Rotating pump

A rotary pump and rotary axis technology, applied in the direction of rotary piston pumps, pumps, rotary piston machines, etc., can solve problems such as difficult to achieve discharge, difficult to ensure the durability of the sealing mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

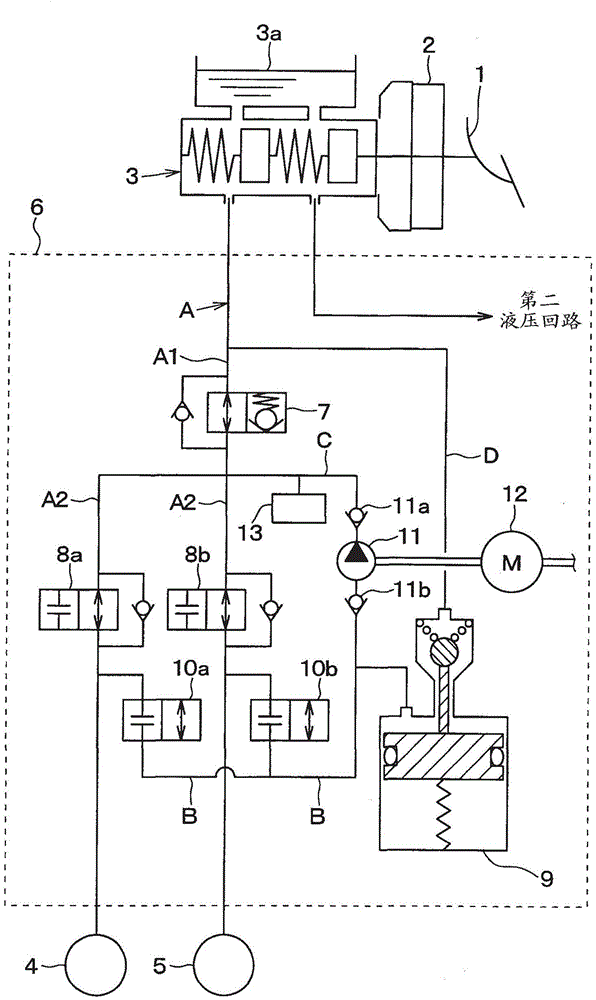

[0030] refer to figure 1 , shows an automotive braking system equipped with a rotary pump that is part of the hydraulic circuit of the braking system. The braking system referred to herein is designed as a so-called diagonal distribution system comprising two brake hydraulic circuits, one of which controls the right front wheel and the left rear wheel, Another brake hydraulic circuit controls the left front and right rear wheels, but the brake system can also be designed as a front / rear split system.

[0031] The braking system is equipped with a brake pedal 1 (that is, a brake actuating member), a brake booster 2, a master cylinder 3, a wheel cylinder 4, a wheel cylinder 5, and a brake pressure control actuator 6, the brake pedal 1 Depressed by a vehicle occupant or driver to apply the brakes to the vehicle. A master cylinder 3 , which will be described in detail later, is used to generate brake hydraulic pressure in response to the operation of a brake actuating member, ie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com