Patents

Literature

49results about How to "Guaranteed tightness and stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

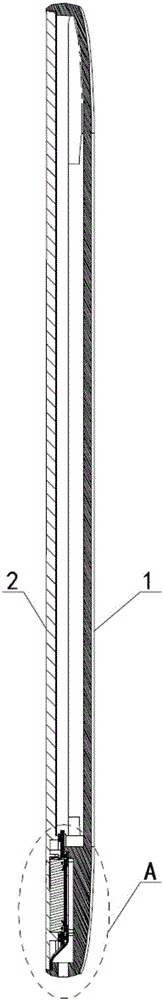

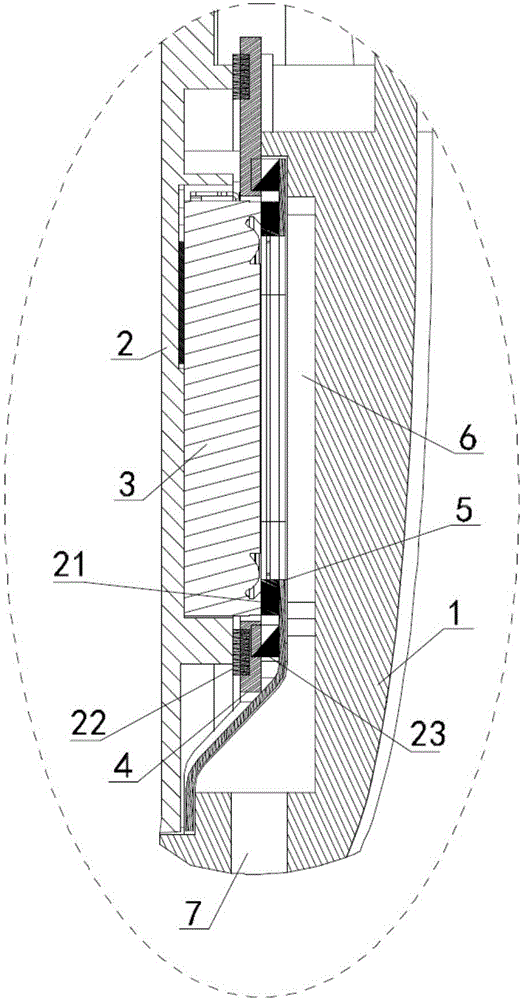

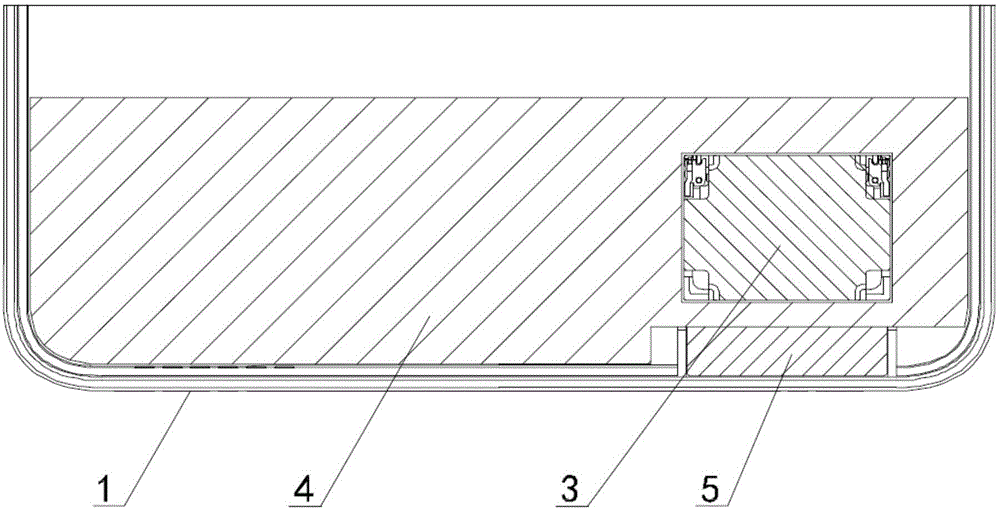

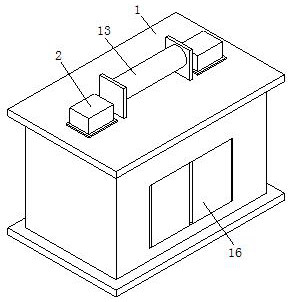

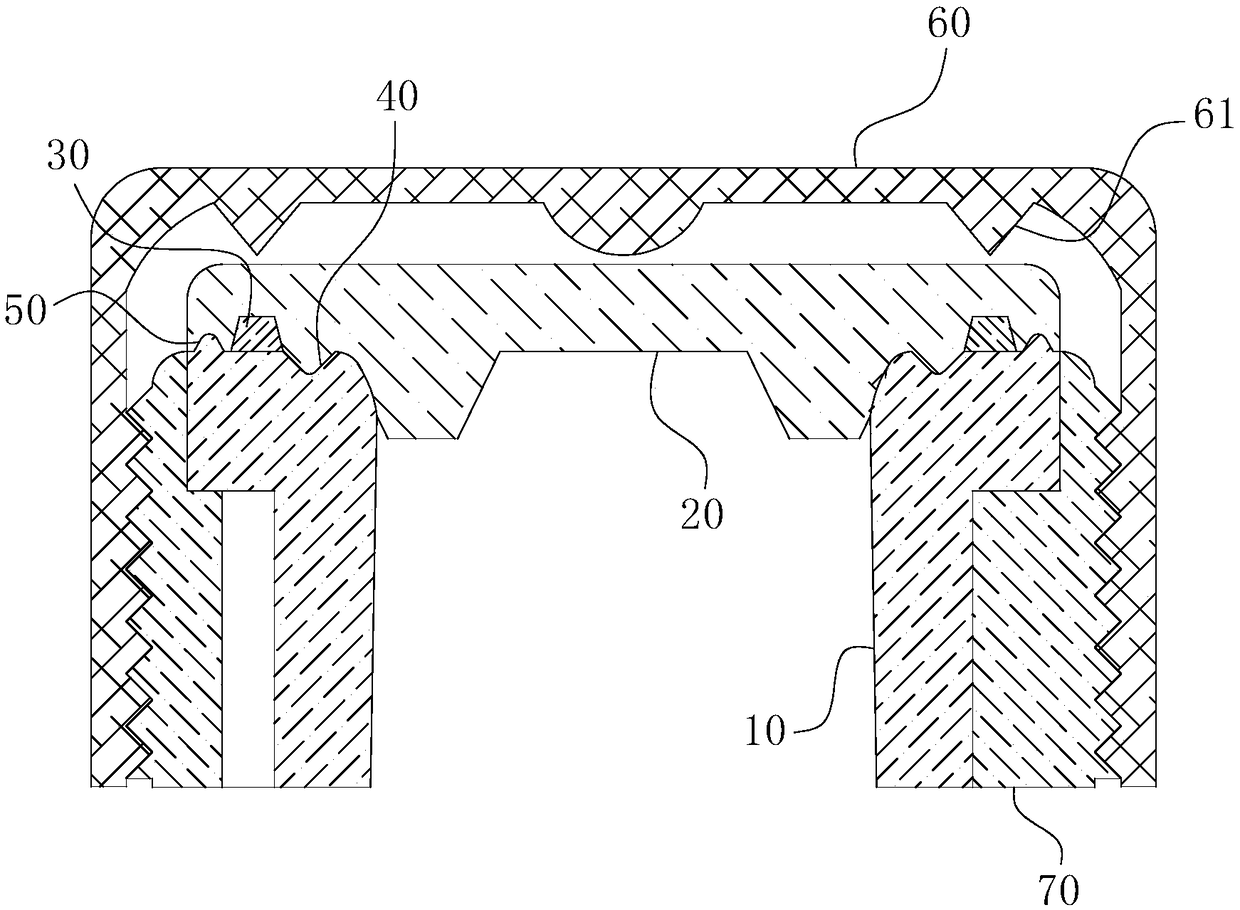

Sound cavity structure and mobile terminal

ActiveCN106714047AReduce manufacturing costImprove sealingElectrical transducersTelephone set constructionsComputer terminalEngineering

The invention discloses a sound cavity structure and a mobile terminal. The sound cavity structure comprises a shell and a circuit board, a loudspeaker and a supporting plate which are arranged in the shell. The shell comprises a first shell body and a second shell body which are mutually connected. The first shell body is provided with a sound outlet hole penetrating through the first shell body. The internal side of the first shell body is provided with a front cavity channel communicated with the sound outlet hole. The internal side of the second shell body is provided with a slot body used for accommodating the loudspeaker. The mobile terminal comprises the sound cavity structure and a display screen. The display screen is installed at the external side of the second shell body. The sound cavity structure can be applied to the technical field of communication electronics, the defects in the prior art can be effectively overcome by applying the sound cavity structure, an independent application of the integrated BOX can be replaced by the optimized connection arrangement of the component, the limitation caused by the mould manufacturing period and the manufacturing cost of the integrated BOX can be eliminated, the concrete composition of the sound cavity structure can be optimized, the sealing problem caused by the integrated BOX can be avoided and the overall sealing performance of the structure can be enhanced.

Owner:NUBIA TECHNOLOGY CO LTD

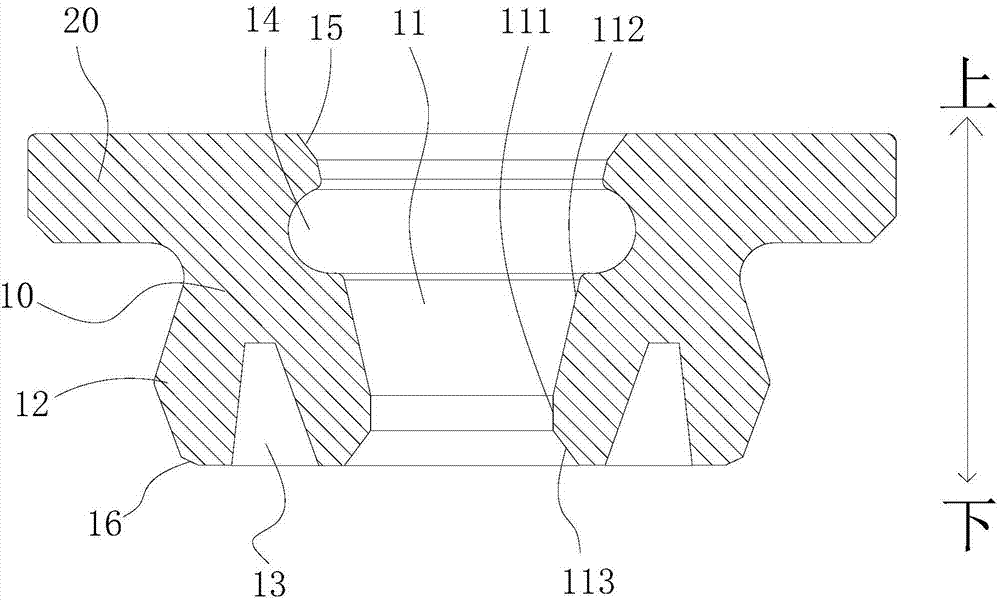

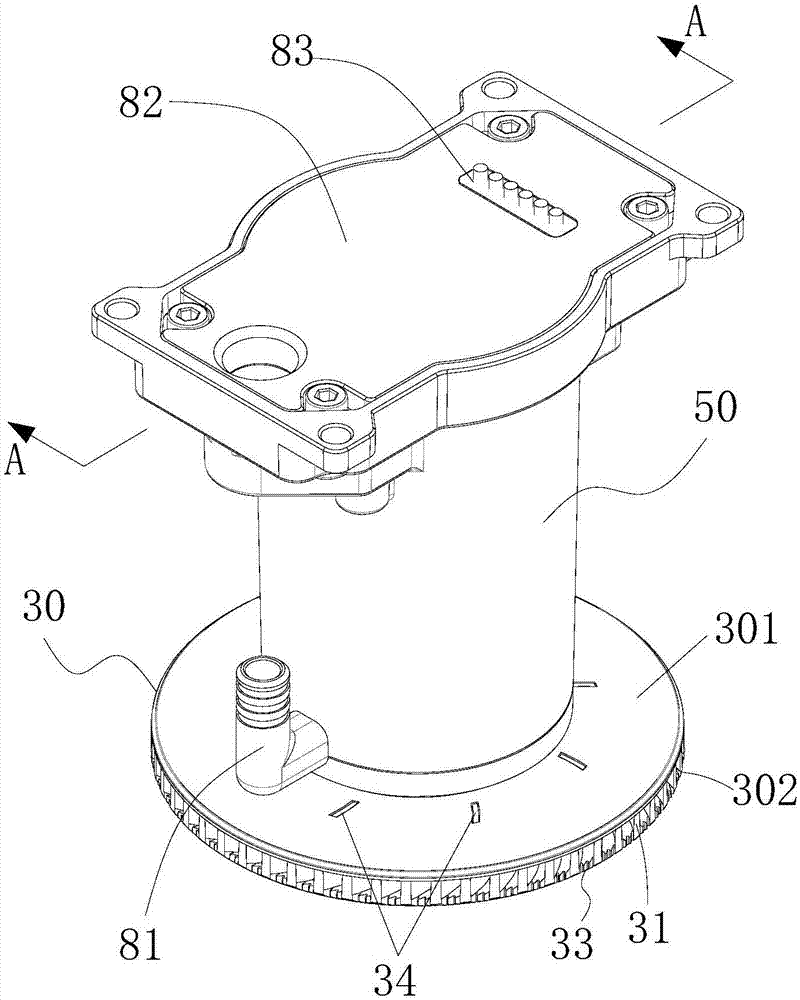

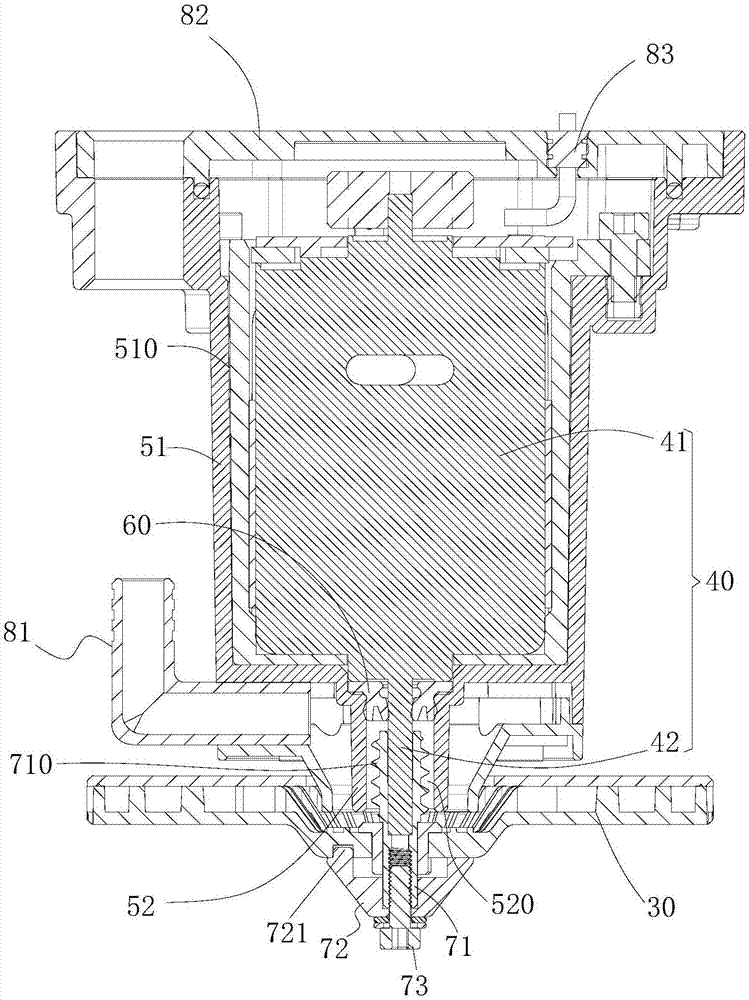

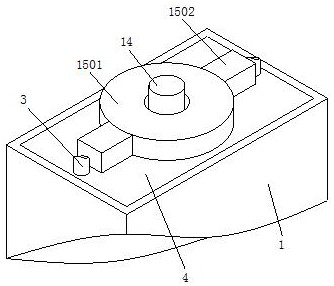

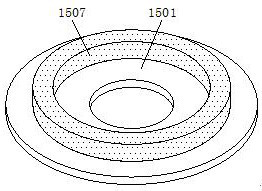

Shaft sealing washer, spraying device and unmanned aerial vehicle

ActiveCN107269844AImproved ability to optimize dynamic adaptive elastic deformationImprove elastic deformation abilityAircraft componentsEngine sealsDrive shaftEngineering

The invention provides a shaft sealing washer, a spraying device and an unmanned aerial vehicle. The shaft sealing washer is used for mounting a drive shaft and comprises a sealing washer body; the sealing washer body is provided with a first end and a second end opposite to the first end; the sealing washer body is provided with an assembly through hole penetrating through the first end and the second end of the sealing washer body; the first end of the sealing washer body is provided with a contracting groove close to the assembly through hole; a contact portion, between the assembly through hole and the contracting groove, of the sealing washer body is elastic; and when the drive shaft penetrates through the assembly through hole, the contact portion of the sealing washer body moves towards the contracting groove under abutting-pressing of the drive shaft to generate elastic deformation. By the adoption of the technical scheme, the technical problem that sealing performance between a drive shaft and a mounting shell is poor due to poor elastic deformation performance of a sealing washer in the prior art can be solved.

