to an outer safety shell in a suspension manner; step 4. carrying outinner safety shell prestressing force treatment; and step 5. connecting and fixing the inner casing side body in the elastic connecting piece to an inner casing pre-embedded ring plate in the elasticconnecting piece. The method can successfully complete the installation of the elastic connecting piece and ensures the successful construction progress.

Owner:CHINA NUCLEAR IND 23 CONSTR

Keyboard light guide film and manufacturing method thereof

InactiveCN103672739AMaintain curved shapePrevent shape deformationMechanical apparatusElectric switchesLight guideAdhesive

The invention aims to provide a keyboard light guide film and a manufacturing method thereof. Even if a thick reflection board is not used or double-sided adhesives enabling the reflection board to adhere to a light leading-in portion are not used, the distance between the light leading-in portion and a light source can be shortened to the maximum, shape deformation or movement of the light leading-in portion can be avoided and the light leading-in efficiency of the light leading-in portion can be further improved. According to the light guide film, a bent shape portion is formed on the light leading-in portion, and therefore the distance between the light source and the light leading-in portion is shortened; the inner portion of the bent shape portion is filled with shape maintaining bodies, and therefore the shape of the bent shape portion is maintained firmly. In addition, the light guide film is manufactured through a manufacturing procedure of a light guide raw sheet, a cutting procedure of the light guide raw sheet and a separating procedure of the light guide raw sheet.

Owner:MAGMA

A cold pressing process of mixed solid-liquid electrolyte lithium battery

ActiveCN110048168BPrevent shape deformationFully exhaustedFinal product manufactureLi-accumulatorsPhysical chemistryBattery cell

The invention discloses a cold-pressing process for a mixed solid-liquid electrolyte lithium storage battery, which relates to the field of solid-state batteries. The saponified liquid circulates inside the fixture; Step 3: Apply pressure to the battery in stages. In the process of cold pressing, the saponification liquid is used for cooling and the pressure is applied in stages, which can ensure that the gas in the package can be discharged into the air bag during the formation process of the battery, so as to improve the quality of the battery core and at the same time, It can also realize the rapid molding of the battery core.

