Valve plug

A valve core and water hole technology, applied in the valve core field, can solve problems such as poor valve core sealing, and achieve the effects of improving sealing performance, improving sealing stability and eliminating unstable factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

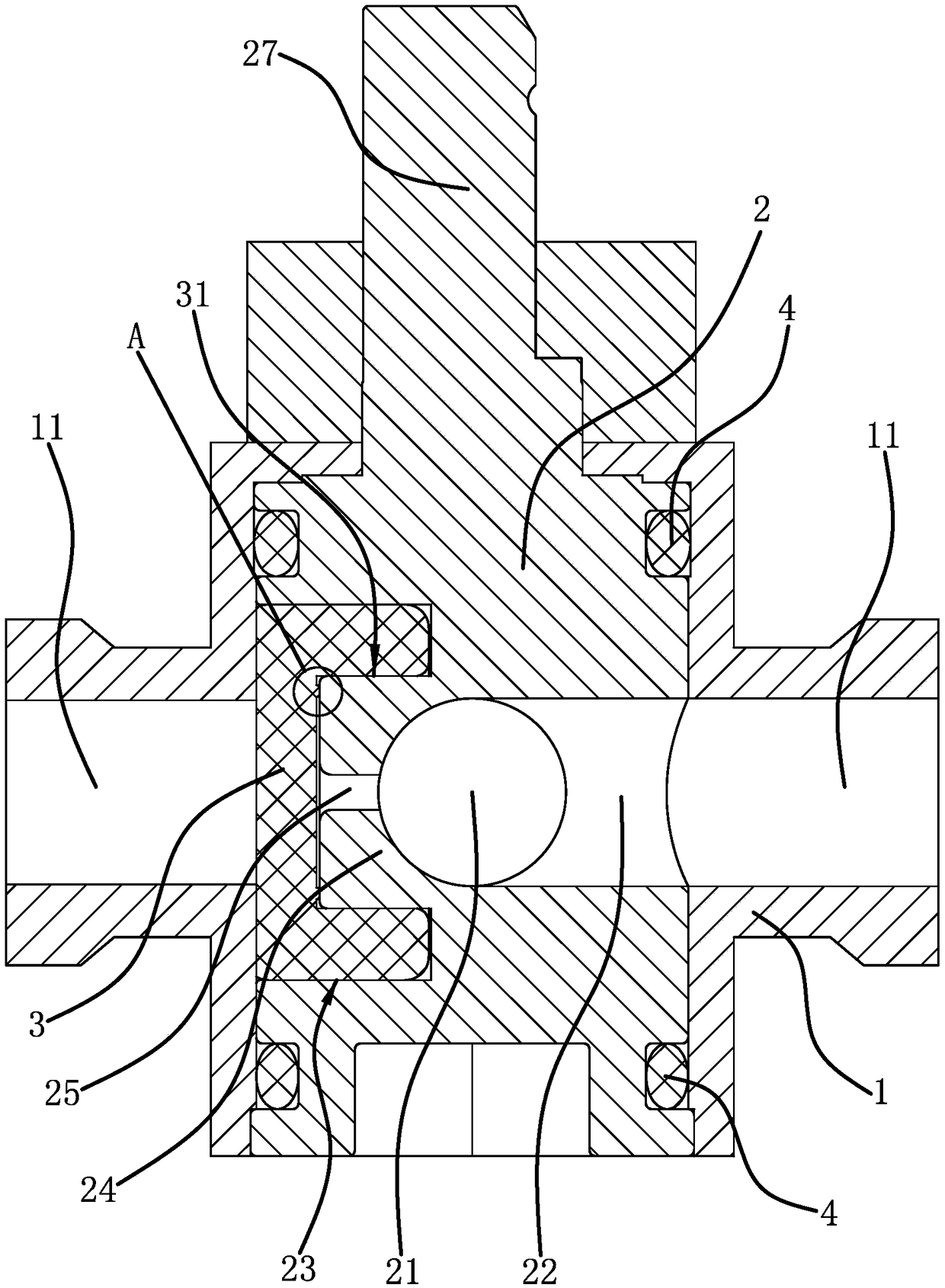

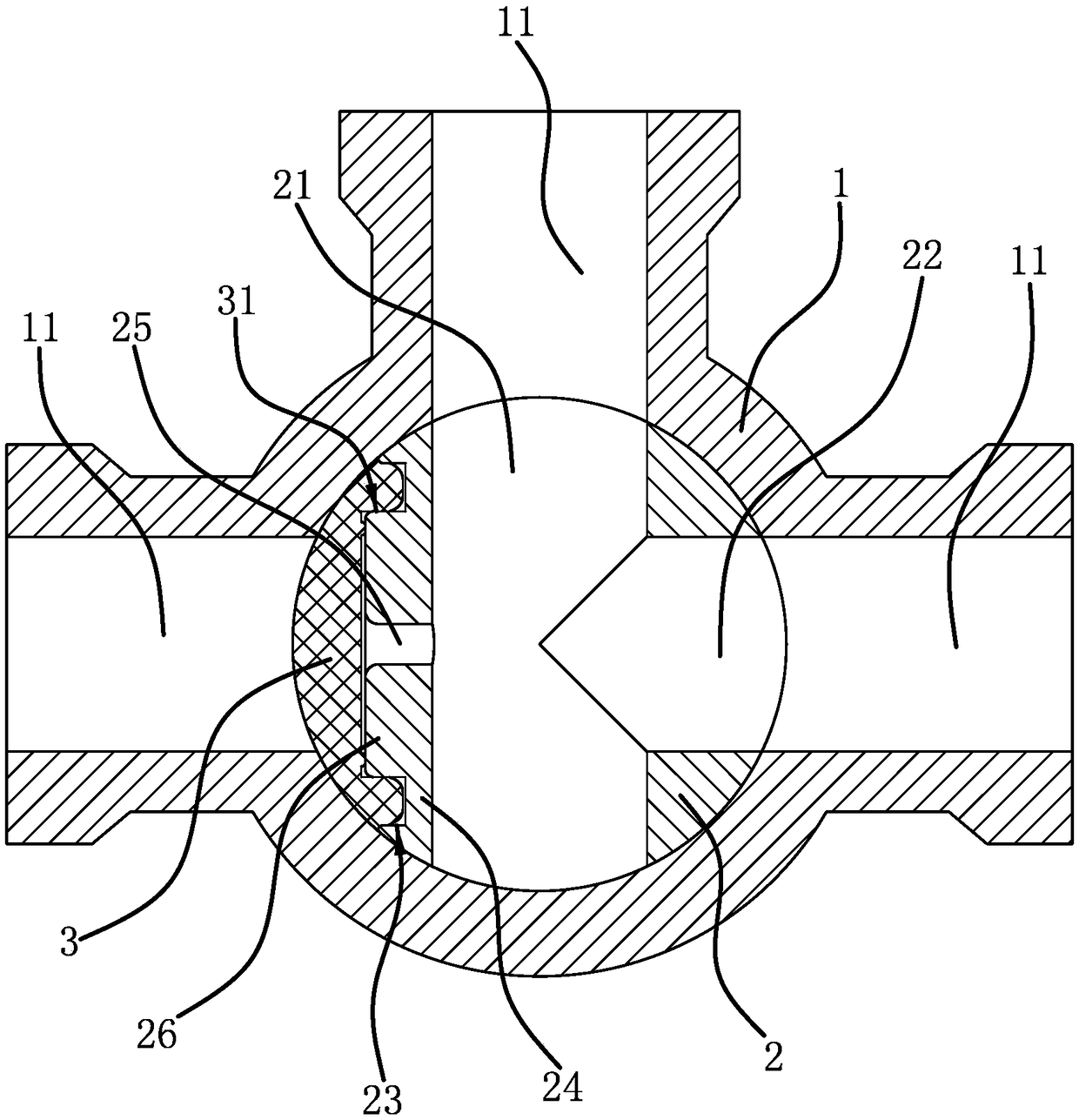

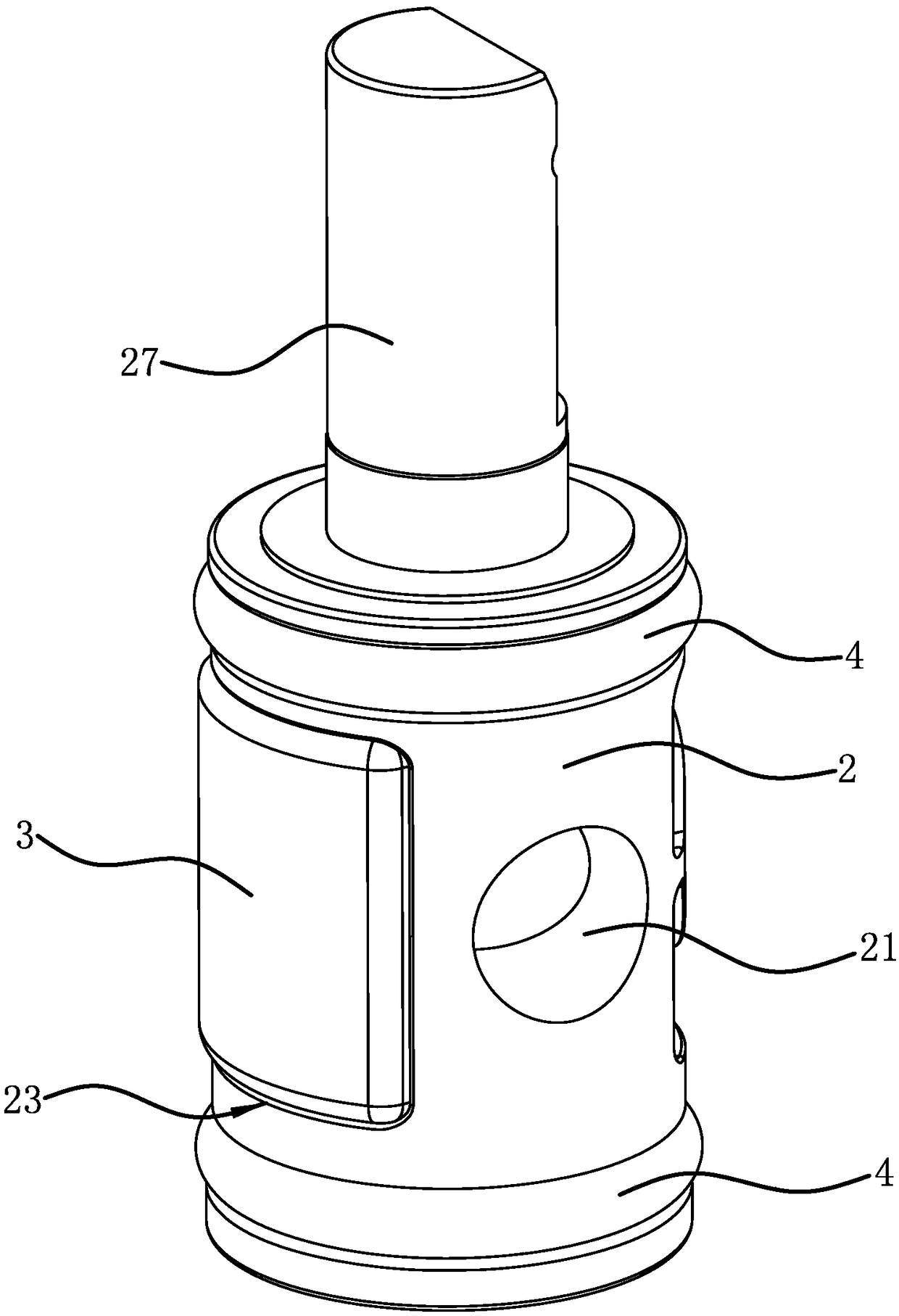

[0032] Such as figure 1 As shown, a valve core includes a body 2, the valve core is applied to a three-way valve body 1, the body 2 is columnar, the lower end of the valve body 1 is open, the upper end is closed, and the body 2 is rotatably arranged in the valve body 1 , the upper end of the body 2 has a valve stem 27, the valve stem 27 protrudes upwards from the valve body 1, and there is a pressure