Mounting device for push head for maintenance of large and medium-size water-turbine generator set

A technology for generating sets and installation devices, which is applied to hydroelectric power generation, engine components, machines/engines, etc. It can solve problems such as human deviation, low efficiency, and many disadvantages, and achieve the improvement of installation work efficiency, stable lifting, and avoiding rework problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

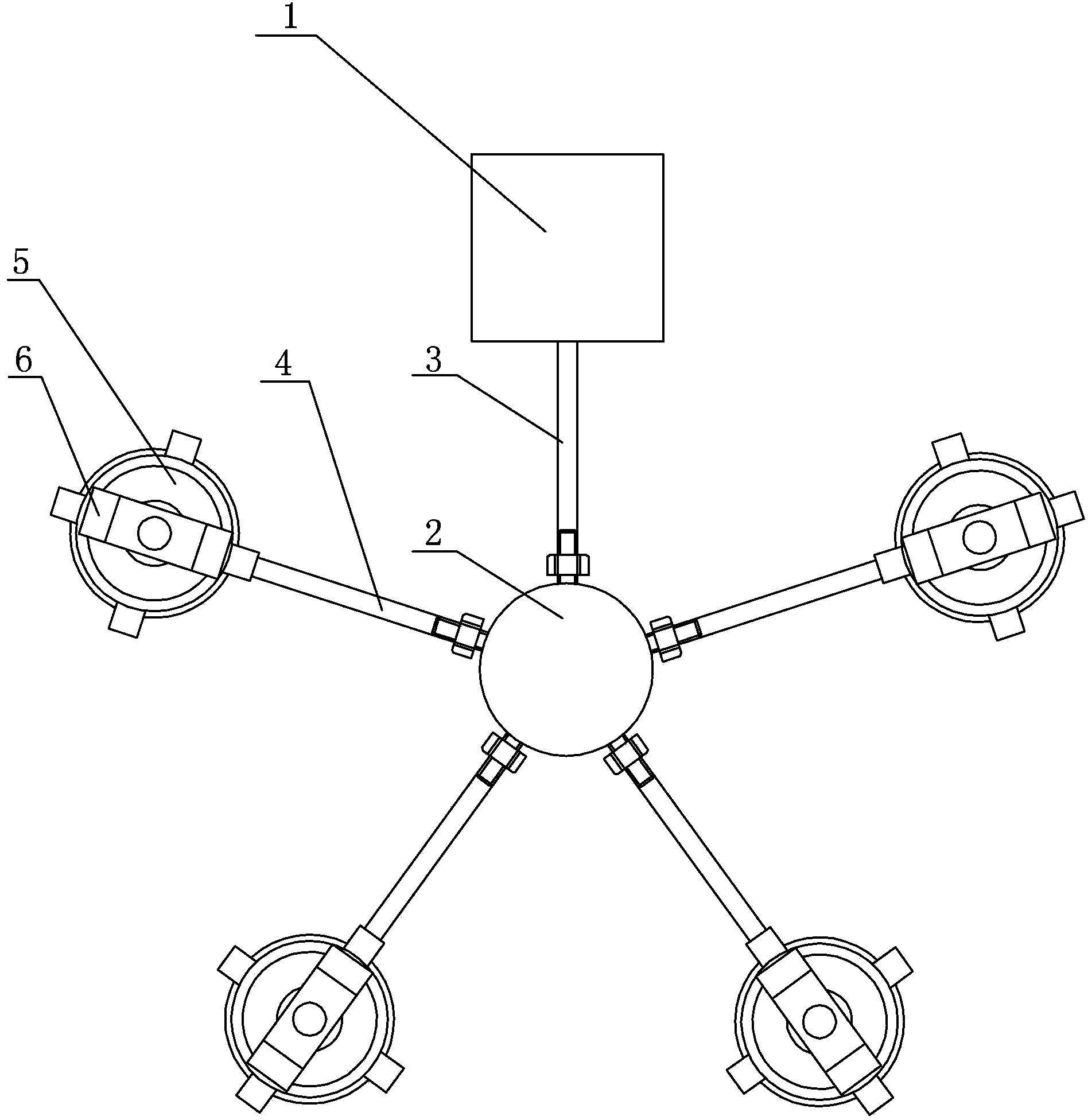

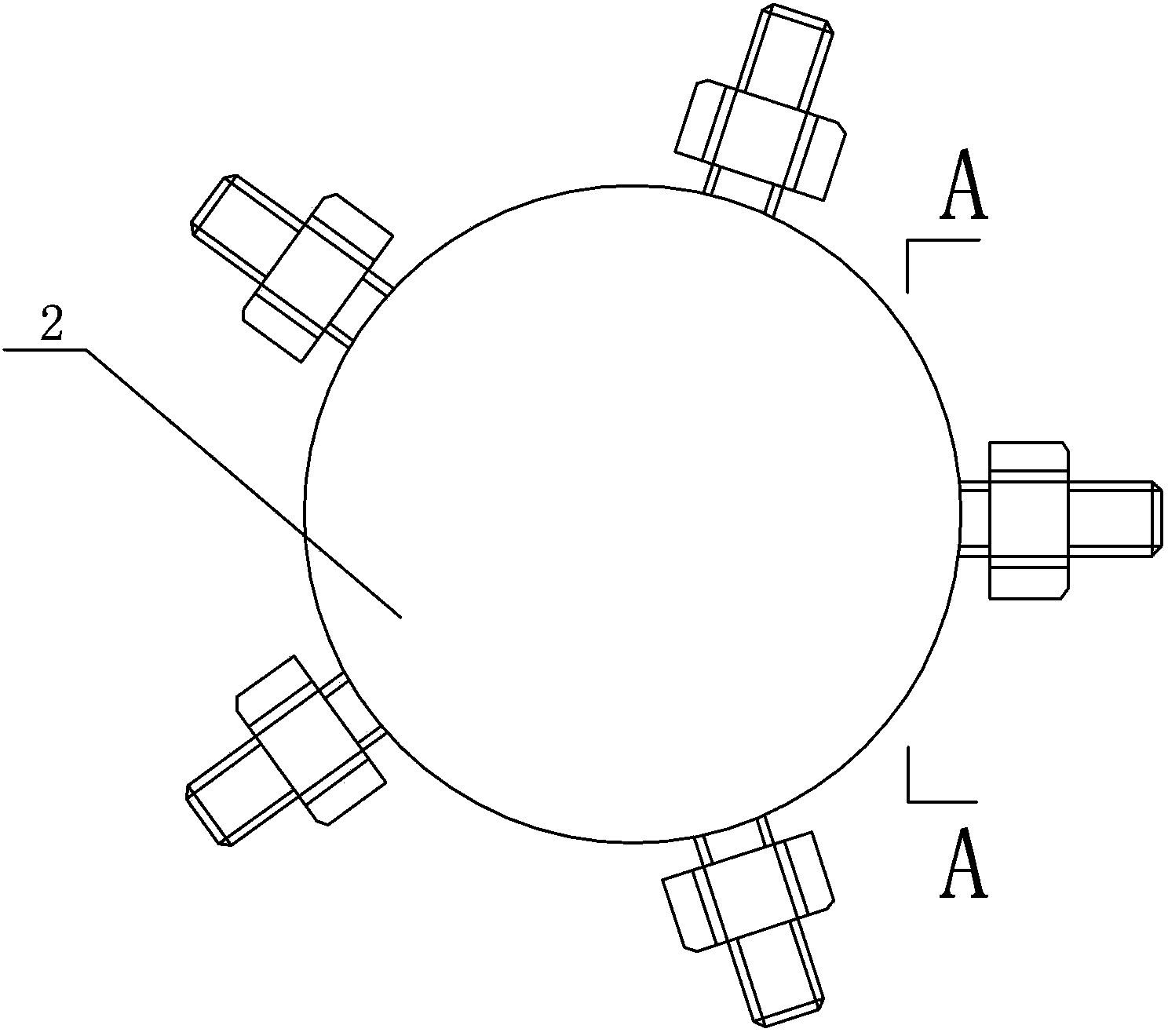

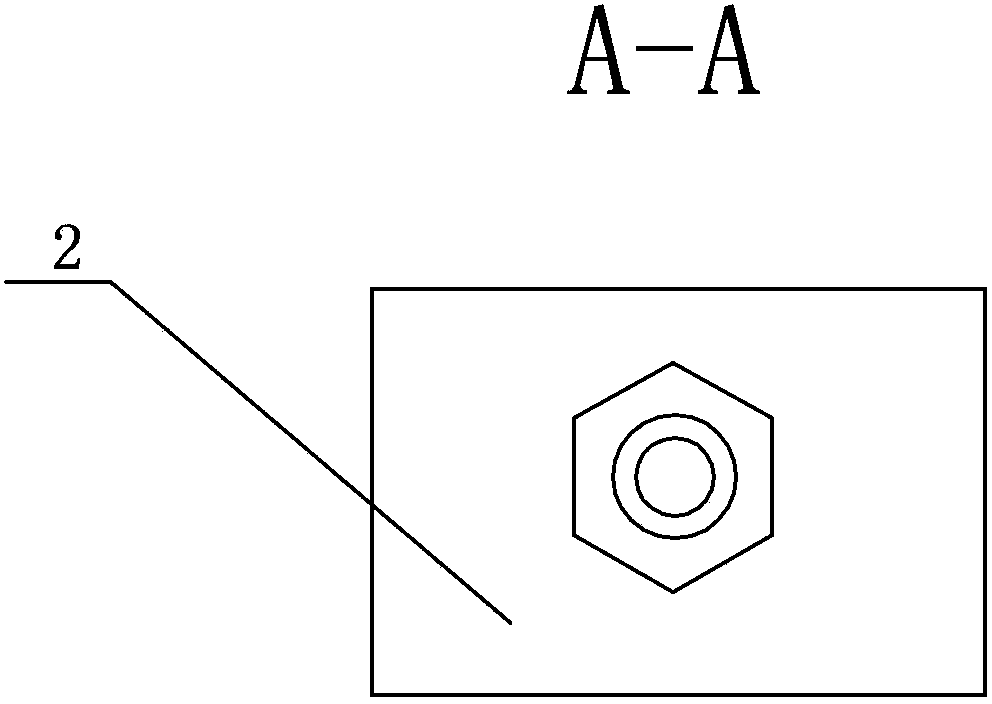

[0007] Specific implementation mode one: combine Figure 1 to Figure 7 This embodiment is described. The thrust head installation device described in this embodiment includes a high-pressure electric