Rail clamping device

A rail-clamping and wedge-shaped technology, applied in transportation and packaging, brakes interacting with the rails, railway car body parts, etc. , the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

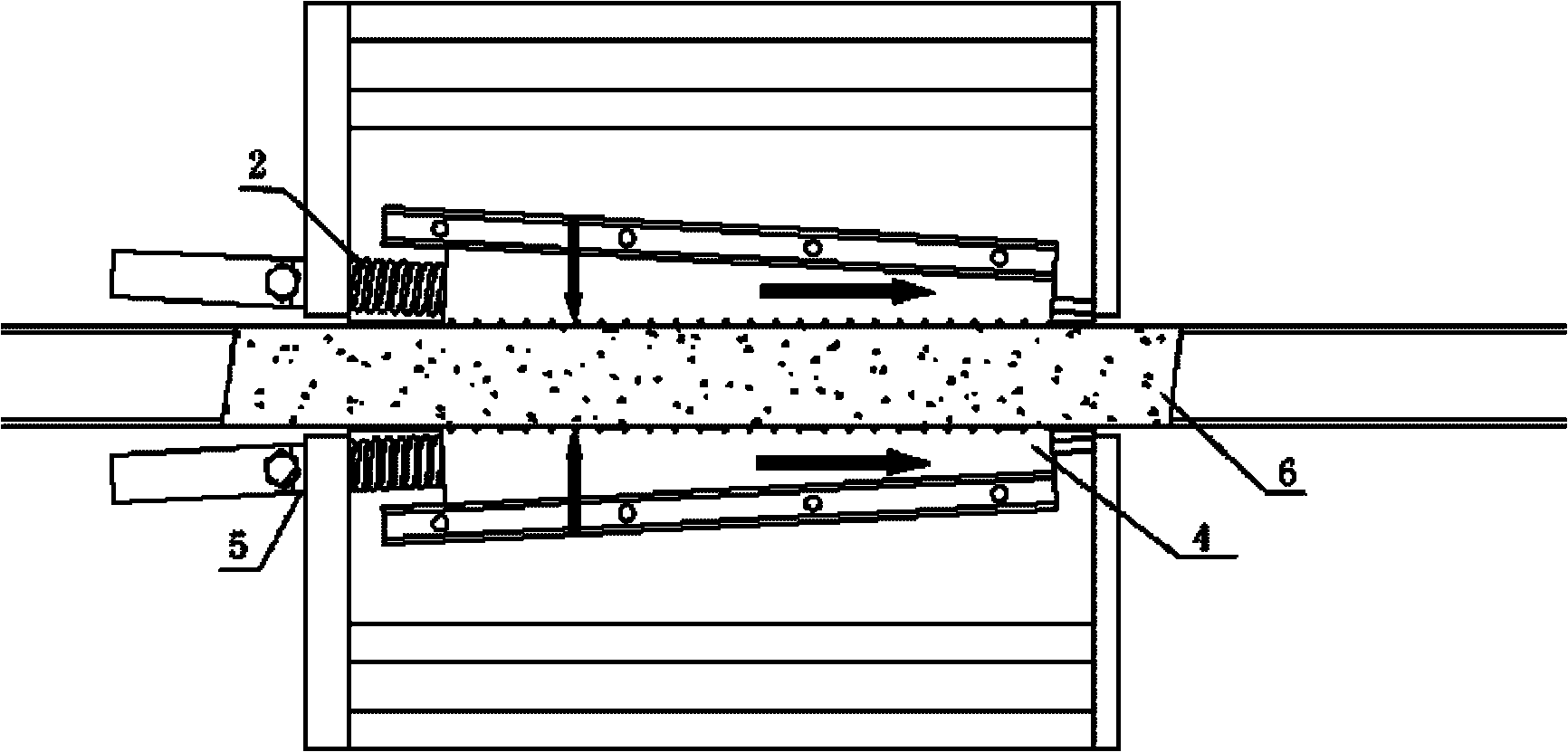

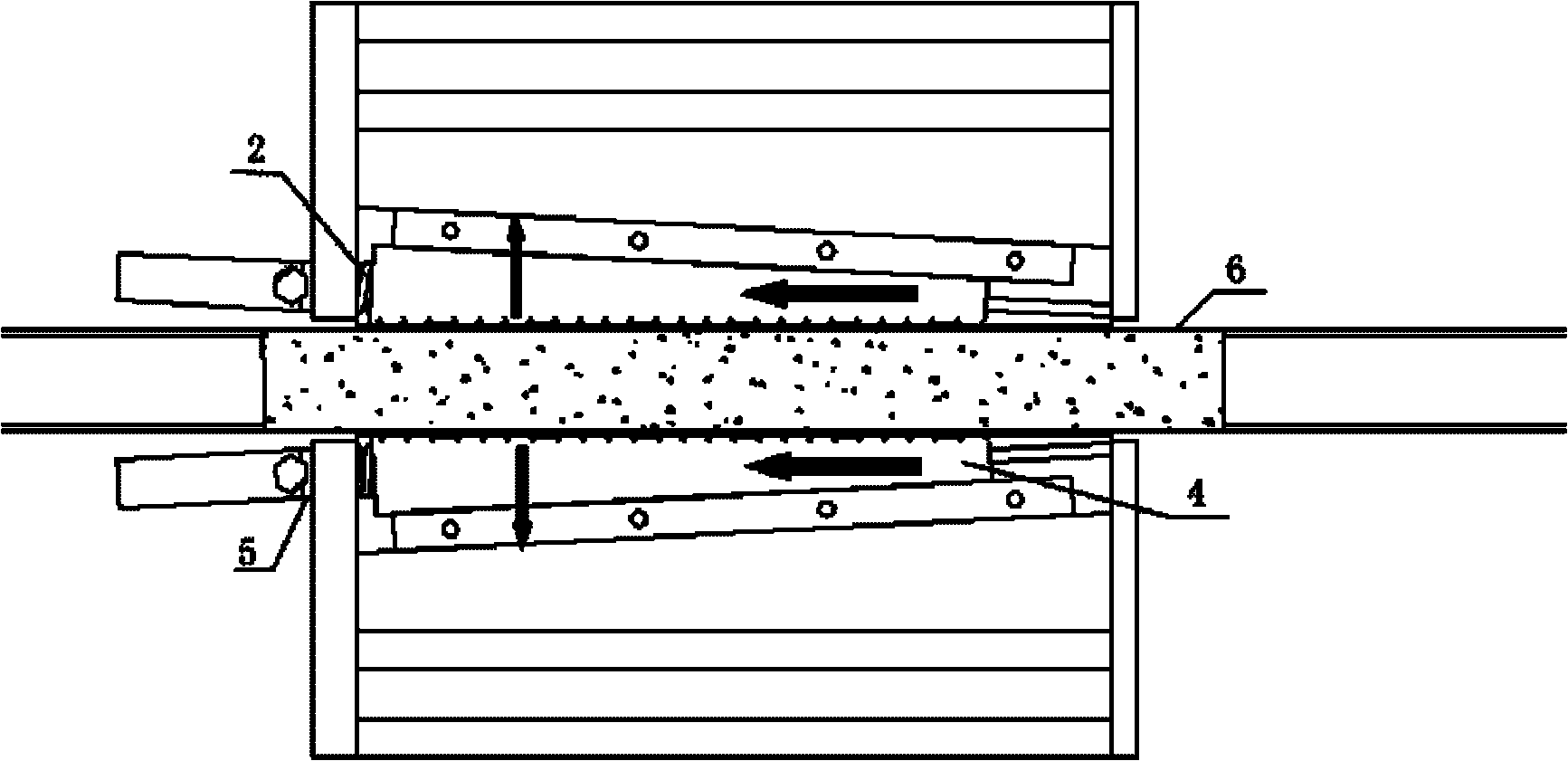

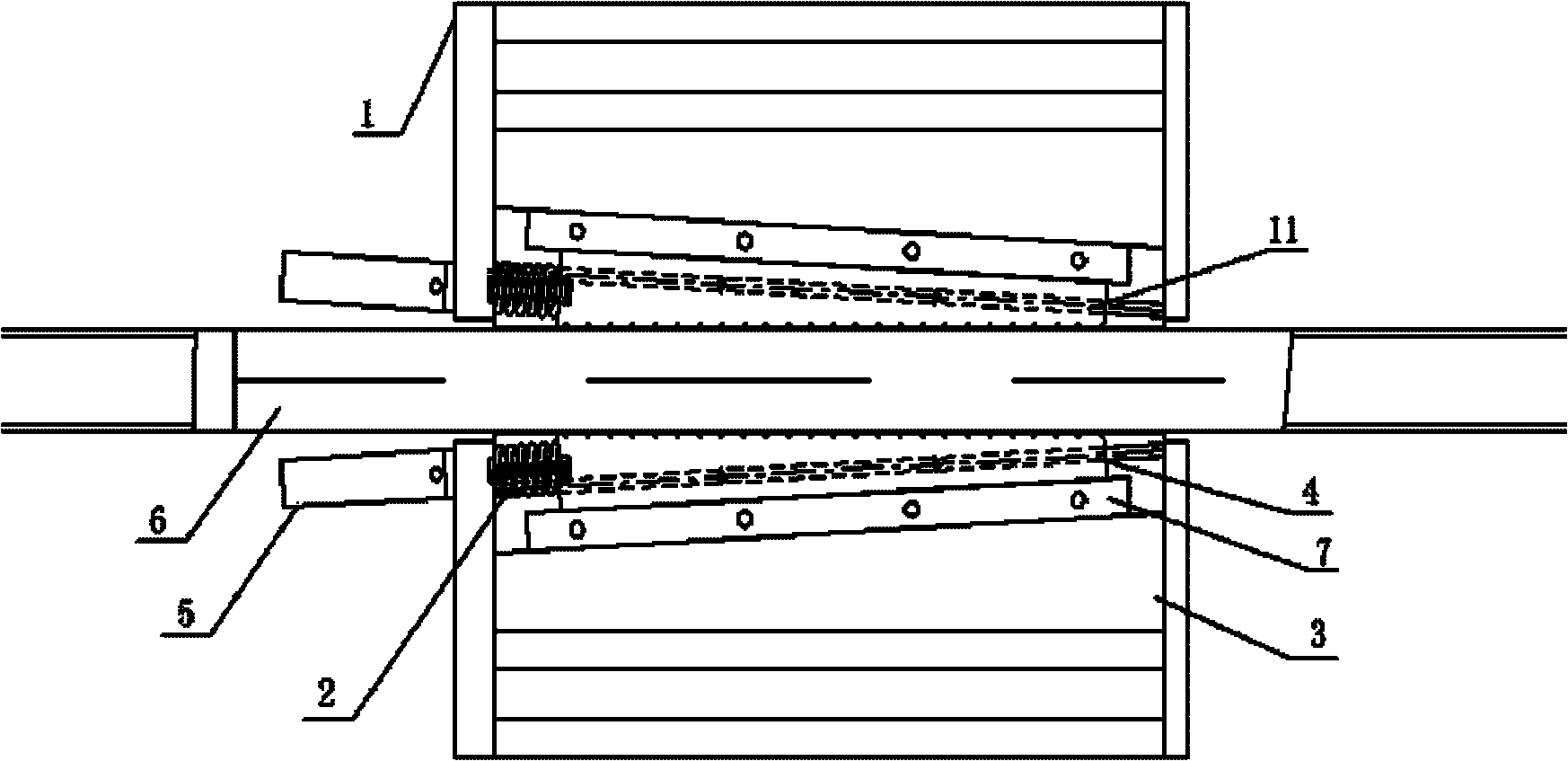

[0023] Such as Figure 1-3 , is a schematic diagram of the structure of the rail clamping device, the rail clamping device includes a housing 1, the inside of the housing 1 is a wedge-shaped base 3, the inside of the wedge-shaped base 3 is a wedge-shaped block 4, and the wedge-shaped block 4 and the wedge-shaped base 3 are arranged Slide block 7. As can be seen in the figure, there are two wedge-shaped bases 3, wedge-shaped blocks 4 and stoppers 7, and every two wedge-shaped bases, wedge-shaped blocks and sliding pads are mirror images. The wedge block 4 is equipped with a sliding guide 11 . A back-moving spring 2 is installed on the top of one side of each wedge block 4 . A single-acting oil cylinder 5 is installed outside the housing on which the return spring 2 is installed. The track 6 passes between the two wedge blocks, and the track equipment is stopped by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com