Method of installing elastic connecting pipe of gate of nuclear power plant equipment

A technology of elastic connectors and installation methods, which is applied in nuclear power generation, nuclear engineering, climate sustainability, etc., and can solve the problem of the huge change in the gap between the inner containment and outer containment elastic connectors and the inability to predict the deformation of the inner containment Quantity, shell capping construction progress and other issues, to achieve the effect of shortening the construction period, reducing the occupation, and saving the occupation of the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further introduced below in conjunction with the accompanying drawings and embodiments.

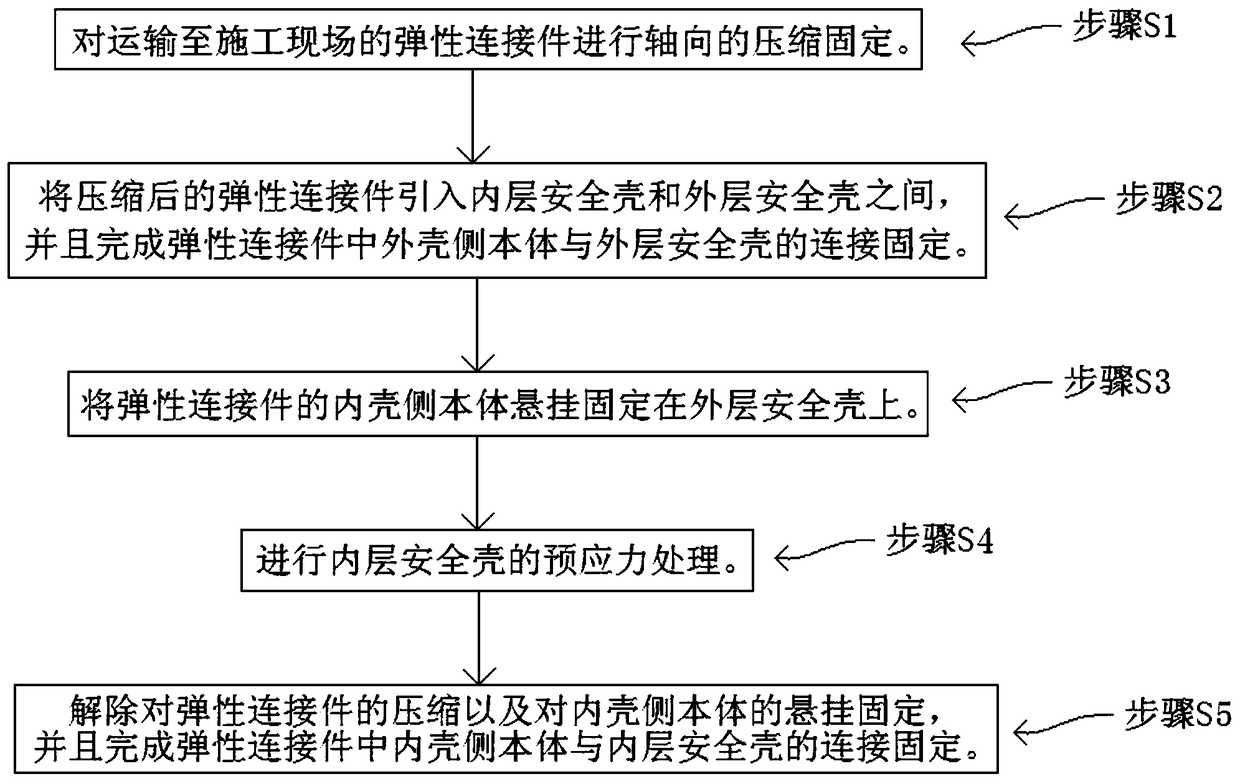

[0029] combine figure 1 As shown, the specific steps for installing the elastic connector of the nuclear power plant equipment gate by the method of the present invention are:

[0030] Step S1, perform axial compression and fixation on the elastic connector transported to the construction site.