oil pump 1, a multi-way joint 2, a main pipeline 3, a plurality of branch pipelines 4, and a plurality of lifting tools 5. and a plurality of fixed frames 6, a plurality of lifting tools 5 are arranged in a circle, a multi-way joint 2 is arranged in the center of the circle, and a fixed frame 6 is respectively fixedly installed on the upper end of each lifting tool 5, and a high-pressure electric oil pump 1 The oil outlet is connected with the oil inlet of the multiway joint 2 through the main pipeline 3, and each oil outlet of the multiway joint 2 is connected with the oil inlet of a corresponding lifting tool 5 through a branch pipeline 4 respectively.

[0008] In this embodiment, the high-voltage electric oil pump 1 is equipped with a pressure relief component, which can releas...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination Figure 4 and Figure 5 Describe this embodiment, a thrust head installation device for large and medium-sized hydroelectric generating units in this embodiment. Each lifting tool 5 includes a lifting main body 5-1 and a lifting push rod 5-2. The lifting push rod 5-2 The lower end is inserted in the lifting main body 5-1, and the upper end of the lifting push rod 5-2 is connected with the lower end of a corresponding fixing frame 6. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination Figure 6 and Figure 7 To illustrate this embodiment, each fixing frame 6 of the thrust head installation device described in this embodiment is U-shaped, and the bottom of each fixing frame 6 is opened with a through hole 6-1. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com