Keyboard light guide film and manufacturing method thereof

A light guide film and keyboard technology, applied in the direction of light guide, optics, optical components, etc., can solve the problems of low workability and productivity, high price, increased labor and material costs, etc., to improve assembly and productivity, The effect of reducing manufacturing cost and simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

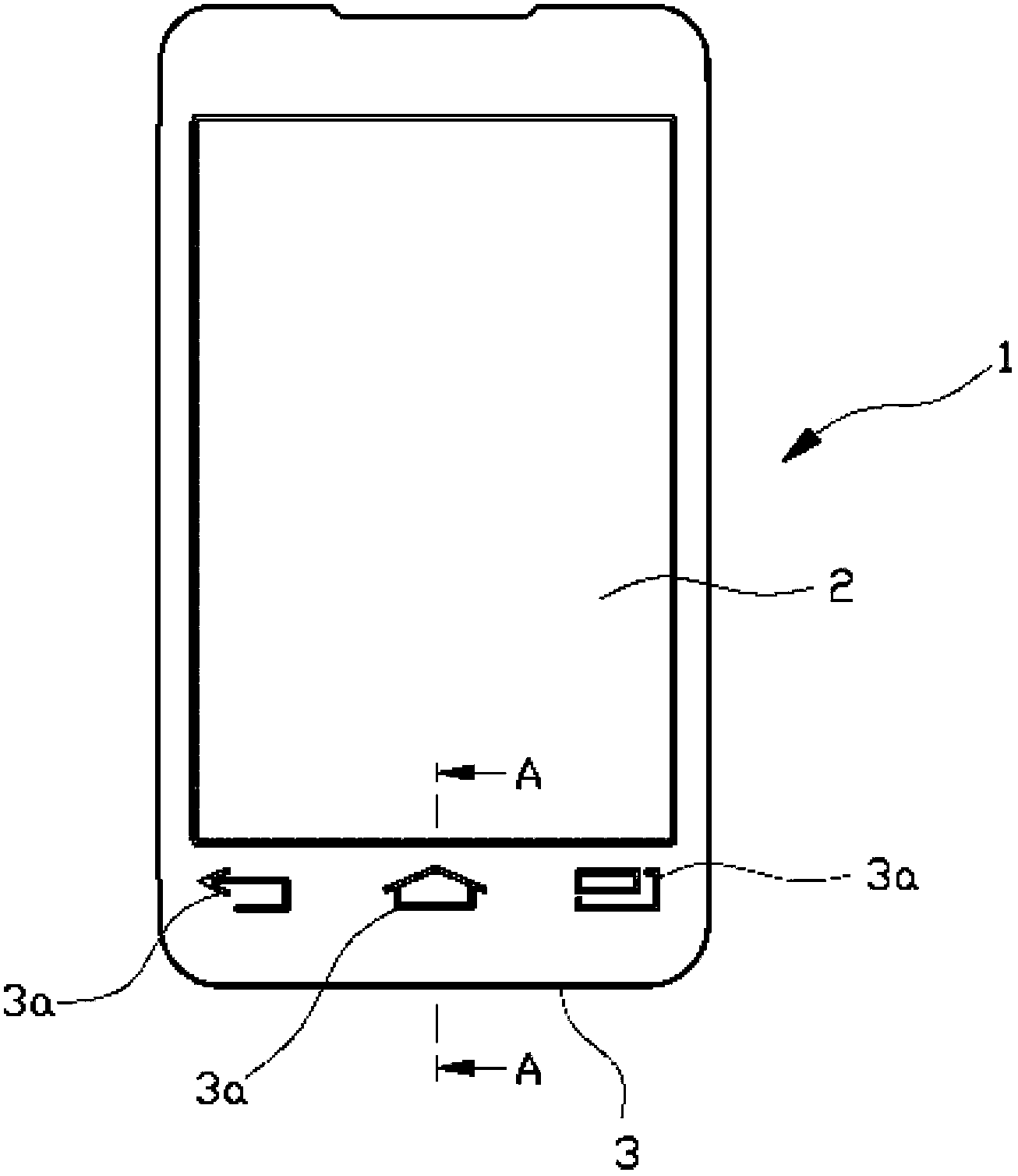

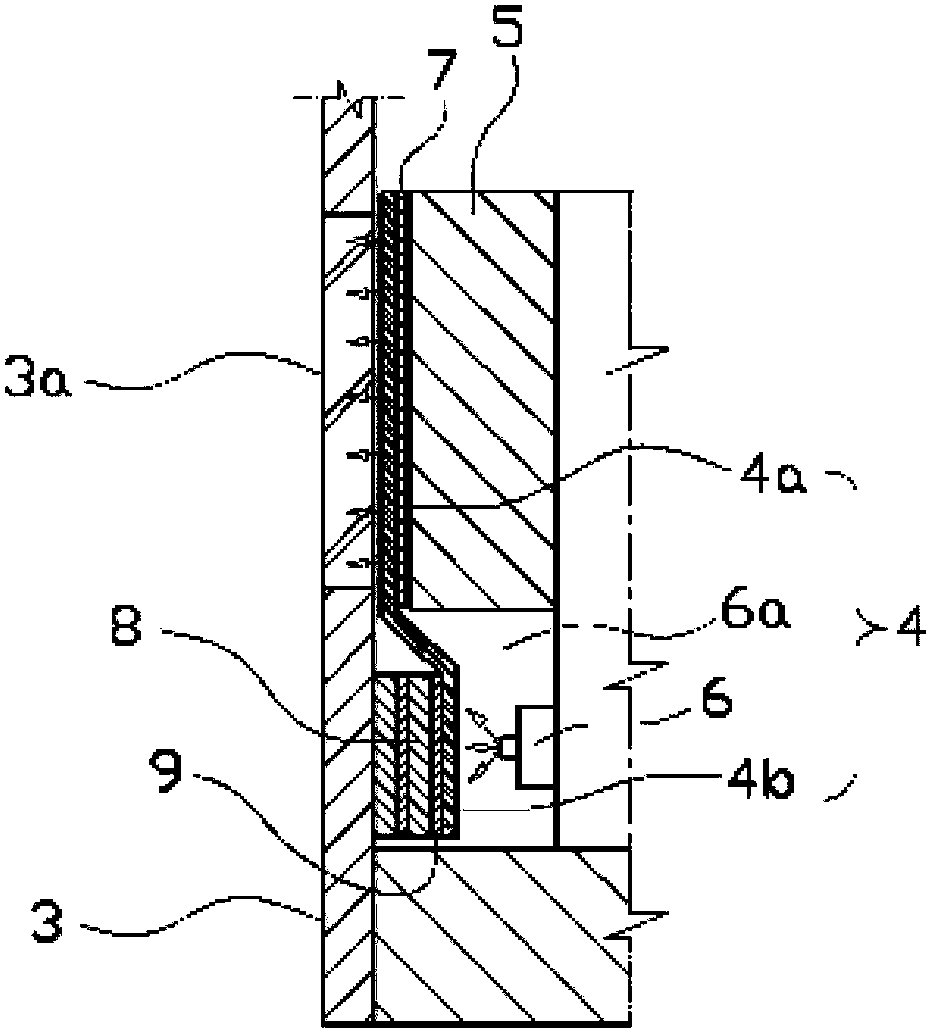

