Synchronizing device of aerated concrete block side face cutting machine

A technology of aerated concrete and synchronization device, which is applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., and can solve the problem of not having a synchronization device for plate knives of side cutters, which cannot meet the requirements of existing products, construction technology, cutting It is difficult to guarantee the dimensional accuracy of the green body and other problems, so as to achieve the effects of easy maintenance and repair, improved timeliness and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

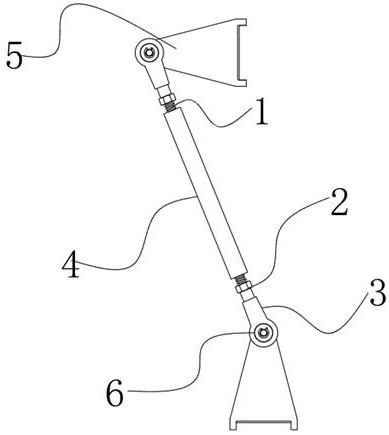

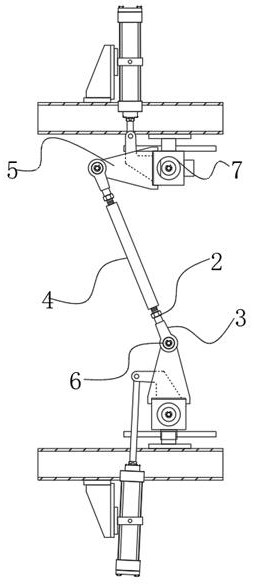

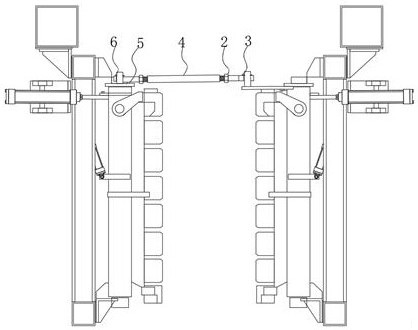

[0015] refer to Figure 1-3 , a synchronous device for aerated concrete block side cutting machine, comprising a hollow connecting rod 4, the inner side of the hollow connecting rod 4 is provided with an internal thread, and both ends of the hollow connecting rod 4 are threadedly connected with a threaded rod 1, two threaded rods 1. A joint bearing 3 is provided at the end far away from the hollow connecting rod 4, and pin rods are inserted in the bearing holes of the two joint bearings 3, and both pin rods are connected with a seat plate 5.

[0016] In the present invention, the two pin rods are provided with annular clamping grooves, and the spacers 6 are clamped i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com