Glass ribbon producing apparatus and process for producing the same

A technology for a manufacturing device and a manufacturing method, which is applied to a glass ribbon manufacturing device and its manufacturing field, can solve problems such as damage, breakage, and cutting of the glass ribbon, and achieve the effect of preventing shape deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Embodiments of the present invention will be described below with reference to the drawings.

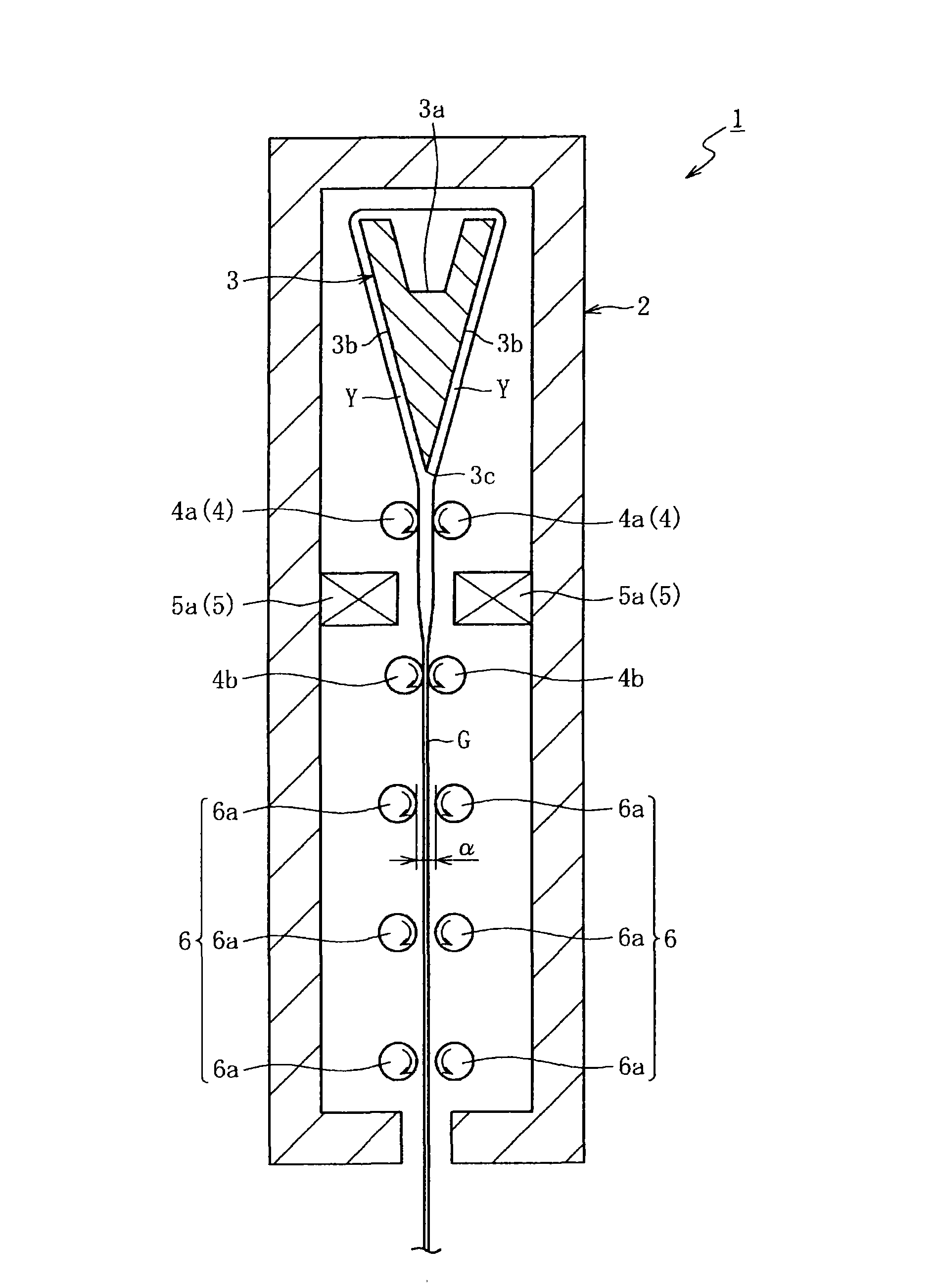

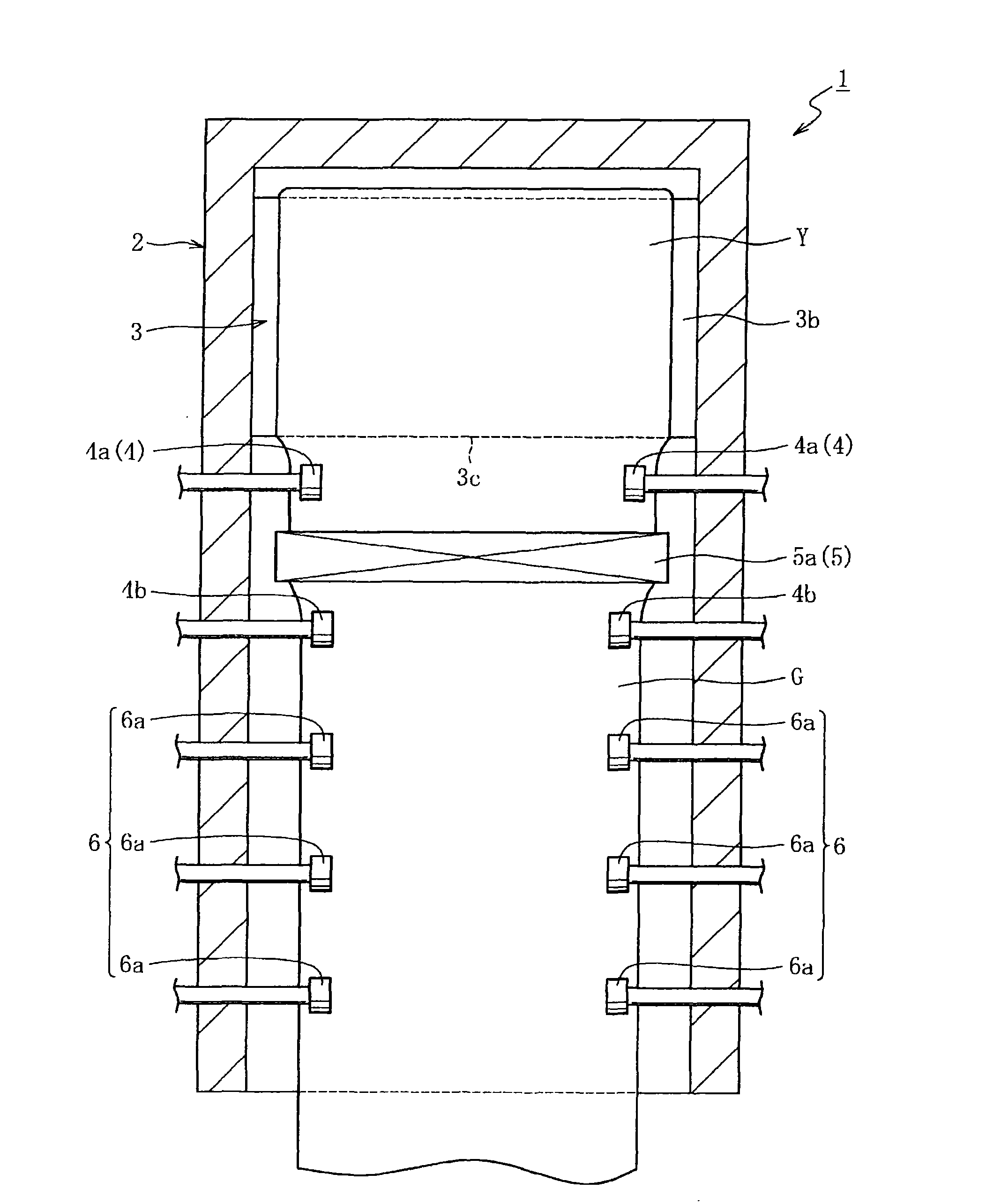

[0043] figure 1 It is a schematic vertical side view schematically showing the internal state of the glass ribbon manufacturing apparatus which concerns on one Embodiment of this invention. figure 2 is a schematic longitudinal front view schematically showing the internal state of the manufacturing apparatus. As shown in each figure, the manufacturing apparatus 1 has a molded body 3, a cooling mechanism 4, a reheating mechanism 5, and a guide mechanism 6 sequentially from above inside a furnace 2 made of refractory tiles.

[0044] The forming body 3 is a member having a wedge-shaped cross section and having an overflow groove 3a at the top, and the molten glass Y supplied to the overflow groove 3a overflows from the top, and the overflowing molten glass Y flows down along both side surfaces 3b of the forming body 3 On the other hand, it fuses at the lower end part 3c of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com