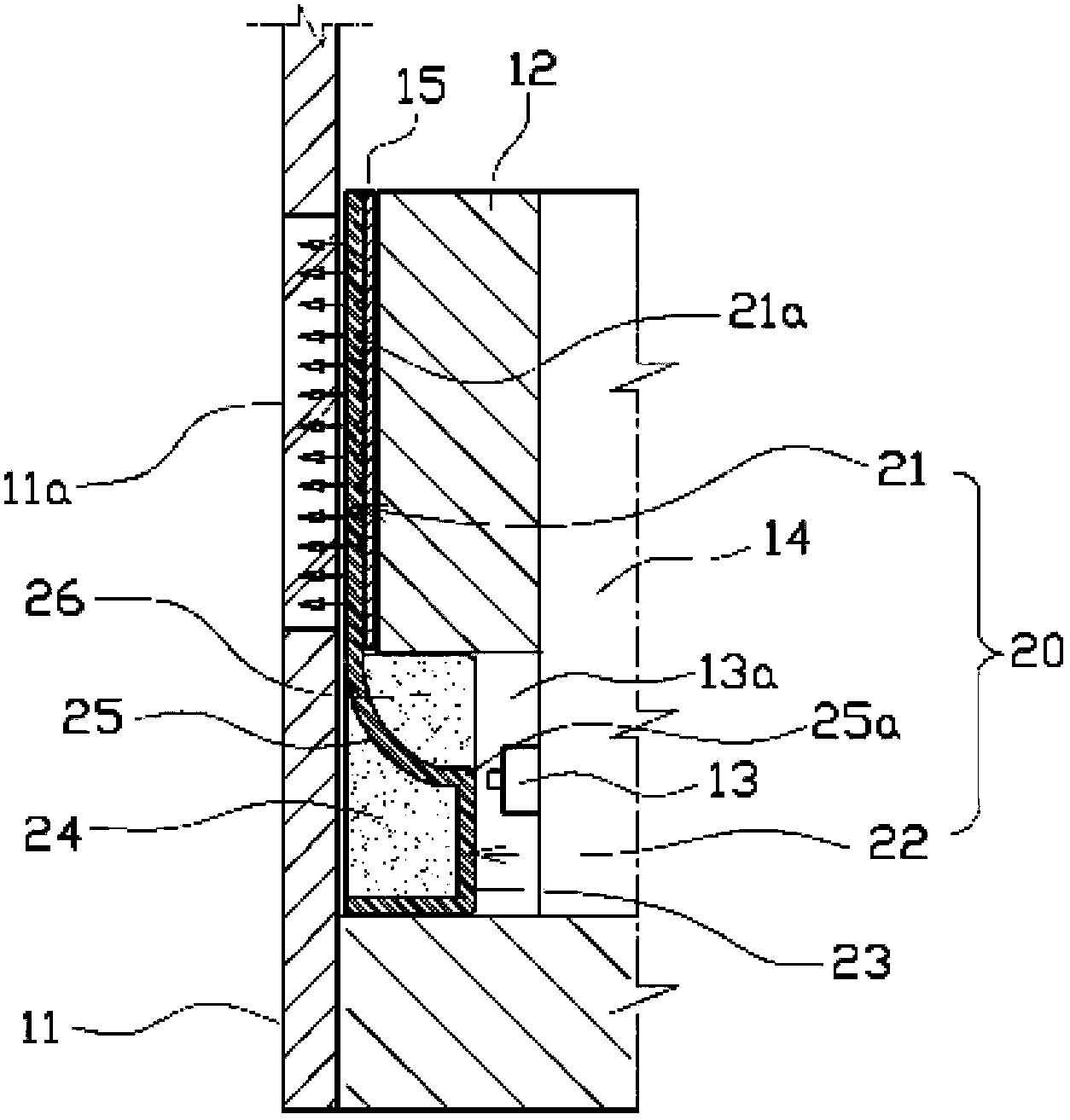

[0043] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. Figure 3 to Figure 5 It represents the setting state and main components of the keyboard light guide film according to the present invention, such as image 3As shown, the light guide film 20 of the present invention is installed between the key portion 11 and the keyboard 12 provided for various functions and switch operations in a mobile terminal such as a mobile phone or an electronic device.

[0044] The light guide film 20 is composed of a light diverging part 21 located below the display part 11 a of the key part 11 and a light introducing part 22 provided on the printed circuit board 14 and located above the light source. The light guide film 20 is manufactured by injection molding of a light diffusing material such as PC (polycarbonate) or PET (polyethylene terephthalate) resin.

[0045] The light guide film 20 configured as abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com