Vacuum pressure paint dipping equipment

A technology of vacuum pressure dipping and equipment, which is applied in the direction of controlling mechanical energy, manufacturing motor generators, electrical components, etc. problems, to achieve the effect of convenient operation, ensuring vacuum, and ensuring support stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in detail below in conjunction with accompanying drawing:

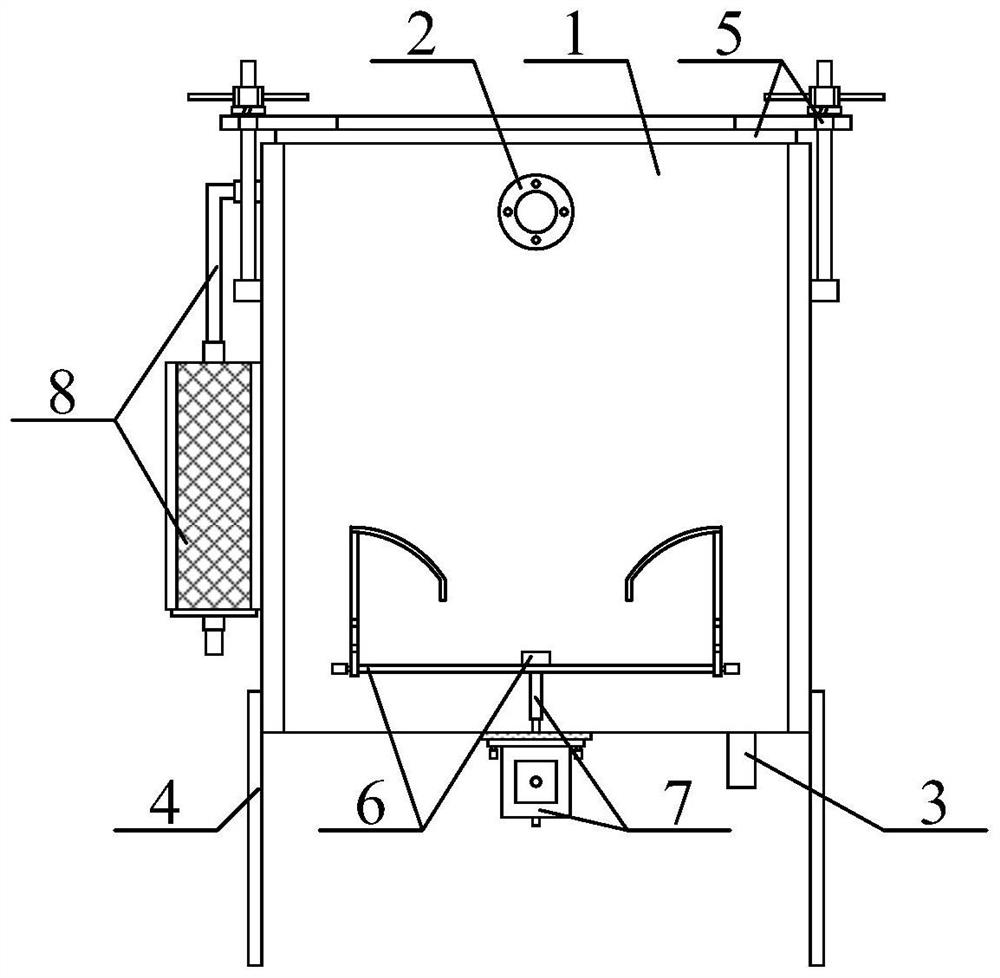

[0032] as attached figure 1 And attached figure 2 As shown, the vacuum pressure impregnation equipment of the present invention includes a paint dipping tank 1, a vacuum pipe 2, a return pipe 3 and a support leg 4, and a vacuum pipe is threaded at the outlet of the upper middle part of the front part of the paint dipping pot 1 2. The four corners of the bottom of the paint dipping tank 1 are bolted to support legs 4, which can ensure the stability of the dipping paint.

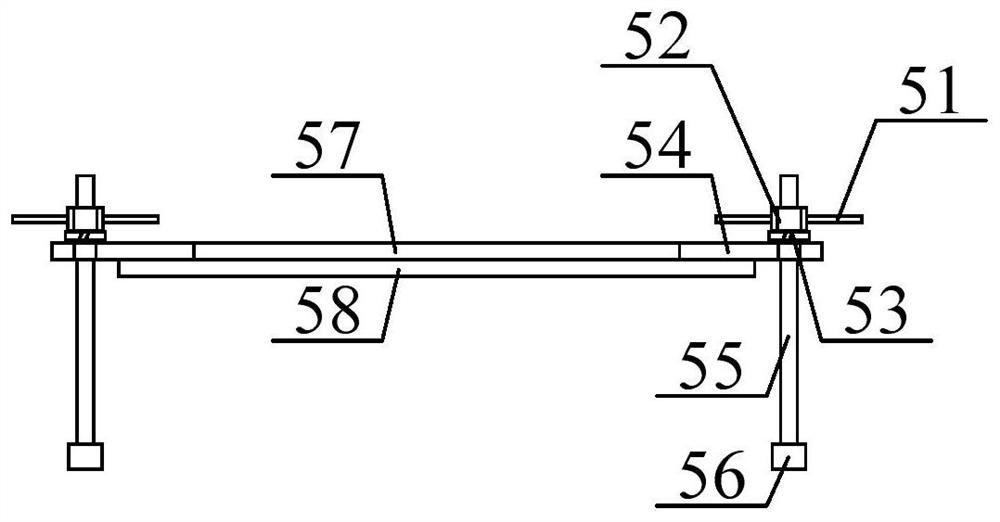

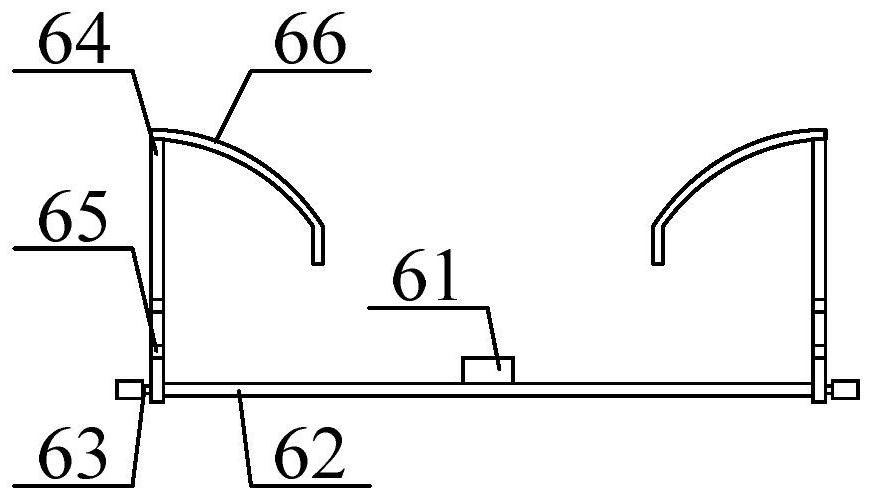

[0033] Among them, the vacuum pressure impregnation equipment also includes an observable sealed opening and closing cover structure 5, an adjustable product clamping impregnation tray structure 6, a rotary impregnation machine structure 7 and an anti-particle paint filter tube structure 8. Observe that the sealed opening and closing cover structure 5 is connected with the paint dipping tank 1; the adjustab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com