A floating ball valve

A floating ball valve and valve body technology, applied in the field of valve manufacturing, can solve the problem that the floating ball valve cannot take into account the installation stability of the valve stem and the overall sealing performance of the ball valve, and achieve the effects of preventing leakage, ensuring stability and ensuring sealing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

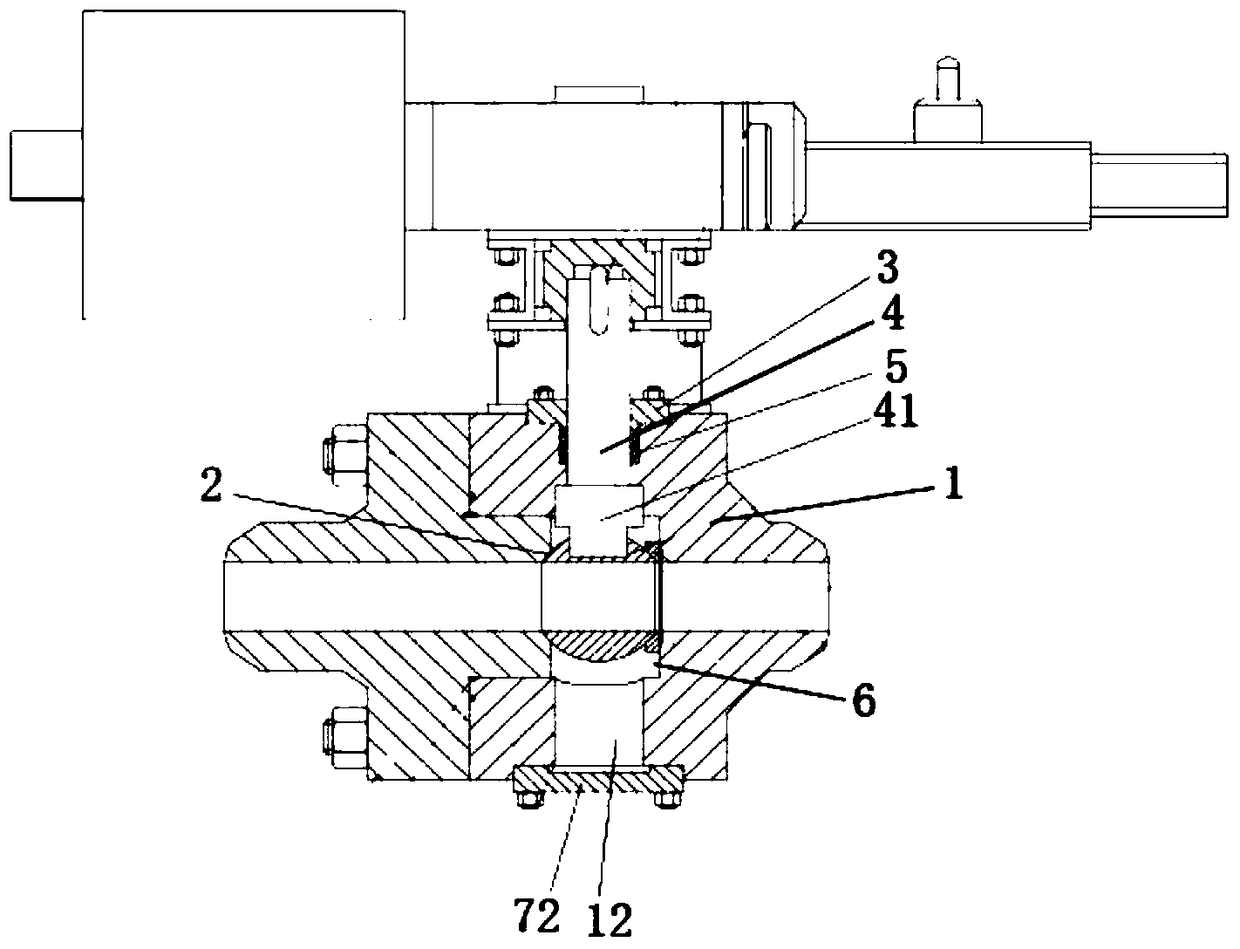

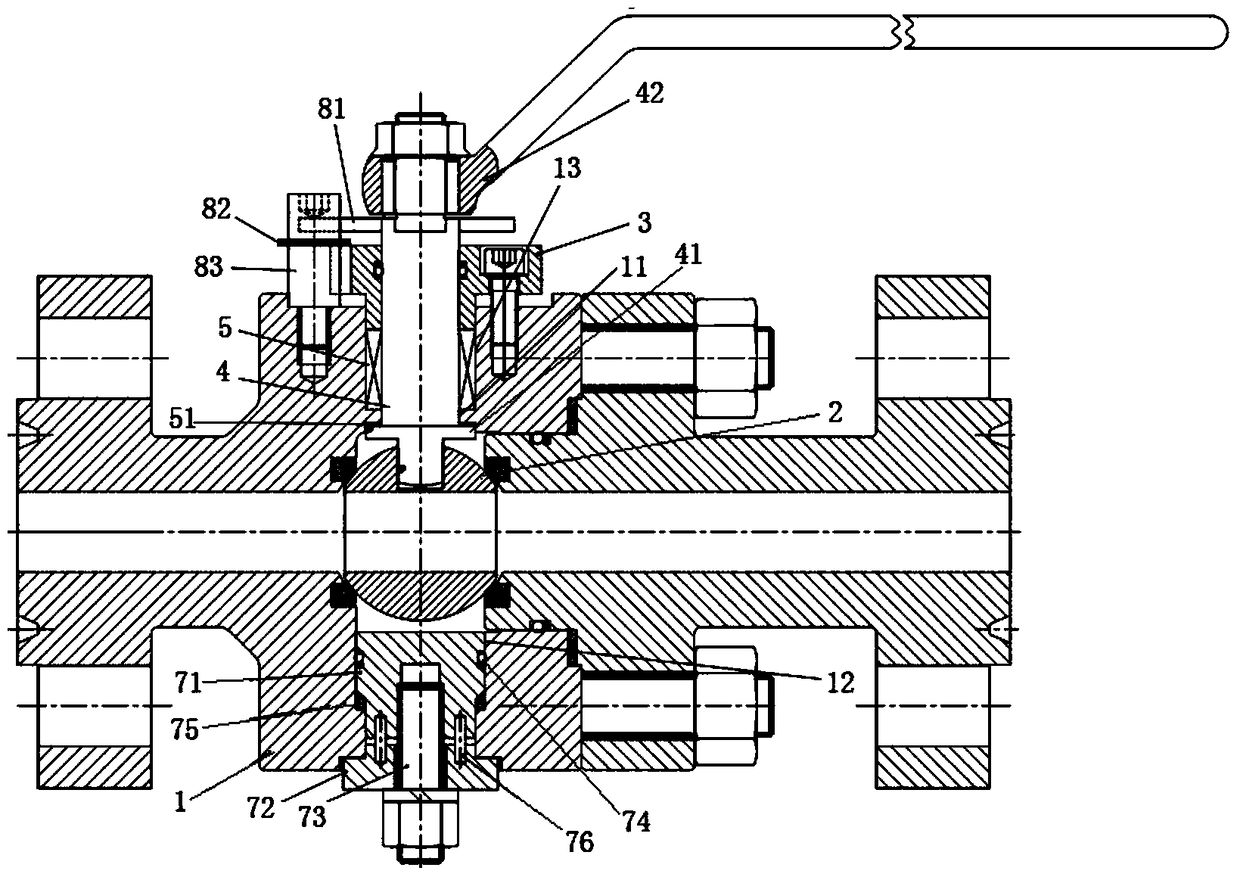

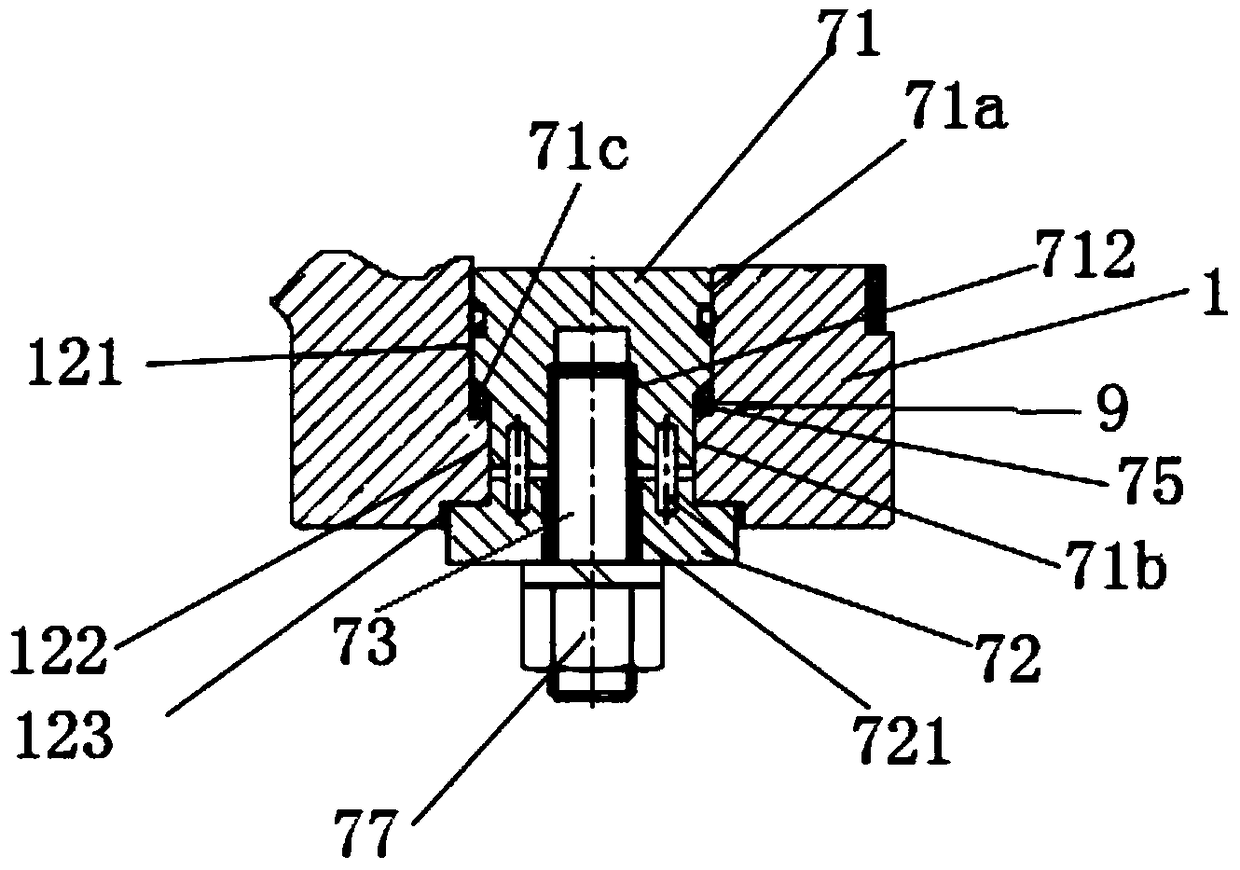

[0037] This embodiment provides a floating ball valve, including: a valve body 1, a valve core 2 arranged in the valve body 1, a valve stem installation hole 11 arranged on the valve body 1, a cover mounted on the valve stem The upper cover plate 3 on the installation hole 11 passes through the upper cover plate 3 and the valve stem installation hole 11 and extends into the valve body 1 and the valve stem 4 which is set in conjunction with the valve core 2 , the valve