Square stirrup discharge device

A technology of unloading device and stirrup, which is applied in the direction of loading/unloading, transportation and packaging, wire netting, etc. It can solve the problems of low efficiency of manual unloading, labor waste, shape deformation, and messy stacking, etc., and achieve good overall structural strength, Short length and material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

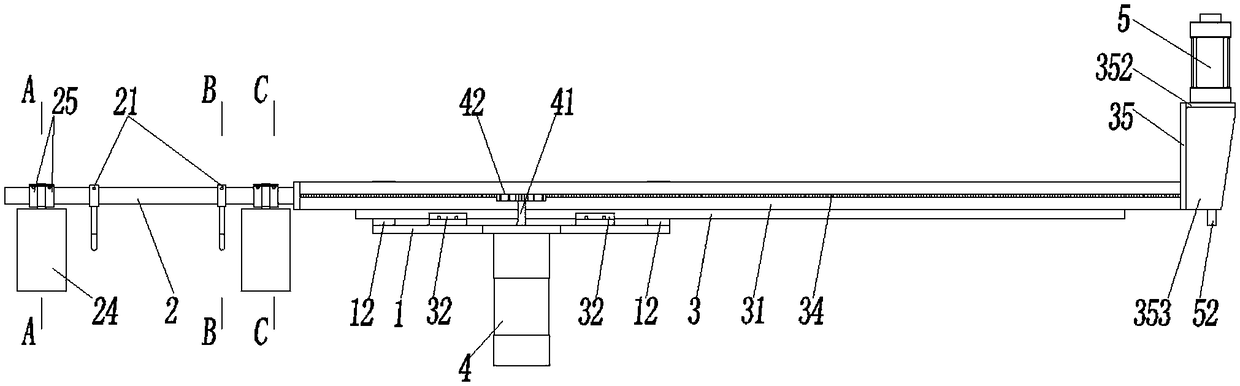

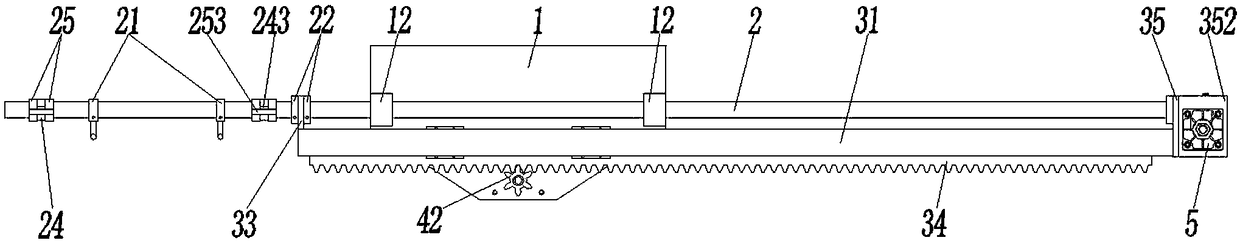

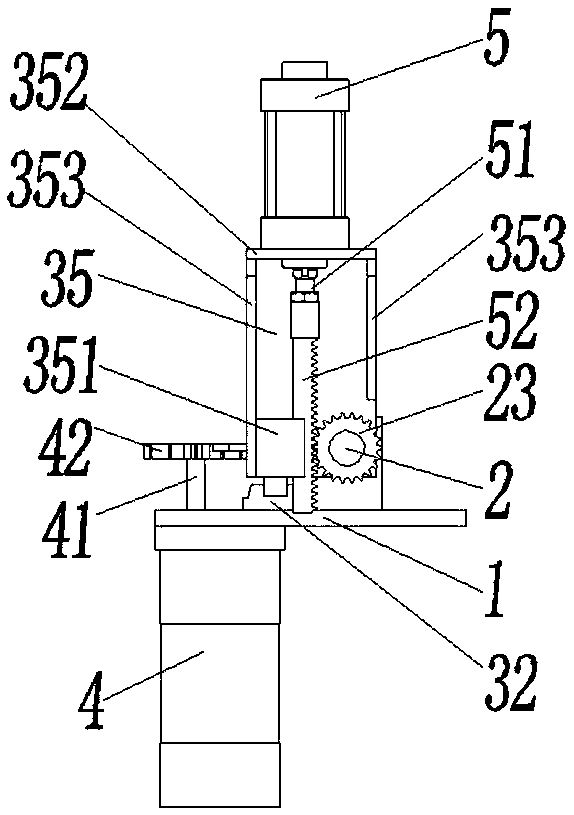

[0046] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0047] see figure 1 , Image 6 , a square stirrup unloading device, comprising a bottom plate 1, two shaft seats 12 are arranged at intervals on the bottom plate 1, and a horizontal unloading shaft 2 is installed in the two shaft seats 12 which are rotatable and can move along their own axial direction, One end of the blanking shaft 2 is provided with two blanking hooks 21 at intervals for receiving square stirrups. The blanking hook 21 includes an integrated hook portion 211 and an annular portion I212, and is sleeved on the blanking shaft 2 through the annular portion I212 so that the blanking hook 21 can move along the blanking shaft 2. Axially slide the distance between the blanking hooks 21 to adjust the distance between the hooks 21. A threaded through hole I213 is provided on the ring part I212 along its radial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com