Ceramic vessel opening part sealing structure and preparation method thereof

A technology of packaging structure and ceramic container, which is applied in the field of storage and sealing containers, can solve the problems of unsuitable drinking, damaged storage, poor packaging, etc., and achieve long-term and reliable quality preservation effect, long storage period, high quality and storage period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

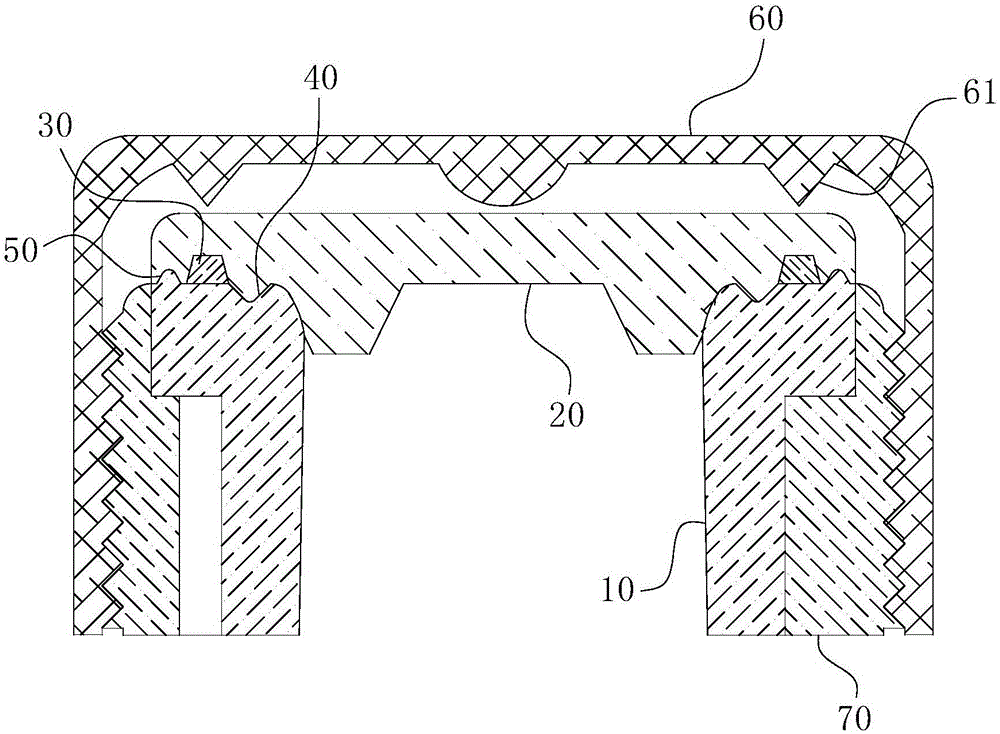

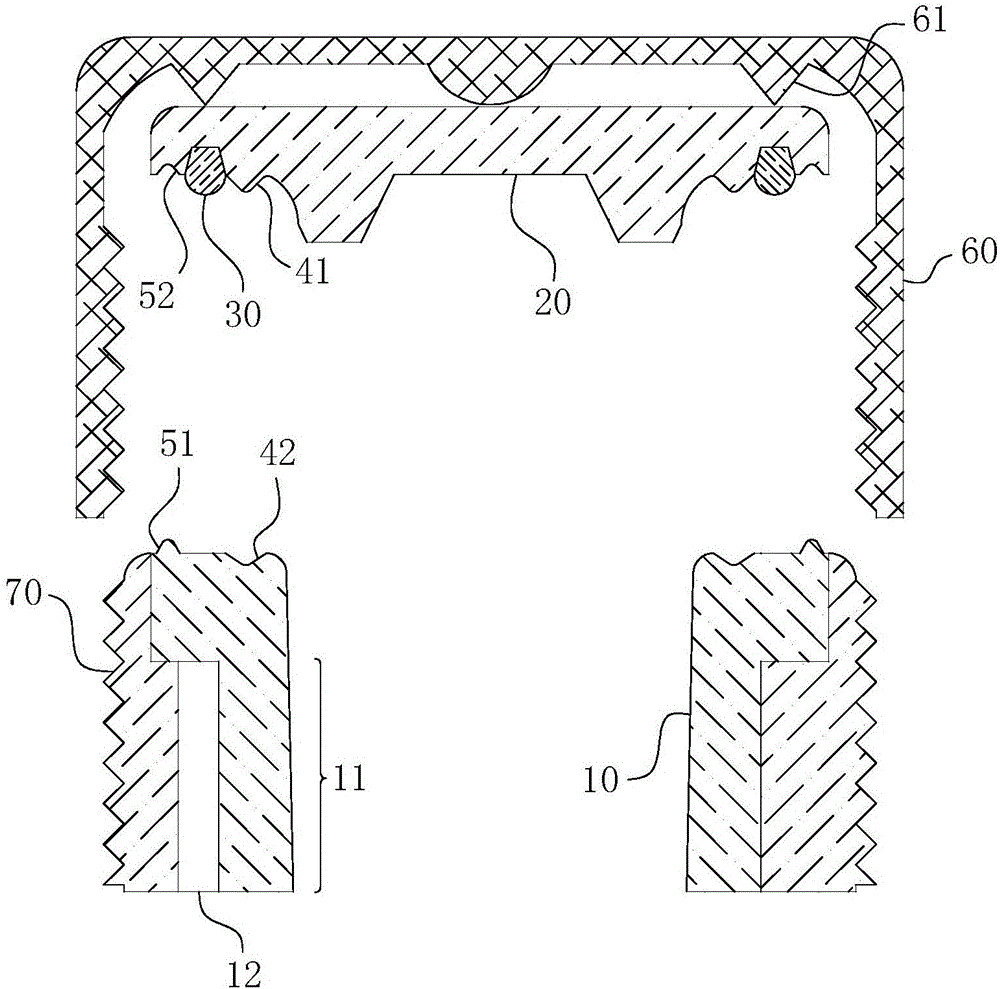

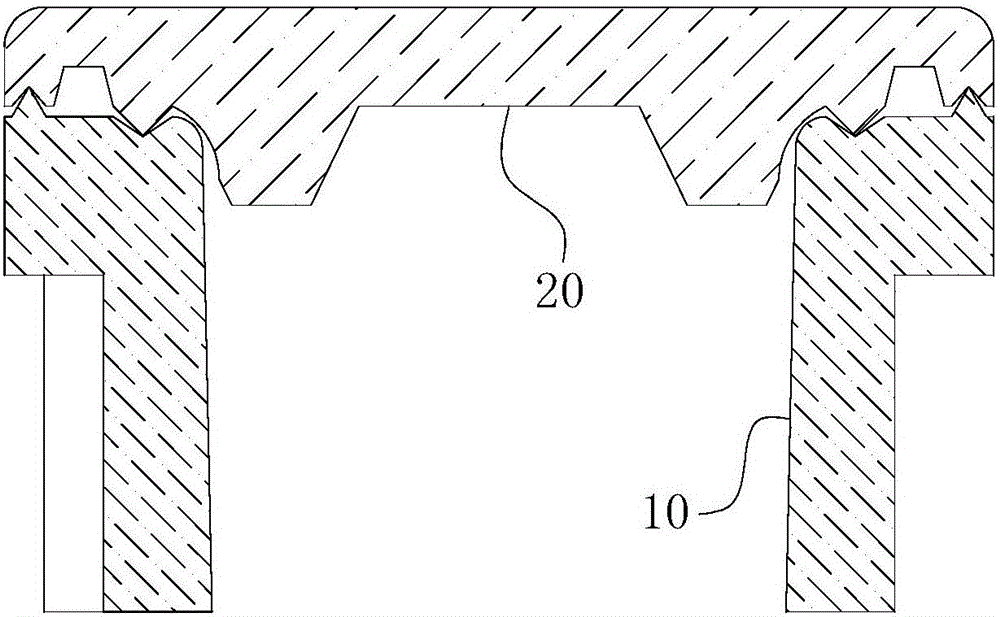

[0040] For ease of understanding, here, with the wine jar as the specific embodiment of the above-mentioned ceramic container, in conjunction with the accompanying drawings, the specific implementation structure and work flow of the present invention are described as follows:

[0041] The present invention is aimed at the wine jar of large caliber and the wine jar of small caliber, has two specific embodiment structures respectively. Such as Figure 1-9 Shown is the screw-fit mouth seal method used in small-bore wine jars. Of course, it can also be used in large-caliber wine jars in actual use. It specifically includes: from bottom to top, it includes a threaded sleeve 70 arranged on the altar, a mouth 10 located in the threaded sleeve 70, a cover 20 above the mouth 10, and wrapping the cover 20 and connecting with the threaded sleeve. 70 form the outer cover body 60 that is threaded. The cavity of the threaded sleeve 70 is in the shape of a stepped hole, so as to form a soc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com