Middle shield and tail shield sealing connection device, shield body of shield machine, and shield machine

A connecting device and shield machine technology, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of shield joint seal failure, mud backflow, etc., and achieve the effect of avoiding seal failure and ensuring seal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

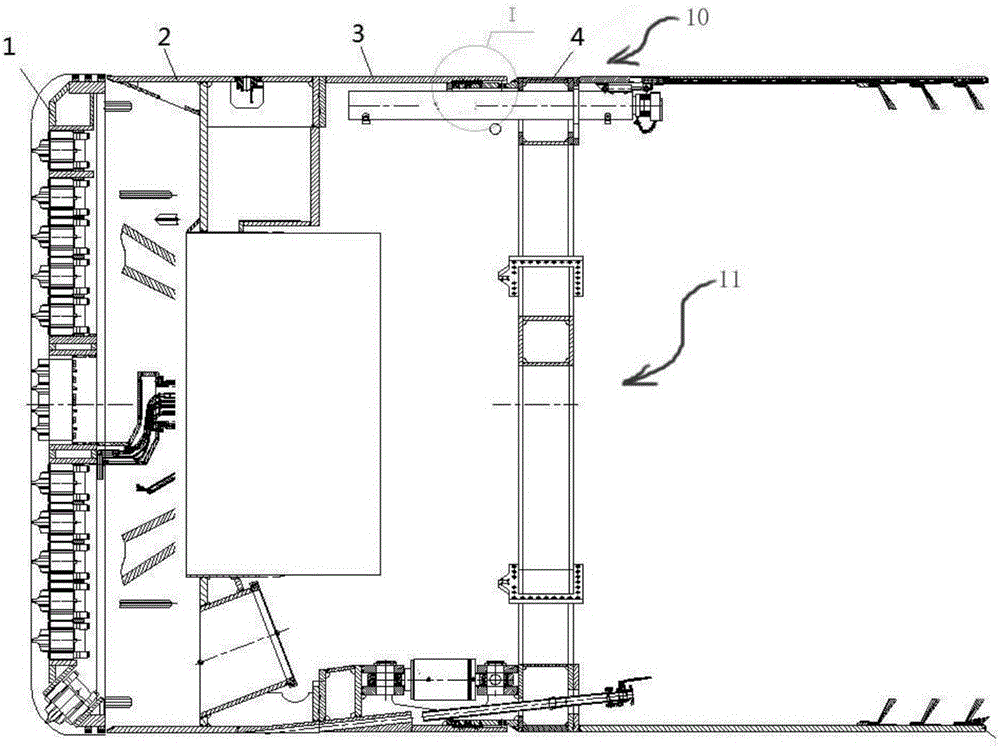

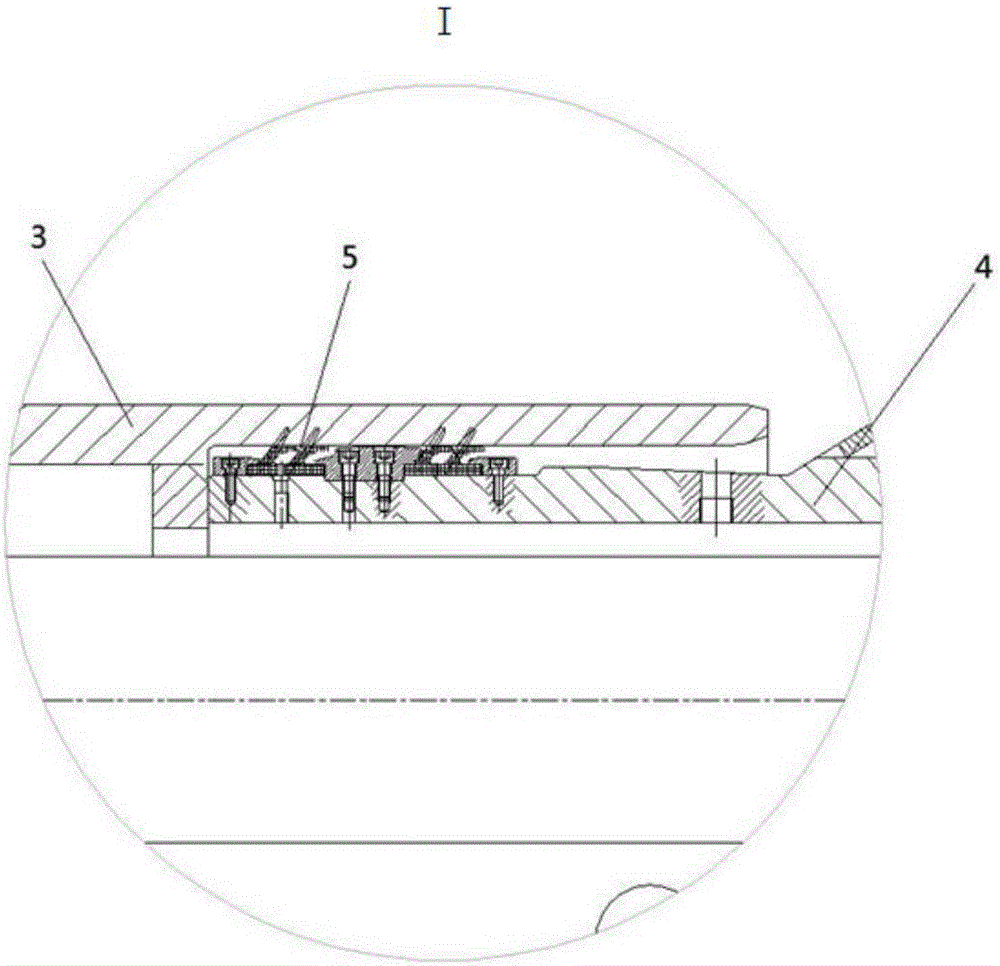

Method used

Image

Examples

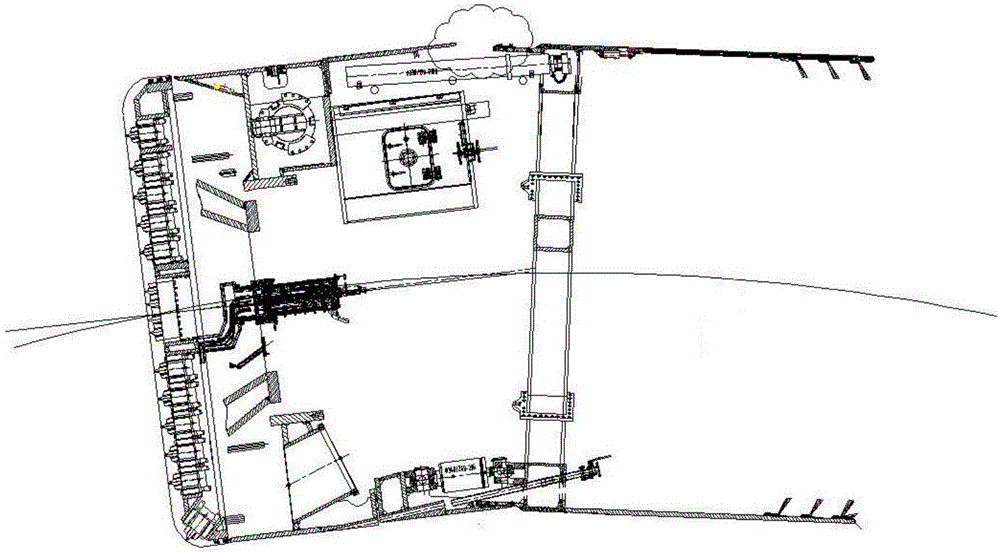

Embodiment 2

[0043] like Figure 10 As shown, the difference between the present embodiment and the first embodiment lies in that the position of the connecting piece 7 is different, the position of the finger seal brush 12 is different, and the position of the pin shaft 93 in the limit assembly 9 is different. The connecting piece 7 in this embodiment is fixedly arranged on the end of the middle shield 3, and the connecting piece 7 is coaxially sleeved on the outer peripheral surface of the front end of the tail shield 4, and the spherical contact surface on the connecting piece 7 is arranged on the connecting piece. On the inner peripheral surface of member 7, the midpoint of the spherical contact surface is located on the axis of the shield. The finger-type sealing brush 12 is fixedly arranged on the outer peripheral surface of the front end of the tail shield 4, and is sealingly matched with the spherical contact surface. The pin shaft 93 of the limit assembly 9 is fixedly arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com