High-temperature and high-pressure valve packing sealing structure

A packing seal, high temperature and high pressure technology, applied in the shaft seal, valve details, valve device, etc., can solve the problems that affect the sealing stability of the bonnet and valve stem, the medium leaks to the outside of the bonnet, and the packing and valve stem are easy to corrode. , to achieve the effect of preventing fugitive leakage, preventing filler deformation and chemical reaction, and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below by means of specific embodiments:

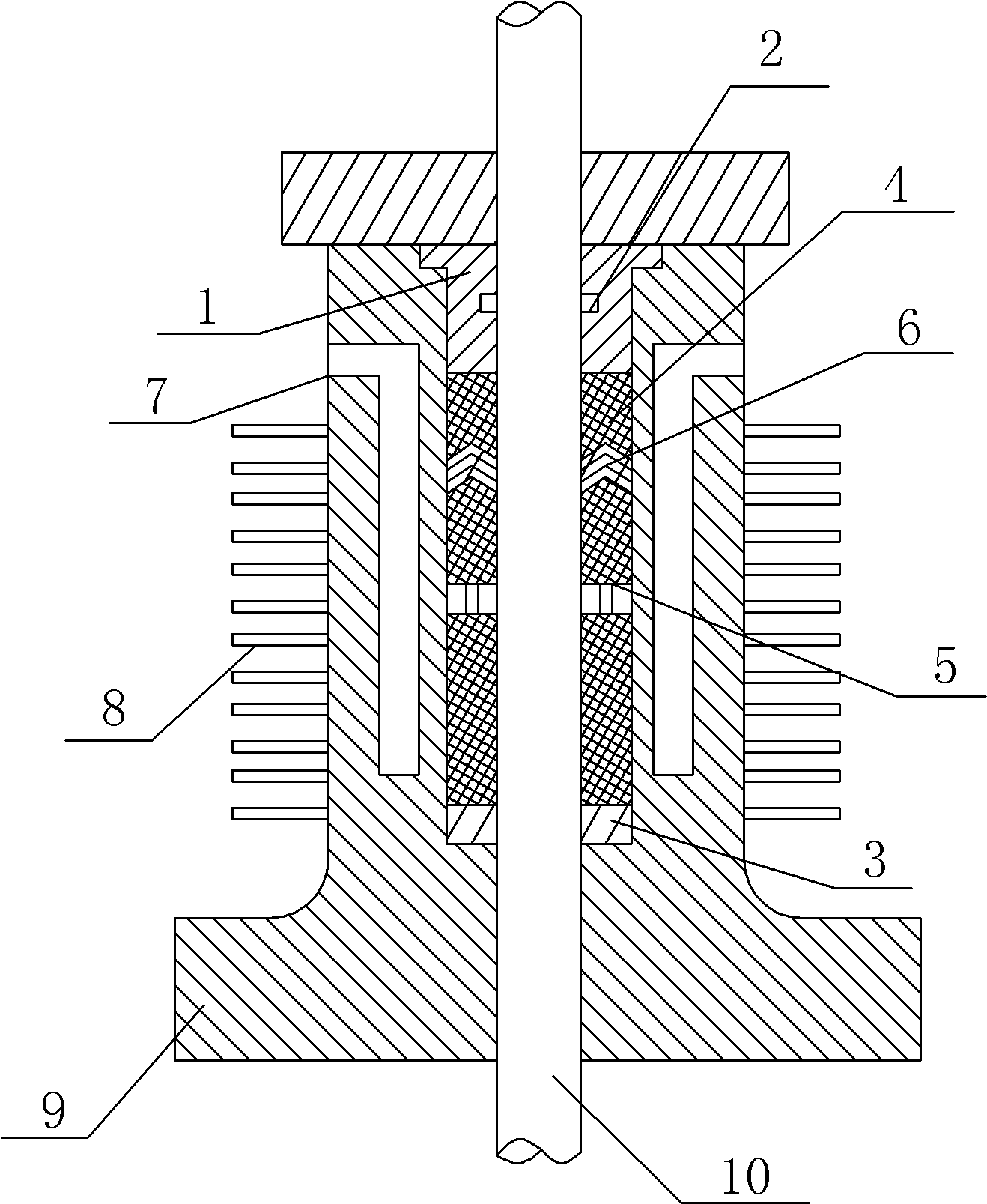

[0013] Instructions attached figure 1 The reference signs in include: 1-packing gland, 2-O type sealing ring, 3-bottom gasket, 4-carbonized fiber impregnated PTFE braided packing / braided packing, 5-spacer ring, 6-V-shaped four Fluorine filler, 7-cooling water channel, 8-fan heat fin, 9-bonnet, 10-valve stem.

[0014] The embodiment is basically as attached figure 1 As shown: the high temperature and high pressure valve packing seal structure is located in the packing chamber of the valve cover 9, and the valve stem 10 axially penetrates the packing chamber. The high-temperature and high-pressure valve packing sealing structure in this embodiment includes a packing gland 1, which is located at the upper port of the packing chamber and closes the upper port, and the packing gland 1 leaves only the valve stem for the valve stem 10 to move There is a sealing groove on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com