An integrated program-controlled valve group formed by 3D printing

A technology of 3D printing and program-controlled valve group, which is applied in the direction of multi-way valves, valve devices, valve details, etc., can solve the problem of poor surface performance of the flow channel wall, and achieve a compact structure of the valve area, high safety, and strong reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

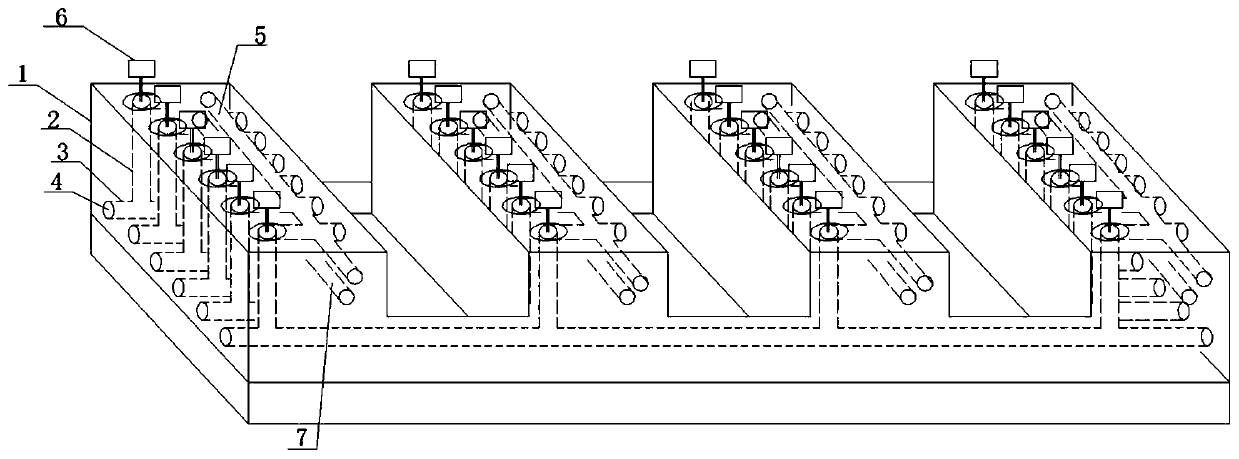

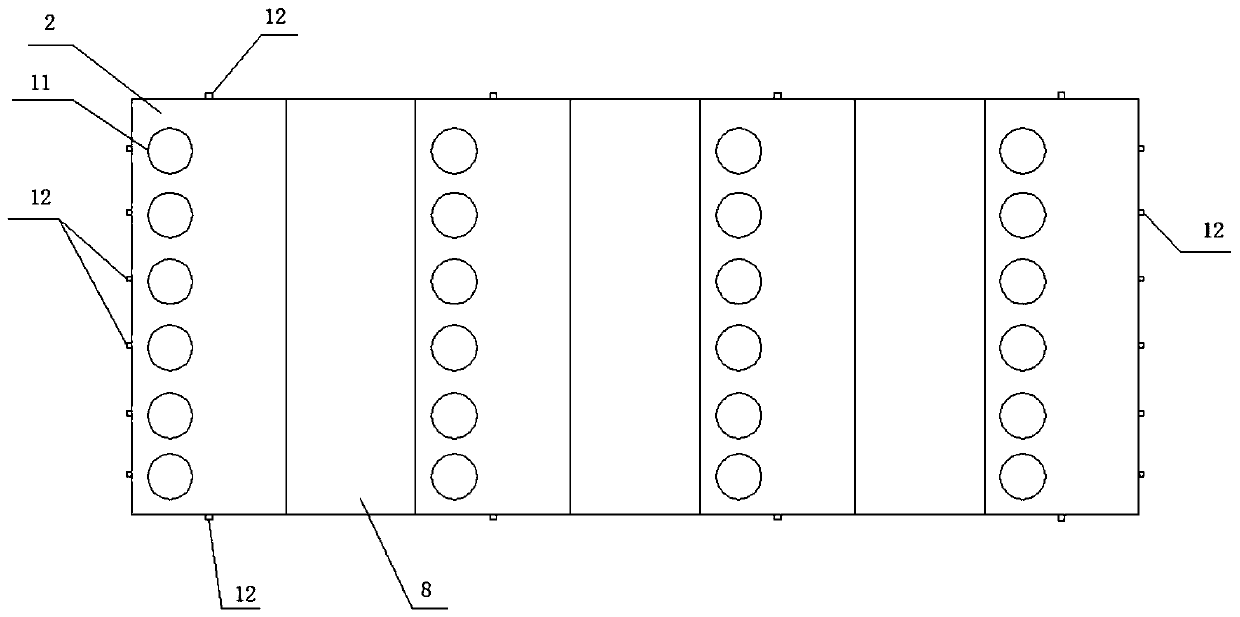

[0081] This embodiment provides an integrated program-controlled valve group for the problem that the valve area of the existing adsorption treatment system is too large and is not convenient for integrated skid-mounted design, specifically including: the valve group body; the valve group body is set There are several unit blocks 1, and the bottom is provided with several converging flow channels 3 that pass through the unit blocks 1 left and right; the unit block 1 is provided with an inlet flow channel 7 and an outlet flow channel 5 that pass through the unit block 1 front and rear, and A plurality of branch channels 2 corresponding one-to-one to the converging channel 3; one end of each of the branch channels 2 is communicated with the outlet channel 5, and the other end is in communication with the corresponding converging channel 3, and each of the branch channels Channels 2 are provided with controllable valves 6; the surface of the unit block 1 is provided with opening...

