Oil-cooled compressor with multiple pipelines and control method

A control method and compressor technology, applied in pump control, mechanical equipment, machine/engine, etc., can solve problems such as reduced production efficiency, loud compressor noise, and inability to work normally, to increase overall reliability, reduce noise, The effect of reducing the transmission of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

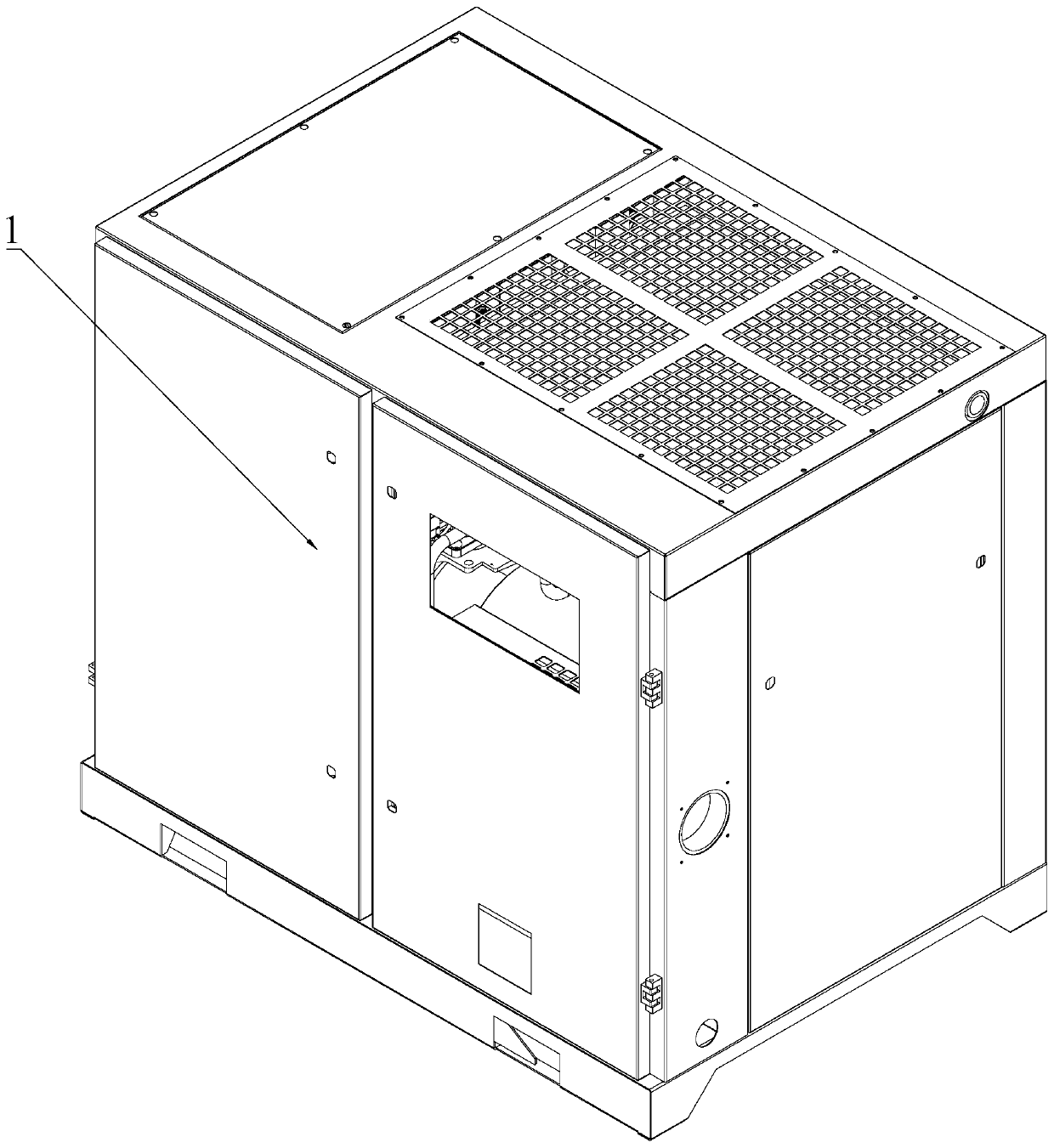