Owner:GUANGZHOU XAIRCRAFT TECH CO LTD

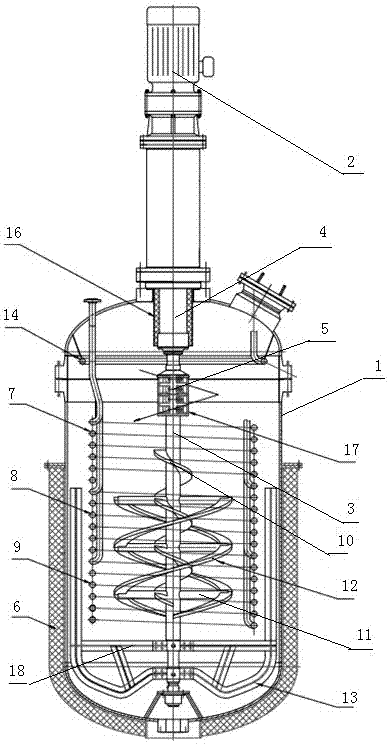

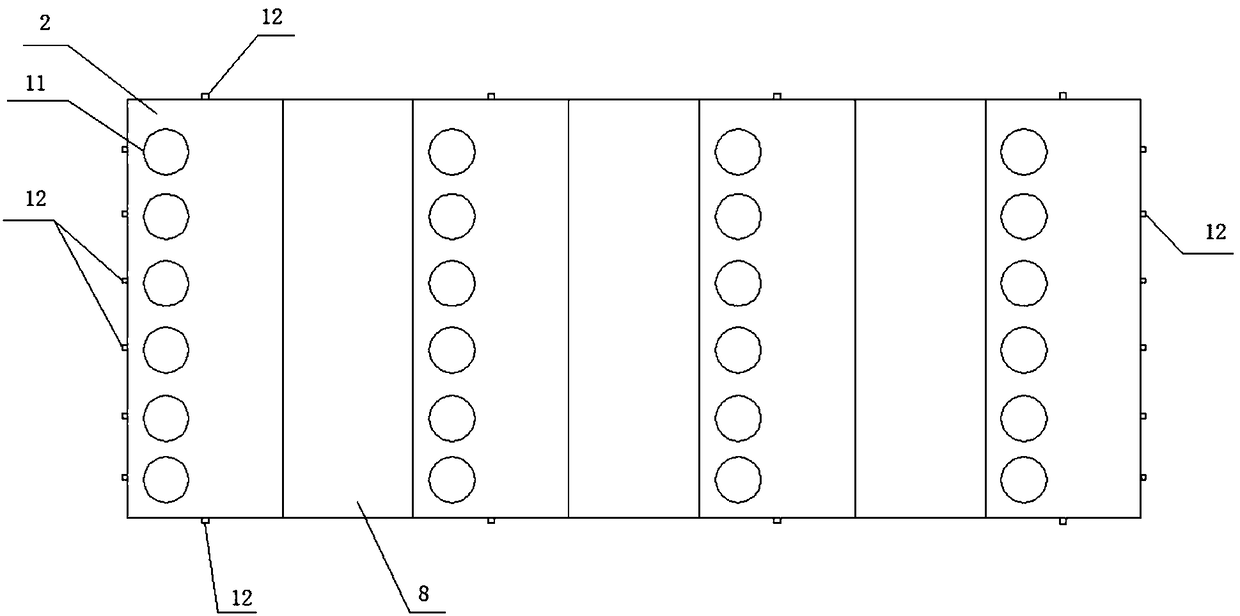

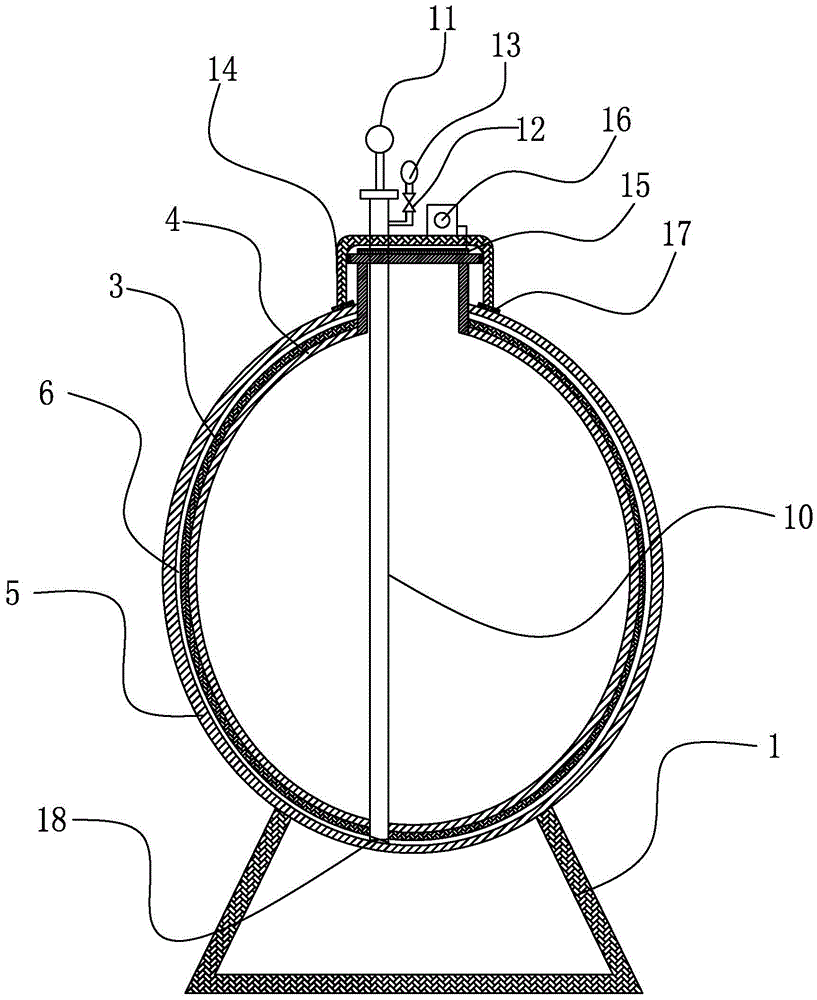

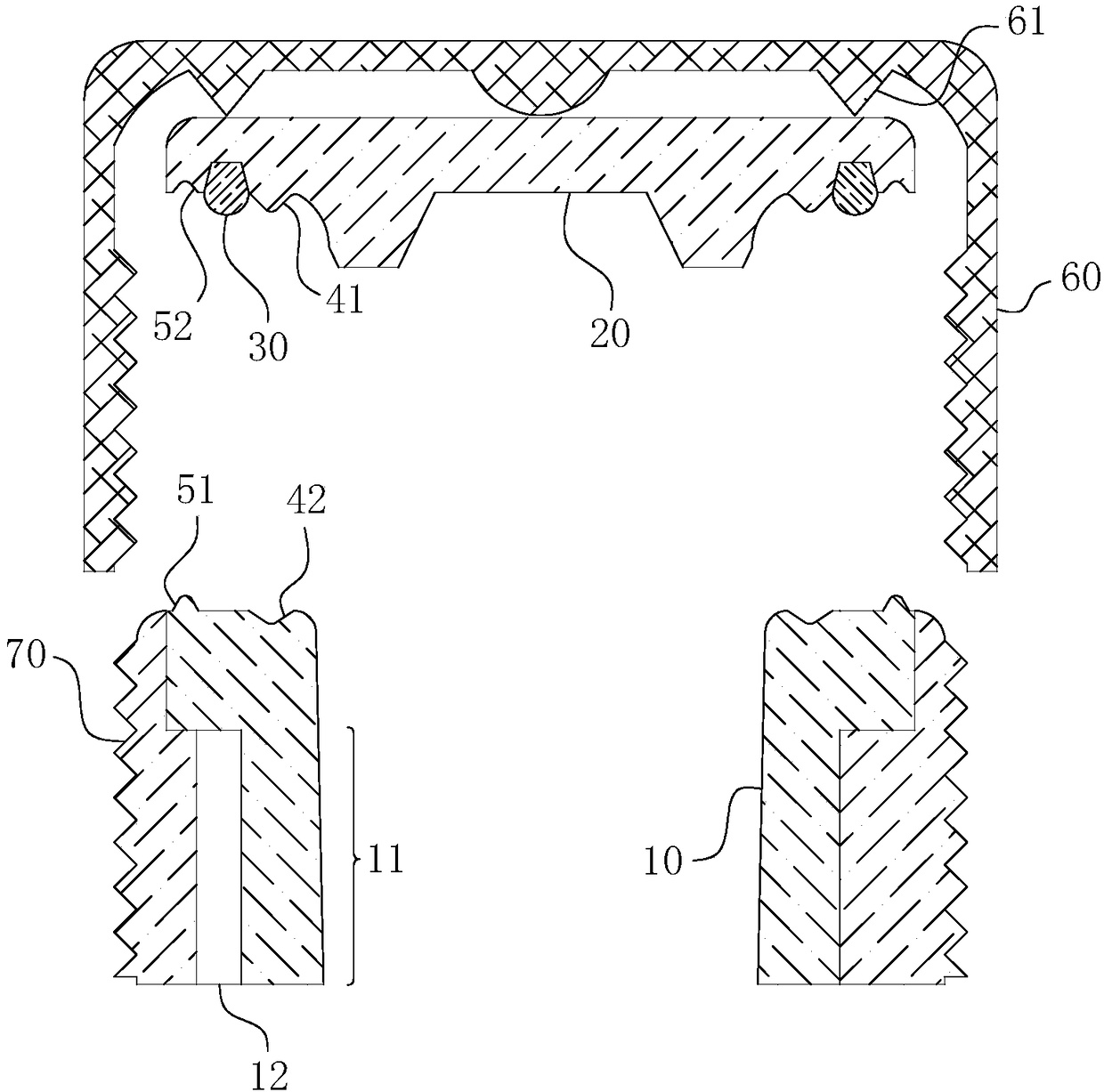

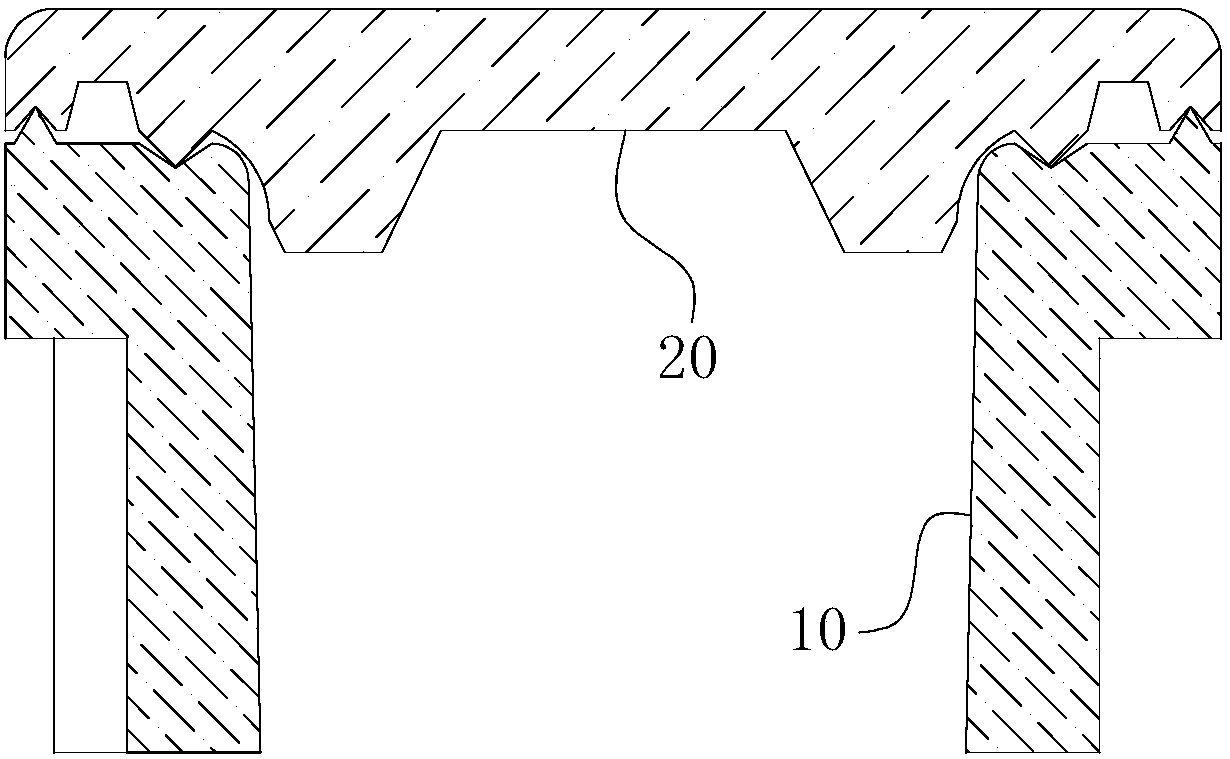

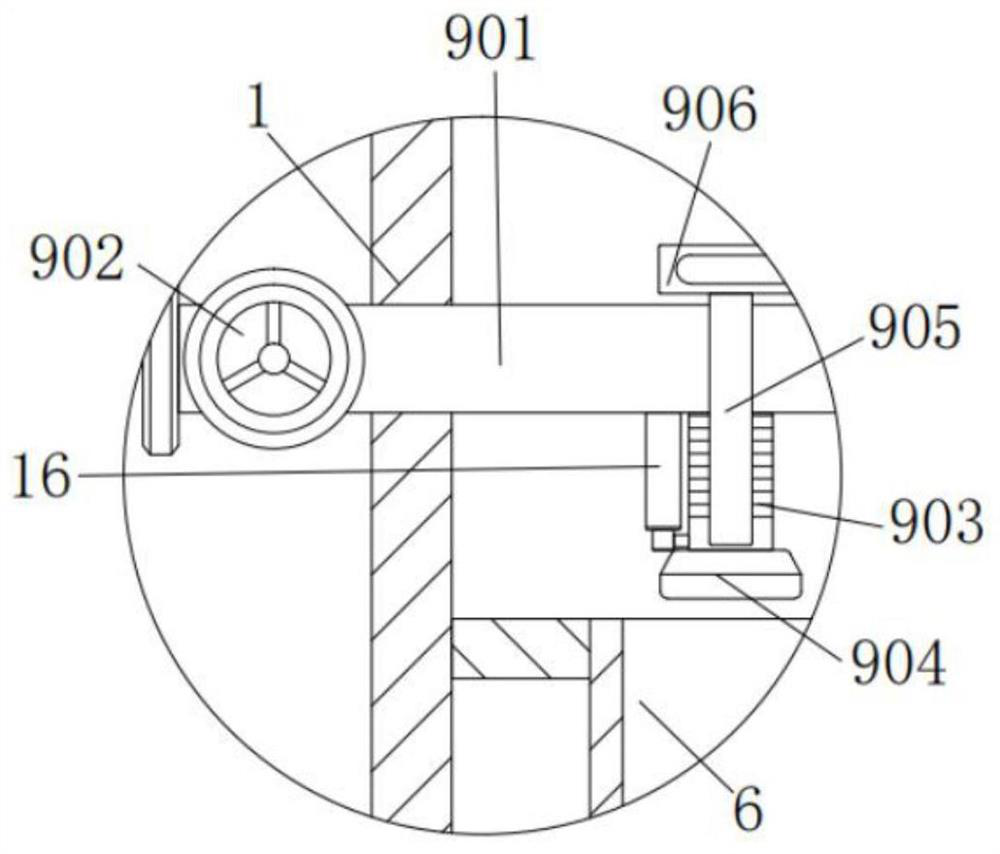

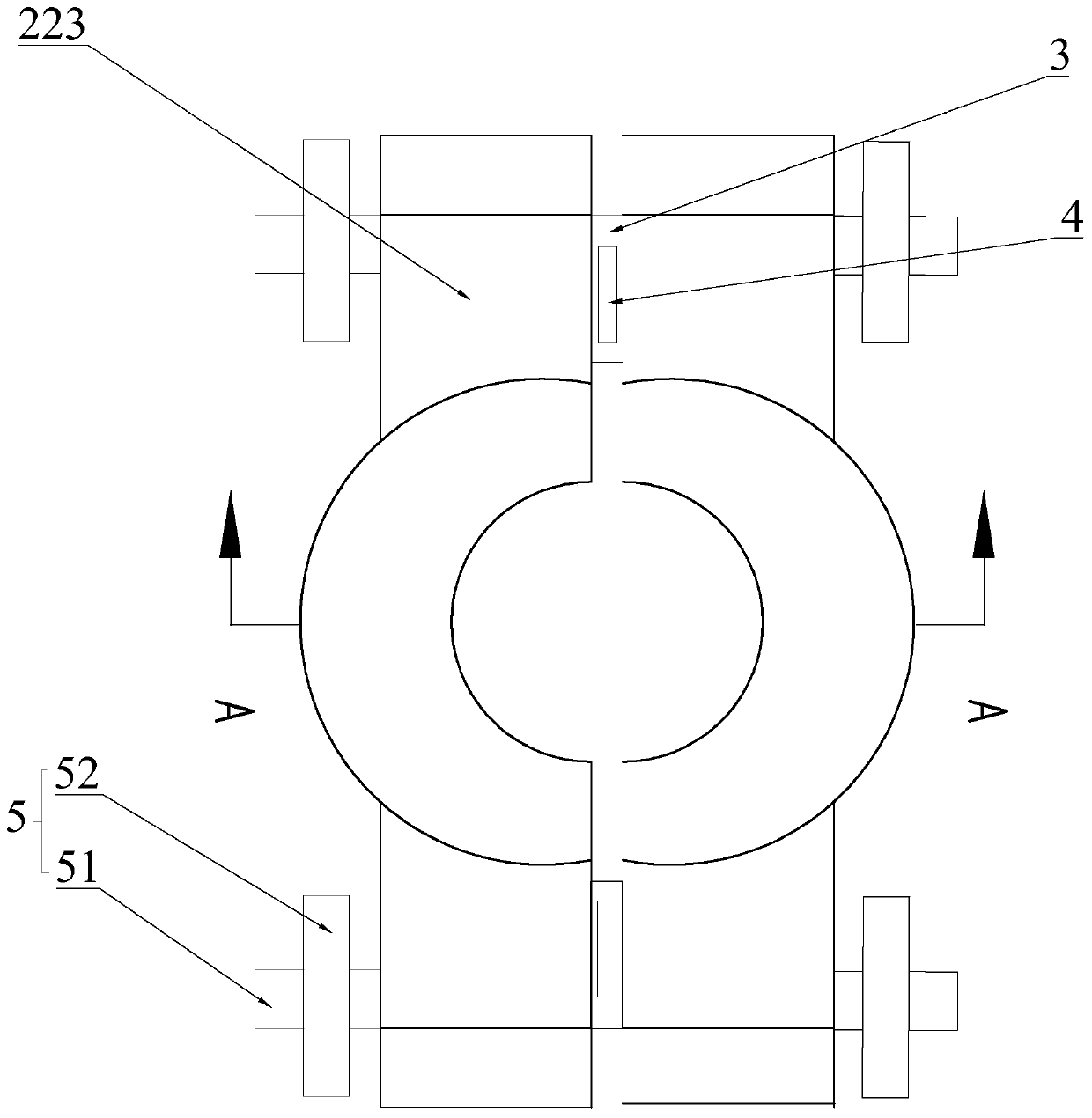

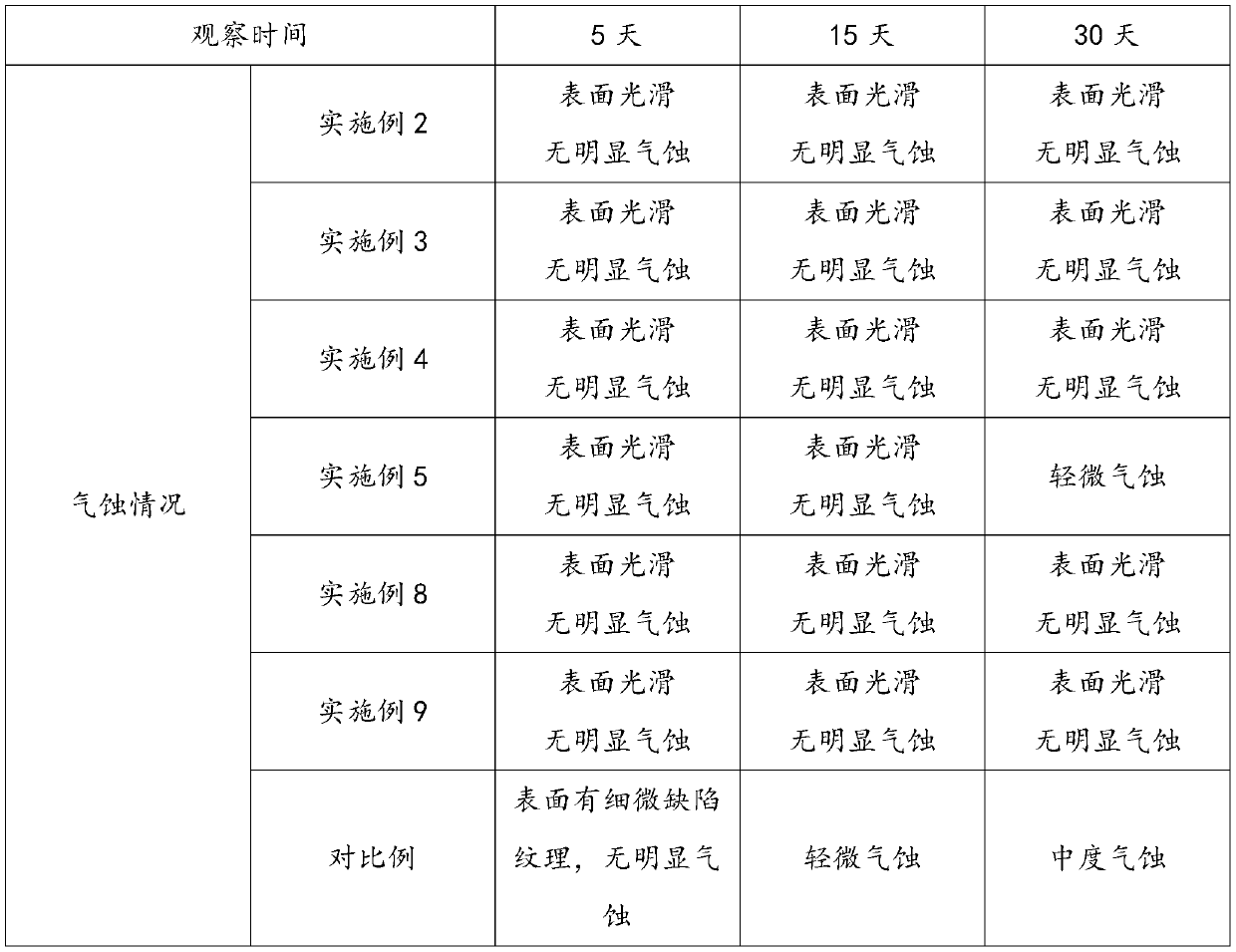

Polymeric reactor for polyphenylene sulfide

PendingCN107570086AGuaranteed tightness and stabilityReduce exchangePressurized chemical processChemical/physical/physico-chemical stationary reactorsTemperature controlManufacturing technology

The invention relates to the technical field of chemical mechanical stirring reactor manufacturing and specifically relates to a polymeric reactor for polyphenylene sulfide. The polymeric reactor comprises a kettle body, a stirring motor, a stirring shaft, a stirrer and a magnetic coupling sensor, wherein the stirring motor is arranged above the kettle body; an output shaft of the stirring motor is connected with a magnetic coupling driver inserted into the kettle body; the upper end of the magnetic coupling driver is connected with the stirring motor; the lower end of the magnetic coupling driver is connected with the stirring shaft through a coupler; the stirrer is arranged on the stirring shaft; the polymeric reactor is characterized in that an external quick temperature control mechanism, an internal auxiliary temperature control mechanism and an anti-adhesion stirring mechanism are arranged on the kettle body. The polymeric reactor has the advantages of simple structure, convenience in cleaning, stable and easy controllable reaction temperature, benefit in continuous operation high efficiency, high yield, and the like.

Owner:WEIHAI CHEM MACHINERY

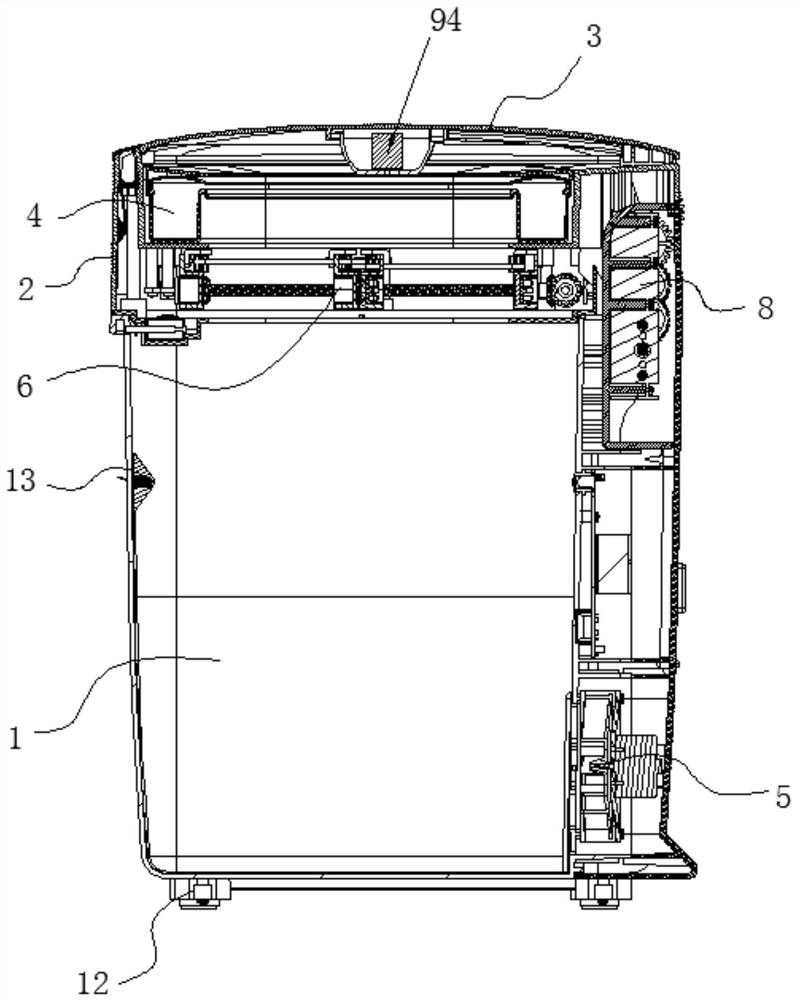

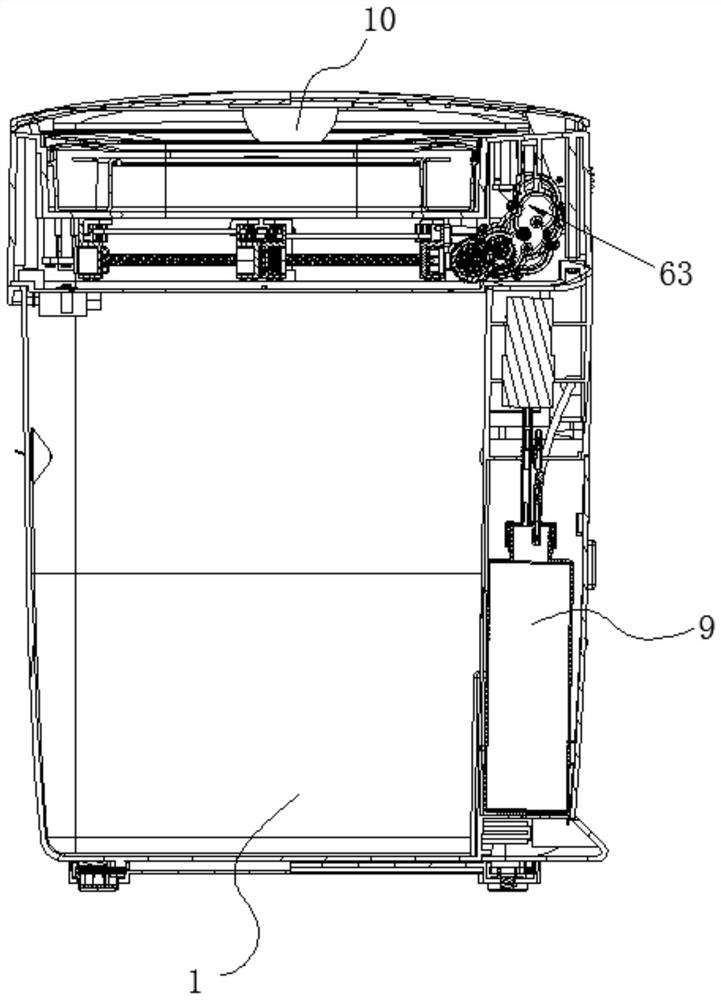

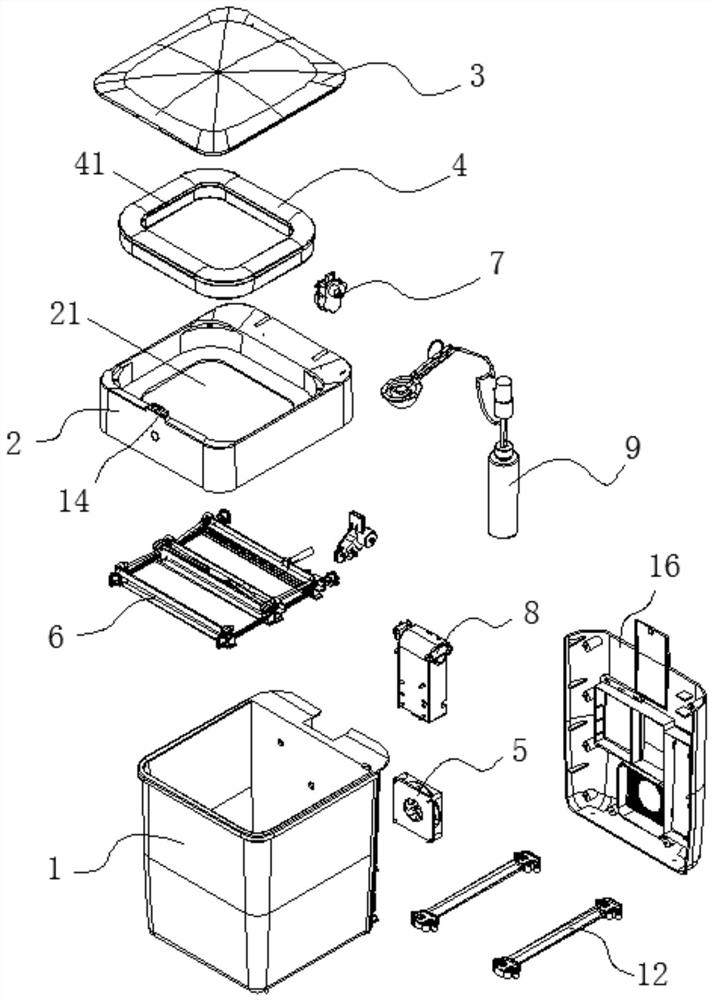

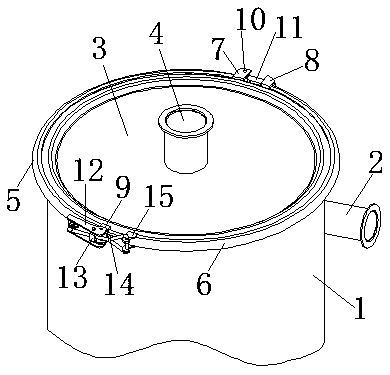

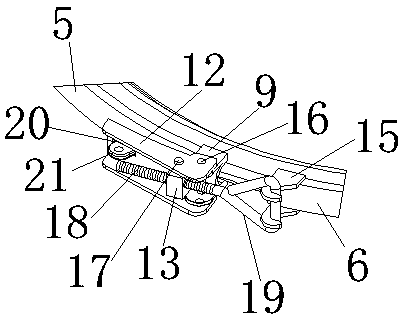

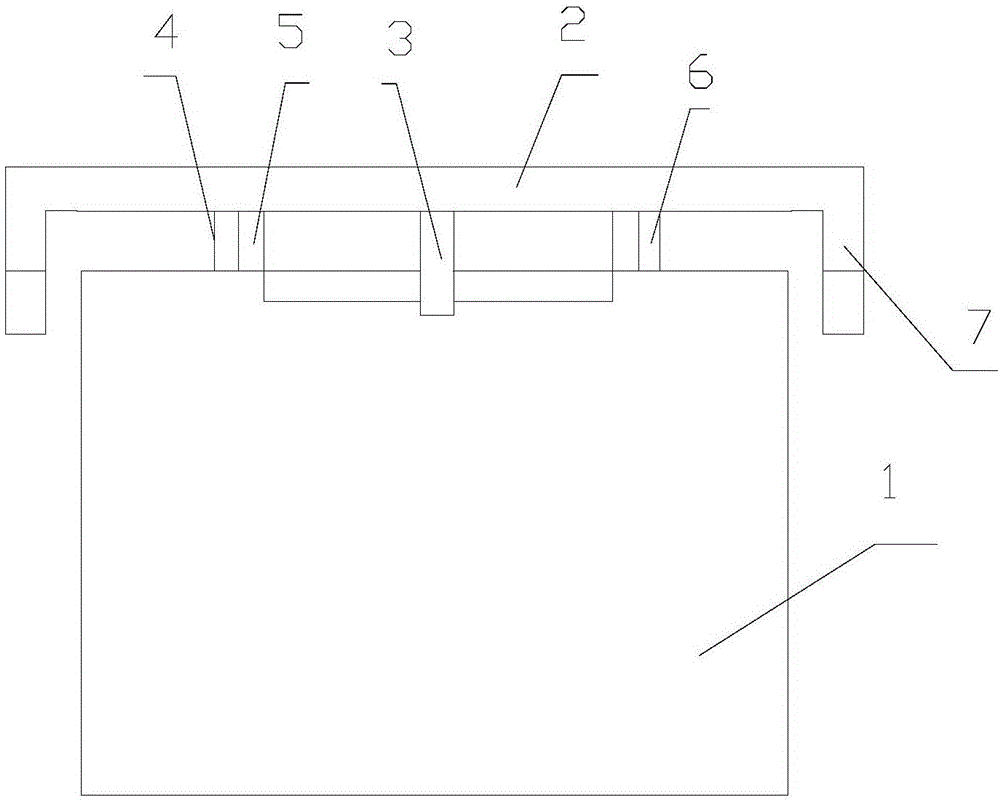

Novel automatic packaging intelligent garbage can

ActiveCN114194667AAchieve a well-proportioned finishEvenly around the doseWaste collection and transferRefuse receptaclesPlastic packagingEngineering

The novel automatic packaging intelligent garbage can comprises a can body, a middle cover, a top cover and a garbage bag box, an exhaust fan is arranged at the lower end of the can body, and an automatic closing thermal plastic sealing cutting mechanism is arranged in the middle cover; the automatic closing-up thermal plastic sealing cutting mechanism comprises a first lead screw, a second lead screw, a lead screw driving device, a folding rod set used for forcing a garbage bag opening to be folded inwards left and right, and a thermal plastic sealing bag cutting device used for conducting thermal plastic sealing on the garbage bag and cutting off the garbage bag. The cold pressing end device is used for being matched with the thermal plastic packaging bag cutting device to tightly press a garbage bag opening front and back, and the folding rod set comprises a first folding rod, a second folding rod, a third folding rod and a fourth folding rod. According to the garbage can, automatic packaging and sealing operation of the garbage bag can be achieved, the automatic closing-up thermal plastic sealing cutting mechanism is simple in structure, stable in sealing quality and high in speed, uniform closing-up of the garbage bag can be achieved, a uniform and flat packaging and sealing face is formed on the opening of the garbage bag, and the using amount of the periphery of the garbage bag is uniform.

