Patents

Literature

70 results about "Wedge base" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A wedge base is a type of electrical connector used as a fitting for small light bulbs. It is similar to the bi-pin connector, except that the two "pins" are the same wires that extend into the bulb (rather than being rigid), and the wires are bent up onto the sides of the base, where they make contact with the socket. The wires are usually inserted into a plastic base that the bulb is mounted in, and which is often narrower at the tip than at the bulb, giving it a wedge shape and usually ensuring a tight connection, depending on manufacturing tolerances. Some bulbs have no plastic base, and the wires are simply bent up to the sides of the bulb's glass base.

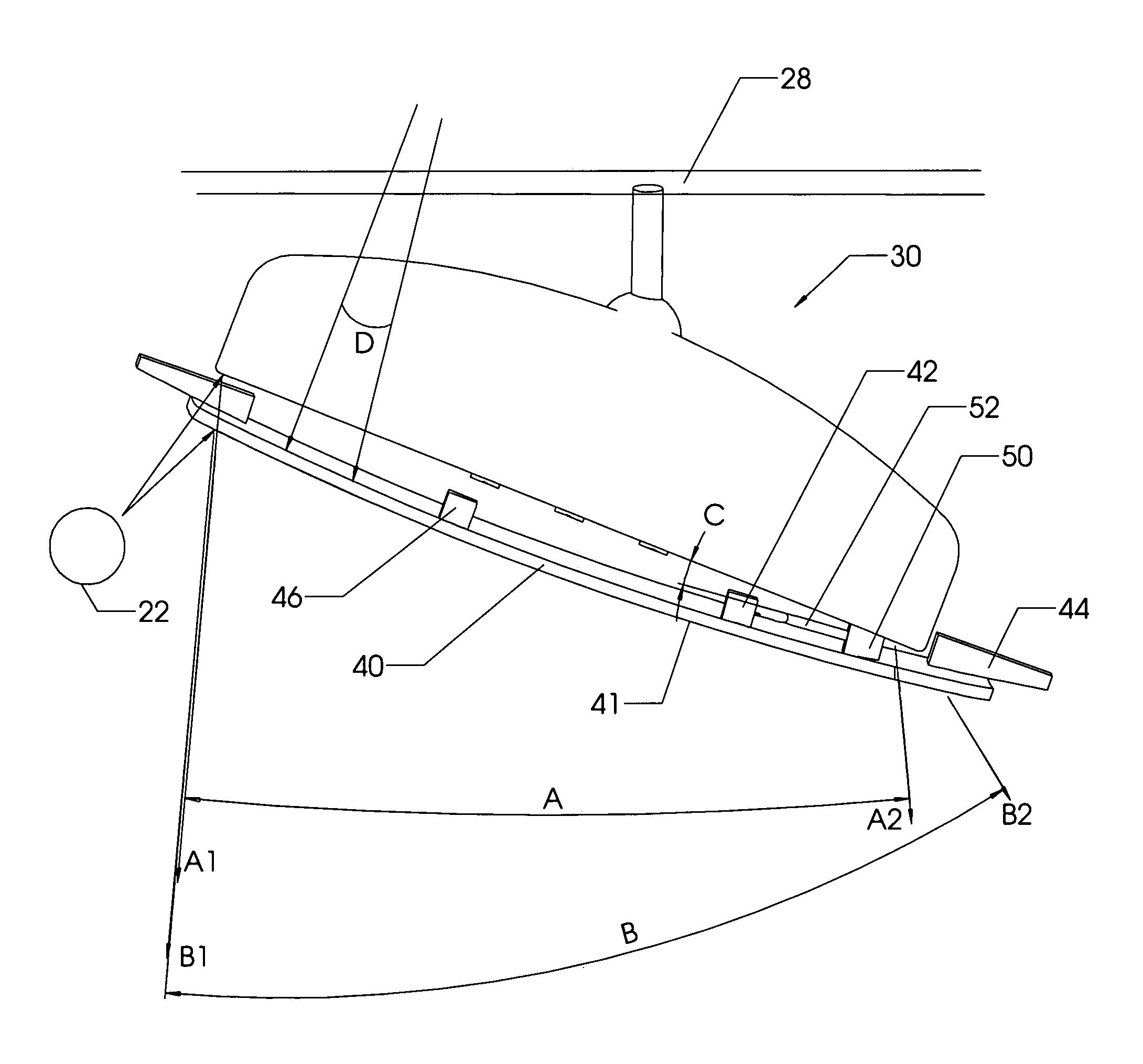

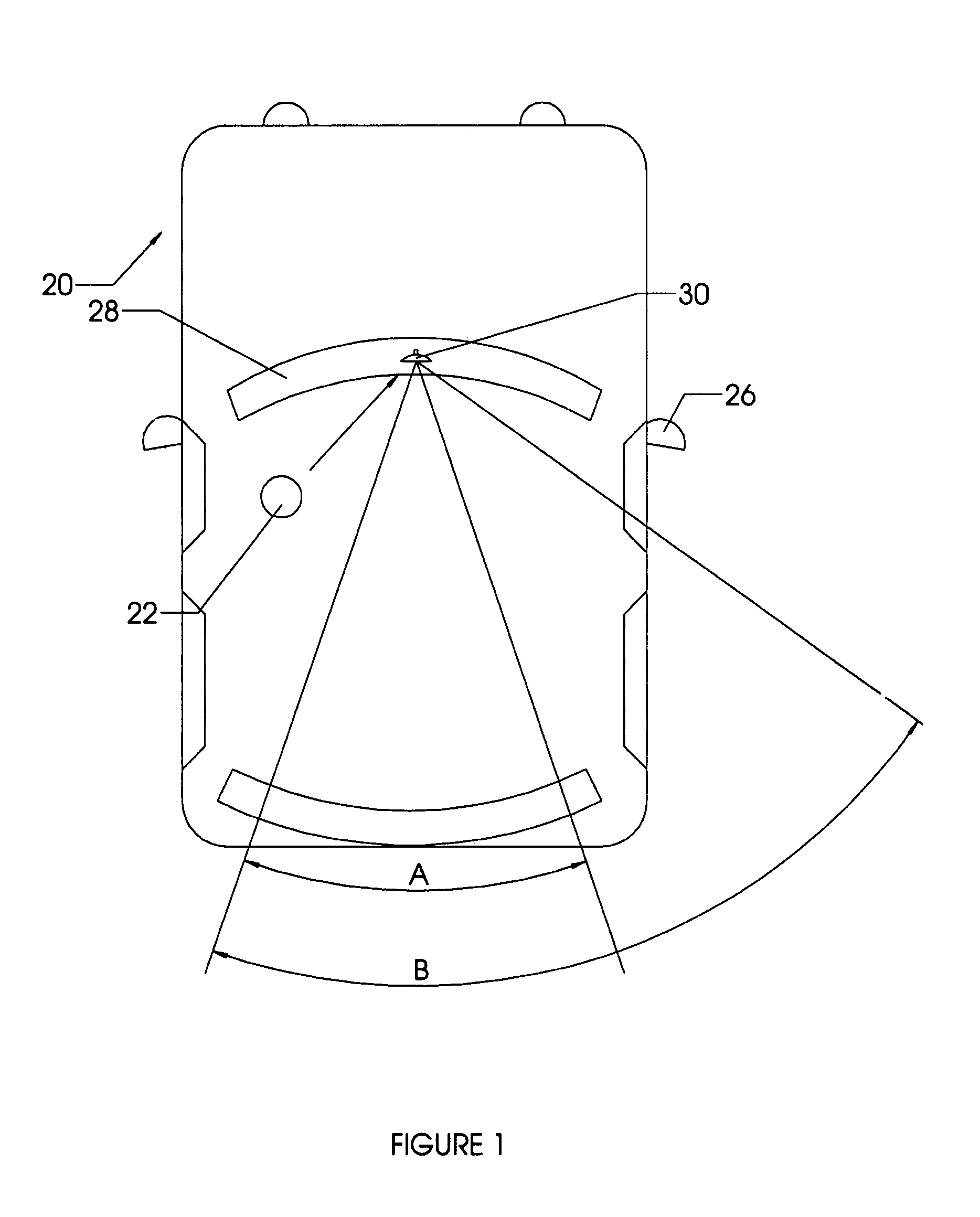

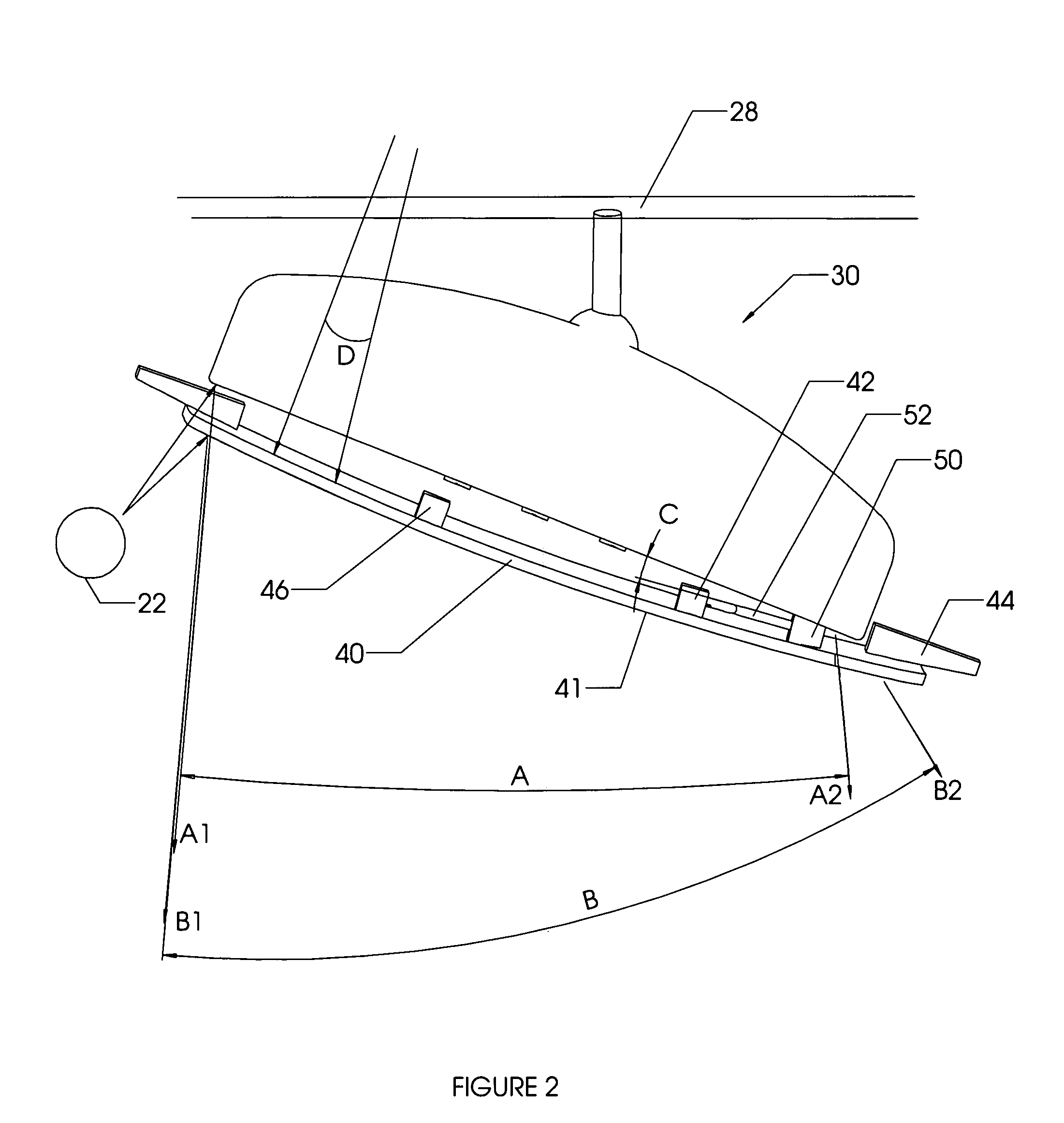

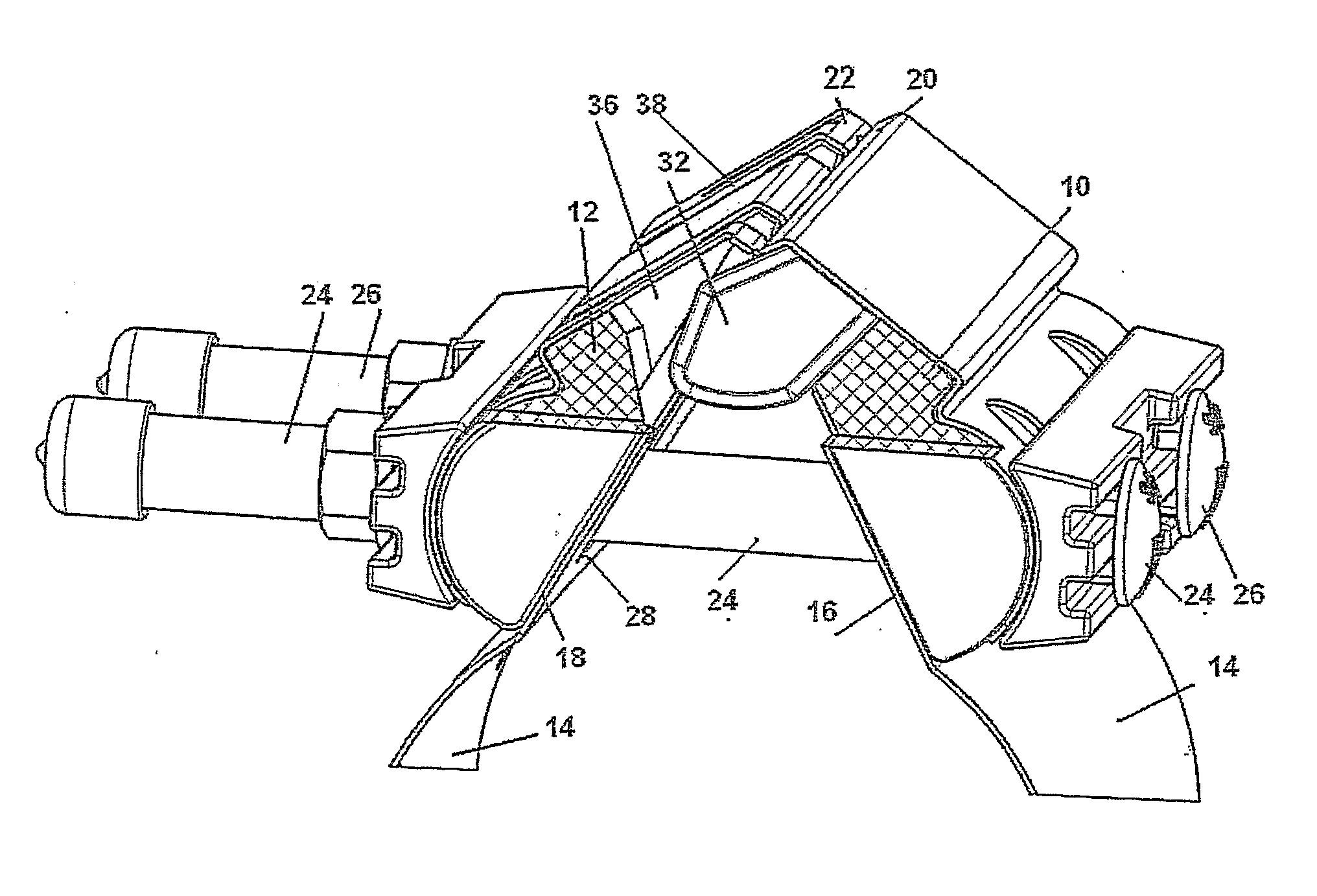

Flip-up convex mirror attachment

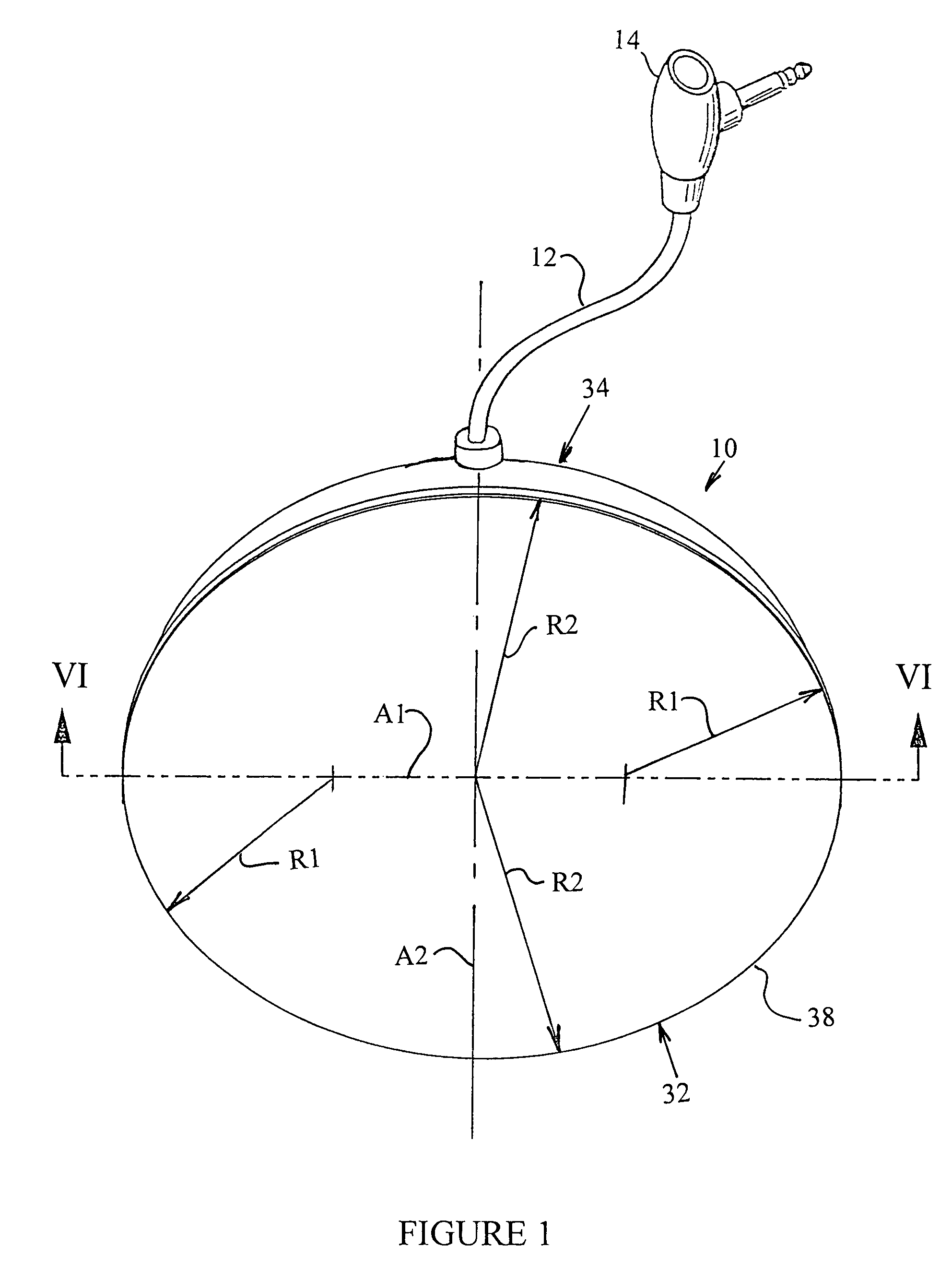

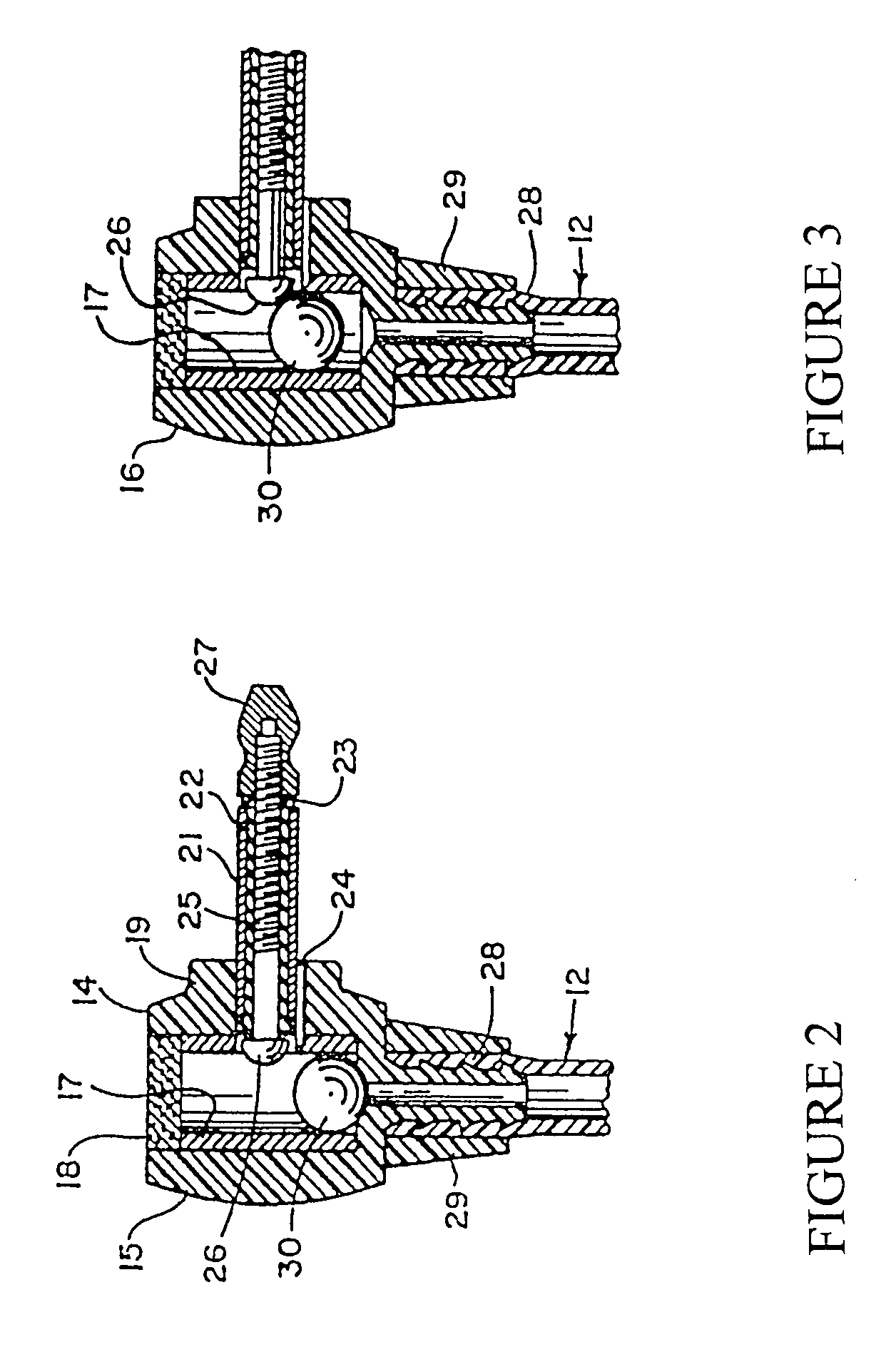

A flip-up convex mirror attachment for installation onto the original equipment mirror in vehicles with either a left-side or right-side driver. The flip-up convex mirror attachment attaches to the mirror surface of the original equipment interior mirror found in most motor vehicles. The flip-up convex mirror attachment contains an angled hinge block for creating a predefined offset angle between the flip-up convex mirror and the OEM mirror such that the reflected image on the side of the mirror nearest the driver is maintained at generally the same point behind the vehicle as the original equipment mirror. The wedge-based hinge assembly may be attached to the flat mirror surface on either a left-side or right-side driver vehicle and still maintain the desired angular offset between the OEM and flip-up convex mirrors.

