Dry pulse bag type dust collector and application thereof

A dust collector and pulse technology, applied in the field of environmental protection equipment, can solve the problems of high pressure resistance, unfavorable anti-vibration service life, unintegrated manufacturing field, unfavorable filtration, etc. The effect of seal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

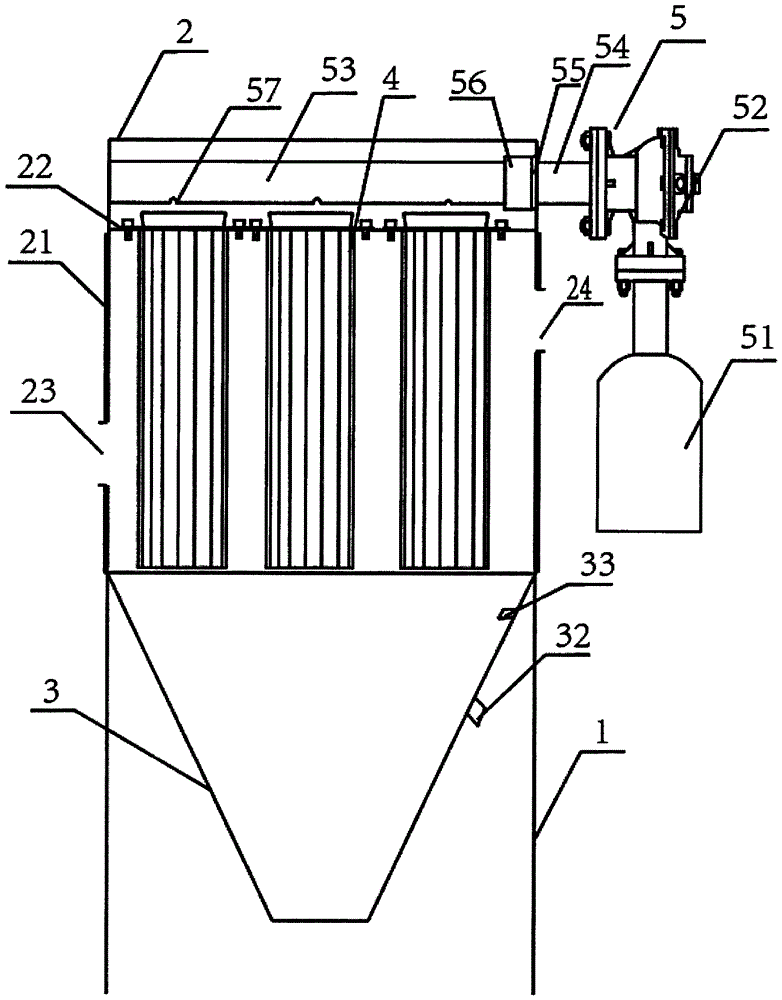

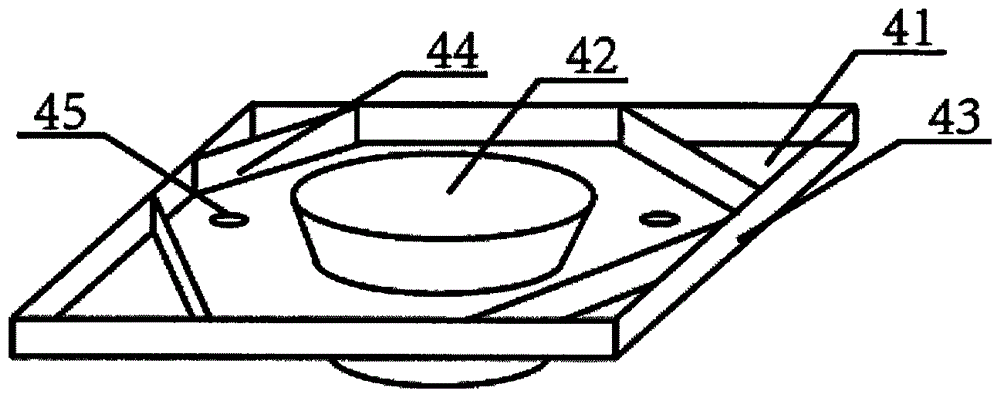

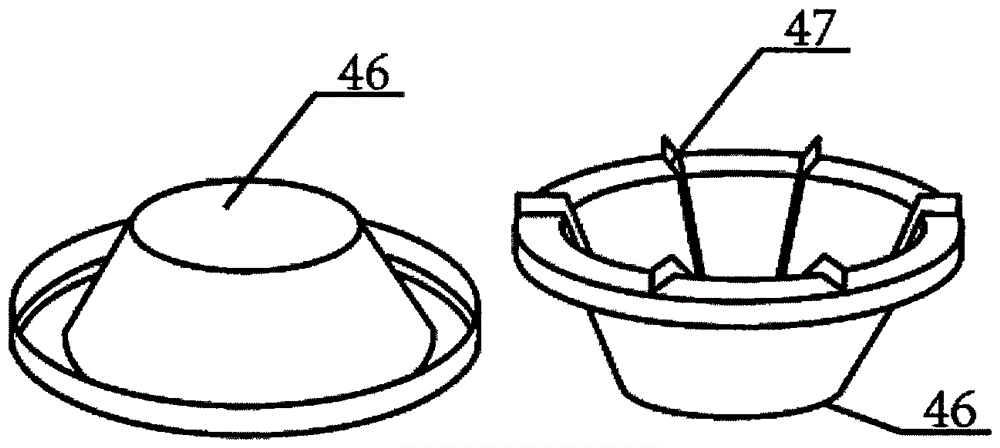

[0032] See attached figure 1 , a dry pulse bag filter, including a bracket 1, a square shell 2, an ash hopper 3, a filter 4 and an air blowing device 5; the square shell is installed on the bracket, and the ash hopper is installed under the square shell; the shell There is an opening on the bottom of the body, an opening on the top of the ash hopper, and a dust outlet at the bottom of the ash hopper (this figure is not marked for simplicity, see Figure 5 ), the outer wall of the ash hopper is provided with a vibrating device 32, and the inside of the ash hopper is provided with a high material level detection device 33. The ash hopper is a four-sided platform structure, and the angle between the side edge of the four-sided platform and the upper bottom surface is 65 degrees; the shell The area of the bottom surface is consistent with the area of the top surface of the ash hopper, and the shell is connected with the ash hopper; a mounting plate 22 is arranged above the ins...

Embodiment 2