Owner:邹志刚

3D printing and forming integrated program-controlled valve group

ActiveCN109323019ACompact structureReduce volumeAdditive manufacturing apparatusMultiple way valvesCavitationEngineering

The invention discloses a 3D printing and forming integrated program-controlled valve group. The advantage of quick and precise forming of a 3D printing technique is used, so that the integrated program-controlled valve group in which a flow channel is integrated is obtained; multiple complex pipelines and valve components are integrated with the integrated program-controlled valve group in the mode of unit blocks in the prior art, so that an onsite valve area of an adsorption processing system has the advantages of the compact structure, small size and convenience in modularization, skid mounting, equipping and vehicle mounting. Additionally, for the integrated program-controlled valve group, a novel 3D printing and forming process in which a printing and forming process, a permeating process and a sintering process are combined is provided, the quick forming characteristic of 3D printing is taken, after a workpiece is formed, the surface of the inner wall of a complex flow channel issmooth and has excellent antiwear cavitation resistant capability, and the problems of difficulty in processing and forming and poor surface performance of the wall of the flow channel after formingwhen the integrated level of the designed flow channel is overhigh in the skid mounting design process of the valve area of the adsorption processing system are completely solved.

Owner:ZHEJIANG TIANCAIYUNJI TECH CO LTD

New energy automobile cooling water pump sealing performance detection structure

InactiveCN113720551AImprove practicalityImprove intuitivenessPump testingMeasurement of fluid loss/gain rateHydraulic cylinderNew energy

The invention relates to the field of water pump detection, and in particular, relates to a new energy automobile cooling water pump sealing performance detection structure which comprises a structure shell, a hydraulic cylinder and a steam generator are fixedly welded to the top end face of the structure shell, a hydraulic rod is connected to the output end of the hydraulic cylinder, and a mounting plate is fixedly welded to the bottom end of the hydraulic rod; the mounting plate is slidably connected into the structural shell in a limiting manner, a driving assembly and a detection assembly are mounted on the mounting plate, a fixed bottom plate is fixedly welded to the bottom end face of the interior of the structural shell, a clamping and positioning assembly is mounted in the fixed bottom plate, and a first sealing assembly is mounted on the driving assembly; a second sealing assembly is mounted at the bottom end of an elastic telescopic hose, and the elastic telescopic hose is fixed to the mounting plate through bolts; and the problems that an existing detection structure cannot conduct rapid, accurate and visual detection analysis and comparison work on the sealing performance of a water pump to be detected in the using process, and practicability is poor are solved.

Owner:山东万合大数据有限公司

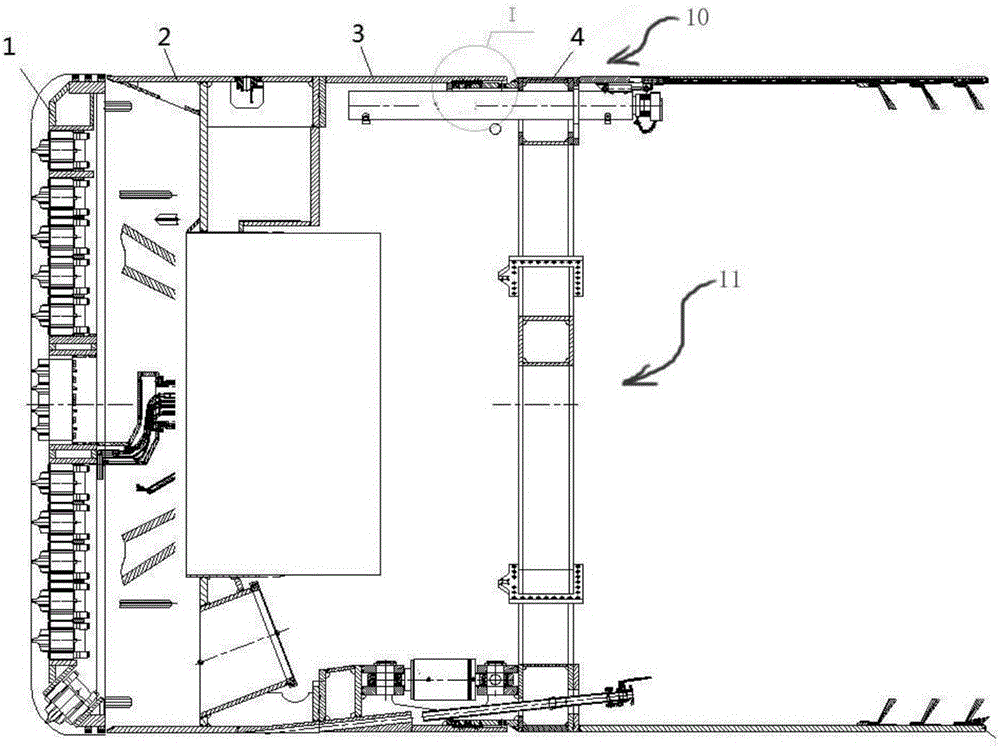

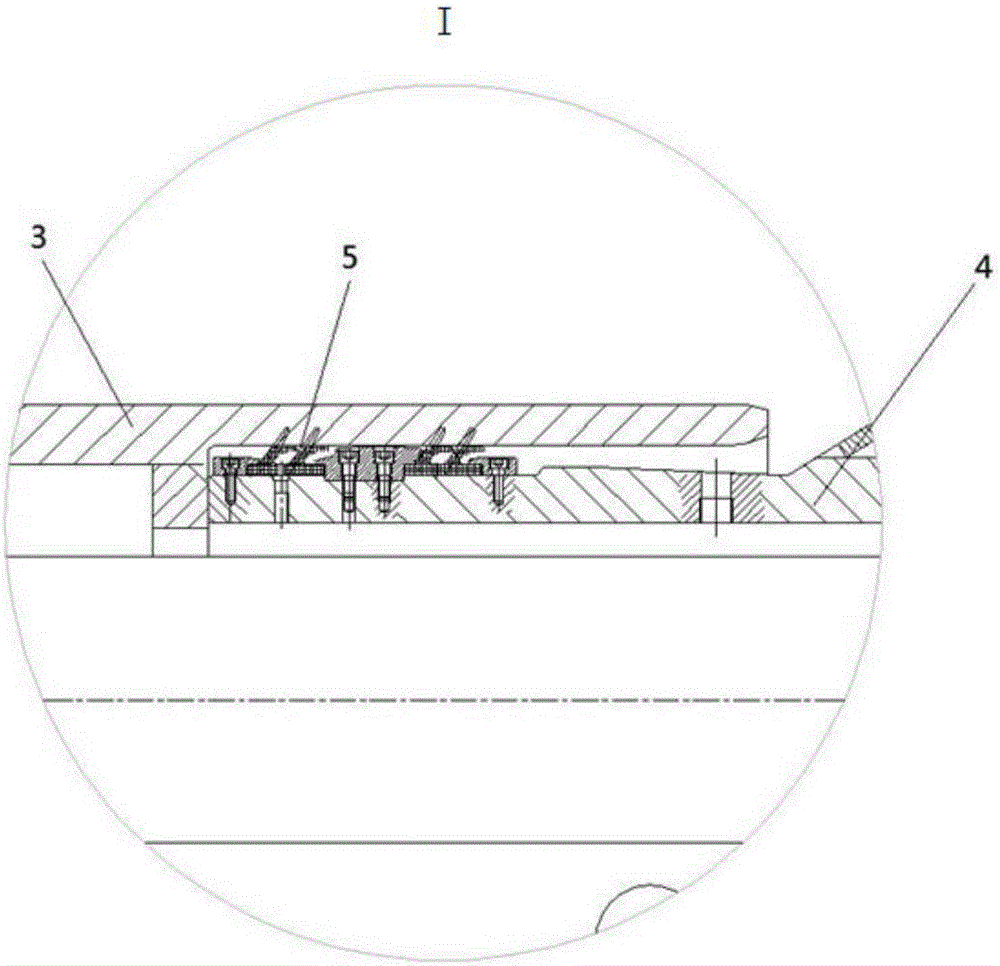

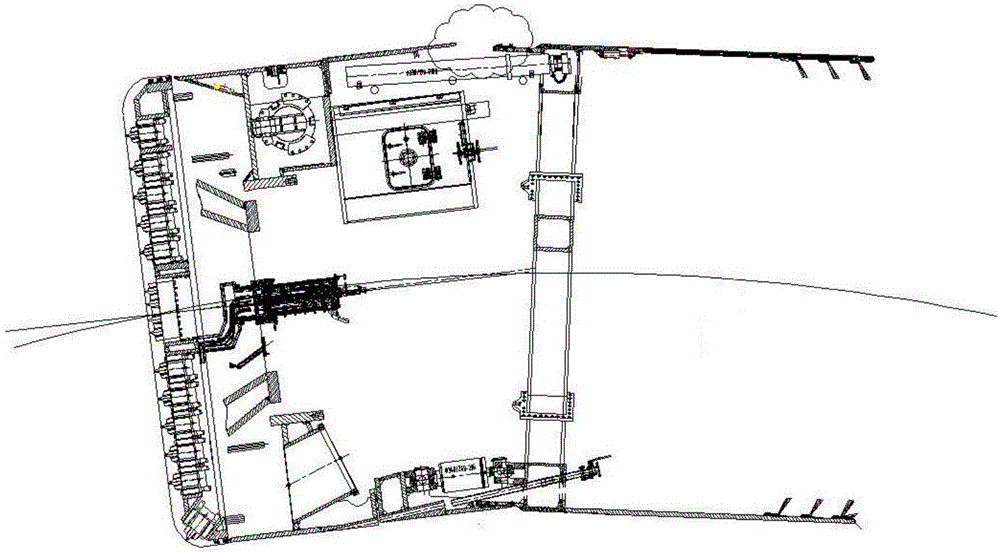

Middle shield and tail shield sealing connection device, shield body of shield machine, and shield machine

The invention belongs to the technical field of tunneling equipment, and particularly discloses a middle shield and tail shield sealing connection device; further, the invention a discloses a shield body of a shield machine using the sealing connection device and the shield machine using the shield body of the shield machine. The middle shield and tail shield sealing connection device provided by the invention comprises a connecting mechanism and a sealing mechanism, wherein the connecting mechanism is connected between the middle shield and the tail shield and allows the middle shield to rotate left and right relative to the tail shield; the sealing mechanism is correspondingly arranged on the middle shield or the tail shield and is in sealing cooperation with the connecting mechanism. The sealing connection mechanism provided by the invention can guarantee that the middle shield and the tail shield rotate relatively to adapt to the turning radius when the shield body turns in the tunnel, and also can maintain sealing isolation of the internal part of the shield body and the external part of the shield body to prevent slurry from reversely pouring and entering the internal part of the shield body.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