Owner:ZHEJIANG FUNLITHIUM NEW ENERGY TECH CO LTD

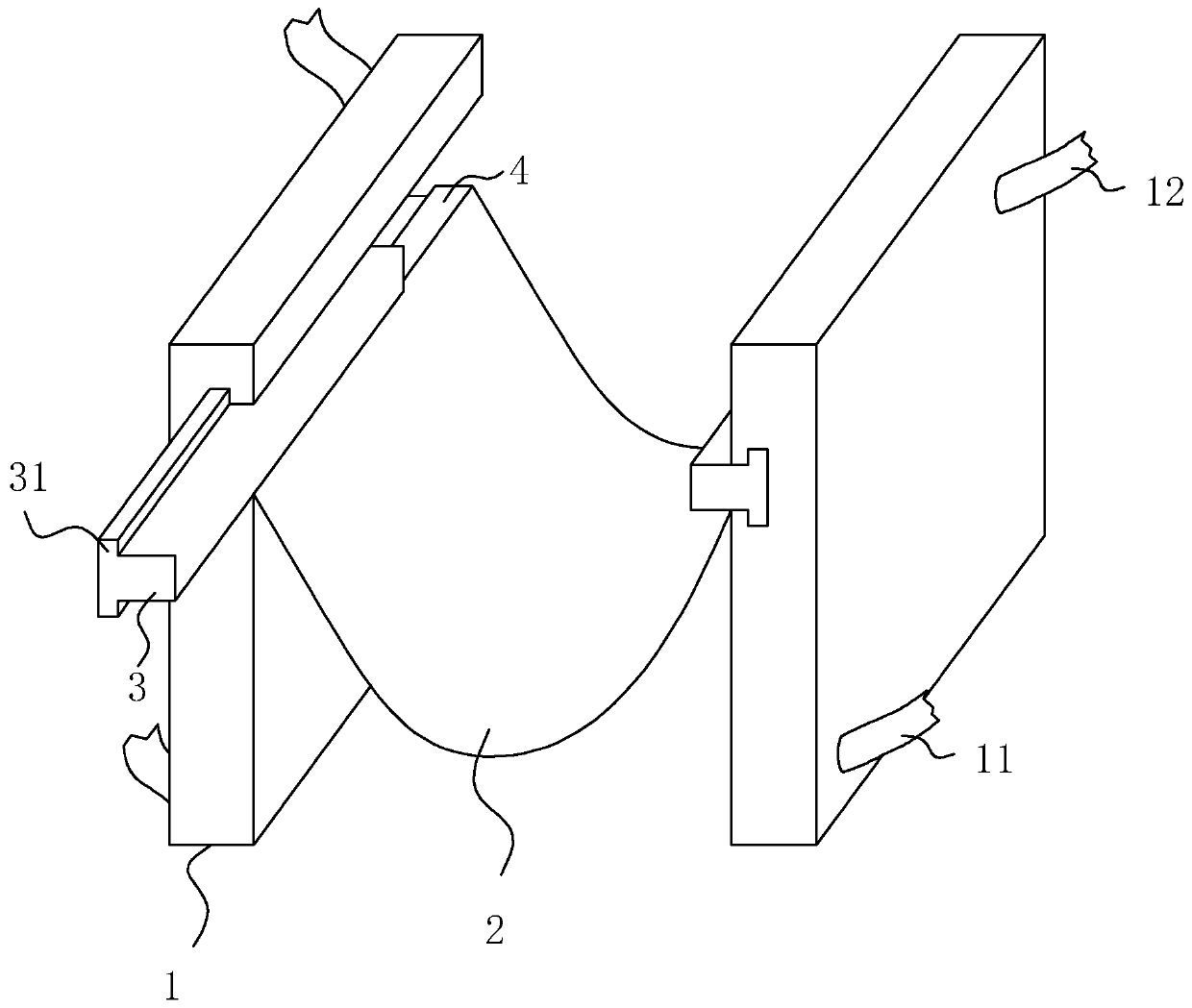

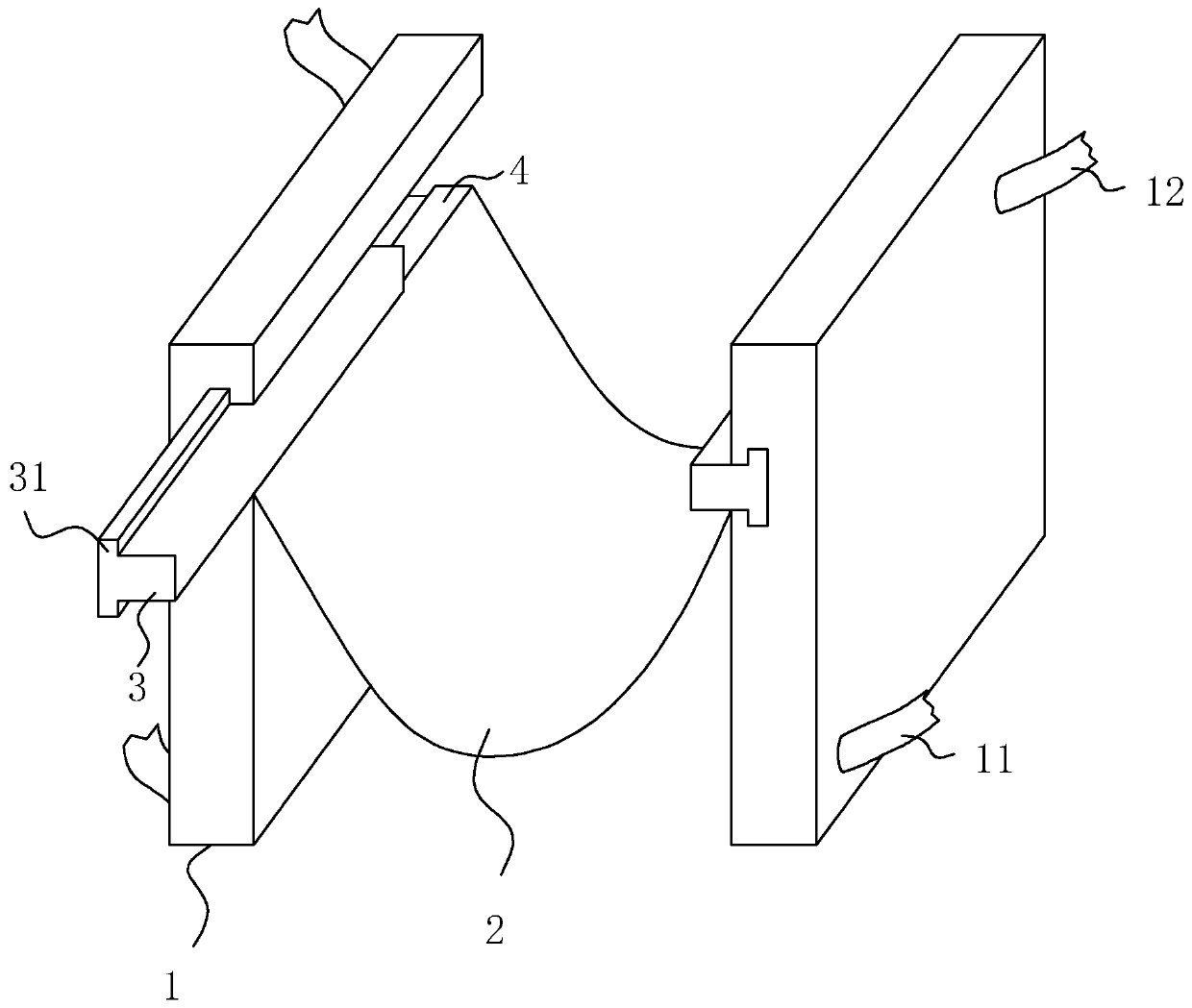

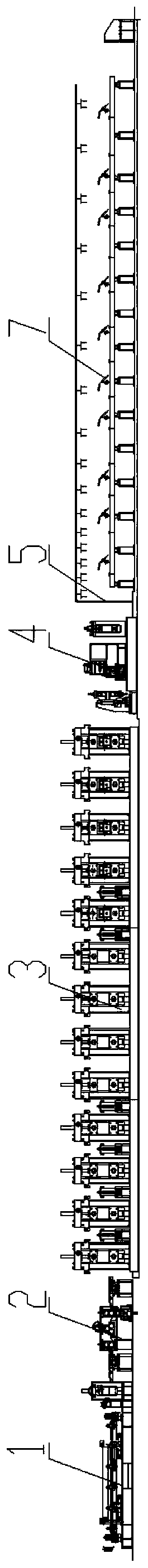

The connection method of continuous hot bending forming and closed welding process

The invention discloses a linking method for continuous hot bending forming and closing welding work procedures, that is, a device capable of releasing a clamping hoop is arranged at the outlet end ofa continuous hot bending unit, so that the clamping hoop is used for performing clamping shape determining on a closing type steel component after being formed through the continuous hot bending unit, and then the closing type steel component subjected to clamping shape determining through the clamping hoop is conveyed to a welding station to be subjected to closing welding. The method can effectively solve the component shape deforming problem caused by the factors of the internal heat stress generated due to the temperature drop of the component and the self hot bending springback, and therefore the purpose of guaranteeing the closing welding end face shape is achieved. Flexible linking between the continuous hot bending unit and the welding station is further achieved, so that a wholeproduction line can be continuously arranged, athe production line is more continuous and compact, and the production efficiency and the welding quality can be improved easily.

