Method for producing portable information storage device

A storage device and manufacturing method technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as deformation, easy deformation, appearance defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

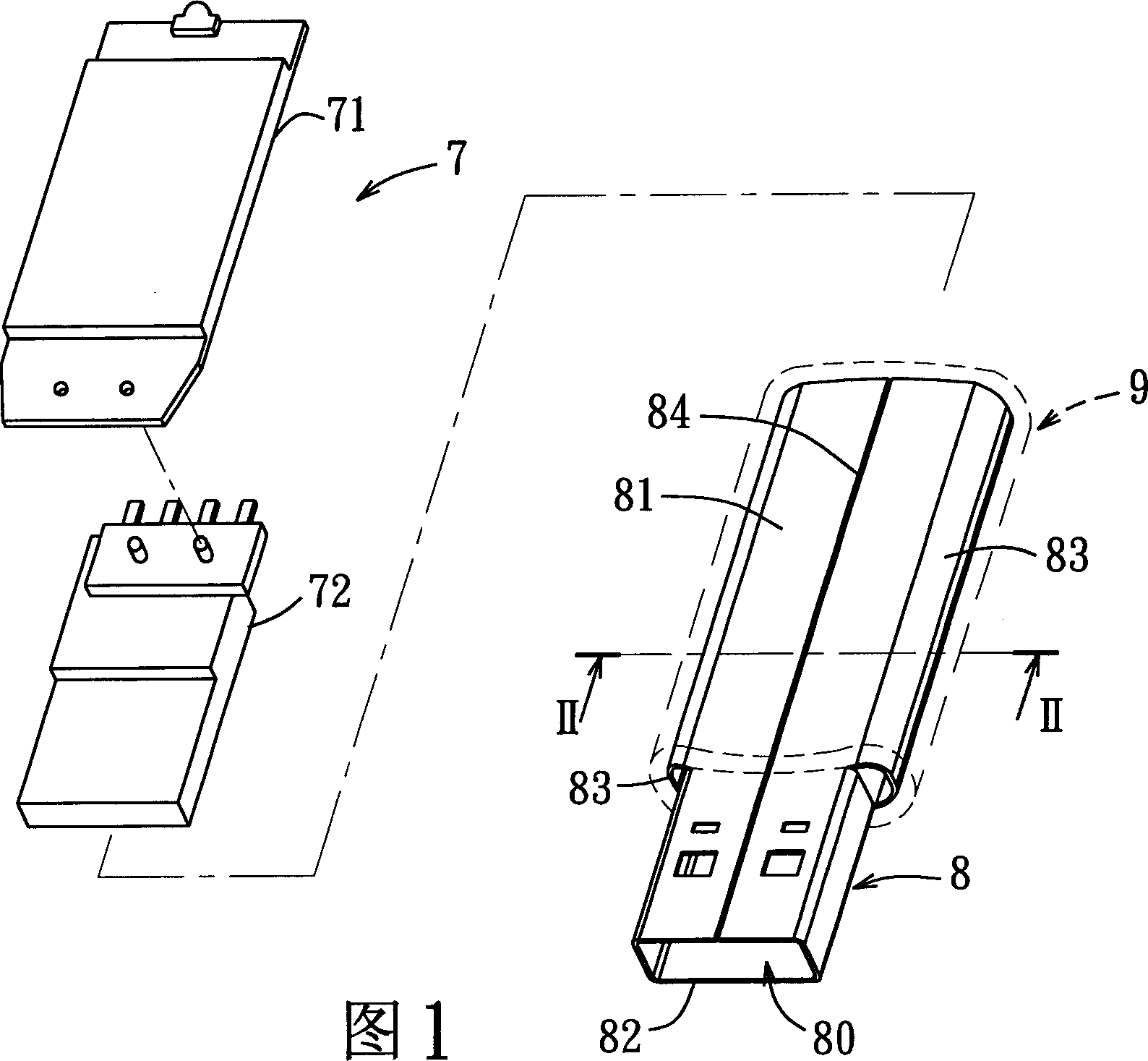

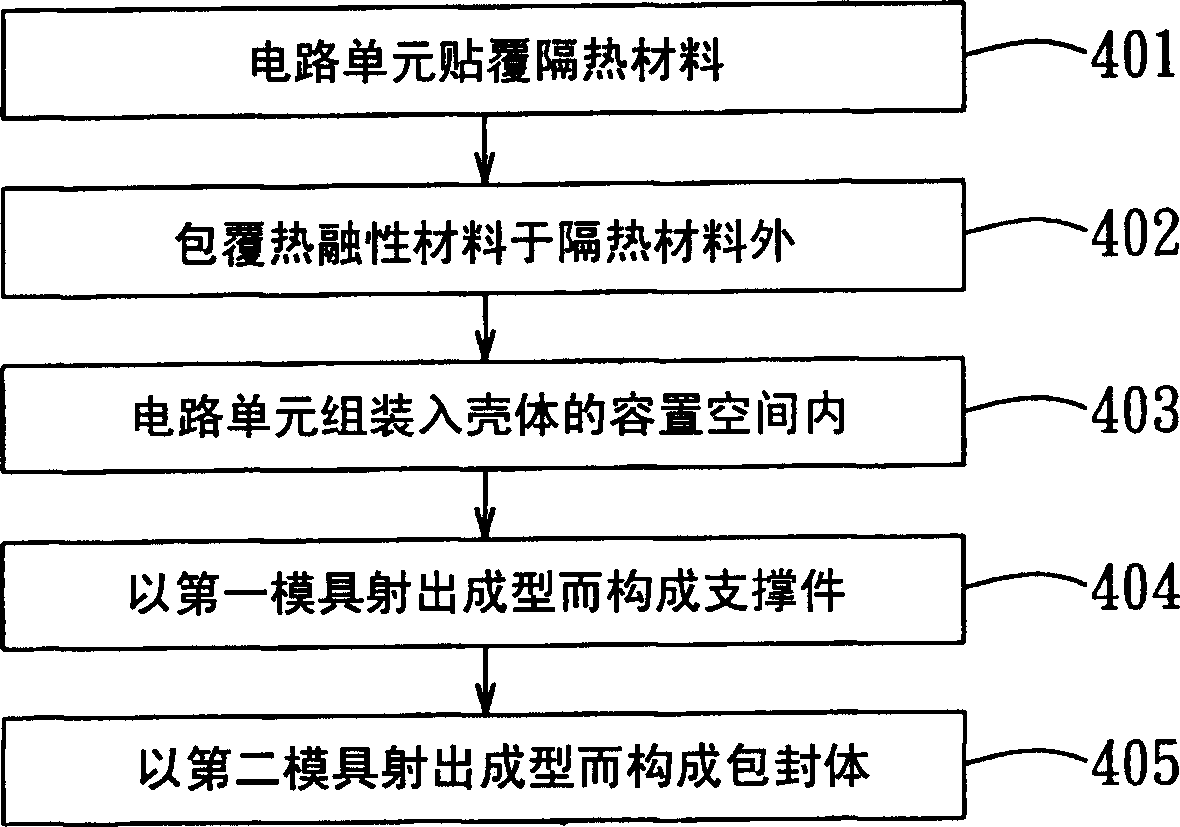

[0032] refer to image 3 A preferred embodiment of the manufacturing method of the portable information storage device of the present invention is applied to a USB disk.

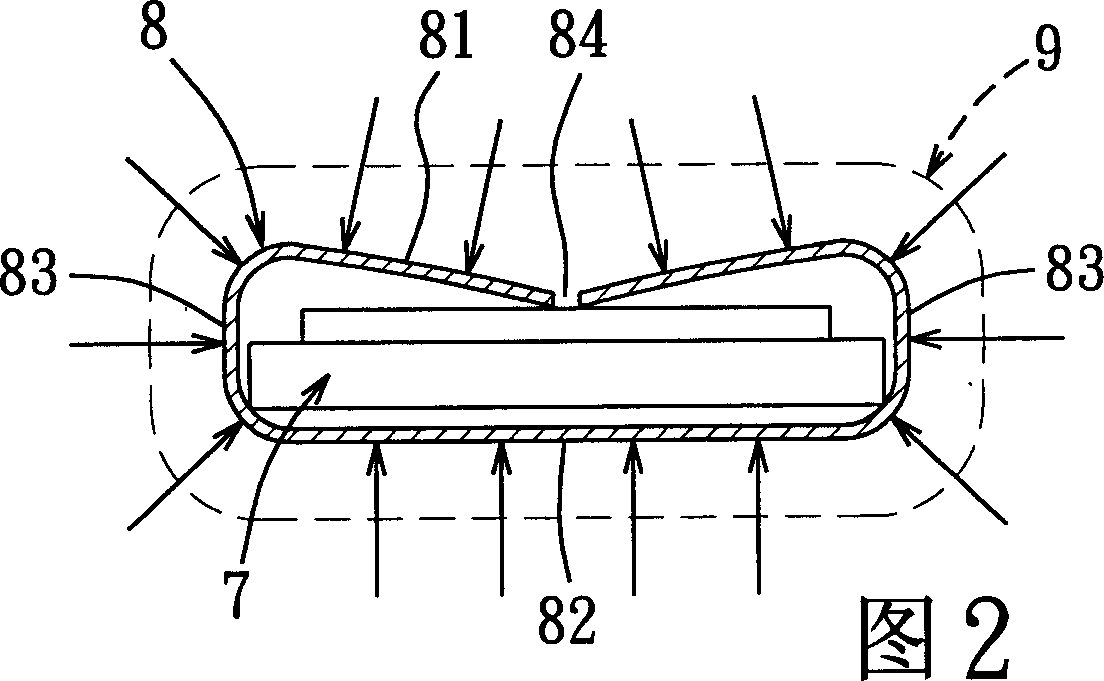

[0033] As shown in Fig. 4 and Fig. 5, the basic structure of the information storage device made by the present invention includes a circuit unit 1, a metal casing 2 and an encapsulating body 3 (described later) that is coated on the outside of the casing 2 by injection molding. ). The circuit unit 1 includes a circuit substrate 11 and an electrical connector 12 connected to the USB interface at the end of the circuit substrate 11, and the housing 2 is formed by stamping and bending a metal sheet, so that the interior constitutes a capacity enough to accommodate the circuit unit 1. The accommodating space 20 can be correspondingly divided into a body part 201 for accommodating the circuit board 11 and a plug-in part 202 for accommodating the electrical connector 12 in conjunction with the structure of the ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com