Gear quenching equipment special for hoisting forklift

A technology for quenching equipment and gears, which is applied in the field of gear quenching, can solve the problems of easy wear of teeth, reduce gear quality, shorten service life, etc., and achieve the effect of eliminating internal micro-fission, preventing excessive deformation and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

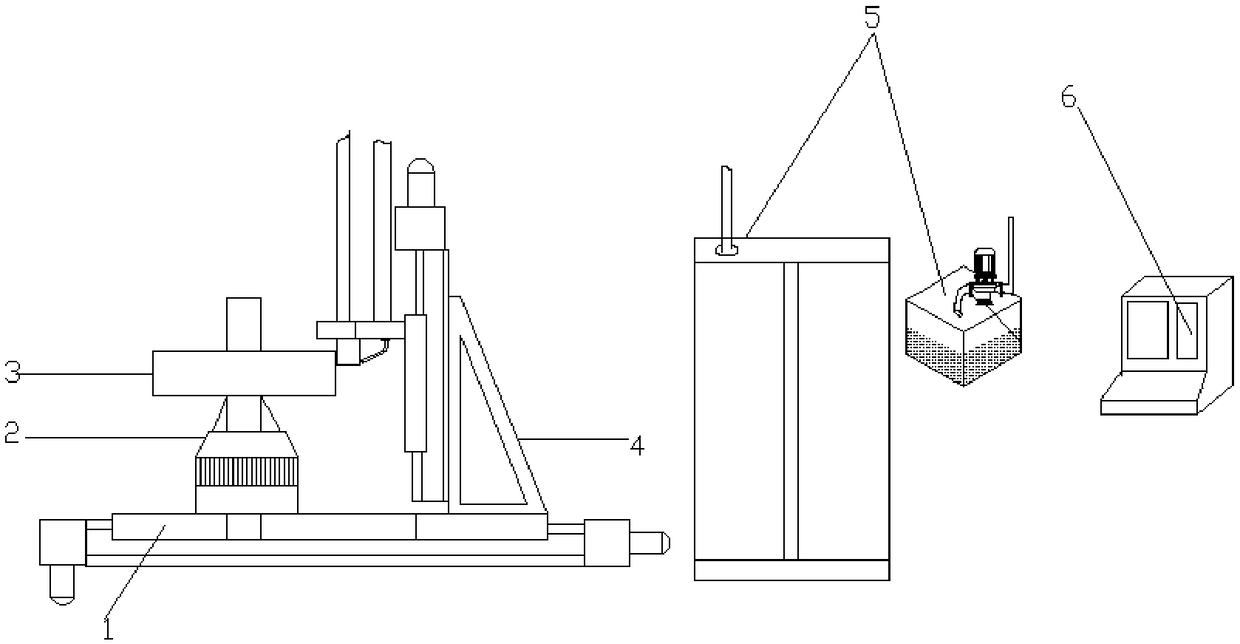

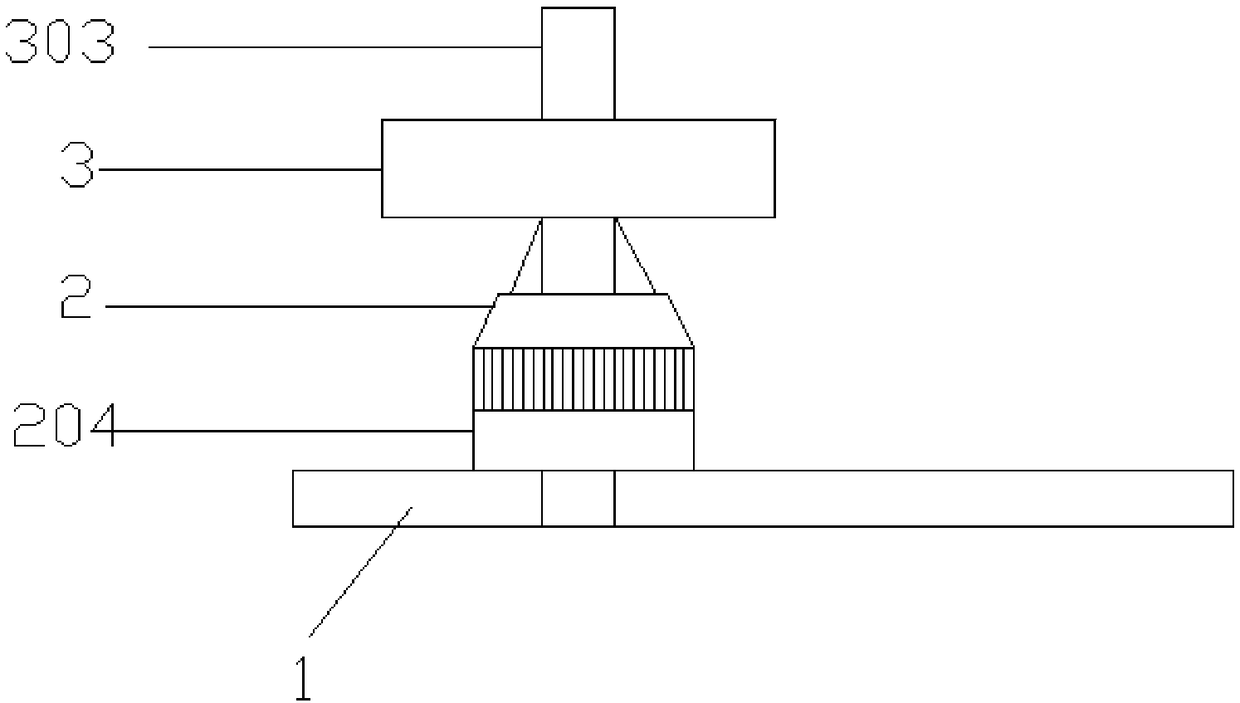

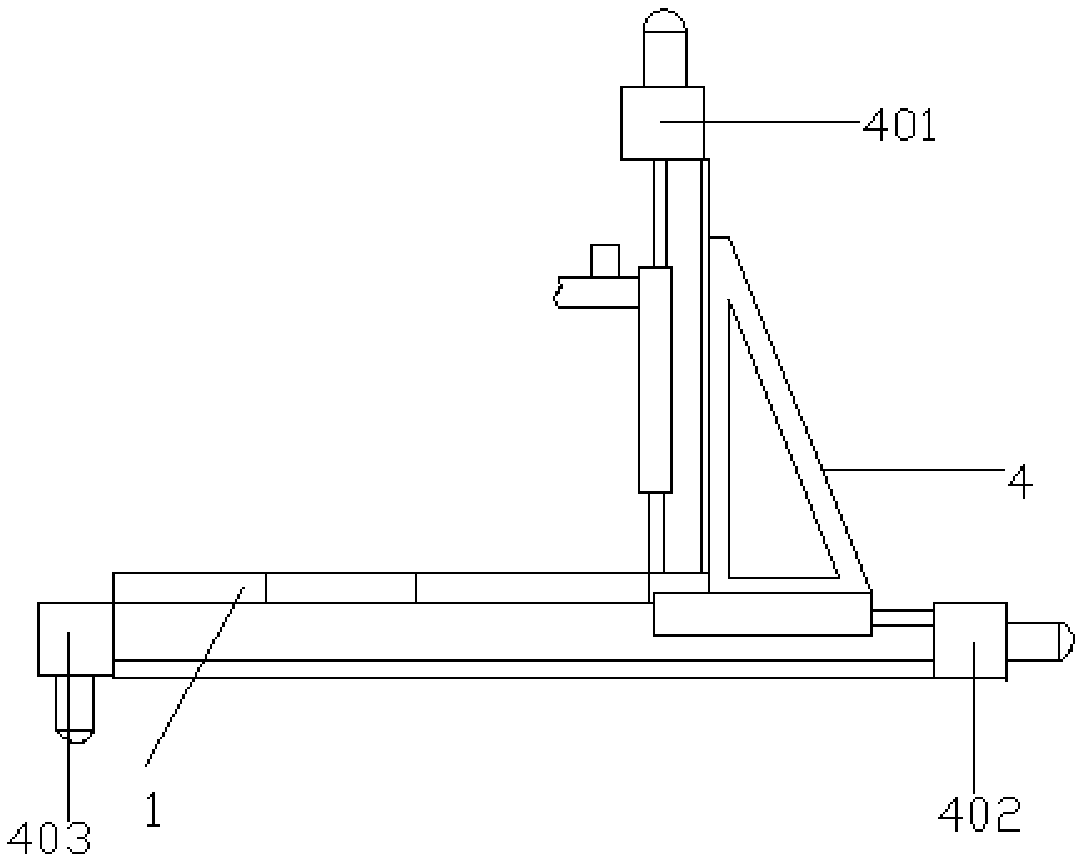

[0065] In actual use, the clamping and positioning device 2 fixes and clamps the shaft 303 of the gear 3 on the chuck 204 of the platform on the base 1, and the gear attitude adjustment system 4 adjusts the platform on the base 1, wherein the user respectively passes X The direction adjustment mechanism 402 or the Y direction adjustment mechanism 403 or the Z direction adjustment mechanism 401 adjusts the distance and gap between the induction heater 5011 and the gear teeth 301, and aligns the position of the induction heater 5011 with the position where the gear teeth 301 need to be quenched ( Gear tooth load surface 302), the controller uses the transformer 5012 to control the quenching equipment to quench the gear teeth 301 according to the quenching parameter requirements, and adjusts the induction frequency and voltage and current output parameters of the transformer 5012 or induction heater 5011 according to the quenching requirements. At the same time, The controller als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com