Owner:CISDI RES & DEV CO LTD

Installation method of elastic connectors for nuclear power plant equipment gates

ActiveCN109192334BThe introduction was smooth and fastChange the installation processNuclear energy generationContainmentClassical mechanicsStructural engineering

Owner:CHINA NUCLEAR IND 23 CONSTR

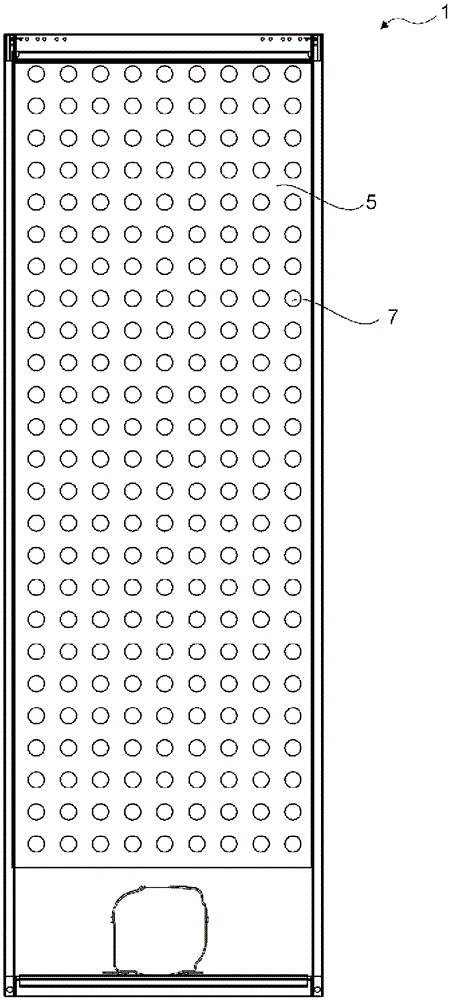

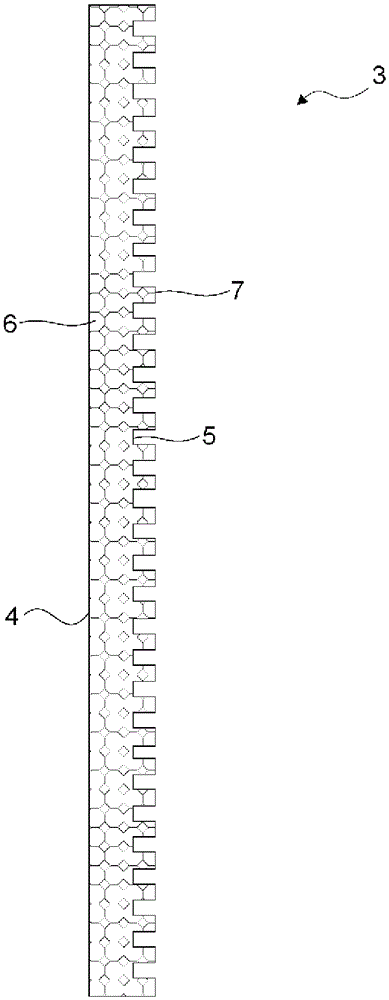

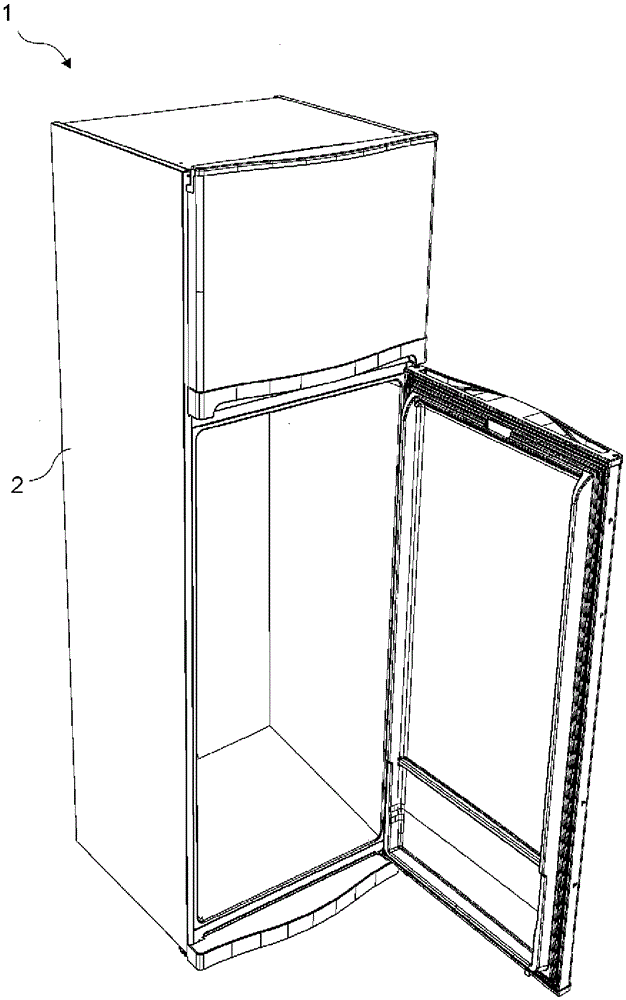

Cooling device comprising a rear wall having an outer surface made of fibrous material

ActiveCN103890513BPrevent shape deformationDomestic cooling apparatusLighting and heating apparatusMechanical engineeringEngineering

Owner:ARCELIK AS

A method for making a hollow glazed camel

ActiveCN107512850BImprove fluencyImprove cooling effectSpecial ornamental structuresGlass blowing apparatusFritSolid structure

The invention discloses a manufacturing method of a hollow coloured glaze camel, belonging to the technical field of coloured glaze preparation. The hollow coloured glaze camel is prepared from transparent glass frit, ceramic white material and brown transparent glass frit. A manufacturing process mainly comprises the steps of preparing materials, nesting materials, manufacturing a hollow structure, manufacturing a solid structure, fine trimming and annealing; wherein in a hollow structure manufacturing process, shaping is carried out according to the order of rear legs, humps, front legs and neck, and the hump parts are manufactured by a manner of combination of blowing, pulling and internal ejecting, so that shape deformation caused by sticky wall appeared at bulging parts and the manufacturing is failed are prevented; the trunk, limbs and the hump parts of the camel are integrally formed to increase the fluency of the whole coloured glaze camel. The coloured glaze camel prepared by the manufacturing method provided by the invention is vivid in figure and color and high in yield, has simple method and is capable of meeting the industrial large-scale batch production; the ornamental value of animal-shaped coloured glaze products is improved.