[0038] Dry pulse bag filter, including bracket, square shell, ash hopper, filter and air blowing device; the square shell is installed on the bracket, and the ash hopper is installed under the square shell; the bottom of the shell is open, and the top of the ash hopper The bottom of the ash hopper is equipped with a dust outlet, the outer wall of the ash hopper is equipped with a vibration device, and the inside of the ash hopper is equipped with a high material level detection device. is 65 degrees; the bottom surface area of the shell is consistent with the top surface area of the ash hopper, and the shell is connected with the ash hopper; there is a mounting plate on the top of the shell, and the filter is installed on the mounting plate, and the filter includes a filter The upper plate of the filter, the lower plate of the filter, and the filter bag between the upper plate of the filter and the lower plate of the filter; the upper plate of the filter includes a filter s...

Embodiment 3

[0040]A dry-type pulse bag dust collector, the main structure is consistent with the first embodiment, including a bracket, a square shell, an ash hopper, a filter, and an air blowing device; among them, the following parts are different in size ① The ash hopper is a square platform structure, The angle between the side edges of the four-sided platform and the upper bottom surface is 75 degrees; ②The pulse air inlet is a Venturi tube structure, the lower part is cylindrical, the upper part is truncated conical, and the height of the cylindrical shape is 1.4 times the height of the truncated conical shape.

[0041] Coal-fired flue gas enters the interior of the shell from the gas inlet of the square shell, passes through the filter, and performs flue gas dust removal; at the same time, the diaphragm valve is opened every 20 minutes to pulse compressed air into the pulse air inlet of the filter, and the gas source pressure is greater than 0.5Mpa, the pulse flushing sequence and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com