A new type of linked rotary wedge

A rotating wedge and linkage technology, which is applied in forming tools, manufacturing tools, transportation and packaging, etc., to achieve the effects of strong applicability, saving development costs and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below the present invention is further described:

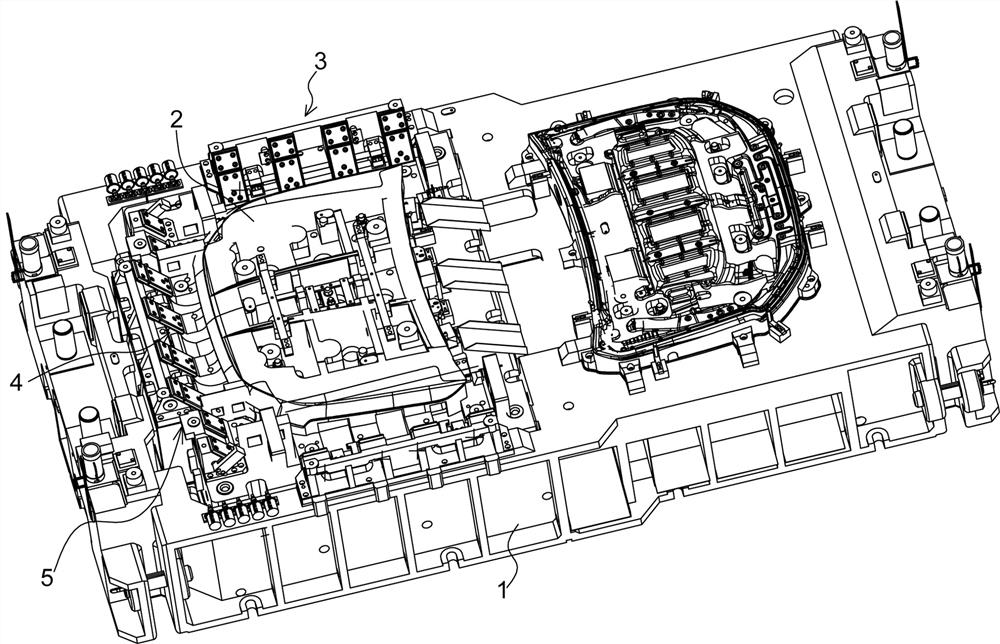

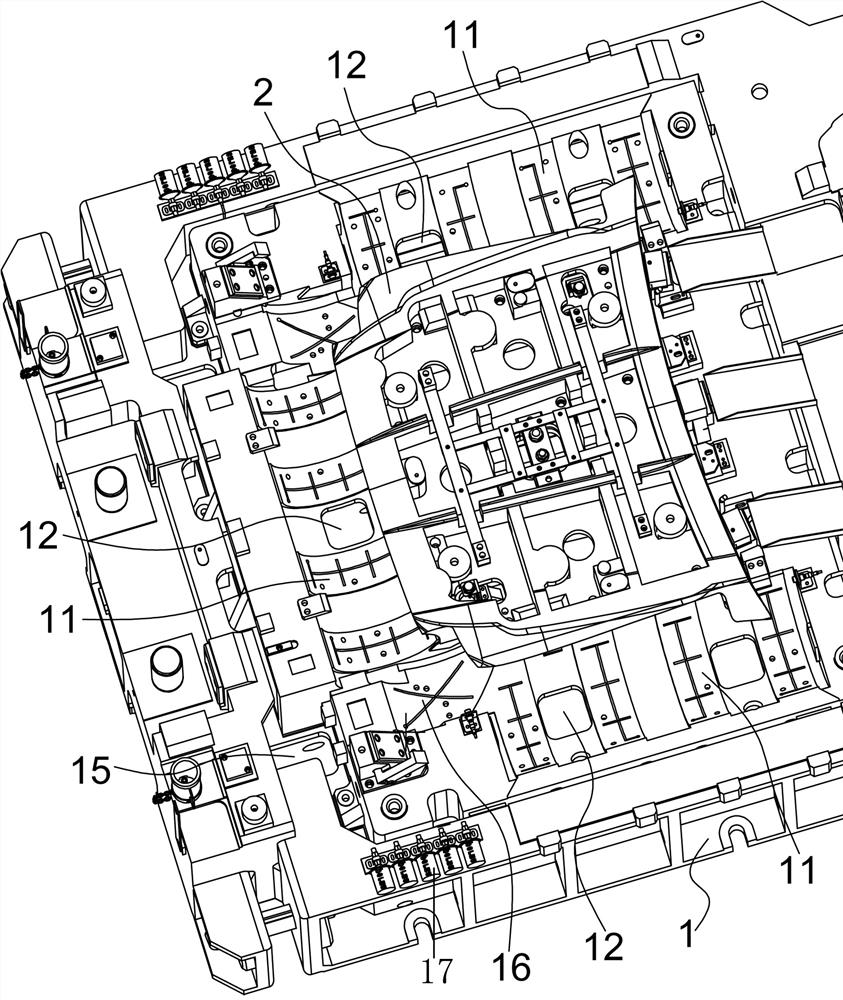

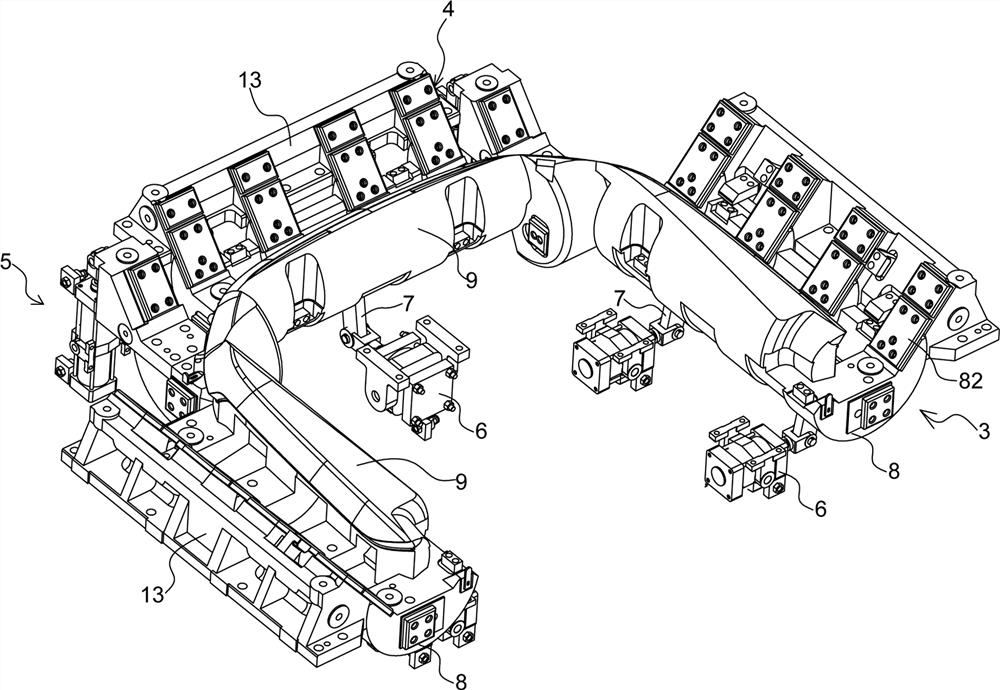

[0020] see Figure 1-5 ,

[0021] The invention discloses a novel linkage rotating wedge, which comprises a wedge base 1, a punch 2 with an engine cover outer plate on the upper surface of the wedge base 1, and two rollovers on both sides of the punch 2 A side mechanism 3, the front end of the punch 2 is provided with a middle screen side flanging mechanism 4, and two lamp mouth corner flanging mechanisms 5 are arranged between the side flanging mechanism 3 and the middle mesh side flanging mechanism 4 ; During work, after the center grid side flanging mechanism 4 and the two lamp opening angle flanging mechanisms 5 rotate clockwise for 25° at the same time, the two side flanging mechanisms 3 rotate clockwise for 15°, and the above actions pass The air source switch controls the cylinder. Through the above actions, the problem of picking up parts after negative angle flanging of the circle is solved. At the same time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com