High-temperature-resistant three-eccentric center butterfly valve

A triple eccentric butterfly valve, high temperature resistant technology, applied in the direction of valve lift, valve details, valve device, etc., can solve the problems affecting the sealing and normal use of the butterfly valve, poor high temperature resistance performance of the butterfly valve, uneven force on the valve body, etc. The force is uniform, the opening and closing torque is small, and the effect of reducing sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

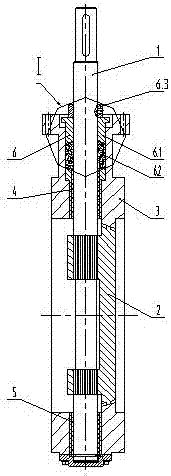

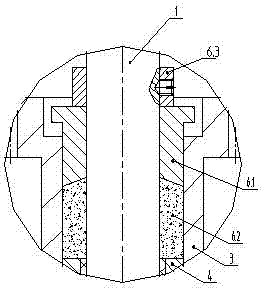

[0020] The high temperature resistant triple eccentric butterfly valve shown in the accompanying drawings includes a valve stem 1, a valve plate 2 and a valve body 3, and the valve stem 1 and valve plate 2 are connected by a spline structure. The valve rod 1 is respectively supported on the upper part and the lower part of the valve body 3 through the upper bearing 4 and the lower bearing 5 arranged up and down. The upper bearing 4 and the lower bearing 5 are composite sliding bearings, which are composed of an outer bush and an inner bush. The outer bush is made of carbon steel, alloy steel or cast iron, and the inner bush is made of friction-resistant, high-temperature-resistant, Made of alloy material with low coefficient of friction, the outer wall of the inner bush is provided with an annular protrusion embedded in the ring groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com