Patents

Literature

33results about How to "Realize stamping and forming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

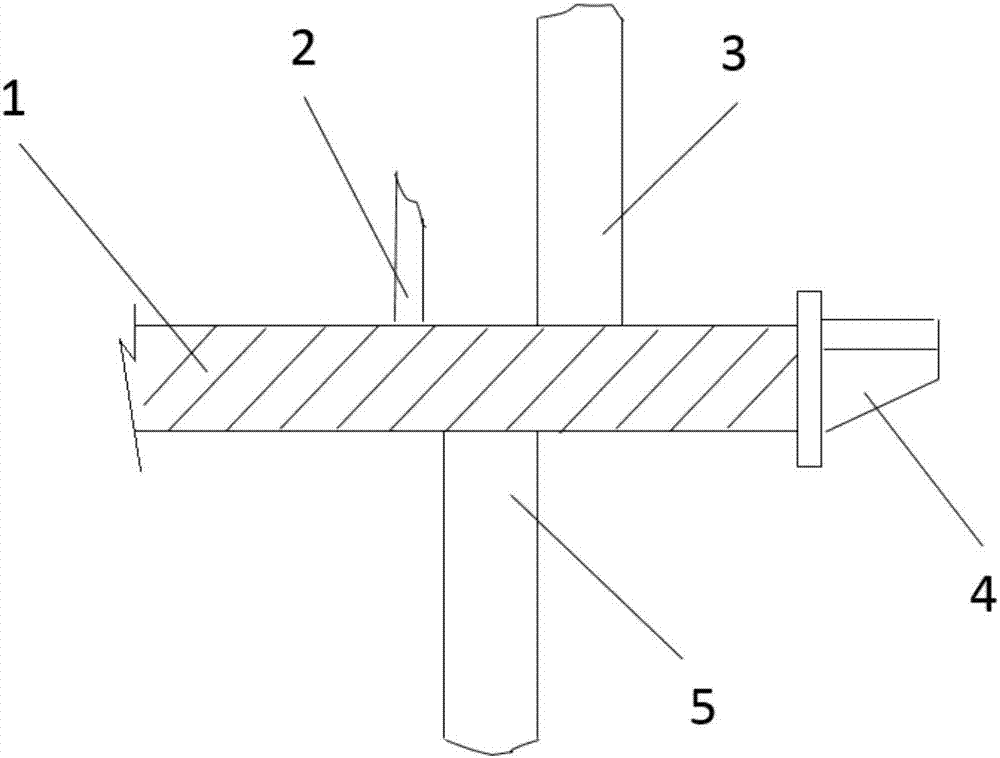