Owner:淄博赛奥玻璃科技有限公司

A ceramic container mouth packaging structure and its preparation method

The invention belongs to the technical field of storage sealing vessels, and particularly relates to a ceramic vessel opening part sealing structure and a preparation method thereof. The sealing structure comprises an opening part and a sealing cover. At least two sealing sections are arranged between the opening part and the sealing cover. The two sealing sections comprise a rubber sealing ring which is arranged on the upper surface of the opening part and / or the lower surface of the sealing cover and surrounds the axis of the opening part, and at least one circle of matting sealing ring which is located on the inner side of the rubber sealing ring and surrounds the axis of the opening part. By the adoption of the sealing structure, storage quality of reserved substances can be guaranteed while a normal packaging effect on the opening part by a traditional sealing cover is ensured. In the machining process, a carborundum grinding mode is used, and the top of an annular sealing ridge conducts rotating and grinding relative to the corresponding surface of the sealing cover or the opening part so that an annular sealing groove can be formed; and the top of an annular supporting ridge conducts rotating and grinding relative to the corresponding surface of the sealing cover or the opening part so that an annular supporting groove can be formed, and thus reliable machining of the structure can be guaranteed conveniently, rapidly and efficiently.

Owner:景德镇醉妙堂陶瓷有限公司

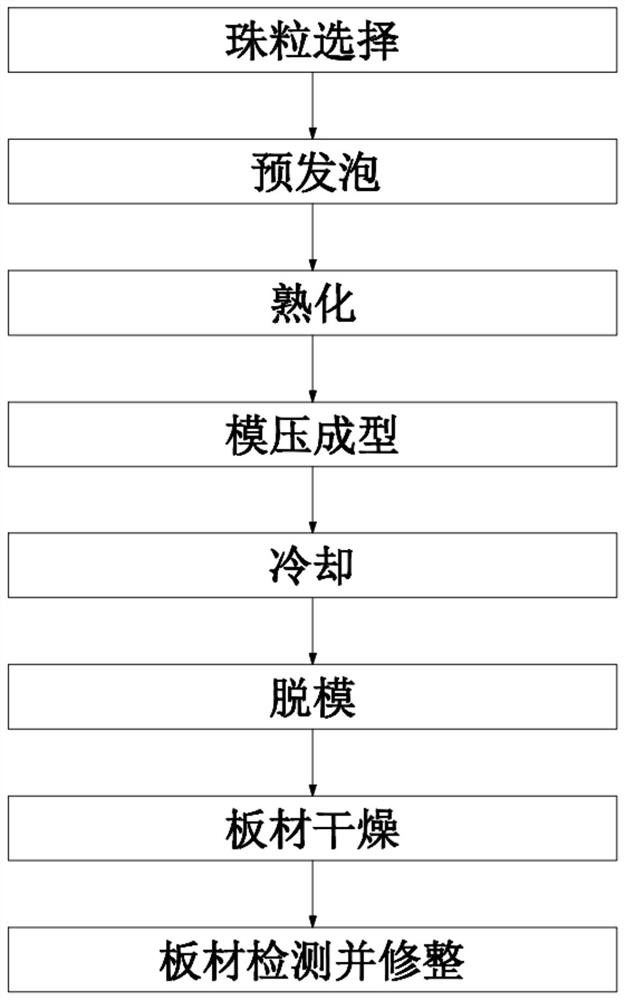

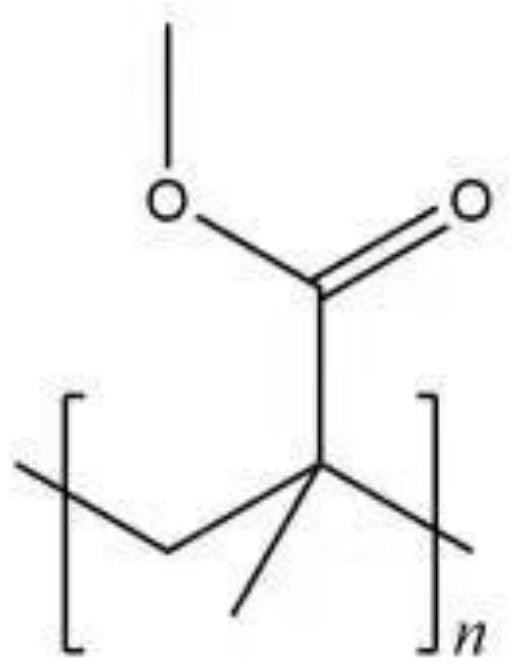

Full-mold casting plane plate evanescent mode and preparation method thereof

PendingCN114407382ASolve defects such as carbon depositsImprove yieldFoundry mouldsFoundry coresCompression moldingDuctile iron

The invention belongs to the technical field of evanescent modes, and particularly relates to a full-mold casting plane plate evanescent mode, and the large-size full-mold casting plane plate evanescent mode adopts a HOOCC (CH3) 2CH2CH3 polymer as a raw material. The preparation method of the large-size full-mold casting plane plate evanescent mold comprises the following specific steps: S1, selecting beads; s2, pre-foaming is carried out; s3, performing curing; s4, compression molding; s5, cooling; s6, demolding is conducted; s7, board drying; and S8, the plate is detected and trimmed. The method comprises the process steps of particle selection, pre-foaming, curing, compression molding, cooling, demolding, plate drying and the like. According to the scheme, the defects of carbon deposition and the like on the surfaces of the cast ductile iron and steel castings can be fundamentally overcome. By means of the manufacturing method, deformation of the manufactured lost foam pattern can be prevented, the bonding strength between the beads is improved, sufficient fusion of the beads is guaranteed, the yield of castings is greatly increased, and the comprehensive production cost of the castings is further reduced.

