Hot melting bonding processing system and process of environment-friendly multilayer fiber composite felt

A multi-layer fiber and composite material technology, applied in adhesives, textiles and papermaking, non-woven fabrics, etc., can solve the problems of increased manpower, lack of integrated planning of composite materials, low degree of automation, etc., and achieve the effect of improving the degree of production automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

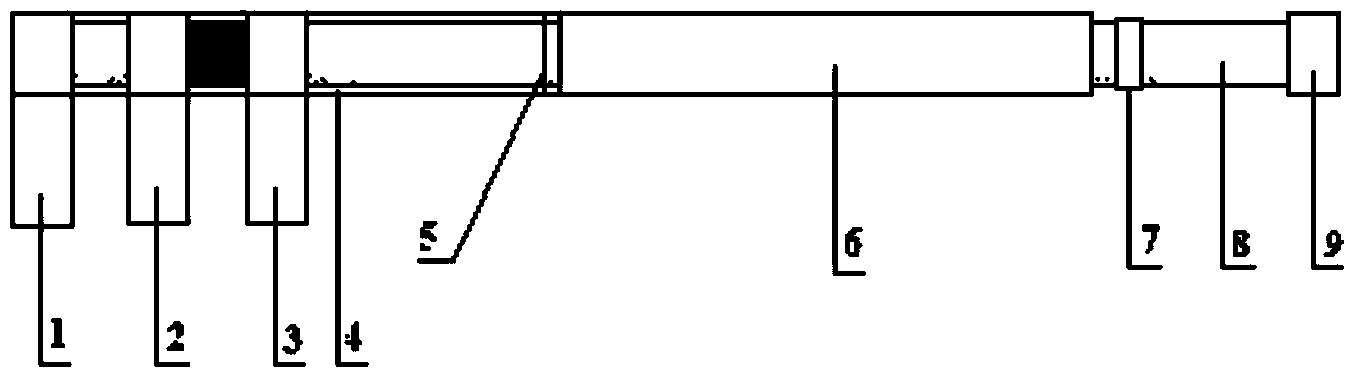

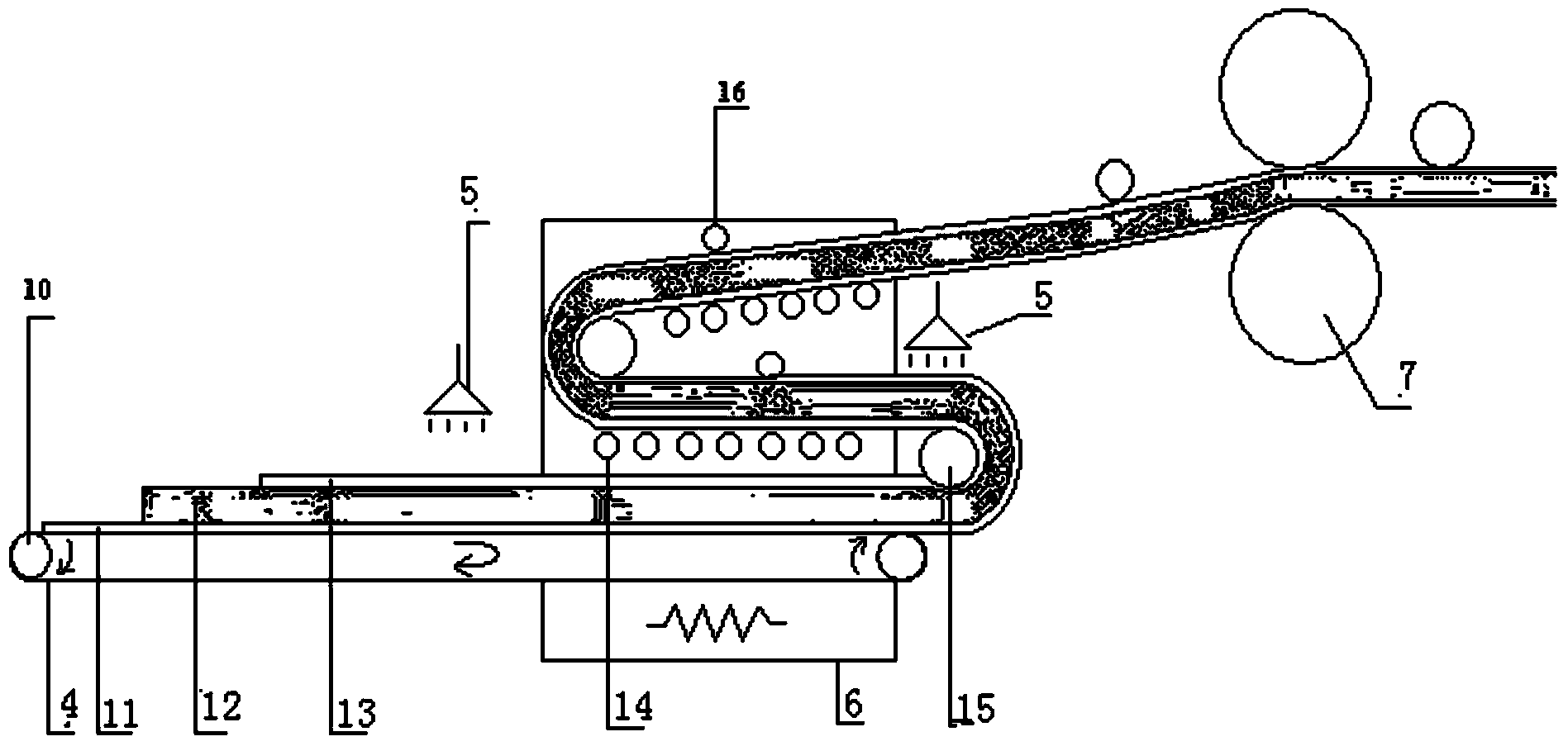

[0028] As shown in the figure, the hot-melt bonding processing system for the environment-friendly multi-layer fiber composite material mat includes a plurality of parallel fiber web generating devices, the fiber web generating device is connected to the oven 6 through the bottom curtain 4 below it, and the bottom curtain 4 is set There is a drive structure 10, and the oven 6 is extended to the winding device 9 through the hot pressing device. The oven 6 is provided with a fabric guide roller 15 and a support delivery roller 14 that wind the multi-layer fiber web sent from the bottom curtain into an S shape. The hot pressing device is a pair of heating and pressing rotating rollers 7, and the fiber web generating device includes an opening device, a carding device and a web laying device connected in sequence. The oven 6 is provided with a spraying device 5 for spraying additives on both sides of the fiber web. There are three fiber web generating devices, namely fiber web gen...

Embodiment 2

[0039] The hot-melt bonding processing system for the environment-friendly multi-layer fiber composite material mat includes multiple parallel fiber web generating devices, the fiber web generating device is connected to the oven 6 through the bottom curtain 4 below it, and the bottom curtain 4 is provided with a driving structure 10, The oven 6 passes through the hot pressing device and extends to the winding device 9. The oven 6 is provided with a fabric guide roller 15 and a supporting conveying roller 14 that wind the multi-layer fiber web sent from the bottom curtain into an S-shape. The hot pressing device It is a pair of heated and pressurized rotating rolls 7, and the fiber web forming device includes an opening device, a carding device and a web laying device connected in sequence. There are two fiber web generating devices, which respectively produce fiber webs made of surface layer material fibers and fiber webs made of core layer material fibers. The web laying met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com