Middle-small modulus gear high-frequency hardening production line automatic control system and method

An automatic control system, high-frequency quenching technology, applied in heat treatment process control, manufacturing tools, furnaces, etc., can solve problems such as damage to human health, low degree of automation, and no infrared temperature measurement system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

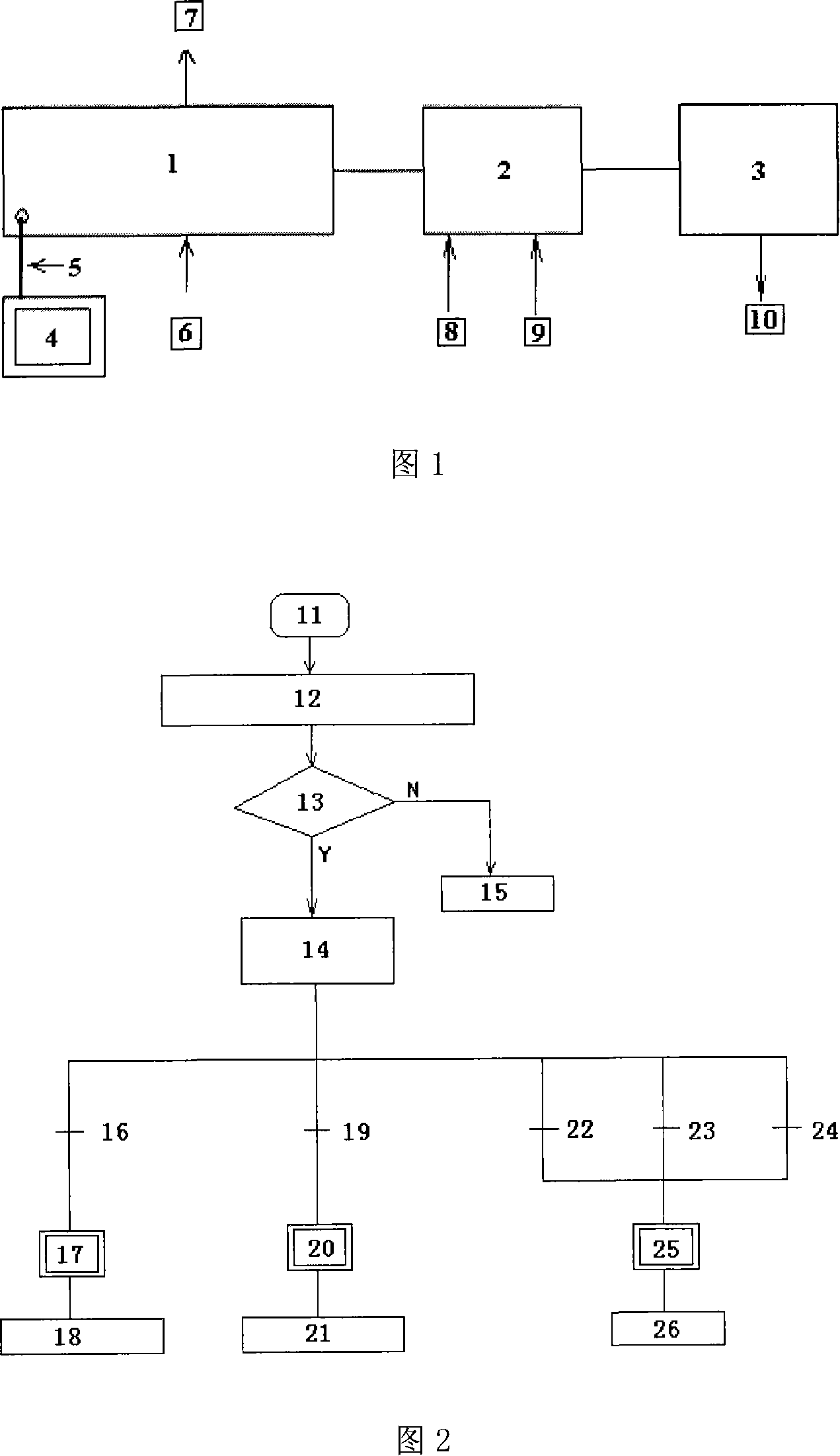

[0088] The embodiment of the automatic control system of the present invention is shown in Figure 1, including a programmable controller PLC host 1, AD function module 2, DA function module 3, and touch screen 4. It is characterized in that the PLC host 1 uses Mitsubishi FX 2N -80MR, the input terminals are respectively connected with the level detection photoelectric switch in the production line, the control buttons and limit switches of the pneumatic manipulator and the quenching machine tool, the high-frequency power failure signal output terminal and the operation panel selection switch 6, which can collect the production line The output terminals are respectively connected with the AC contactor of the trapezoidal feeding mechanism in the production line to realize automatic feeding control, and are connected with the frequency converter of the material conveying mechanism (conveyor belt 1 and conveyor belt 2) in the production line to realize the pressing The speed set by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com