Owner:WUHU GUANFENG MOLD PLASTICS CO LTD

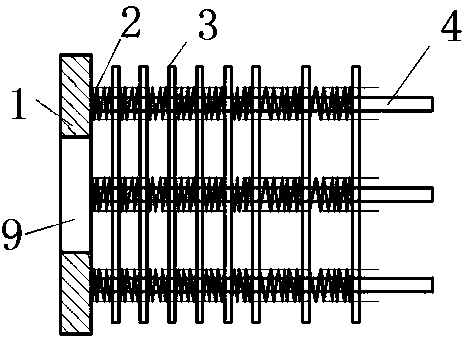

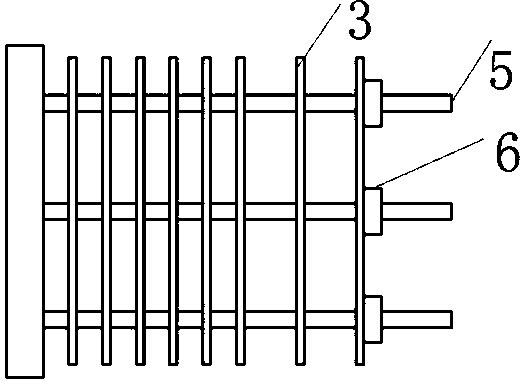

Length-adjustable strip sizing device

The invention discloses a length-adjustable strip sizing device. The length-adjustable strip sizing device comprises a connecting plate, multiple polish rods, multiple lead screws and multiple stand plates; the front ends of the polish rods and the lead screws are fixedly connected to the connecting plate; the stand plates sleeve the polish rods and the lead screws, and slide along the polish rods; the stand plates are in parallel; two adjacent stand plates are connected through springs sleeving the polish rods; nuts sleeve the tail ends of the lead screws; through holes are formed in the connecting plate and each stand plate; the section shape of the through holes are matched with the section shapes of strips; and the through holes are matched to form strip transportation channels. The device can solve the problems of collapse of internal cavities of the strips and shape deformation due to easy influence by gravity or other external environments in strip cooling, and can adjust the working length according to the lengths of the strips.