block at the upper end of the valve stem 27, the pressure block is pressed against the upper end surface of the valve body 1 to realize the valve body 2 Positioning, the outer walls of both ends of the body 2 are provided with sealing rings 4, and the sealing rings 4 are pressed against the inner wall of the valve body 1, thereby sealing both ends of the body 2, combined with figure 2 As shown, the valve body 1 has three water ports 11, the three water ports 11 are arranged in a T shape, that is, the two water ports 11 are on the same straight line, the third water port 11 is per...

Embodiment 2

[0036] The structure of the spool is basically the same as that of Embodiment 1, the difference is that Figure 7 As shown, the valve core is applied to the four-way valve body 1, and the valve body 1 is provided with four water outlets 11, and the sealing block 3 blocks one of the water outlets 11, and the two ends of the water hole 1 21 are respectively connected to two The water outlet 11 and the second water hole 22 communicate with a water outlet 11 .

Embodiment 3

[0038] The structure of the spool is basically the same as that of Embodiment 1, the difference is that Figure 8 As shown, the valve core is used in the five-way valve body 1, the body 2 is provided with a water hole 1 21 and two water holes 22, the valve body 1 is provided with five water ports 11, and the sealing block 3 seals One of the water outlets 11 is blocked, and the two ends of the first water hole 21 are connected to the two water outlets 11 respectively, and the two water holes 22 are connected to the two water outlets 11 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com