Barrel cover sealing device of 3D printing gas filter barrel

A 3D printing and sealing device technology, which is applied in gas treatment, dispersed particle filtration, and process efficiency improvement, etc., can solve problems such as affecting the energy emitted by the laser, affecting the quality of metal moldings, and wasting protective gas, and guaranteeing the cover body. Sealing stability, easy and flexible adjustment of tightness, quick and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

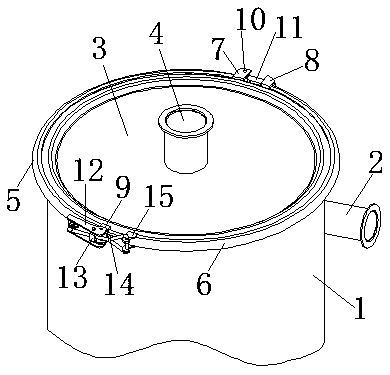

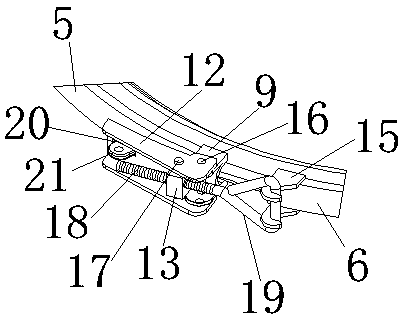

[0015] as attached Figure 1-2 The lid sealing device of a 3D printed gas filter barrel according to the present invention includes a filter barrel 1, an air intake pipe 2, a cover body 3, an exhaust pipe 4, a left half sealing strip 5, and a right half sealing strip 6 , the first connecting head 7, the second connecting head 8, the third connecting head 9, the first rotating shaft 10, the connecting rod 11, the adjusting handle 12, the rotating block 13, the pull rod 14, the hook 15, the second rotating shaft 16, the third rotating shaft 17. Threaded rod 18, triangular hanging ring 19, positioning hole 20 and positioning plate 21, the side of the filter bucket 1 is provided with an air intake pipe 2; the cover 3 is installed at the top of the filter bucket 1; The surface of the cover body 3 is provided with an exhaust pipe 4; the ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com