Owner:张荣斌

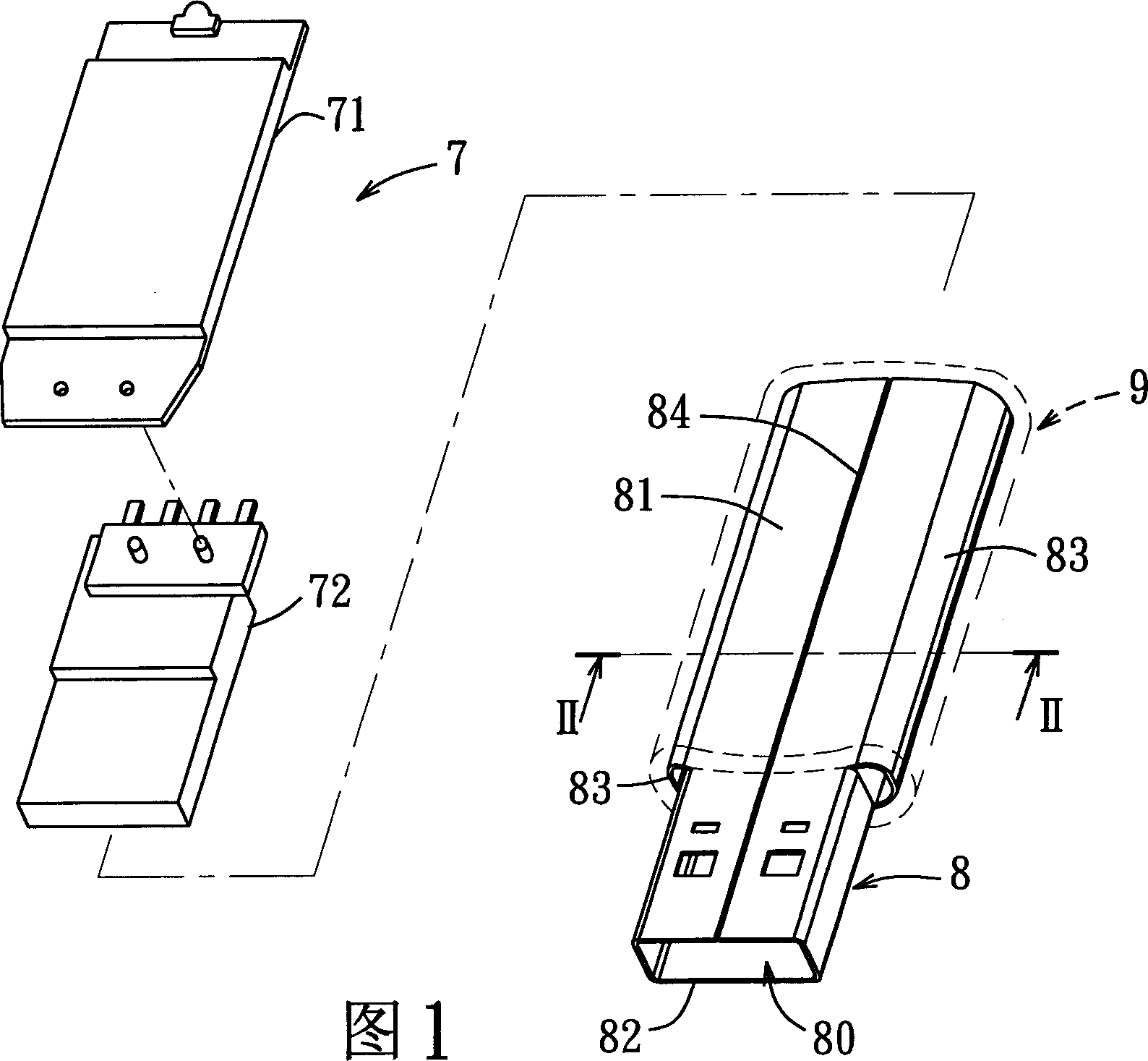

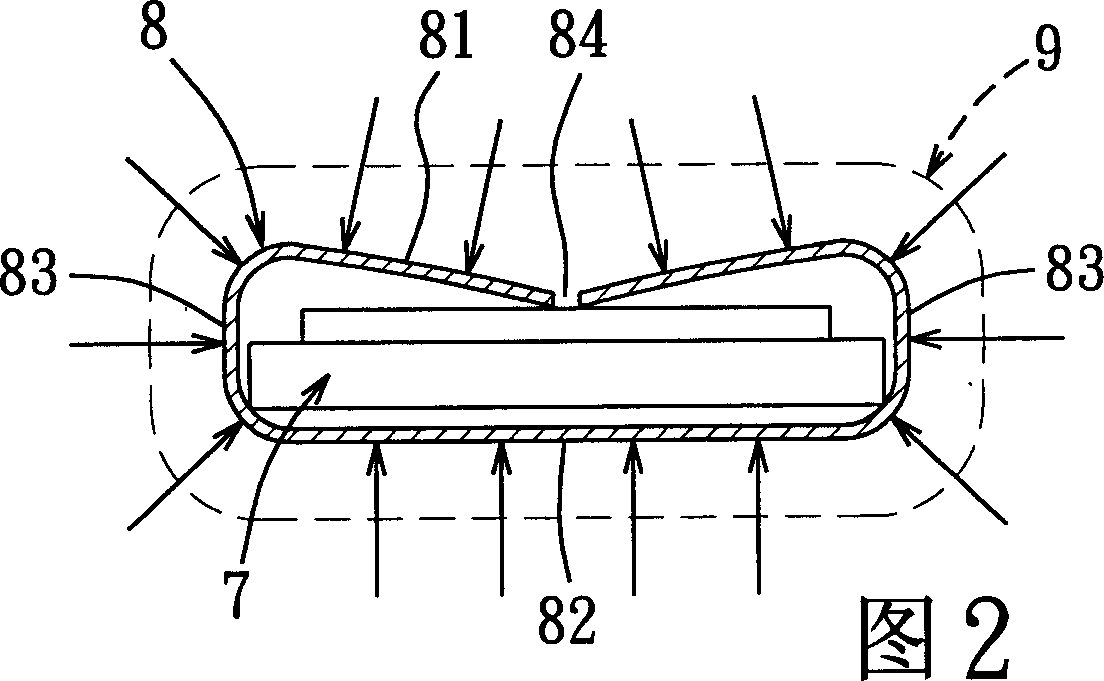

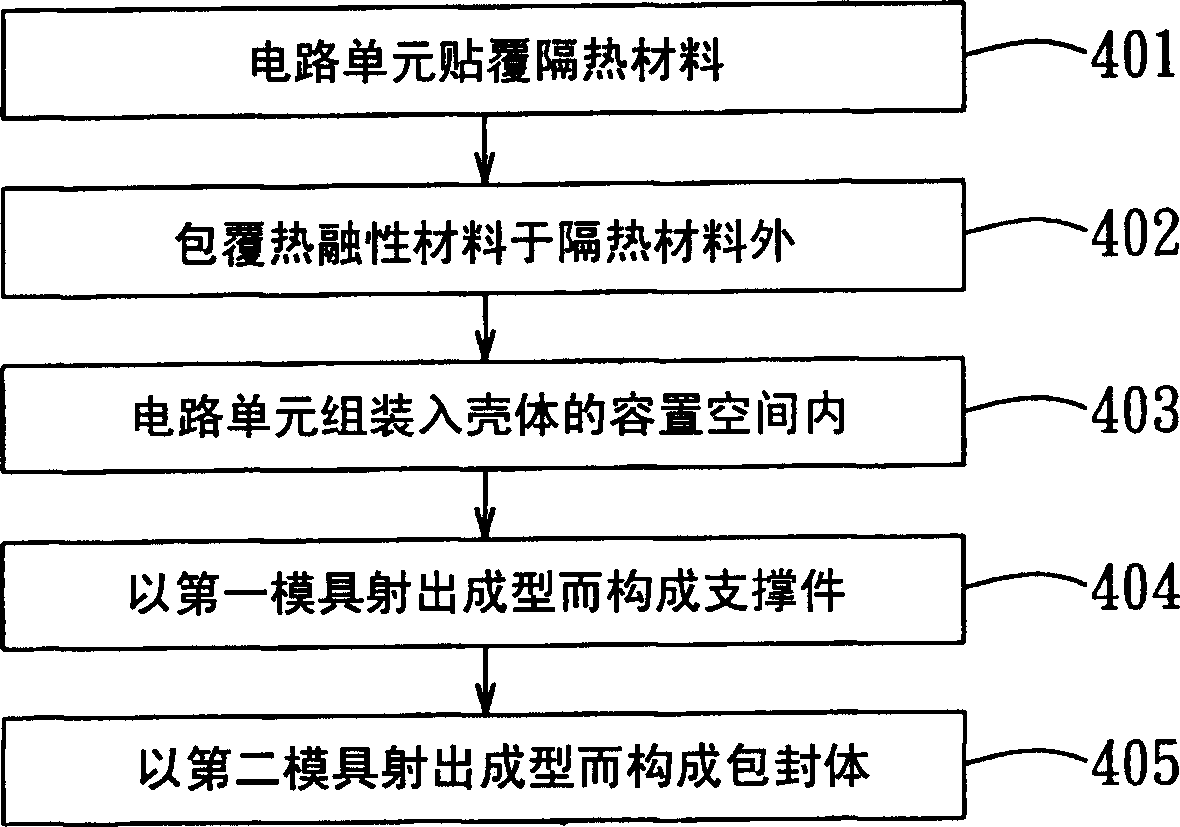

Method for producing portable information storage device

InactiveCN1717170APrevent shape deformationSemiconductor/solid-state device manufacturingElectrical componentsBiomedical engineeringMetal

This invention relates to a manufacturing method for a portable information storage device for manufacturing a portable information storage device containing a circuit unit, a metal shell and a package unit. The method includes taking a thermo material to adhere to the outside of the circuit unit, then putting the circuit unit in a containing space in the shell and positioning it in a die cavity formed by a first die set, filling the thermo material in the containing space of the shell to fill in the space between the circuit unit and the inside wall of the shell to make up of a support in the shell, finally, the assembly got at the previous step is positioned at the die cavity formed by a second die set to enable the thermo material to form a package body covering the shell.