Embodiment 2

[0106] An integrated program-controlled valve group formed by 3D printing, comprising the following steps:

[0107] 1) Raw material preparation: According to the needs of the integrated program-controlled valve group, prepare skeleton materials, permeable materials and support materials;

[0108] 2) Printing and molding: use a multi-nozzle 3D printer to print layer by layer according to the shape and size of the integrated program-controlled valve group, and form a preliminary molded part; each layer is made of skeleton material, permeable material and support material. one or more of the constituents of

[0109] 3) Part sintering: the preliminary shaped part obtained in step 2 is preheated, supported material consolidated, carburized, quenched and tempered to obtain a sintered shaped part;

[0110] 4) Part cleaning: After blowing off the pyrolysis residues and ultrasonic water washing of the sintered shaped part obtained in step 3, the shaped part is obtained.

[0111] Wher...

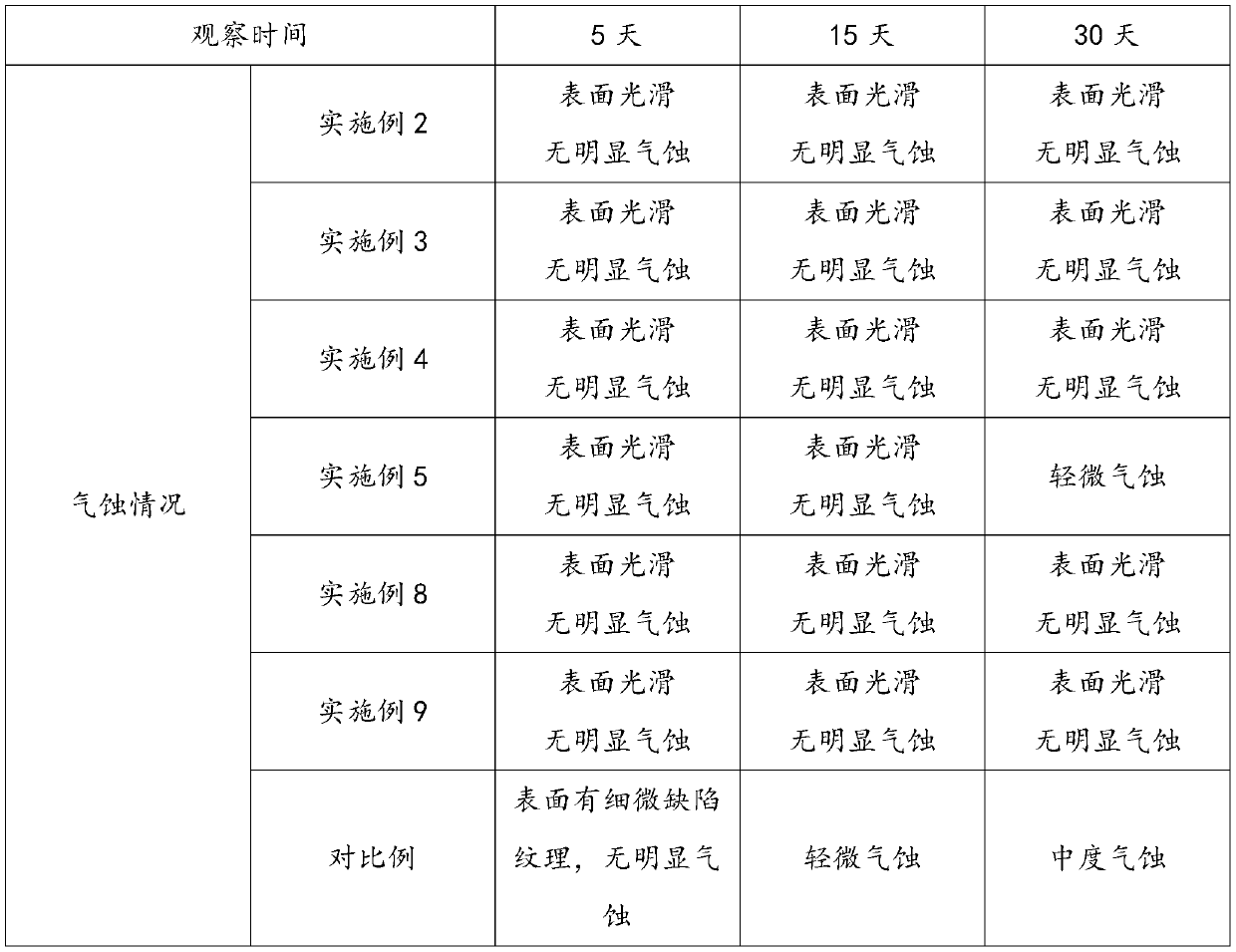

Embodiment 3

[0125] An integrated program-controlled valve group formed by 3D printing, comprising the following steps:

[0126] 1) Raw material preparation: According to the needs of the integrated program-controlled valve group, prepare skeleton materials, permeable materials and support materials;

[0127] 2) Printing and molding: use a multi-nozzle 3D printer to print layer by layer according to the shape and size of the integrated program-controlled valve group, and form a preliminary molded part; each layer is made of skeleton material, permeable material and support material. one or more of the constituents of

[0128] 3) Part sintering: the preliminary shaped part obtained in step 2 is preheated, supported material consolidated, carburized, quenched and tempered to obtain a sintered shaped part;

[0129] 4) Part cleaning: After blowing off the pyrolysis residues and ultrasonic water washing of the sintered shaped part obtained in step 3, the shaped part is obtained.

[0130] Wher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com