Owner:ROOSE ALISON L

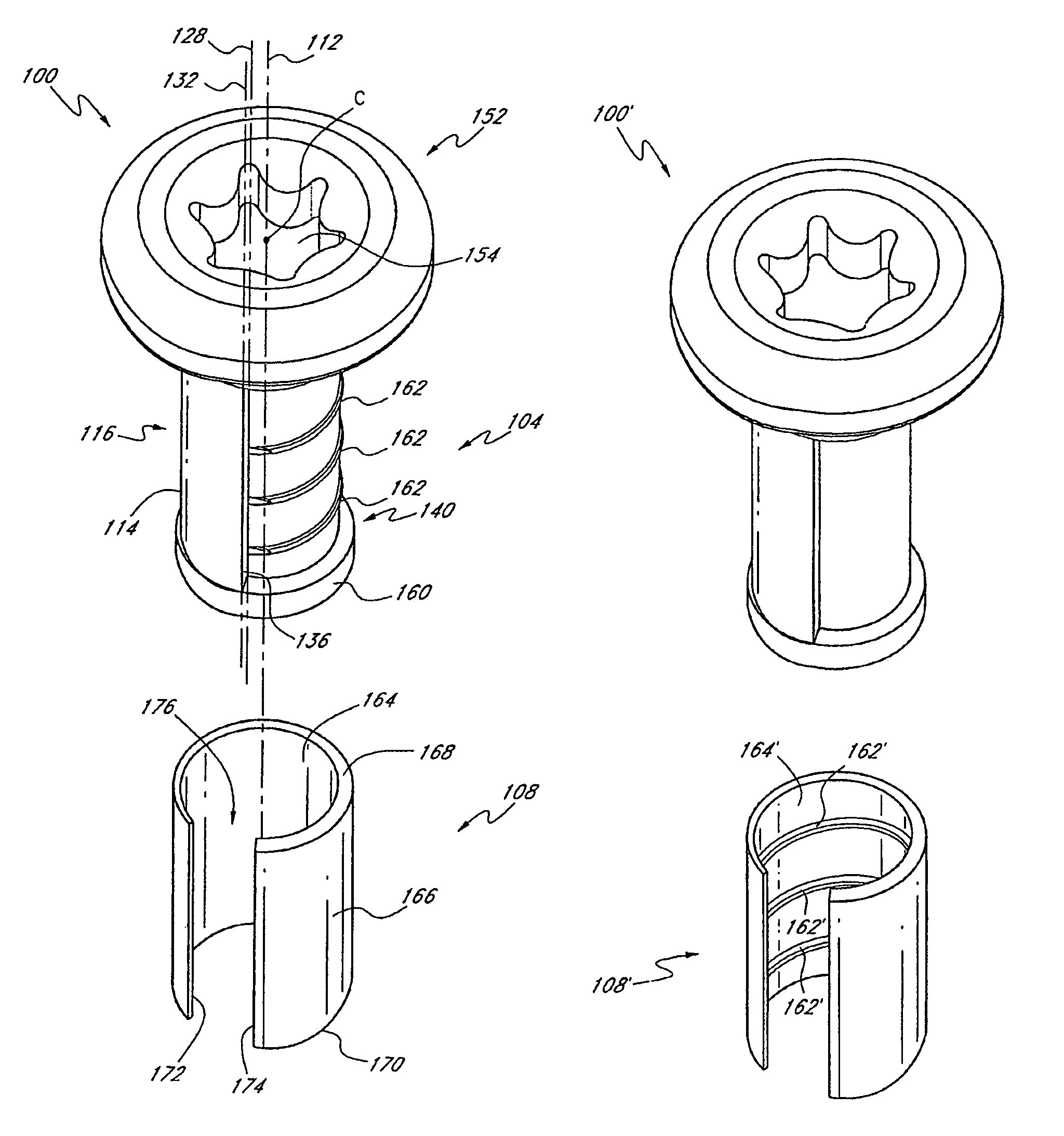

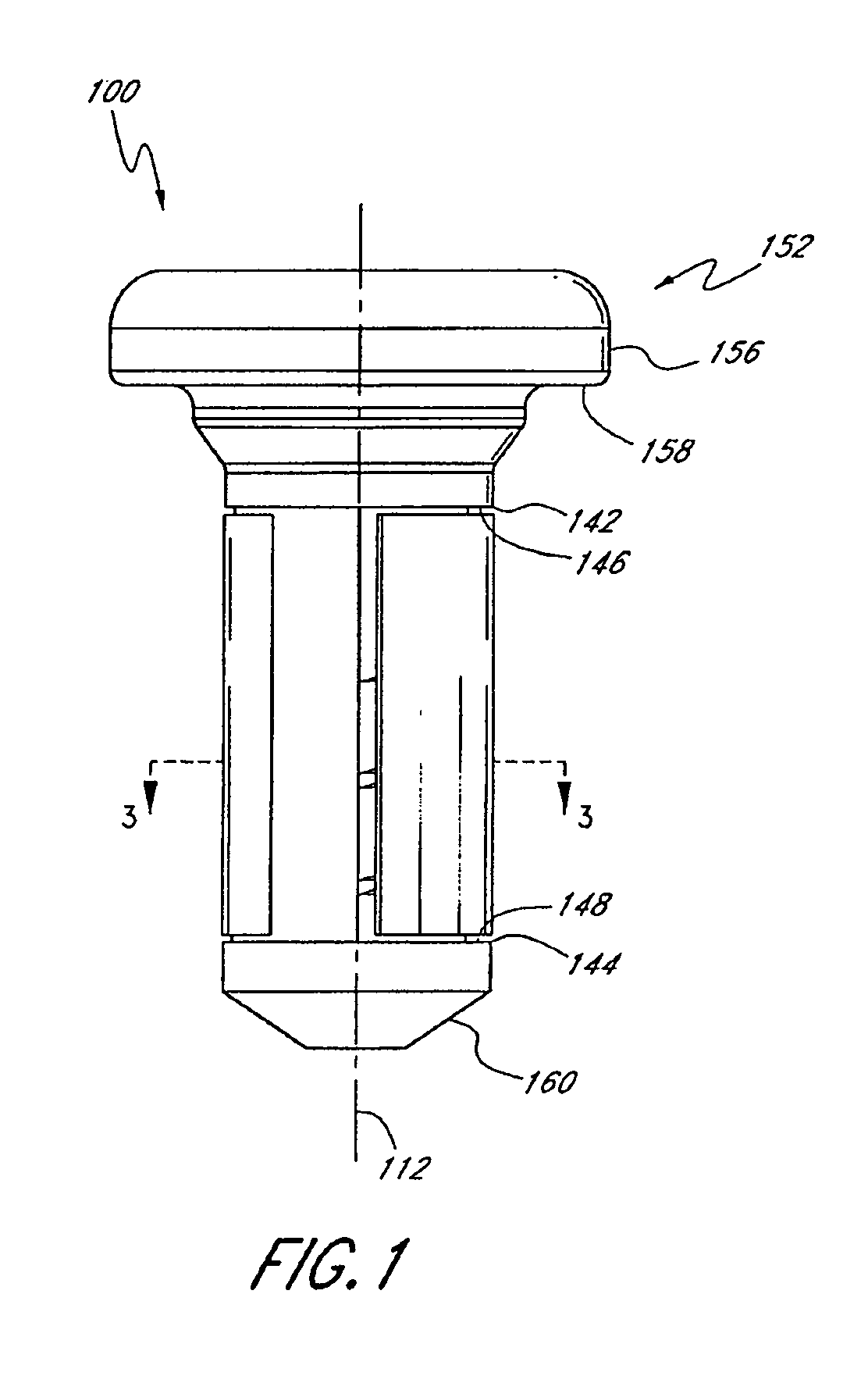

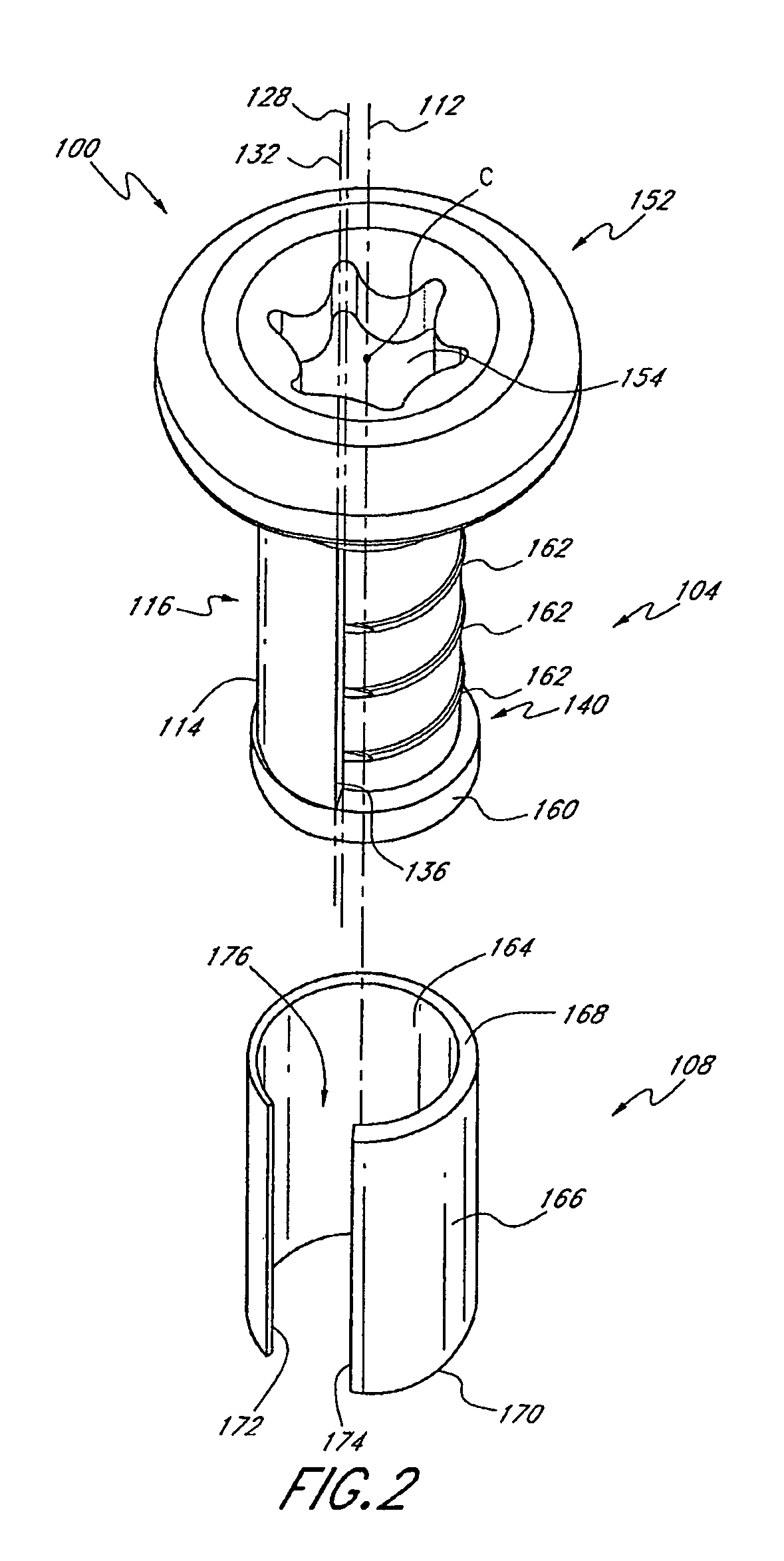

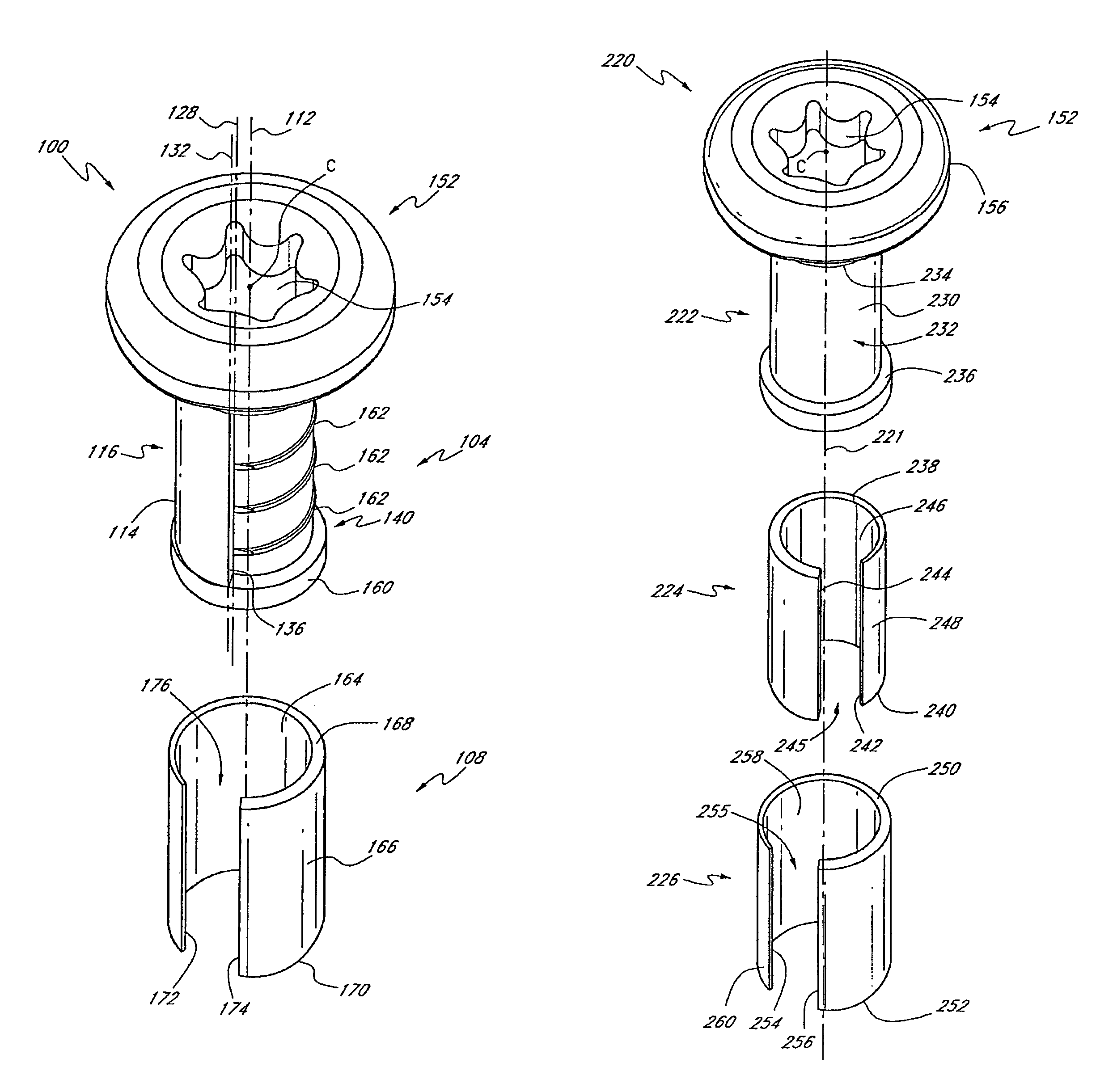

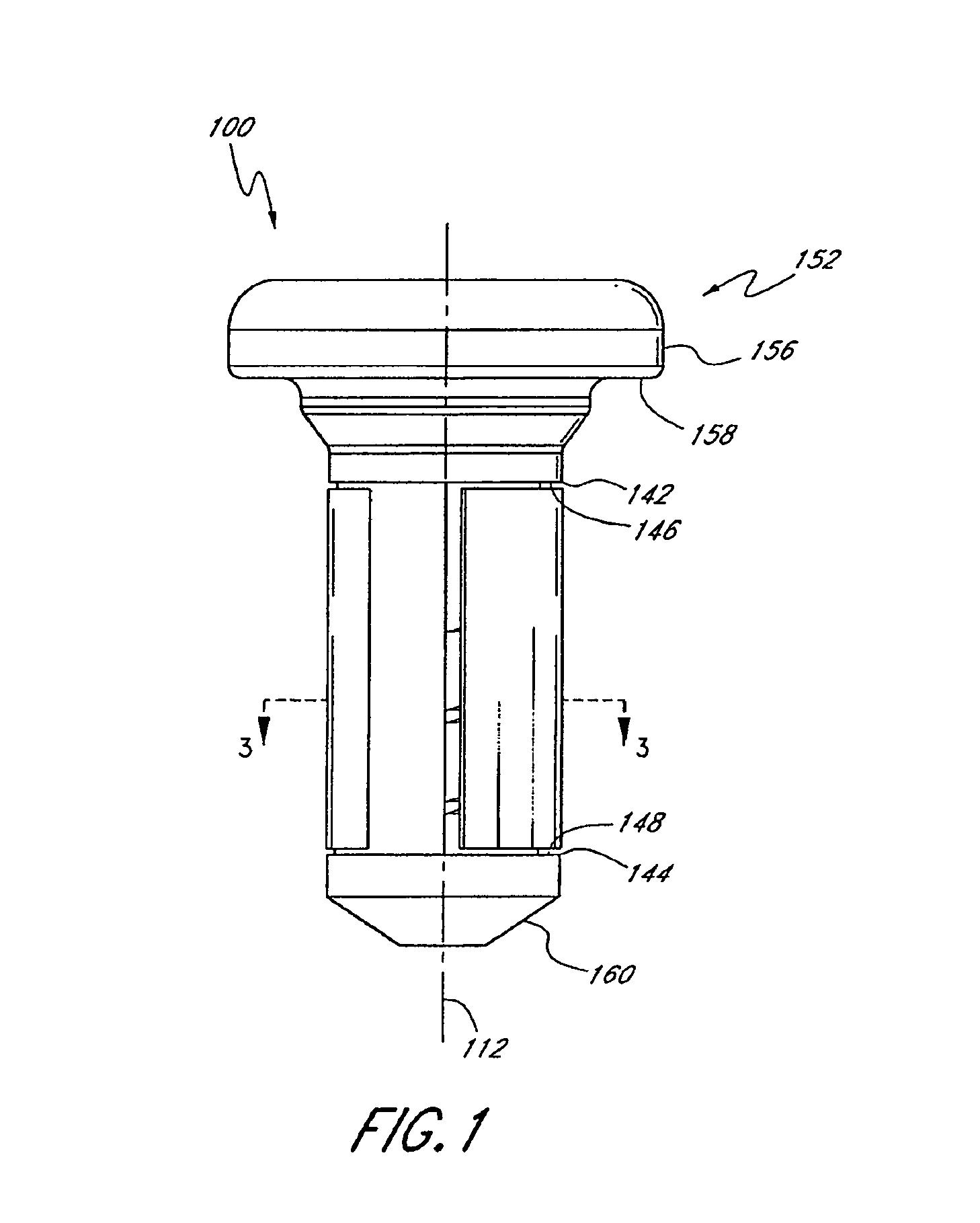

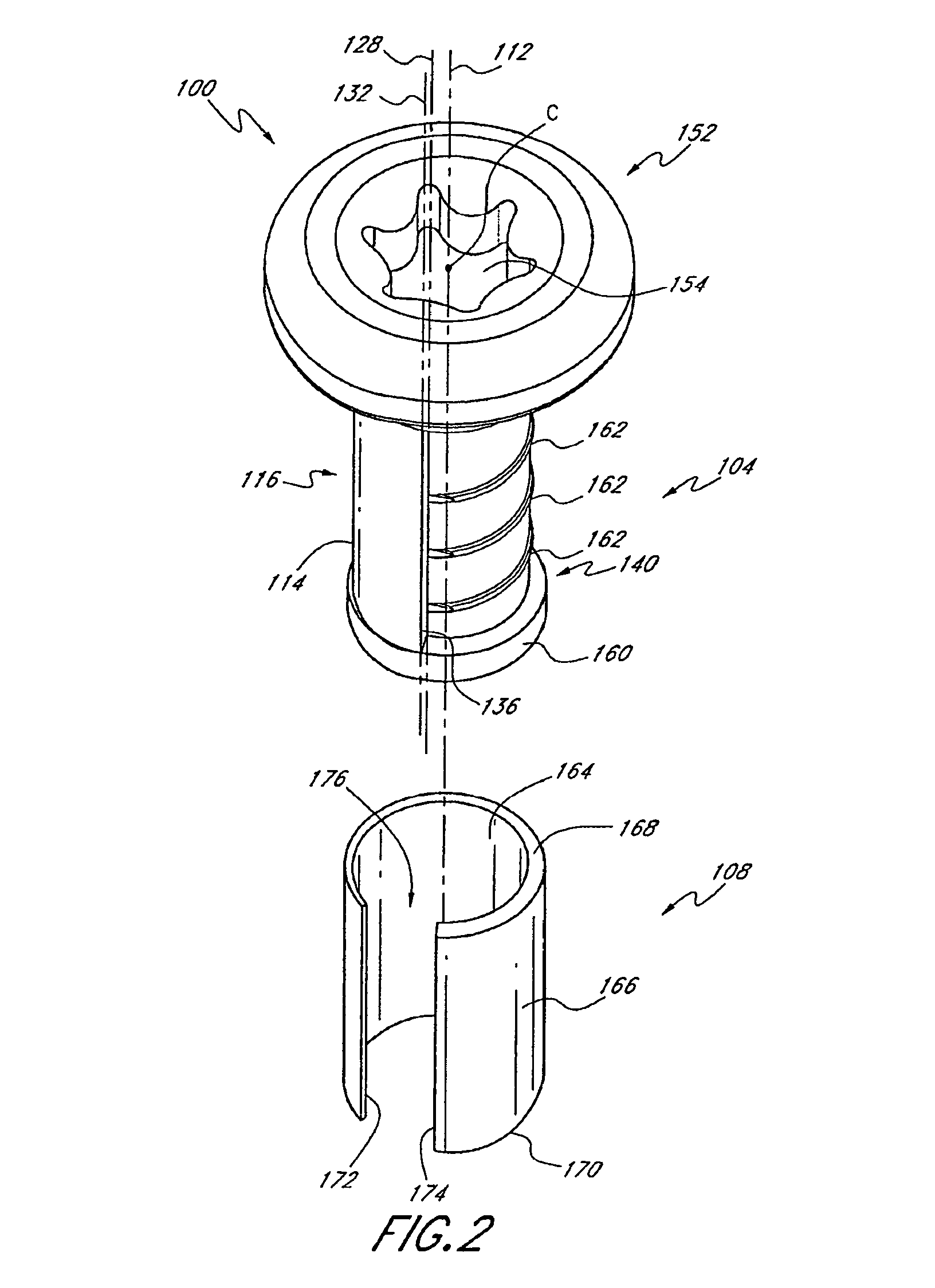

Wedge based fastener

A fastener that includes a shaft and a sleeve is provided. The shaft extends along a longitudinal axis that passes through a central portion, e.g., the centroid of a head of the shaft. The sleeve is wrapped partially around the shaft. The sleeve has a gap that separates first and second circumferential extents thereof, a first thickness adjacent the first circumferential extent, and a second thickness between the second circumferential extent and the first circumferential extent. The first thickness is less than the second thickness. The sleeve has a first rotational position relative to the shaft and a second rotational position relative to the shaft different form the first rotational position. The longitudinal axis is in substantially the same location in both the first and second rotational positions.

Owner:WESTERN DIGITAL TECH INC

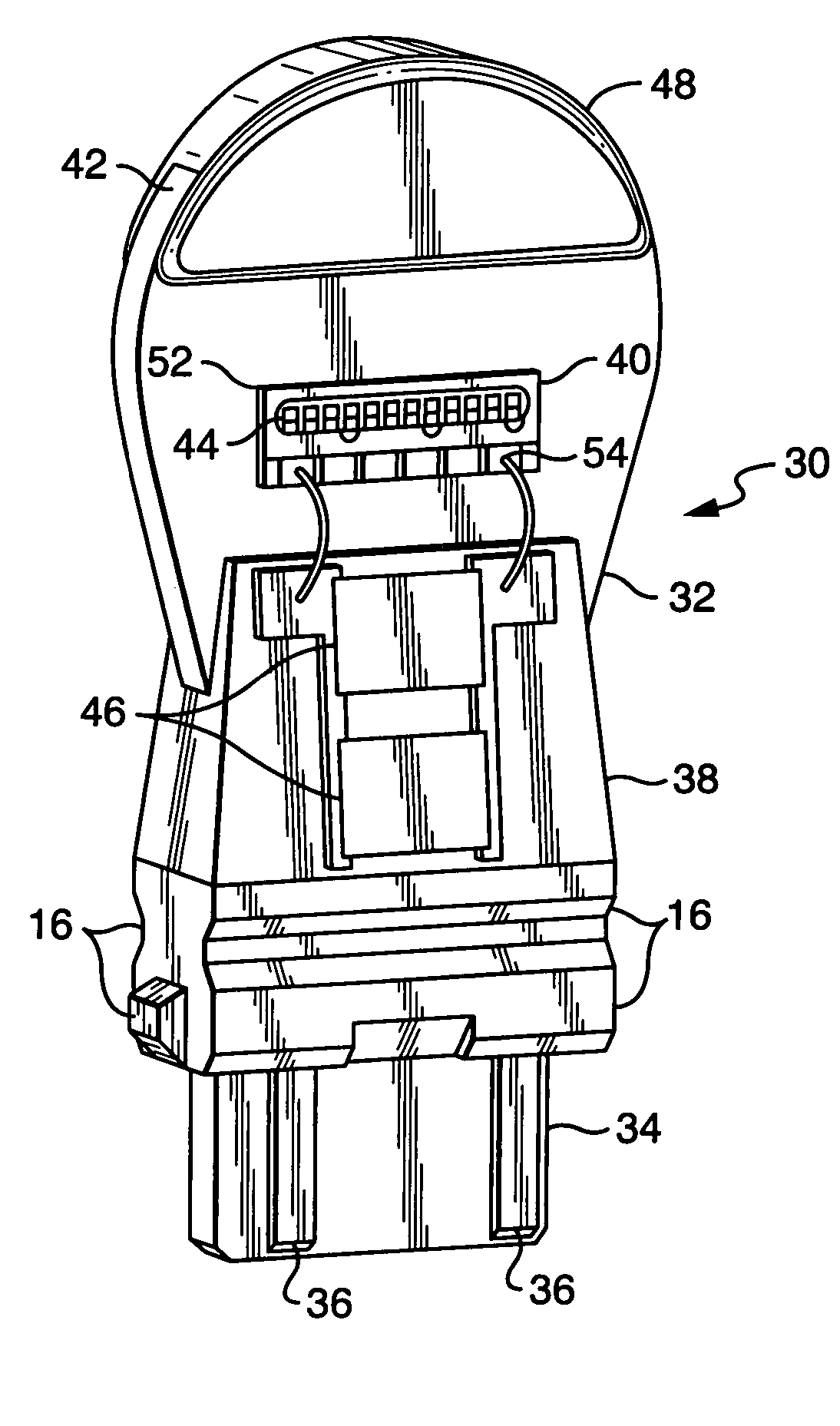

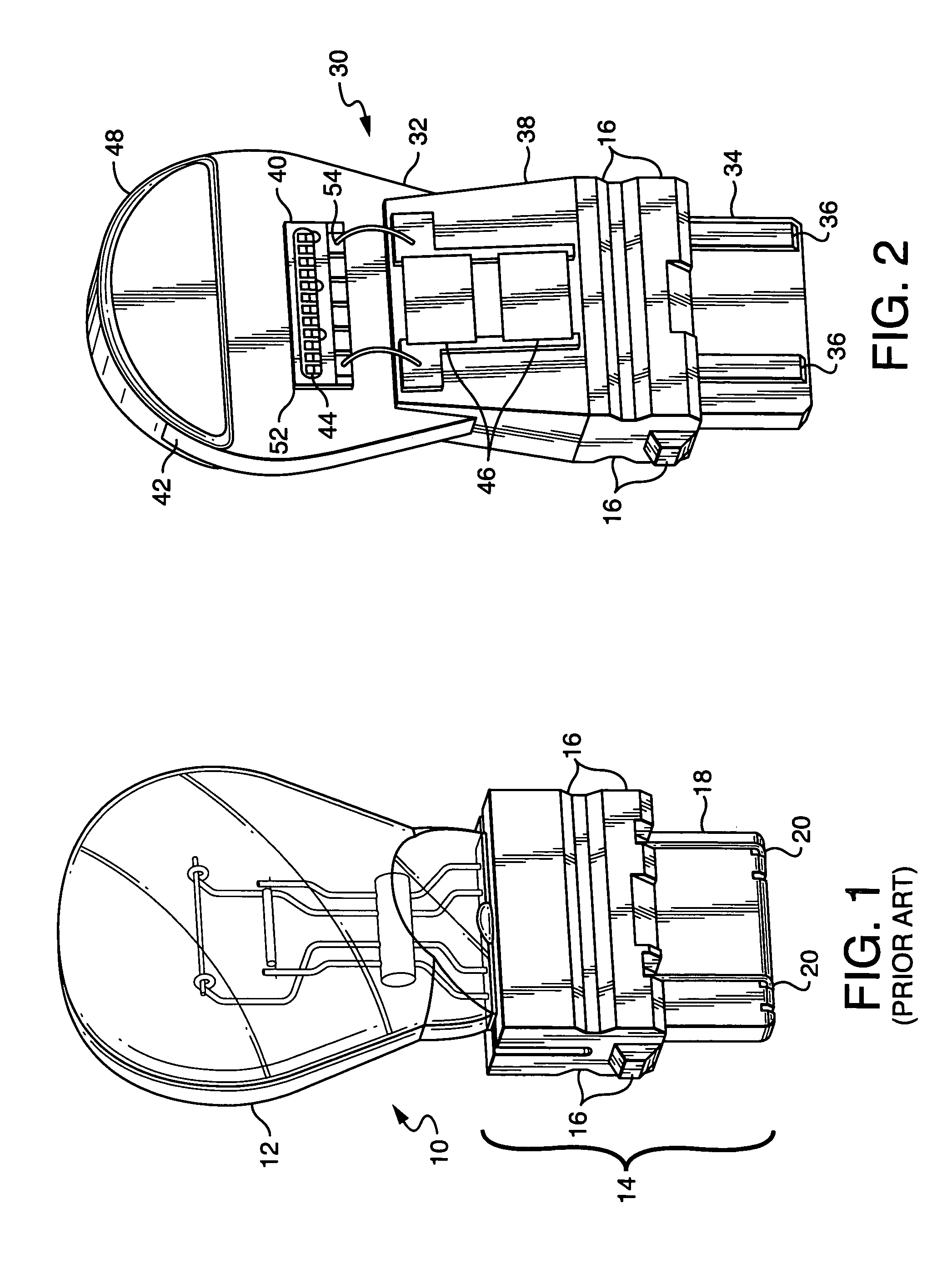

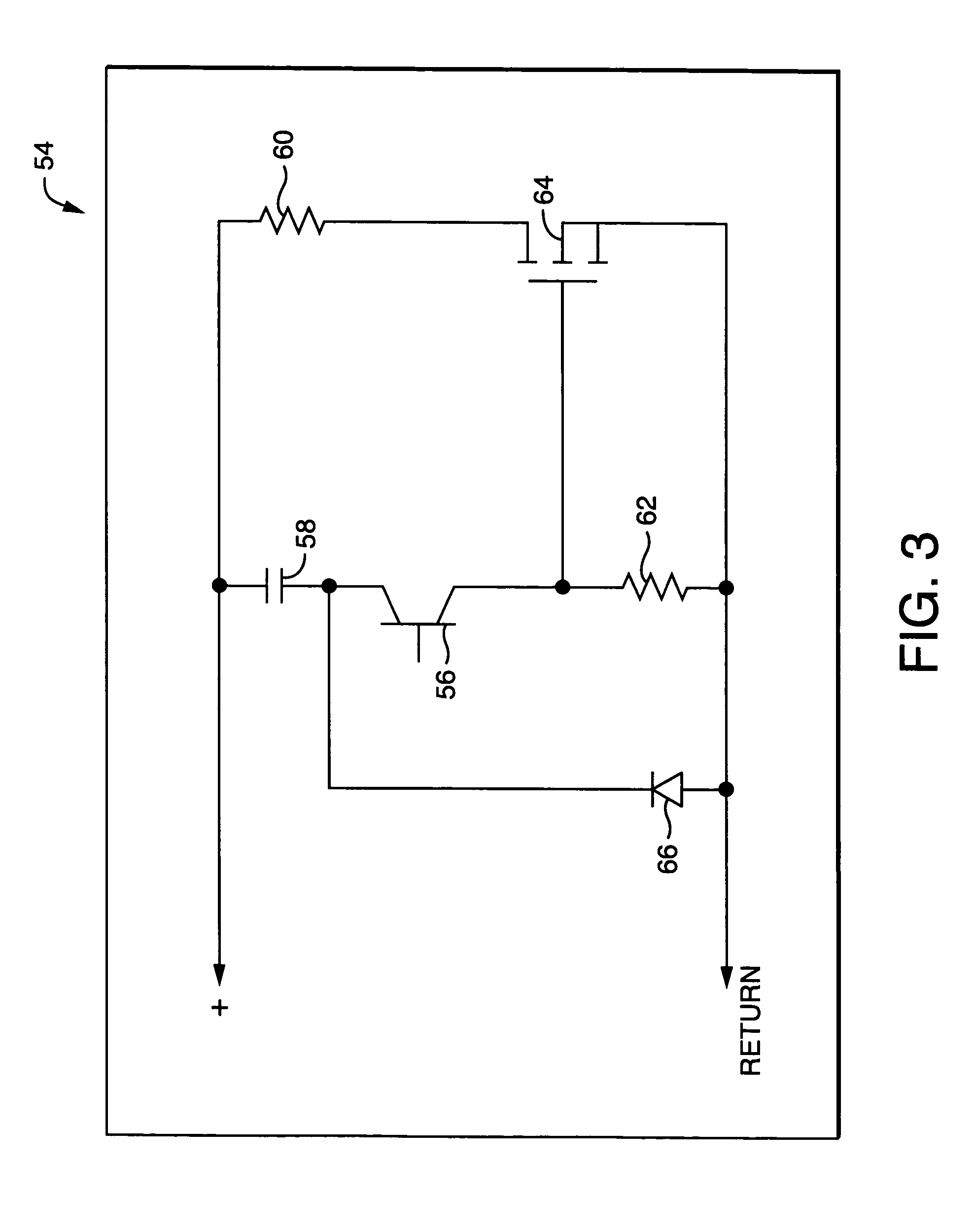

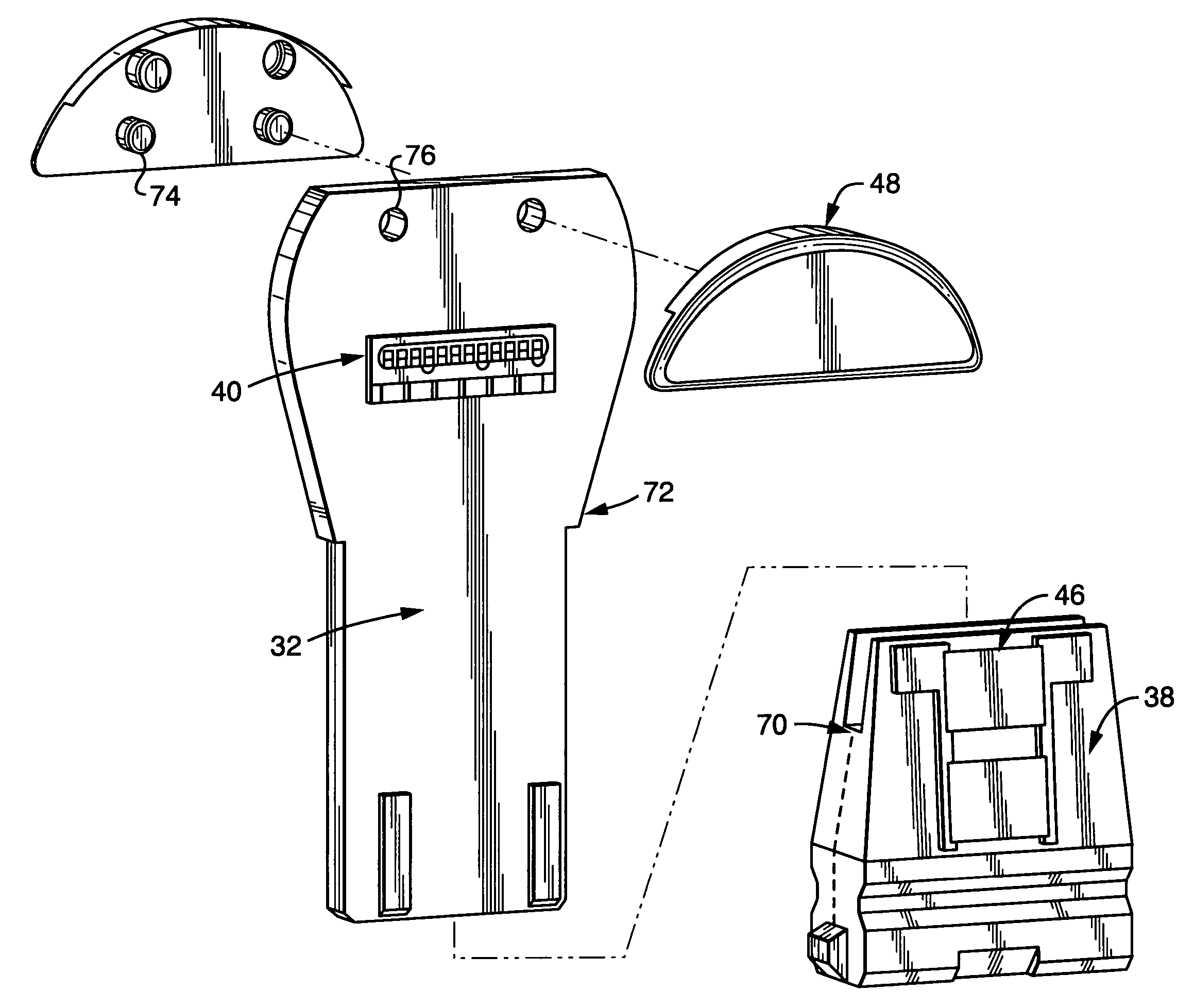

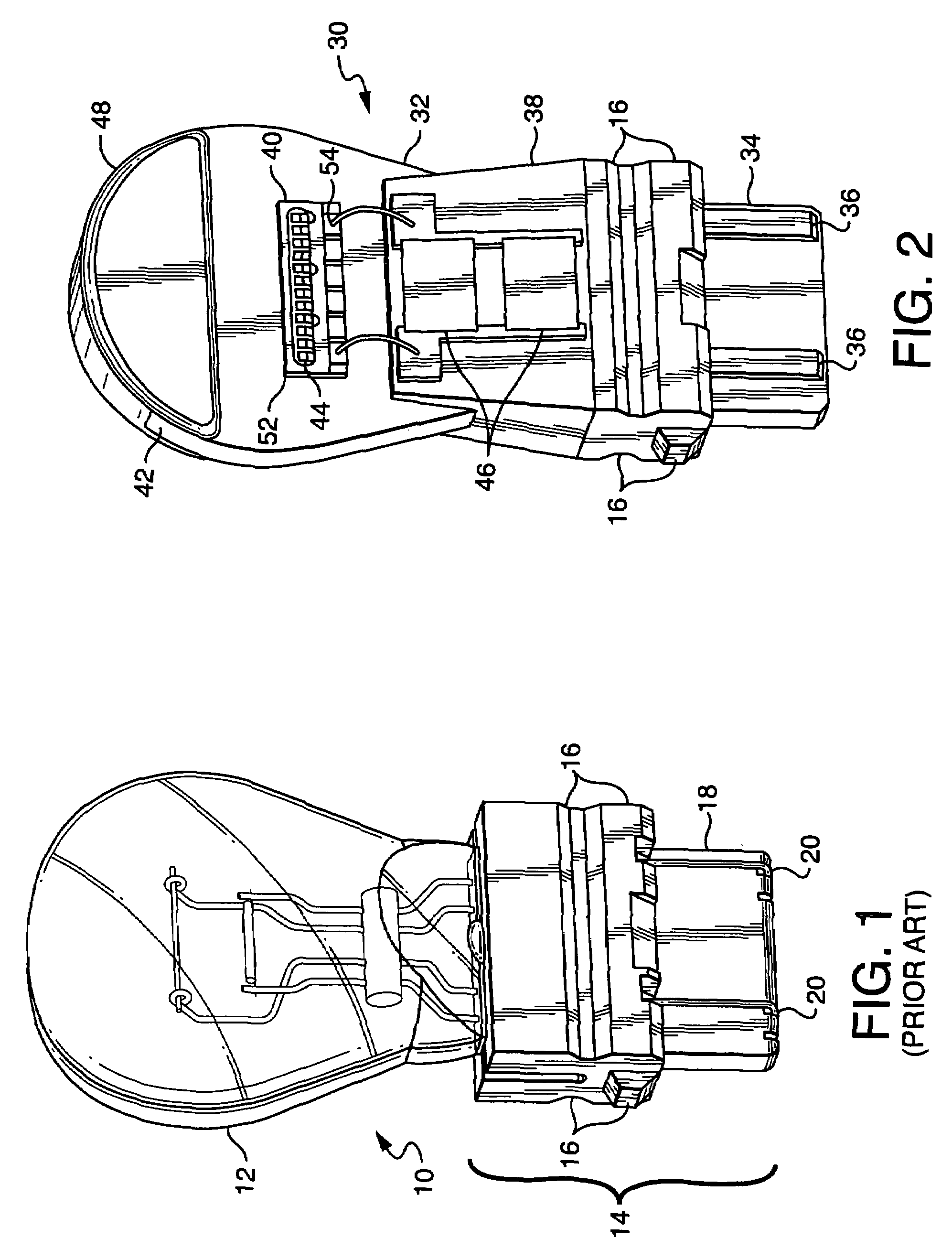

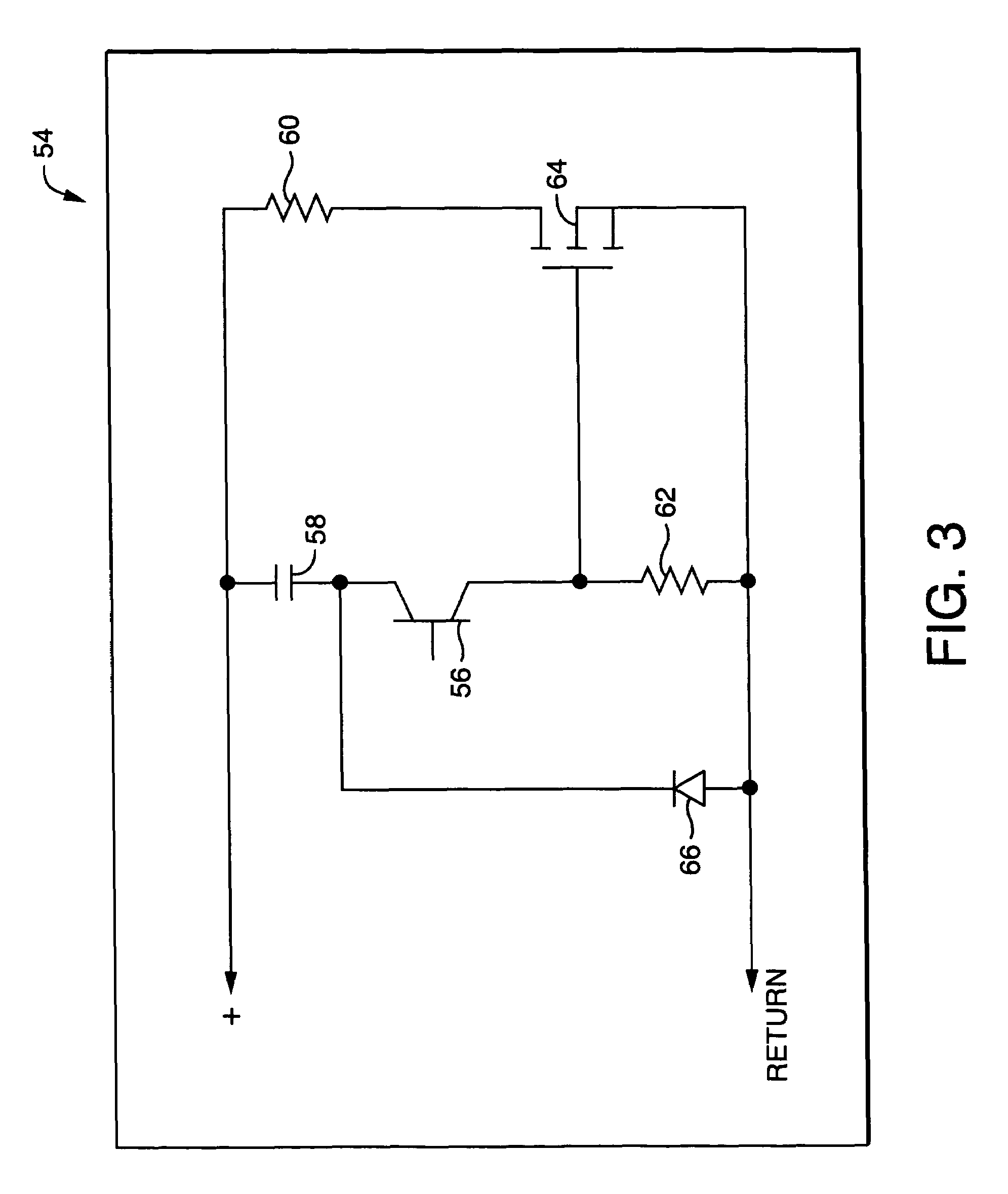

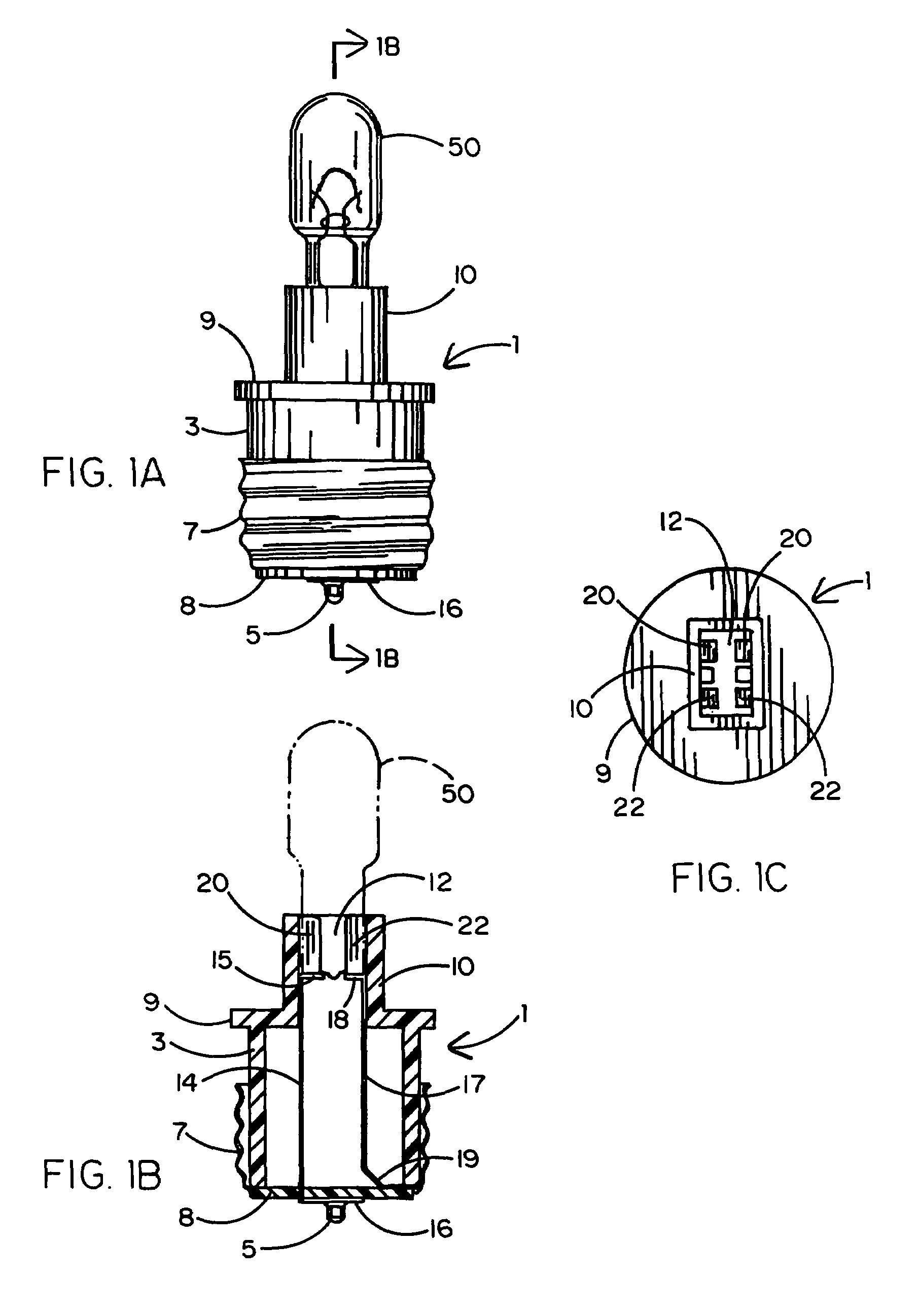

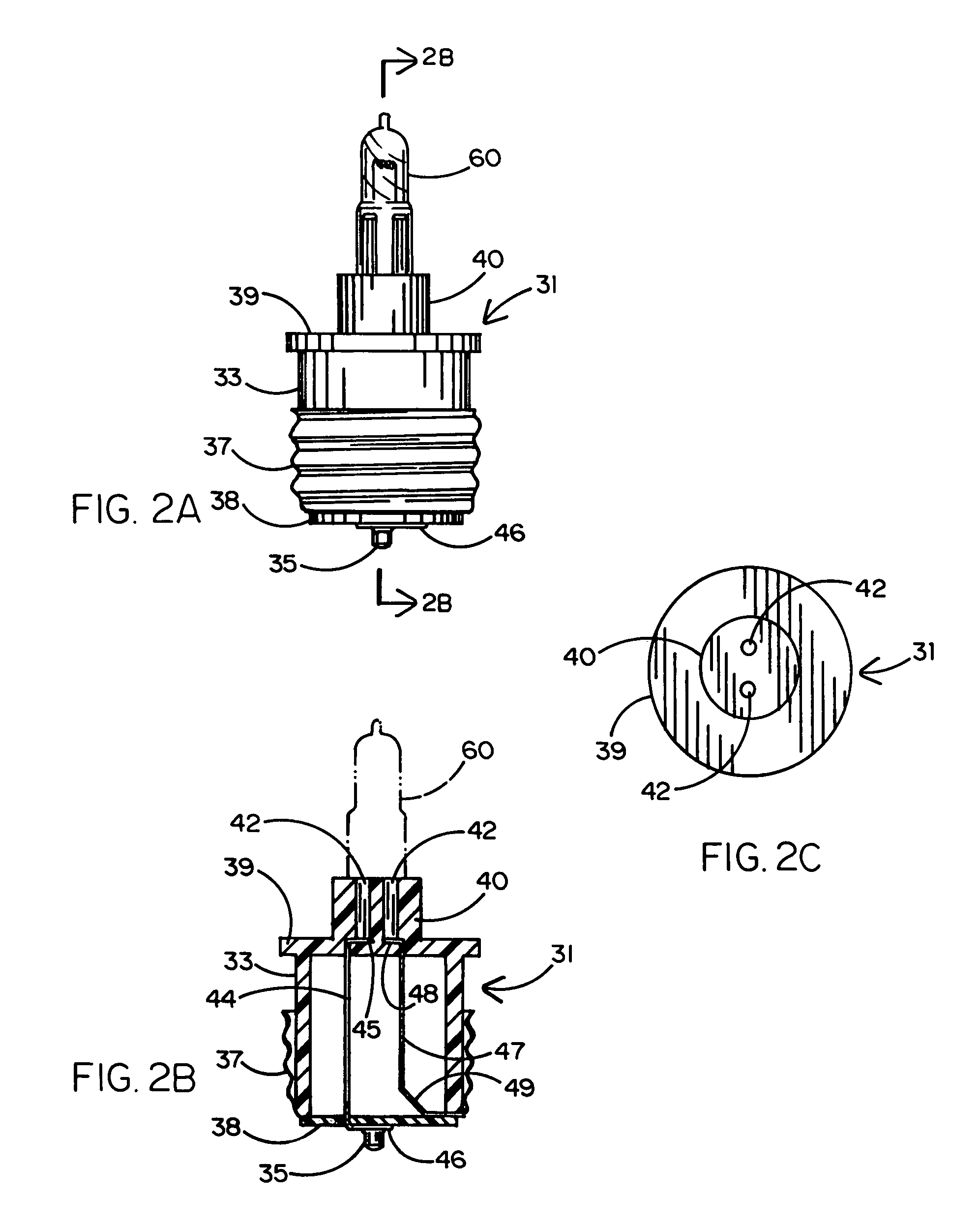

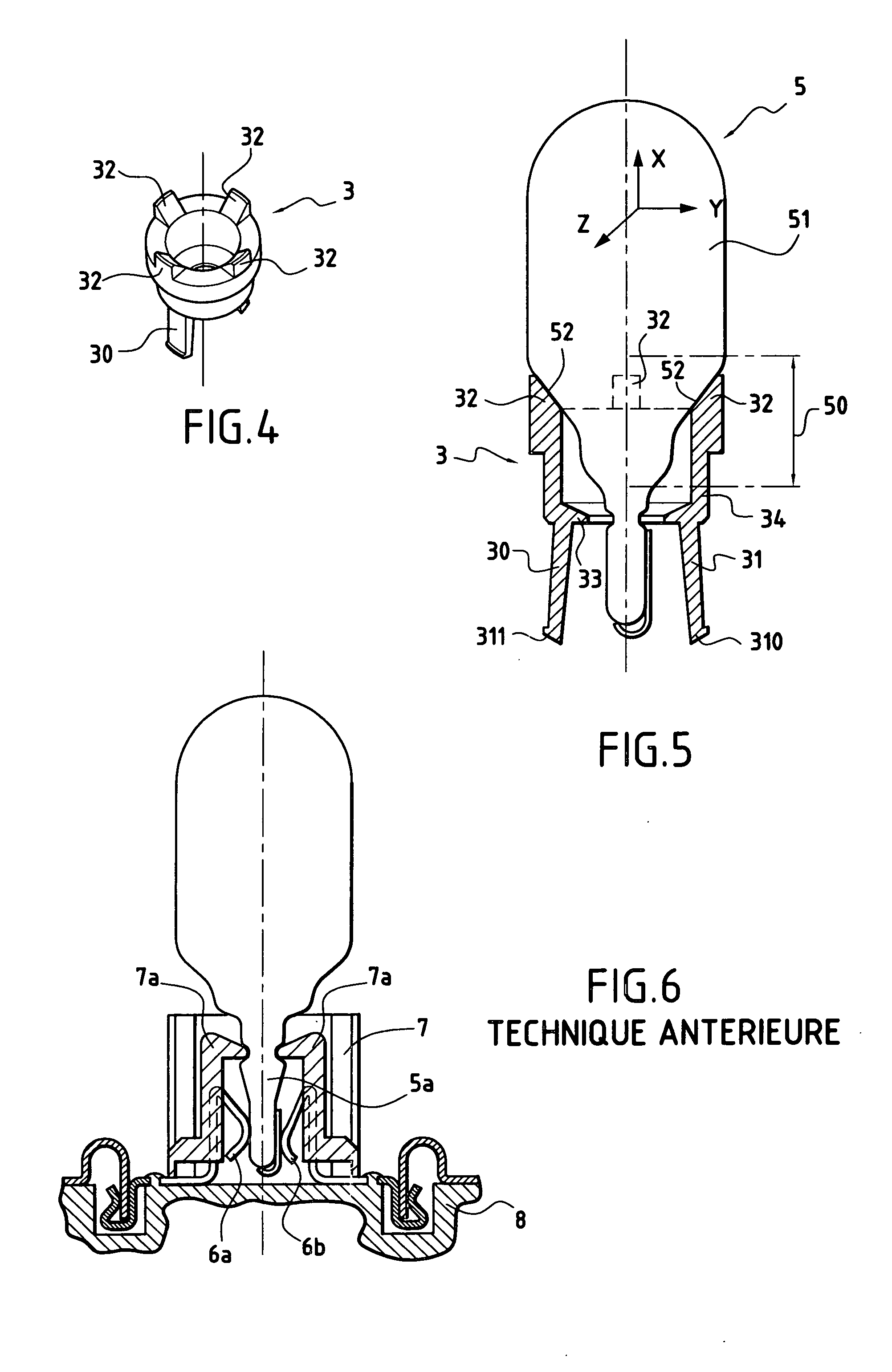

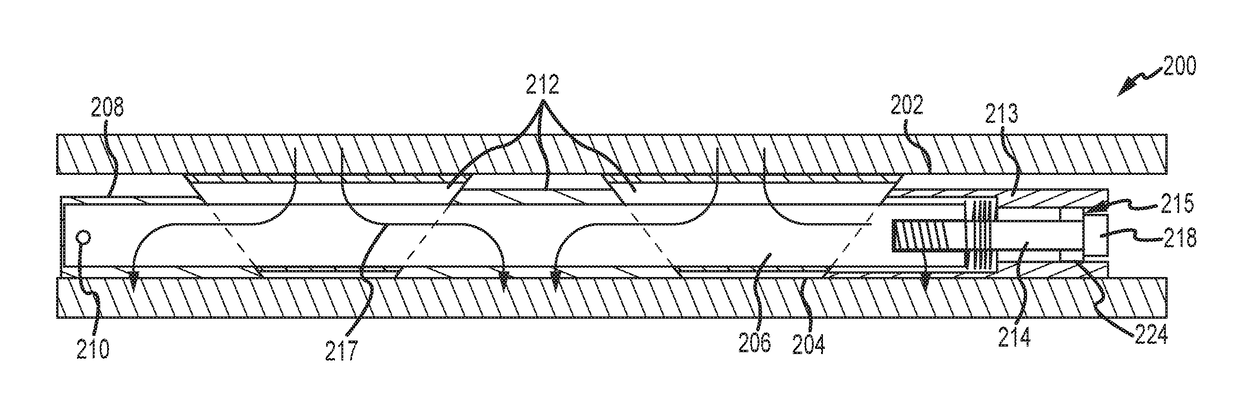

Wedge-based lamp with LED light engine and method of making the lamp

InactiveUS20050276063A1Coupling device connectionsLighting support devicesElectricityElectrical connection

An LED wedge-based lamp and method of making the lamp, where the lamp has a generally planar circuit board having one end that has electrical connections exposed thereon and a connecting part that is adapted to mechanically couple the lamp to a wedge-based lamp socket. The lamp includes an LED light engine near a second end of the circuit board, where the light engine includes plural laterally aligned LEDs whose light output mimics the light output of an incandescent lamp, such as used in automobile stop and turn signals. The lamp includes a load resistor, whose load mimics that of the incandescent lamp, on an exterior surface of the connecting part. The connecting part may be a sleeve that slides onto the circuit board. A hand grip / heat sink may be provided at the second end of the circuit board.