Owner:DATAFAB SYST

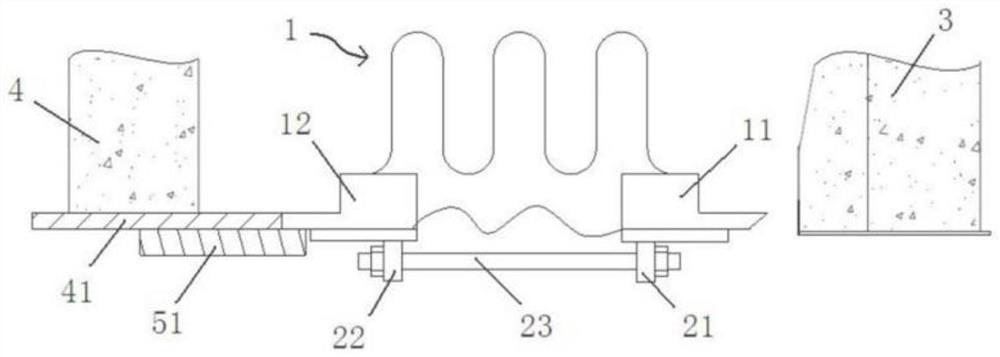

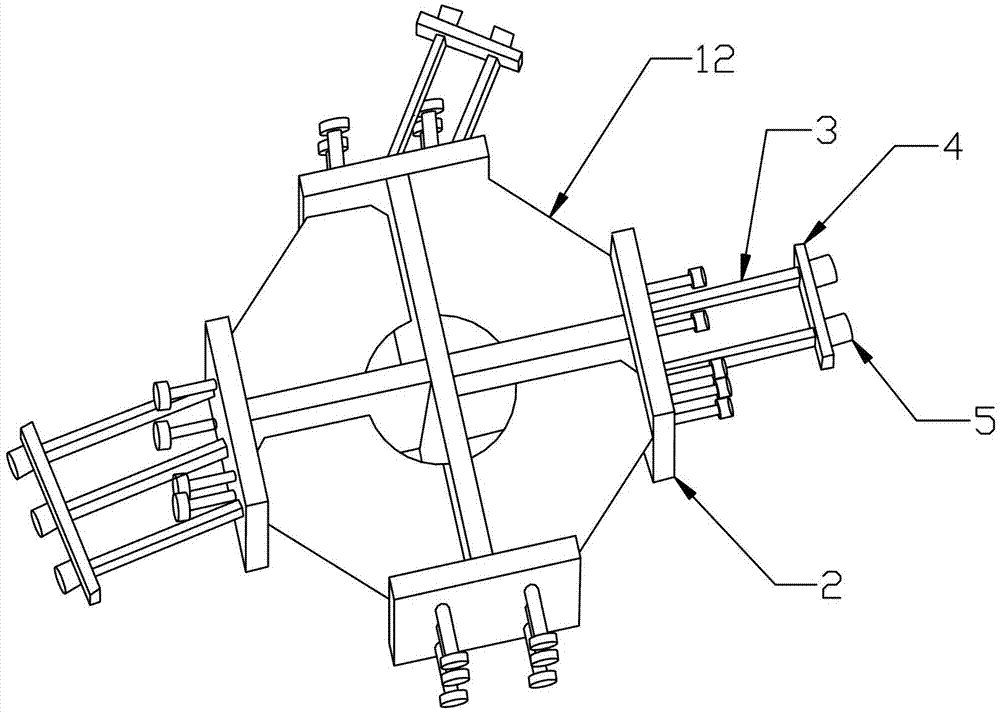

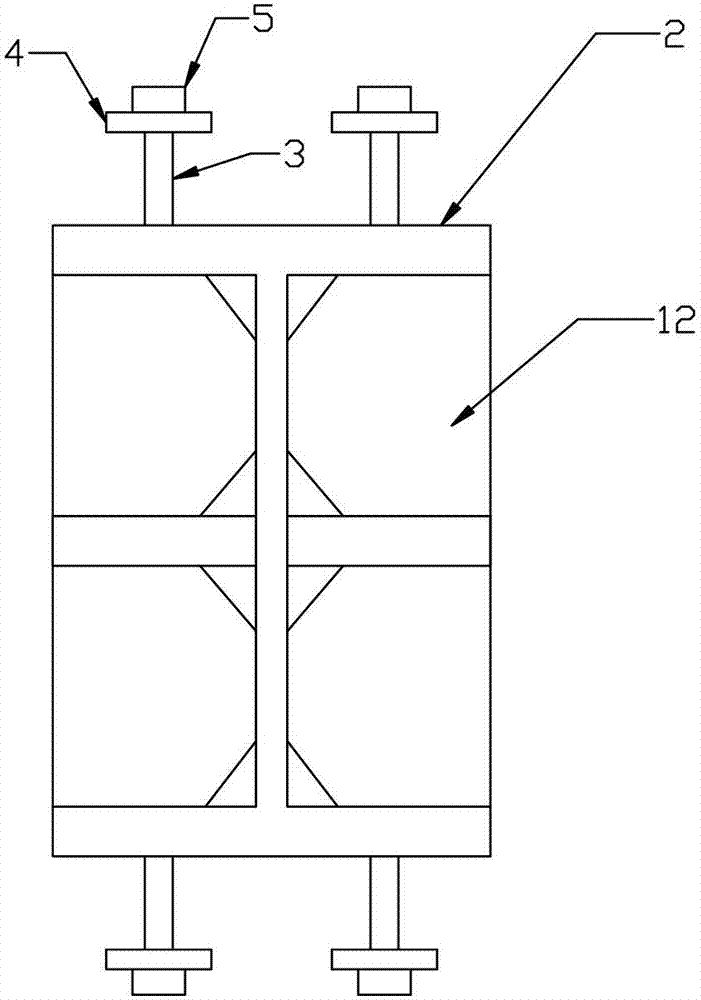

Hybrid Structural Rebar Connection Nodes

InactiveCN103046648BEasy constructionQuality improvementBuilding reinforcementsChinese charactersConcrete beams

