Cold pressing technology of solid-liquid hybrid electrolyte lithium storage battery

A lithium battery and electrolyte technology, which is applied in the field of cold pressing process, can solve the problems such as the inability to discharge the gas in time, the deformation and breakage of the battery package, and achieve the effect of improving the cooling effect, avoiding the deformation of the shape, and having a long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

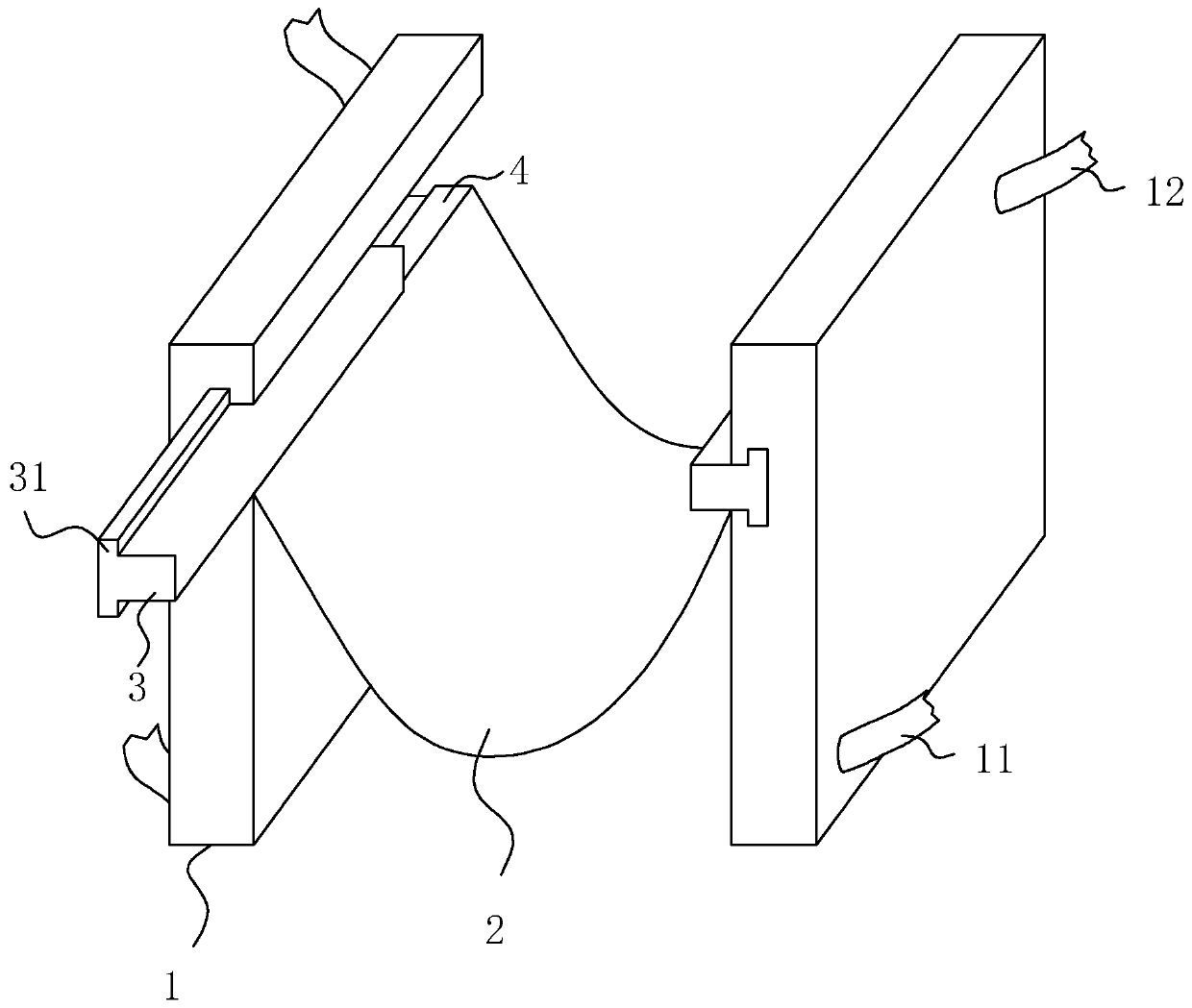

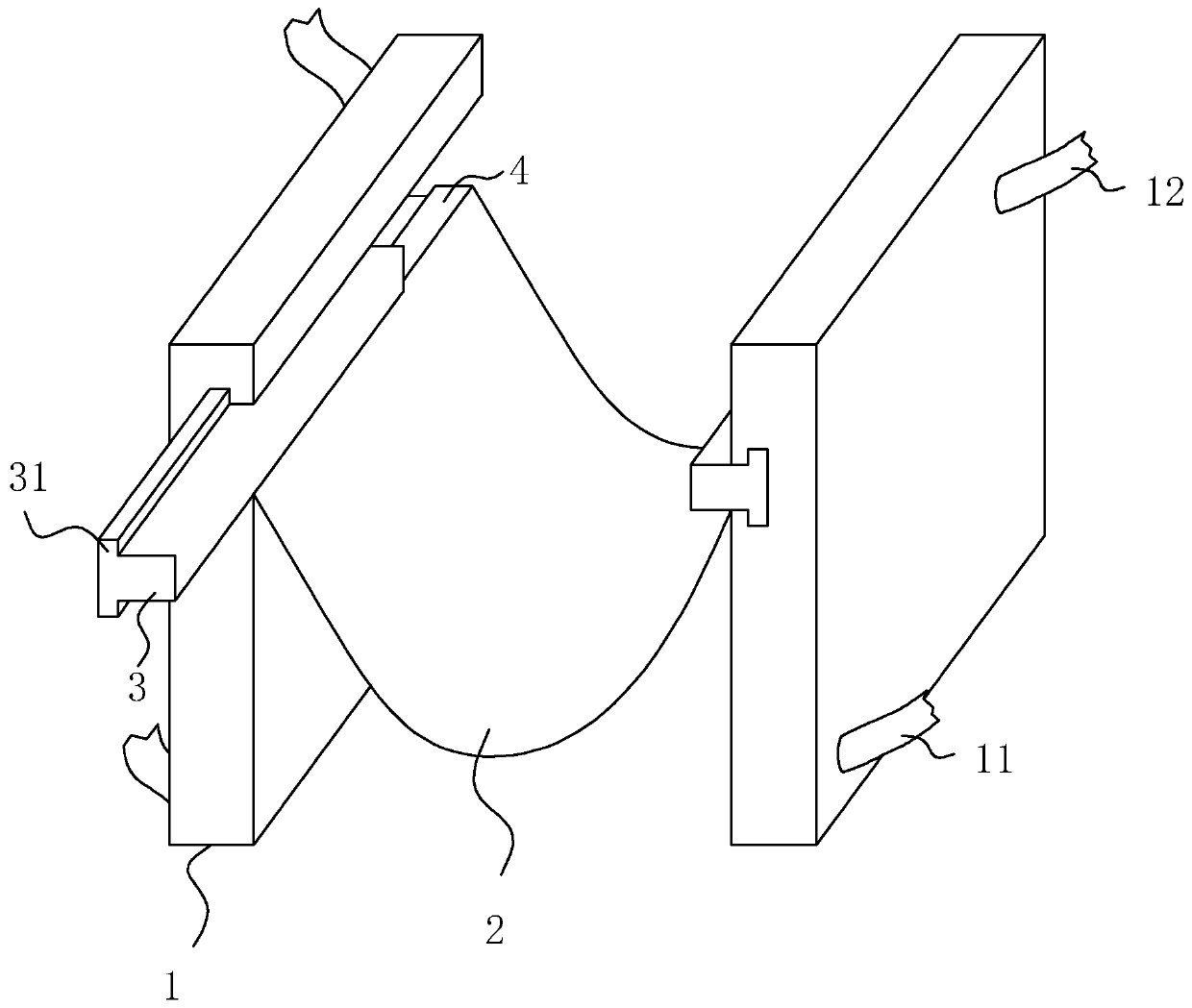

[0037] A cold press fixture, as attached figure 1 As shown, the laminate 1 is included, and there is a driving mechanism on the laminate 1, which can drive the pressure between the two laminates 1. The specific driving mechanism can be selected according to the actual situation. An oil cylinder is respectively arranged on the back side.

[0038] In addition, there is a supporting film 2 between the two layers of boards 1 , and the upper edges of the supporting films 2 are respectively fixed to the positions close to the upper edge of the laminate 1 , so that the supporting film 2 can be used to carry electric cores. At the same time, the inside of the two-layer board 1 has a cavity, and the opposite side of the two-layer board 1 has a liquid inlet pipe 11 and a liquid outlet pipe 12 communicating with the cavity. And the liquid inlet pipe (11) is above and the liquid outlet pipe (12) is below.

[0039] Moreover, a protruding strip 3 is installed on the opposite sides of the ...

Embodiment 2

[0041] A process for forming a mixed solid-liquid electrolyte lithium storage battery, comprising the following steps:

[0042] Step 1: Charge the cell with a temperature of 45°C, a pressure of 0.3Mpa, a constant current of 0.2C and a cut-off voltage of 3.75V;

