Double-horn-mouth type vertical kiln lower discharging hopper structure and work method thereof

A technology with double horns and a hopper, which is applied in the field of shaft kiln, can solve problems such as the narrowing of the gap between round steel bars or even being blocked by materials, the failure of cooling air to enter the shaft kiln smoothly, and the burning of the belt conveyor of finished products, so as to achieve convenient process layout. , easy installation and maintenance, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

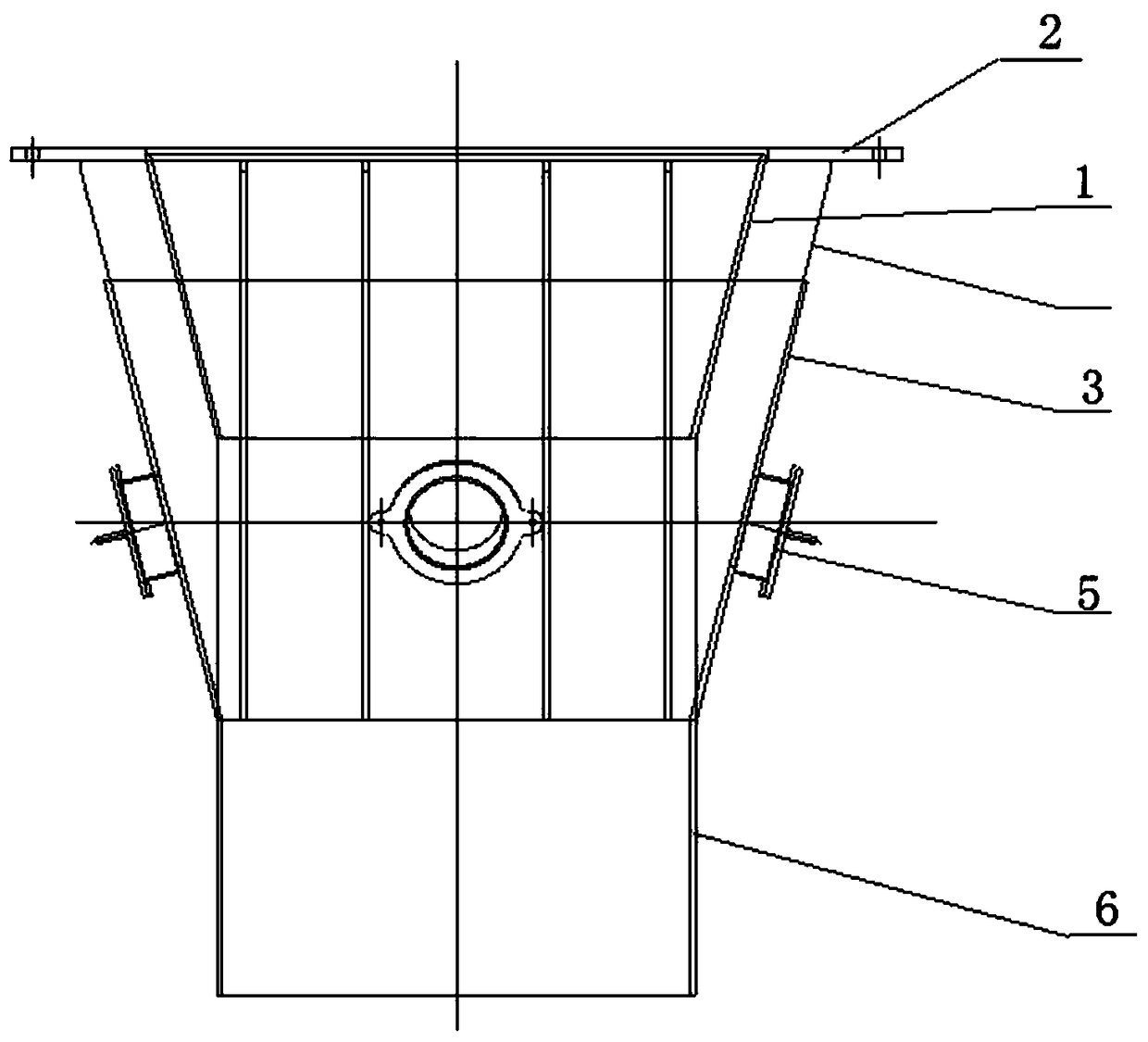

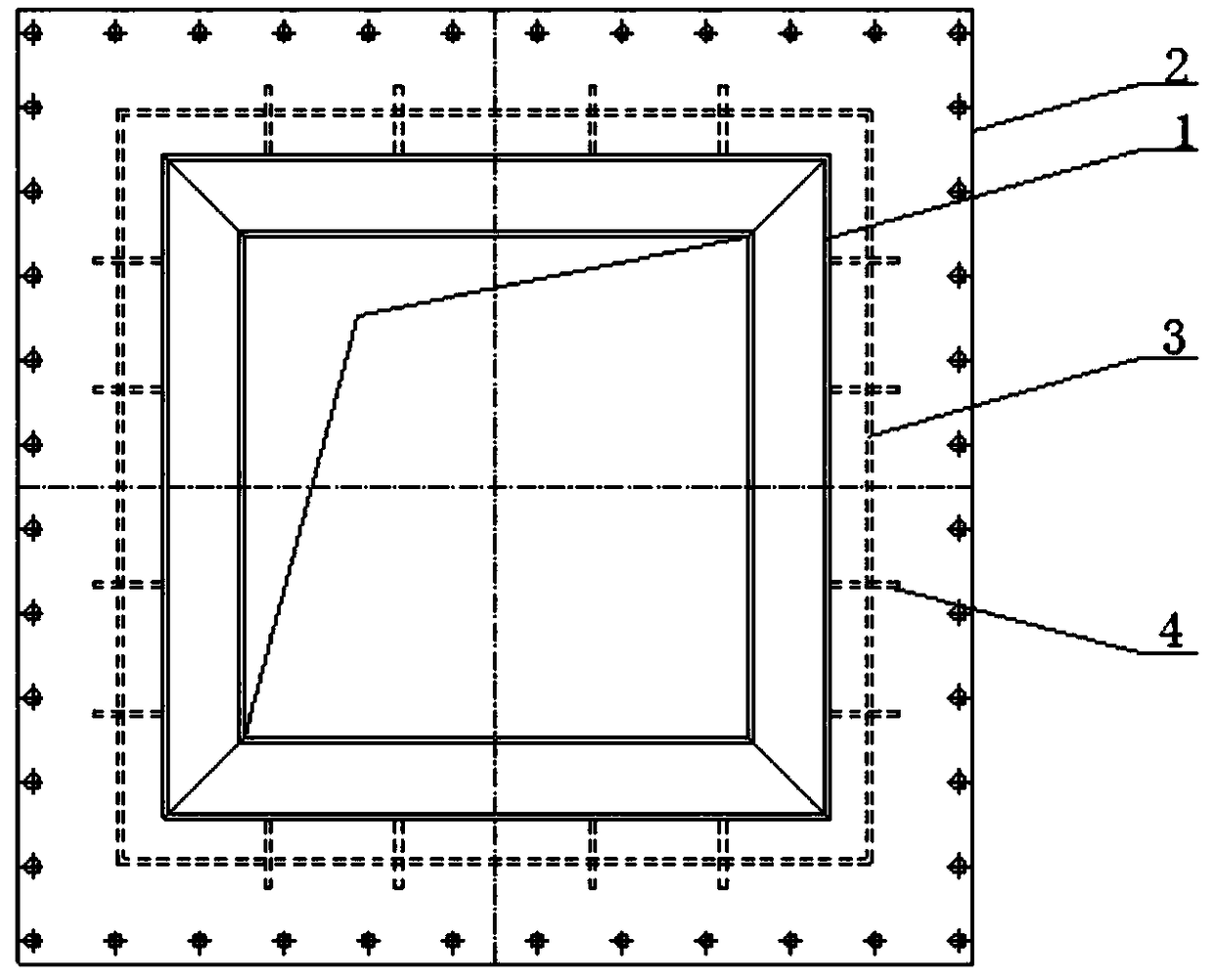

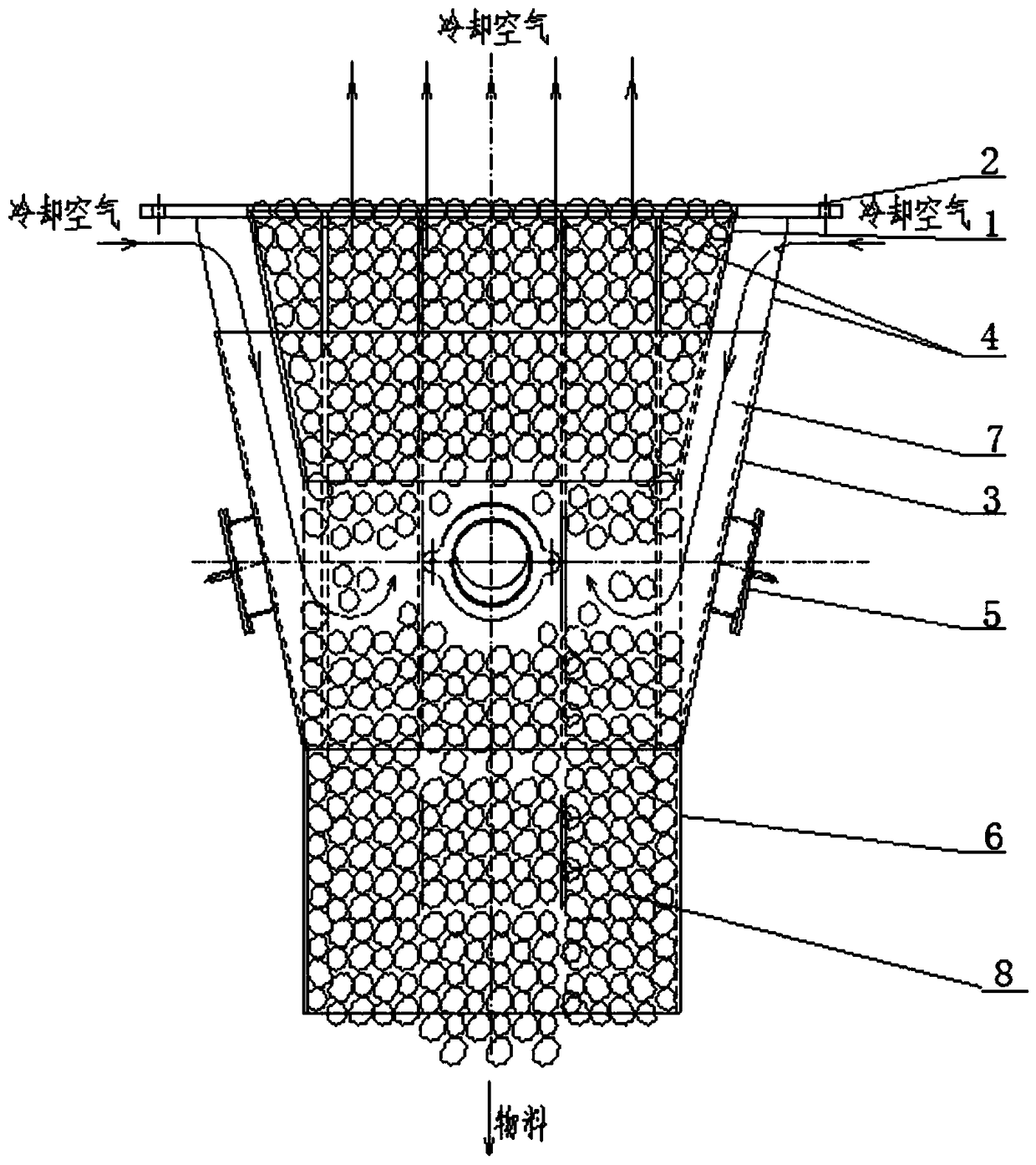

[0021] Such as figure 1 , figure 2 As shown, a double bell-mouth type shaft kiln discharge hopper structure according to the present invention is located at the lower part of the cooling section of the vertical kiln operated by full negative pressure; it includes inner peripheral groove 1, peripheral groove 3, reinforcing rib plate 4 and The straight pipe section 6, the inner peripheral groove 1 and the peripheral groove 3 are fixedly connected by a plurality of stiffener plates 4 evenly arranged along the circumferential direction; the inner peripheral groove 1 and the peripheral groove 3 both have a trumpet structure with a large top and a small bottom , there is a uniform gap between the two to form a cooling air passage 7; the top of the inner peripheral groove 1 is higher than the top of the peripheral groove 3, thereby forming a top annula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com