Mandrel type hanger of all-metal multi-stage and equidimension sealing structure

A sealed structure, all-metal technology, used in sealing/isolation, wellbore/well components, earth-moving drilling, etc., can solve the problems of poor metal sealing, unfavorable promotion, failure of rubber parts, etc., to ensure the stability of sealing , easy to promote and use, improve the effect of using time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the embodiments and the drawings.

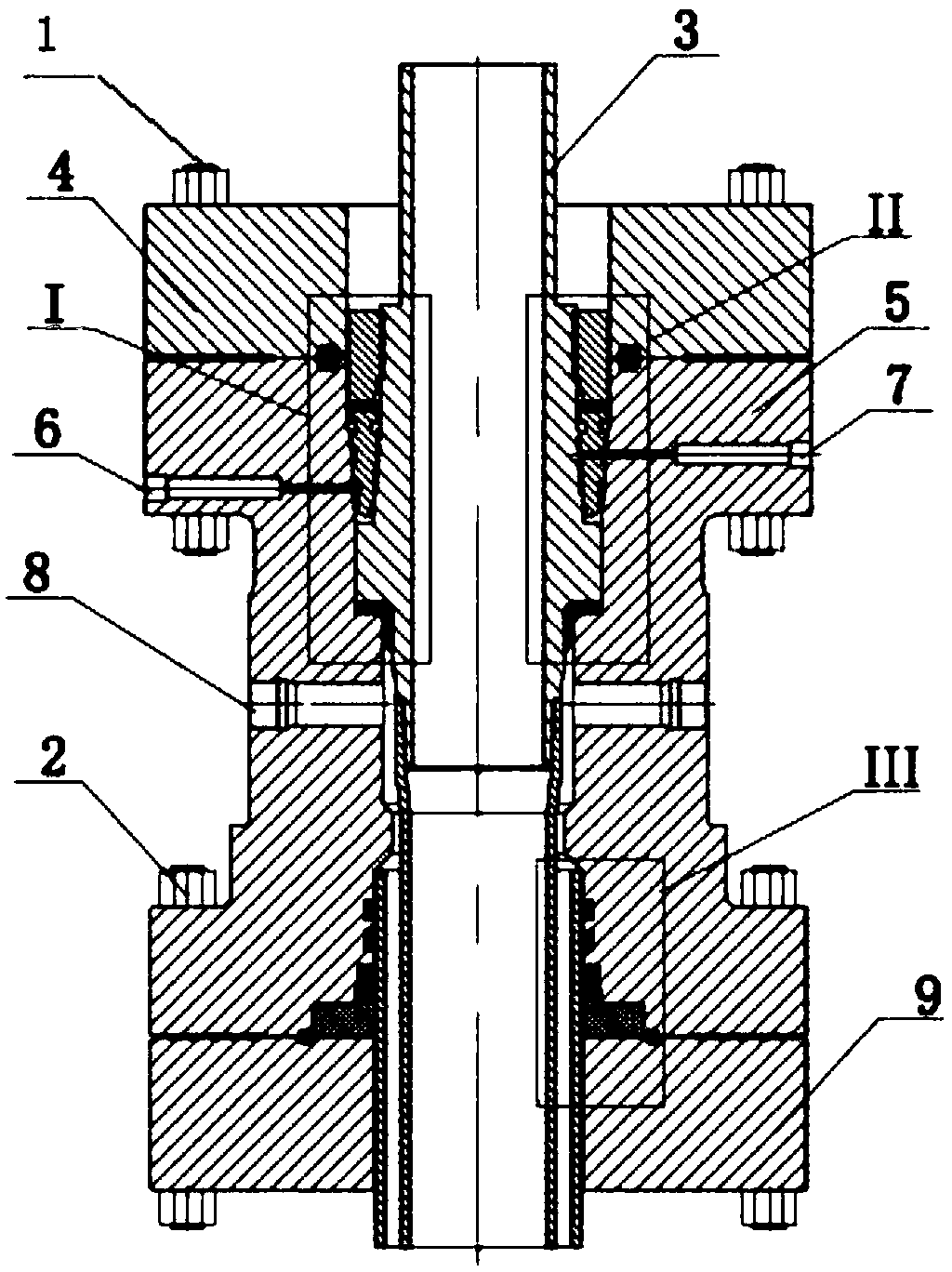