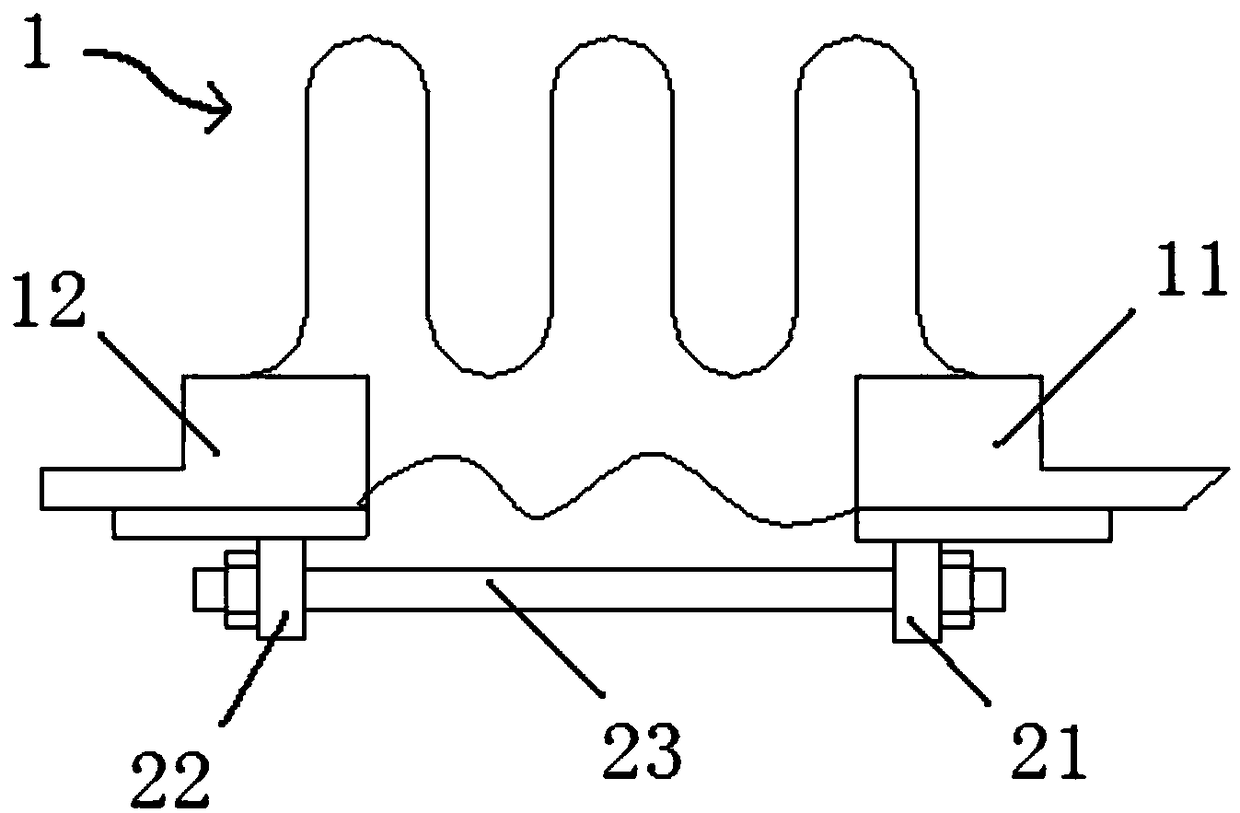

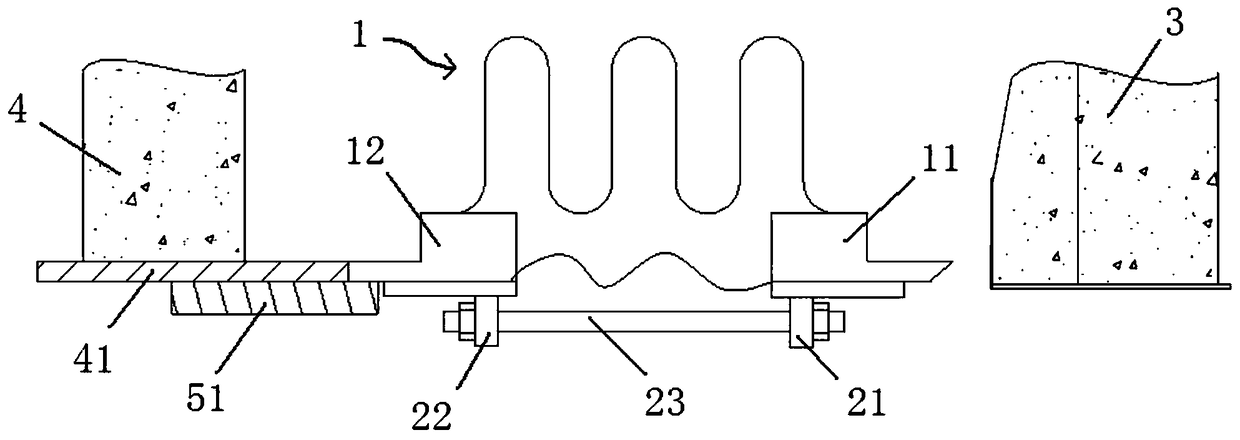

[0031] combine figure 2 As shown, in this embodiment, the elastic connecting member 1 is axially compressed and fixed by means of an adjustment auxiliary. Wherein, the adjustment auxiliary parts include an adjustment lug 21 on the inner shell side, an adjustment lug 22 on the outer shell side, and an adjustment rod 23 . The adjusting lug 21 on the inner shell side is welded and fixed on the inner shell side body 11 of the elastic connector 1, the adjusting lug 22 on the outer shell side is welded and fixed on the outer shell side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com