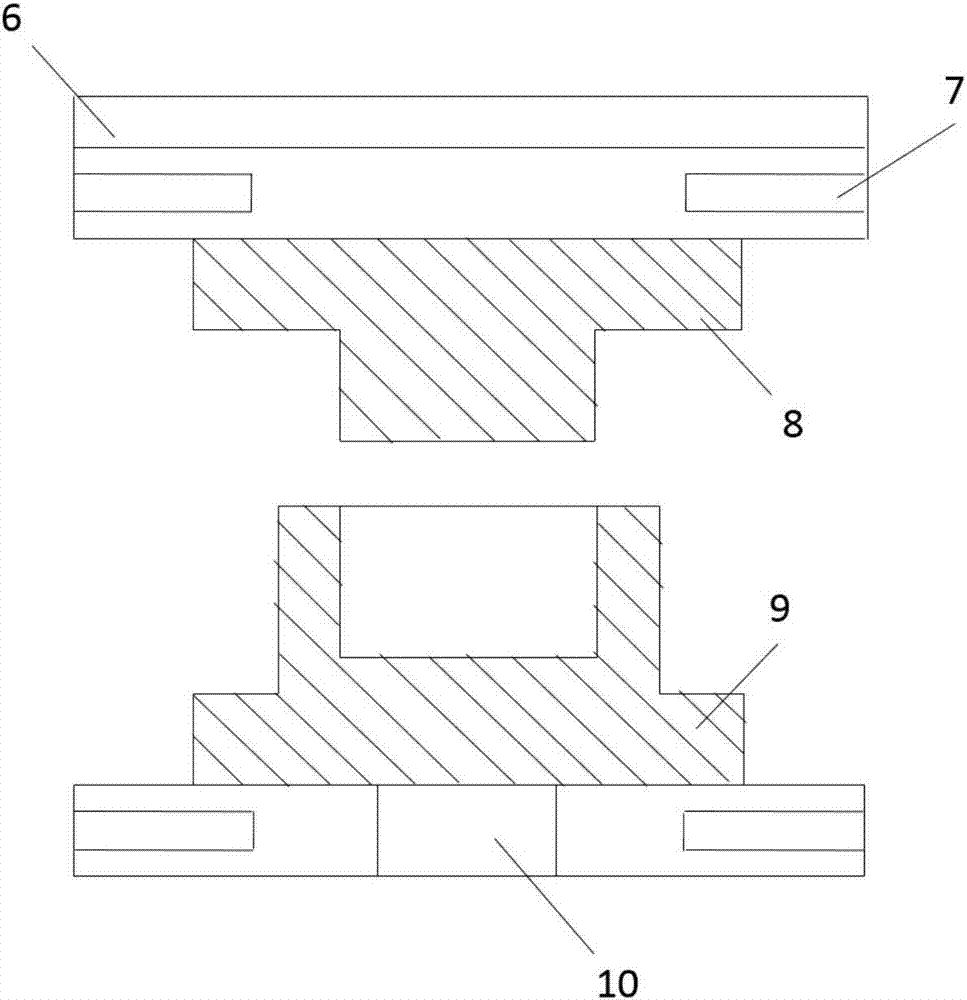

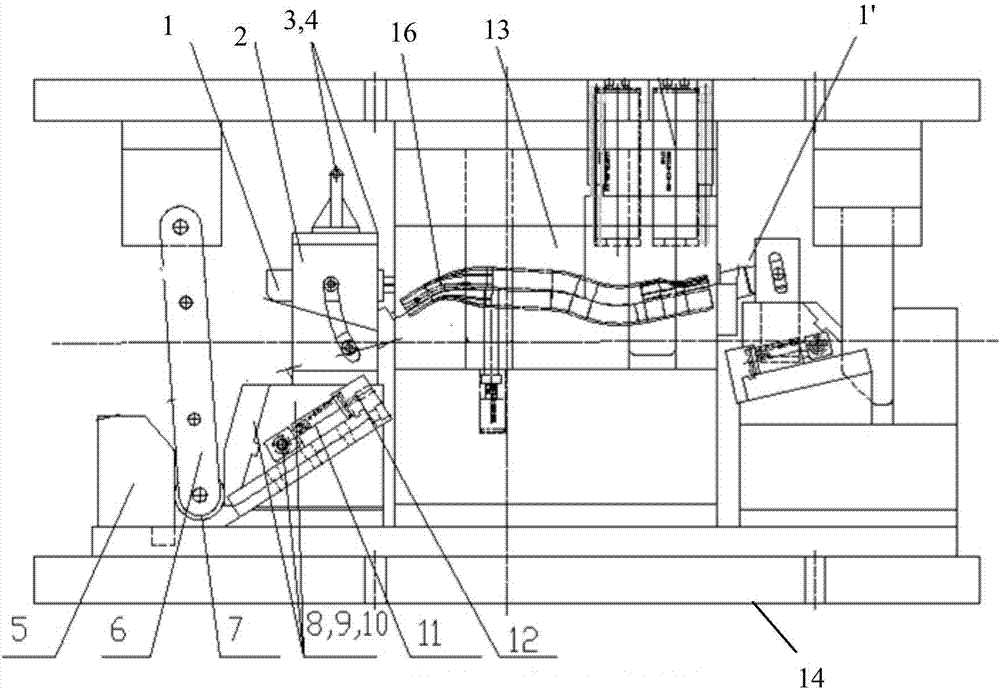

Thin-wall sheet metal part stamping molding method