Owner:OSRAM SYLVANIA INC

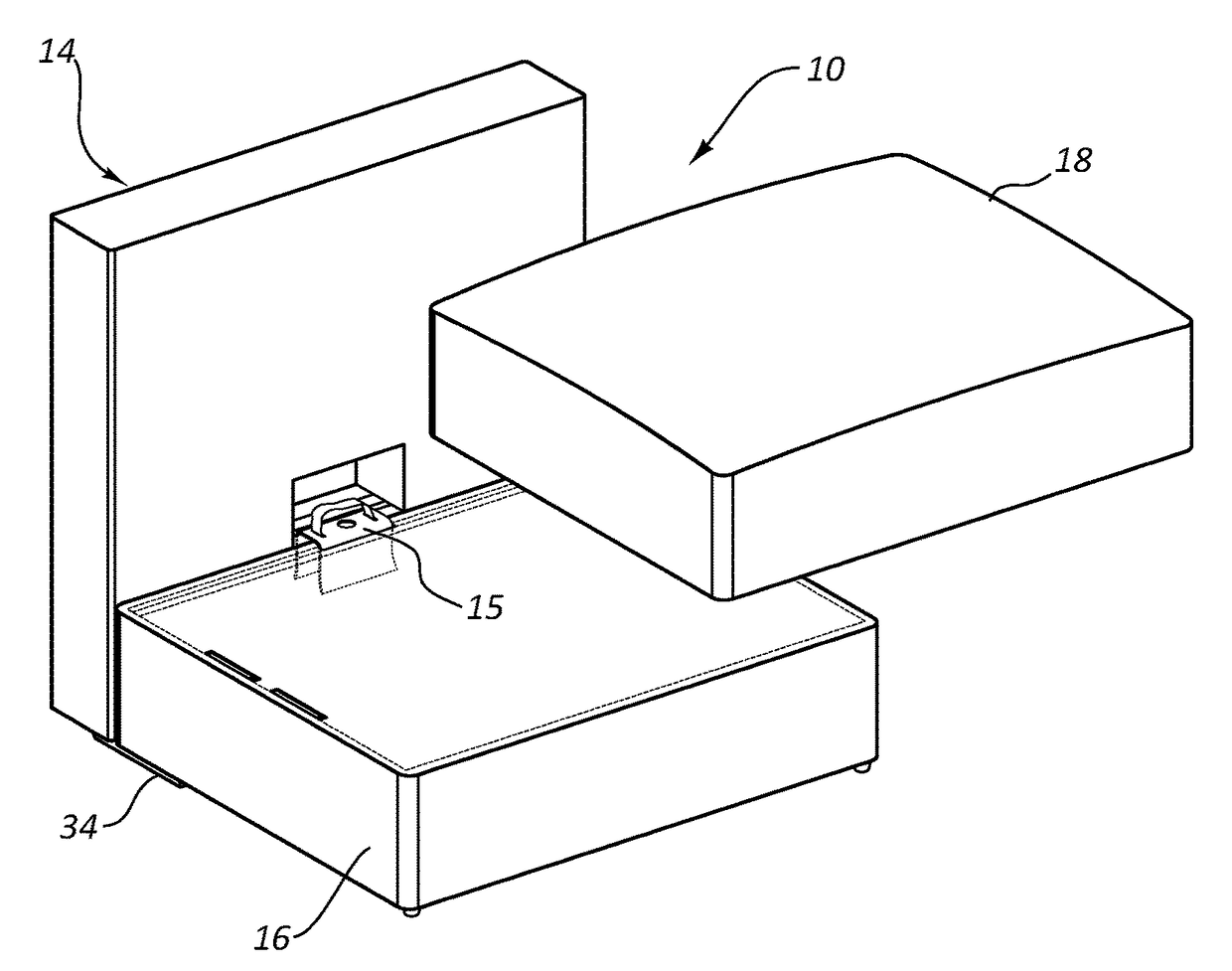

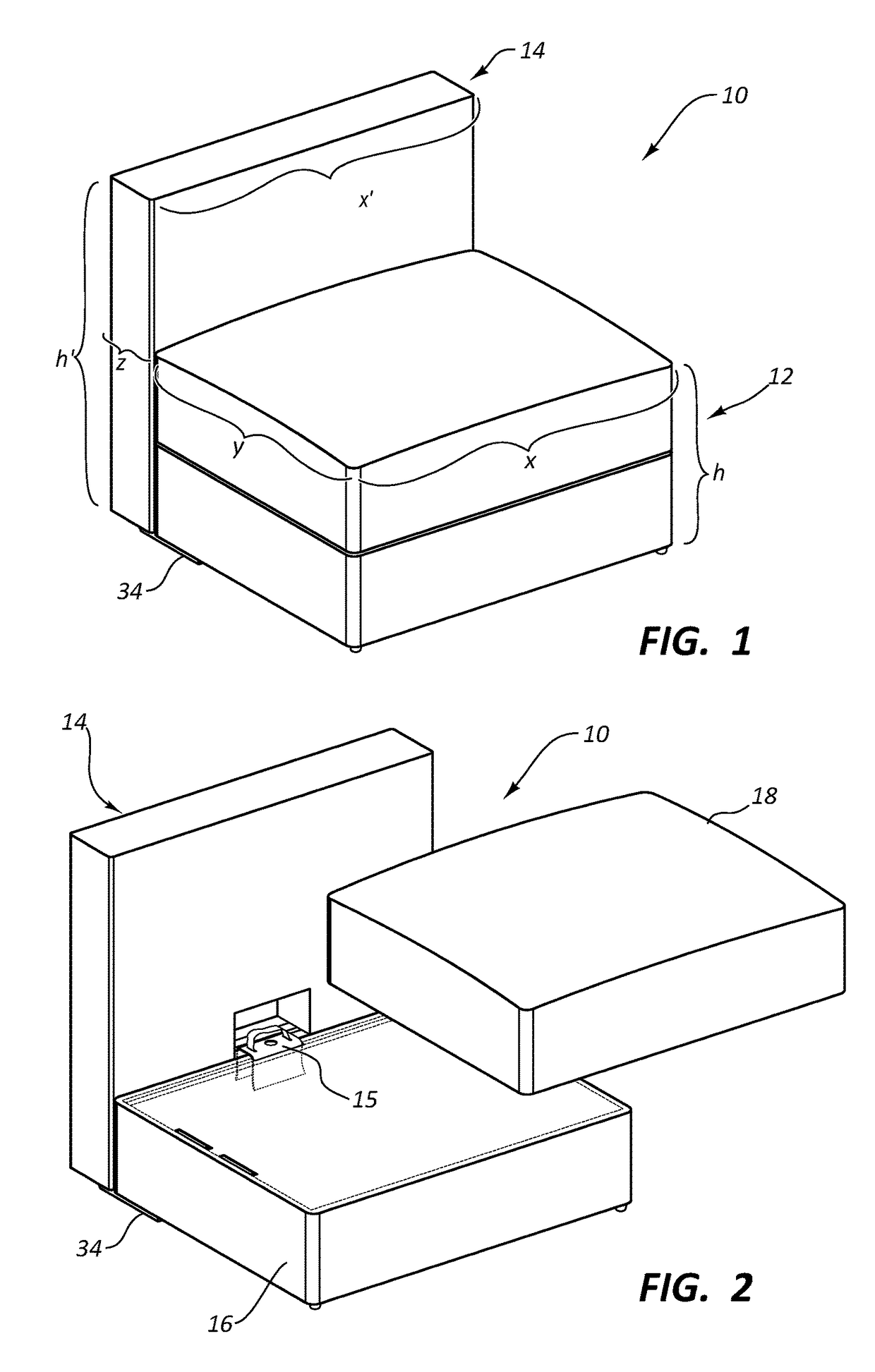

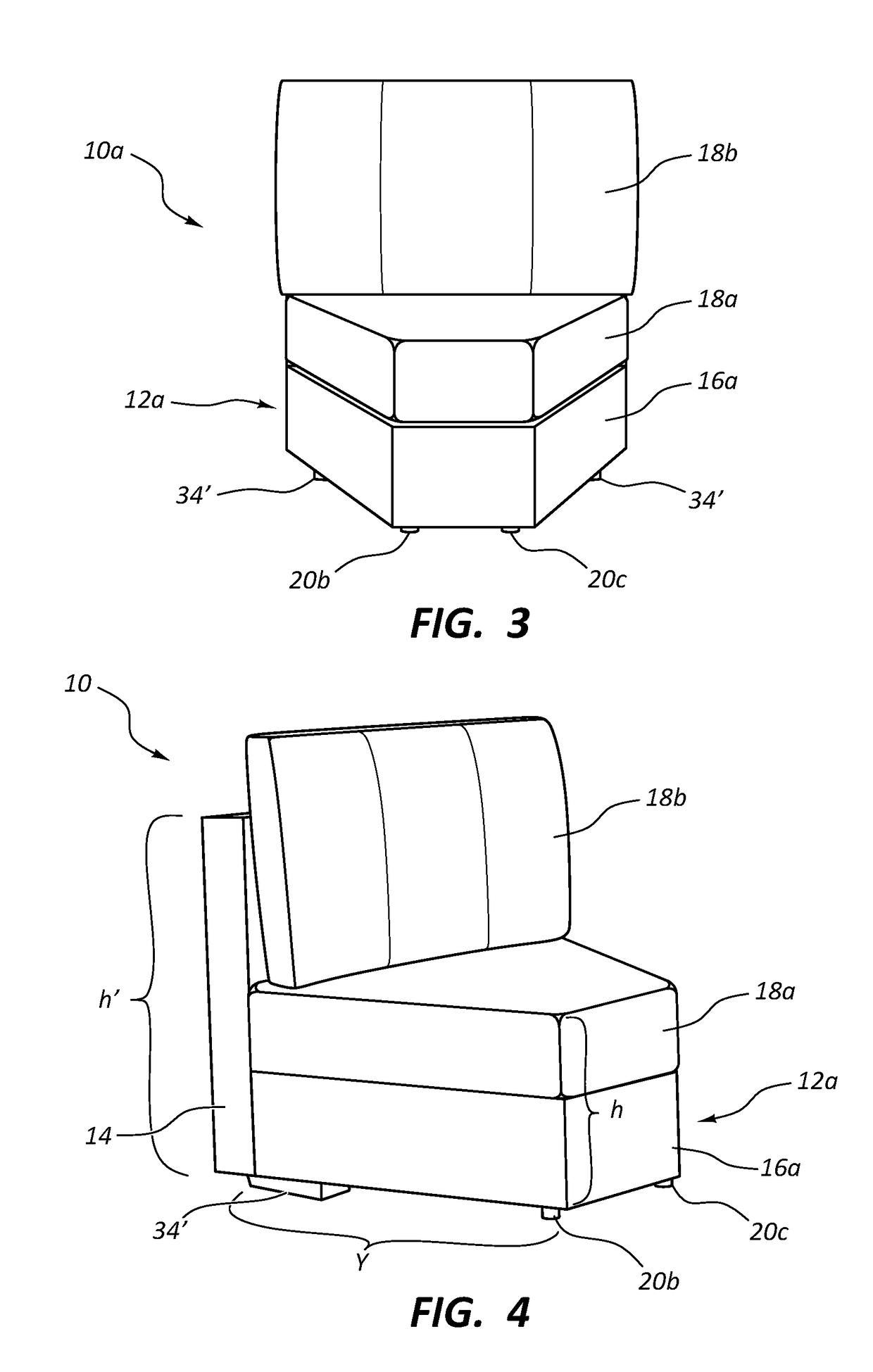

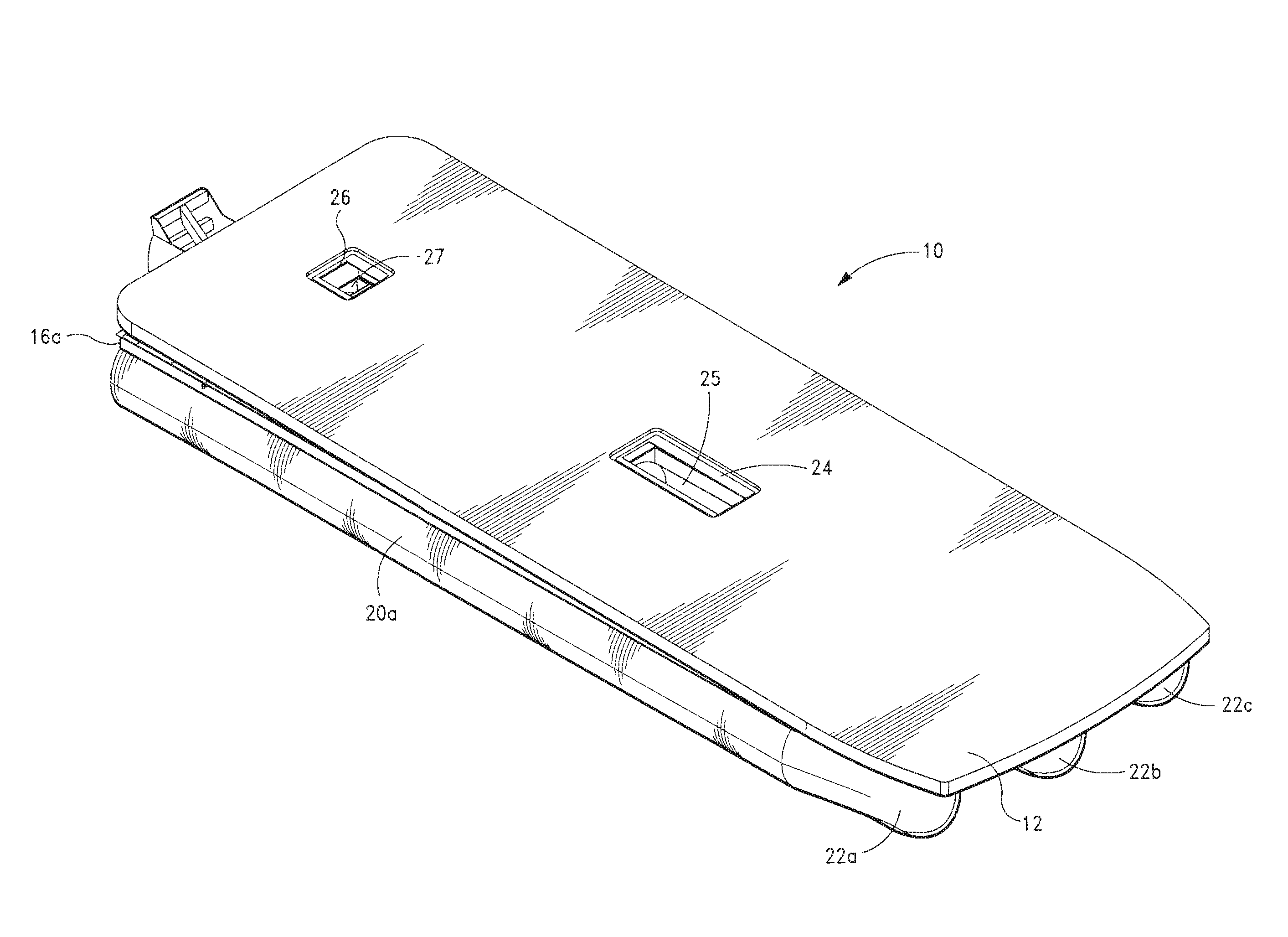

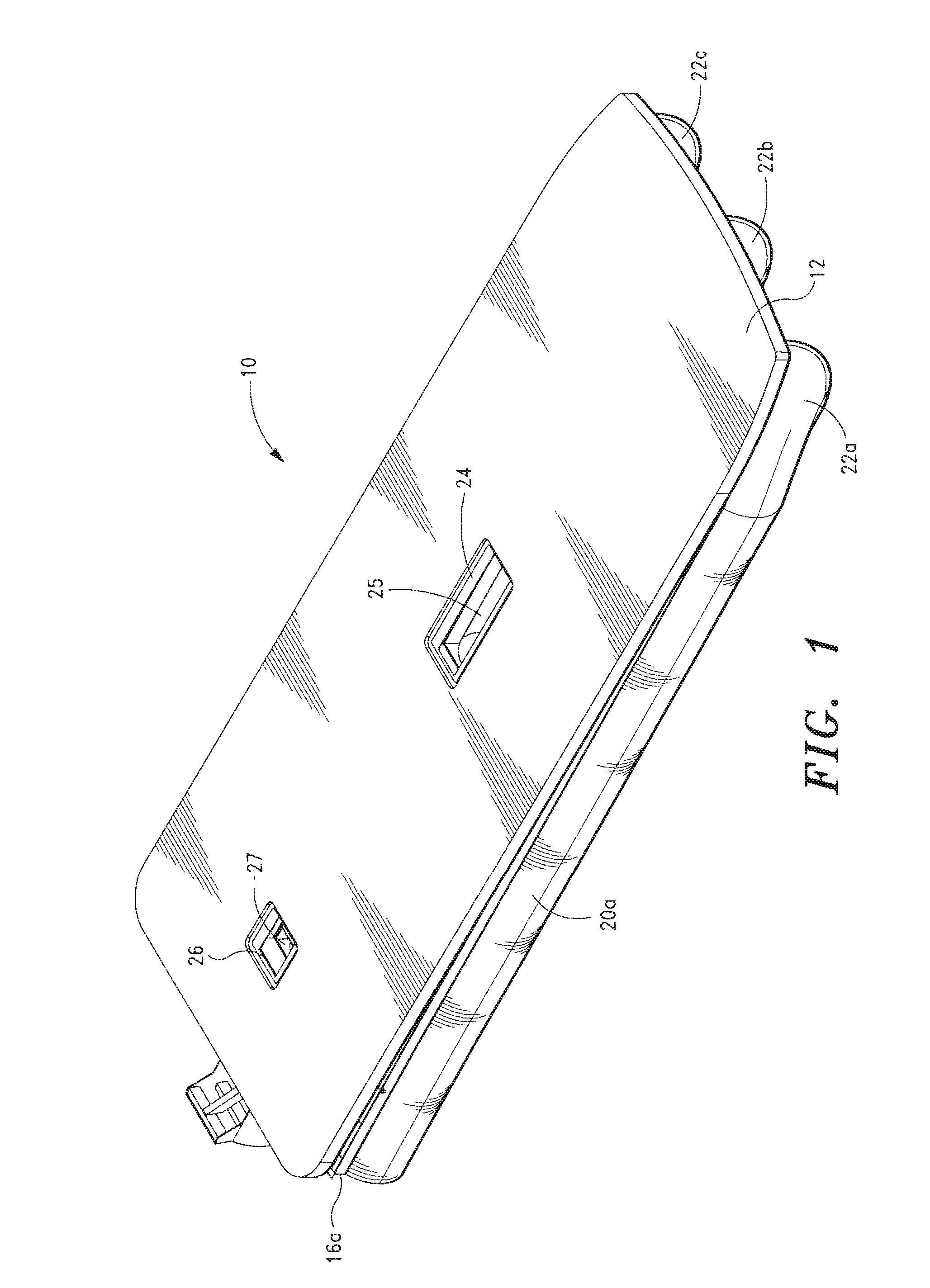

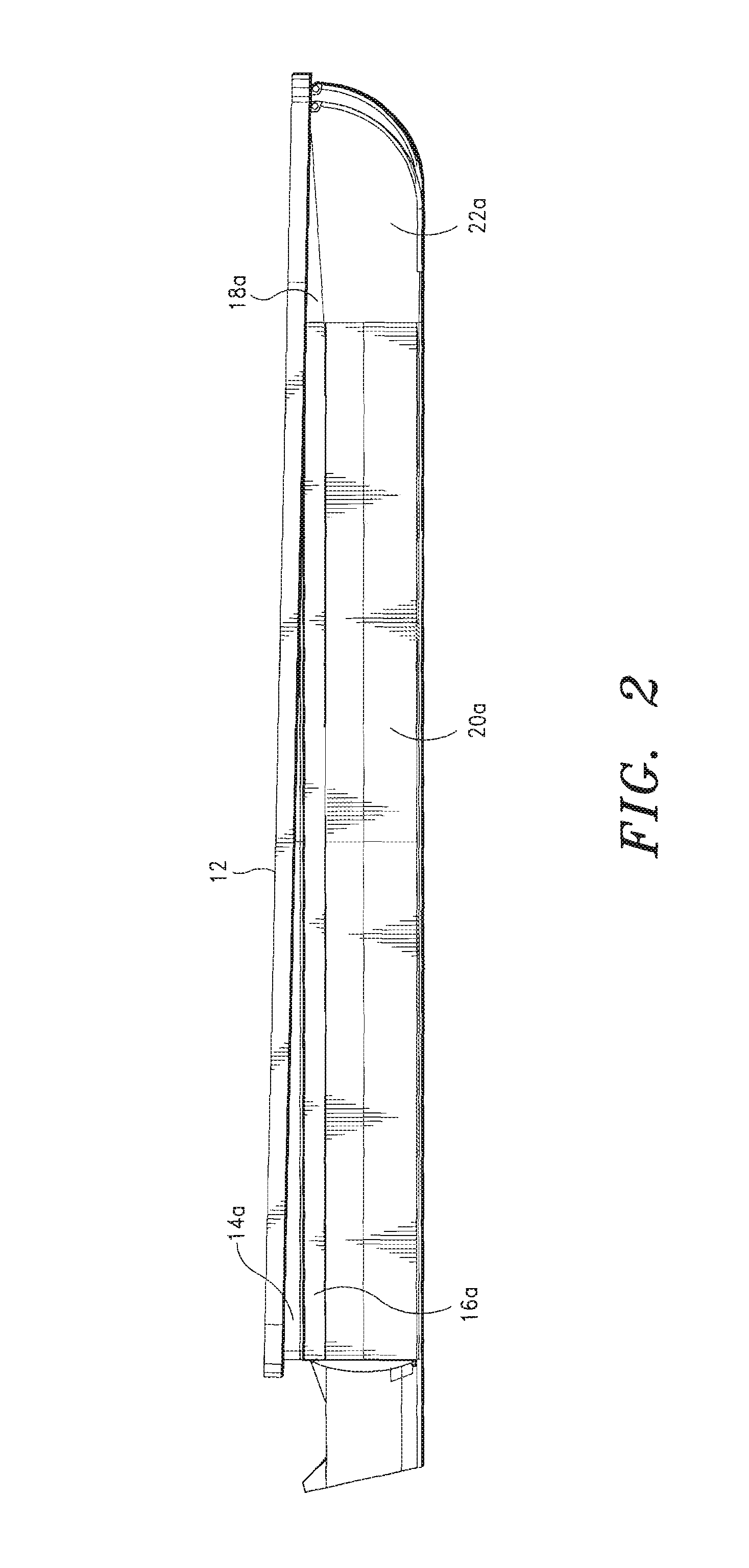

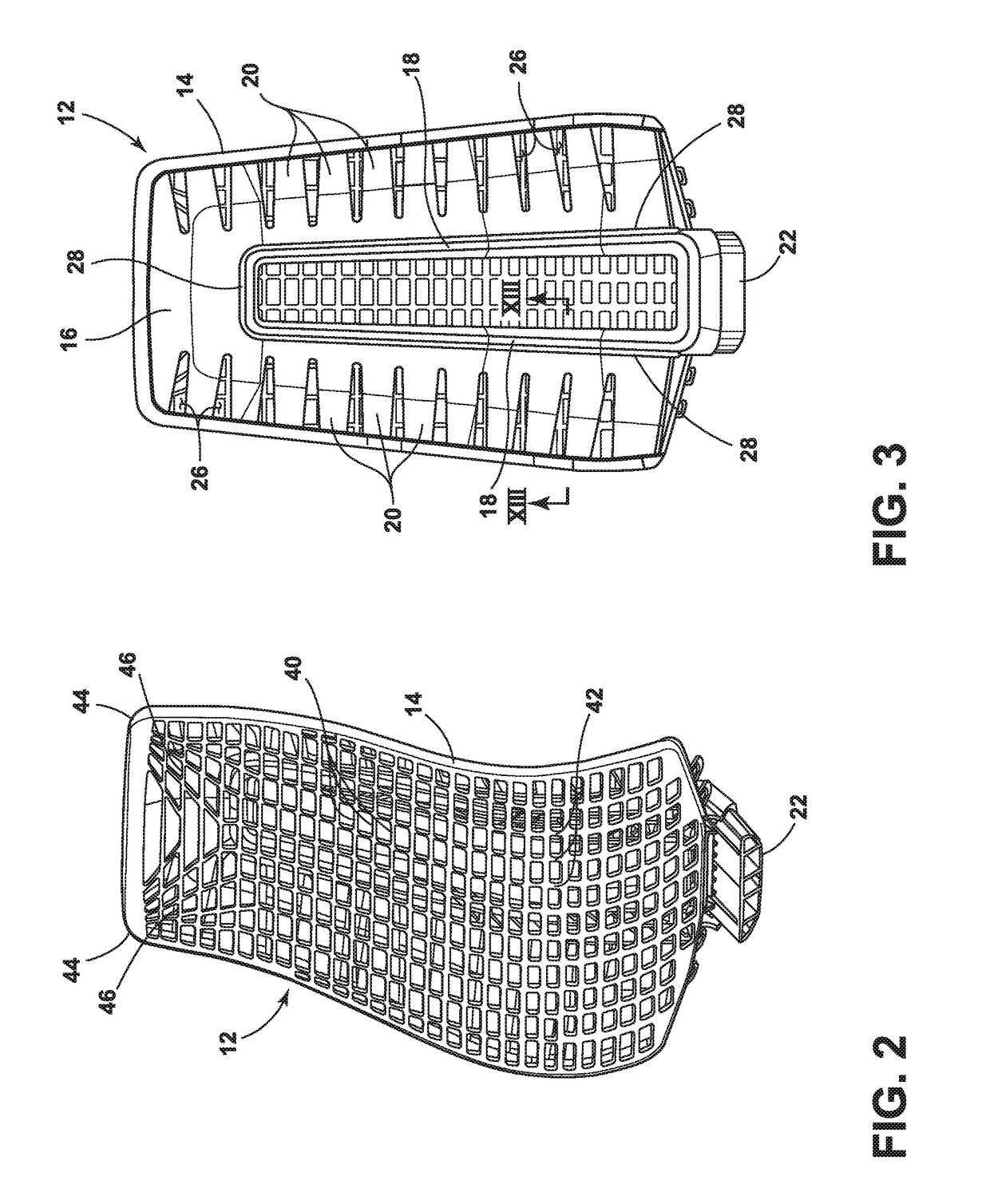

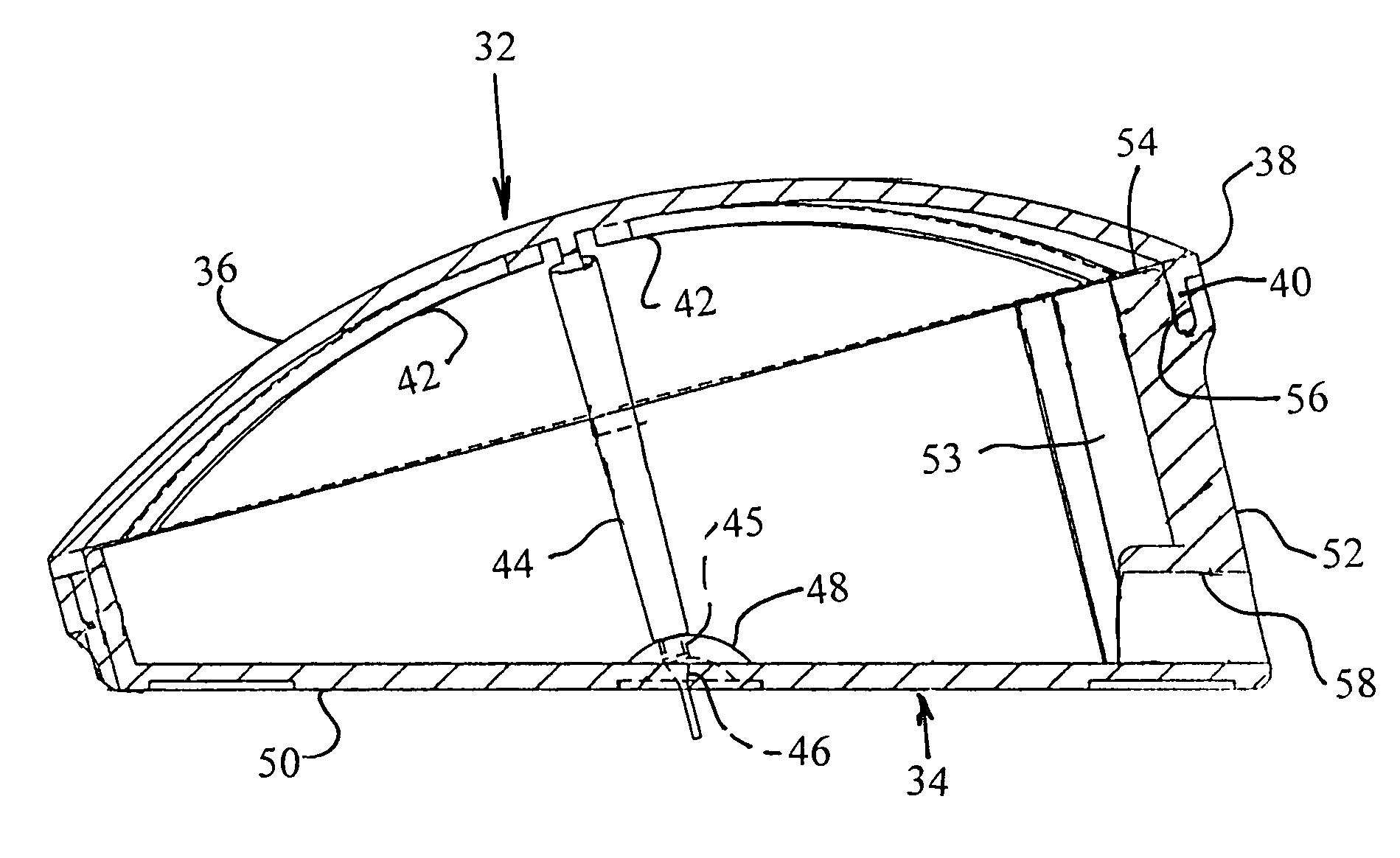

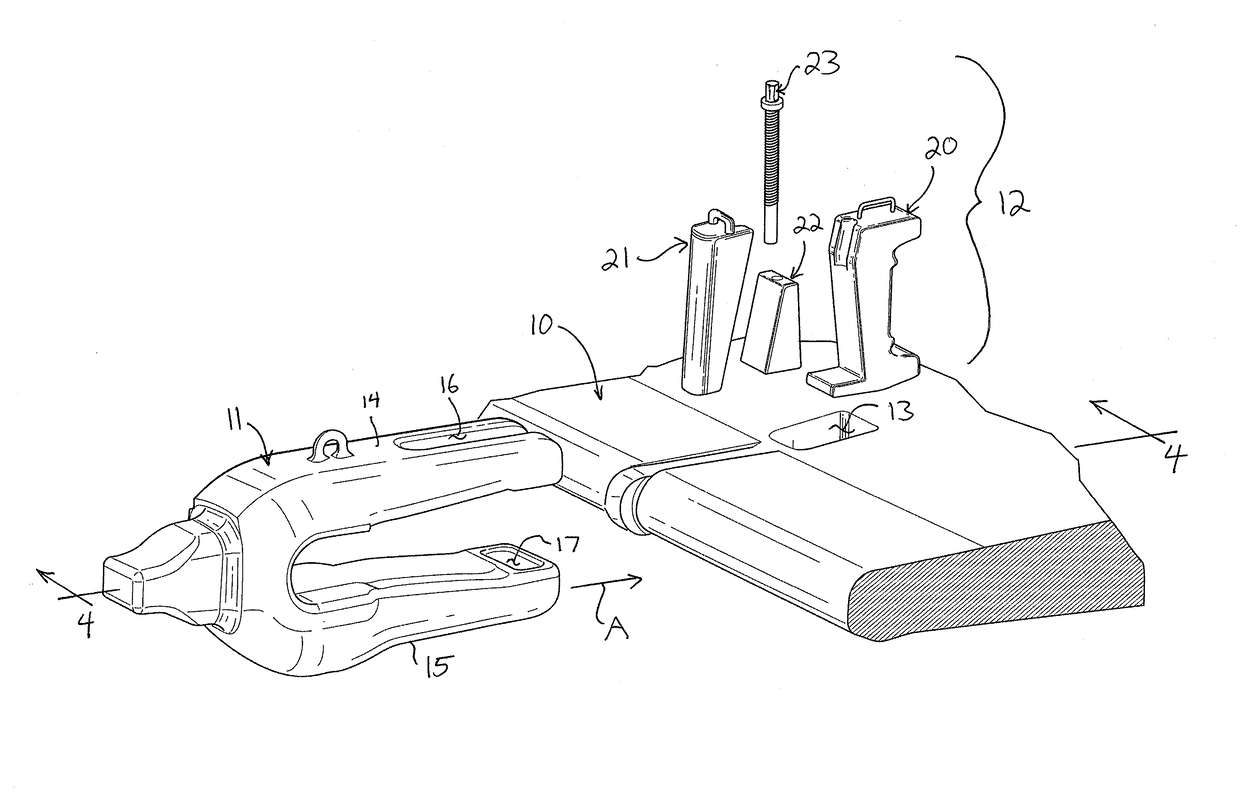

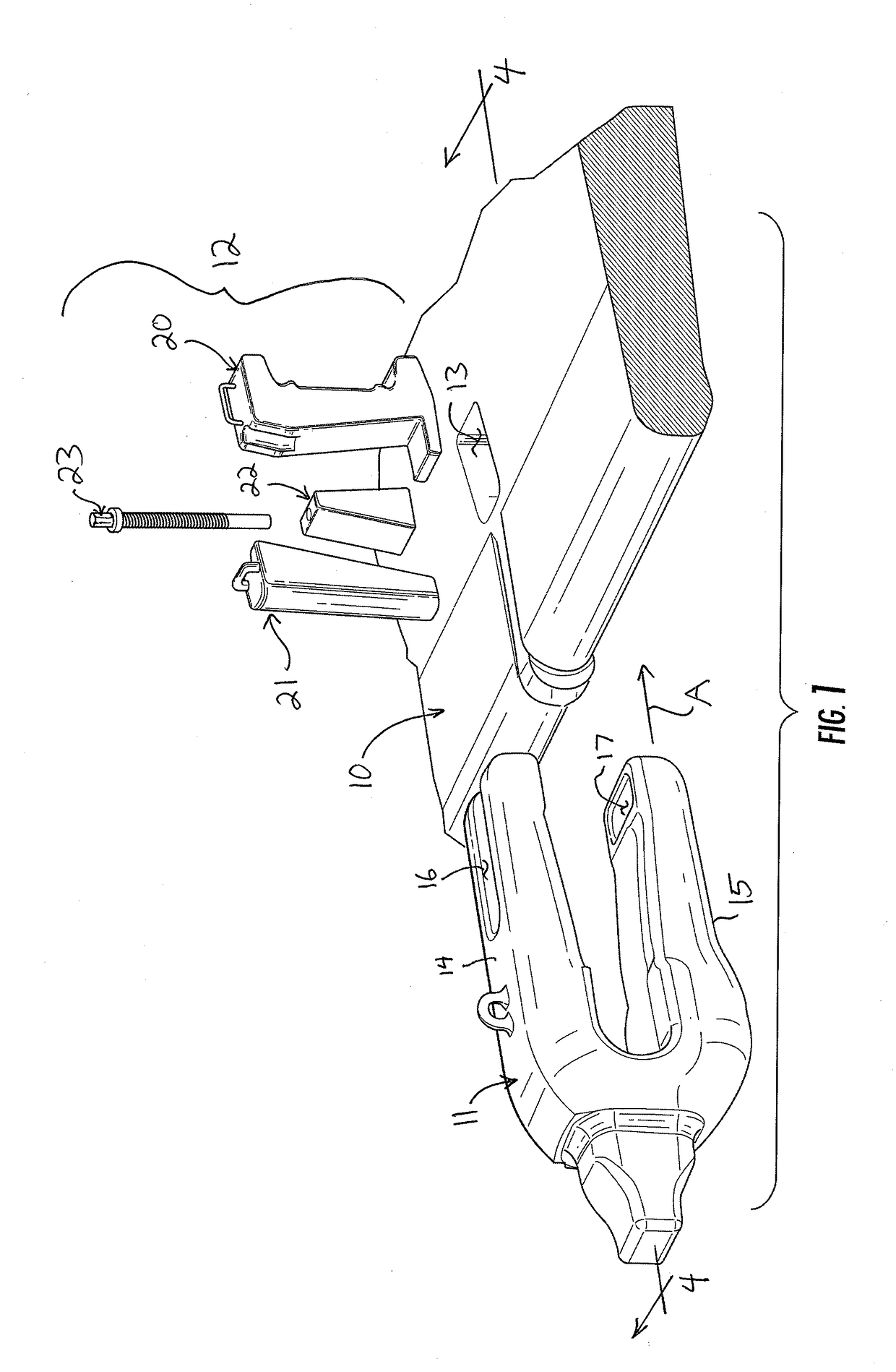

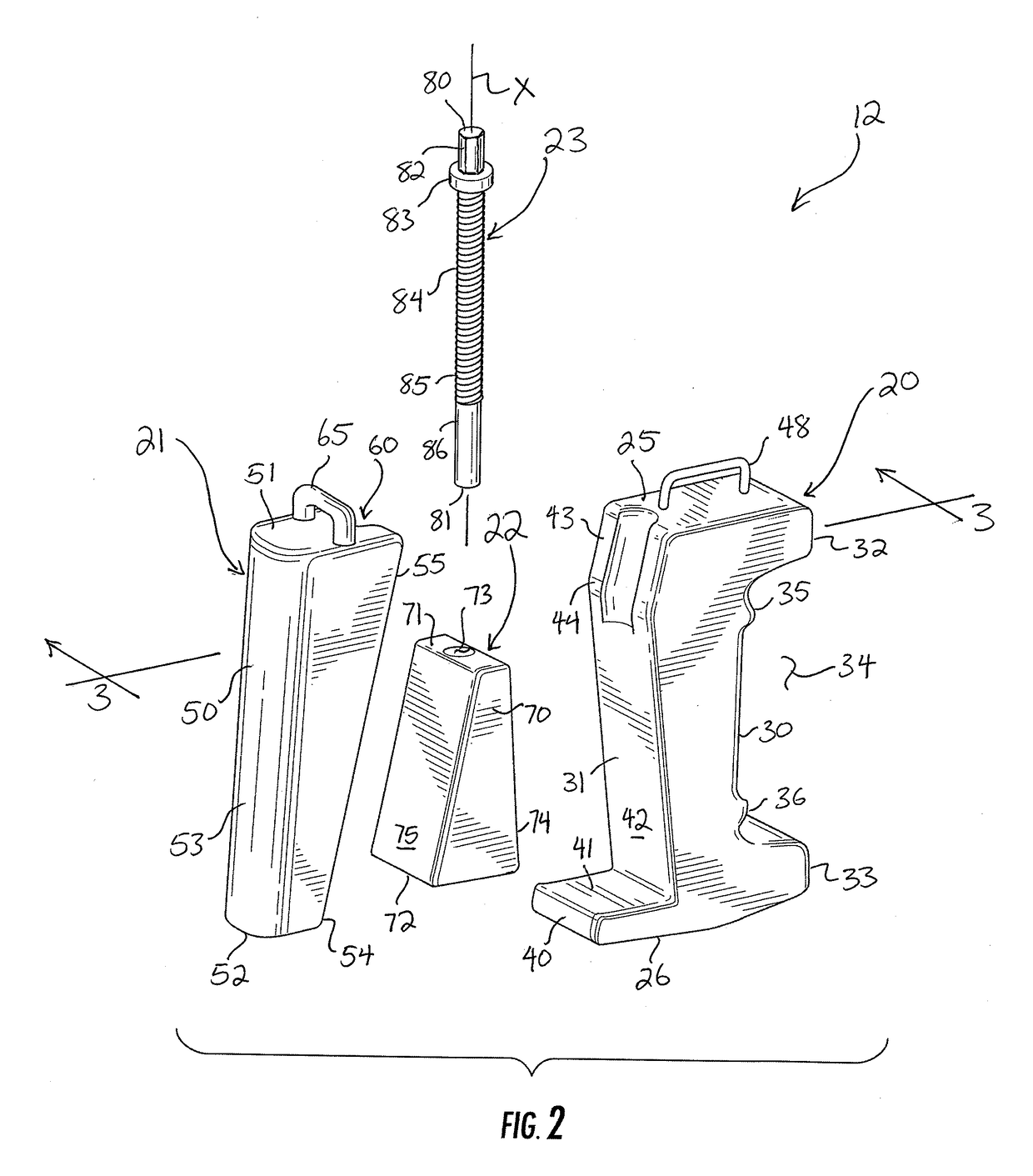

Modular Furniture Assembly Corner Seating System

InactiveUS20170367486A1Increase varietyConvenient corner and angleBenchesDismountable chairsModularityEngineering

A modular furniture assembly including a wedge shaped base for use with other modular furniture system rectangular bases and transverse members, all of which components adhere to an (x)=(y)+(z) relationship, wherein (x) is the length of the back of the wedge shaped base, the length of the transverse member, and the length of the rectangular base. (y) is both the length of the angled side(s) of the wedge shaped base, and the width of the rectangular base. (z) is the width (i.e., thickness) of the transverse member. The angled sides of the wedge shaped base can be at or about 45° relative to one another. The rectangular bases and wedge shaped bases are of the same height, and all can be coupled together in a wide variety of modular furniture configurations.