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

An anti-ultraviolet photovoltaic cable processing and stranding equipment and its application method

ActiveCN107742550BPrevent twistingPrevent shape deformationPlastic/resin/waxes insulatorsInsulated cablesFiberPolyolefin

The invention discloses an anti-ultraviolet photovoltaic cable and relates to special equipment or method for manufacturing conductors or cables. The problems that according to existing stranding technologies, after an anti-ultraviolet filling material where carbon black fibers with the particle size of 50 nm are added and a wire drawing machine is used, special-shaped insulating wire cores are likely to turn over, accordingly cables are twisted, the cable cores become loose, the tensile strength is reduced, and the cables deform are solved. The cable comprises an outer protective layer, an armor layer, an inner protective layer, an insulating layer and a conductor layer which are sequentially wrapped from outside to inside, wherein four to six anti-shielding layers are distributed on theouter ring of the conductor layer, the shielding layers are located between the conductor layer and the insulating layer, the portion between the conductor layer and the insulating layer is further filled with an anti-ultraviolet filling material, and the outer protective layer uses an irradiation cross-linked polyolefin sheath. According to the technical scheme, the situation that the special-shaped insulating wire cores turn over and accordingly the cables are twisted is prevented. The invention further discloses stranding equipment for processing the anti-ultraviolet photovoltaic cable.

Owner:欧耐特线缆集团有限公司

Glass ribbon producing apparatus and process for producing the same

ActiveCN101528618BRestriction disorderPrevent shape deformationGlass forming apparatusEngineeringMolten glass

The invention provides a glass ribbon producing apparatus (1) adapted to feed molten glass (Y) to molding member (3) and to cause the molten glass (Y) to flow downward from the molding member (3) so as to form sheetlike glass ribbon (G), comprising guide means (6) disposed on a transport route for the glass ribbon (G) flowing downward, which guide means (6) has a gap of dimension larger than the sheet thickness at across-the-width both ends in the direction of thickness of the glass ribbon (G) and guides within the bound of the gap only the across-the-width both ends of the glass ribbon (G).

Owner:NIPPON ELECTRIC GLASS CO LTD

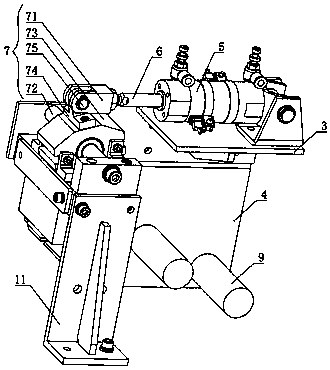

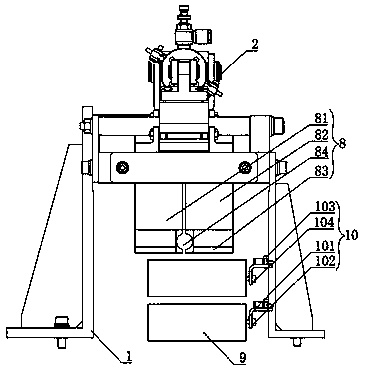

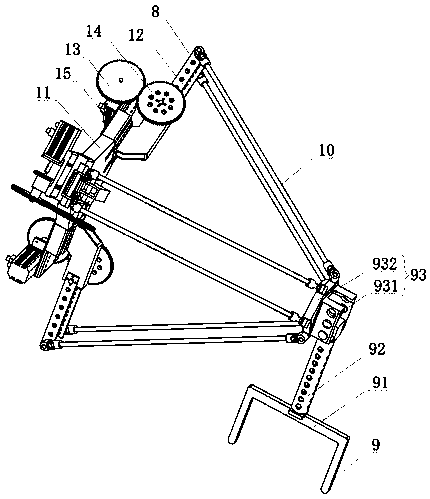

Square stirrup discharge device

ActiveCN108097849BHigh degree of automationReduce labor costsWire networkLoading/unloadingDischarge efficiencyEngineering

The invention relates to a square stirrup discharging device which comprises a baseplate, wherein two shaft seats are arranged on the baseplate; shaft holes which are positioned in one and the same straight line are correspondingly formed in the shaft seats; an unloading shaft penetrates through the shaft holes and is rotatably mounted on the shaft seats; at least two unloading hooks are arrangedat one end of the unloading shaft in a spacing manner and used for bearing square stirrups; an axial motion driving mechanism and a rotation driving mechanism are connected with the unloading shaft; the axial motion driving mechanism is used for driving the unloading shaft to move along the axial direction of the shaft holes; the rotation driving mechanism is used for driving the unloading shaft to rotate. By adoption of the square stirrup discharging device provided by the invention, the formed square stirrups can be steadily borne at a preset bearing position and conveyed to a preset discharging position for being stably discharged, thereby achieving the high degree of automation, reducing the labor cost, and improving the discharging efficiency; and through the cooperation with a synchronously-distributed accommodating box, the square stirrups can correctly fall into the preset accommodating box below in a vertical state, thereby solving the problems that the square stirrups are disorderly stacked, the appearances of the square stirrups are easy to damage, and the shape deformation is caused.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

Manufacturing equipment and method of long screw rod

Owner:江苏飞博尔新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com