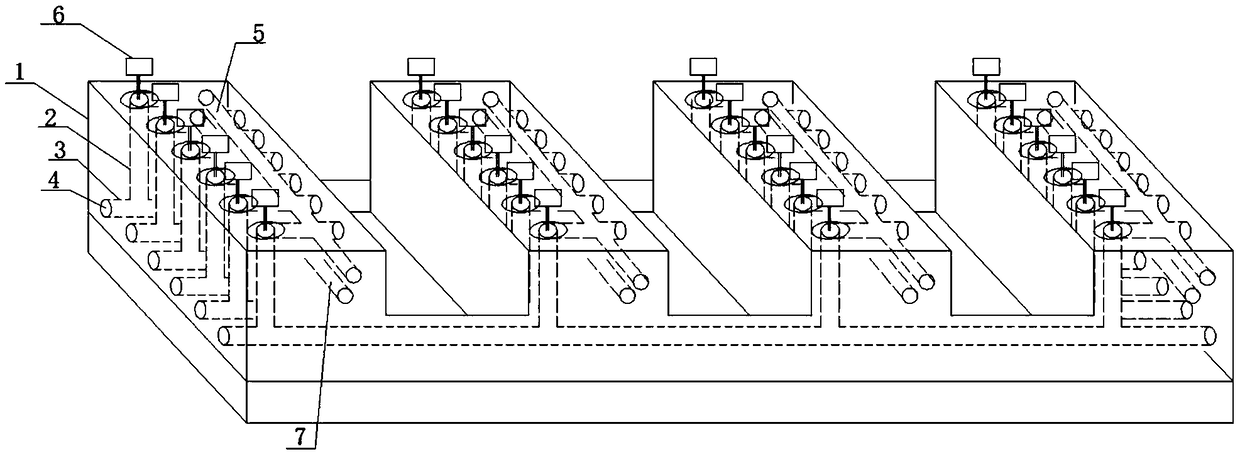

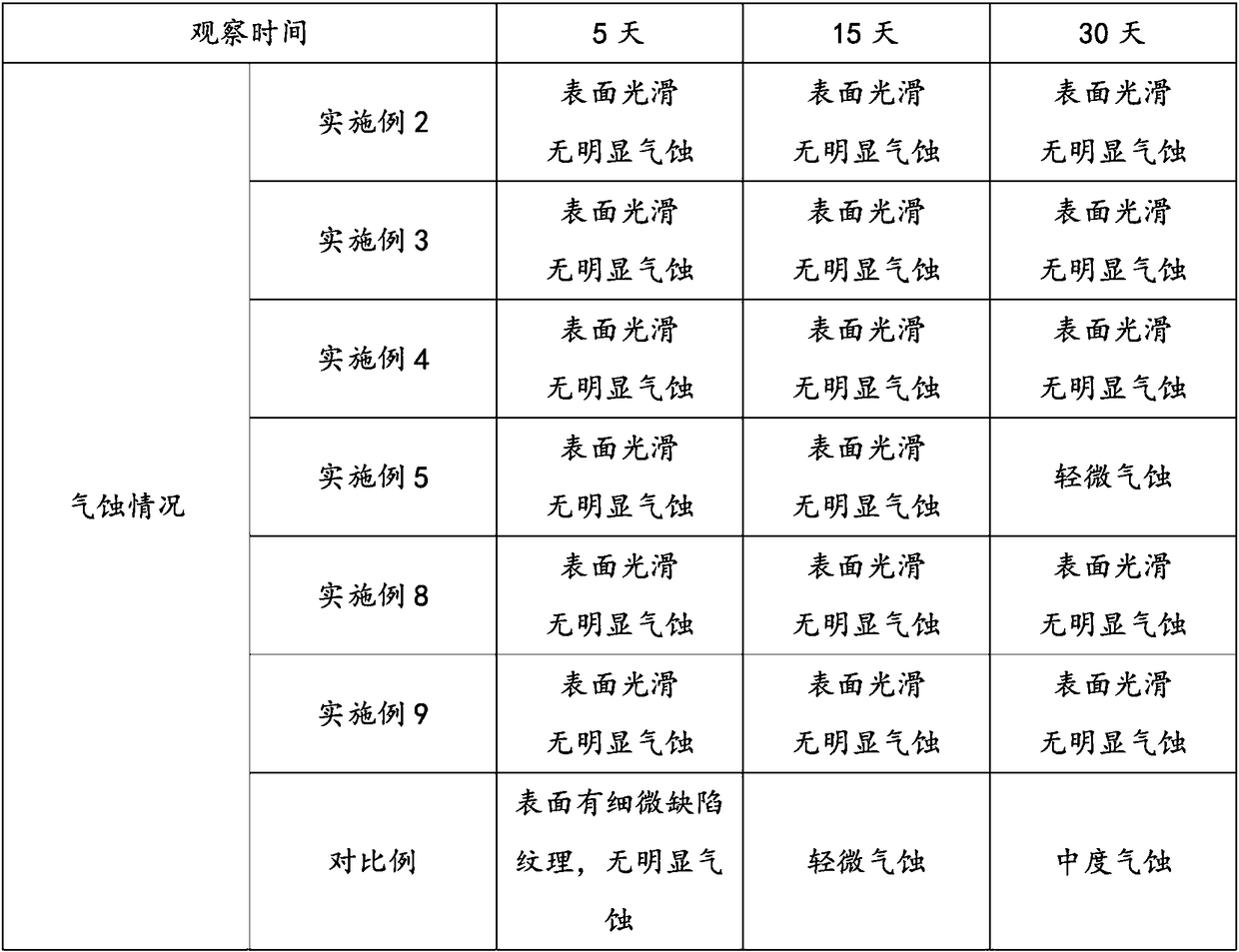

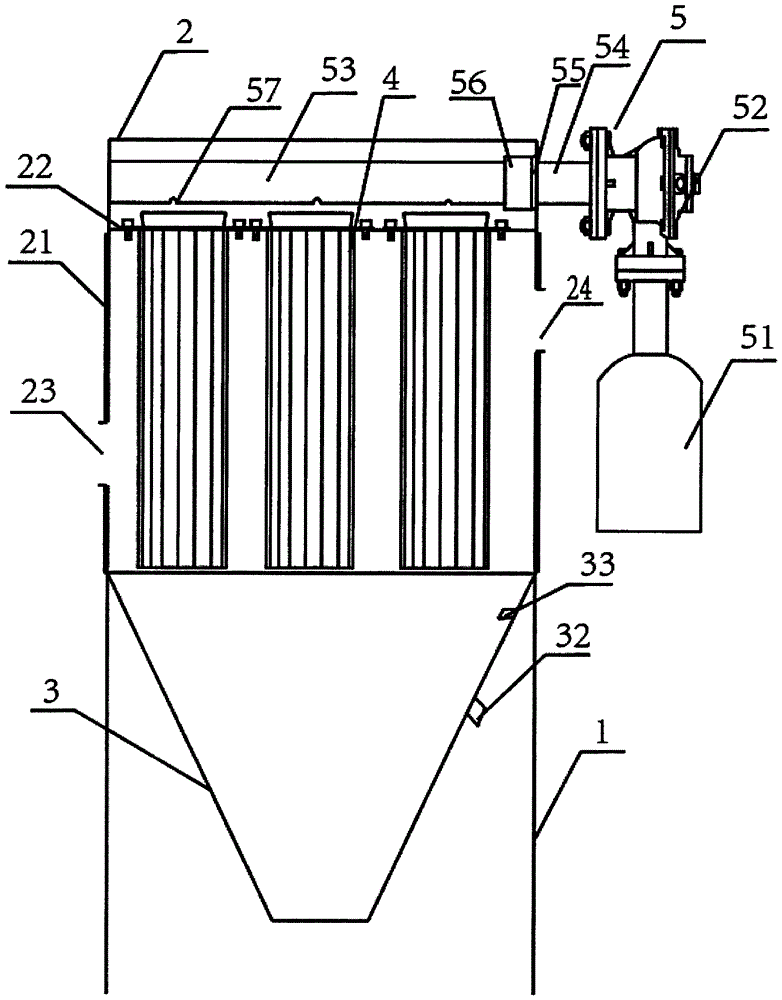

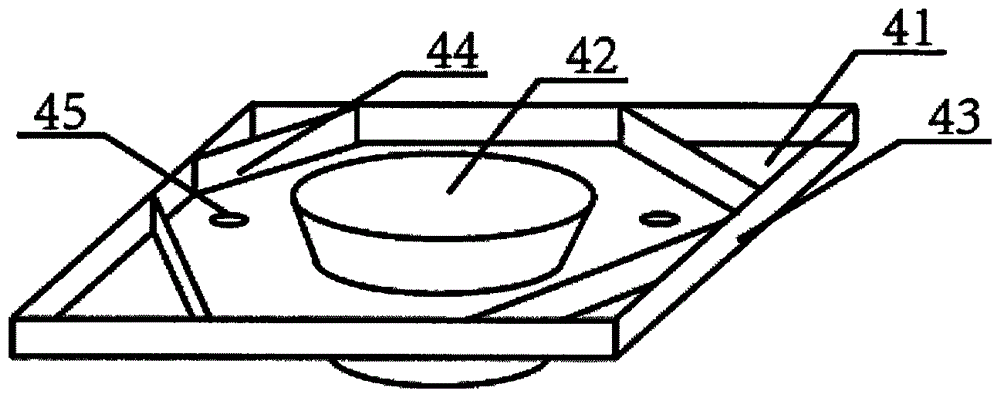

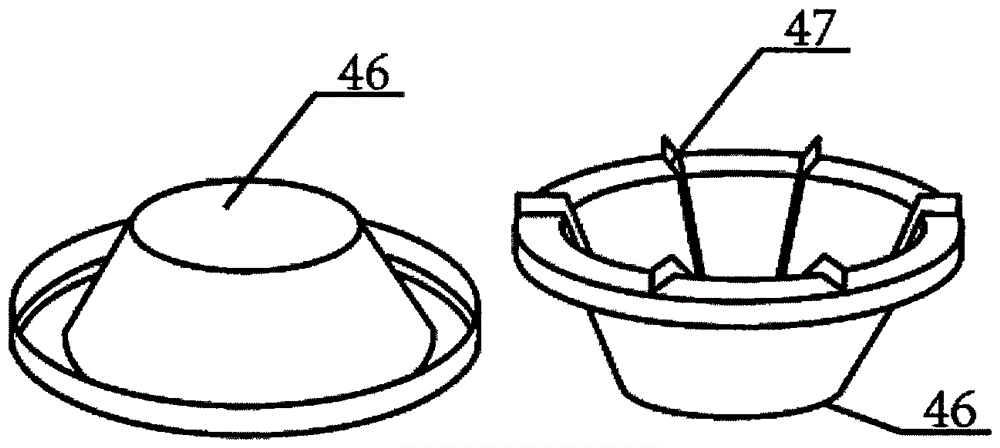

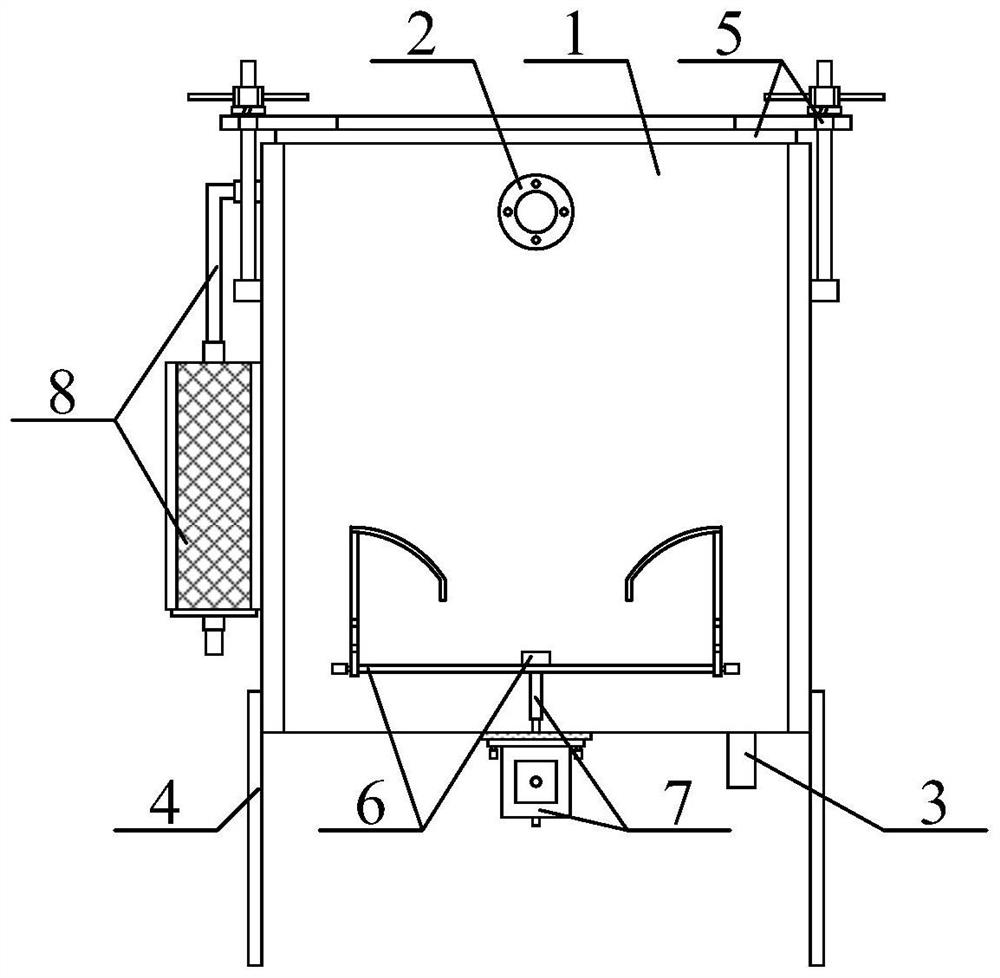

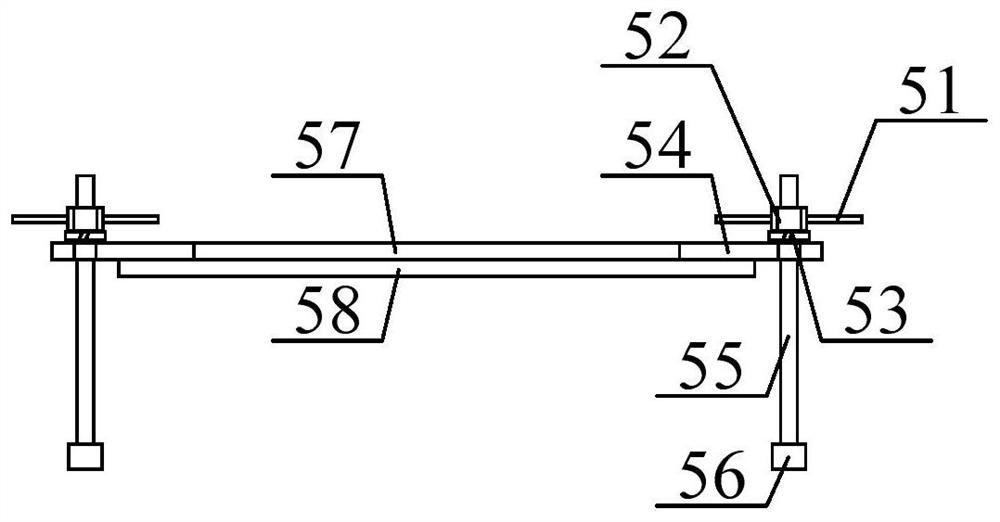

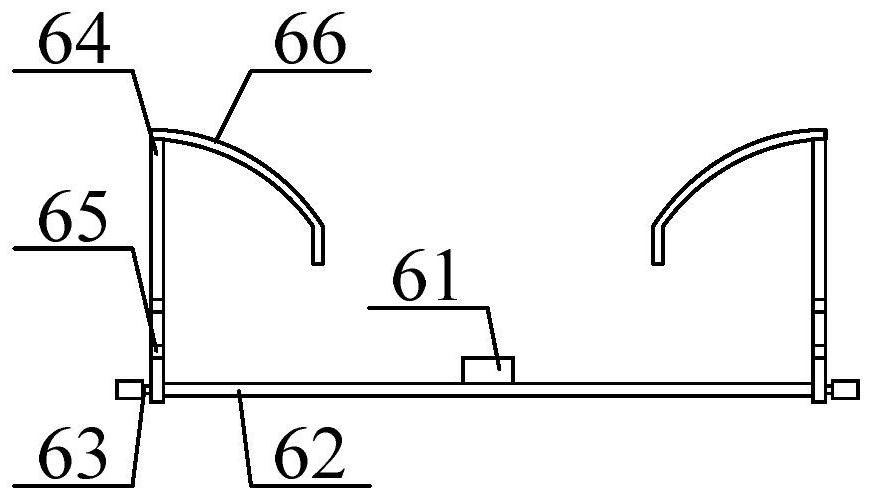

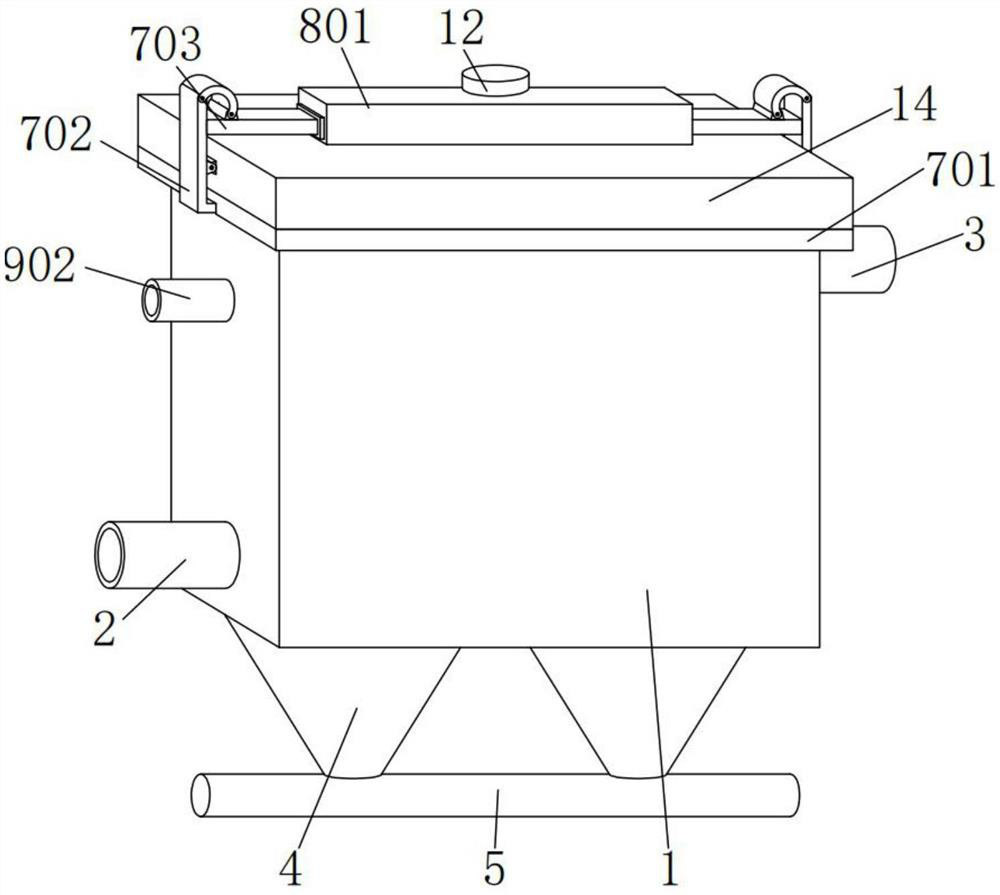

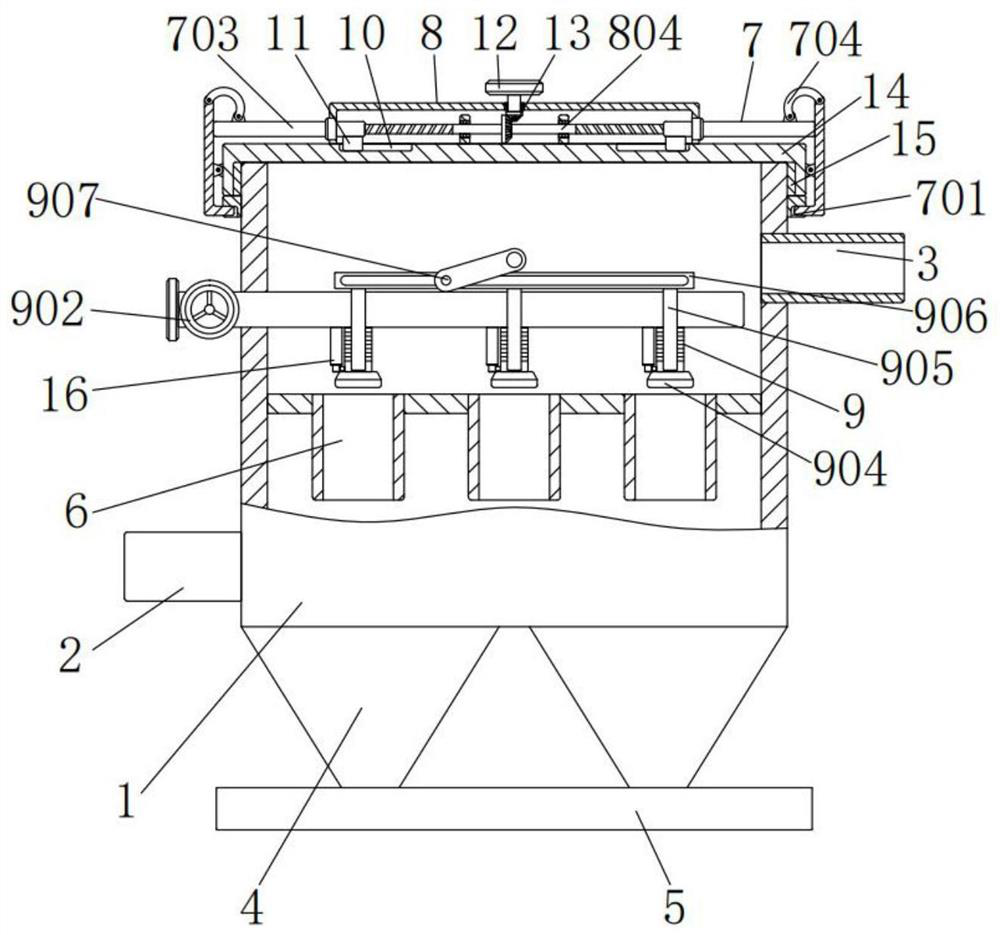

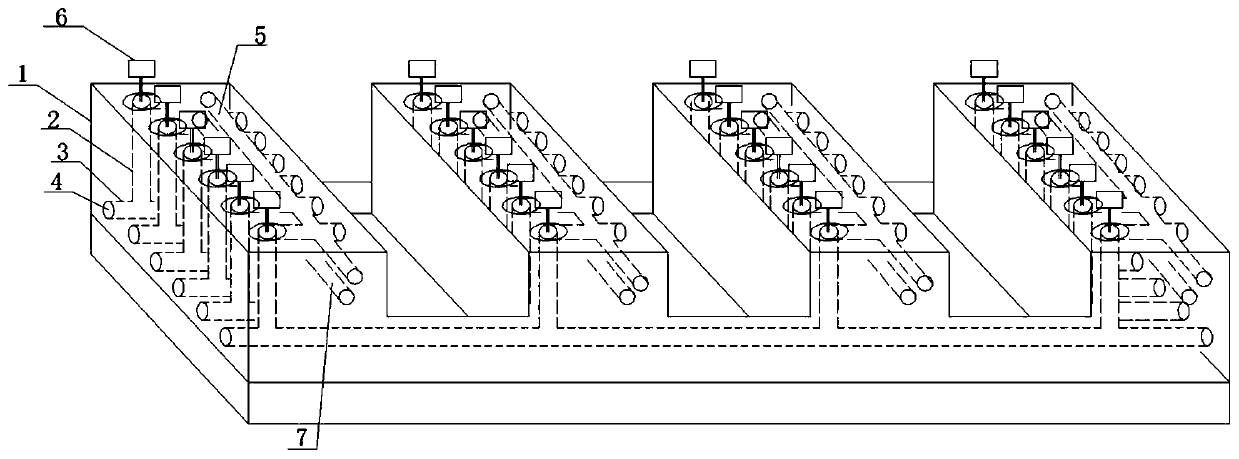

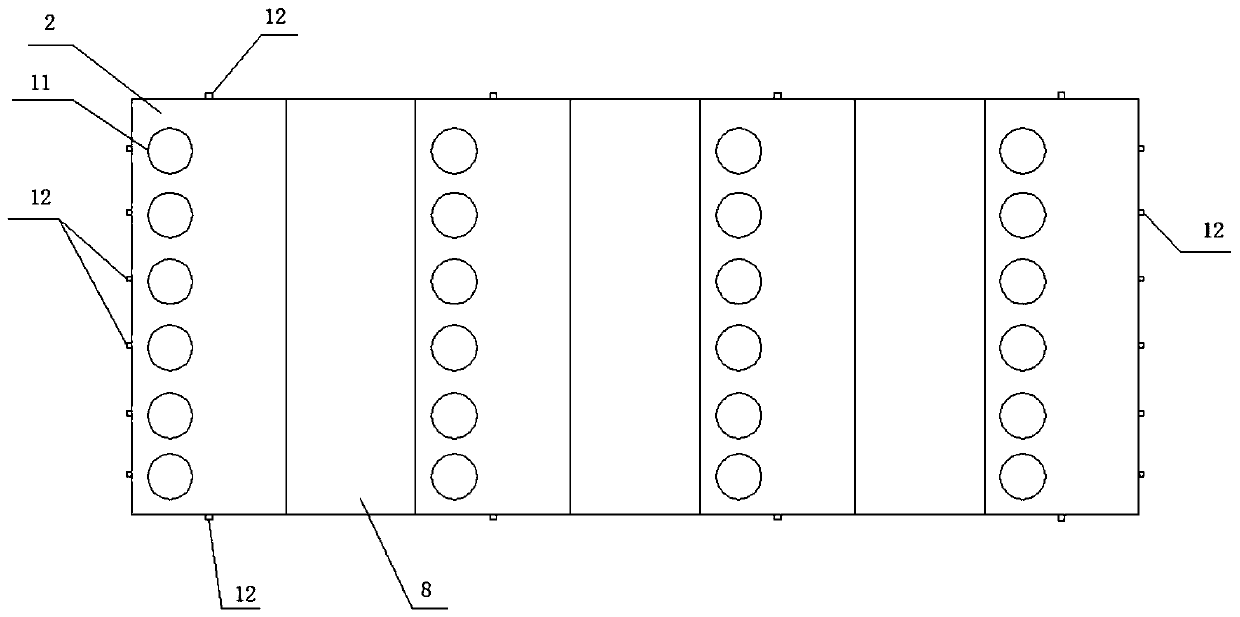

Dry pulse bag type dust collector and application thereof

InactiveCN105771454AHigh mechanical strengthImprove filtering effectDispersed particle filtrationBiochemical engineeringFlue gas

The invention discloses a dry pulse bag type dust collector and application thereof. The dry pulse bag type dust collector comprises a bracket, a square shell, an ash bucket, a filter and an air blowing device, wherein a synergistic effect is achieved by a lower disk of the filter and an upper Venturi-tube pulse airflow inlet, so that a pulse flushing effect is achieved, pulse airflow flow into a filter bag efficiently and more easily, solid impurities on the filter bag are removed effectively, a very good removing effect is achieved, and the filter bag of the filter does not need to be replaced, namely, the filter bag can be recycled. The dry type pulse bag has a reasonable structure, is easy to detach, is suitable for various filter bags; the novel air blowing device is designed, so that a large amount of pulse airflow is introduced effectively, dust sucked by the filter bag is shaken off, and a best cleaning effect is achieved; meanwhile, equipment has long service life, and is suitable for removing dust from high-temperature acid and alkaline coal-fired flue gas.

Owner:SUZHOU BEIJIE ENVIRONMENTAL PROTECTION EQUIP CO LTD

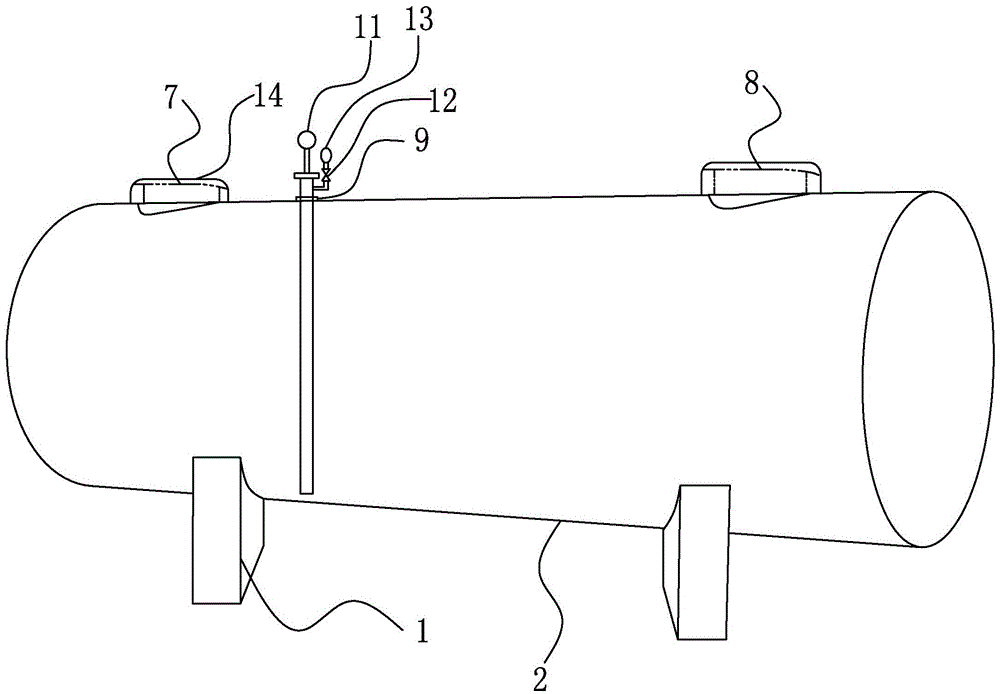

Oil storage tank with sealing property

The invention relates to an oil storage tank with the sealing property. The oil storage tank comprises two or more supports and a tank body arranged on the supports, wherein the supports and the tank body are fixedly connected. The oil storage tank is characterized in that the tank body comprises a tank wall layer, a static conducting coating arranged in the tank wall layer and an anticorrosive layer arranged outside the tank wall layer; a vacuum layer is formed between the tank wall layer and the anticorrosive layer, and an oil inlet, an oil outlet and an inspection port all communicated with the cavity of the static conducting coating are formed in the top of the tank body; sealing covers are installed on the oil inlet and the oil outlet respectively. The oil storage tank has the advantages that the structure is simple, use and installation are convenient, the n-shaped sealing covers integrally formed are used for connecting the oil inlet to the oil outlet through threads, and the sealing stability of the oil storage tank is guaranteed.

Owner:平湖市欧迪雅厨卫设备有限公司

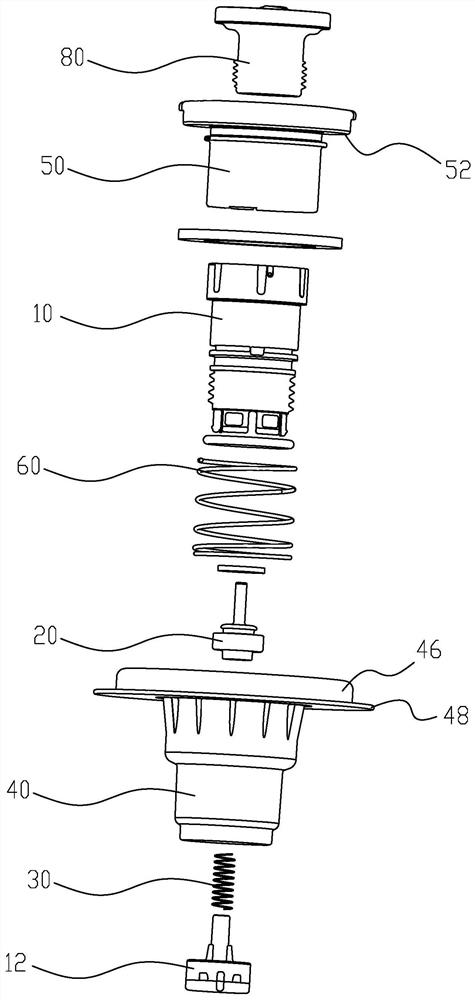

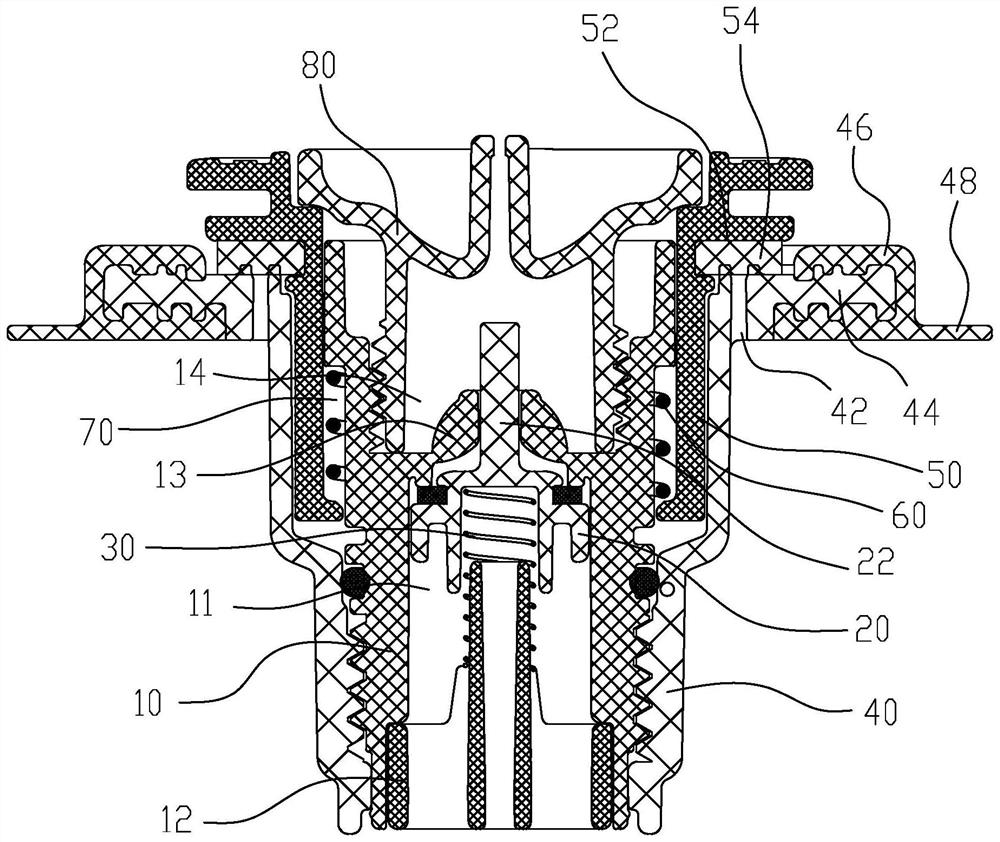

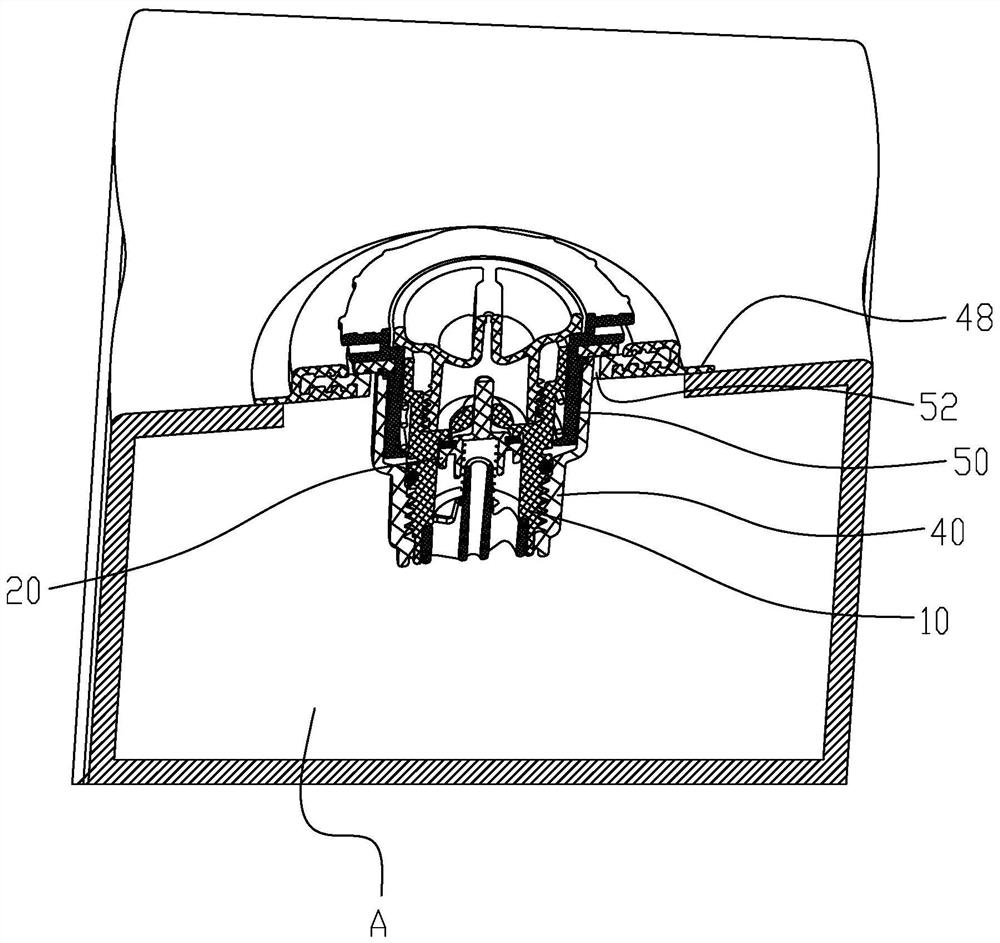

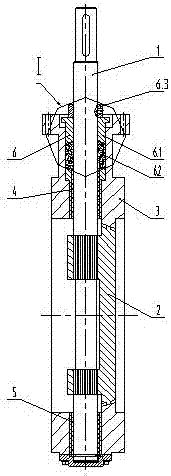

One-way valve with pressure relief protection function

PendingCN111720594AGuaranteed tightness and stabilityPlay the function of pressure relief protectionCheck valvesEngineeringStructural engineering

The invention discloses a one-way valve with a pressure relief protection function. The one-way valve comprises an inner valve sleeve and a one-way valve element. An input hole is formed in the innervalve sleeve, and one elastic part pushes the one-way valve element to move in the axial direction to close the input hole. The one-way valve further comprises an outer valve sleeve and a pressure relief valve element. The outer valve sleeve sleeves the inner valve sleeve, and the outer valve sleeve and the inner valve sleeve are connected together. A pressure relief hole is formed in the outer valve sleeve. The other elastic part pushes the pressure relief valve element to move in the axial direction to close the pressure relief hole. Thus, the one-way vale can achieve one-way feeding, more importantly, the pressure relief protection function is achieved in the feeding process, and the advantage of good safety is achieved. Moreover, during mounting, only one mounting hole needs to be reserved for a closing container, mounting is simple and convenient, and sealing stability of the closing container is effectively guaranteed.

