Polymeric reactor for polyphenylene sulfide

A technology of polymerization reaction kettle and polyphenylene sulfide, which is applied in chemical/physical/physical chemistry fixed reactors, chemical instruments and methods, methods of chemically changing substances by atmospheric pressure, etc., can solve the problem of sticking to the kettle wall And internal parts surface, quality substandard, incomplete response and other problems, to achieve the effect of improving the accuracy of internal temperature control, low heat loss, and ensuring flexibility and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

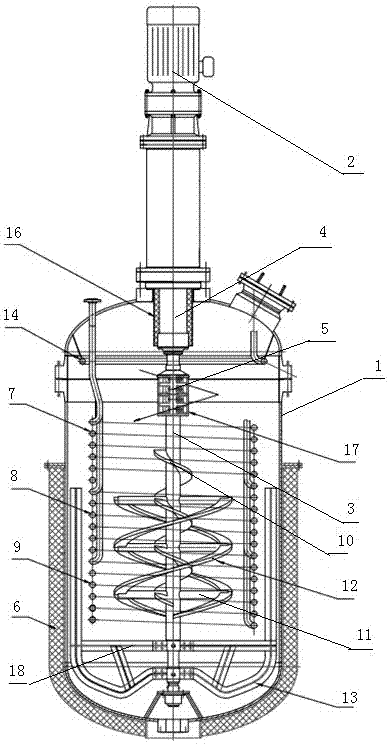

[0015] Below in conjunction with accompanying drawing, the present invention is further described:

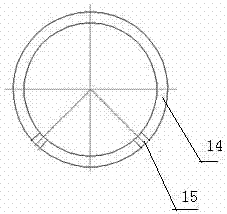

[0016] As shown in the drawings, a polyphenylene sulfide polymerization reaction kettle includes a kettle body 1, a stirring motor 2, a stirring shaft 3, an agitator and a magnetic coupling drive 4, and a stirring motor is arranged above the kettle body 1 2. The output shaft of the stirring motor 2 is connected with the magnetic coupling drive 4 extending into the kettle body 1, the upper end of the magnetic coupling drive 4 is connected with the stirring motor 2, and the lower end of the magnetic coupling drive 4 passes through the coupling 5 Connected with the stirring shaft 3, the stirring shaft 3 is provided with a stirrer, the structure of the above-mentioned components and the interconnection relationship between them are the same as those of the prior art, which will not be described in detail here, it is characterized in that the kettle body 1 An external rapid temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com