stem 4 and the valve body 1 are sealed and connected through the sealing packing 5, the bottom of the valve body 1 is provided with a through hole 12 opposite to the valve stem installation hole 11, and the through hole 12 is sealed. A sealing assembly for the hole 12, the through hole 12 has a first through hole portion 121 and a second through hole portion 122 connected to the first through hole portion 121 and having an inner diameter smaller than the first through hole portion 121, the sealing assembly It inc...

Embodiment 2

[0063] This embodiment provides a floating ball valve, which is a deformation on the basis of Embodiment 1. It differs from Embodiment 1 only in the setting of the fixing structure, such as Image 6 As shown, in the fixing structure of this embodiment, the stud 73 is directly formed on the end of the valve plug 71 close to the lower cover plate 72 (that is, the end of the valve plug 71 close to the lower cover plate 72 has a columnar protrusion, and the protrusion The outer surface of the raised portion is formed with threads, so that the raised portion becomes a stud 73), and the arrangement of the nut 77 and the lower cover plate 72 is the same as in Embodiment 1. The stud 73 is directly molded on the valve plug 71 to make installation and disassembly more convenient.

Embodiment 3

[0065] This embodiment provides a floating ball valve, which is a deformation on the basis of Embodiment 1. It differs from Embodiment 1 only in the setting of the fixing structure, such as Figure 7 As shown, the fixing structure of this embodiment includes four screw holes 712 symmetrically formed on the valve plug 71 , and similarly, the number of mounting holes 721 and nuts 77 is also four. Certainly, other numbers of the screw holes 712, the installation holes 721 and the nuts 77 may also be used. After a plurality of screw holes 712 , installation holes 721 and nuts 77 are provided, the connection between the valve plug 71 and the lower cover plate 72 is more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com