Owner:INTEX IND (XIAMEN) CO LTD

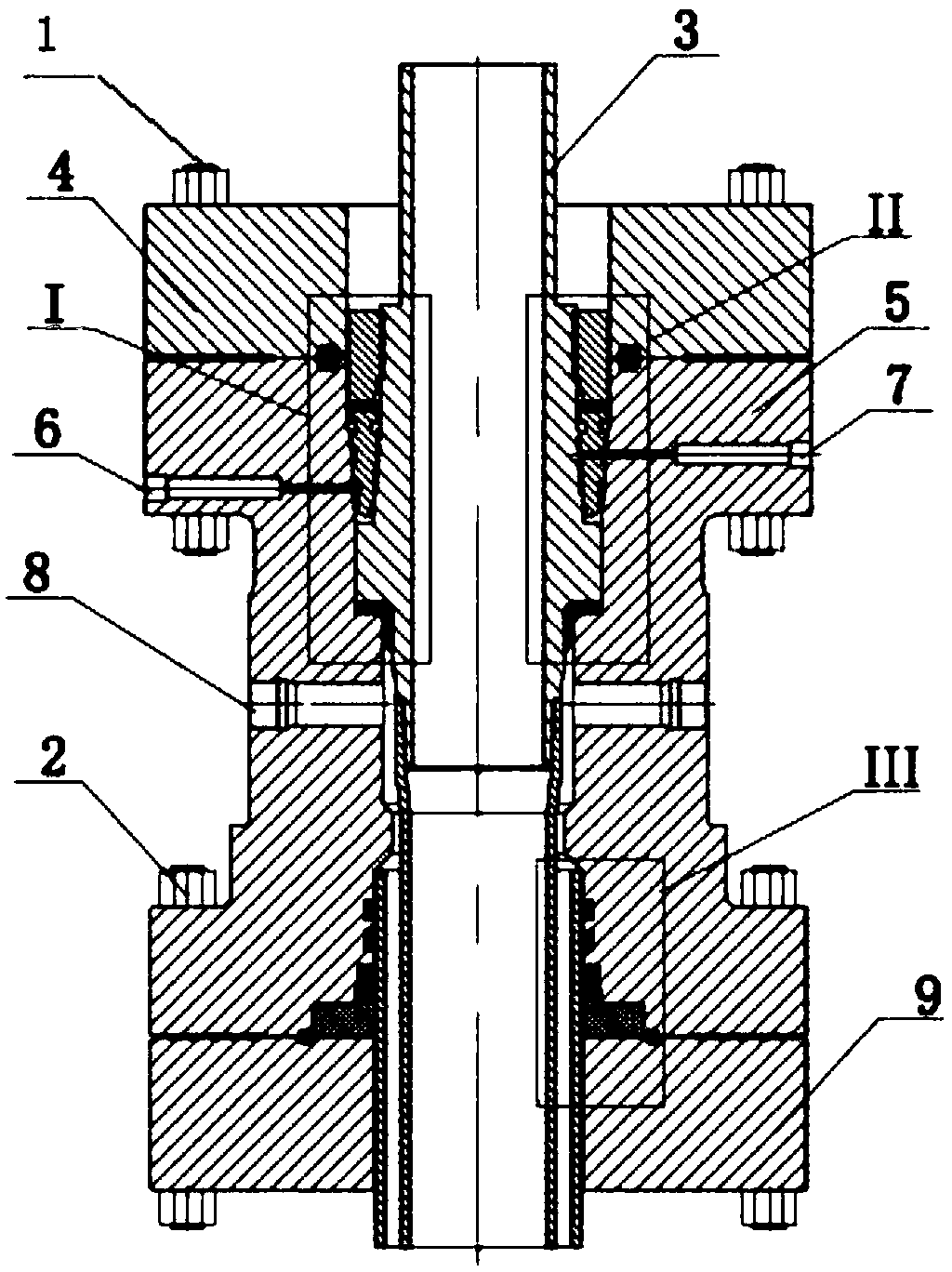

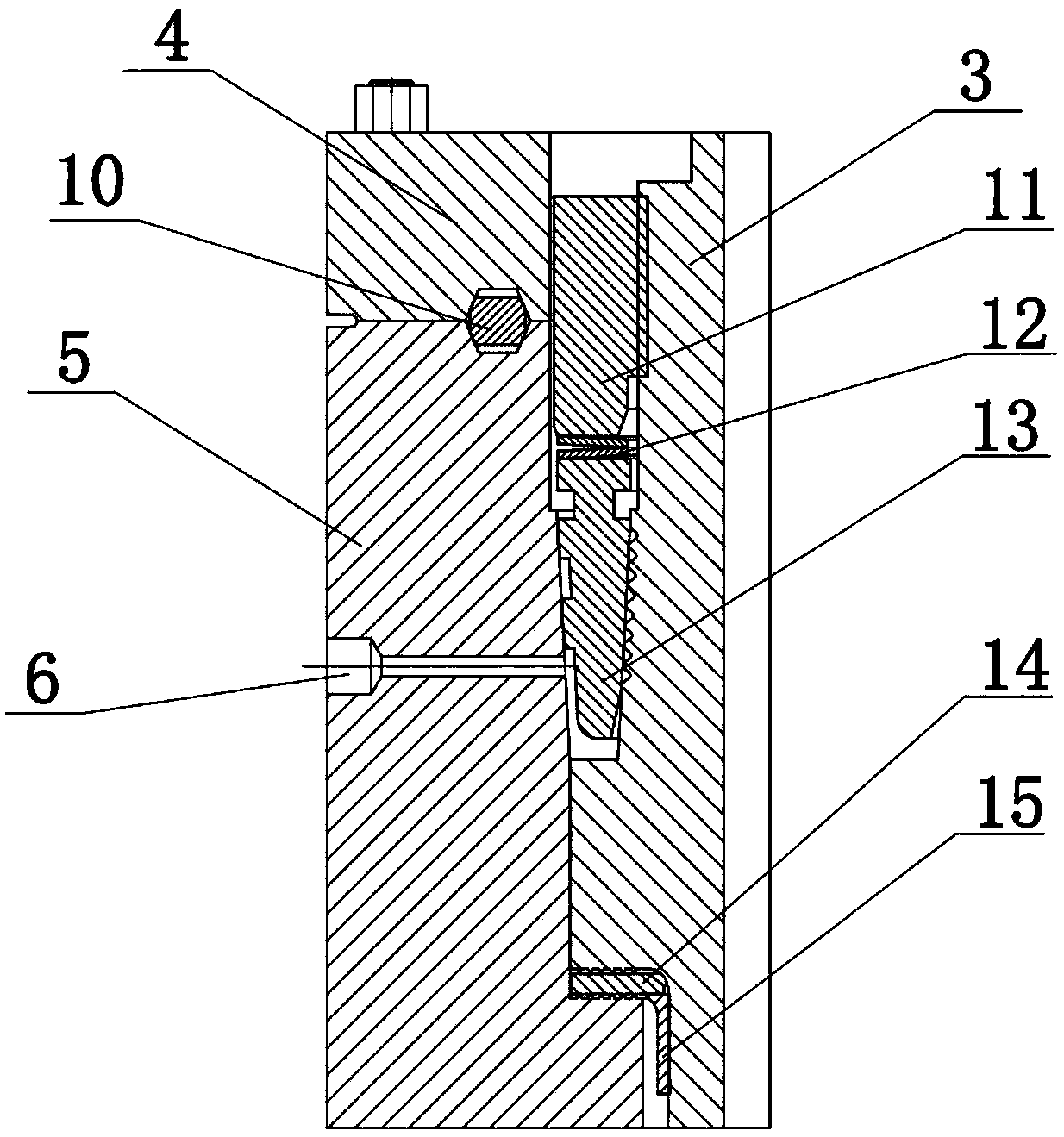

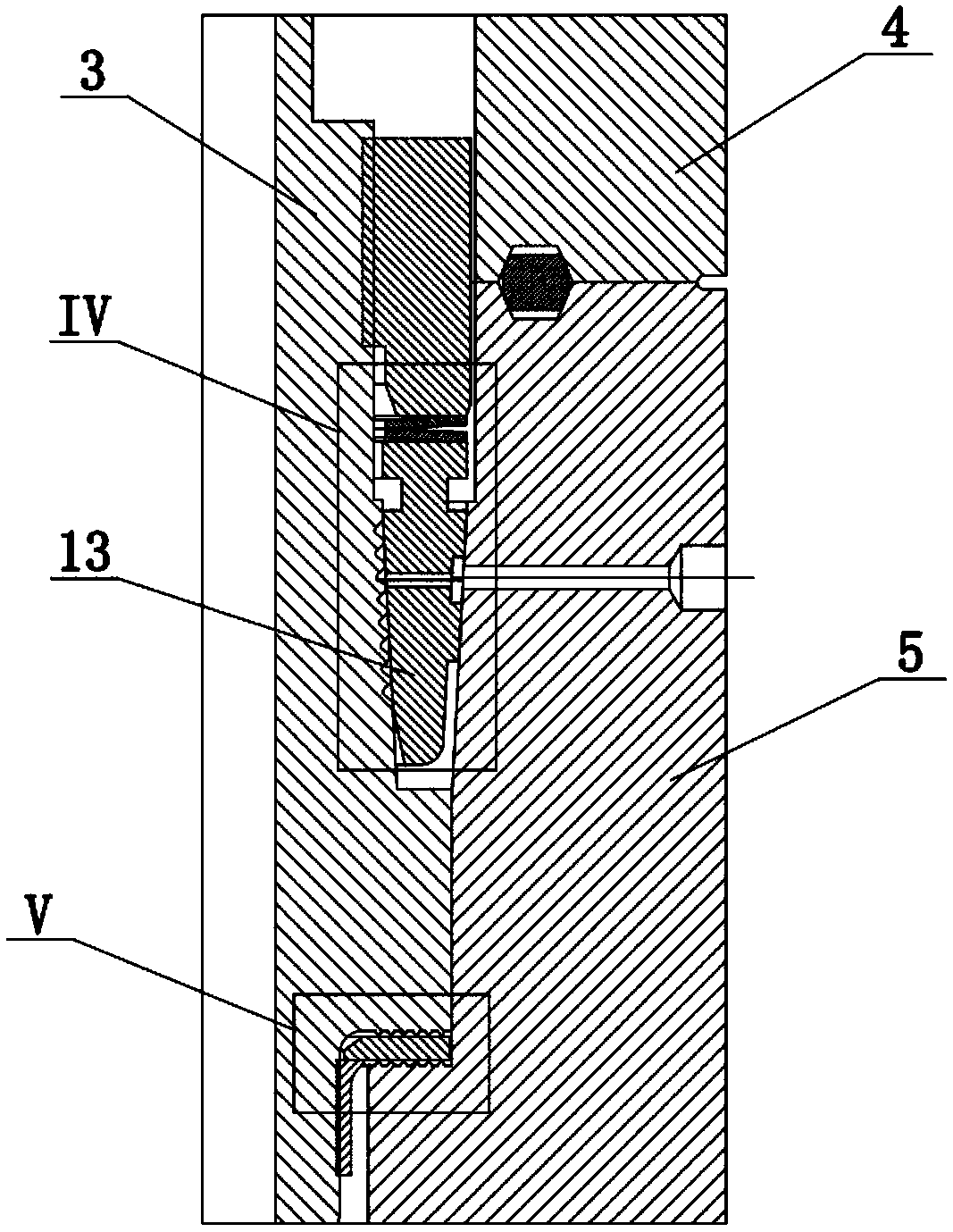

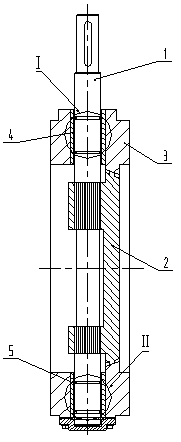

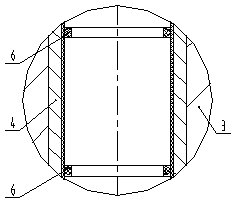

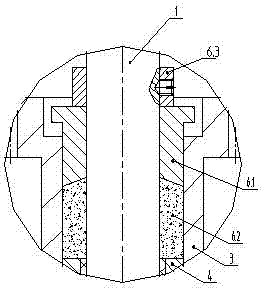

Mandrel type hanger of all-metal multi-stage and equidimension sealing structure

PendingCN108412449AExtended use timeGuaranteed tightness and stabilitySealing/packingEngineeringService time

The invention discloses a mandrel type hanger of an all-metal multi-stage and equidimension sealing structure. The mandrel type hanger of the all-metal multi-stage and equidimension sealing structurecomprises a mandrel, an upper flange, a cross, a lower flange, a spinning sleeve, a cone sealing ring, a sealing backing ring, a positioning ring, a suspension sleeve, a surface layer sleeve, a metalcompression ring, an X type sealing ring and a support backing ring. The mandrel is provided with a neck section, an upper stage section, a conical surface section, a lower stage section, a connectingthread section and a cone thread section from top to bottom, and the mandrel is axially arranged in the cross. A cone gap is formed between the conical surface of the cross and the conical surface section of the mandrel, the cone sealing ring is arranged in the cone gap, and the spinning sleeve is connected to the upper stage section of the mandrel in a threaded mode and presses the cone sealingring. The metal compression ring, the X type sealing ring and the support backing ring are arranged in an annular ladder slot on the lower portion of the cross. The mandrel type hanger of the all-metal multi-stage and equidimension sealing structure does not involve rubber sealing parts and is able to withstand various adverse environmental impacts, and service time is greatly improved and the overall sealing stability of a casing head is ensured.

Owner:SOUTHWEST PETROLEUM UNIV

High-temperature and high-pressure valve packing sealing structure

InactiveCN104358923AAvoid deformationAvoid reactionSpindle sealingsValve members for heating/coolingEngineeringHigh pressure

The invention belongs to the technical field of valves with packing boxes. A high-temperature and high-pressure valve packing sealing structure comprises a packing gland which is used for sealing an upper port of a packing cavity of a valve cover, wherein a sealing groove is formed in the inner wall of the packing gland; an O-shaped sealing ring is mounted in the sealing groove. The high-temperature and high-pressure valve packing sealing structure is characterized in that a bottom pad is arranged at the bottom of the packing cavity; a soaking packing assembly is arranged between the packing gland and the bottom pad and comprises braided packing; the braided packing is provided with polytetrafluoroethylene packing and a spacer ring; a cooling water runner which surrounds the exterior of the packing assembly is arranged in the valve cover. The high-temperature and high-pressure valve packing sealing structure has the advantages of high corrosion resistance and higher sealing stability.

Owner:CHONGQING SHANNENG INSTR

Barrel cover sealing device of 3D printing gas filter barrel

InactiveCN108580898AAdjust the tightness reasonablyPrevent popupAdditive manufacturing apparatusGas treatmentEngineering3d printed

The invention relates to a barrel cover sealing device of a 3D printing gas filter barrel. An intake pipe is arranged on the side surface of a filter barrel; a cover body is mounted in an upper port of the filter barrel; an exhaust pipe is arranged on the surface of the cover body; a left half sealing strip and a right half sealing strip are arranged in the edge joints of the cover body and the filter barrel; a first connecting head and a third connecting head are mounted at the two ends of the left half sealing strip; a second connecting head and a hanging hook are mounted at the two ends ofthe right half sealing strip; a connecting rod is movably mounted on the first connecting head through a first rotating shaft; an adjusting handle is movably connected to the third connecting head through a second rotating shaft; a rotating block is mounted at the middle part of the adjusting handle through a third rotating shaft; a rod piece at the back end of a pull rod is a thread rod; a threadhole is formed in the surface of the rotating block; and a triangular hanging ring is arranged at the front end of the pull rod. The barrel cover sealing device of the 3D printing gas filter barrel is simple in structure, fast in disassembly, firm in module connection and convenient to adjust.

Owner:安徽隆源成型科技有限公司

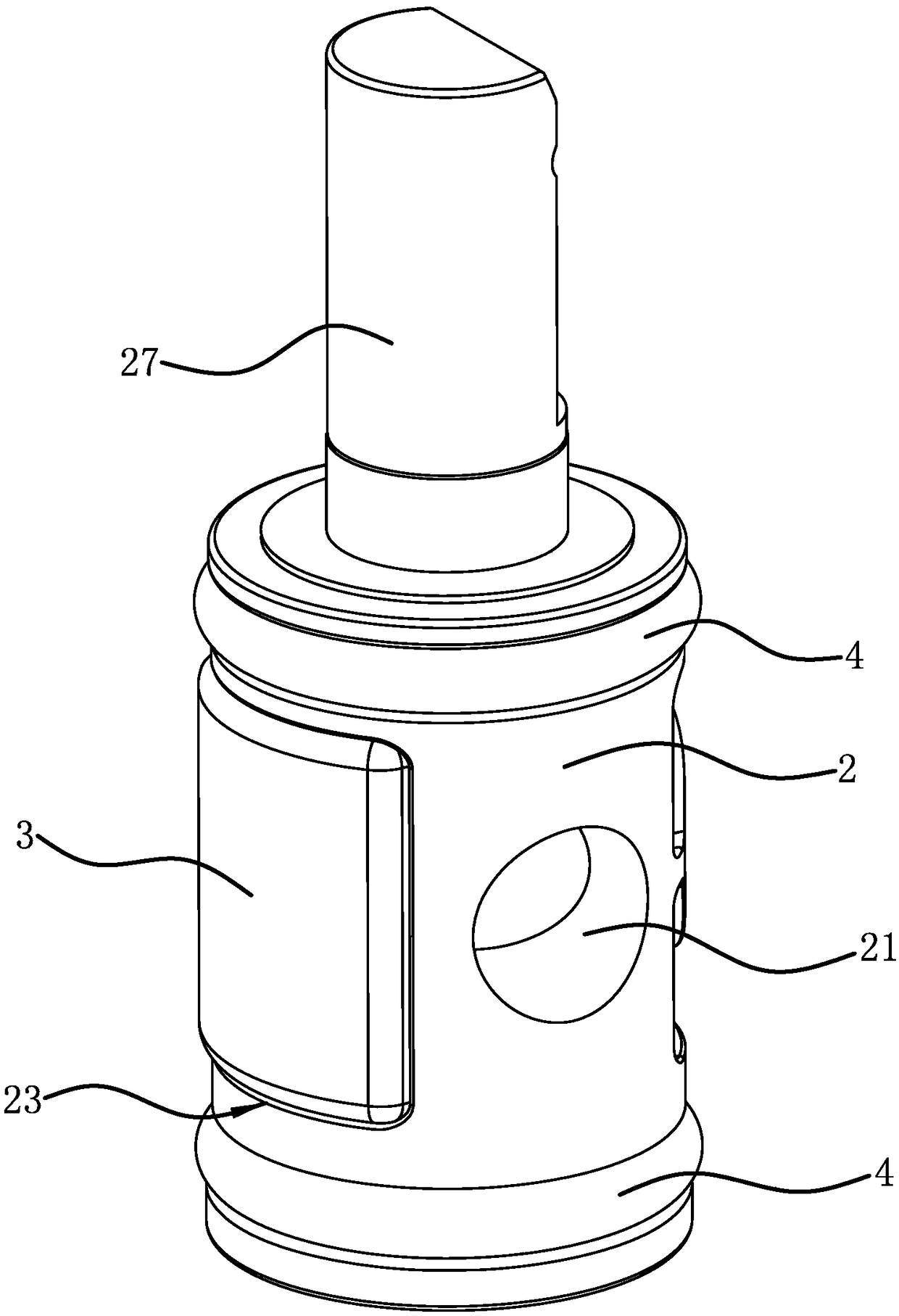

Valve plug

PendingCN108708992AAvoid direct impactPrevent water seepagePlug valvesMultiple way valvesEngineeringMechanical engineering

The invention provides a valve plug and belongs to the technical field of valves. The valve plug solves the problem that an existing valve plug is poor in sealability. The valve plug comprises a cylindrical body; a water inflow hole I and at least one water inflow hole II which intersect and communicate are formed in the side wall of the body; the water inflow hole II is located on one side of thewater inflow hole I; a buffering cavity is formed in the part, on the other side of the water inflow hole I, of the side wall of the body; a sealing block is arranged in the buffering cavity; a partition part is arranged between the buffering cavity and the water inflow hole I; a communicating hole communicating the buffering cavity with the water inflow hole I is formed in the partition part; and the diameter of the communicating hole is less than that of the water inflow hole II. The sealability of the valve plug is better.

Owner:TAIZHOU RIVHOME ECO TECH CO LTD

Vacuum pressure paint dipping equipment

PendingCN114247600AEasy to observeEasy to operateLiquid surface applicatorsManufacturing dynamo-electric machinesVacuum pressureEngineering

The vacuum pressure paint dipping equipment comprises a paint dipping tank, a vacuum pipe, a backflow pipe and supporting legs, and the vacuum pipe is in threaded connection with an outlet in the middle of the upper side of the front portion of the paint dipping tank; supporting legs are connected to the four corners of the bottom of the paint dipping tank through bolts; the observable sealing opening and closing cover structure is connected with the paint dipping tank; and the adjustable product clamping paint dipping disc structure is connected with the rotary paint dipping machine structure. Through the arrangement of the dismounting rod, the dismounting nut, the spring washer, the opening and closing cover, the supporting screw rod, the mounting base, an observation window and a sealing ring, observation is facilitated, opening and closing cleaning can be conducted, operation is convenient, the dismounting nut can be rotated down by holding the dismounting rod by hand, at the moment, the opening and closing cover can be taken down from the outer wall of the supporting screw rod, cleaning and maintenance can be conducted, and use is convenient. The paint dipping condition can be observed through the observation window, the sealing stability can be guaranteed through the sealing ring, then the vacuum performance is guaranteed, and the holding-down stability is guaranteed through the spring washer.