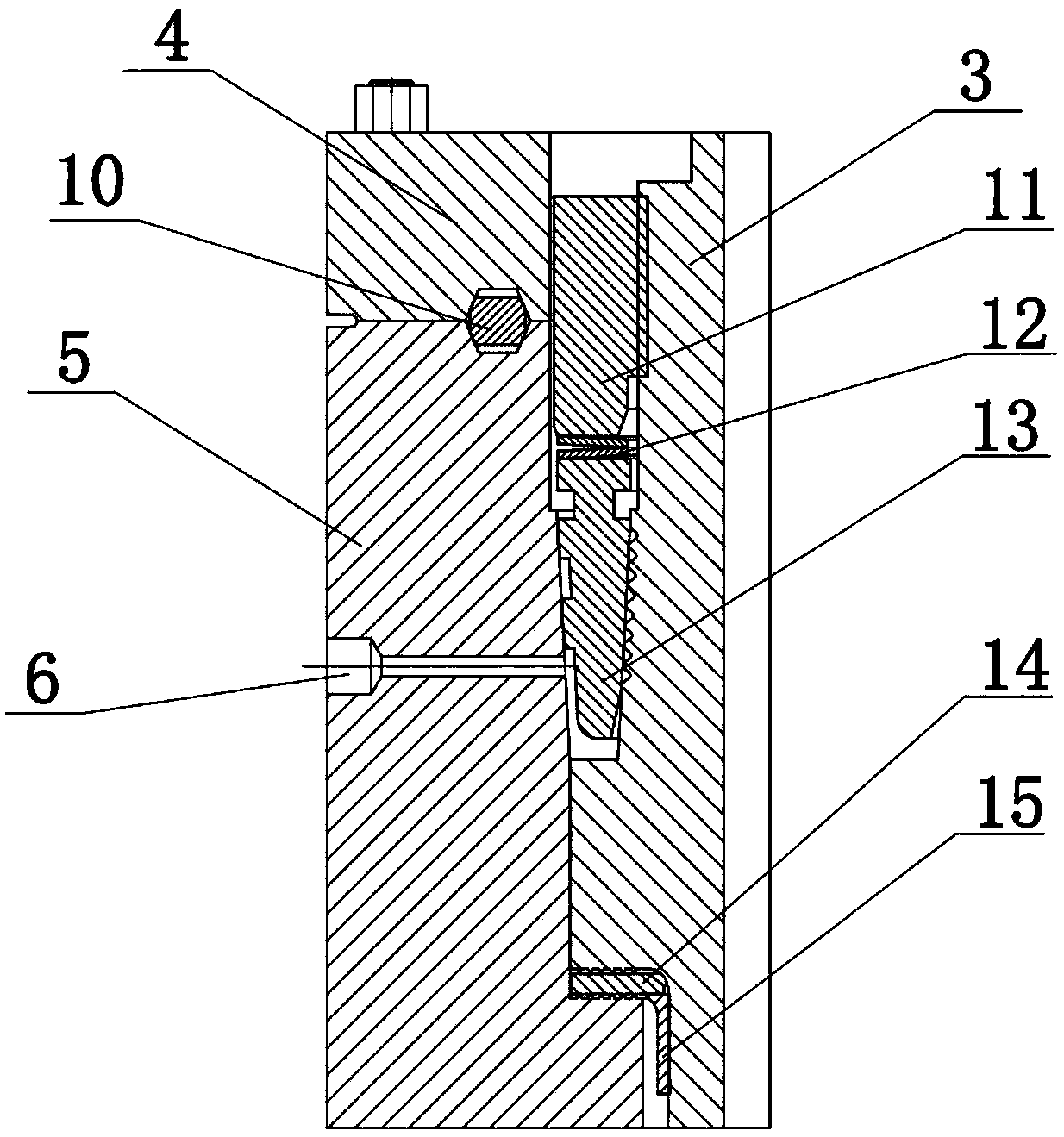

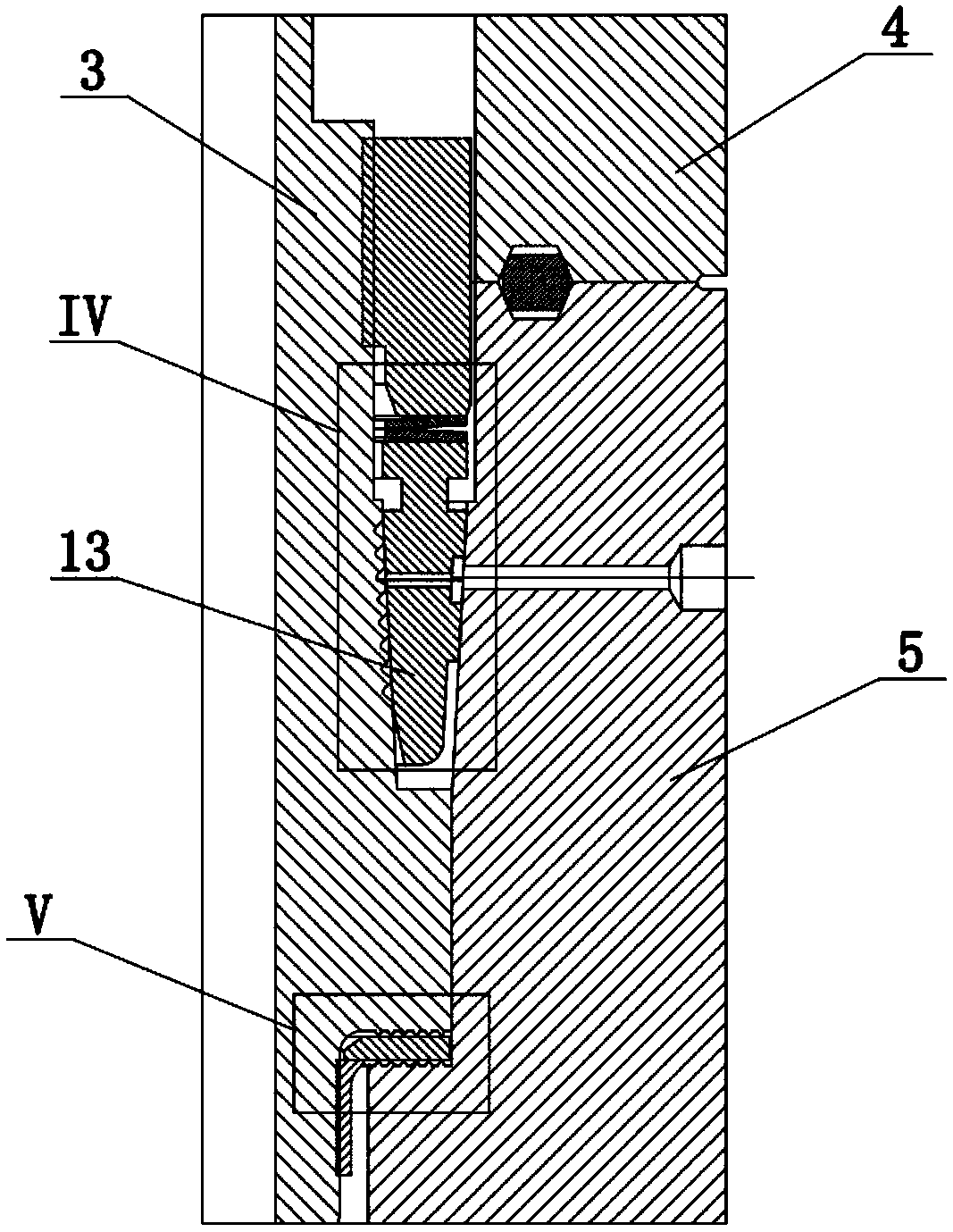

[0040] Such as figure 1 Shown, including mandrel 3, upper flange 4, cross 5, lower flange 9, spinning sleeve 11, tapered sealing ring 13, gasket ring 14, positioning ring 15, suspension sleeve 16, surface sleeve 17. Metal pressure ring 21, X-shaped sealing ring 22, support gasket 23;

[0041] The mandrel 3 includes a neck section 31, an upper stage 32, a conical surface section 33, a lower stage 34, a connecting thread section 35, and a tapered thread section 36 from top to bottom. The upper part of the inner wall of the four-way 5 is provided with a conical surface , With a shoulder in the middle and an annular step groove in the lower part;

[0042] The positioning ring 15 is threadedly connected to the connecting thread section 35, the sealing ring 14 is fixed on the lower end surface of the lower stage 34 through the positioning ring 15, and the suspension sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com