Owner:THE LOVESAC CORP

Wedge-based lamp with LED light engine and method of making the lamp

InactiveUS7261437B2Coupling device connectionsLighting support devicesElectrical connectionEngineering

An LED wedge-based lamp and method of making the lamp, where the lamp has a generally planar circuit board having one end that has electrical connections exposed thereon and a connecting part that is adapted to mechanically couple the lamp to a wedge-based lamp socket. The lamp includes an LED light engine near a second end of the circuit board, where the light engine includes plural laterally aligned LEDs whose light output mimics the light output of an incandescent lamp, such as used in automobile stop and turn signals. The lamp includes a load resistor, whose load mimics that of the incandescent lamp, on an exterior surface of the connecting part. The connecting part may be a sleeve that slides onto the circuit board. A hand grip / heat sink may be provided at the second end of the circuit board.

Owner:OSRAM SYLVANIA INC

Pipe clamp with self-aligning mechanism while closiing of same

The invention relates to a pipe clamp. The invention provides an improved external clamp for use on pipes, provided with a self-aligning mechanism. The self-aligning means is particularly useful in combination with a band pipe clamp or a band pipe coupling. The means comprising a first and a second rounded wedge-like shapes, the wedge base of the two shapes being disposed at an acute angle to each other when installed, the rounded wedge tips being in contact with each other, the metal band of the pipe coupling or clamp, when tightened by at least one screw fasteners reducing the acute angle between the bases of the wedge-like shapes. The wedge like position being provided with at least one aperture allowing passage for at least one screw fastener therethrough. The first wedge being provided with an alignment projection while the second wedge being provided with a complementary recess.

Owner:KRAUSZ INDS DEVMENT

Multi-hull platform boat

ActiveUS9475548B1Less dragLower resistanceNon-magnetic metal hullsHull decksContinuous/uninterruptedEngineering

In a first aspect, a multi-hull platform boat comprises an upper deck or platform that is secured to a plurality of longitudinally extending hulls via a plurality of corresponding longitudinally extending connectors. Each connector extends from the bottom of the platform above a corresponding hull. The platform is constructed with a continuous uninterrupted planar lower support spanning the area between the connectors. The lower support is preferably made from one or more moldable materials and may be covered with a finish coating. In a second aspect, a multi-hull platform boat has a platform with a relatively planar upper support surface and a wedge-shaped base extending from the upper support surface of the platform to the bottom of the hulls. The base is wedge-shaped such that it increases in height from the front to the rear of the boat.

Owner:COBALT BOATS

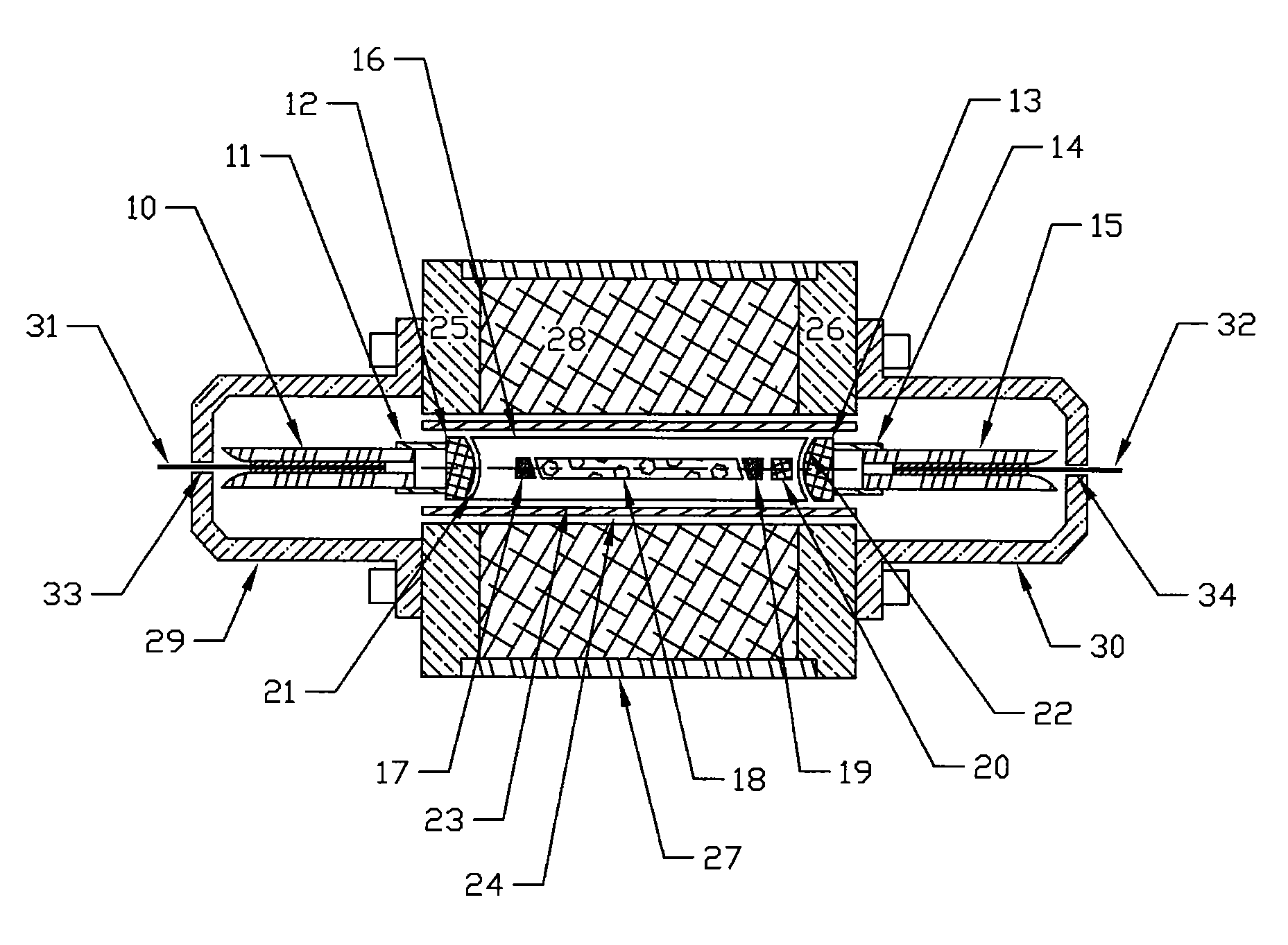

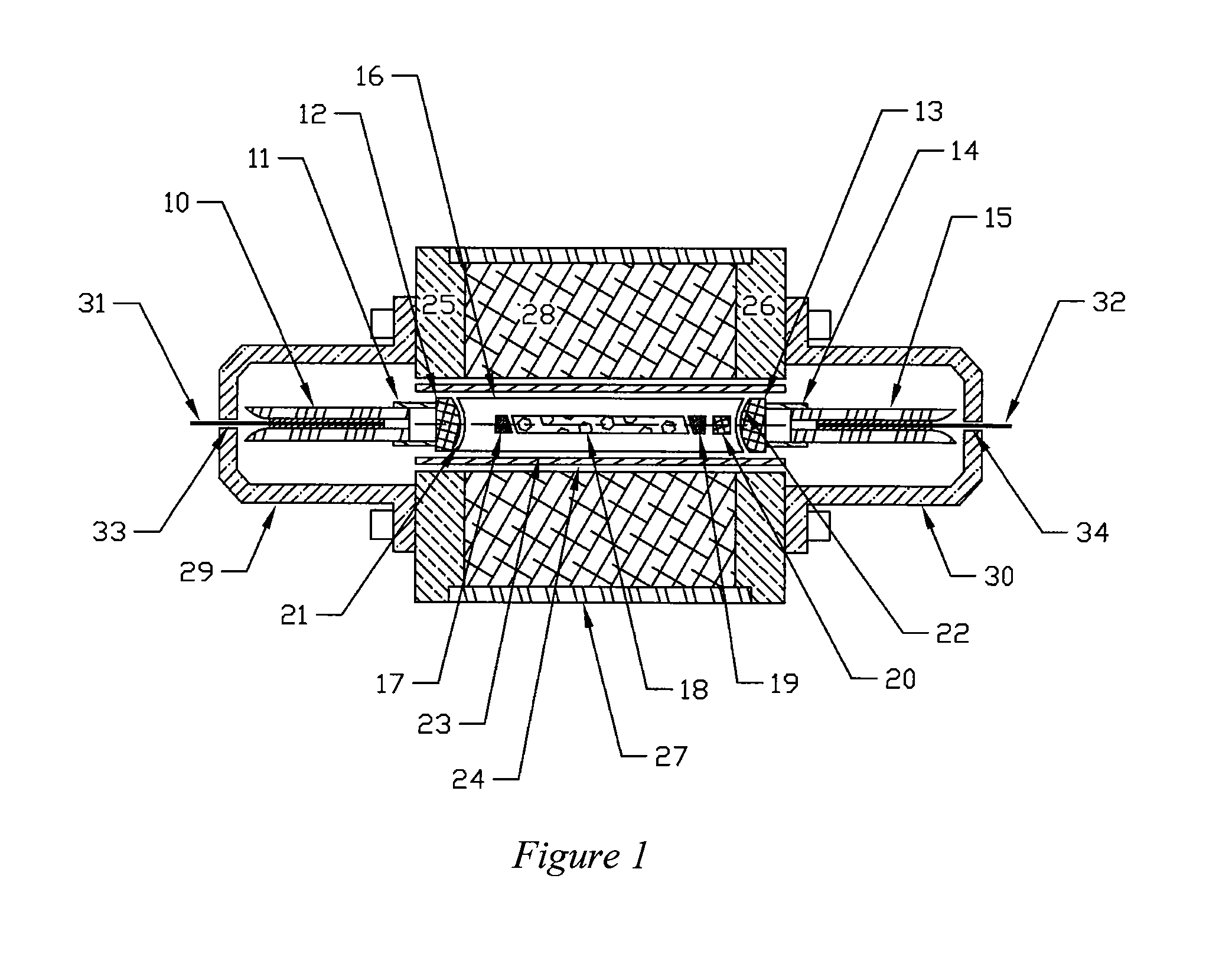

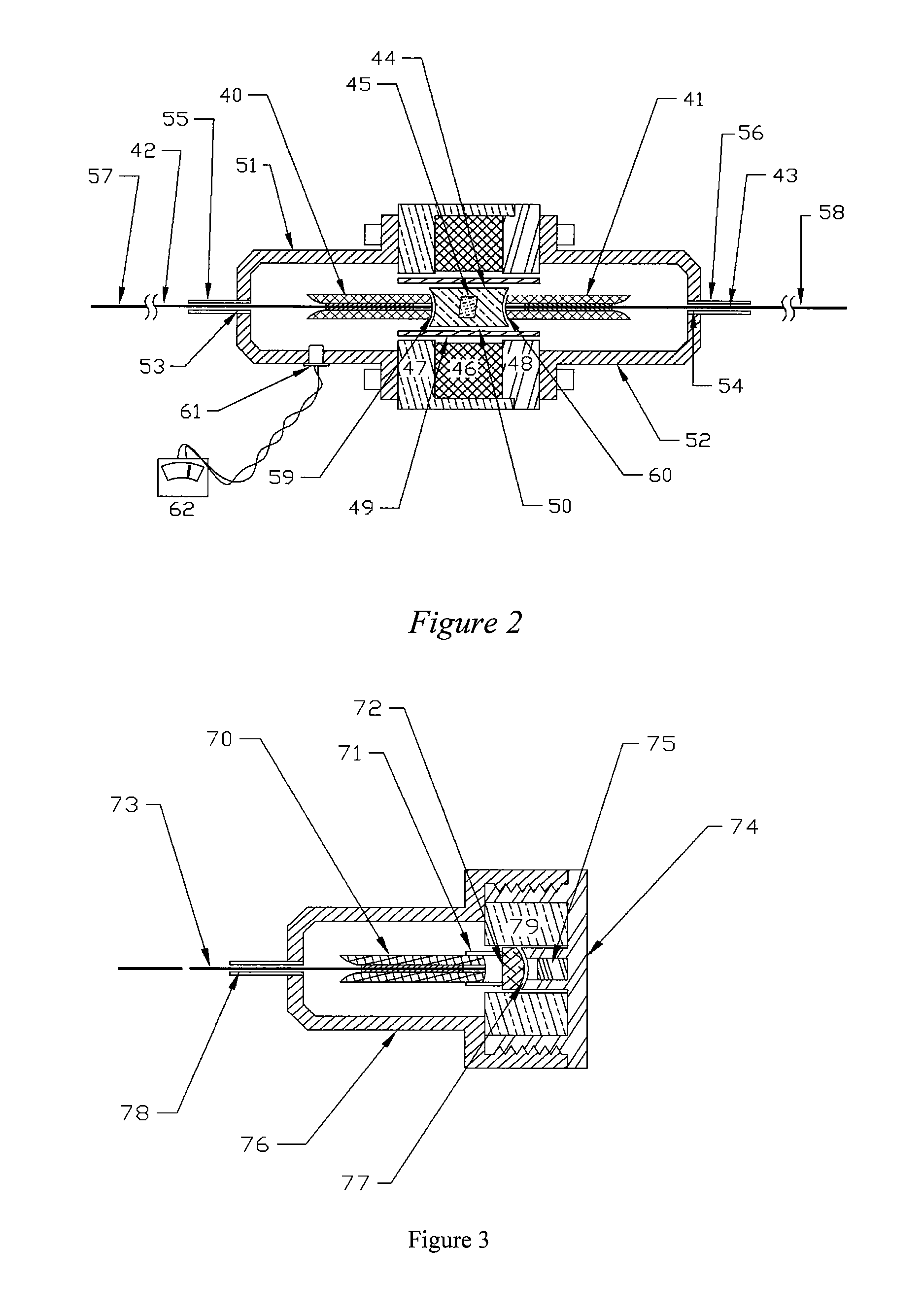

Compact, high power, fiber pigtailed faraday isolators

Faraday rotator or isolator with mode stripping ferrules and collimators having fiber pigtailed mode stripping components. An example is a compact Faraday Isolator module employing mode stripping ferrules and mode stripping collimators at the input and / or at the output of a fiber pigtailed Faraday Isolator. Two basic isolator types are a Polarization Independent Faraday isolator and a Polarization Maintaining Faraday isolator. The device is substantially immune to damage due to back-reflection, thermal lensing, energy leakage and absorption. Mode stripped optical energy propagating in the reverse direction is diverted onto a heat absorbing and heat sinking structure, as for example at the input of a compact birefringent wedge-based PI isolator. Alternatively, the optical energy propagating in the reverse direction is angularly refracted away from the forward incident beam path and is coupled into the energy dispersive cladding of the input fiber or the ferrule itself.

Owner:ELECTRO OPTICS TECH

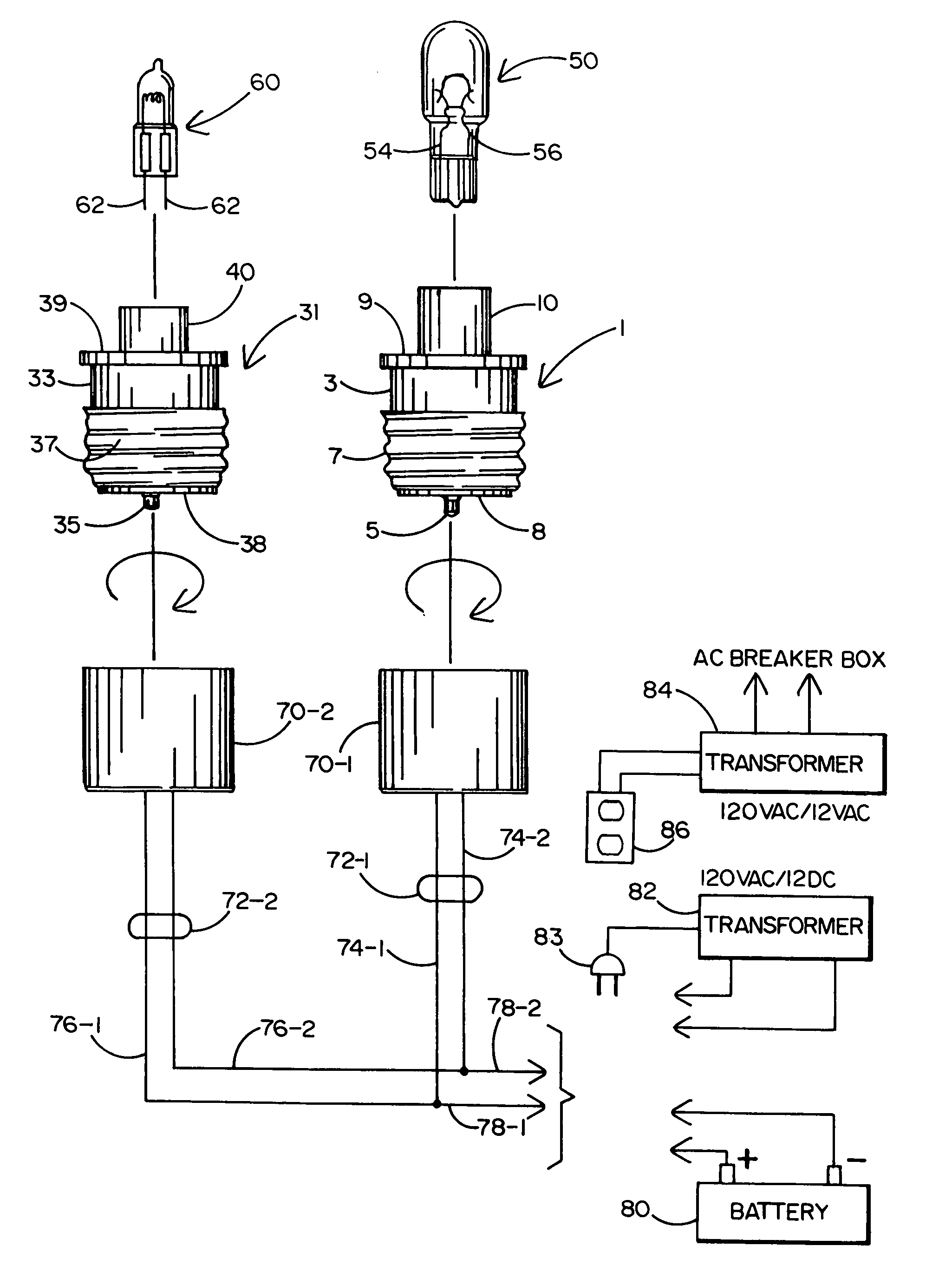

Adapter for connecting a low voltage light bulb to a standard electrical light socket

InactiveUS7407418B1Energy efficiencyElectric discharge tubesTwo-part coupling devicesLow voltageEngineering

A lamp socket adapter to receive a relatively low cost, low voltage (e.g., wedge base or bipin) light bulb so that the light bulb can be powered from a source of 12 volts AC or DC. The lamp socket adapter of this invention is adapted to be rotated into mating engagement with a standard Edison-type lamp socket that is to be connected to receive one of an AC or DC voltage. By virtue of the foregoing, an efficient light bulb circuit is available by which one or more low voltage light bulbs can provide bright light over an area to be illuminated with reduced power consumption relative to a conventional 120 volt AC-powered incandescent light bulb. The lamp socket adapter includes an upstanding bulb pedestal to which the light bulb is attached and supported. First and second electrically-conductive strips extend through the lamp socket adapter by which to connect the low voltage light bulb seated upon the bulb pedestal to the Edison lamp socket so that the light bulb can be powered by the 12 volts AC or DC supplied to the lamp socket.

Owner:HARLAN WHIL

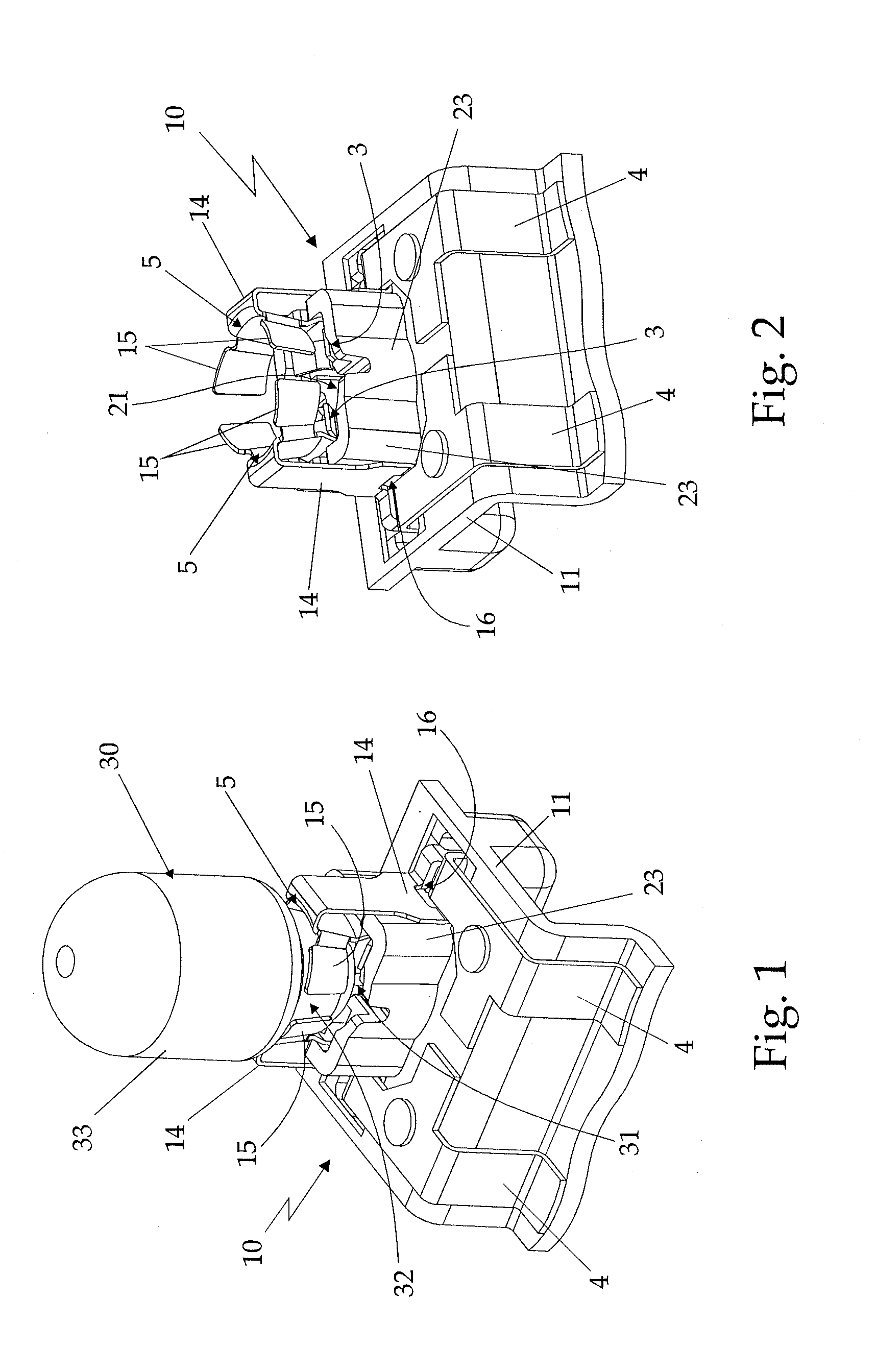

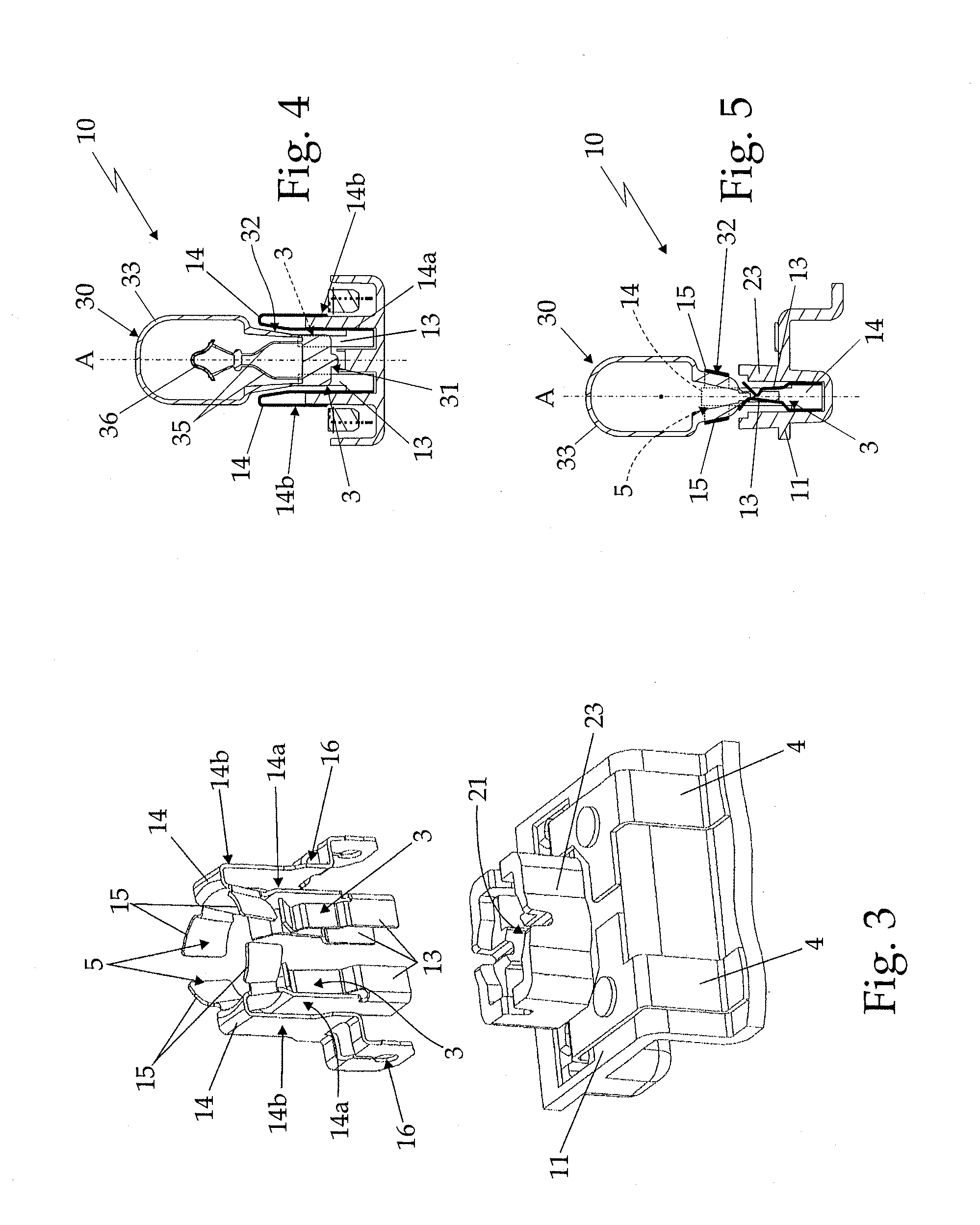

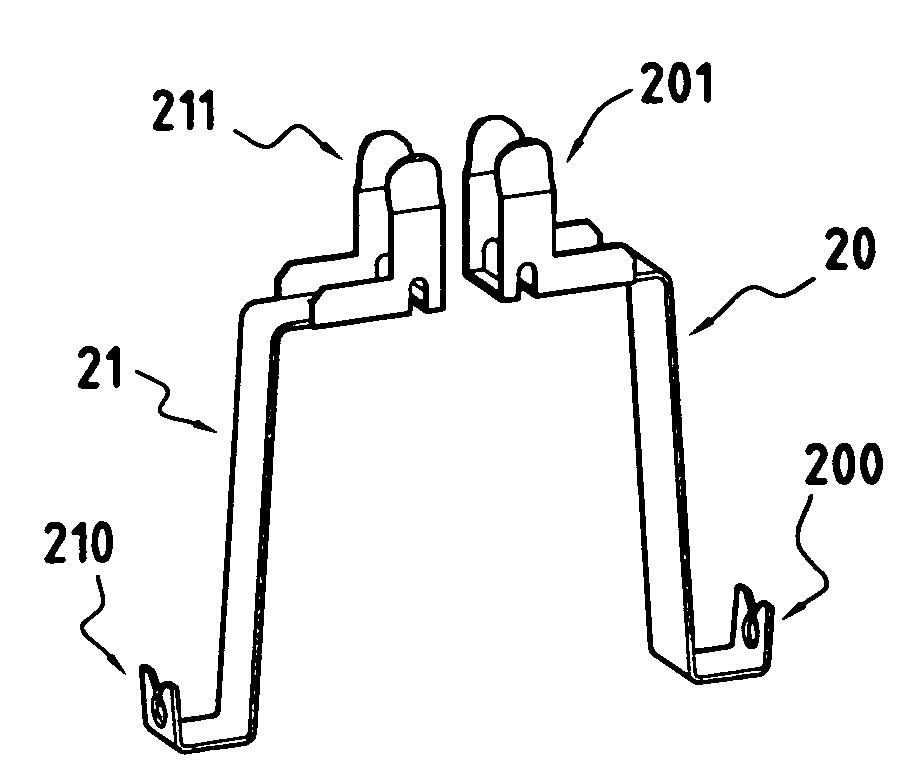

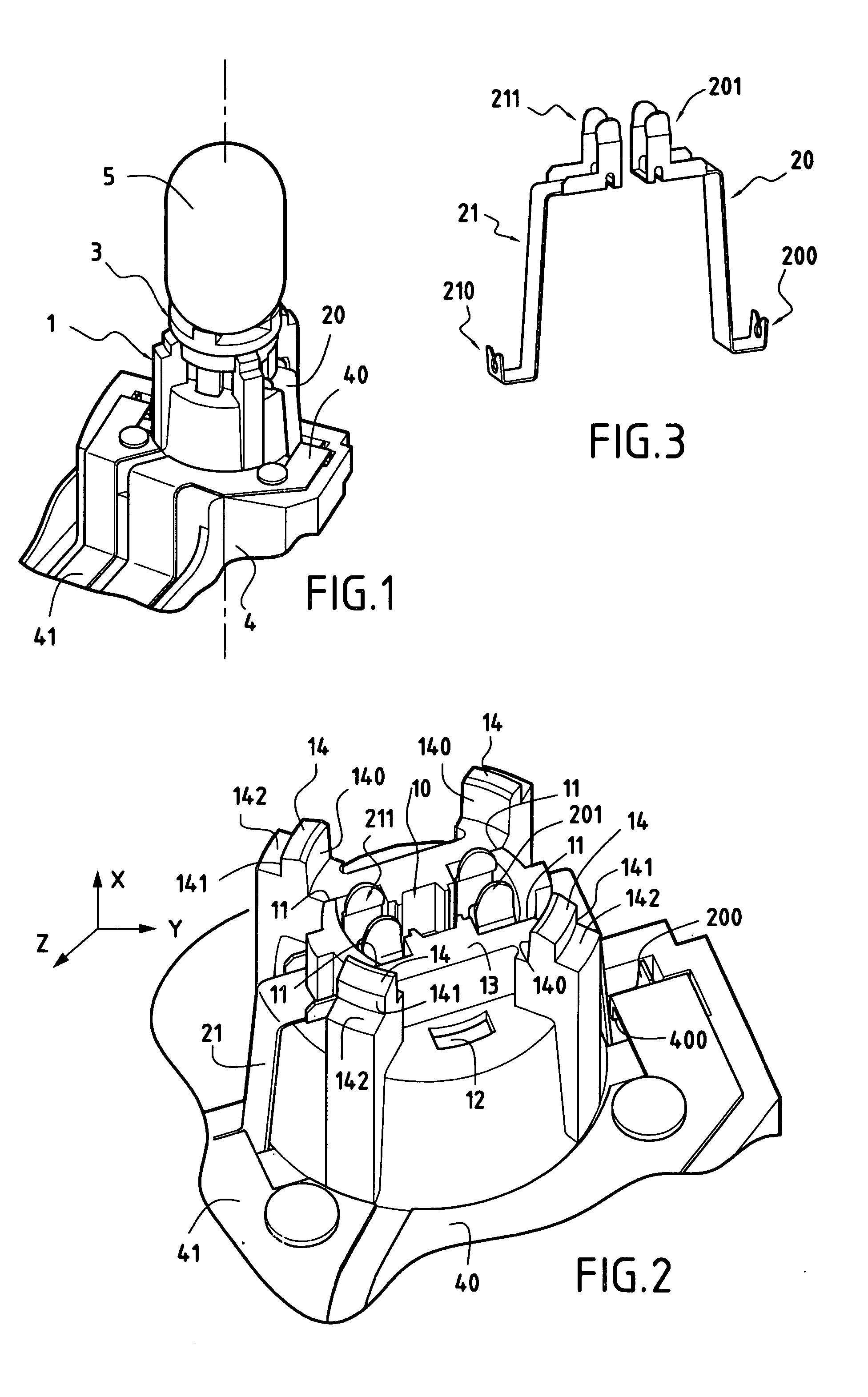

Wedge-Base Bulb Socket and Automotive Light for Motor Vehicles and Similar Provided With Said Socket

ActiveUS20120120675A1Reduce manufacturing costMeet the requirementsVehicle headlampsLighting support devicesPower flowCoupling

Wedge-base bulb socket comprising: a supporting base provided with a coupling seat dimensioned to house the plug of the light bulb; two coupling and connecting members which are located inside the coupling seat, and are structured to separately hold the wedge-shaped plug of the light bulb fitted into the coupling seat, and to feed electric current to said light bulb; two electrically conductive elements which extend on the surface of the supporting base up to the edge of the entrance of the coupling seat, on opposite sides of said entrance, and then descend into the coupling seat up to reach each a respective coupling and connecting member; and two respectively-facing additional supporting jaws which are supported by the two electrically conductive elements so as to be located substantially on opposite sides of the entrance of the coupling seat, and structured to clamp the wedge-base light bulb fitted into the socket, so as to firmly hold said wedge-base light bulb in the wedge-base bulb socket.