Owner:张家港市益成机械有限公司

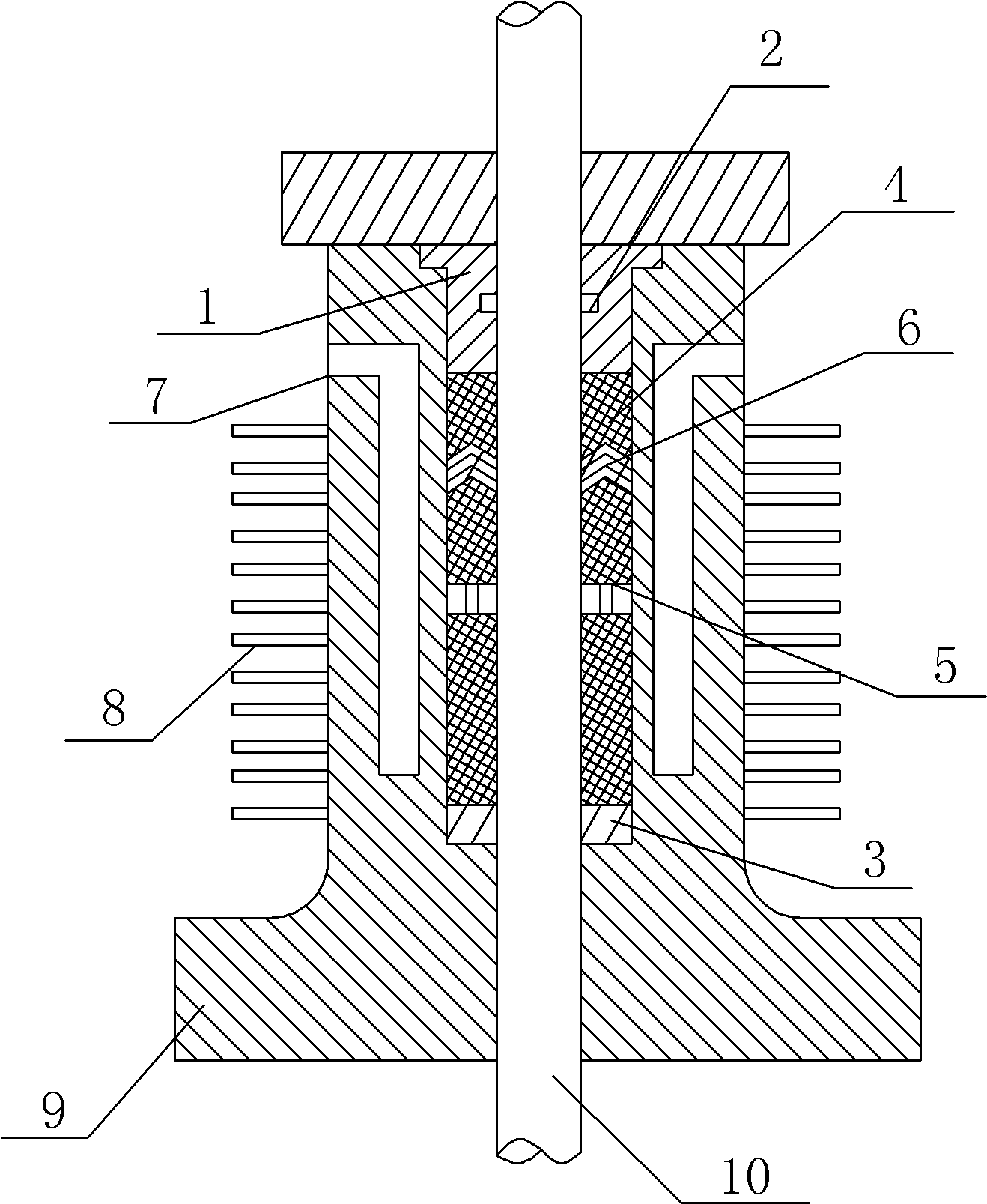

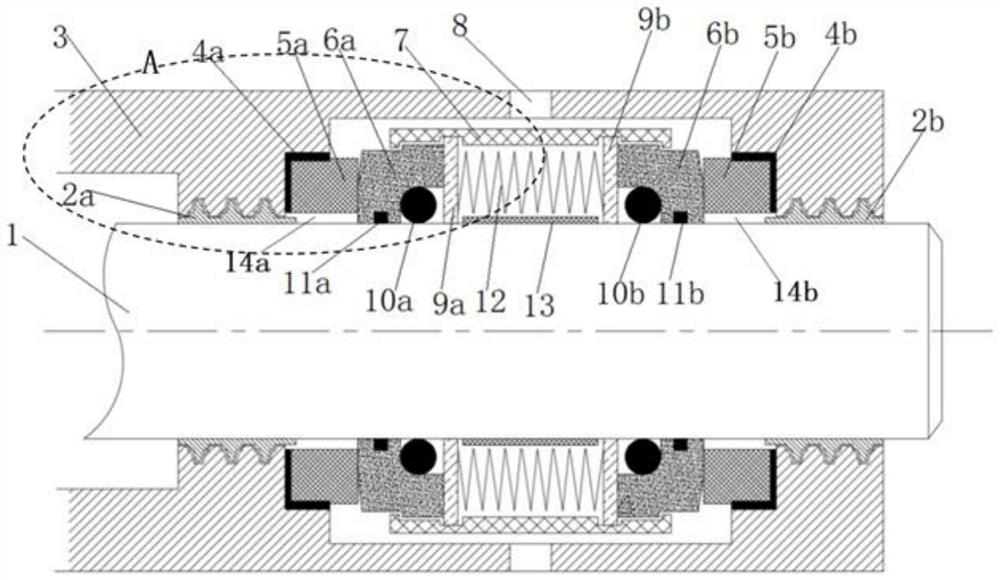

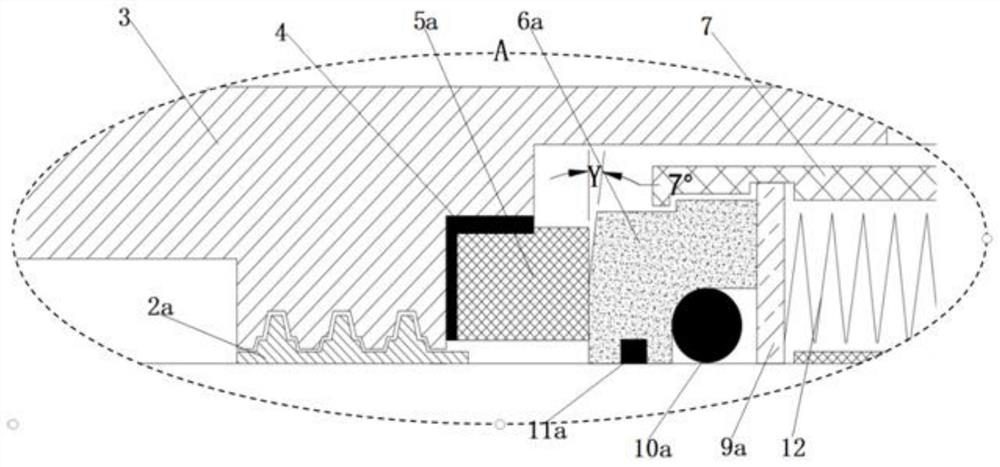

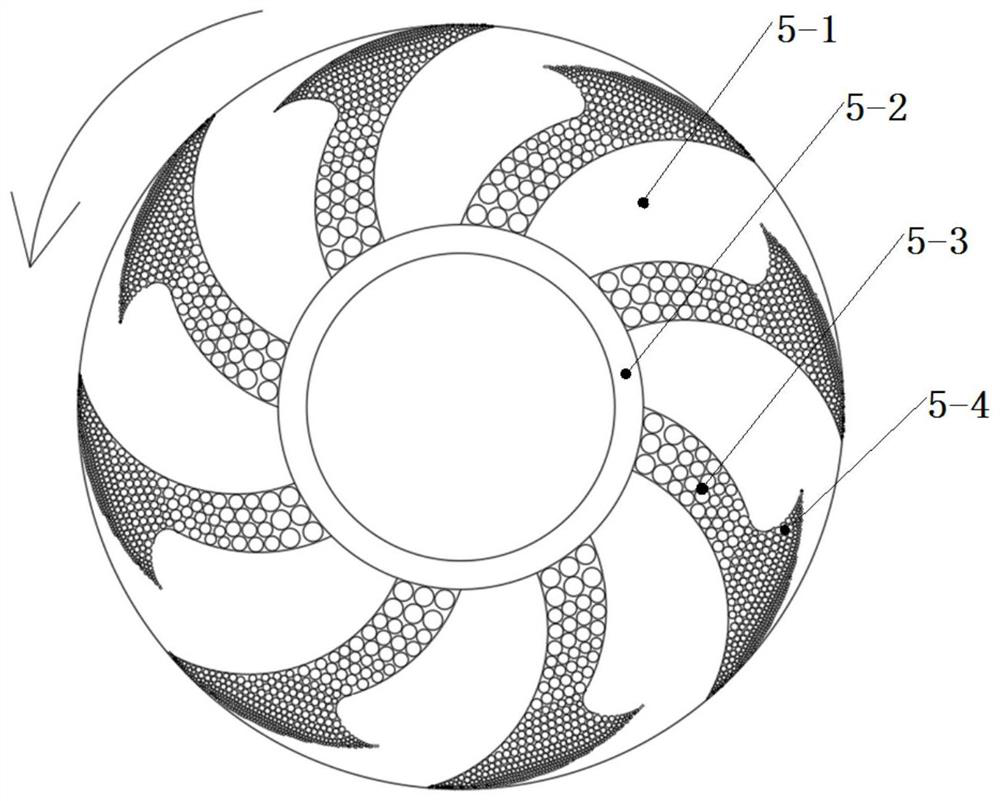

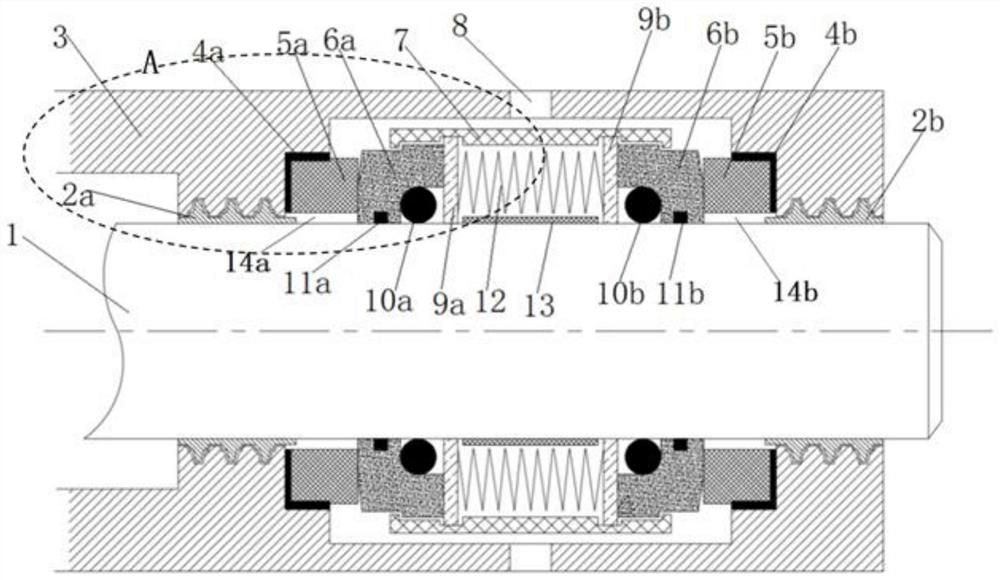

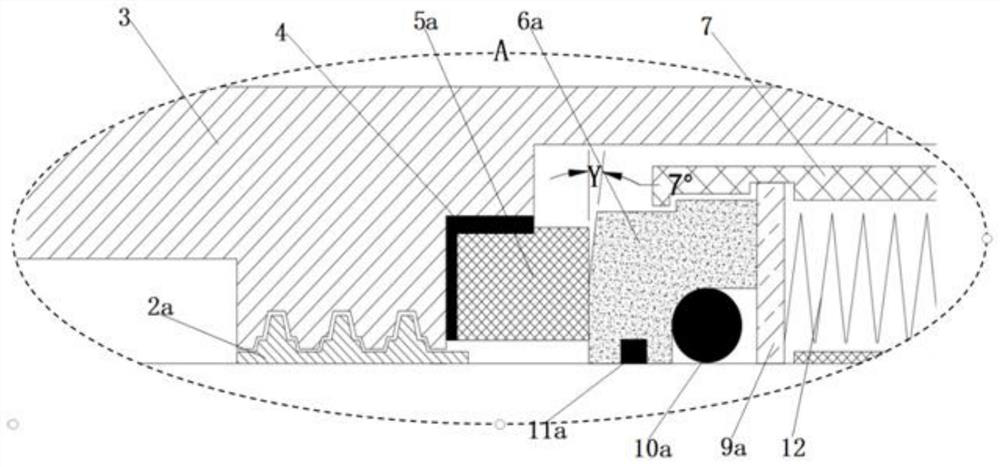

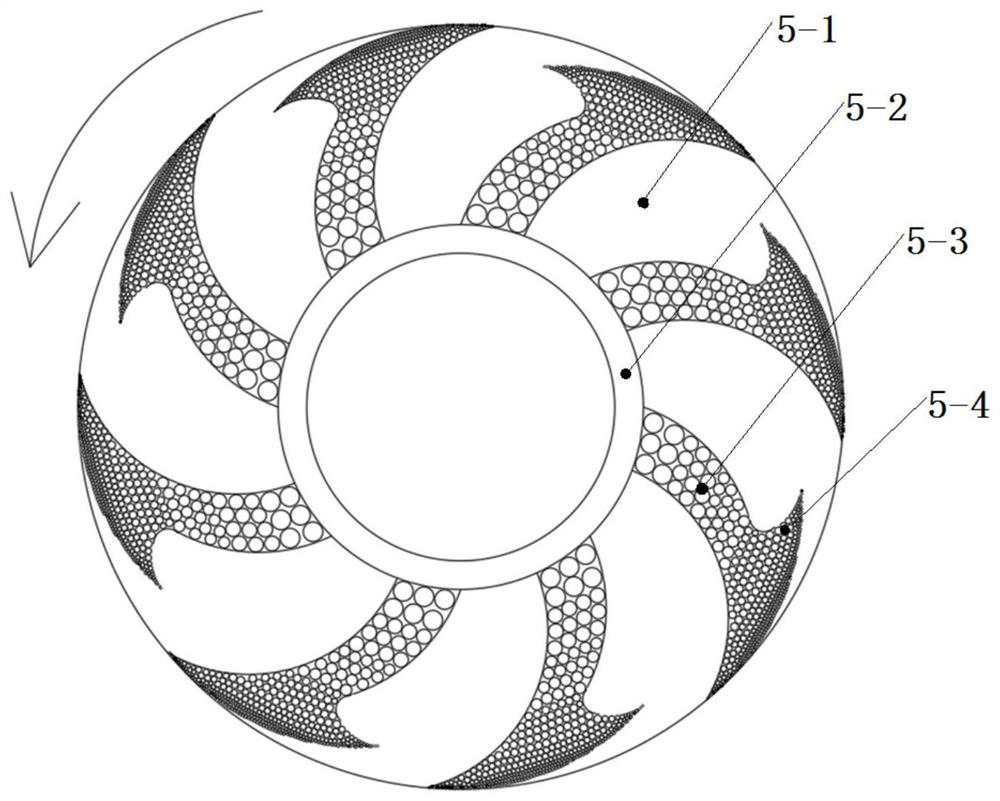

Sealing device for variable-working-condition gas-liquid two-phase fluid medium

The invention relates to a sealing device for a variable-working-condition gas-liquid two-phase fluid medium. The sealing device is provided with a rotating shaft and a shell, and a cavity formed by the shell is used for containing a gas-liquid two-phase fluid medium; and the sealing device further comprises a labyrinth sealing mechanism and a fluid dynamic pressure mechanical sealing mechanism with double end faces, the labyrinth sealing mechanism and the fluid dynamic pressure mechanical sealing mechanism cooperate with each other, a sealing buffer cavity is formed between the labyrinth sealing mechanism and the fluid dynamic pressure mechanical sealing mechanism, and the fluid dynamic pressure mechanical sealing mechanism is provided with a static ring and a movable ring which abut against each other. Through the design of the stepped trapezoidal convex teeth of a labyrinth sealing channel and the utilization of the throttling and pressure reducing effects of the labyrinth sealing,the attenuation of the sealing buffer cavity to the medium pressure fluctuation, the structural design of a micropore group of the end surface of the static ring, the inclined design of the seal end surface of the movable ring and the limiting effect of a limiting sleeve, good sealing performance and sealing stability of dynamic pressure sealing of the variable-working-condition gas-liquid two-phase fluid medium are achieved.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

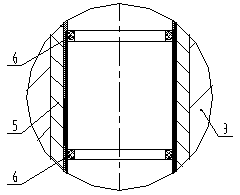

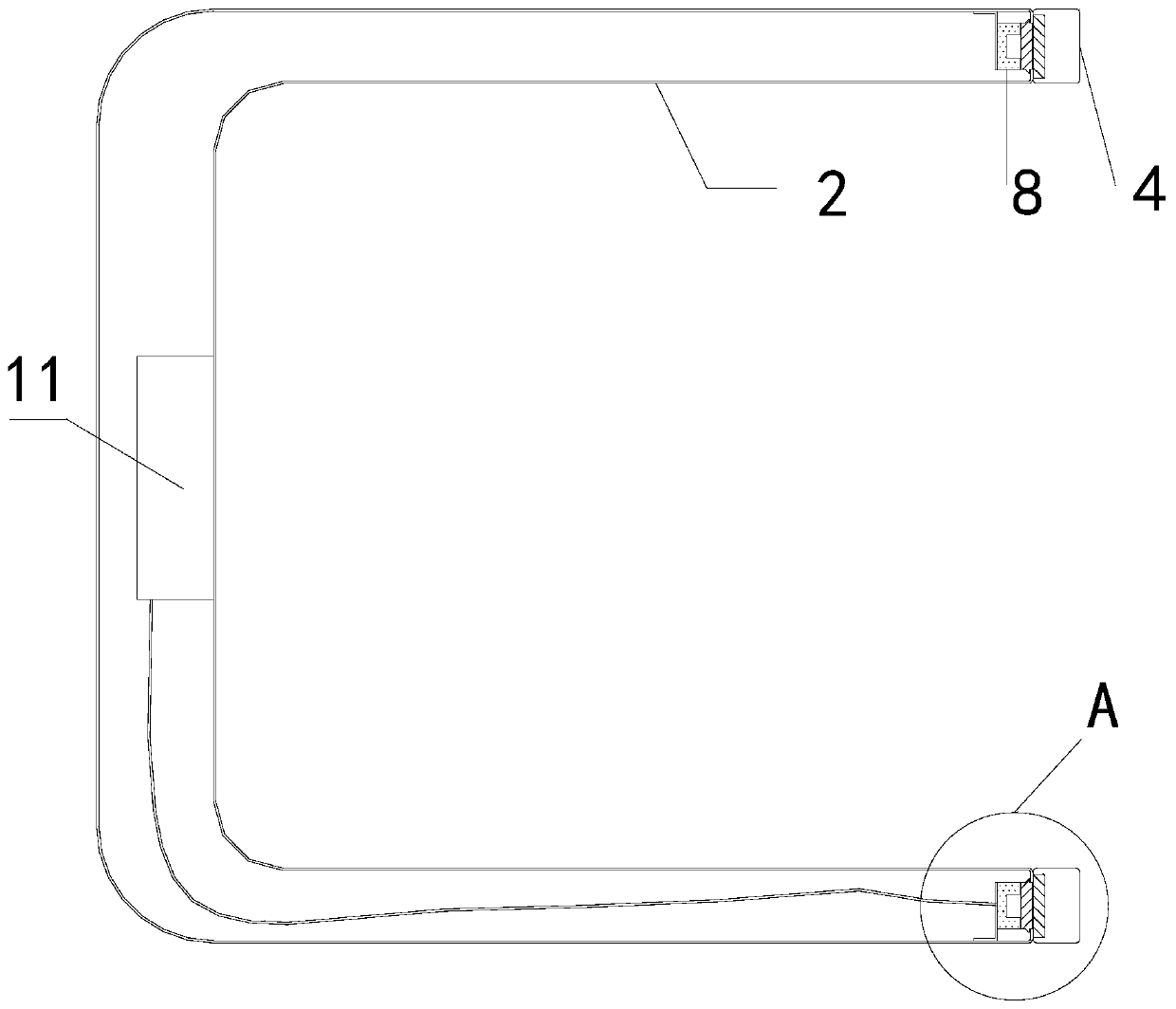

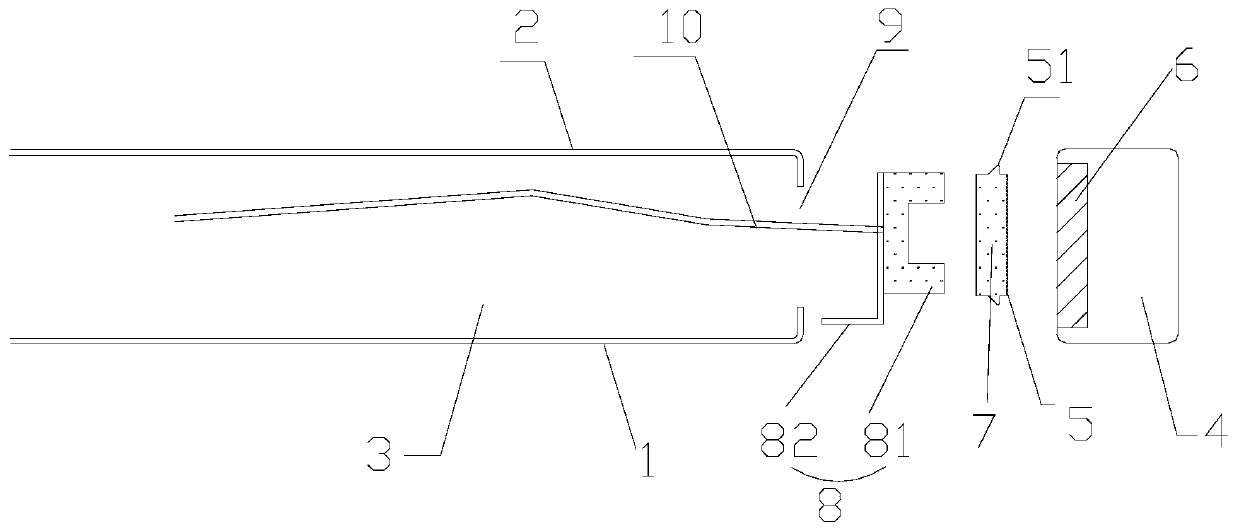

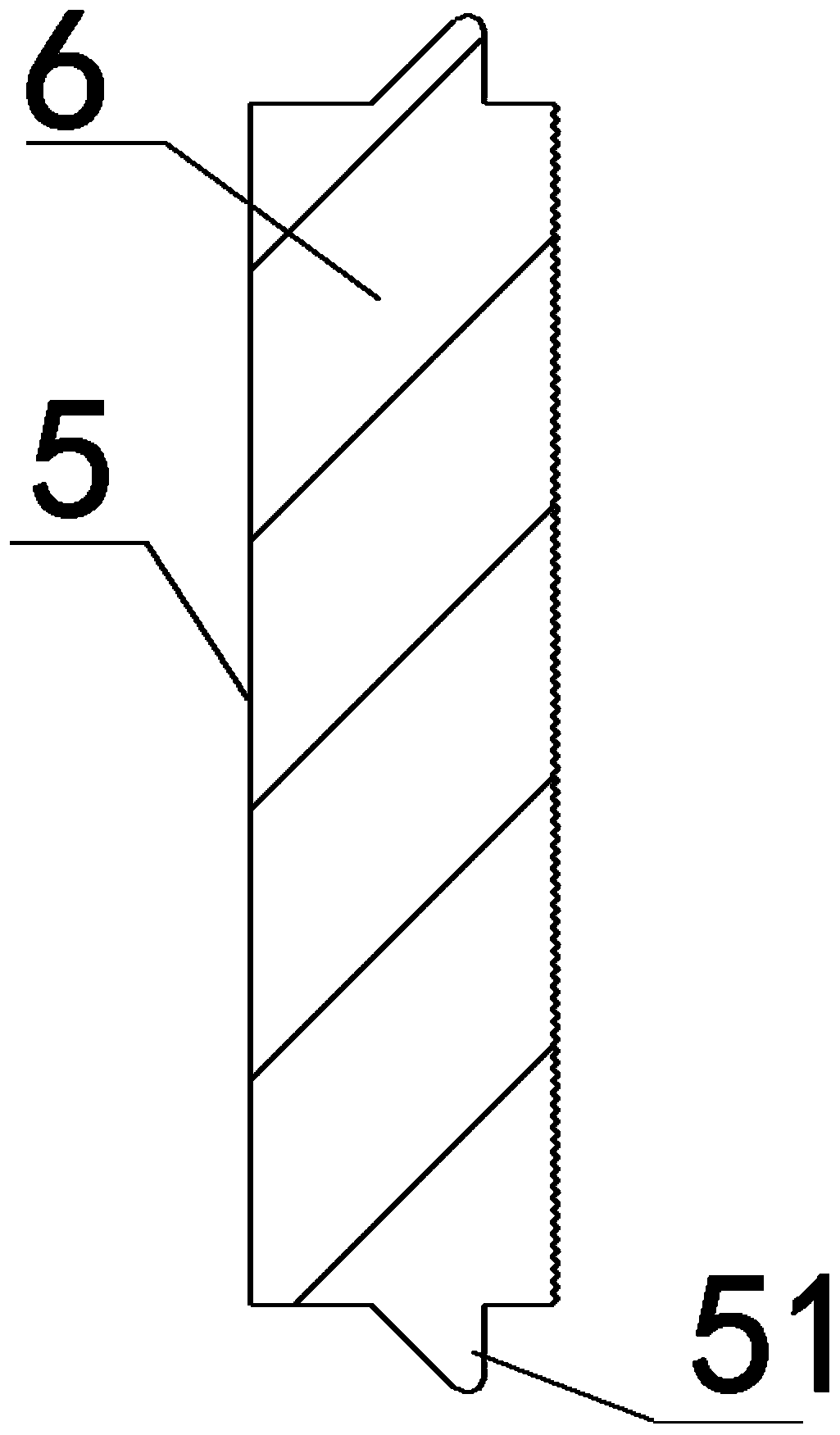

Switch cabinet box body

InactiveCN106532449AGuaranteed tightness and stabilityOvercome heat dissipationSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsFlangeComputer engineering

The invention discloses a switch cabinet box body, which comprises a housing (1), a top plate (2) and a first ventilation fan (3), wherein an opening is formed in the top of the housing (1); the top plate (2) is arranged at the vertical upper part of the housing (1) along a horizontal direction and the periphery of the top plate (2) protrudes out of the housing (1); a flange (7) is arranged on the periphery of the top plate (2) along a vertical downward direction; a support part (4) is arranged between the housing (1) and the top plate (2); the first ventilation fan (3) is fixedly connected to the top plate (2) and arranged in the opening; and an air outlet end of the first ventilation fan (3) faces toward the outside of the housing (1). According to the switch cabinet box body, the problem that the switch cabinet box body cannot ensure the air-tightness under the condition of meeting good heat dissipation in the prior art is solved.

Owner:ANHUI ROBUTEC

A sealing device for gas-liquid two-phase fluid medium under variable working conditions

The invention relates to a sealing device for a gas-liquid two-phase fluid medium under variable working conditions. The sealing device has a rotating shaft and a casing, and the cavity formed by the casing is used to accommodate the gas-liquid two-phase fluid medium; the sealing The device also includes a cooperating labyrinth seal mechanism and a double-end hydrodynamic mechanical seal mechanism, and a seal buffer chamber is arranged between the labyrinth seal mechanism and the fluid dynamic mechanical seal mechanism, wherein the hydrodynamic mechanical seal The mechanism has a stationary ring and a moving ring that are in contact with each other. Through the design of the stepped trapezoidal convex teeth of the labyrinth seal channel, the throttling and pressure reduction effect of the labyrinth seal, and the attenuation of the medium pressure fluctuation by the seal buffer chamber, the structural design of the micropore group on the static ring end face, the dynamic ring seal end face The inclination design and the limit function of the limit sleeve realize the good sealing performance and sealing stability of the dynamic pressure seal of the gas-liquid two-phase fluid medium under variable working conditions.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

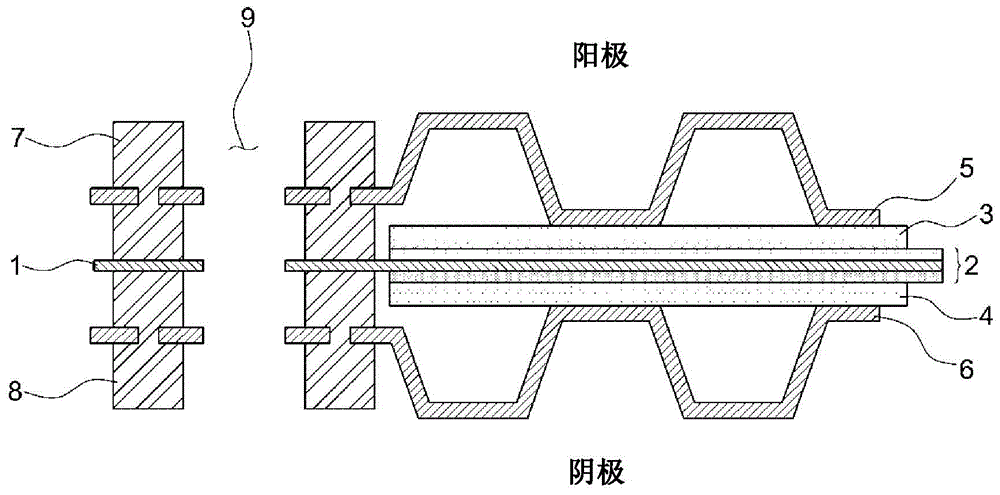

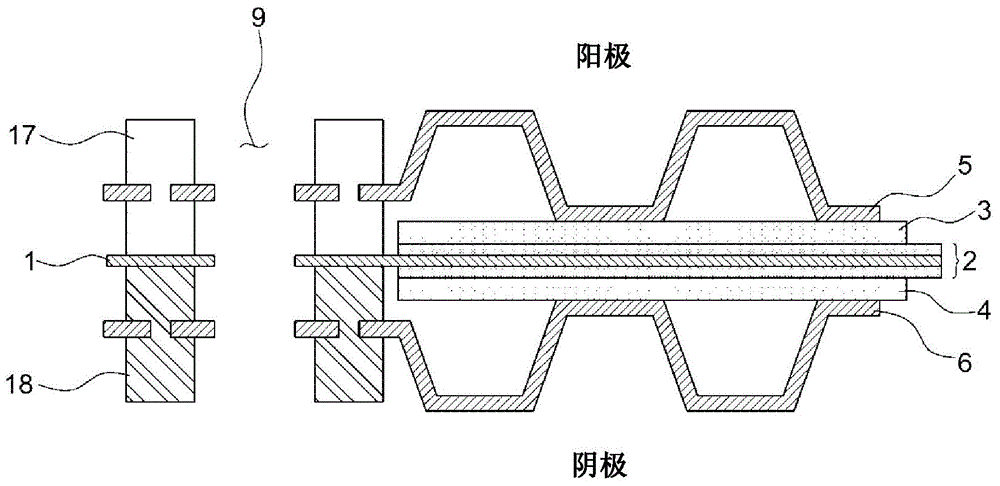

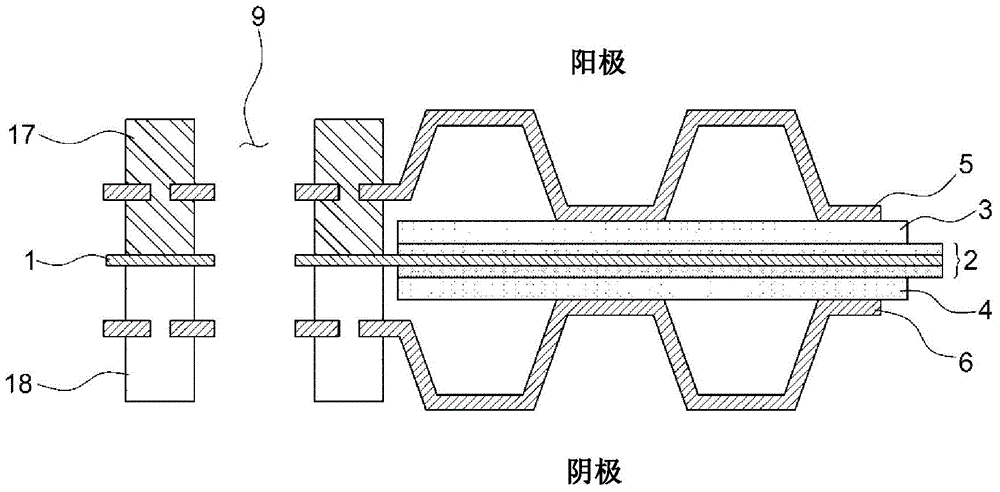

Gasket device for a fuel cell stack

ActiveCN104103840AGuaranteed tightness and stabilityGuaranteed resistance to elution of impuritiesCell sealing materialsMotive system fuel cellsFuel cellsBattery pack

Provided is a gasket device for a fuel cell stack in which gaskets of different materials are integrally molded in an anode separator (or an anode gas diffusion layer) and a cathode separator (or a cathode gas diffusion layer) to provide sealing stability at low temperatures and long-term stability at high temperatures in a fuel cell integrated with a conventional single material and evenly securing the required physical properties of the fuel cell stack gasket.

