Method of detecting tooth defects of wedges based on edge detection

A technology of edge detection and defect detection, applied in image data processing, instruments, calculations, etc., can solve the problems of slow manual detection, human error, low efficiency, etc., to improve the degree of production automation and product quality, fast detection speed , the effect of accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

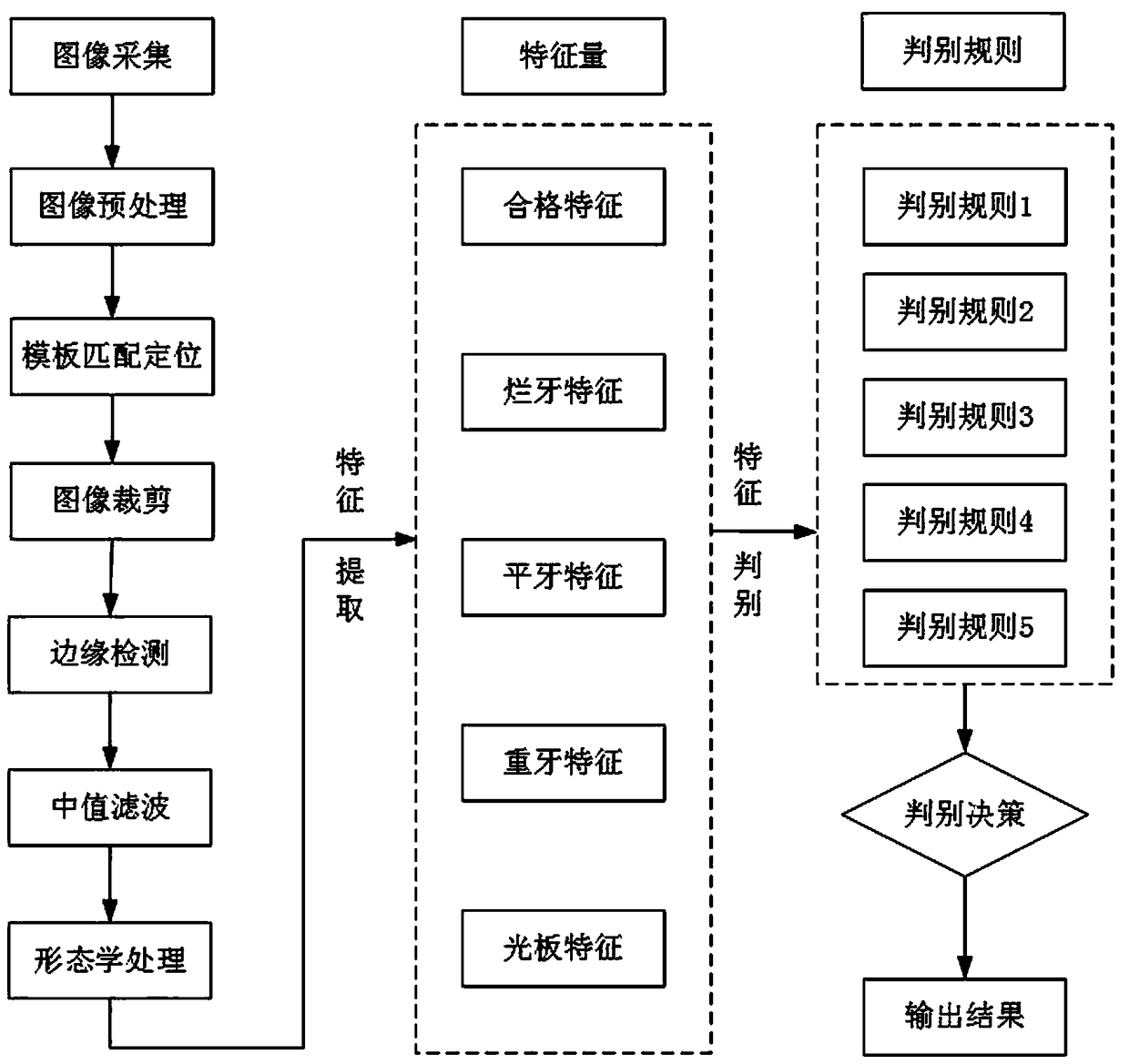

[0044] Such as figure 1 Shown is a method for detecting a clip tooth shape defect based on edge detection, comprising the following steps:

[0045] (1) Image acquisition and preprocessing of the clip workpiece;

[0046] (2) Perform image template matching positioning and image cropping on the workpiece;

[0047] (3) Carry out edge detection to the image;

[0048] (4) Perform median filtering and morphological processing on the image;

[0049] (5) Carry out feature extraction and discrimination.

[0050] In step (1),

[0051] The image acquisition of the clip workpiece is through the forward illumination of a red bowl-shaped diffuse reflection light source, and the image of the clip workpiece is collected by using a CCD industrial camera and an image acquisition card. The image of the workpiece is an RGB image, and then the image of the workpiece is transmitted to the host computer;

[0052] The preprocessing is to perform grayscale conversion and grayscale adaptation on t...

Embodiment 2

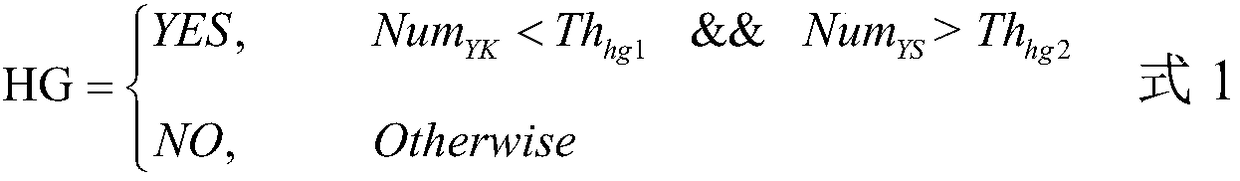

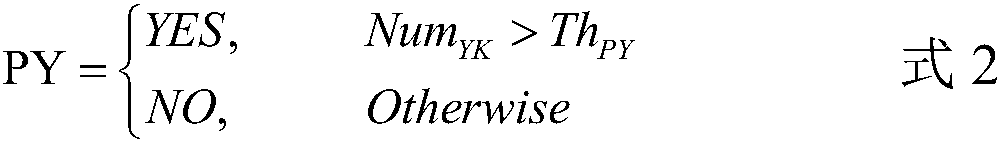

[0081] according to figure 1 In the principle flow chart in the example 1, defect features are extracted through the image processing algorithm in embodiment 1, and a discrimination rule base is formulated through data analysis and statistics.

[0082] Description of the overall process: The clip workpiece to be inspected is transmitted to the inspection station through the feeding mechanism, the photoelectric sensor triggers the camera to take pictures and collects a frame of image and transmits it to the industrial computer in real time, the upper computer performs defect detection through the defect detection algorithm, and reports the detection results Send it to the lower computer through serial communication. The lower computer will eliminate the unqualified products according to the inspection results, and the qualified products will enter the next process, and finally realize the intelligent sorting of the workpieces.

[0083] The invention effectively solves the prob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com