Powder material processing and integration device

An integrated device and powder material technology, which is applied in the integrated equipment of automatic discharge and dust removal, screening, powder collection material feeding, and mixing fields, can solve the problems of low labor efficiency, low efficiency, and poor working environment, etc. Reach the effect of reducing production cost, improving working environment and reducing dust volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

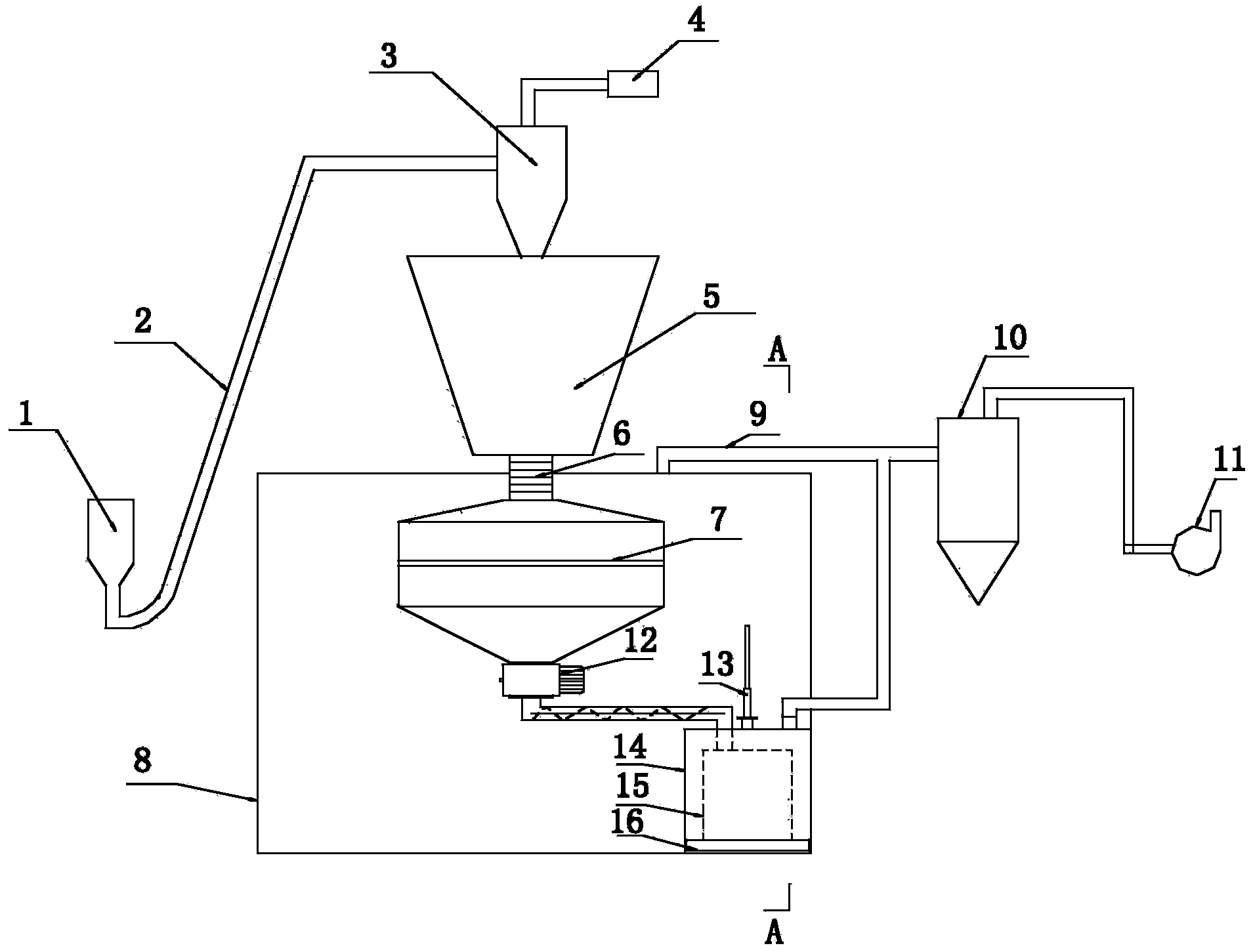

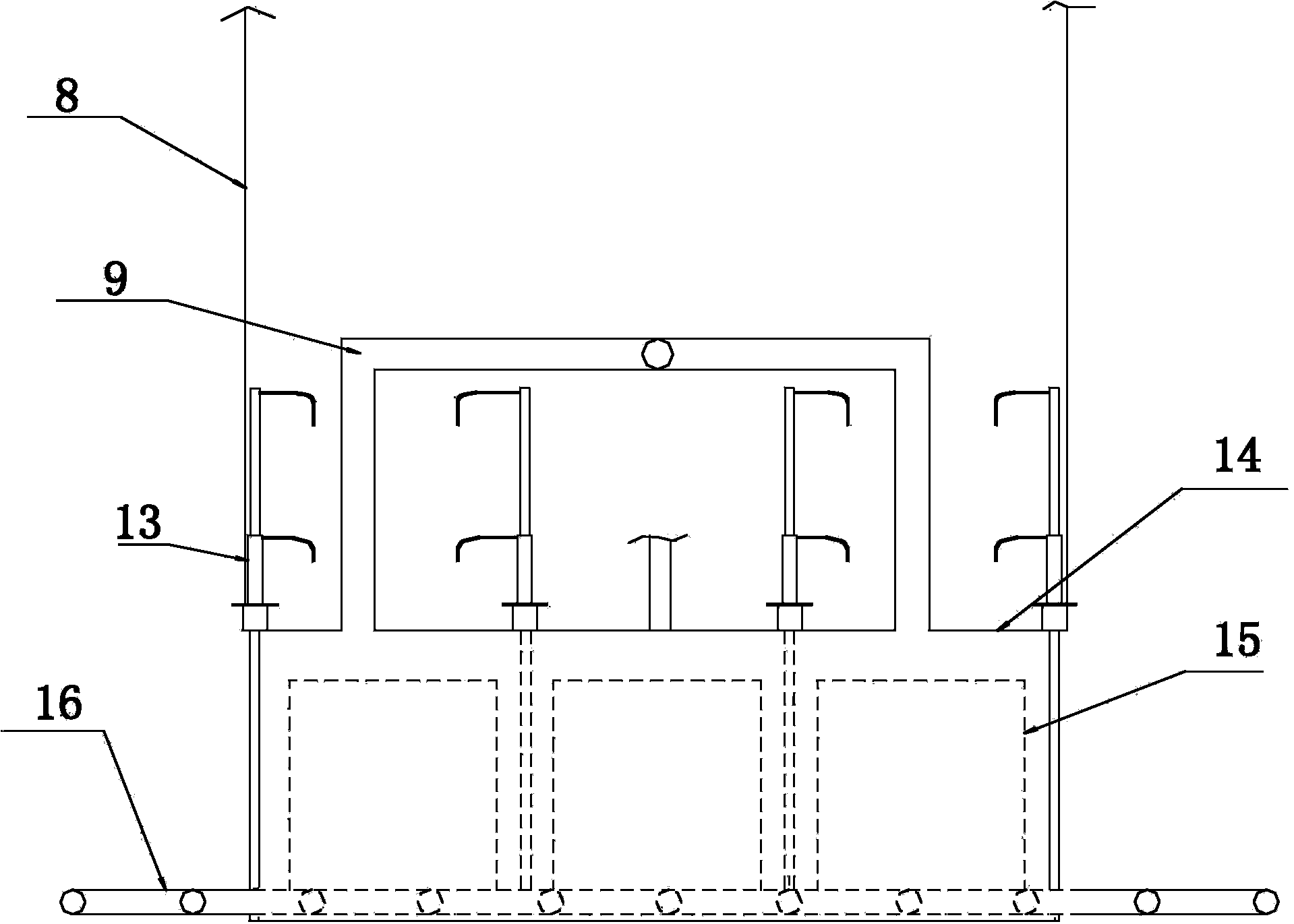

[0018] figure 1 with figure 2 The reference signs in the figure are: floor material bin 1, material conveying pipe 2, negative pressure bin 3, vacuum pump 4, mixing bin 5, flexible connecting pipe 6, grading screen 7, airtight chamber 8, dust removal pipe 9, dust removal box 10 , Fan 11, quantitative discharge valve 12, sealing partition 13, discharge bin 14, barrel 15, frequency conversion speed regulation metering conveyor 16.

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. Such as figure 1 As shown, the powder material processing integrated device of the present invention is provided with a floor material bin 1, a material delivery pipeline 2, a negative pressure bin 3, a mixing bin 5, a flexible connecting pipe 6, a grading screen 7, and a quantitative discharge unit that are sequentially sealed and connected. Valve 12 and discharge bin 14.

[0020] The vacuum pump 4 is located at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com