Owner:HYUNDAI MOTOR CO LTD

High pressure resistant eccentric butterfly valve

InactiveCN105987180AImprove sealingImprove pressure resistanceSpindle sealingsLift valveWear resistantEngineering

The invention discloses a high pressure resistant eccentric butterfly valve. The high pressure resistant eccentric butterfly valve comprises a valve rod, a valve plate, a valve body, an upper shaft sleeve and a lower shaft sleeve; the upper shaft sleeve is arranged at the upper portion of the valve body, and the lower shaft sleeve is arranged at the lower portion of the valve body; the valve rod is supported on the valve body through the upper shaft sleeve and the lower shaft sleeve which are arranged up and down; two ring grooves are formed in the positions, in an inner hole of the upper shaft sleeve, of the surface of the valve rod in a spaced manner, a sealing ring is arranged in each ring groove, and a dual radial shaft sealing structure is formed; and two ring grooves are formed in the positions, in an inner hole of the lower shaft sleeve, of the surface of the valve rod in a spaced manner, a sealing ring is arranged in each ring groove, and a dual radial shaft sealing structure is formed. A further improvement is that metal wear-resistant coatings are arranged on the surface of the inner hole of the upper shaft sleeve and the surface of the inner hole of the lower shaft sleeve; and the valve rod and the valve plate are connected through a spline structure. The high pressure resistant eccentric butterfly valve is reliable in sealing, the leakage amount of the valve is less, high pressure resistance is achieved, and the service life is long.

Owner:JIANGSU ZHONGHAO MARINE VALVE MFG

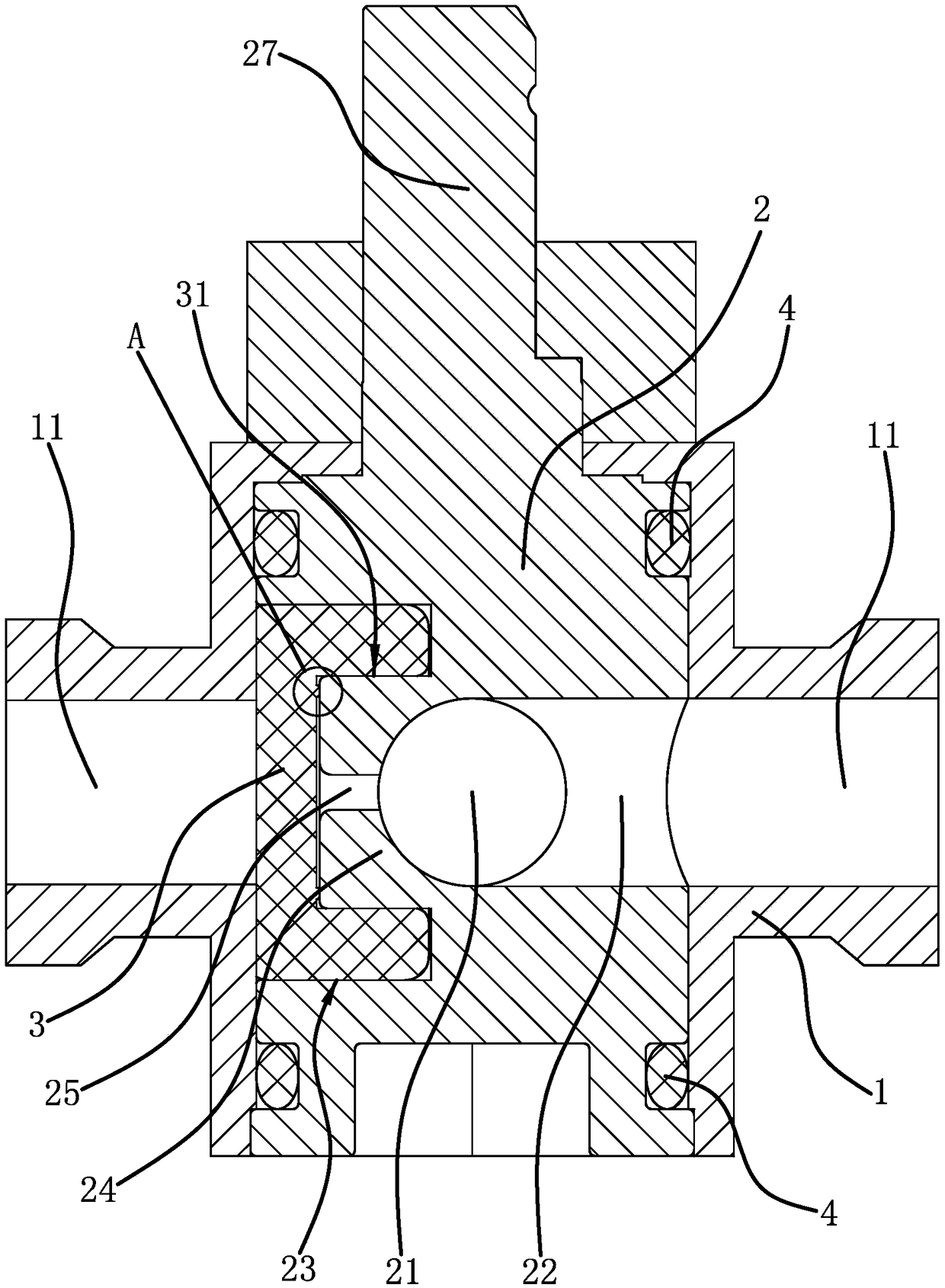

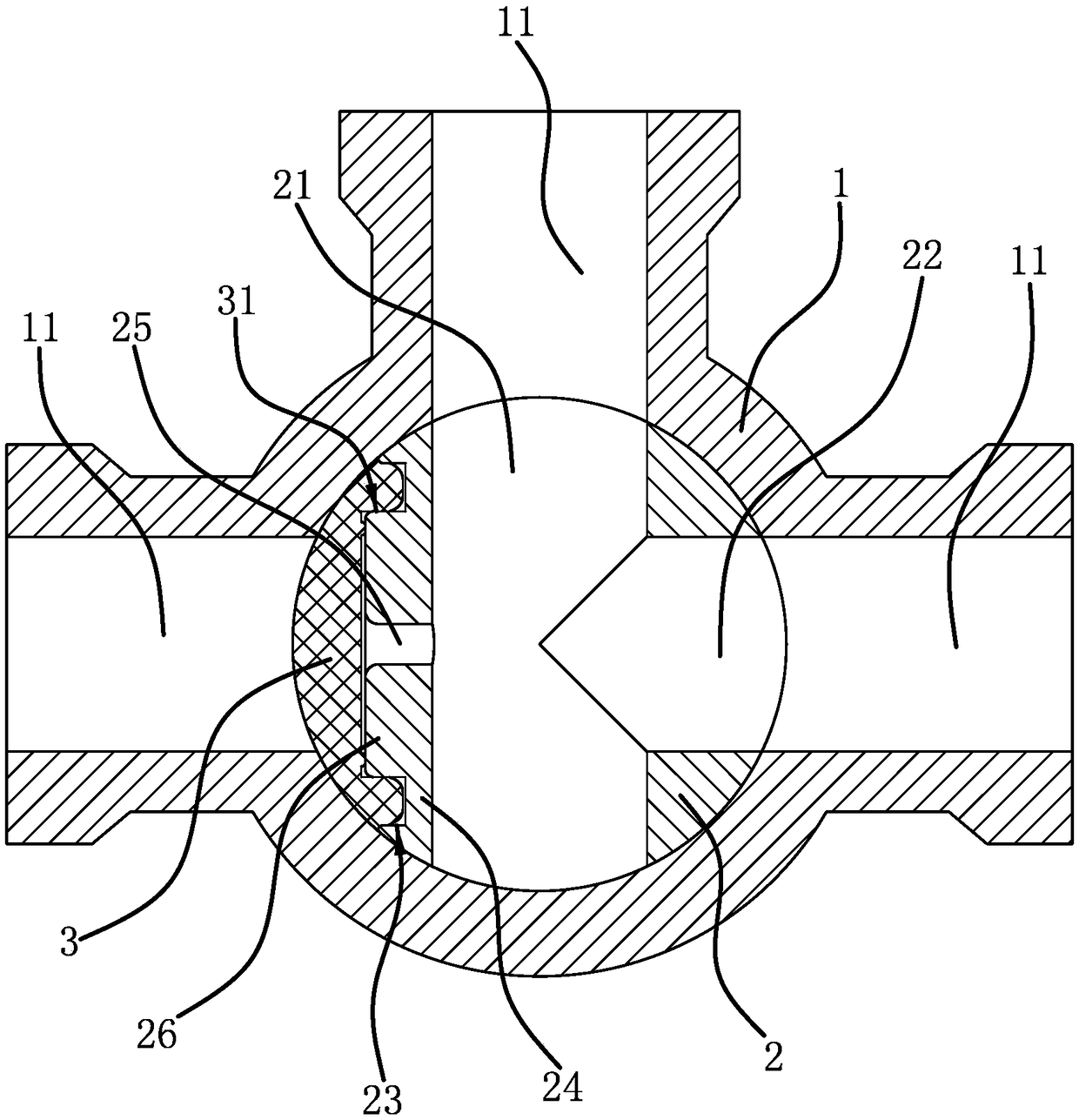

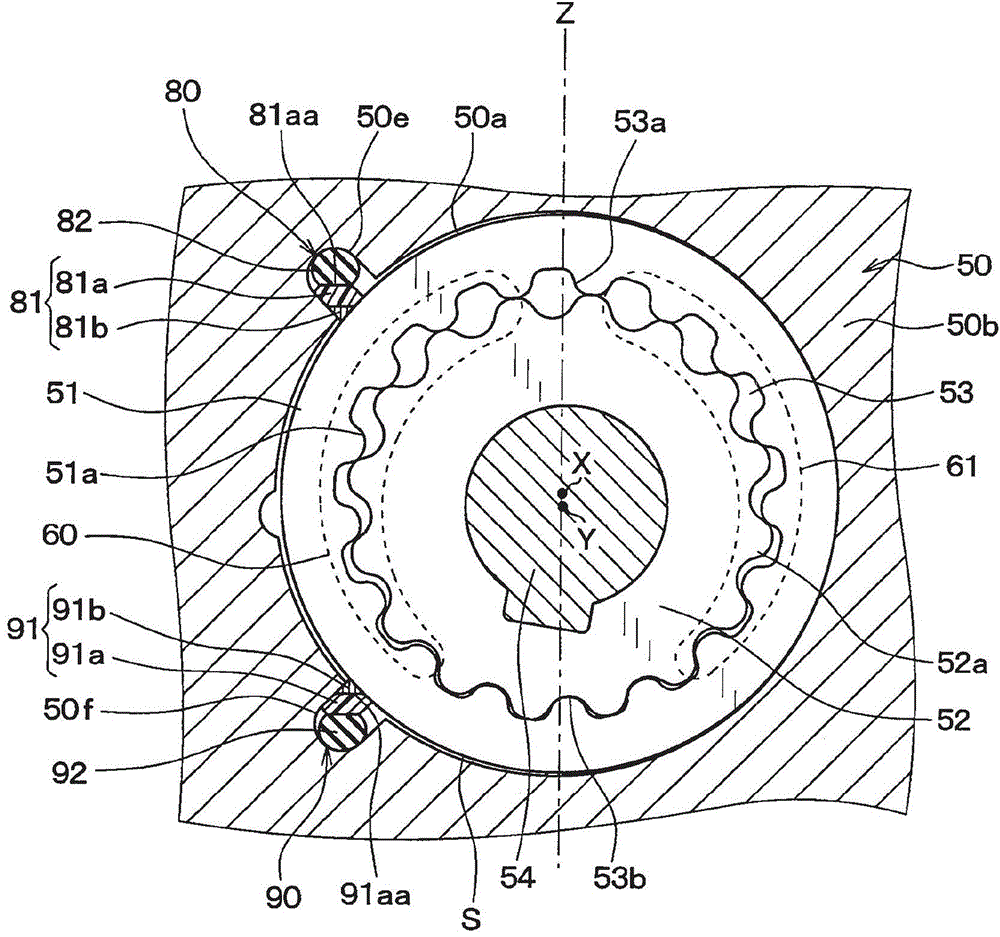

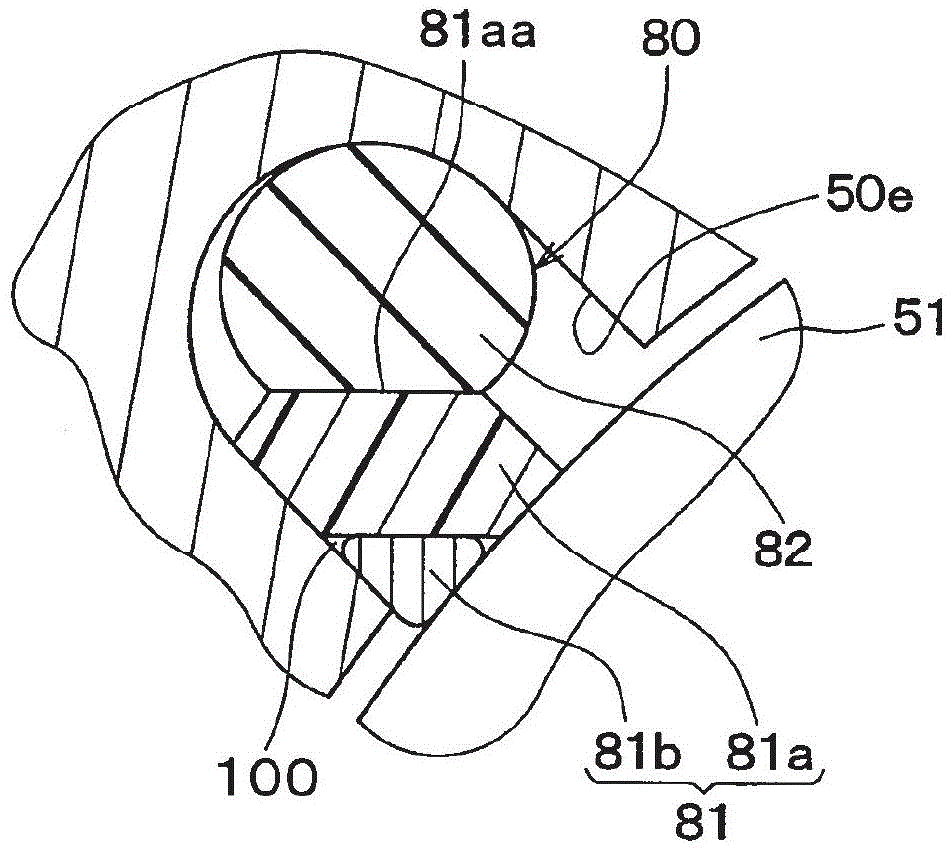

Rotating pump

InactiveCN104828061AGuaranteed tightness and stabilityEngine sealsSealing arrangements for enginesRotary pumpEngineering

A rotating pump includes an outer and an inner rotor disposed in a casing with a gap between the casing and the outer rotor. The rotating pump also includes a first and a second sealing member in the casing to define a low-pressure region and a high-pressure region within the gap. Each of the first and second sealing members is made up of a seal functioning portion and an elastically pressing portion. The seal functioning portion includes a resinous member and a deformation-suppressing member. The resinous member contacts the outer rotor and a low-pressure side inner surface of the casing to establish a difference in pressure between the low-pressure region and the high-pressure region. The deformation-suppressing member works to stop the resinous member from deforming undesirably. This minimizes the risk of breakage of the resinous member and enables the rotating pump to discharge the fluid at an increased pressure.

Owner:ADVICS CO LTD

Domestic electric appliance cabinet door sealing structure

PendingCN111173426AEasy to openAdsorption capacity disappearsWing accessoriesWing fastenersMagnetic tension forceStructural engineering

The invention provides a domestic electric appliance cabinet door sealing structure. The sealing structure comprises a shell, a cabinet door assembly, a sealing ring, a magnetizer and an electromagnetassembly; an inner container is arranged on the inner side of the shell, and a sealing cavity is formed between the shell and the inner container; the cabinet door assembly is arranged on the inner container and is suitable for sealing the shell; the sealing ring is arranged on one of the sealing cavity and the cabinet door assembly, and the sealing ring is filled with magnetic fluid; the magnetizer is arranged on the other one of the sealing cavity and the cabinet door assembly; and the electromagnet assembly is arranged opposite to the sealing ring, and the sealing ring is arranged betweenthe electromagnet assembly and the magnetizer. The magnetic fluid serves as a magnetic conduction medium and can transmit magnetic force generated by the electromagnet assembly to the magnetizer, andat the moment, the sealing ring adsorbs the cabinet door assembly so that the cabinet door assembly cannot be freely opened; and when the cabinet door assembly needs to be opened, the electromagnet assembly is powered off, and at the moment, a user does not need to exert large force.

Owner:GREE ELECTRIC APPLIANCES INC

A ceramic container mouth packaging structure and its preparation method

The invention belongs to the technical field of storage sealing vessels, and particularly relates to a ceramic vessel opening part sealing structure and a preparation method thereof. The sealing structure comprises an opening part and a sealing cover. At least two sealing sections are arranged between the opening part and the sealing cover. The two sealing sections comprise a rubber sealing ring which is arranged on the upper surface of the opening part and / or the lower surface of the sealing cover and surrounds the axis of the opening part, and at least one circle of matting sealing ring which is located on the inner side of the rubber sealing ring and surrounds the axis of the opening part. By the adoption of the sealing structure, storage quality of reserved substances can be guaranteed while a normal packaging effect on the opening part by a traditional sealing cover is ensured. In the machining process, a carborundum grinding mode is used, and the top of an annular sealing ridge conducts rotating and grinding relative to the corresponding surface of the sealing cover or the opening part so that an annular sealing groove can be formed; and the top of an annular supporting ridge conducts rotating and grinding relative to the corresponding surface of the sealing cover or the opening part so that an annular supporting groove can be formed, and thus reliable machining of the structure can be guaranteed conveniently, rapidly and efficiently.

Owner:景德镇醉妙堂陶瓷有限公司

Compact low-resistance bag-type dust collector

InactiveCN113842718AImprove cleaning efficiencyComprehensive contactDispersed particle filtrationDrive shaftStructural engineering

The invention discloses a compact low-resistance bag-type dust collector, which comprises a body, wherein a cover body is attached to the top of the body, a plurality of bags are installed on the inner wall of the body, a cleaning mechanism is arranged at one end of the outer wall of the body, a driving shaft is fixedly connected to the rear end face of the outer wall of a rod body, and the driving shaft is rotationally connected with the inner wall of the body through a bearing. According to the compact low-resistance bag-type dust collector, a driving shaft is connected with an external driving device so as to make the driving shaft drive a rod body and a second sliding block to rotate, when the second sliding block rotates, a sliding groove plate is driven to do reciprocating lifting motion, when the sliding groove plate moves, a supporting rod and a spray head are driven, a corrugated pipe and a telescopic rod stretch out and draw back to drive the nozzle to enter a bag to perform reciprocating lifting motion, then the nozzle drives airflow, and after a cover body is in butt joint with the body, a rubber pad in the cover body can abut against the outer wall of the body, so that the sealing stability of the body and the cover body is guaranteed.

Owner:吉林丰源建设有限公司

High-temperature-resistant three-eccentric center butterfly valve

InactiveCN106931172AImprove high temperature resistanceGuaranteed sealing reliabilitySpindle sealingsLift valveEngineeringGraphite

The invention discloses a high-temperature-resistant three-eccentric center butterfly valve which comprises valve rods, a valve plate and a valve body. The valve rods are supported on the upper portion and the lower portion of the valve body through an upper bearing and a lower bearing which are vertically arranged. A shaft seal structure is arranged at the joint between the upper portion of the valve body and the corresponding valve rod, wherein the shaft seal structure comprises a pressing sleeve, graphite packing and a pressing ring, the valve rod is sleeved with the pressing sleeve front top to bottom, the graphite packing is sealed in an annular groove at the joint between the upper portion of the valve body on the upper portion of the upper bearing and the valve rod, and the pressing ring is installed on the upper end face of the pressing sleeve and fixedly connected with the valve rod. According to the further improvement, the end face, making contact with the graphite packing, of the pressing sleeve is a conical face, and the large end of the conical face is downward; the valve rods and the valve plate are connected through spline structures; and the both the upper bearing and the lower bearing are composite sliding bearings. The high-temperature-resistant three-eccentric center butterfly valve is resistant to high temperature and small in closed torque when in work, the valve body is uniform in stress, sealing is reliable, and maintenance is avoided.

Owner:JIANGSU ZHONGHAO MARINE VALVE MFG

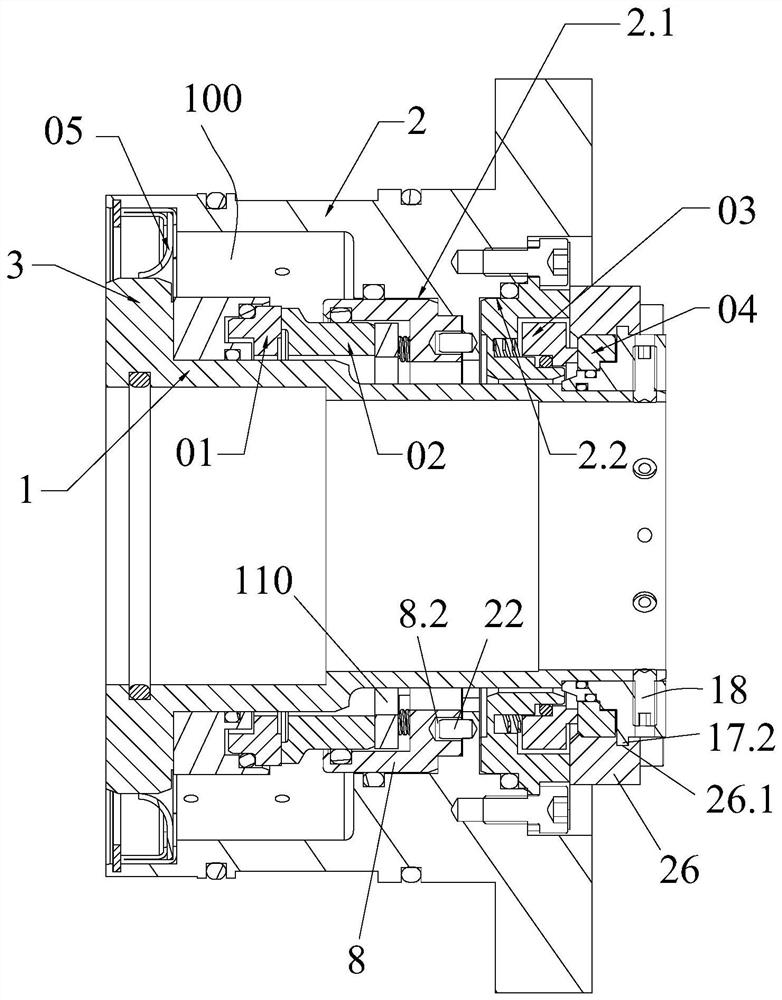

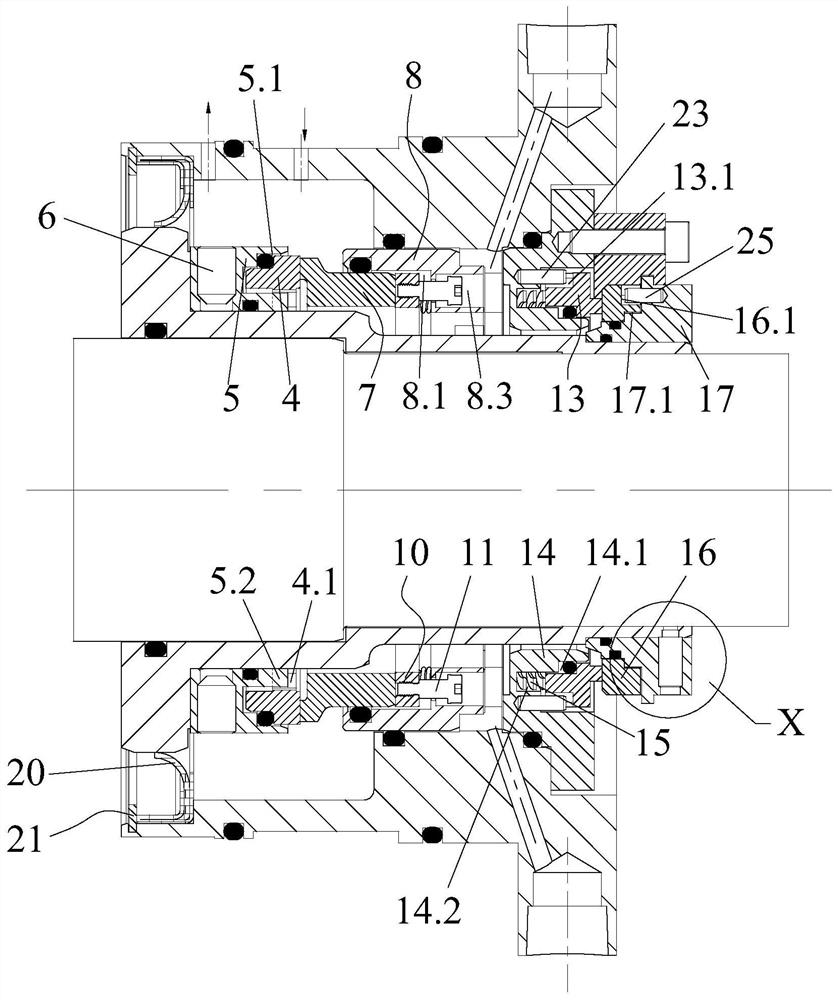

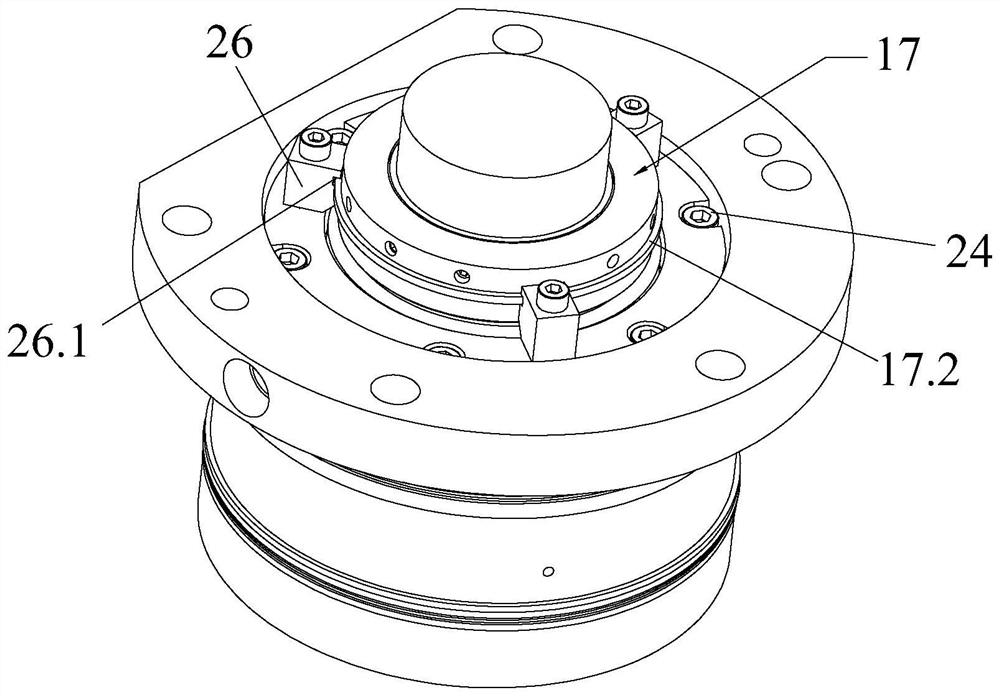

A cartridge mechanical seal for a process screw compressor

ActiveCN112145427BGuaranteed tightness and stabilitySmall sealing spaceSealing arrangement for pumpsRotary piston pumpsEngineeringLip seal

The invention discloses a cartridge mechanical seal for a technological screw compressor, which comprises a sealing cavity and a shaft sleeve pierced through the inner cavity. A main seal and an auxiliary seal are respectively provided between the outside of the shaft sleeve and the interior of the sealing cavity. Seal, and the main seal and auxiliary seal are installed on both sides of the seal cavity in a back-to-back form along the axial direction, and the shaft sleeve, the seal cavity, the main seal and the auxiliary seal are integrated into one-piece structure; the seal cavity is close to the main seal There is also an accommodating cavity on one side of the accommodating cavity, and a lip seal assembly is arranged between the open end of the accommodating cavity and the outer side wall of the mounting boss at one end of the shaft sleeve, so that the accommodating cavity forms a first sealing cavity, which is used to prevent the process The process gas compressed in the compressor enters the working seal cavity of the mechanical seal. The cartridge mechanical seal for a technological screw compressor disclosed by the invention can better adapt to the working conditions of the technological screw compressor, and has more stable sealing performance and long service life.

