Inclined block type push head car pusher for electric trailer for transferring refractory kiln cars and usage method

A technology of refractory materials and oblique blocks, which is applied in the direction of electric charge manipulation, transportation and packaging, railway car body parts, etc., can solve the problems that are not conducive to process layout, reduce the efficiency of land use in the plant, and cannot arrange tracks, etc., to achieve the benefit of process Arrangement, compact structure, and the effect of saving total investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

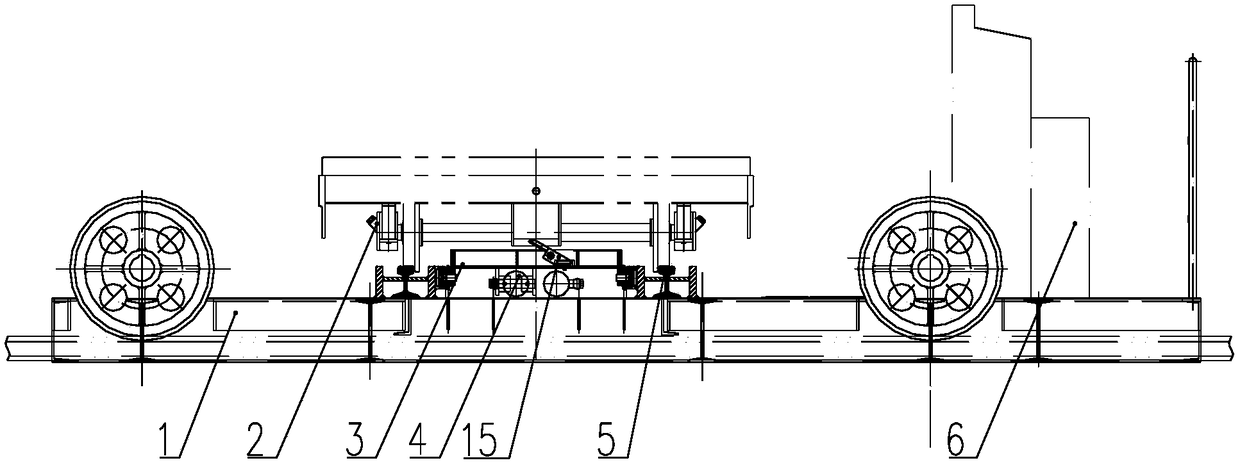

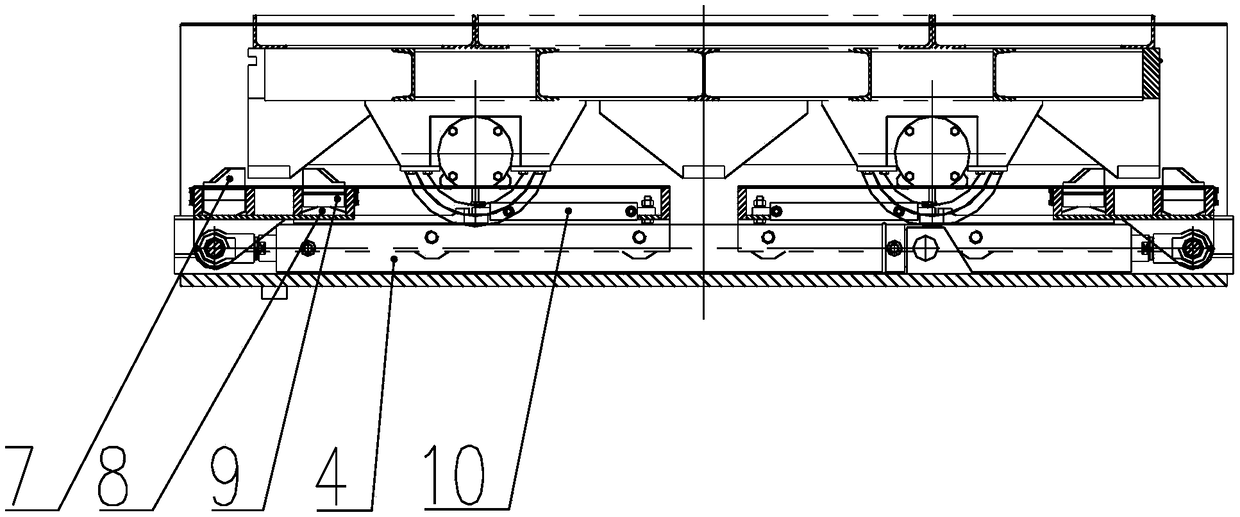

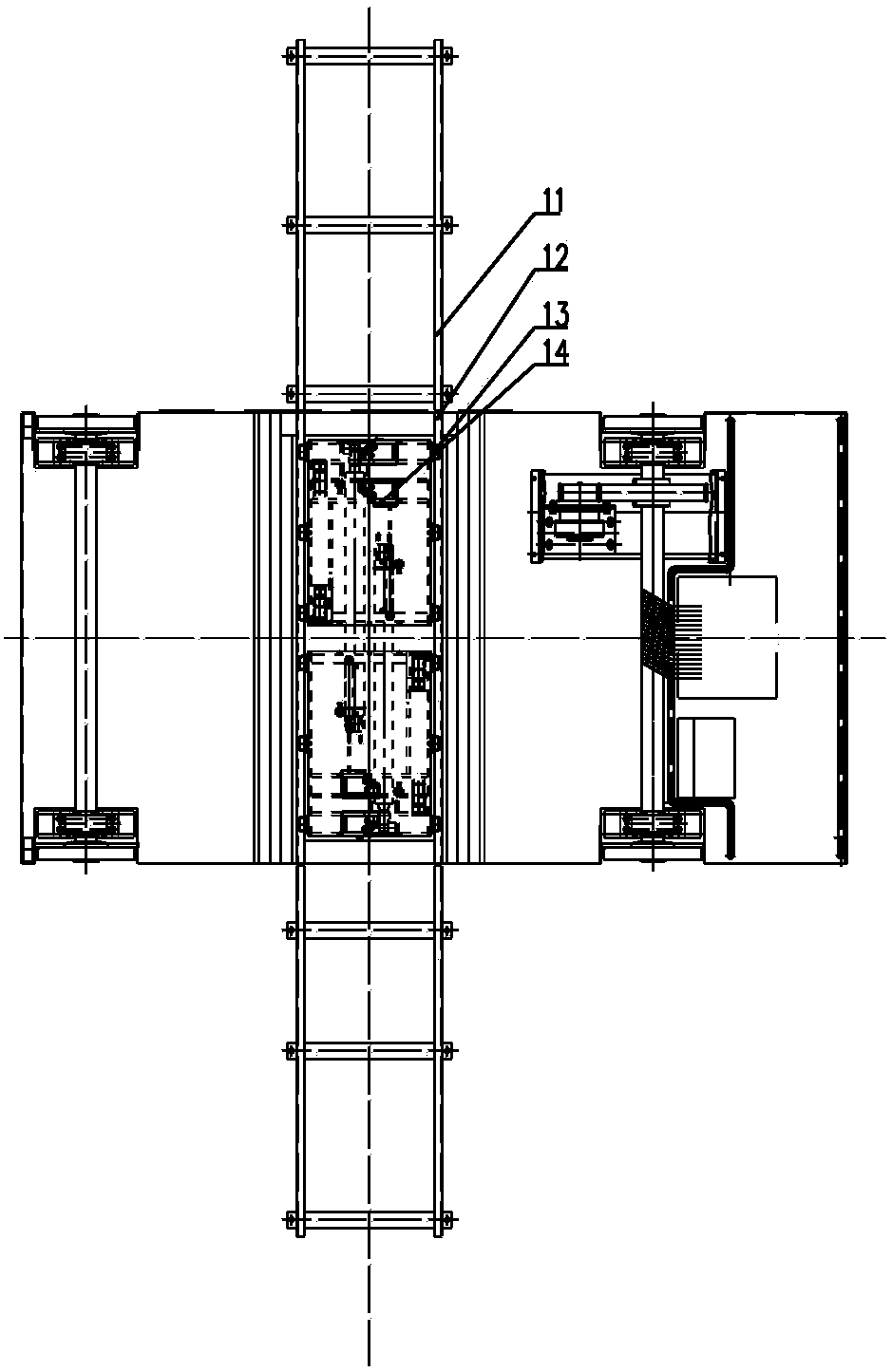

[0024] See Figure 1-Figure 5 , refractory material kiln car transfer electric trailer with inclined block type push head cart, including hydraulic cart machine 3, cart machine oil cylinder 4, cart machine guide rail 12; said hydraulic cart machine 3 includes cart machine frame , reversing oil cylinder 10, inclined block type push head 15, reversing convex block 8, two inclined block type push heads 15 are symmetrically arranged on the cart machine frame, which are respectively the inclined block type push head 7 and the push block type push head for pulling the cart. The inclined block type push head 9 of the car, the inclined block type push head 15 is hinged on the cart machine frame, and naturally becomes a vertical state under the action of gravity. In this state, the inclined block type push head and the push cart machine contact the incline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com