Owner:AUTOMOTIVE LIGHTING ITALA

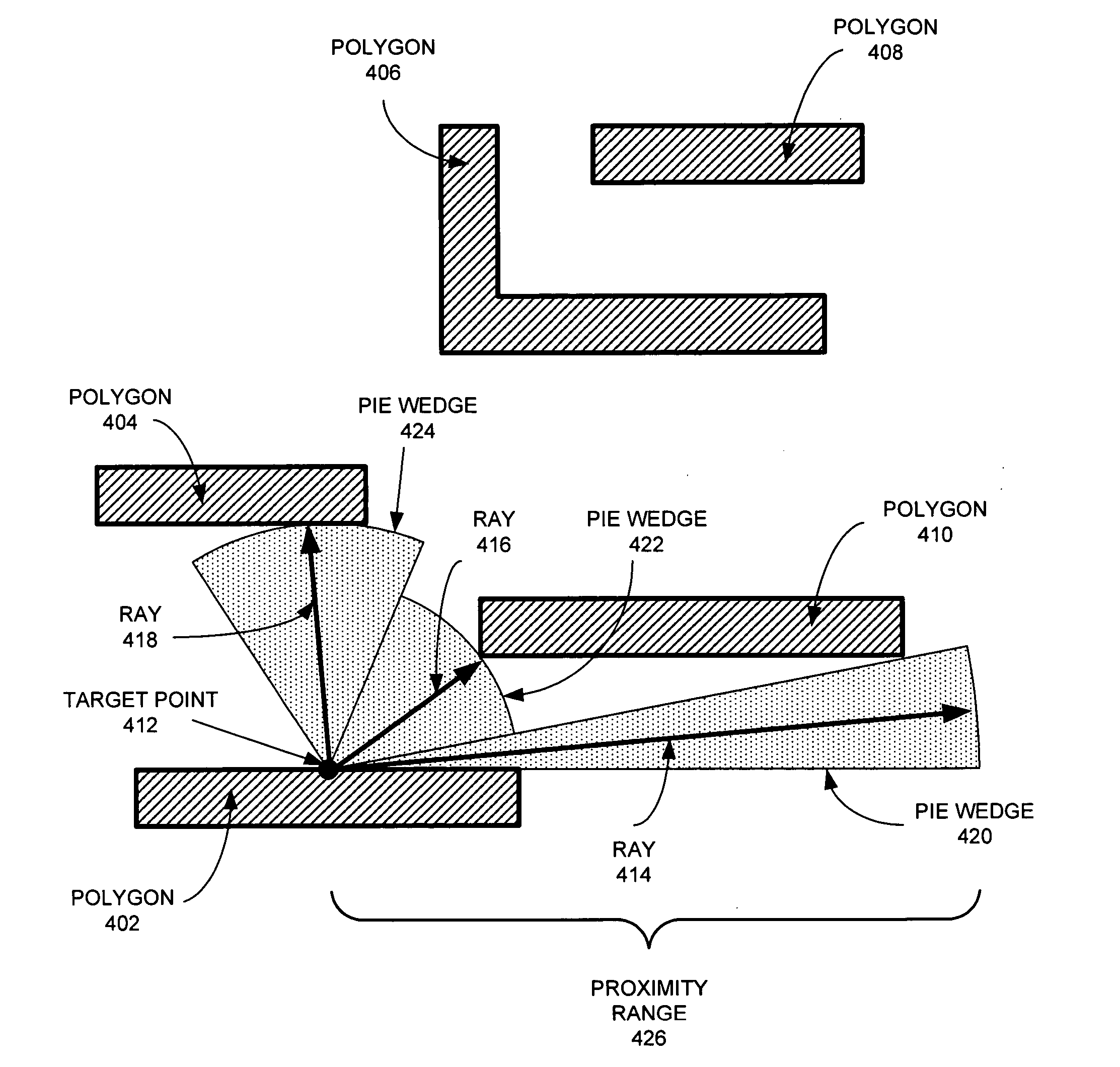

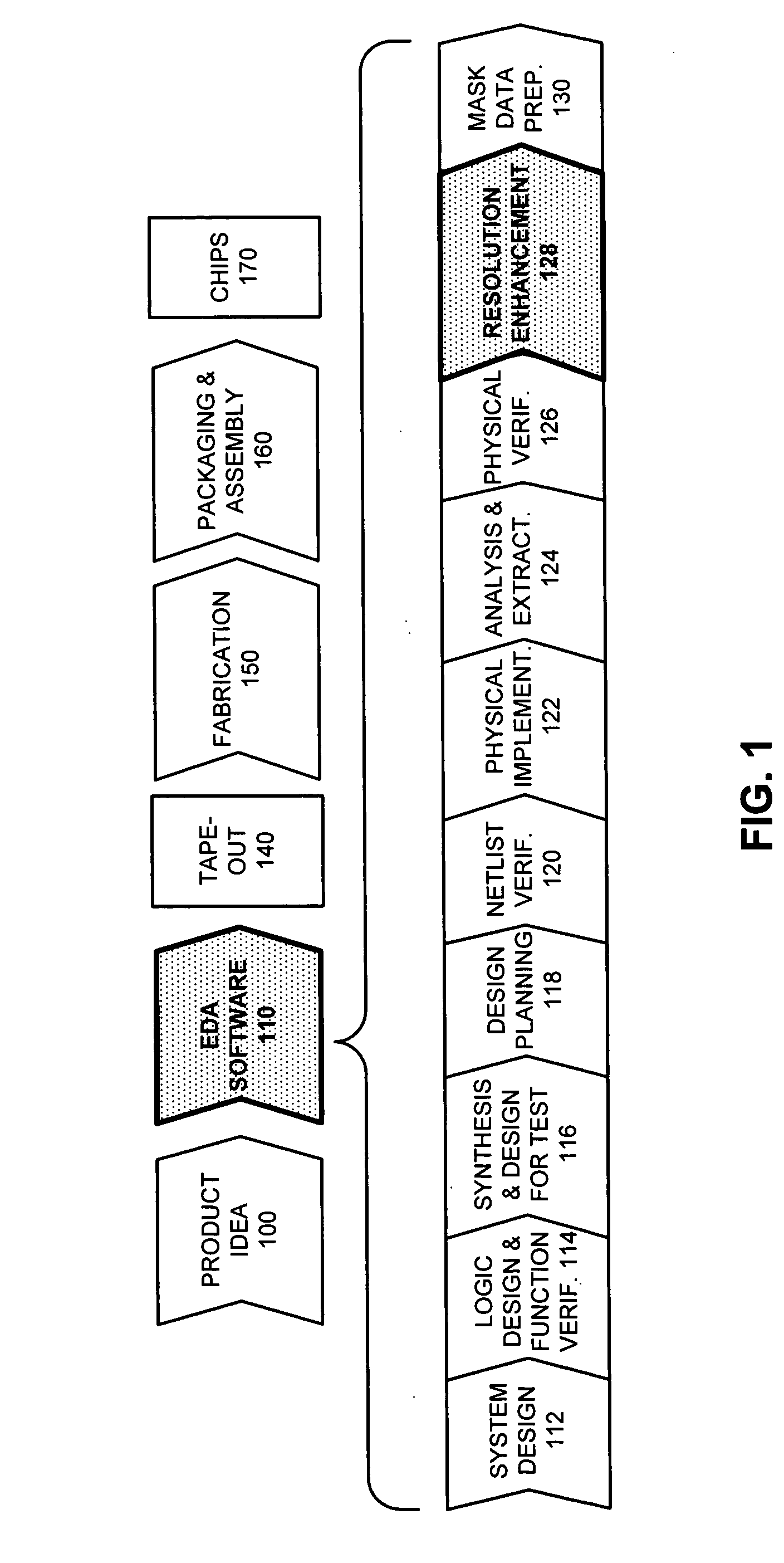

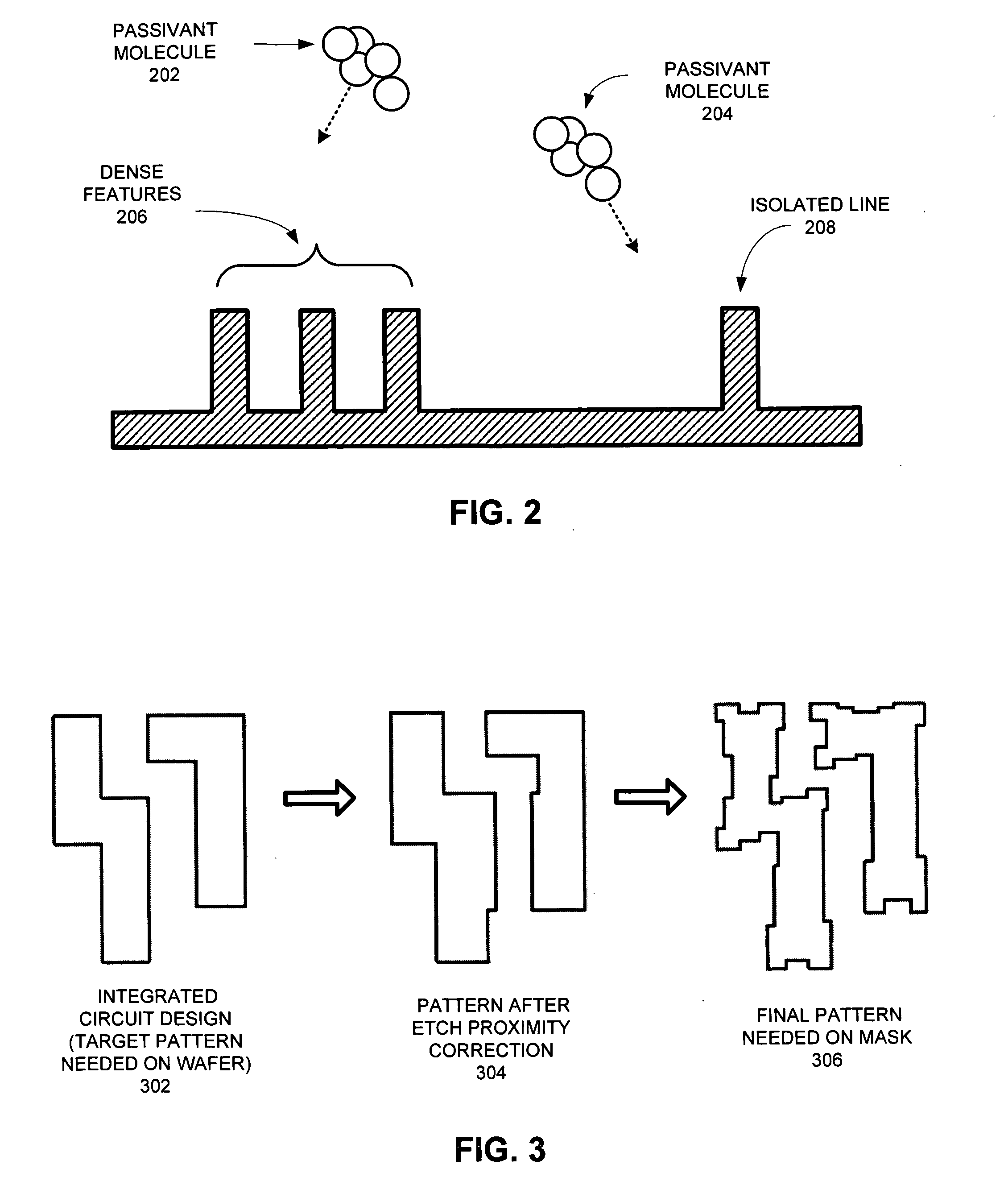

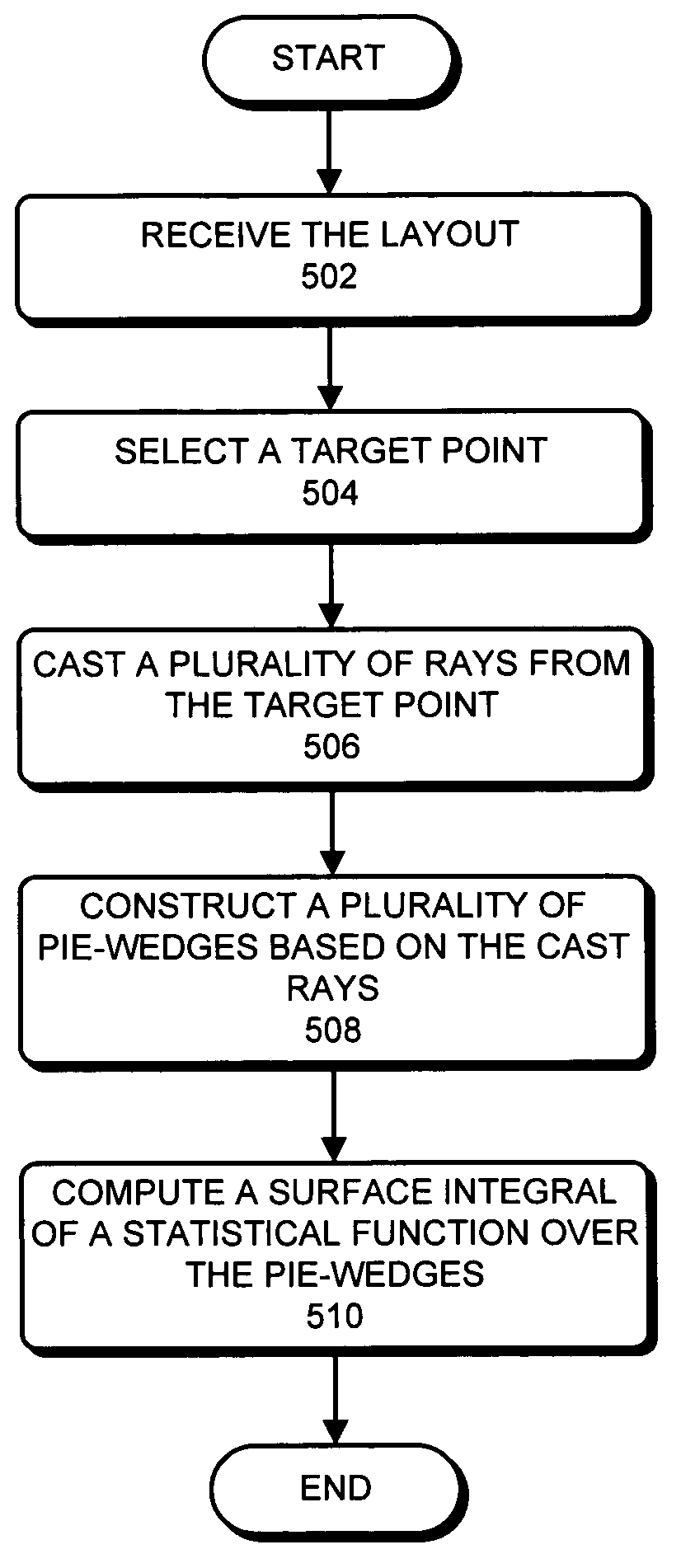

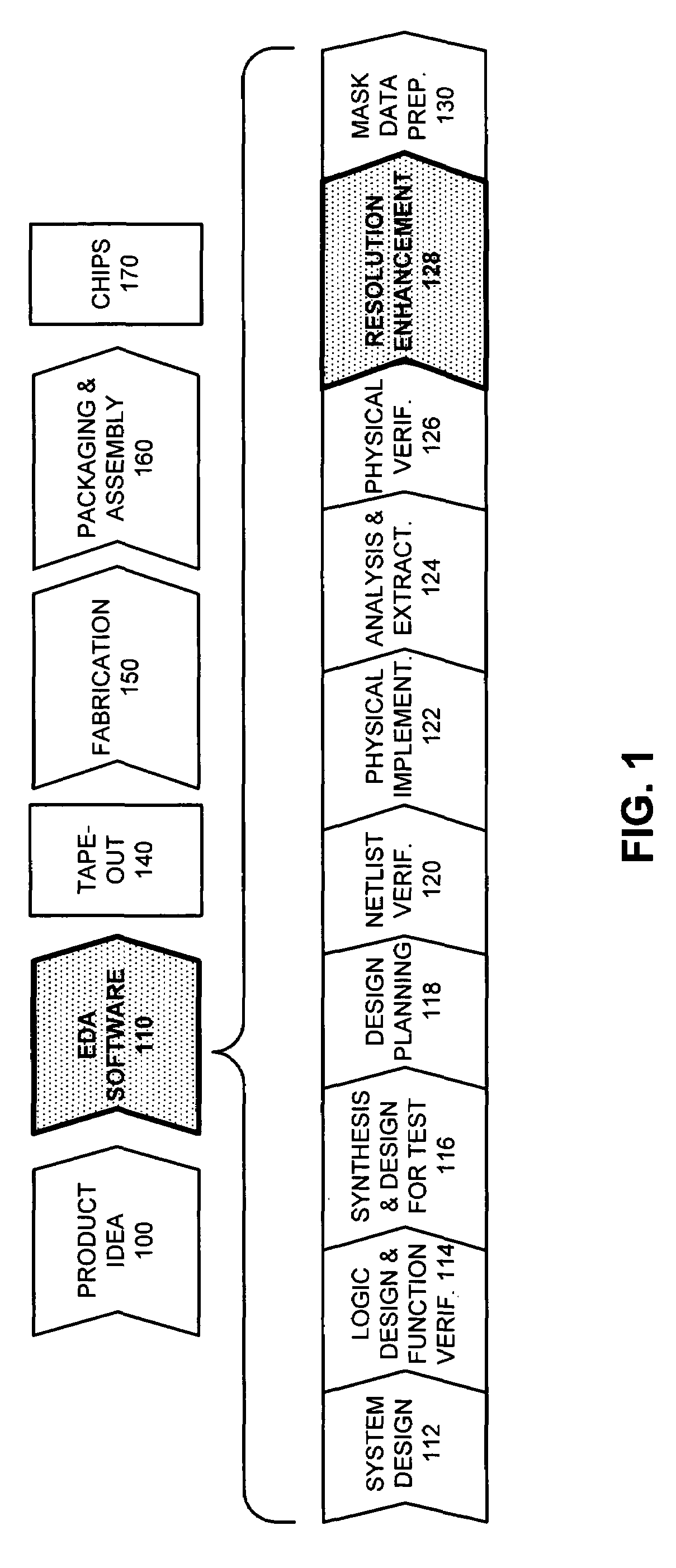

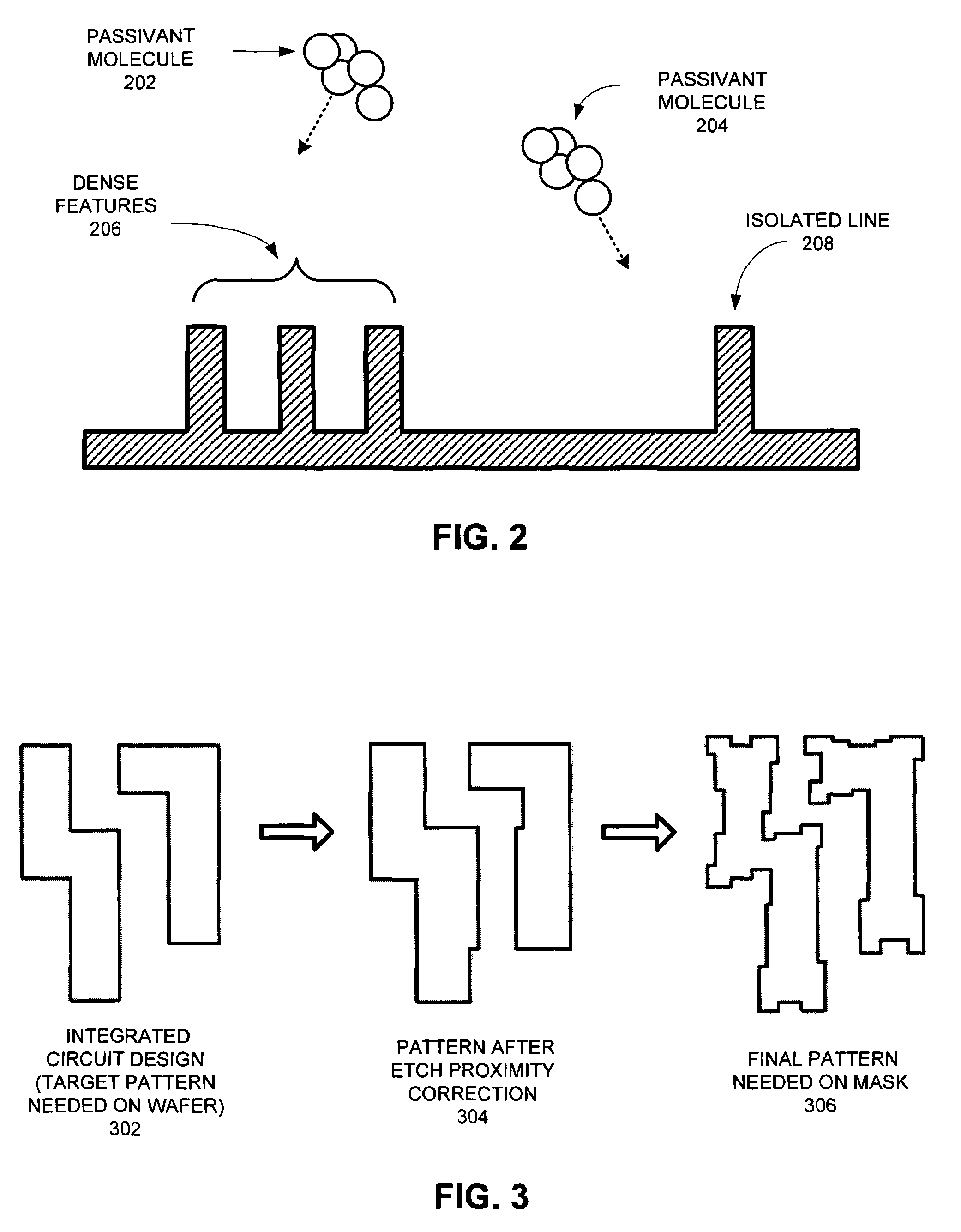

Calculating etch proximity-correction using image-precision techniques

ActiveUS20060075378A1Accurate modelingOriginals for photomechanical treatmentSpecial data processing applicationsEngineeringWedge base

One embodiment of the present invention provides a system that calculates etch proximity-correction during an OPC (Optical Proximity Correction) process. During operation, the system receives a layout for an integrated circuit. Next, the system selects a target point on an edge in the layout. The system then casts a plurality of rays from the target point, and constructs a plurality of pie-wedges based on the cast rays. The system then computes a surface integral of a statistical function over the pie-wedges, wherein the surface integral of the statistical function models the etch bias at the target point. Next, the calculated etch proximity-correction is applied to an area in proximity to the target point.

Owner:SYNOPSYS INC

Calculating etch proximity-correction using image-precision techniques

ActiveUS7207029B2Accurate modelingOriginals for photomechanical treatmentSpecial data processing applicationsEngineeringWedge base

One embodiment of the present invention provides a system that calculates etch proximity-correction during an OPC (Optical Proximity Correction) process. During operation, the system receives a layout for an integrated circuit. Next, the system selects a target point on an edge in the layout. The system then casts a plurality of rays from the target point, and constructs a plurality of pie-wedges based on the cast rays. The system then computes a surface integral of a statistical function over the pie-wedges, wherein the surface integral of the statistical function models the etch bias at the target point. Next, the calculated etch proximity-correction is applied to an area in proximity to the target point.

Owner:SYNOPSYS INC

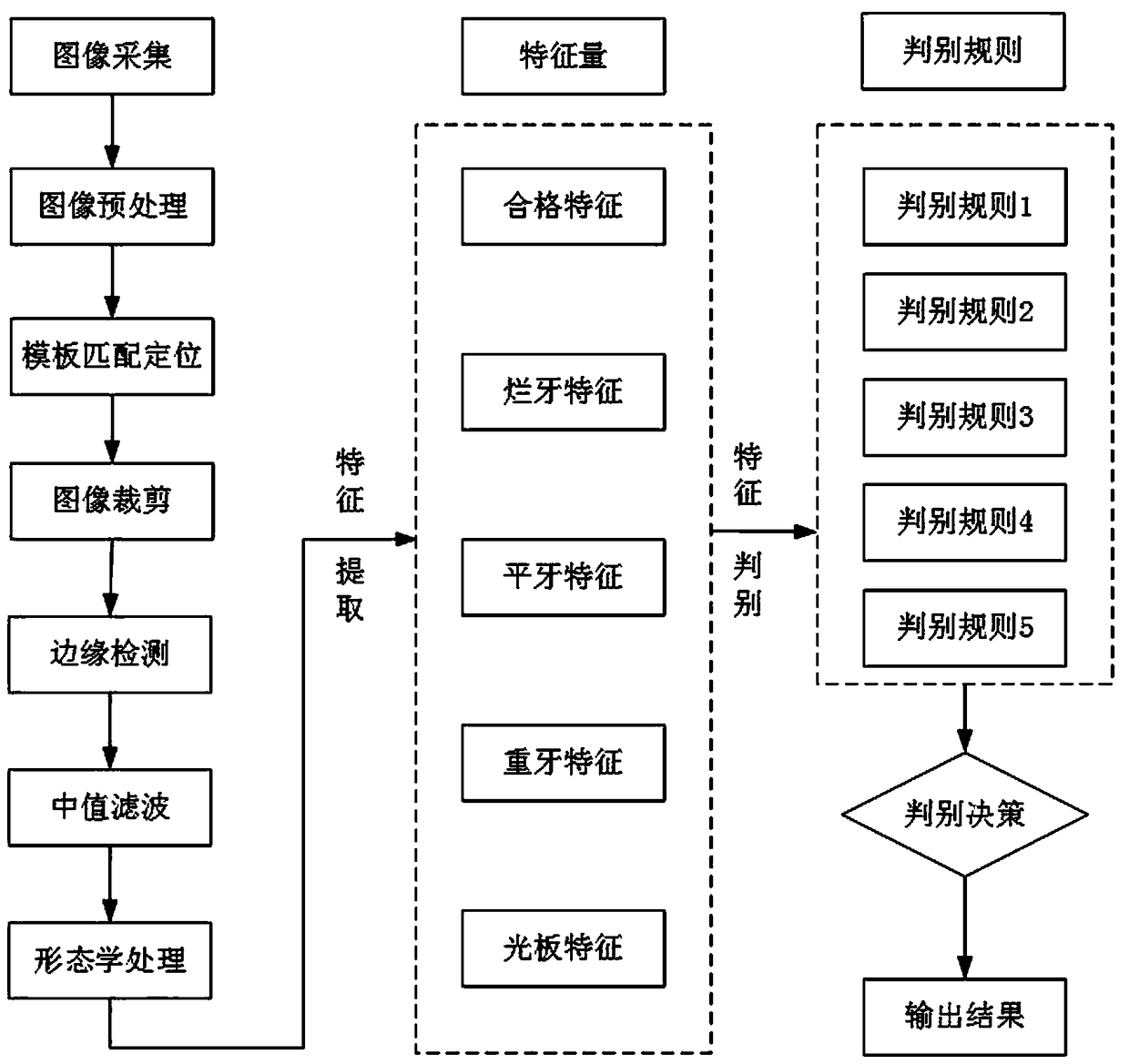

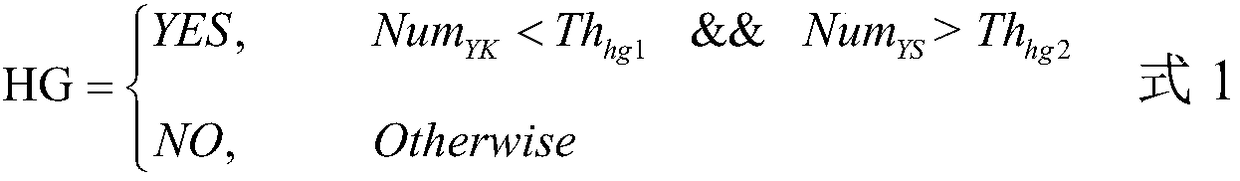

Method of detecting tooth defects of wedges based on edge detection

InactiveCN108280838AGood edge feature extractionHigh degree of production automationImage enhancementImage analysisTemplate matchingProduction line

The invention discloses a method of detecting tooth defects of wedges based on edge detection, comprising the steps of (1) acquiring an image of a wedge workpiece, and preprocessing the image; (2) subjecting the wedge workpiece to image template match positioning and image cutting; (3) subjecting the image to edge detection; (4) subjecting the image to median filtering and morphological processing; (5) performing characteristic extraction and judging. The method is capable of detecting and recognizing tooth defects (flat teeth, broken teeth, overlap teeth and polished plates) of wedges accurately on a production line site, the problem that existing manual detection has low speed, low efficiency and high cost is effectively solved, automation level of wedge production is increased, productquality is improved, and the method has good robustness.

Owner:GUILIN UNIV OF ELECTRONIC TECH

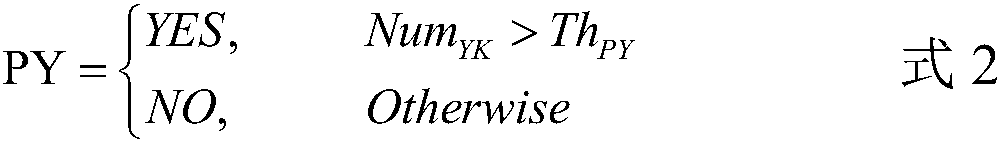

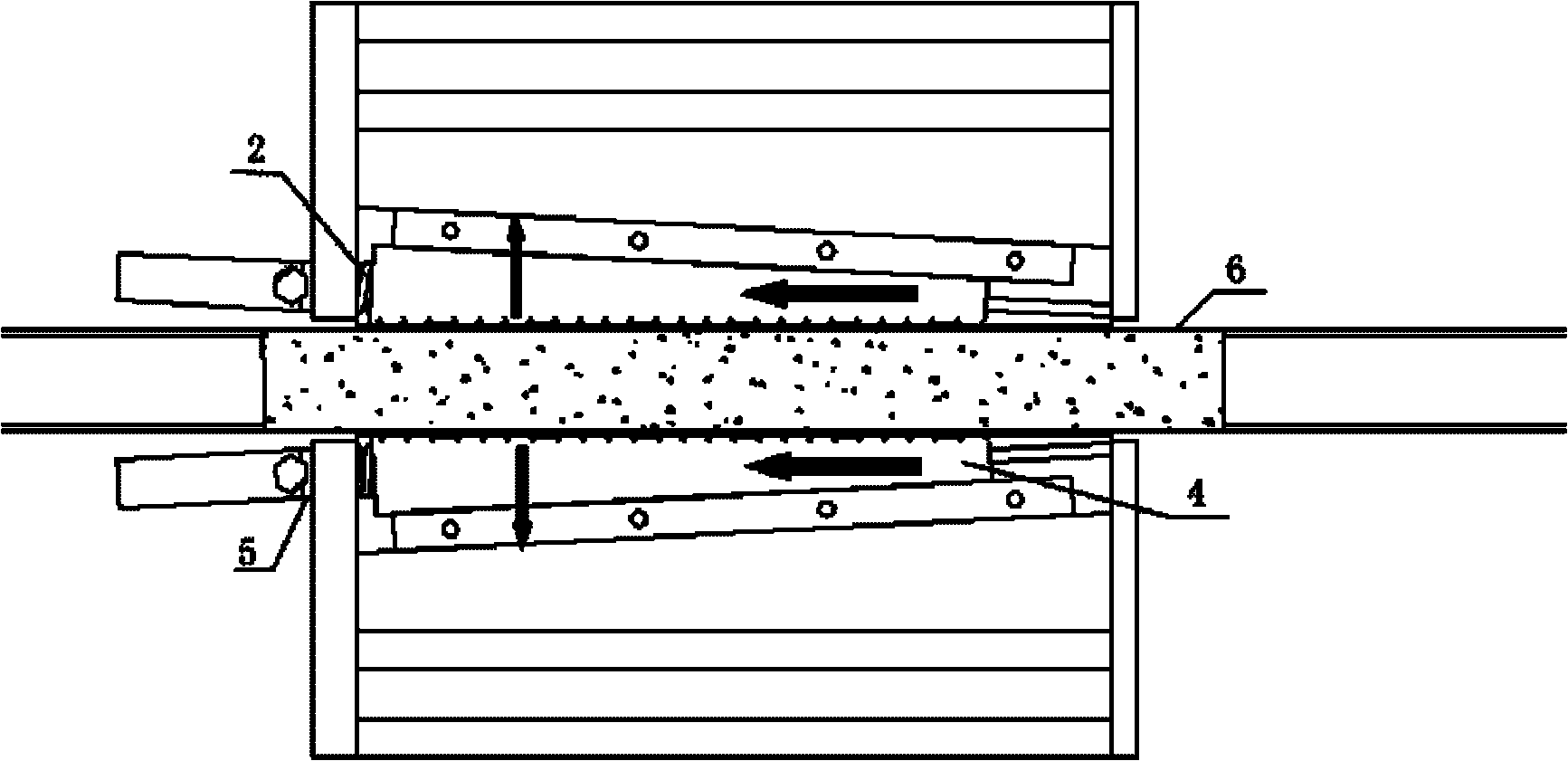

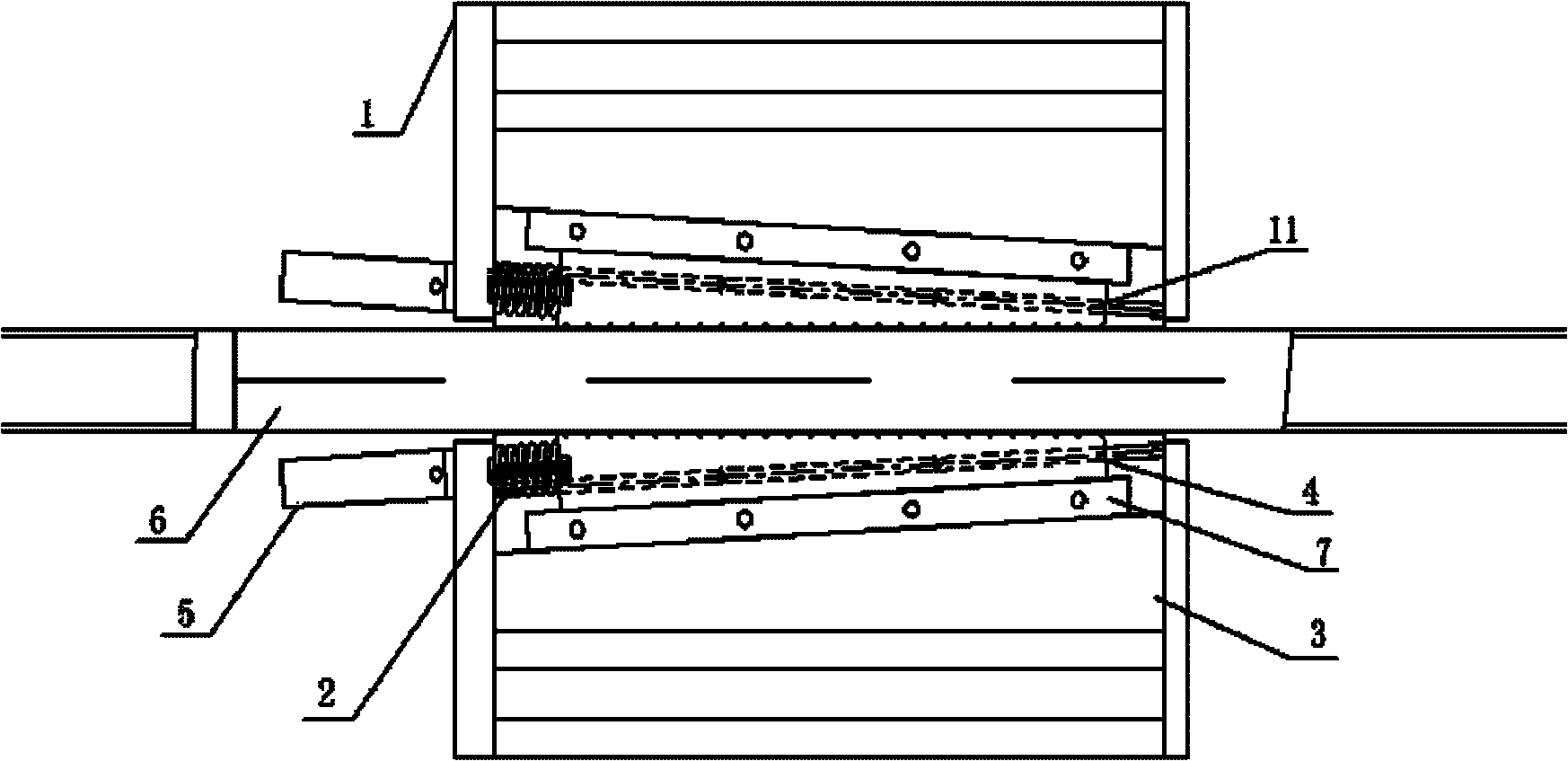

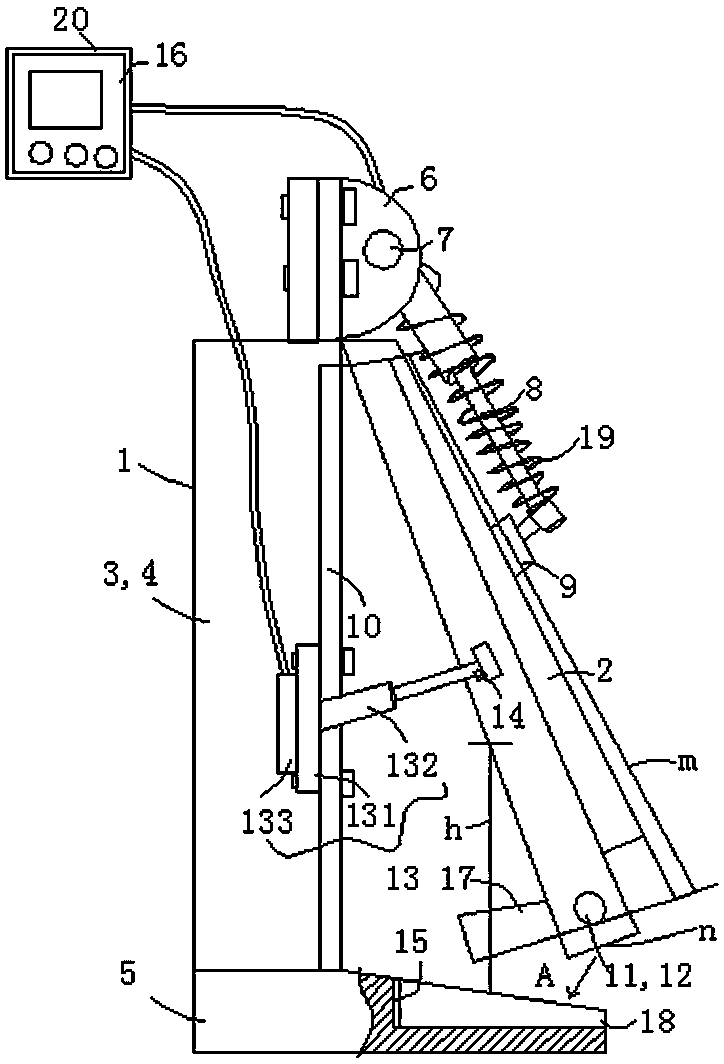

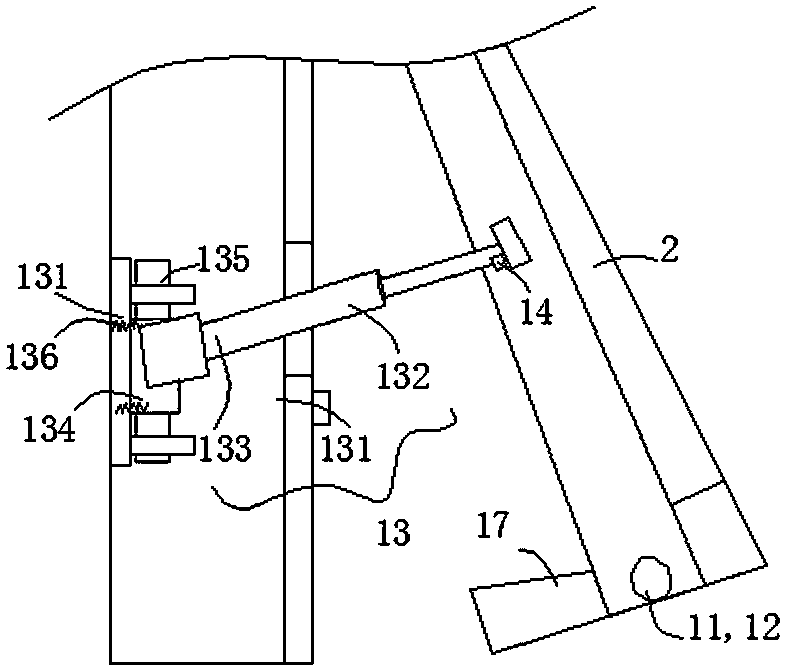

Rail clamping device

InactiveCN102730021AAuxiliary operationAuxiliary stopTrack-braking member co-operationControl mannerEngineering

The invention discloses a rail clamping device. The rail clamping device comprises a shell. The rail clamping device is characterized in that a wedged base is arranged in the shell; a wedged block is arranged in the wedged base; a sliding cushion block is arranged between the wedged block and the wedged base; the wedged block is driven by an oil cylinder; and a spring is reset. With the adoption of the structure provided by the invention, the rail clamping device can be applied to a slope rail, no slipping occurs, and equipment can be still for a long period; not only in a normal state but also in a condition that the equipment is suddenly switched off or has a fault, the rail clamping device can lock a rail in a safe and reliable manner; and the rail clamping device enables the equipment to go forwards or backwards on the premise of ensuring the security in advance under the control of a ruled program. Compared with the traditional rail clamping device, the rail clamping device provided by the invention has the following remarkable characteristics: firstly, the rail can be ensured to be locked at any time in the safe and reliable manner; secondly, the rail clamping device can be applied to a flat ground or a slope; thirdly, the equipment goes forwards and backwards with the adoption of the rail clamping device; and fourthly, the program can be set and operated by a hydraulic oil cylinder in a controlled manner.