Owner:洛普兰机械设备(宁波)有限公司

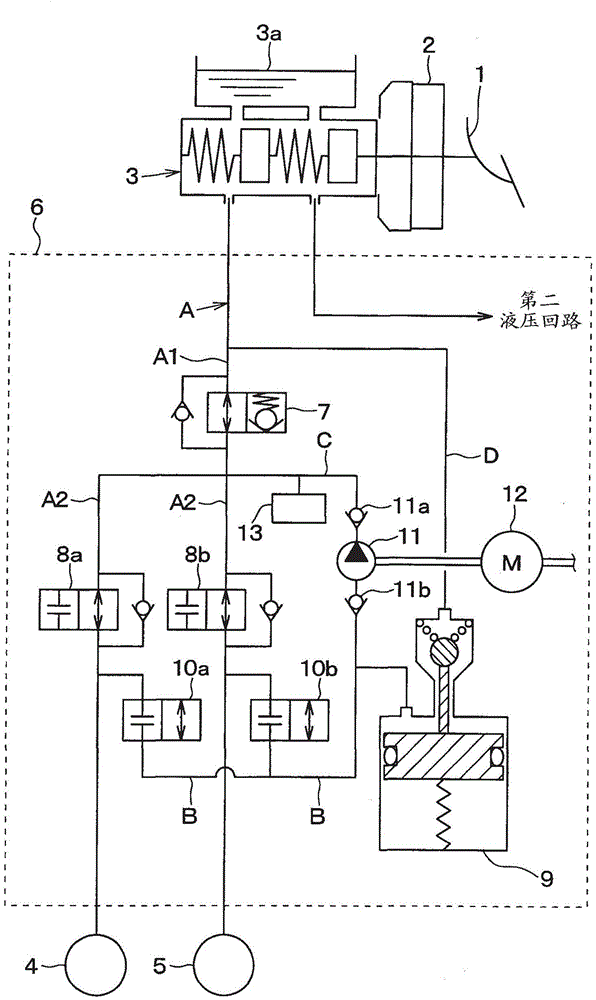

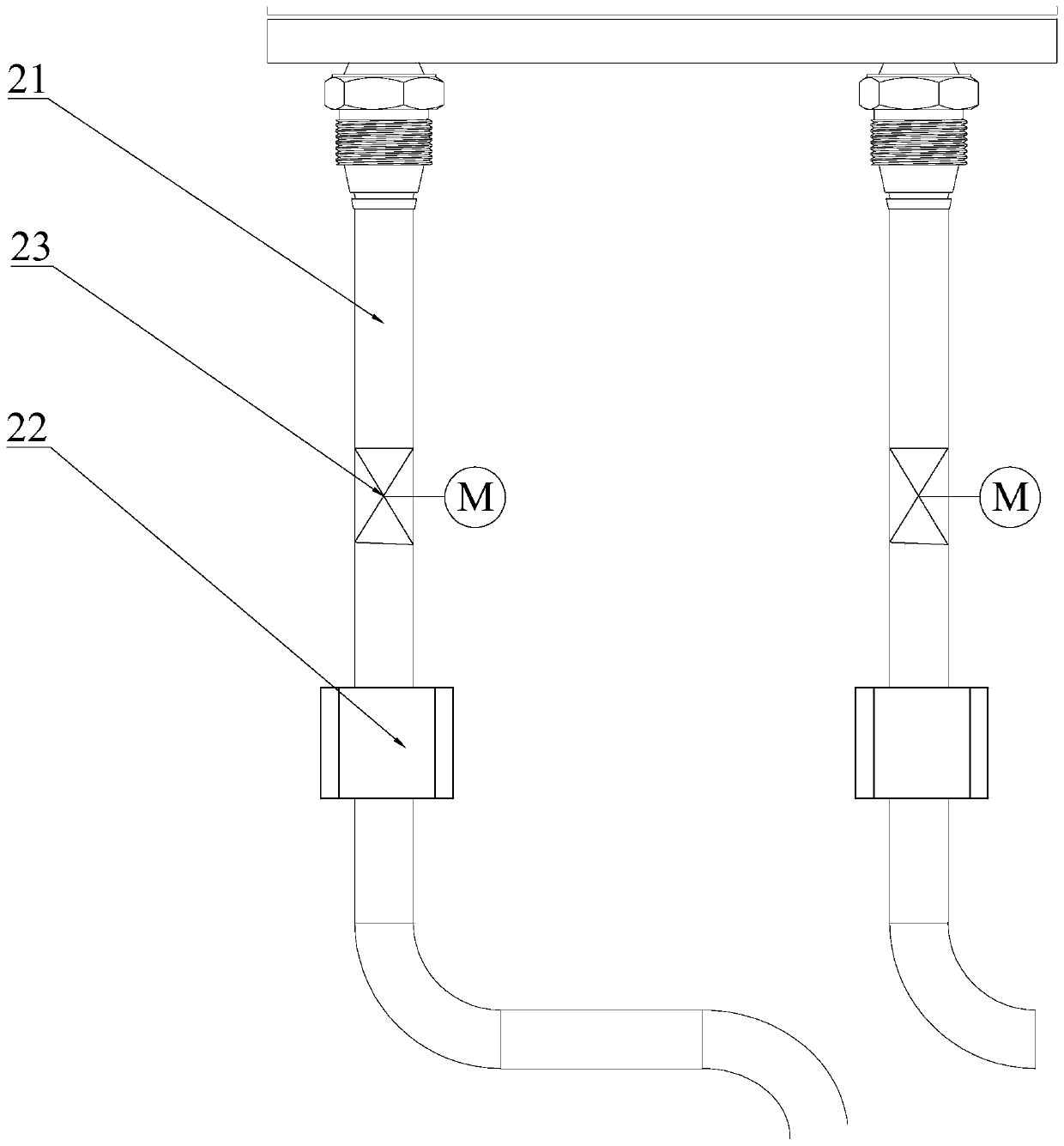

Oil-cooled compressor with multiple pipelines and control method

ActiveCN110925213AReduce deliveryReduce noiseSealing arrangement for pumpsPump controlEngineeringControl valves

The invention discloses an oil-cooled compressor with multiple pipelines and a control method. The oil-cooled compressor comprises a body and an oil cooling mechanism connected to the body. The oil cooling mechanism comprises at least two pipelines and flexible connecting assemblies for connecting the pipelines. Control valves are arranged on the pipelines. The flexible connecting assemblies comprise flexible connecting rings and fixing rings sleeving the flexible connecting rings. At least one clamping groove is formed in each of the two ends of the flexible connecting rings, elastic sealingrings are arranged in the clamping grooves in a cooperating manner, each fixing ring is composed of two spliced fixing semi-rings, elastic parts abut against the portions between the fixing semi-rings, and pressure detection parts are arranged in the elastic parts. The oil-cooled compressor further comprises a control module for receiving and recording pressure values of the pressure detection parts, and the control module controls switching on and off of the control valves.

Owner:江西英赛压缩机有限公司

An integrated program-controlled valve group formed by 3D printing

ActiveCN109323019BCompact structureReduce volumeAdditive manufacturing apparatusMultiple way valves3d printIn vehicle

The invention discloses an integrated program-controlled valve group formed by 3D printing. By utilizing the advantages of fast and accurate molding of 3D printing technology, an integrated program-controlled valve group with its own internal integrated flow channel is obtained. Pipelines and valve components are integrated in the integrated program-controlled valve group in the form of unit blocks, so that the on-site valve area of the adsorption treatment system has a compact structure and reduced volume, which is convenient for modularization, skid-mounting, equipment and vehicle-mounting; at the same time, For this integrated program-controlled valve group, a new 3D printing molding process combining "printing molding + infiltration process + sintering process" is provided, which combines the characteristics of 3D printing rapid prototyping, and makes the inner wall surface of the complex flow channel after the part is formed. It is smooth and has excellent anti-wear and anti-cavitation capabilities, which completely solves the difficulties in processing and forming when the flow channel integration is too high during the skid-mounted design process of the valve area of the adsorption treatment system and the flow channel wall after forming. The problem of poor surface properties.

Owner:ZHEJIANG TIANCAIYUNJI TECH CO LTD

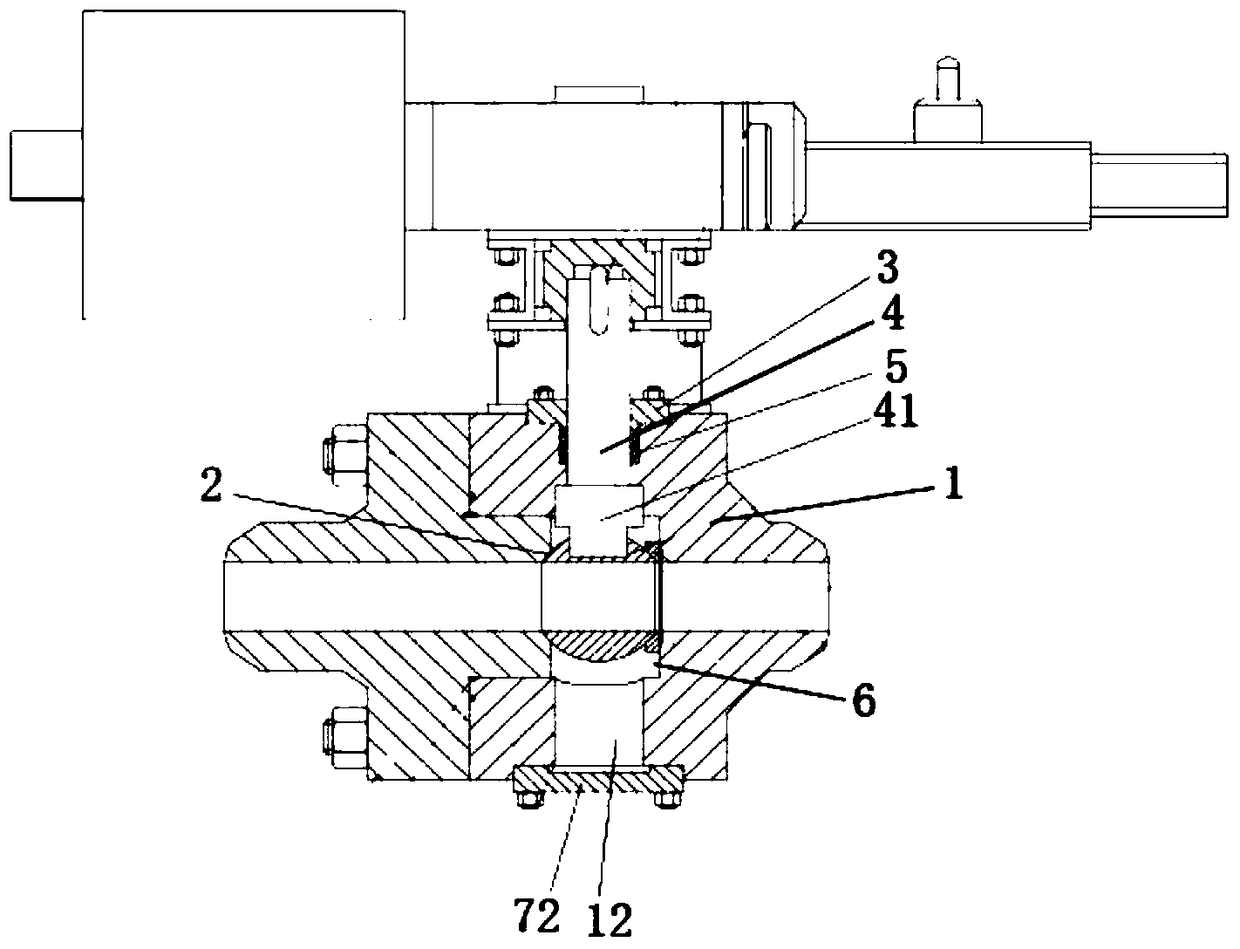

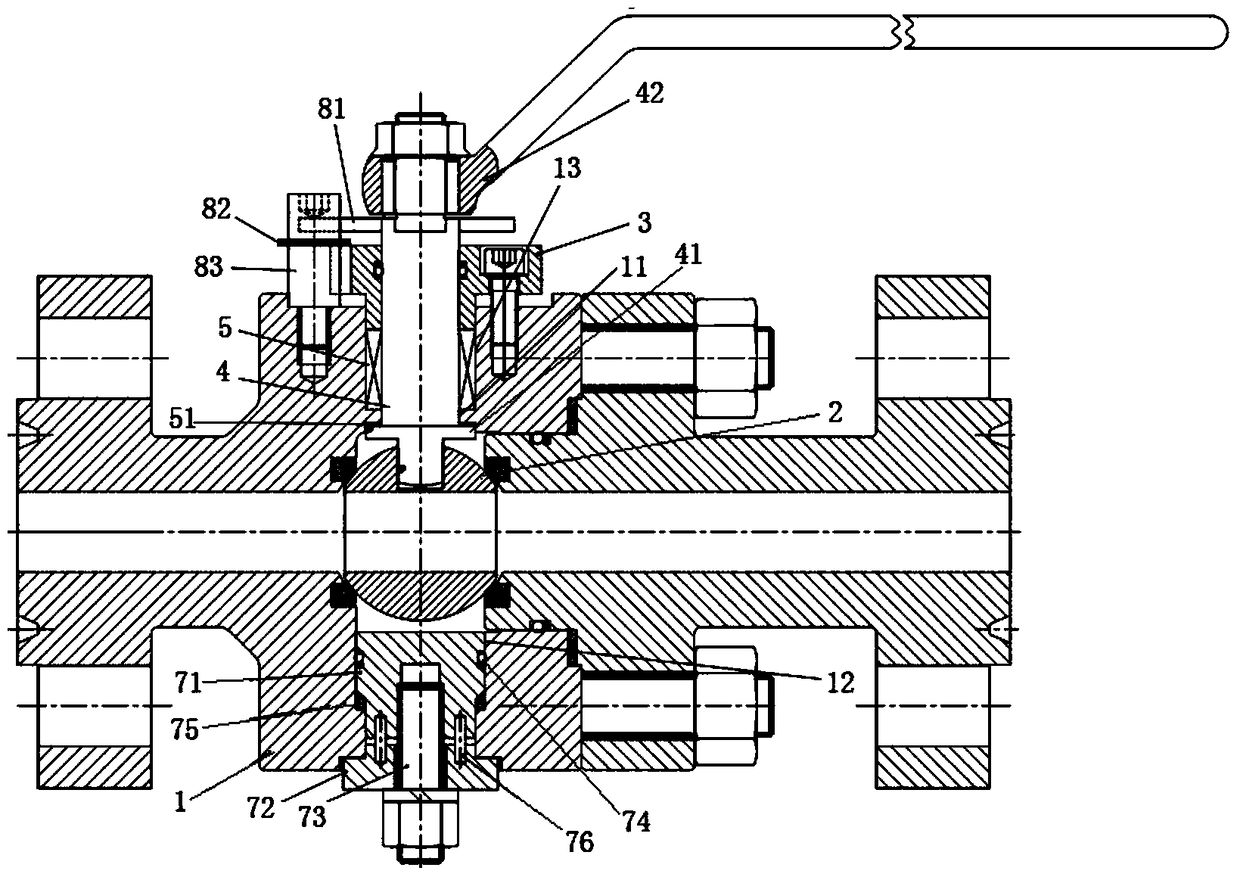

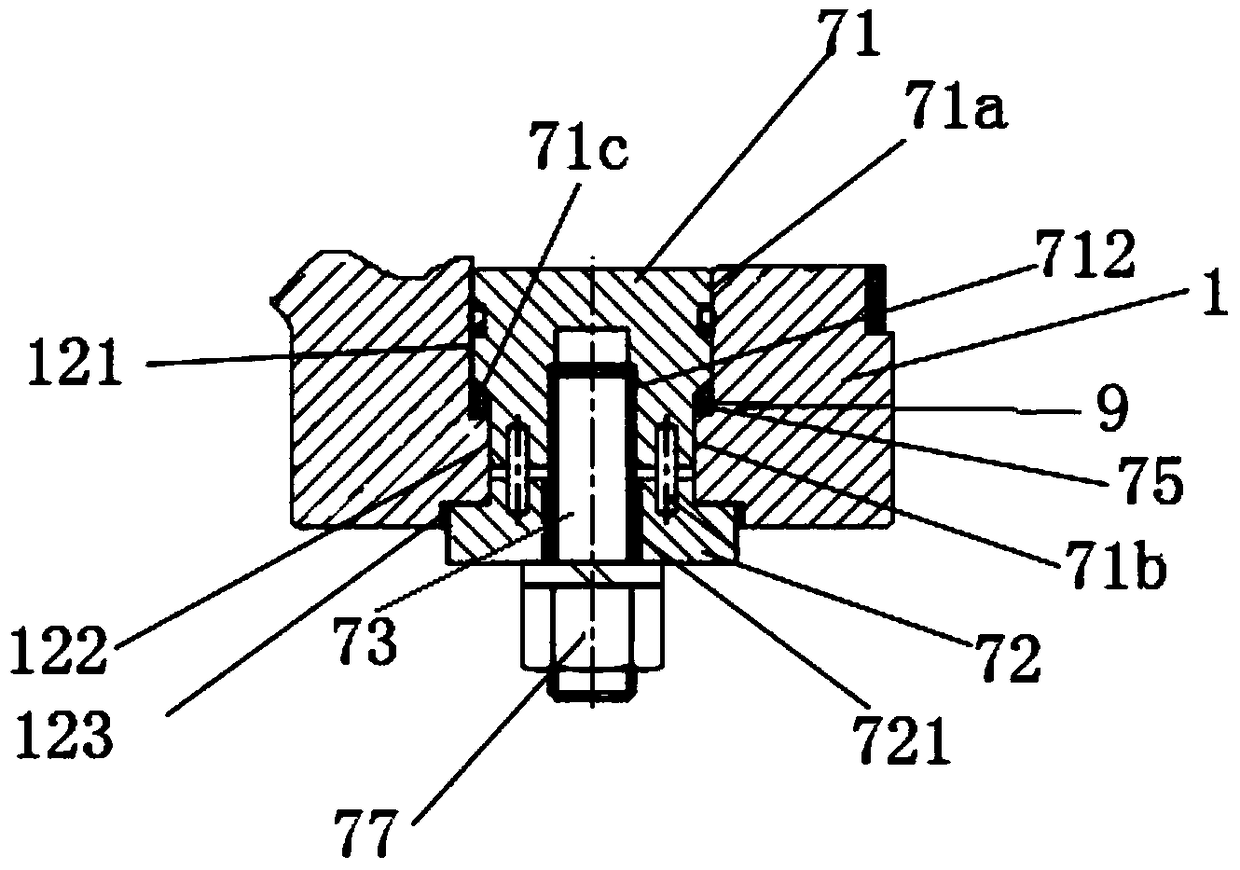

A floating ball valve

ActiveCN104747750BImprove sealingRealize "downloading"Plug valvesValve housingsEngineeringHigh pressure

The invention provides a floating ball valve. A through hole is formed in the bottom of the valve body, so that a valve rod smaller than the inner diameter of the through hole is installed in a valve rod installation hole through the through hole and a cavity, and lower mounting of the valve rod and blowing-out prevention are achieved. In addition, the through hole is set to be of a structure with a first through hole portion and a second through hole portion of which the inner diameter is smaller than that of the first through hole portion, a valve plug can not be blown out of the bottom of a valve body under the action of high-pressure media through the function of a protrusion of the second through hole portion, and after the valve plug is connected with a lower cover board, upward movement of the valve plug is blocked by a valve deck, so that after the valve plug and the lower cover board are connected, upward and downward movement of a whole sealing assembly is limited. Meanwhile, the valve plug is in sealed fit with the inner wall of the first through hole portion and / or the second through hole portion, the high-pressure media are prevented from being leaked from the gap between the through hole and the valve plug, the sealing performance of the ball valve is improved, and the ball valve can adapt to media of higher pressure.

Owner:NEWAY VALVE SUZHOU

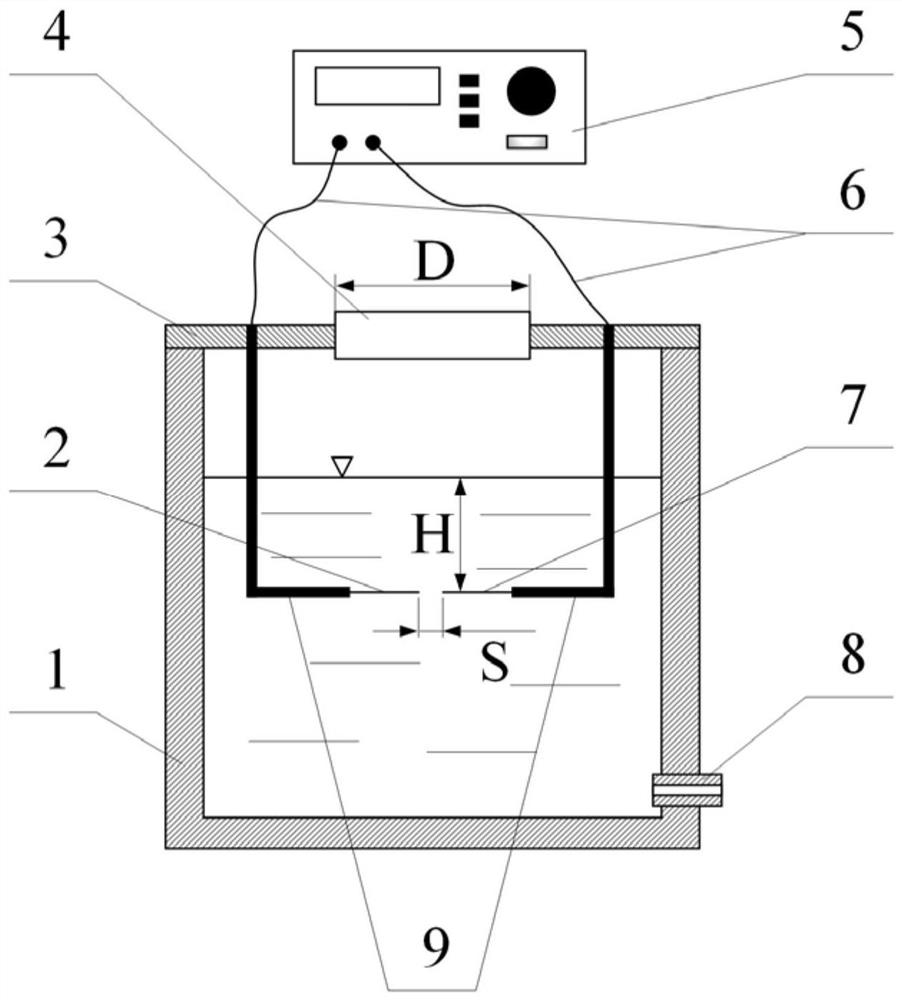

Droplet jetting device and method

The invention discloses a droplet jetting device and method, and belongs to the field of ink-jet printing. The droplet jetting device comprises a cavitation generator, a cavity, a cover plate and a nozzle. The cavitation generator is arranged on the cover plate, a liquid injection port is formed in the bottom of the cavity, and the cover plate and the nozzle are arranged at the upper end of the cavity. According to the device, under a combined action of the cavitation generator and a power supply controller, droplet jetting and conveying are completed through a liquid level breaking jet flow caused by cavitation behaviors near a liquid level, droplet conveying in a liquid level breaking form is adopted, the droplet jetting device is simple, compact, safe and reliable in structure, under the combined action of the cavitation generator and the power supply controller, the droplet jetting and conveying are completed through the liquid level breaking jet flow caused by the cavitation behaviors near the liquid level, no heating device, mechanical structure and other components exist, and the sealing performance and stability of the device are guaranteed. Therefore, the device has the advantages of simple structure, convenience in processing, low maintenance cost, high efficiency, energy conservation and the like.

Owner:浙江清科博动医疗科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com