[0043] Step 2: Place the cell treated in step 1 on the supporting film of the cold-pressing jig of Embodiment 1, and then the cold-pressing jig gently clamps the cell;

[0044] Step 3: Feed circulating saponified liquid into the cavity of the cold press fixture;

[0045] Step 4: After that, the cold-pressing jig applies pressure to the cell in stages. The first stage applies a pressure of 0.06 Mpa for 7 minutes, the second stage applies a pressure of 0.07 Mpa for 15 minutes, and the third stage applies a pressure of 0.325 Mpa for a time of for 45min.

[0046] Step 5: After the pressure is applied, take out the battery cell;

[0047] Among them, the saponified liquid is prepared by mixing 7kg of sodium petroleum sulf...

Embodiment 3

[0051] A process for forming a mixed solid-liquid electrolyte lithium storage battery, comprising the following steps:

[0052] Step 1: Charge the cell with a temperature of 45°C, a pressure of 0.3Mpa, a constant current of 0.2C and a cut-off voltage of 3.75V;

[0053] Step 2: Place the battery cell treated in step 1 on the supporting film of the cold-pressing jig of Embodiment 1, and then the cold-pressing jig gently clamps the battery cell;

[0054] Step 3: Pass circulating deionized water into the cavity of the cold press fixture;

[0055] Step 4: Afterwards, the cold-pressing jig applies pressure to the cell in stages. The first stage applies a pressure of 0.03Mpa for 5 minutes, the second stage applies a pressure of 0.07 Mpa for 15 minutes, and the third stage applies a pressure of 0.25Mpa for a time of 5 minutes. 15min;

[0056] Step 5: After the pressure is applied, take out the battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com