Owner:上海耐斯特液压设备有限公司

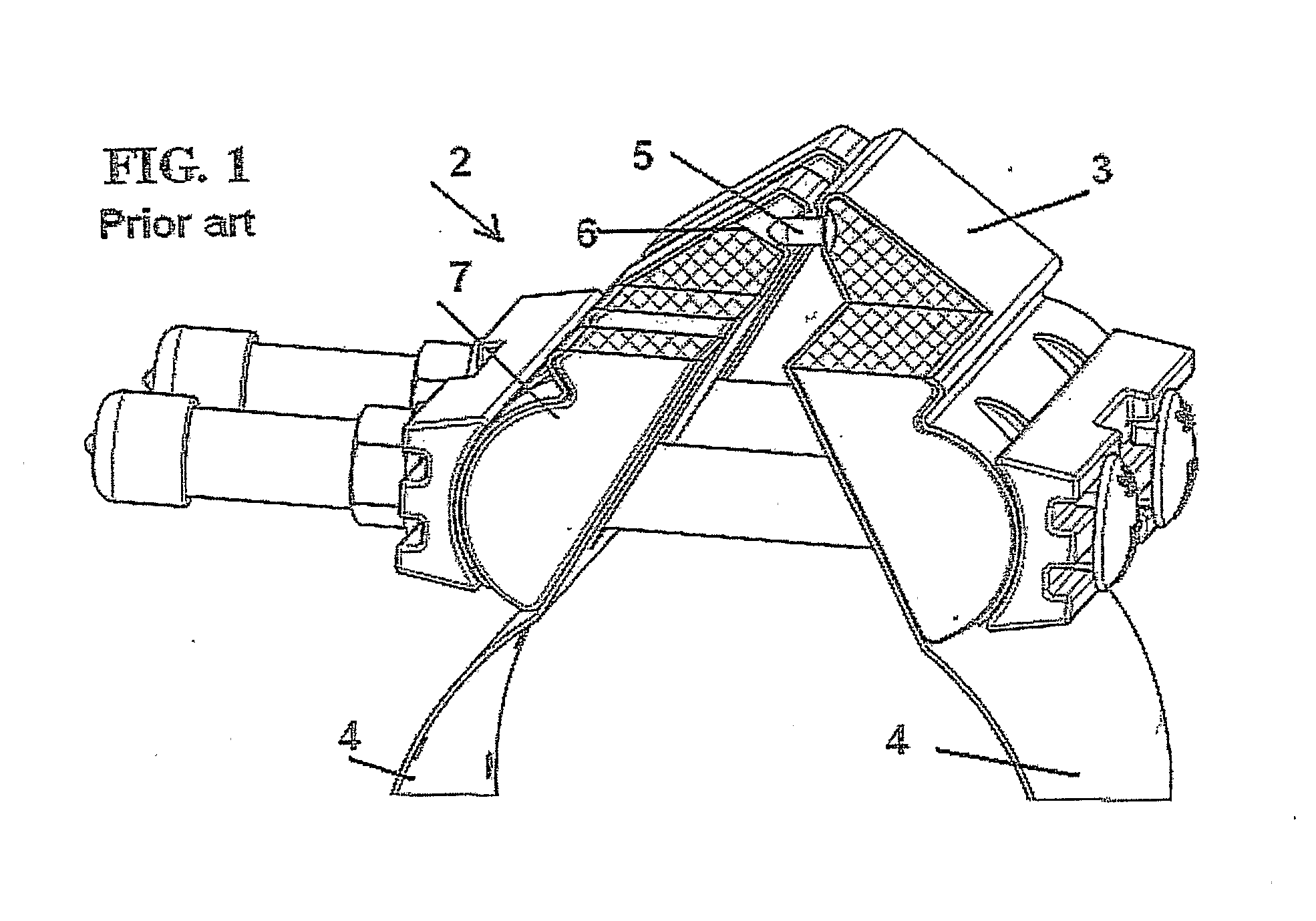

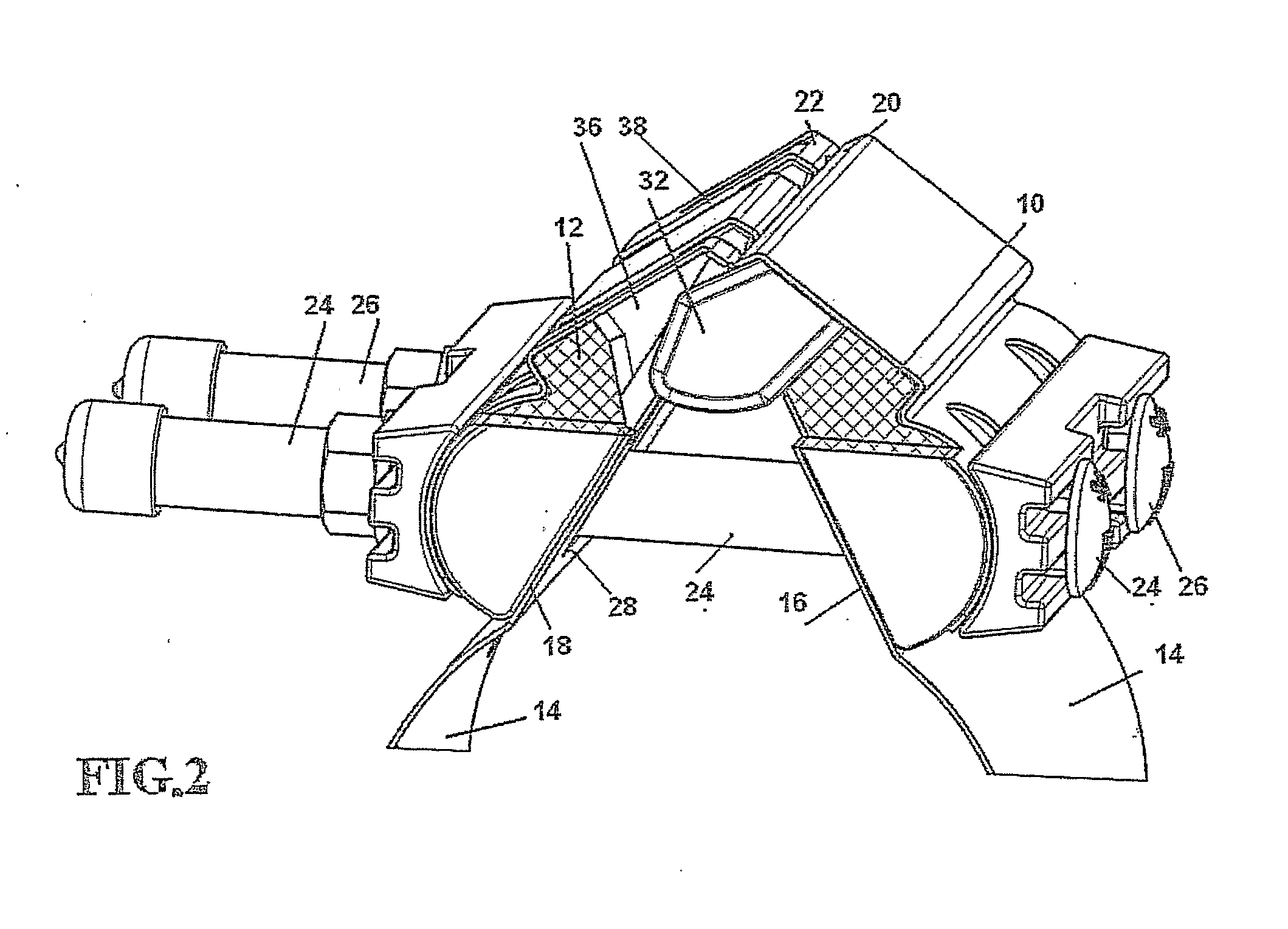

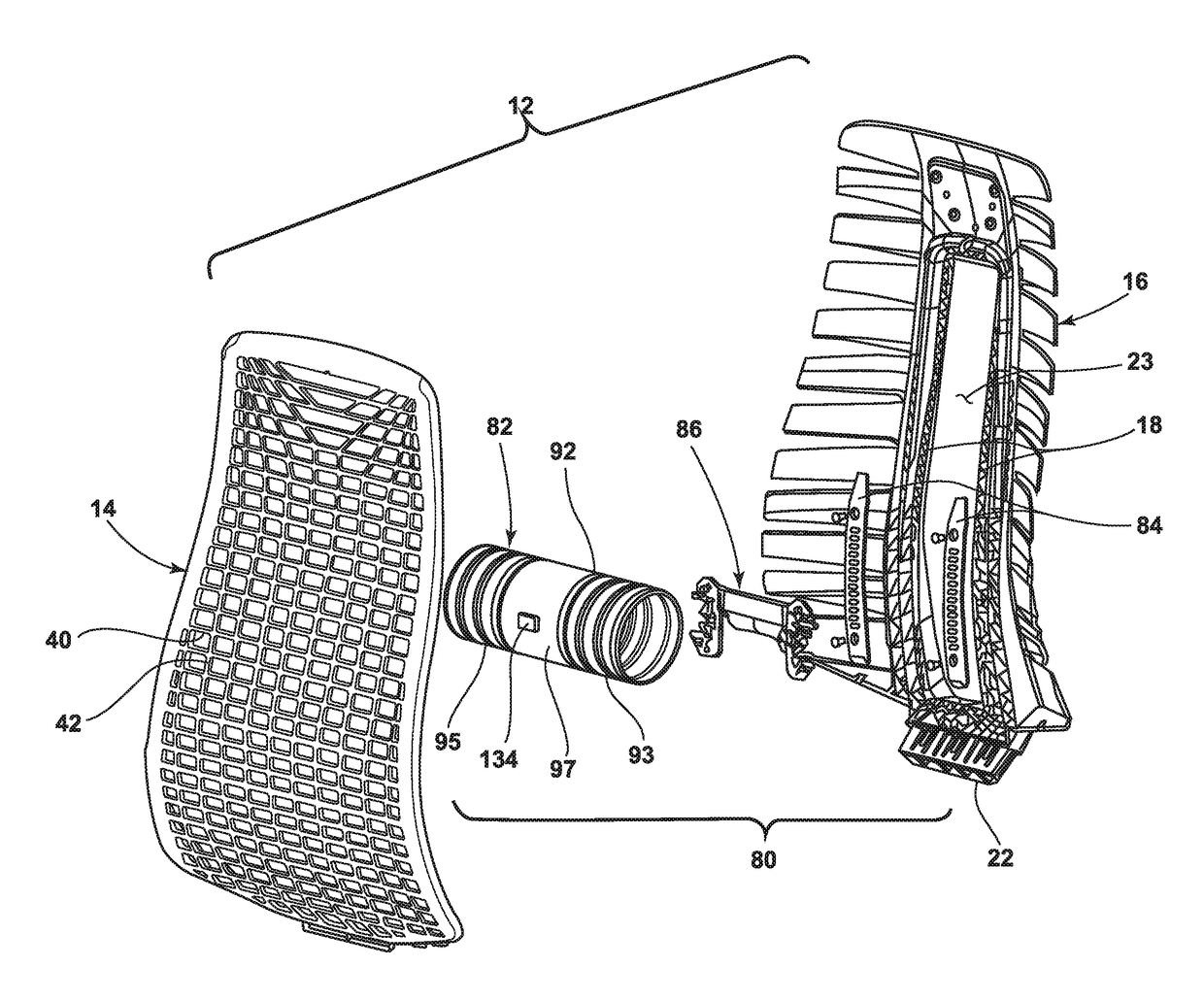

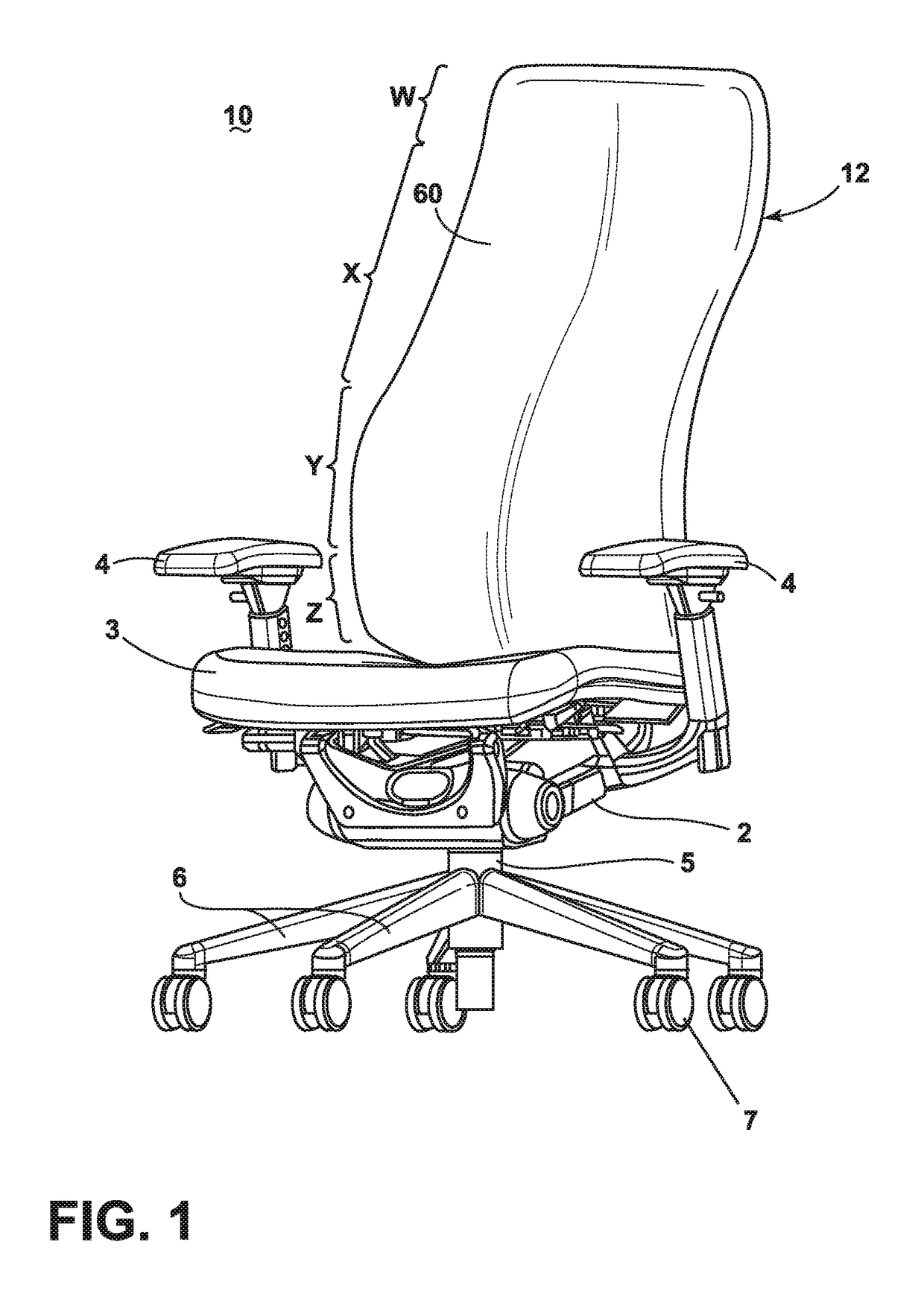

Back support for a chair

An office-type chair including a back support having a suspension mesh back support and a back support frame. The suspension mesh back support has an integral retaining channel disposed at a peripheral edge thereof, and the back support frame includes a central pair of upright support posts and wedge base for mounting to a chair frame. The back support frame includes a plurality of flexible and spaced support arms extending laterally outward from the upright support posts. The support arms each have a peripheral edge configured for fastenerless attachment in a tensioned state within the suspension mesh retaining channel. An upholstery cover encapsulates the suspension mesh and back support frame. The office chair also includes a lumbar mechanism including a resilient cushion that may be positioned in the space between the suspension mesh and the support frame and adjusted along the vertical extent of the back support by rolling the resilient cushion on the rear of the suspension mesh.

Owner:HAWORTH SPA

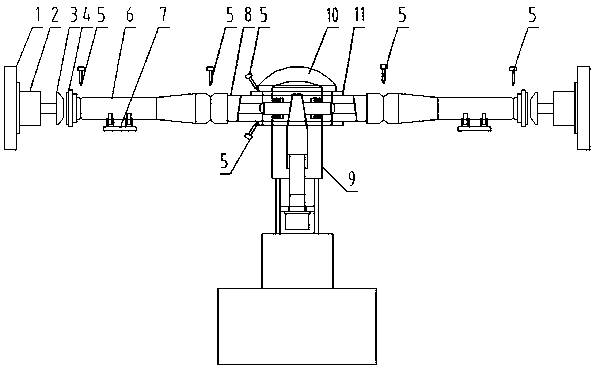

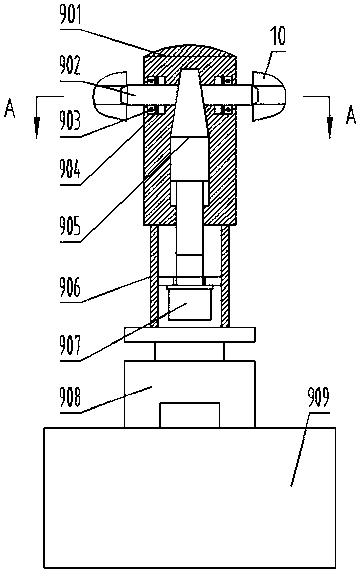

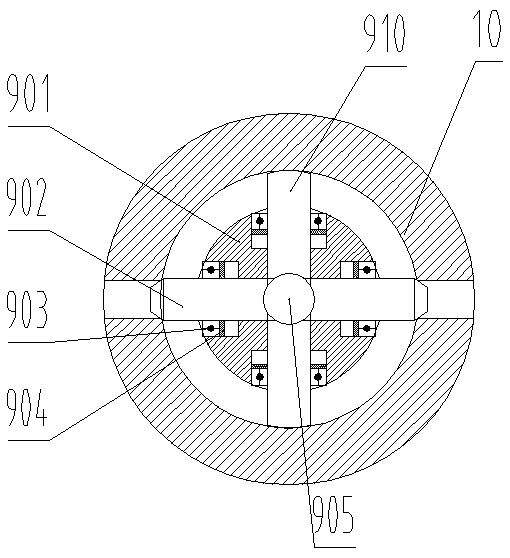

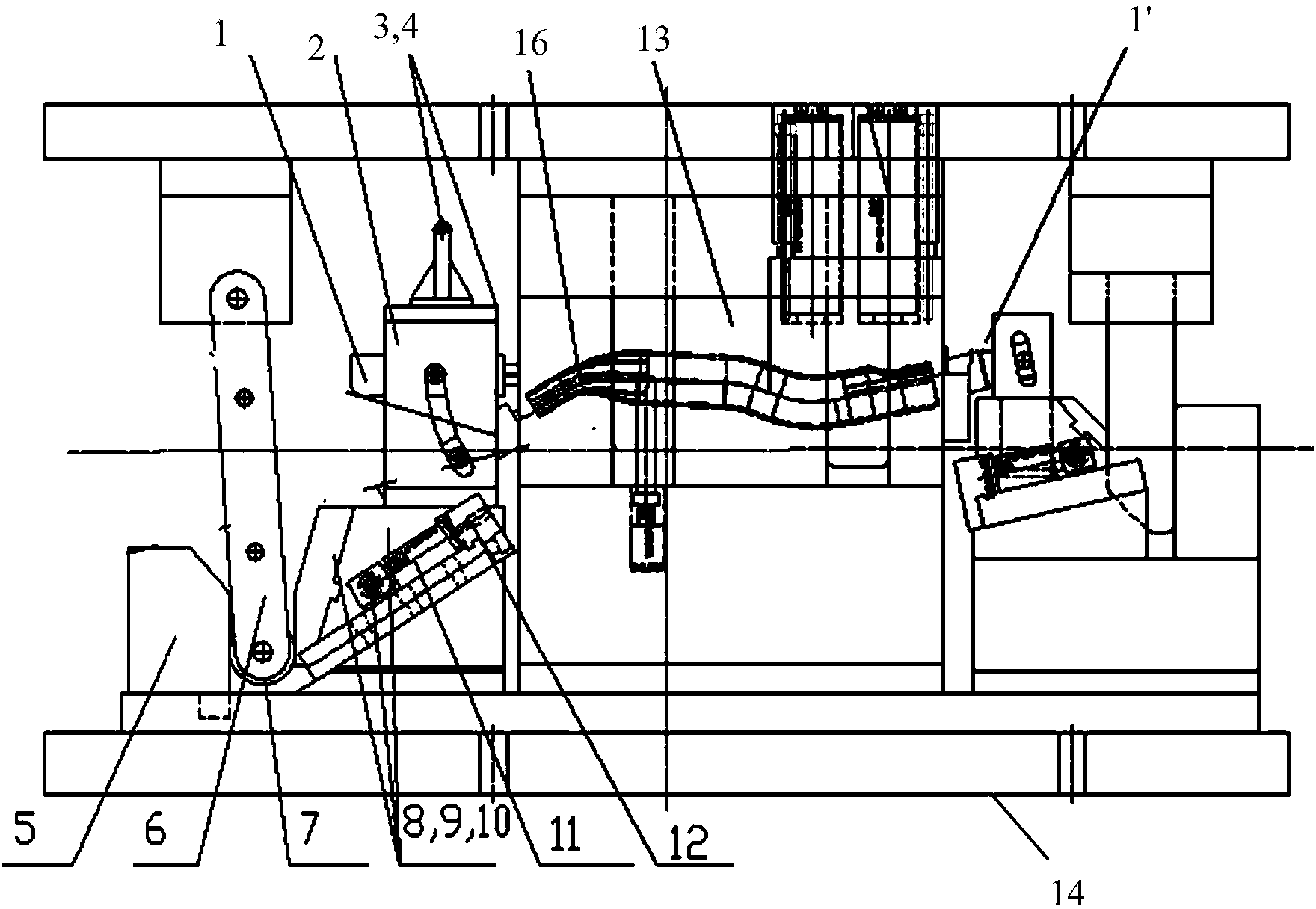

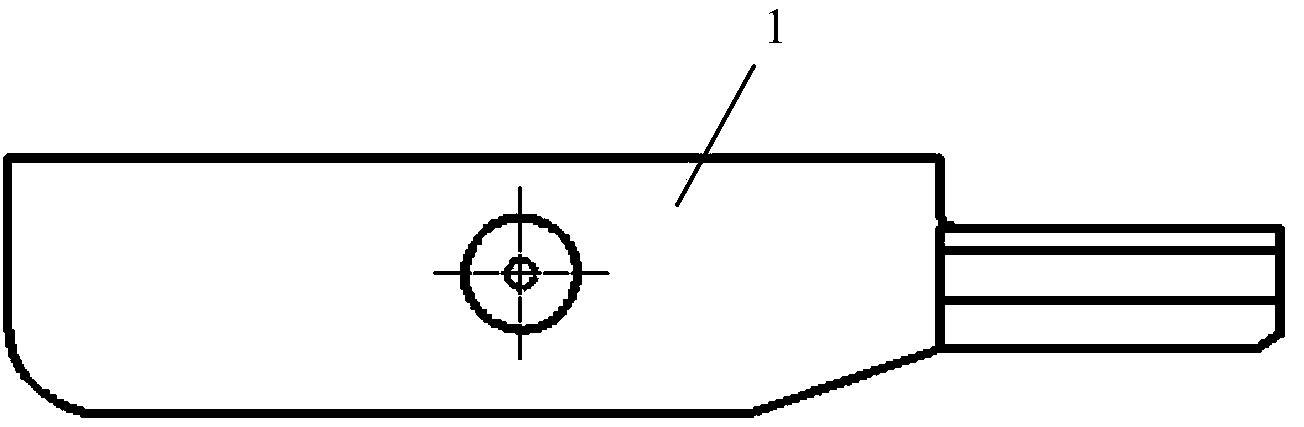

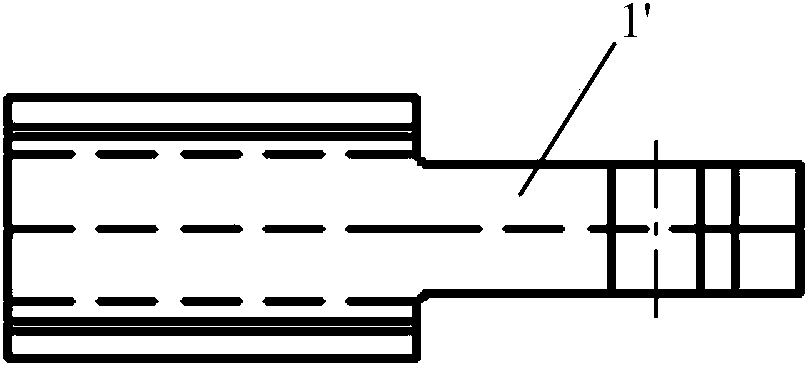

Automatic welding device for automobile rear axle housing

InactiveCN109332979AReduce intermediate handling processSmall footprintWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWeld seam

The invention discloses an automatic welding device and method for an automobile rear axle housing. The welding device is characterized in that a rotary clamping mechanism comprises an oblique wedge,an oblique wedge base, first ejection pins and second ejection pins, the first ejection pins are arranged in first sliding grooves of the oblique wedge base in a symmetrical 180-degree mode, the second ejection pins are arranged in second sliding grooves of the oblique wedge base in a symmetrical 180-degree mode, an 90-degree angle is formed between the first sliding grooves and the second slidinggrooves, the oblique wedge is matched with the first ends of the first ejection pins and the first ends of the second ejection pins, and jacking discs are horizontally arranged at the two ends of theupper portion of a rotary clamping mechanism. The welding method comprises the steps of axle housing cover and reinforcing ring spot welding after positioning, horizontal ring welding seam welding and vertical ring welding seam welding. According to the automatic welding device and method for the automobile rear axle housing, welding of six welding seams is achieved on one device, therefore, theequipment occupation area is decreased, and the equipment cost is reduced; the intermediate part carrying process is omitted, and the welding efficiency can be greatly improved; and a welding gun onlyneeds to have a telescopic function and does not need to conduct welding seam tracing, and the automatic welding device has the advantage of being simple in structure.

Owner:HEFEI CHANGQING MACHINERY

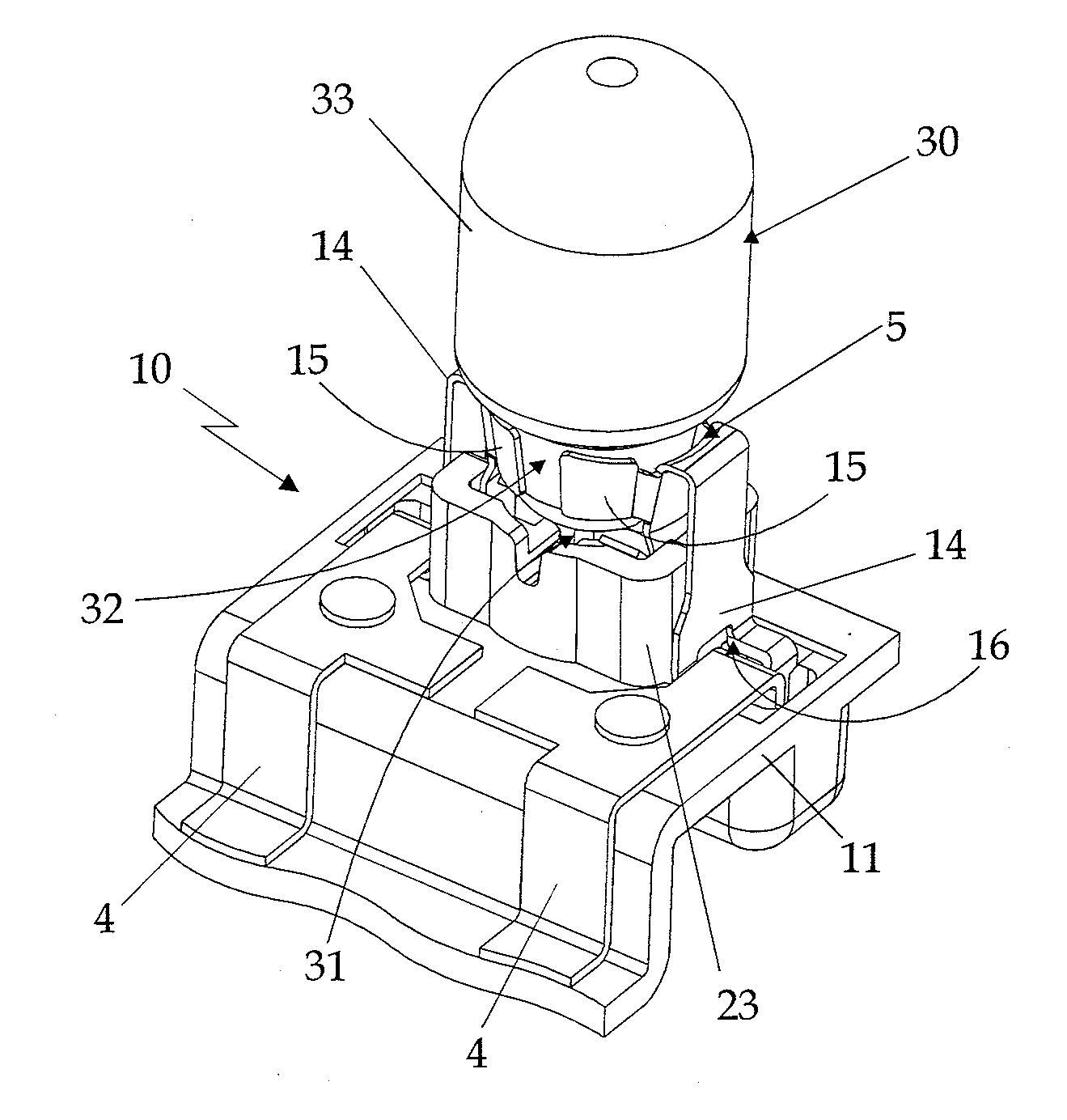

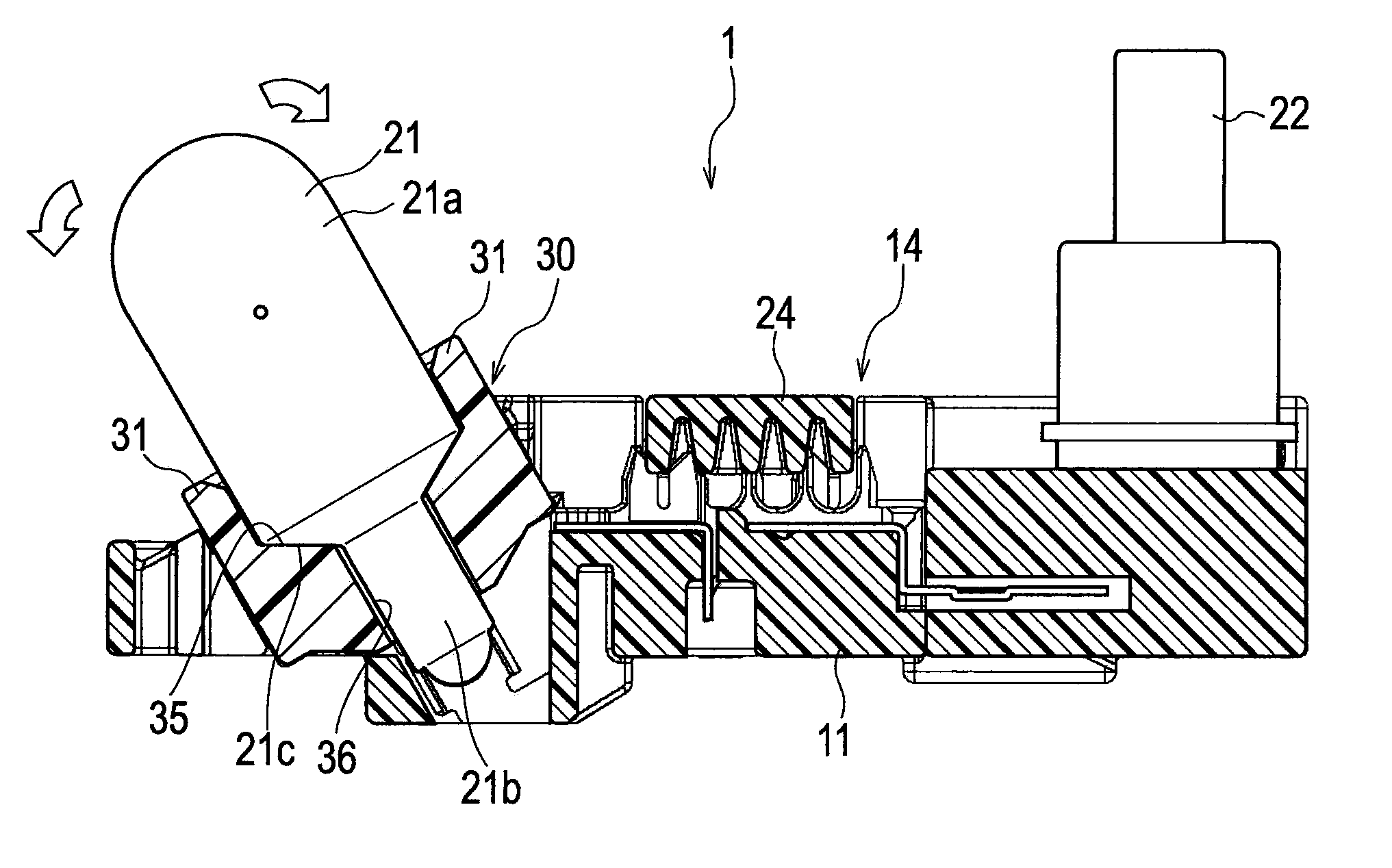

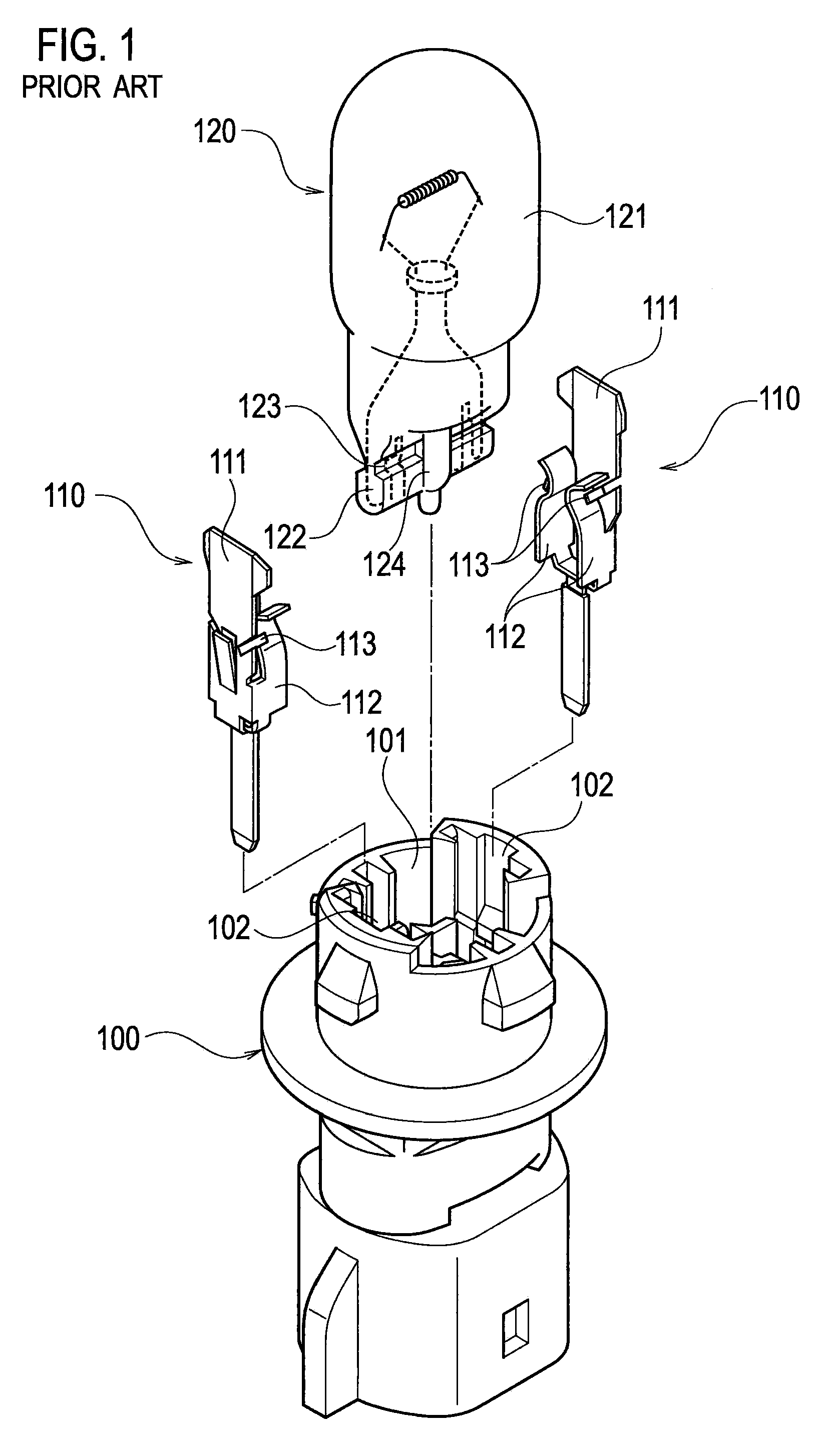

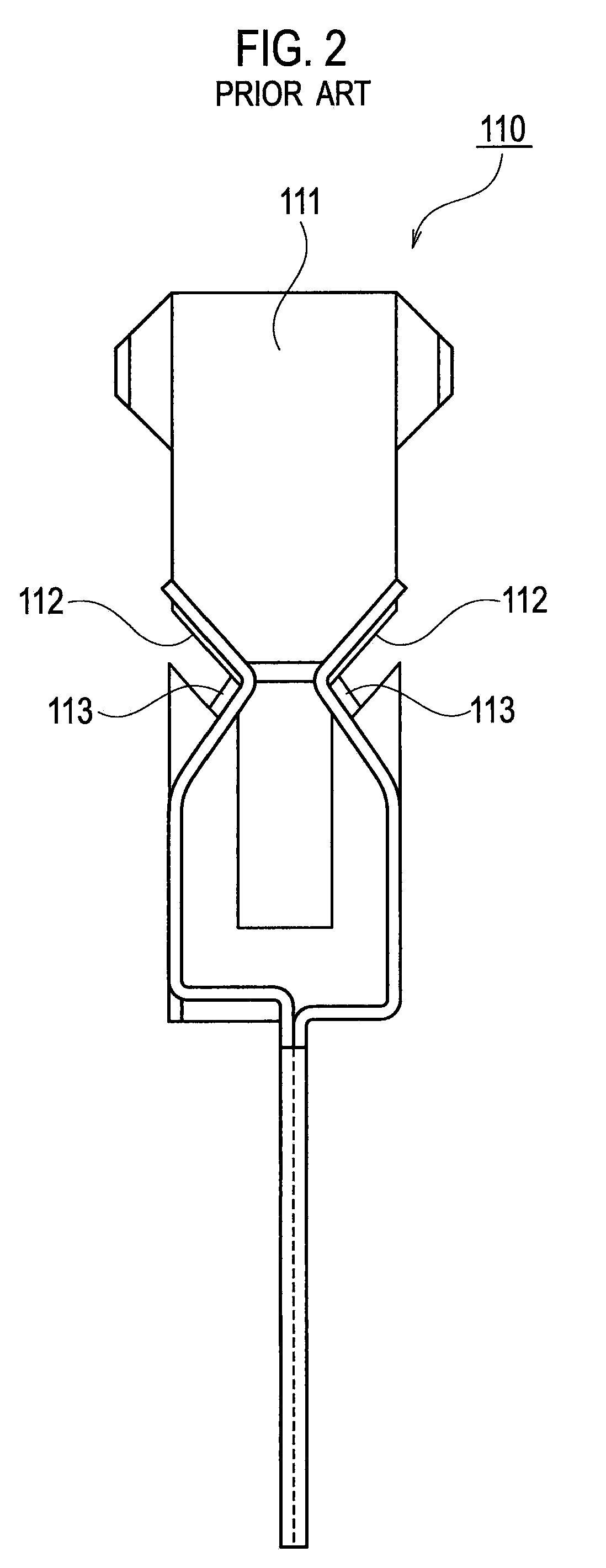

Bulb Socket Structure for Onboard Interior Lighting System

InactiveUS20090191766A1Avoid uneven attachmentElectric discharge tubesIncorrect coupling preventionElectricityLighting system

Disclosed is a bulb socket structure for an onboard interior lighting system, in which: a bulb attachment hole 12 to which a wedge base bulb 21 is attached is formed in a resin-made housing 10 constituting the onboard interior lighting system; and power supply terminals 15 configured to contact, and conduct electricity to, terminals of a base 21b arranged under a bulb part 21a of the wedge base bulb when the base is inserted into the inside of the bulb attachment hole are provided in the inside of the bulb attachment hole. In the bulb socket structure, a spacer 30 is provided to the bulb attachment hole 12. The spacer is includes a supporting cylindrical part 31 capable of supporting the bulb part 21a of the wedge base bulb from its outer periphery. The spacer is capable of causing the power supply terminals 15 to contact the respective terminals of the base part while protecting the power supply terminals. Guiding slopes 35 configured to guide the base 21b to a right position in the inside of the bulb attachment hole 12 while the base is being inserted to the bulb attachment hole are provided to the inside of the supporting cylindrical part.