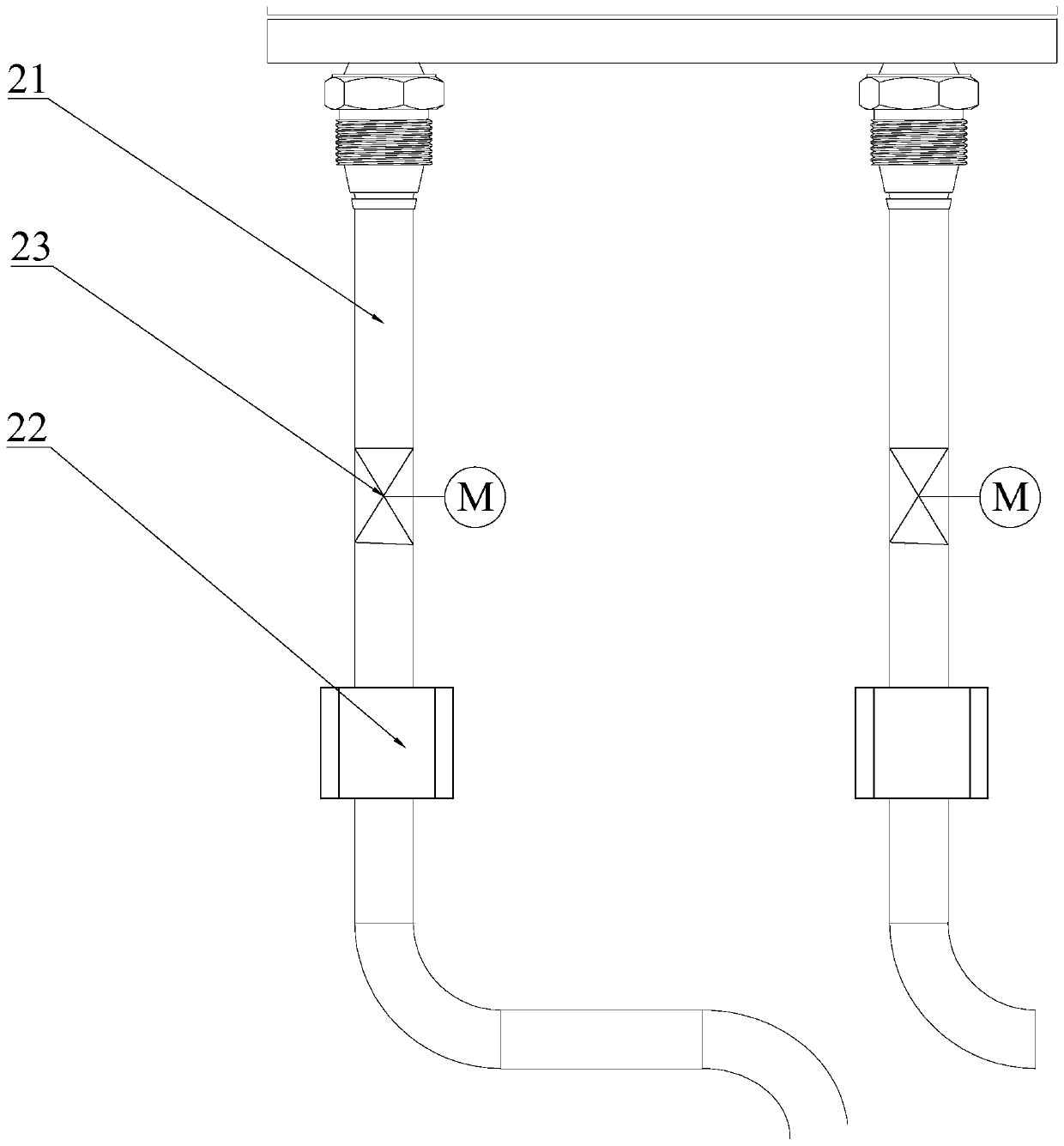

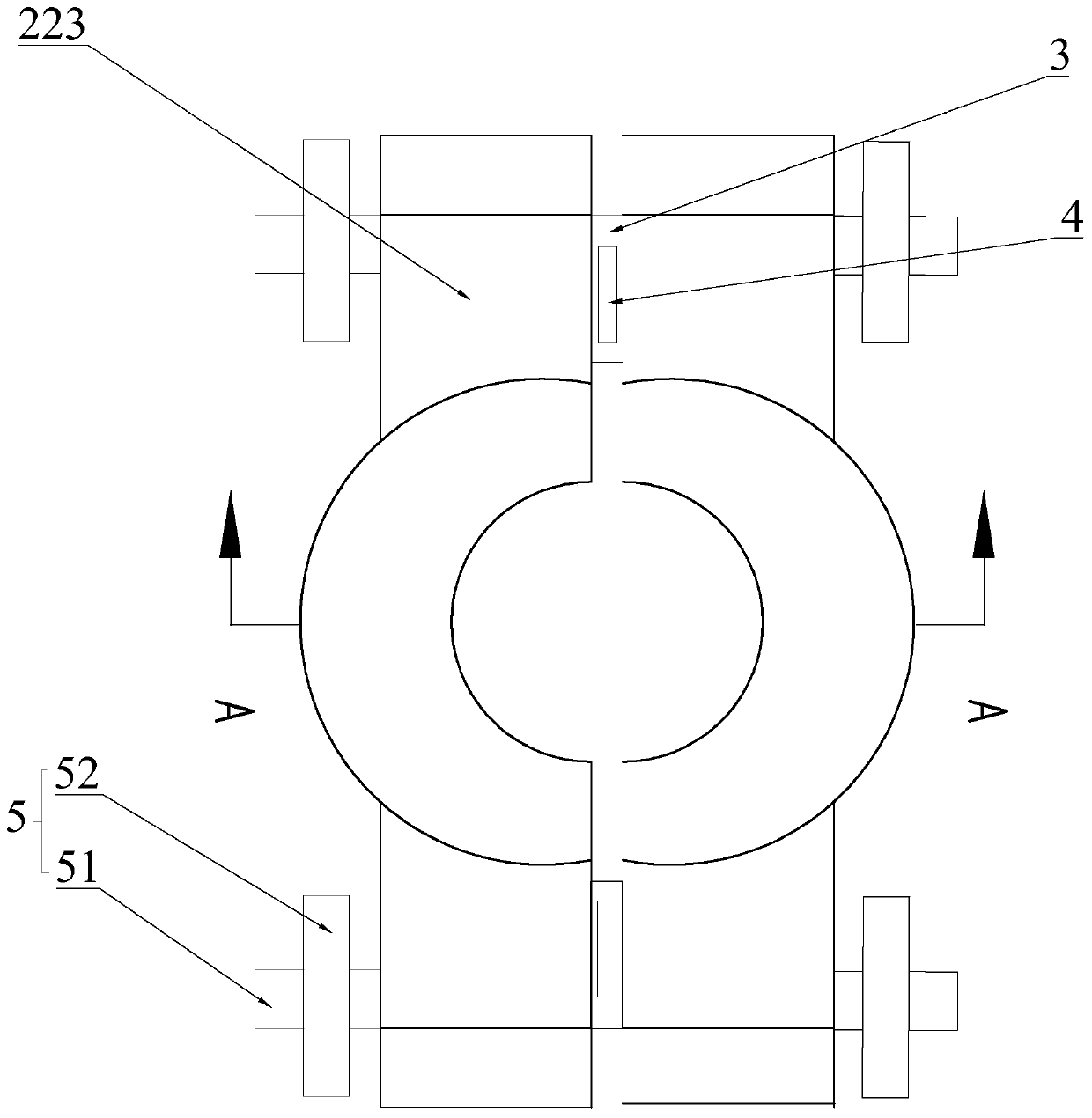

[0030] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the oil-cooled compressor with multiple pipelines of the present invention includes a body 1 and an oil-cooling mechanism 2 connected to the body 1. The oil-cooling mechanism 2 includes at least two pipelines 21 and is used for pipelines. 21 connected flexible connection assembly 22, the pipeline 21 is provided with a control valve 23, the flexible connection assembly 22 includes a flexible connection ring 221 and a fixed ring 223 sleeved on the flexible connection ring 221, the The two ends of the flexible connecting ring 221 are respectively provided with at least one card slot 222, and the elastic sealing ring 224 is fitted in the card slot 222, and the fixed ring 223 is composed of two spliced fixed half rings. The elastic part 3 is in contact with the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com