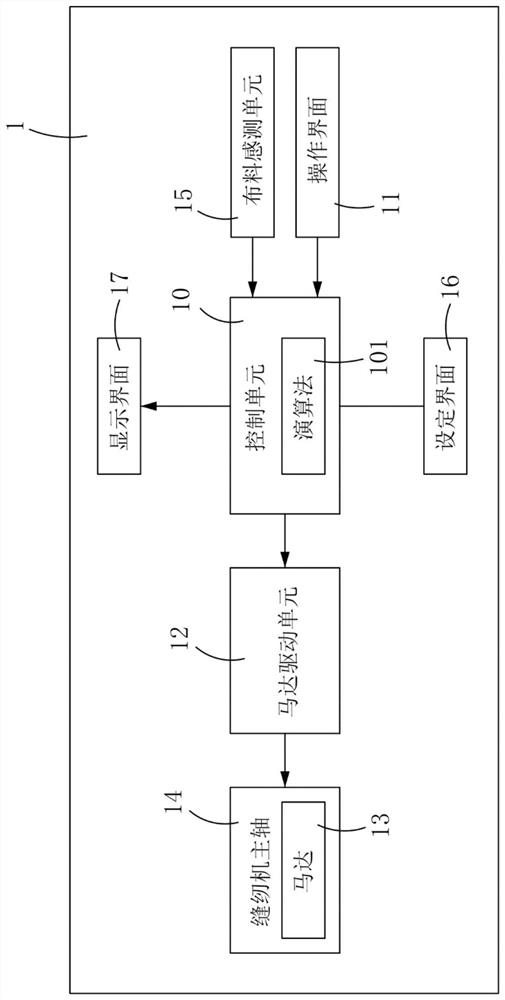

Sewing machine with automatic control mechanism and its automatic control method

A sewing machine and mechanism technology, applied in the field of sewing machines, can solve problems such as the degree of fatigue of technicians in accelerated operations, and achieve the effect of avoiding damage to sewing machines and maintaining production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

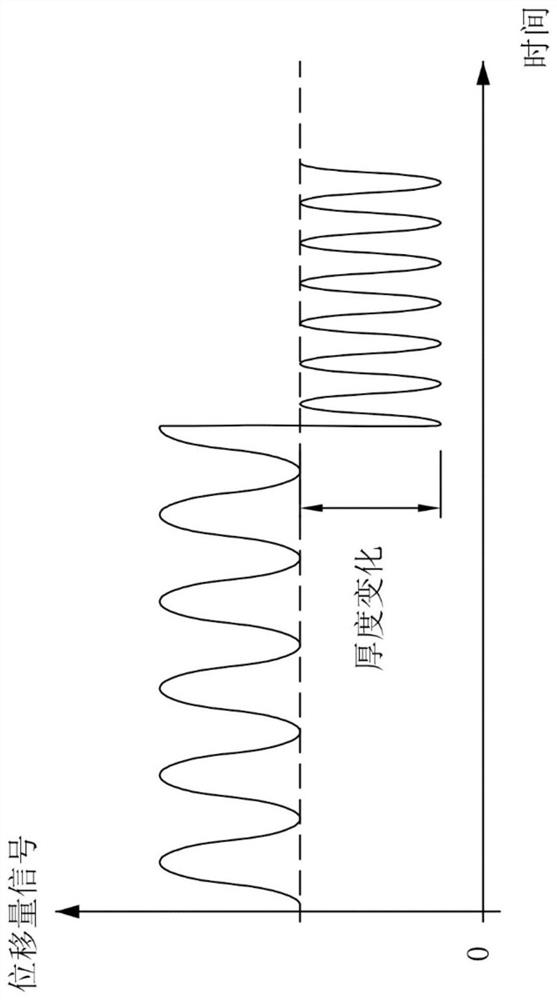

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

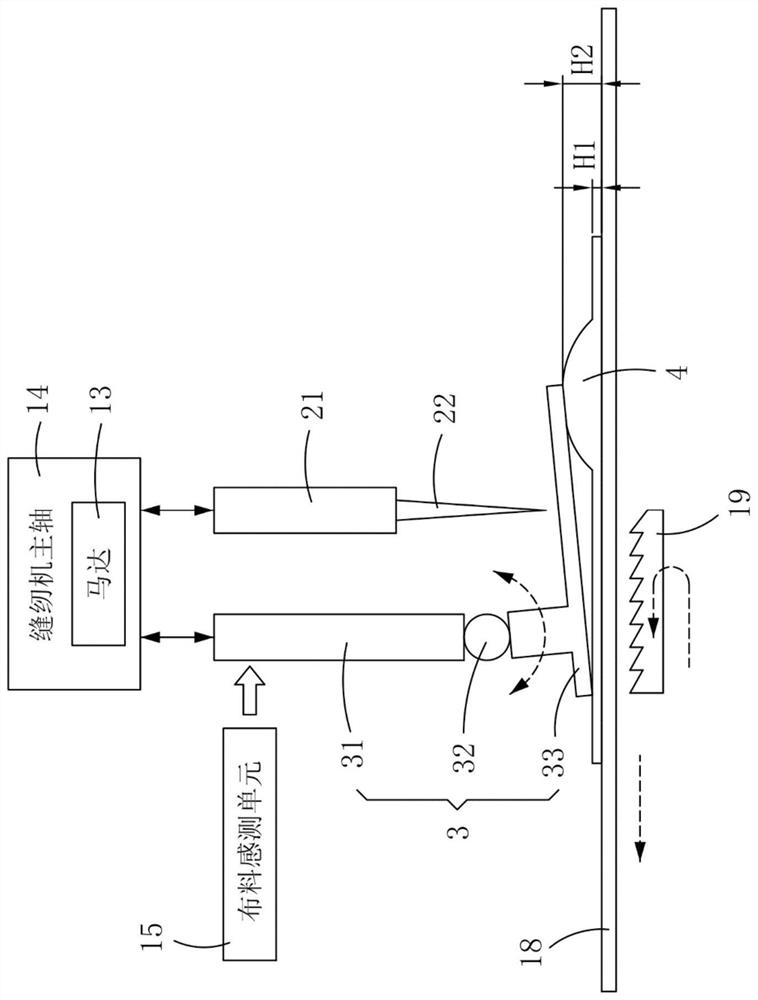

[0088] Such as figure 2 As shown, the sewing machine 1 of the present invention also has a platform 18 arranged horizontally, and the platform 18 is used to place the cloth 4 to be sewed. As mentioned above, the motor 13 of the sewing machine 1 is mainly installed in the main shaft 14 of the sewing machine, and the main shaft 14 of the sewing machine is connected to the needle bar 21 vertically arranged on the platform 18 through a linkage member (not shown in the figure), and the needle bar 21 is positioned close to the platform. One end of 18 is provided with the sewing needle 22 . When the motor 13 is in operation, it can drive the sewing machine main shaft 14, and the sewing machine main shaft 14 can drive the needle bar 21 and the sewing needle 22 to move up and down, thereby sewing the cloth 4 on the platform 18 through the sewing needle 22.

[0089] Such as figure 2 As shown, the bottom surface of the platform 18 is provided with a cloth feeding dog 19 , and the clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com