Full-mold casting plane plate evanescent mode and preparation method thereof

A technology of full mold casting and flat plate, which is applied in the field of lost foam, can solve the problems such as the great influence of casting carbon deposits, and achieve the effects of increasing yield, improving bonding strength, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

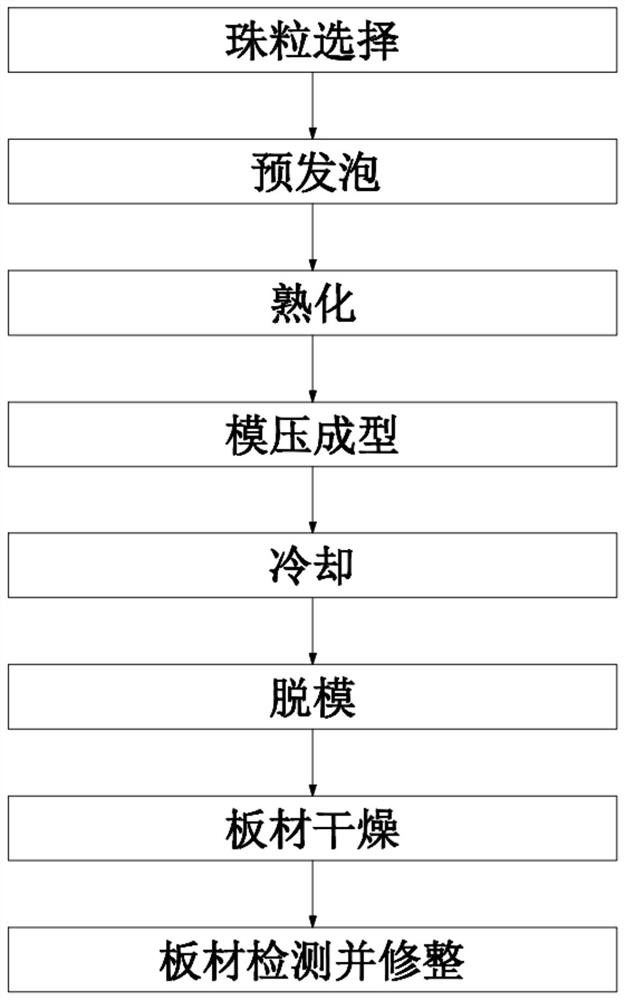

[0027] A method for preparing the lost foam of a full-type casting plane plate, the specific steps of the preparation method of the lost foam of a full-type casting plane plate are as follows:

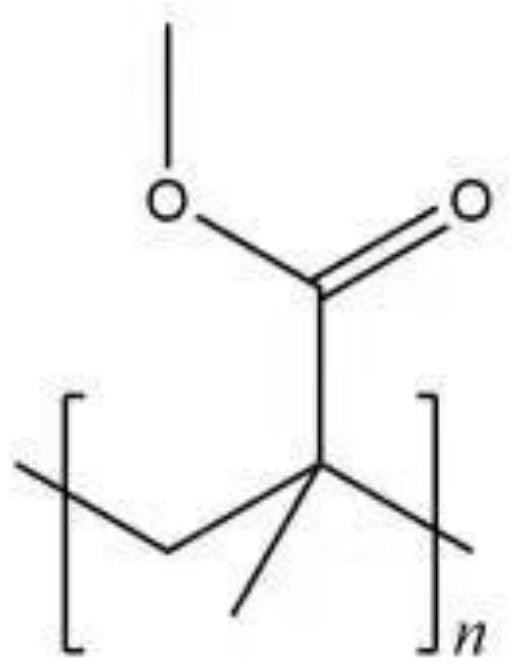

[0028] S1: Bead selection: Select the raw material particles of the lost foam of the full-type casting plate, and weigh the HOOCC(CH3)2CH2CH3 polymer particles according to the amount of the lost foam of the full-type casting plate. The surface of the HOOCC(CH3)2CH2CH3 polymer particles is smooth and the density is uniform. ;

[0029] S2: Pre-foaming: Heat the HOOCC(CH3)2CH2CH3 polymer particles weighed in step S1 to melt at 80-100 degrees Celsius, press inert gas into the molten polymer under pressure, reduce the pressure, and increase the temperature , so that the dissolved gas is released and expanded to pre-foam to obtain a pre-foamed material;

[0030] The pressure under pressurized conditions is 1.5-1.7MPa, after reducing the pressure, the pressure is 1.0-1.2MPa, and the pre-foa...

Embodiment 1

[0039] The specific steps of the preparation method of the lost foam of the solid mold casting plane plate are as follows:

[0040] S1: Bead selection: Select the raw material particles of the lost foam of the full-type casting plate, and weigh the HOOCC(CH3)2CH2CH3 polymer particles according to the amount of the lost foam of the full-type casting plate. The surface of the HOOCC(CH3)2CH2CH3 polymer particles is smooth and the density is uniform. ;

[0041] S2: Pre-foaming: Heat the HOOCC(CH3)2CH2CH3 polymer particles weighed in step S1 to melt at 80-100 degrees Celsius, press inert gas into the molten polymer under pressure, reduce the pressure, and increase the temperature , so that the dissolved gas is released and expanded to pre-foam to obtain a pre-foamed material;

[0042] The pressure under pressurized conditions is 1.5MPa, after reducing the pressure, the pressure is 1.0MPa, and the pre-foaming time is 40min;

[0043] The pre-foamed material is heated to 150 degrees...

Embodiment 2

[0051] The specific steps of the preparation method of the lost foam of the solid mold casting plane plate are as follows:

[0052]S1: Bead selection: Select the raw material particles of the lost foam of the full-type casting plate, and weigh the HOOCC(CH3)2CH2CH3 polymer particles according to the amount of the lost foam of the full-type casting plate. The surface of the HOOCC(CH3)2CH2CH3 polymer particles is smooth and the density is uniform. ;

[0053] S2: Pre-foaming: Heat the HOOCC(CH3)2CH2CH3 polymer particles weighed in step S1 to melt at 80-100 degrees Celsius, press inert gas into the molten polymer under pressure, reduce the pressure, and increase the temperature , so that the dissolved gas is released and expanded to pre-foam to obtain a pre-foamed material;

[0054] The pressure under pressurized conditions is 1.6MPa, after reducing the pressure, the pressure is 1.1MPa, and the pre-foaming time is 35min;

[0055] The pre-foamed material is heated to 125 degrees ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com