Owner:YAZAKI CORP

Socket equipped with a centring ring for a wedge-base

InactiveUS20060052010A1Easy to produceCost advantageVehicle connectorsPoint-like light sourceEngineeringSpring steel

The socket for a wedge-base lamp according to the invention comprises a base and at least two electrical contact blades mounted in the base in order to electrically connect electrodes of the lamp to an electrical supply circuit. The electrical contact blades each comprise an elastic part forming a clamp in which the glass cap of the lamp is inserted. According to a first aspect, the base is provided with at least one part in contact with the bottom of the bulb of the lamp in order to centre the lamp in a predetermined manner in the base and to oppose any movement of the lamp with respect to the base. According to a preferred embodiment, the part of the socket in contact with the bottom of the bulb is included in a centring piece mounted in an intermediate manner between the base and the bulb of the lamp. According to another aspect, the contact blades are produced from spring steel. The invention finds a favoured application in lighting and / or signalling devices for automobiles, in particular signalling lights.

Owner:VALEO VISION SA

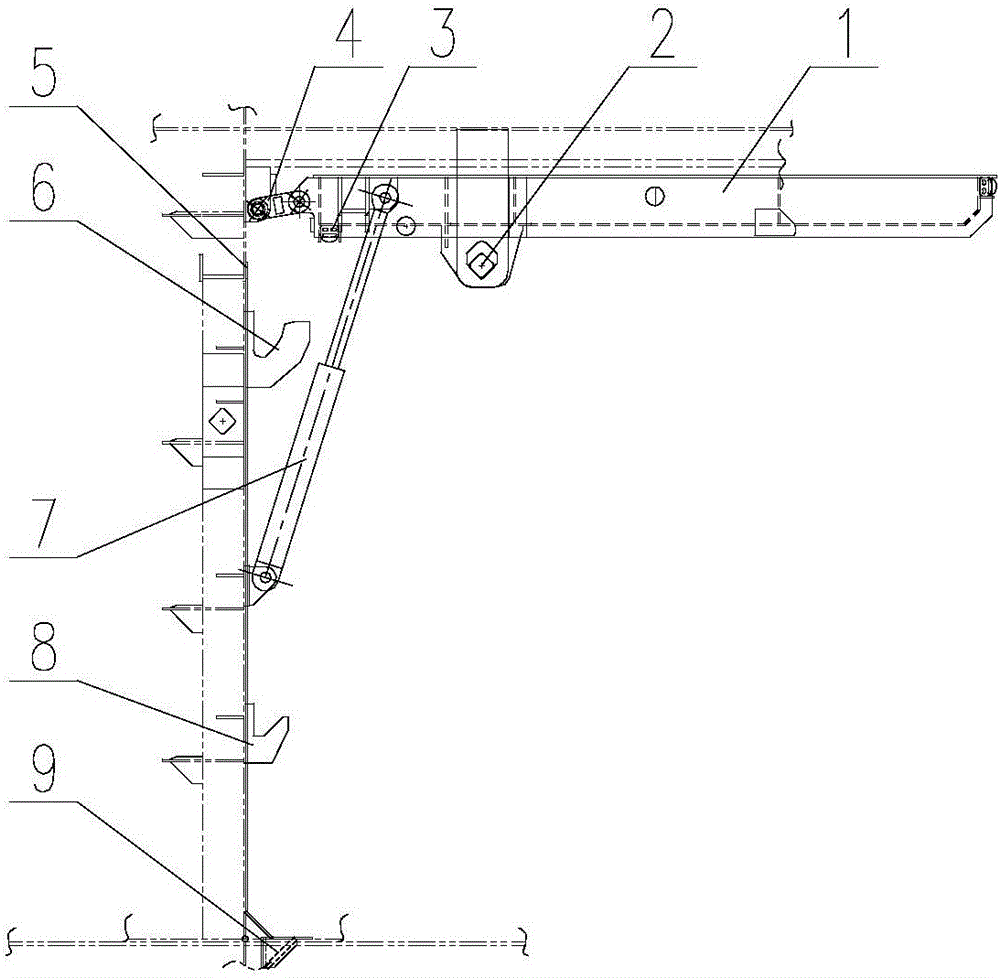

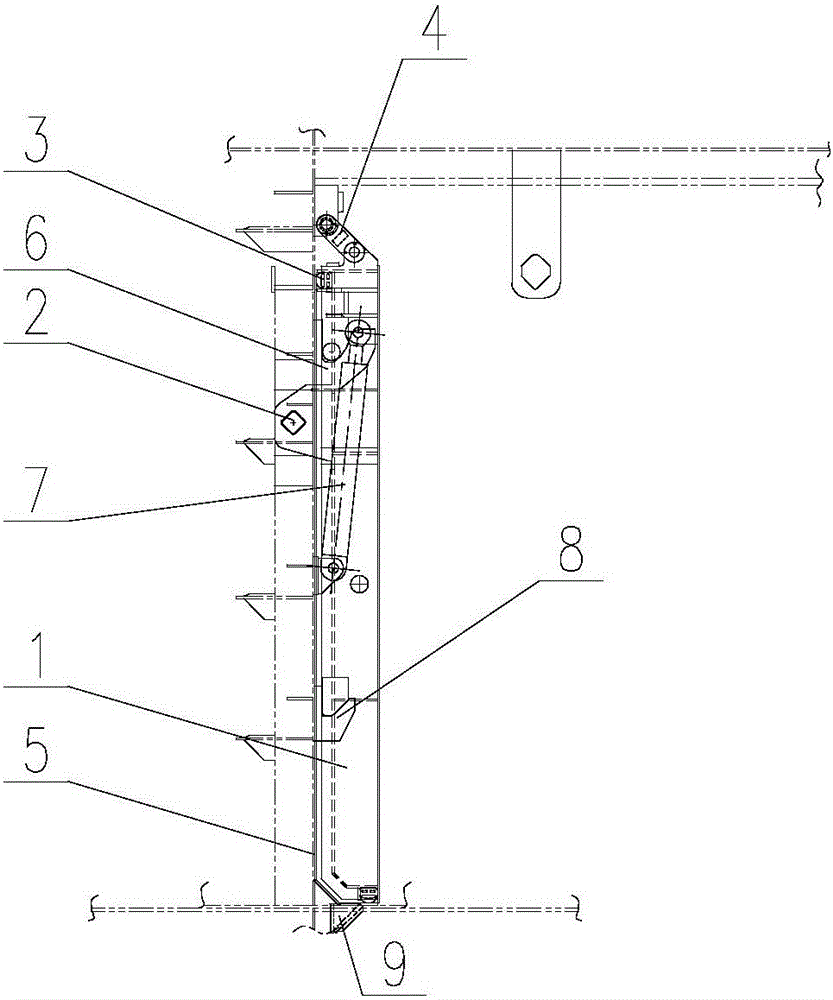

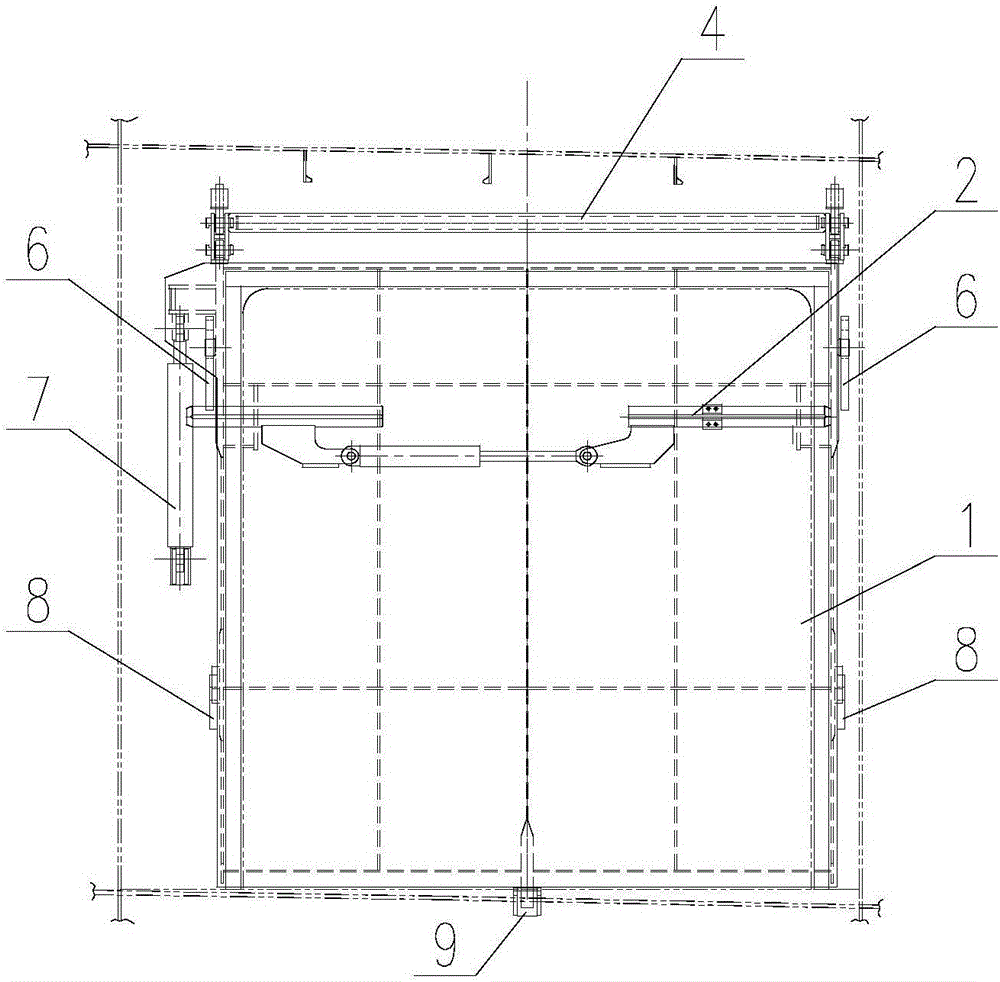

Unilaterally driven horizontal hinge type non-threshold watertight landing gate

ActiveCN105775068AAchieving stationarityGuaranteed sealing performanceWatertight door arrangementsBattenWedge base

The invention relates to a unilaterally driven horizontal hinge type non-threshold watertight landing gate. The unilaterally driven horizontal hinge type non-threshold watertight landing gate comprises a landing gate body, a top two-lug hinge, a drive oil cylinder, watertight rubber arranged on the inner side of the top of the landing gate body, a batten arranged on the bin wall, a bottom pressing wedge base arranged on a bin bottom board. The landing gate body is connected with the bin wall in a floating mode through the top two-lug hinge, and an upturned landing gate is formed. The landing gate body is connected with the bin wall through the drive oil cylinder arranged on the single side so that the landing gate can be opened. Sealing of the top of the landing gate is achieved through linkage of two connecting points on hinge bodies on the two sides of the top two-lug hinge, and the landing gate is opened or closed stably through rigid connection between the hinge bodies on the two sides of the top two-lug hinge. The unilaterally driven horizontal hinge type non-threshold watertight landing gate can be applied to watertight landing gates for ship lifters, and can improve the airtightness and safety of a whole passageway and a whole bin.

Owner:中国船舶重工集团公司第七0四研究所

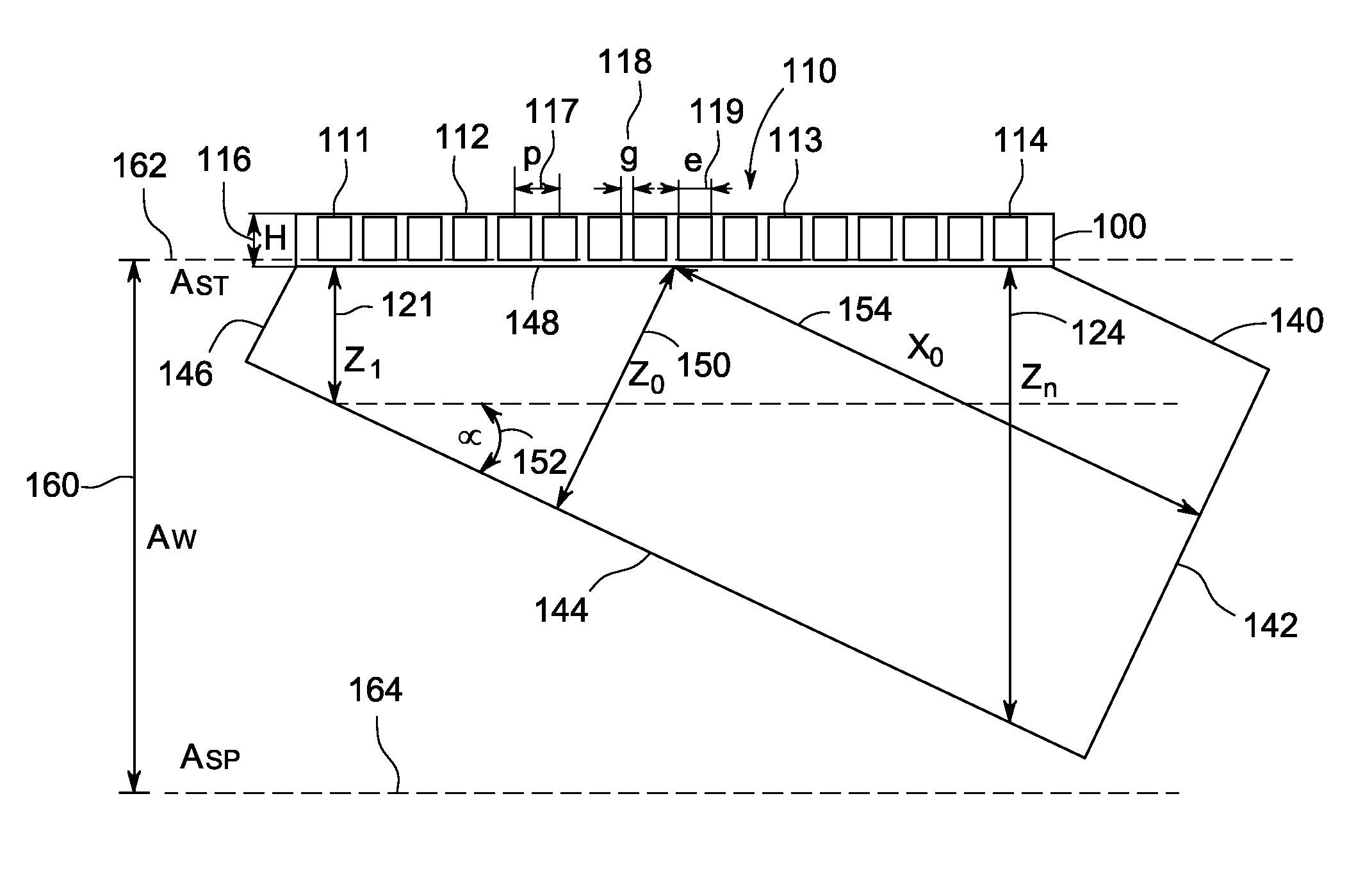

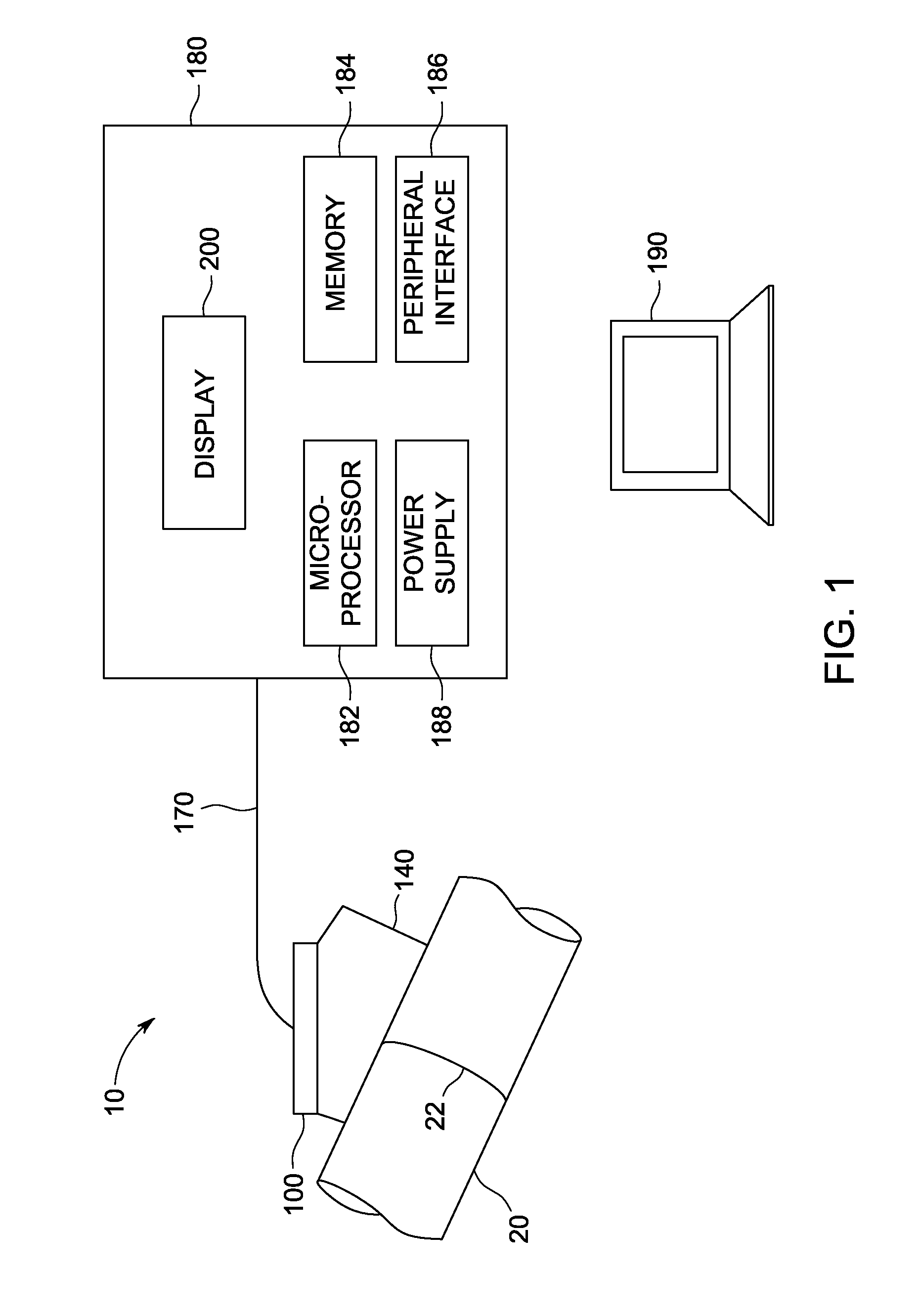

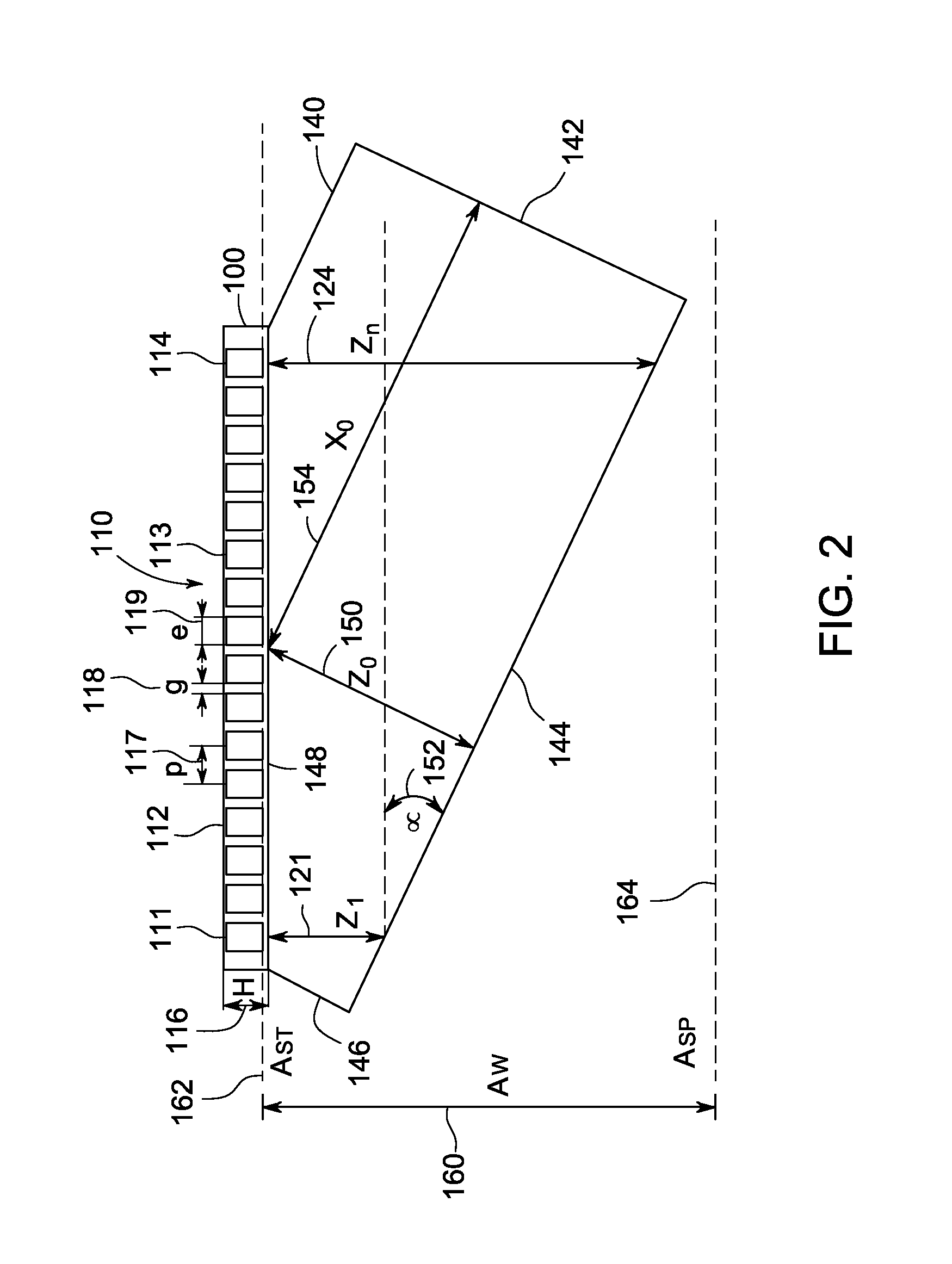

Method and system for calibrating an ultrasonic wedge and a probe

ActiveUS20130192334A1The calibration method is simpleAccurate CalibrationMaterial analysis using sonic/ultrasonic/infrasonic wavesStatic/dynamic balance measurementSonificationPhased array transducer

A method and system for calibrating an ultrasonic wedge and a probe are disclosed. The calibration method includes the steps of automatically determining the ultrasonic signal acquisition width and the first ultrasonic signal gate based on the theoretical parameters of the ultrasonic wedge and the probe. The calibration method can also include the steps of automatically determining the operating status of transducer elements in a phased array transducer and then determining the actual parameters of the ultrasonic wedge based on the live transducer elements.

Owner:GENERAL ELECTRIC CO

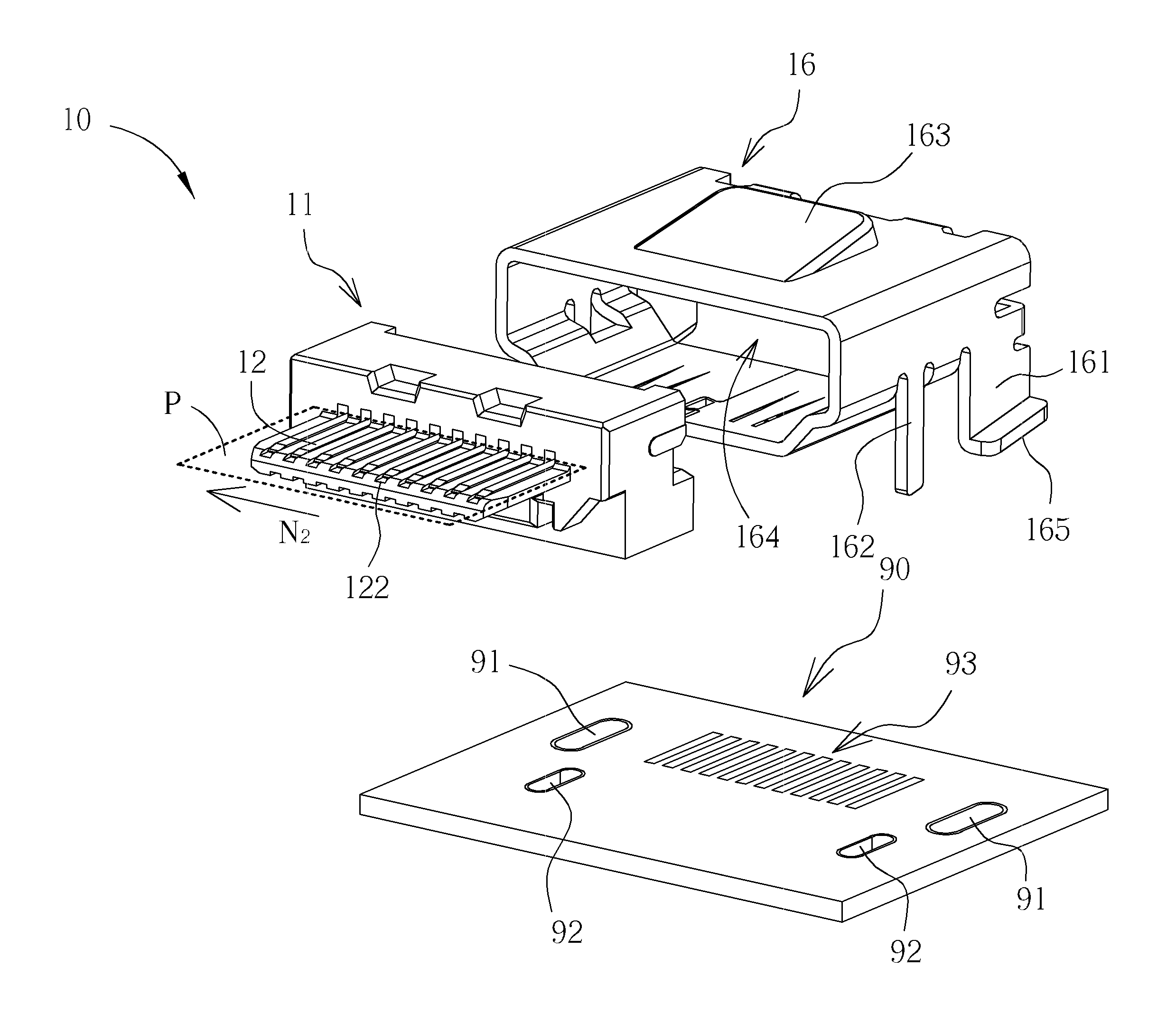

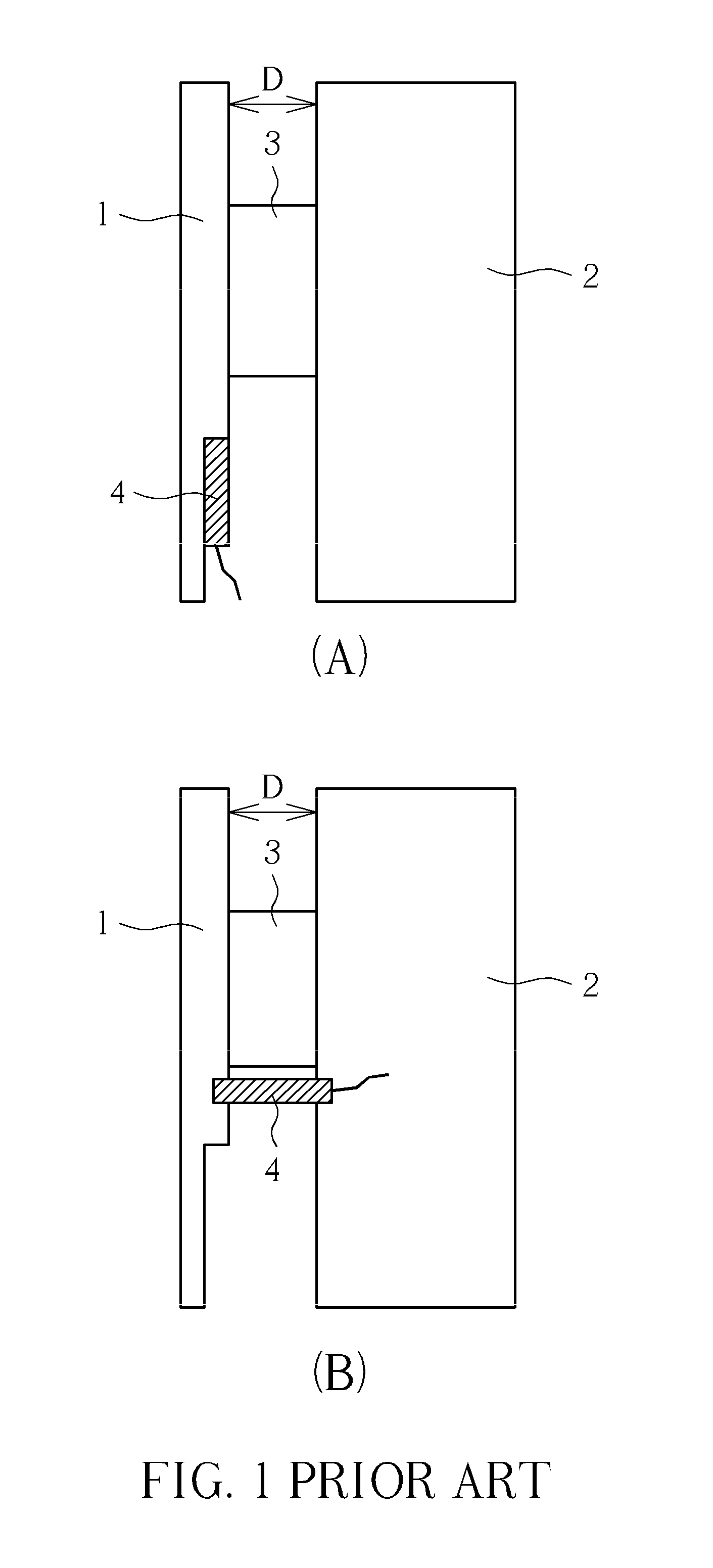

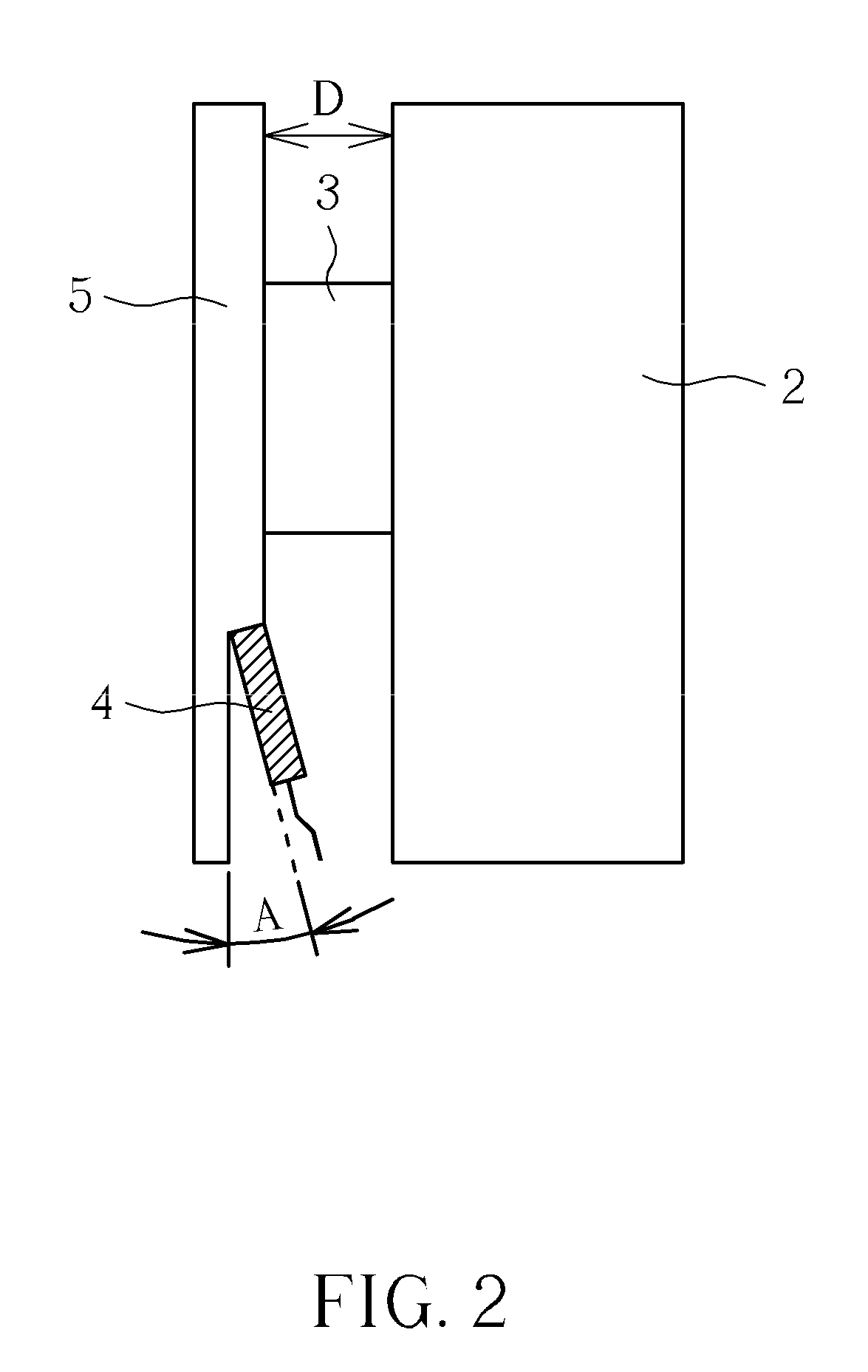

Connector

A connector is mounted on a circuit board via its feet of the housing (and / or a frame's feet) mounted at a tilting angle to the circuit board, or via a wedge base of its connector body such that the signal pins and the opening of the housing extend along a direction at the tilting angle relative to the circuit board. An external connector may be plugged into the tilting-type connector at a tilting angle. The feet and signal pins of the connector may be mounted to the circuit board by use of surface mount device (SMD) technology or direct insertion. A plane may be further deployed on the top of the connector for being used by an SMD equipment.

Owner:AMTRAN TECH

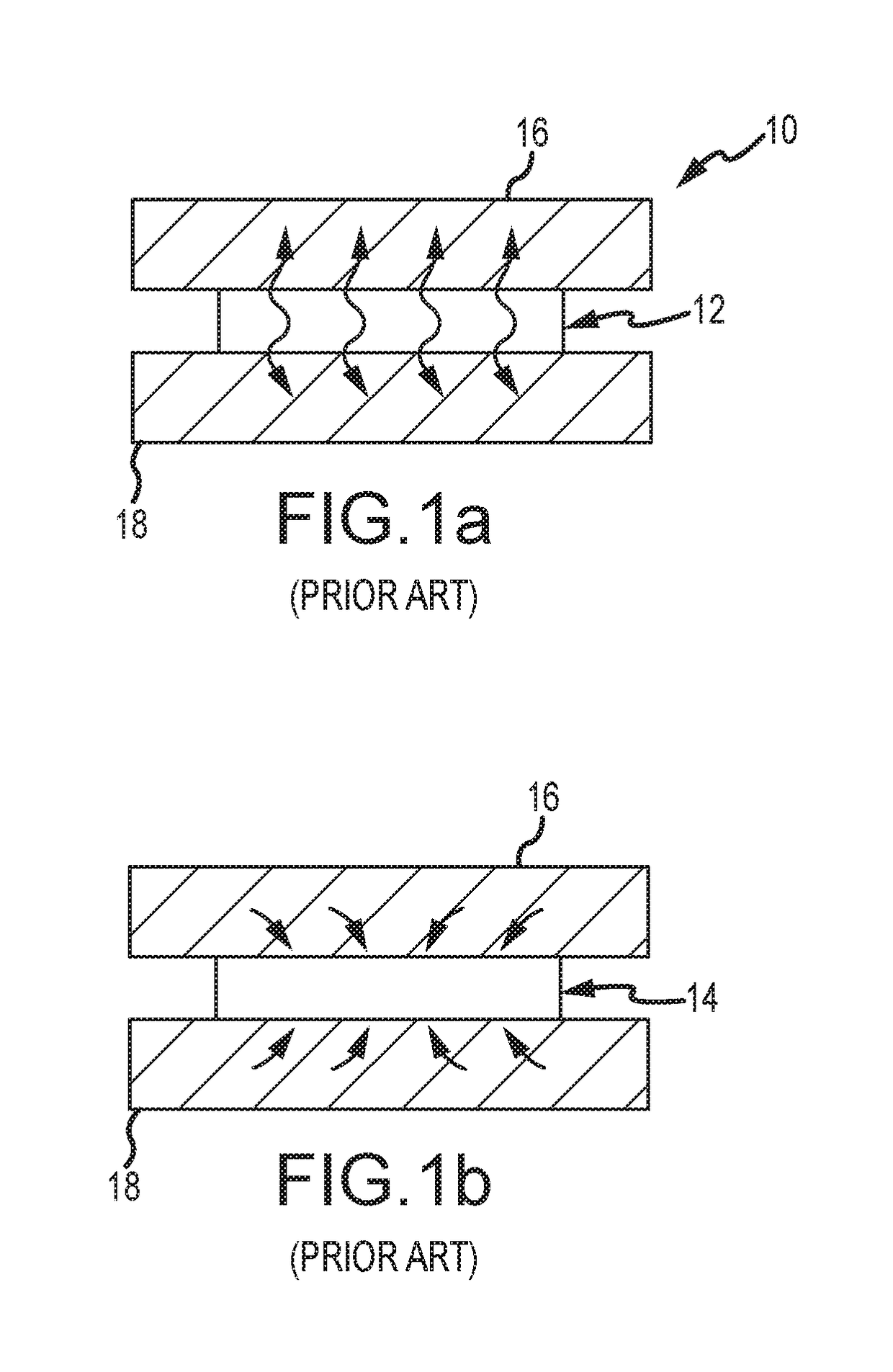

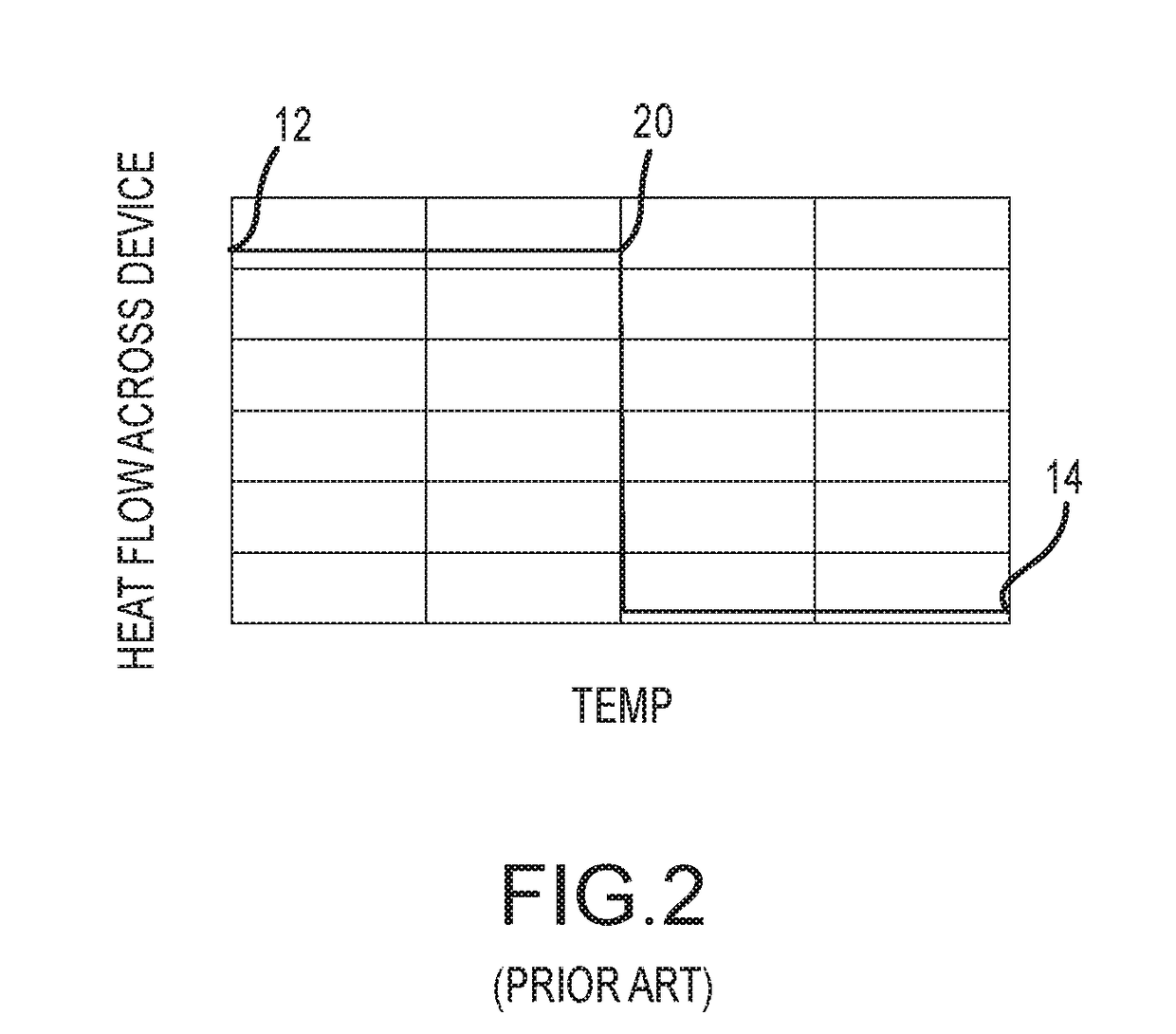

Wedge-based heat switch using temperature activated phase transition material

A wedge-based heat switch includes a plurality of wedge segments on a shaft, an energy storage element (e.g., a spring or pressurized cavity) configured to store (and release) energy via compression or expansion of the element along the shaft and a temperature activated phase transition material. A temperature stimulus activates the phase transition material to release the stored energy and move the wedge segments axially along the shaft to expand or contract the plurality of wedge segments. The wedge-based heat switch may be configured as a unidirectional switch, either conductive-to-insulating or insulating-to-conductive, or a bi-directional switch. The specific design of the wedge-based heat switch is informed by such factors as unidirectional or bi-directional, required preloading of a surface, conductance ratio between conducting and insulating states, temperature stimulus, switching speed and form factor.

Owner:RAYTHEON CO

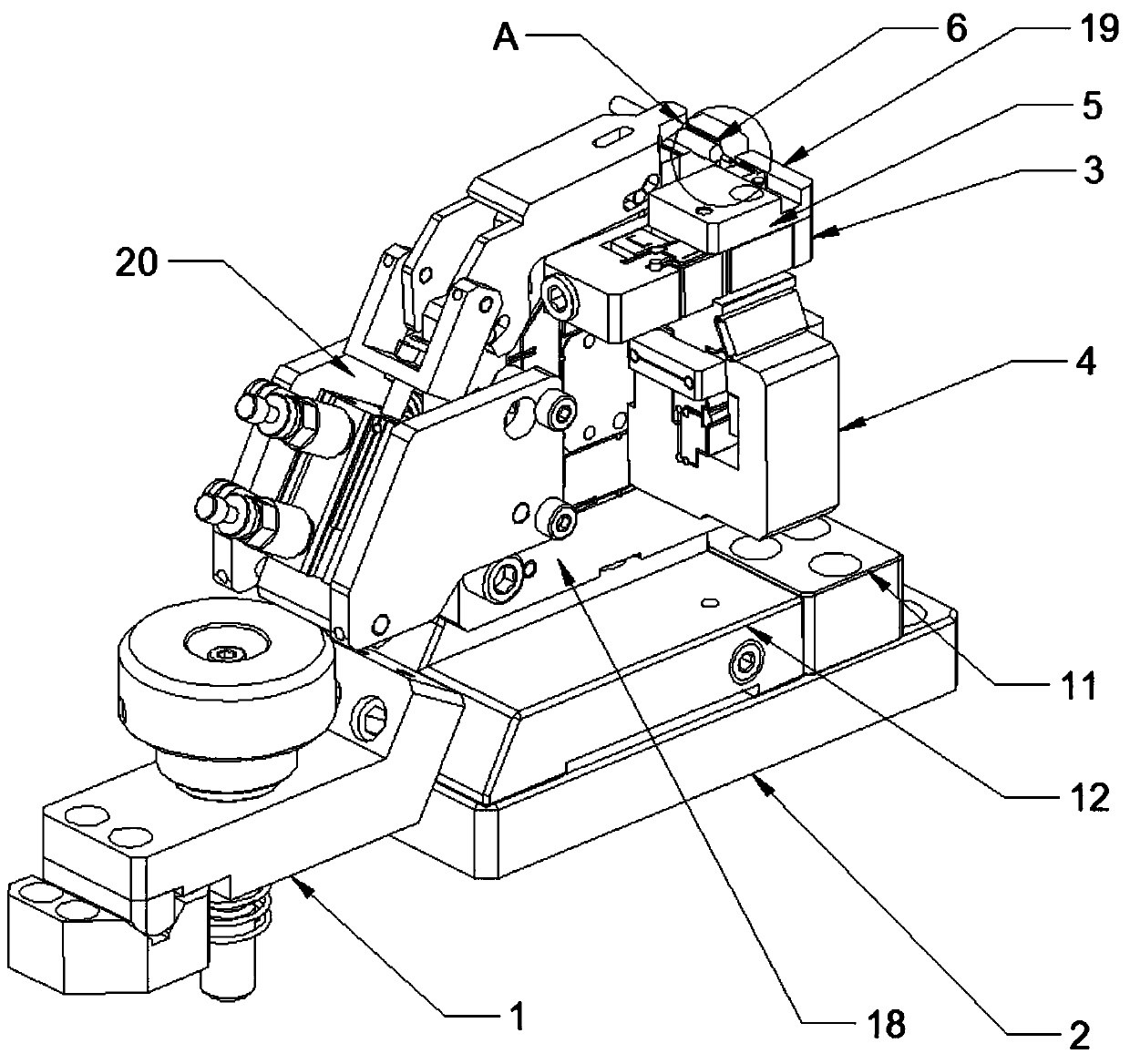

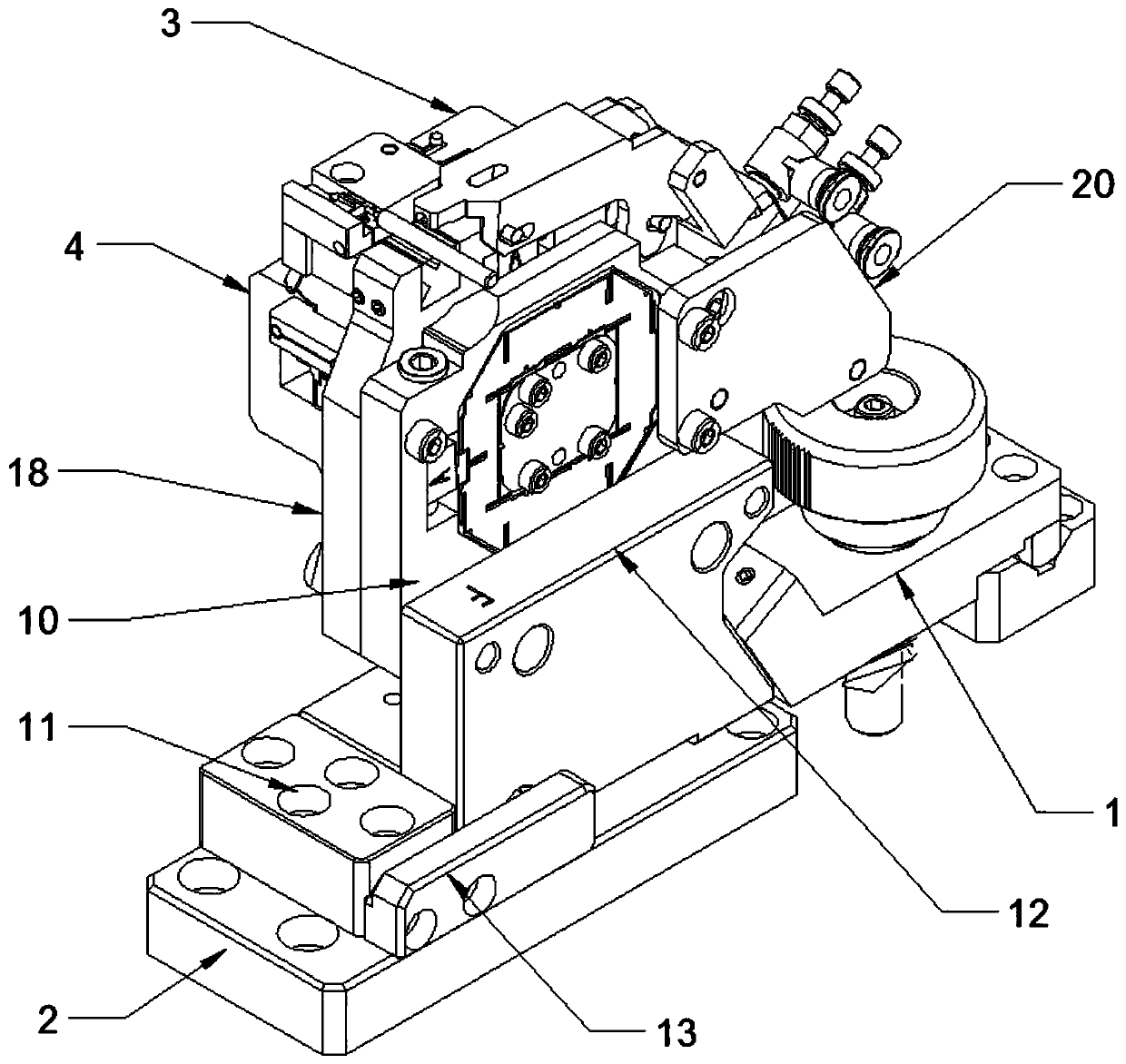

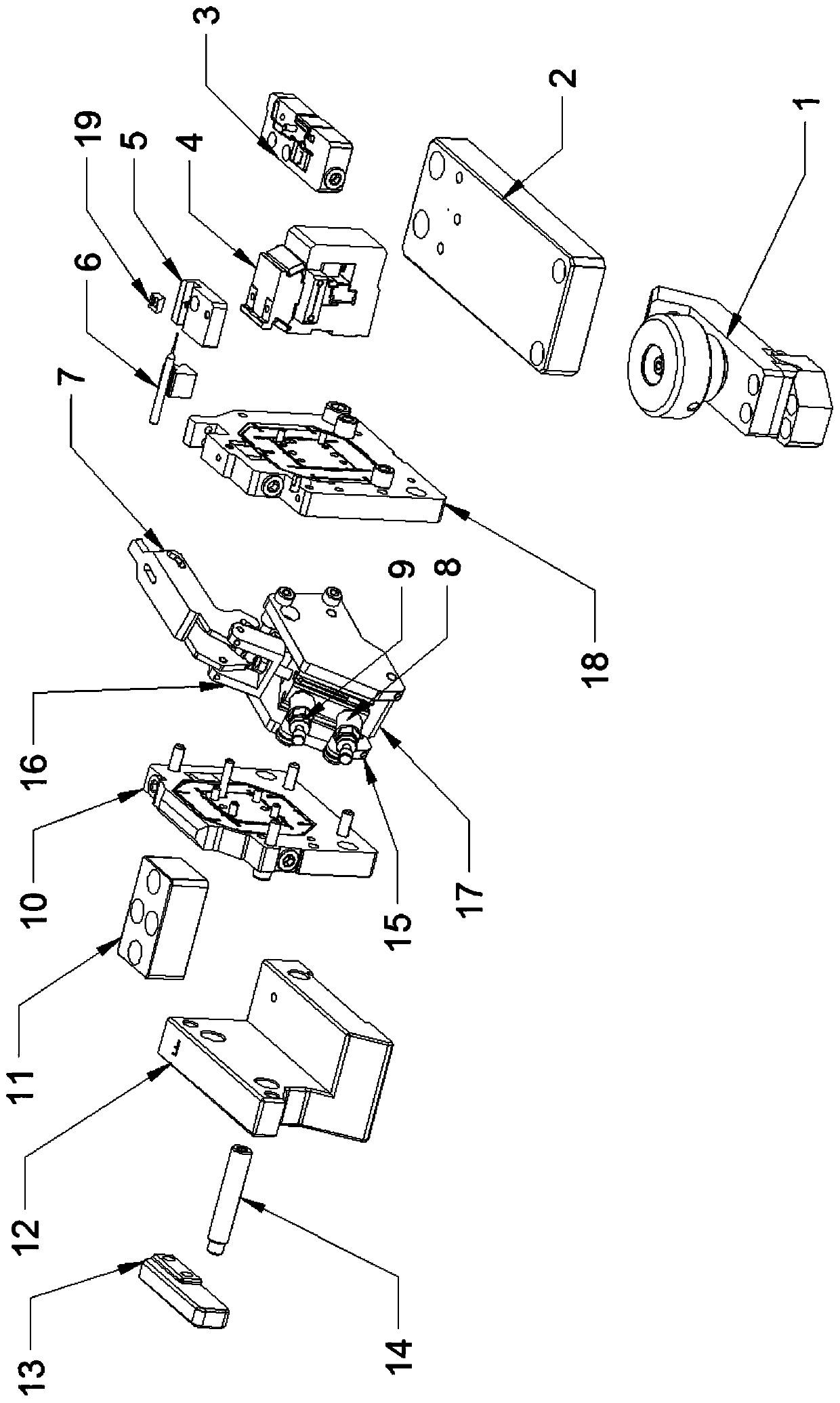

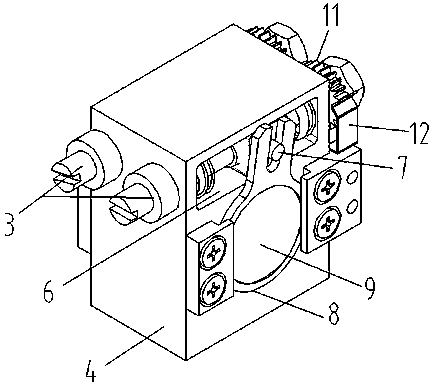

Precise micro-type adjusting base

PendingCN110539187AMeet the needs of useStable clampingLarge fixed membersPositioning apparatusEngineeringWedge base

The invention provides a precise micro-type adjusting base, belongs to the technical field of machining of precision cutting tools and solves the problems about complicated location adjustment, low precision and the like in machining of a cutting tool. The precision micro-type adjusting base comprises a mounting base, a horizontal adjusting mechanism, a vertical adjusting mechanism, an X-axis adjusting plate group, a Y-axis adjusting plate group and a pressing cylinder module; the upper end of the mounting base is fixedly provided with a jig baffle block and a wedge-shaped pedestal; the end part of the wedge-shaped pedestal is provided with a hand wheel pressing mechanism; the X-axis adjusting plate group is arranged on the wedge-shaped pedestal; the Y-axis adjusting plate group is arranged at the side end of the X-axis adjusting plate group; the pressing cylinder module is arranged above the X-axis adjusting plate group and the Y-axis adjusting plate group; the vertical adjusting mechanism is arranged at the side end of the Y-axis adjusting plate group; the horizontal adjusting mechanism is arranged at the upper end of the vertical adjusting mechanism; a hardening block fixing base is arranged at the upper end of the horizontal adjusting mechanism; and a small V-shaped hardening block is fixed to the upper end of the hardening block fixing base. The precise micro-type adjusting base provided by the invention can be used for adjusting the machining position of the cutting tool by adopting multi-directional cooperation, and realizes high machining precision.

Owner:深圳市友创智能设备有限公司

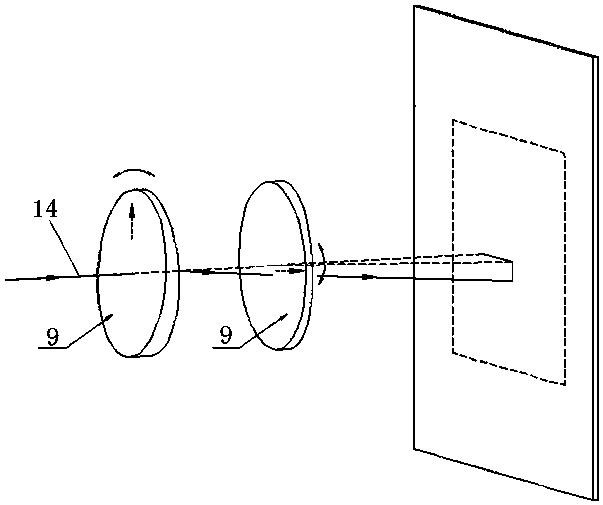

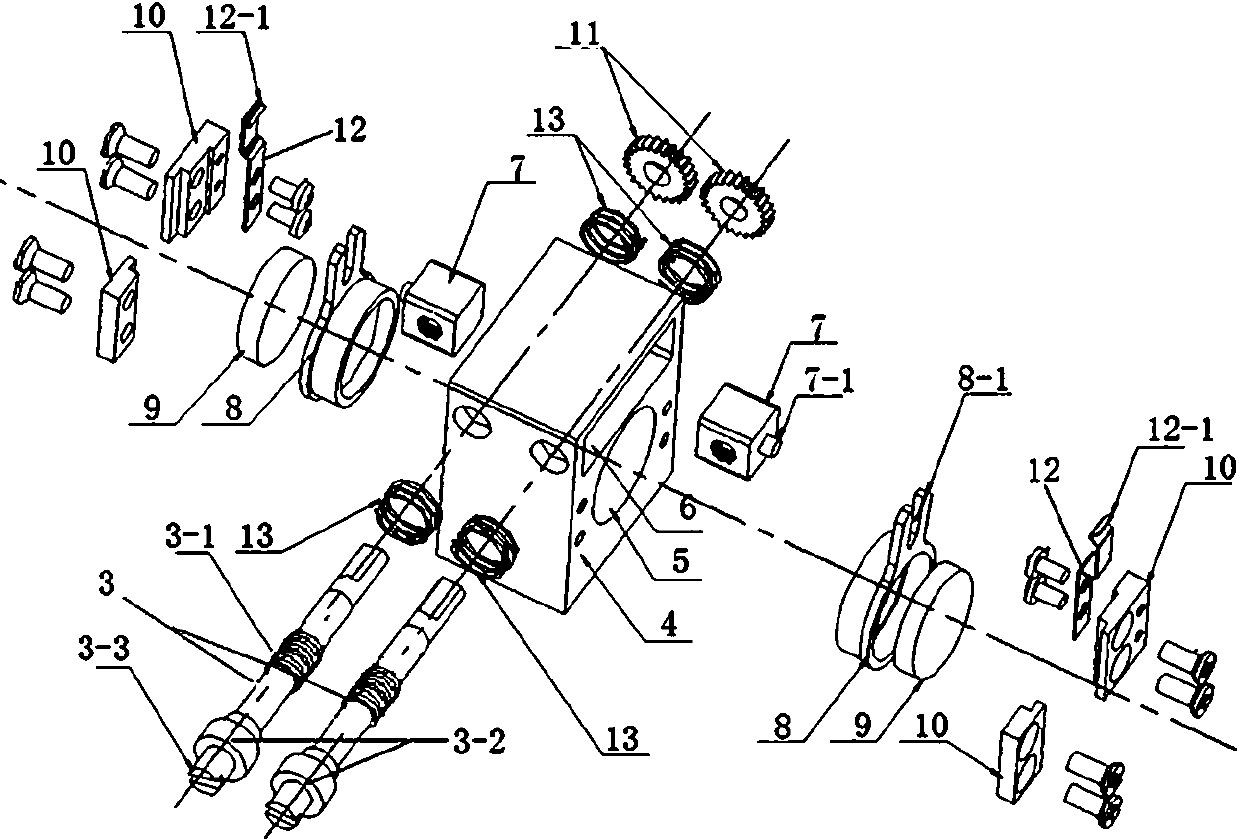

Quasi-orthogonal optical wedge adjustment mechanism

The invention discloses a quasi-orthogonal optical wedge adjustment mechanism and relates to equipment for adjusting laser optical axis direction, specifically a device for adjusting an optical axis through utilization of an optical wedge. The quasi-orthogonal optical wedge adjustment mechanism is equipped with an optical wedge base. Two sets of mutually matching optical wedge adjustment units aremounted at two sides of the optical wedge base. An optical channel which penetrates the optical wedge base is set between the optical wedge adjustment units. An optical wedge adjustment slot which penetrates the optical wedge base is set above the optical channel. Each optical wedge adjustment unit comprises an adjustment screw, a slide block and an optical wedge ring. Threads are set in a middlesection of the adjustment screw. Two ends of the adjustment screw are mirror surfaces. A limiting boss is set at a head part of the adjustment screw. A diameter of the limiting boss is greater than that of a through hole on a side face of an equipment box and is used for limiting with an inner wall of the equipment box. An adjustment knob is set at a top end of the limiting boss. The adjustment knob is smaller than the through hole on the side face of the equipment box, so the adjustment knob can extend to an outer wall of the equipment box. The diameter of the second half section of the adjustment screw is smaller than that of the middle section. The optical wedge ring is annular. An optical wedge is embedded into the ring.

Owner:NO 60 RES INST OF GENERAL STAFF DEPT PLA

Floating core-pulling mechanism for pipe fitting forming

ActiveCN103521627ARealize stamping and formingShaping toolsStripping-off devicesPipe fittingNatural state

Provided is a floating core-pulling mechanism for pipe fitting forming. The floating core-pulling mechanism for pipe fitting forming can be used for replacing a traditional long-stroke hydraulic core-pulling structure. According to the floating core-pulling mechanism for pipe fitting forming, a guide groove is formed in a guide support, the guide groove and a floating core-pulling portion are in sliding fit through a guide pin, a reset spring is assembled between a base body and the floating core-pulling portion, a sliding wedge supports the guide support, a wedge base is provided with a slope, the sliding wedge and the slope are in sliding fit, a limiting link stopper is arranged corresponding to the sliding wedge, a pinch roller is connected with the lower end of a connecting rod, the upper end of the connecting rod is connected with an upper die, namely a movable die, of a die, when the connecting rod moves downwards, the sliding wedge and the limiting link stopper can be separated through the pinch roller, the connecting rod can enter the position between the sliding wedge and the limiting link stopper to push the sliding wedge, the limiting link stopper and the wedge base are arranged on a lower die, namely a stationary die, of the die, and the nature state of a telescopic device is the state that the size of a gap between the sliding wedge and the limiting link stopper is kept to be smaller than the outer diameter of the pinch roller.

Owner:SHANGHAI HUIZHONG AUTOMOTIVE MFG

Elliptical pneumatic actuator with a wedge shaped base

A pneumatically actuated switching device has an elliptical dome with spaced apart support columns protruding from a concave inner face surface for anchoring to a floor of a wedge shaped base. The base is elliptical and bounded by an endless upstanding sidewall having a projected edge that varies continuously in height about one of the major axis and the minor axis, the projected edge having one of a channel and a locking lip and the other of the channel and the locking lip being formed on the elliptical edge for interlocking engagement in an air tight fashion. An electrically conductive switch is coupled by a duct for responding to a volume of pressurized air within the dome and the base by deflection of the convex actuating wall.

Owner:DWYER PRECISION PRODS

Wedge based fastener

A fastener comprises a shaft extending along a longitudinal axis, and a sleeve wrapped partially around the shaft. The sleeve comprises an inner surface adjacent the shaft, an outer surface, an upper extent, a lower extent, a first circumferential extent, a second circumferential extent, and a gap extending longitudinally from the upper extent to the lower extent and separating the first circumferential extent from the second circumferential extent. The sleeve has a first thickness adjacent the first circumferential extent that is less than a second thickness between the second circumferential extent and the first circumferential extent. A cross-sectional centroid of the shaft between the upper extent and the lower extent is in substantially the same location, with the sleeve in different first and second rotational positions.

Owner:WESTERN DIGITAL TECH INC

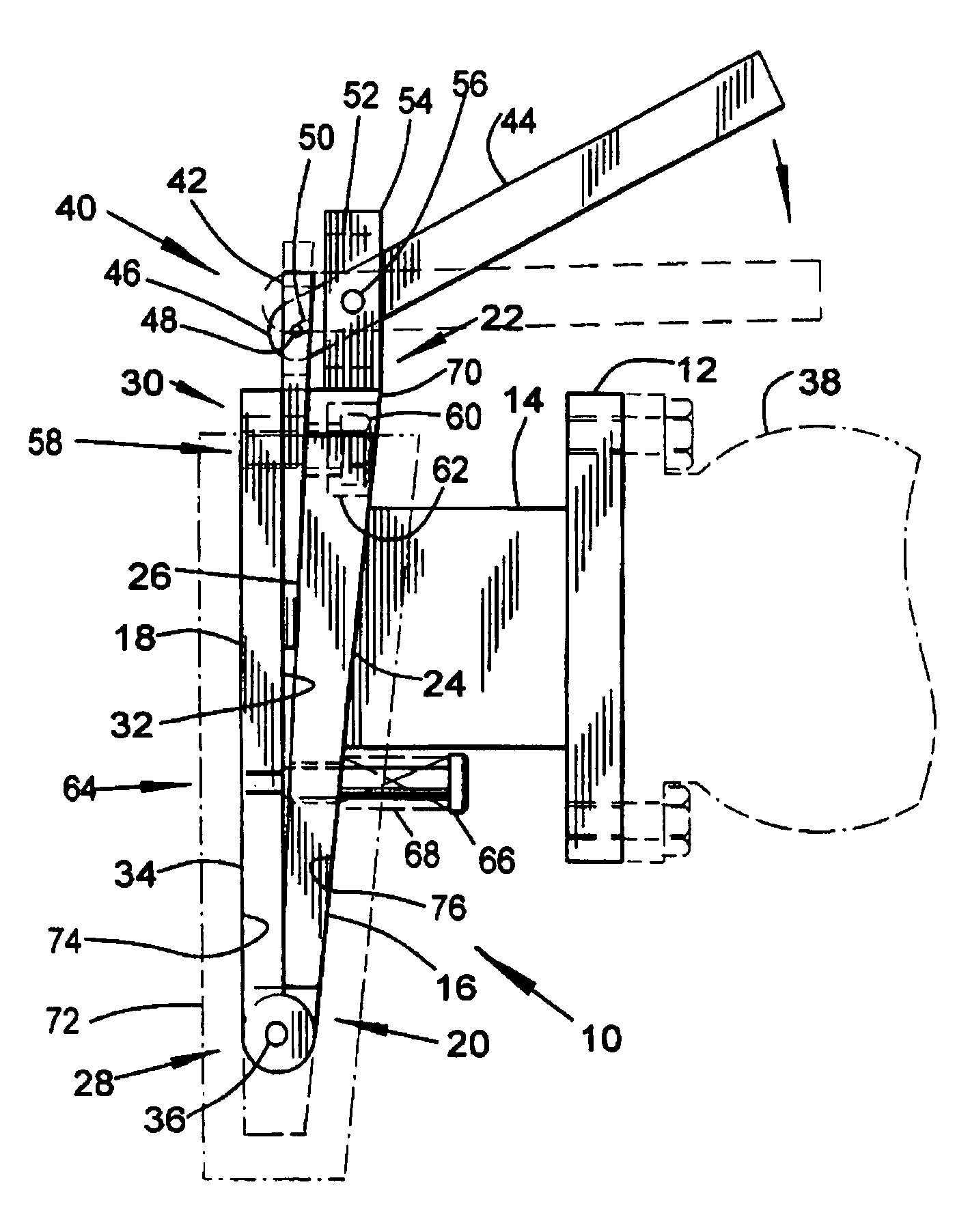

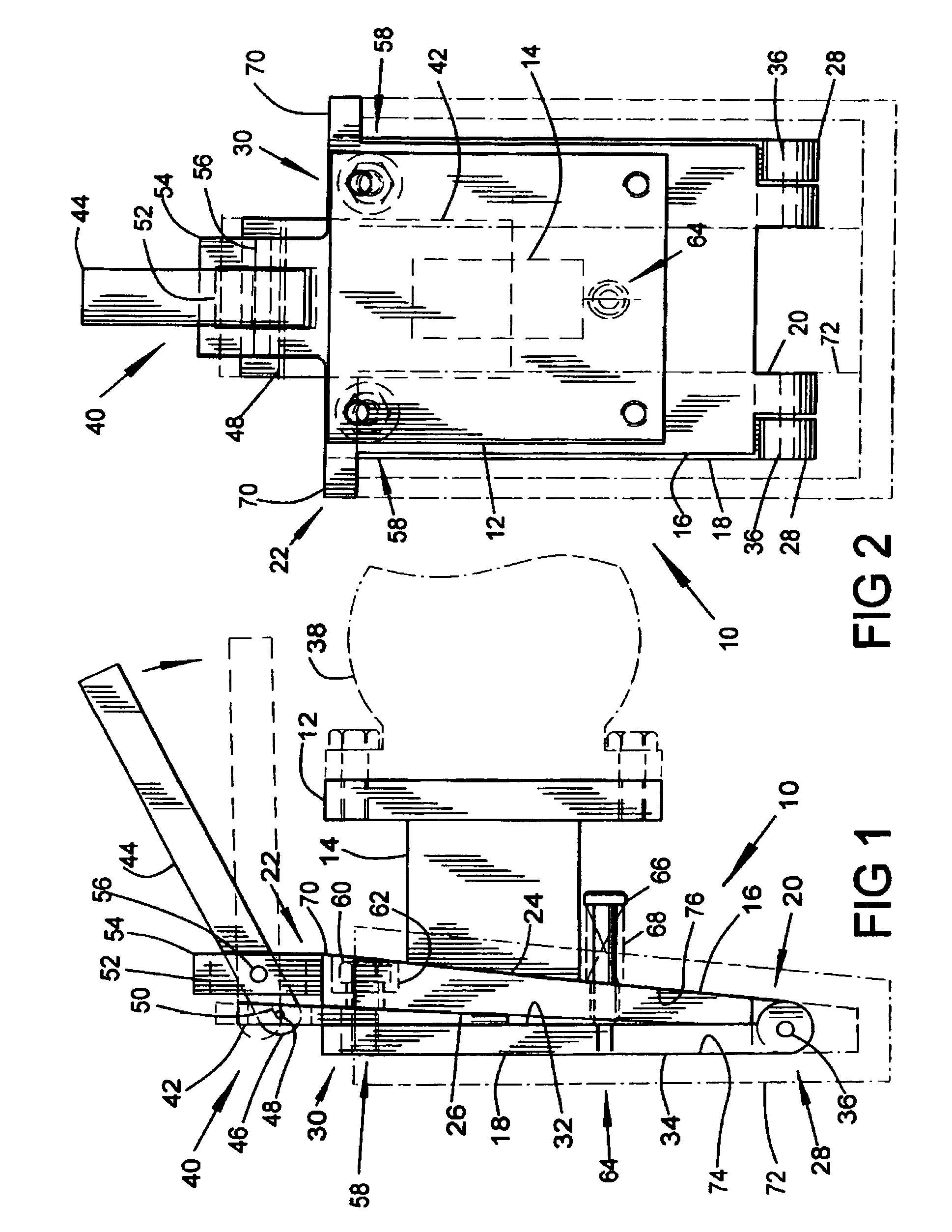

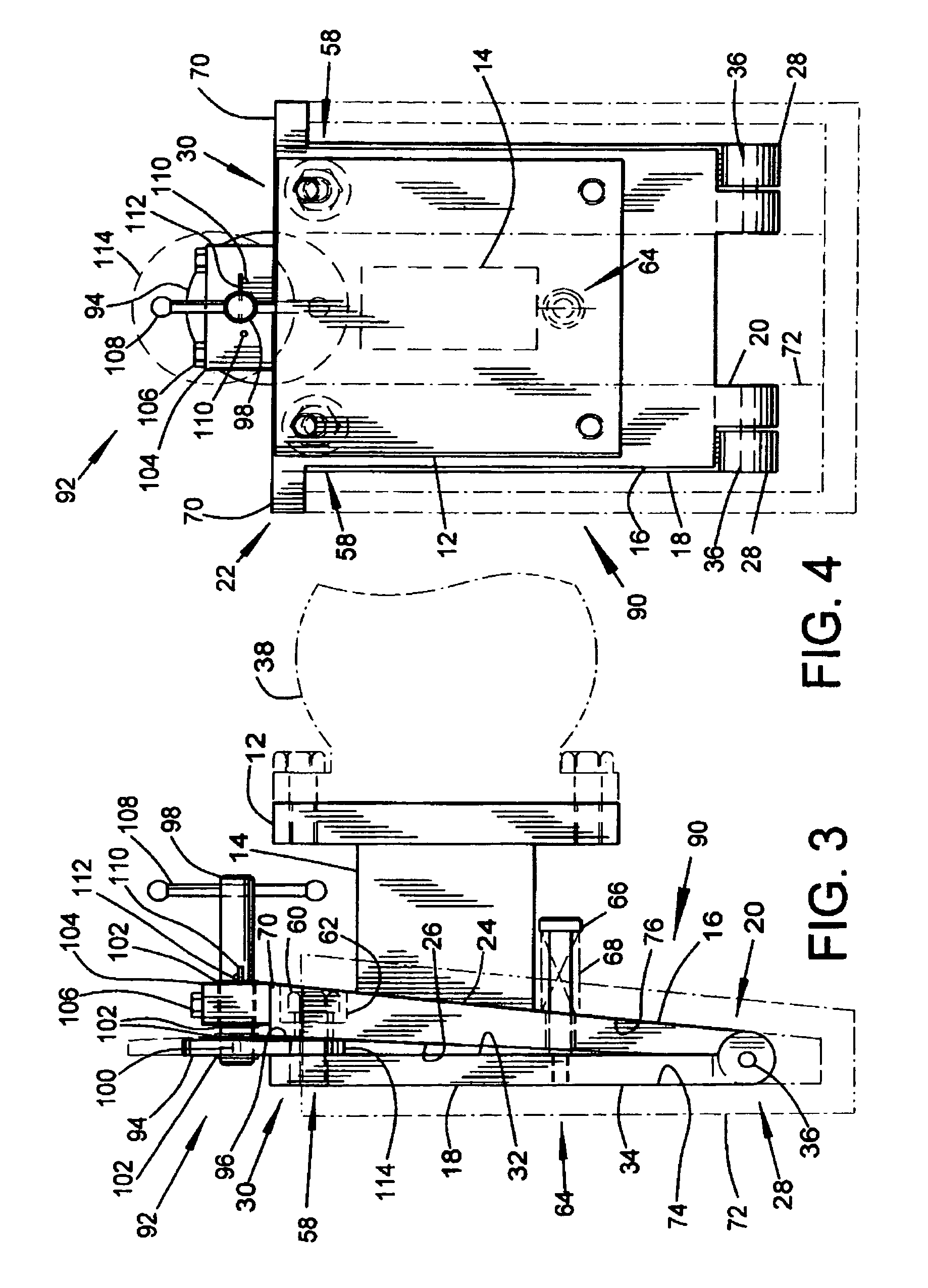

Expandable bracket assembly for a removable car shaker

An expandable vibrator bracket for attaching a car-shaker vibrator to a female receptacle attached to a railroad car to be vibrated. The expandable bracket includes: a vibrator mounting member, a leg member, and a wedge base member. The vibrator mounting member supports the vibrator. The wedge base member further includes a first end, a second end, a first side, and a second side. The wedge plate includes an attaching end, a distal end, an interior side and an exterior side. The attaching end is coupled to the first end of the wedge base member for allowing the distal end to selectively move with respect to the second end of the wedge base member when acted upon by a spreading or expanding force. The second side of the wedge base member and the exterior side of the wedge plate simultaneously abut opposite interior surfaces of the female receptacle during selective urging by the spreading force for holding the expandable vibrator bracket in the female receptacle. The spreading force may include a linear type of wedge, a rotary wedge, springs. The subsequent removal of the spreading or expanding force allows for the removal of the collapsed vibrator bracket from the female receptacle.

Owner:VIBCO

Wedge-Based Earth-Working Tooth Adapter Retention Assembly

A retention assembly for connecting two pieces of heavy equipment, such as a shovel and a tooth adapter, is described. A slot is formed when the tooth adapter is fit over the end of the shovel. The retention assembly includes an adapter configured to fit into the slot and against the shovel or the tooth adapter. A shim is also in the slot, separated from the adapter by a gap. A wedge nut is also applied to the slot, between the adapter and the shim. The wedge nut is applied to a rod. Movement of the wedge nut along the rod imparts a change in dimension of the gap to bind the retention assembly within the slot and thus secure the tooth adapter on the shovel.

Owner:LOMBARDO PASQUALE +1

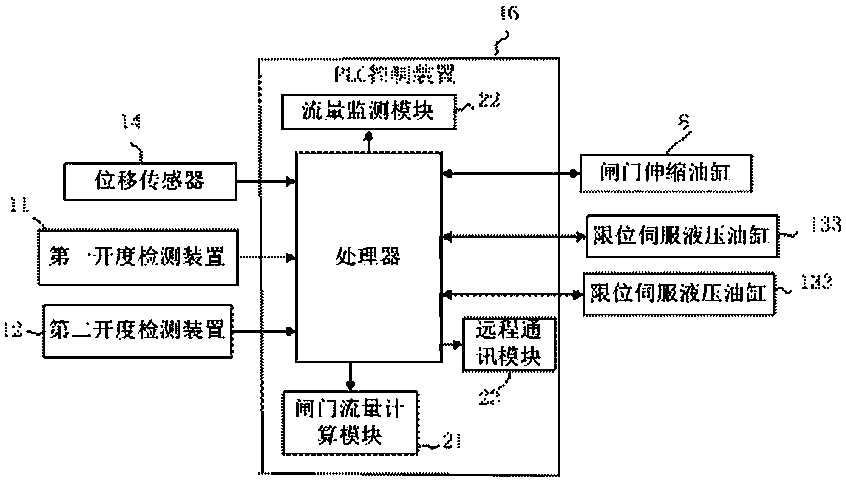

Upturning dam gate capable of realizing instant self-locking control

The invention discloses an upturning dam gate capable of realizing instant self-locking control. The upturning dam gate comprises a gate body whose top is rotationally connected to the top of a closure port, a left embedded bracket, a right embedded bracket, and a wedged base; the top of the gate body is connected to the top of the closure port for rotary opening through a double-lug bracket, a hinge shaft, a gate extension oil cylinder and a tension bracket; limiting modules are connected between the left embedded bracket, the right embedded bracket and the side surfaces of the gate body; anda PLC control device controls the gate extension oil cylinder, a first openness detecting device, a second openness detecting device, two displacement sensors, two limiting servo hydraulic oil cylinders, a gate flow calculating module, a flow monitoring module and a remote communication module. The dam gate is convenient to overturn with labor saving, and can be instantly locked; the gate body with any openness can be controlled to open; the gate flow calculating module can be used for timely calculating the openness of a hydraulic gate with specific flow; and better monitoring performances are achieved.

Owner:李红星 +9

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com