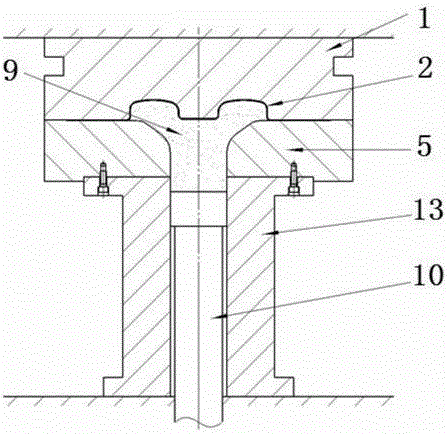

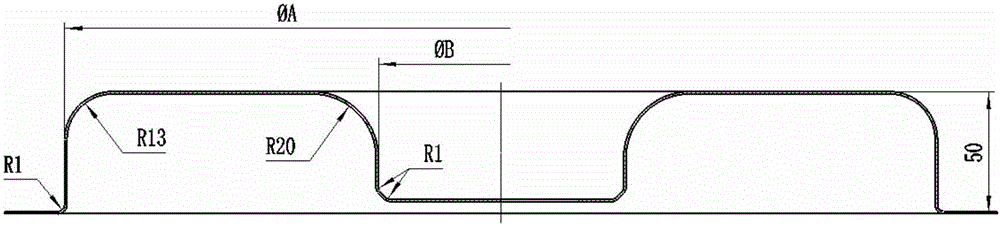

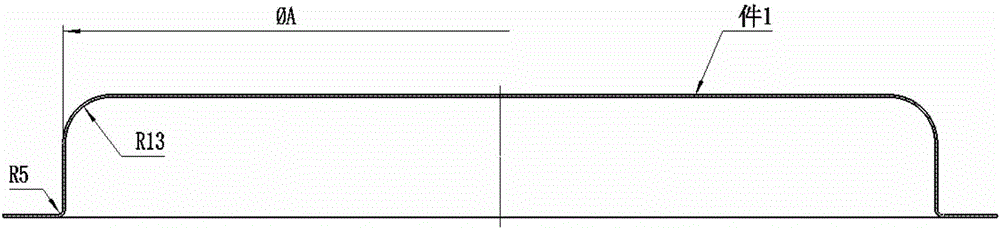

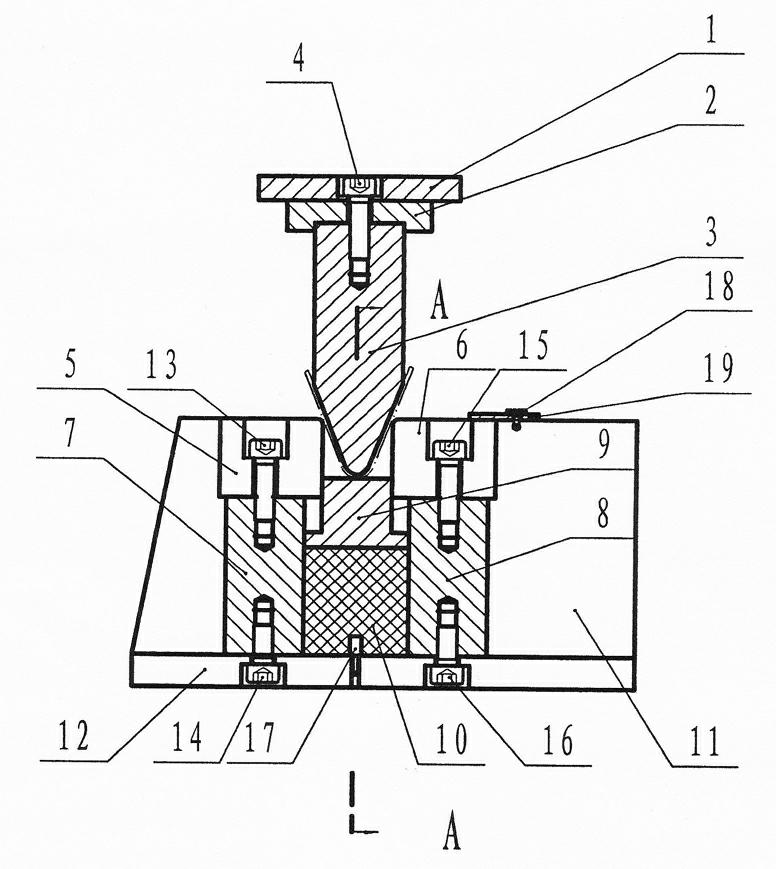

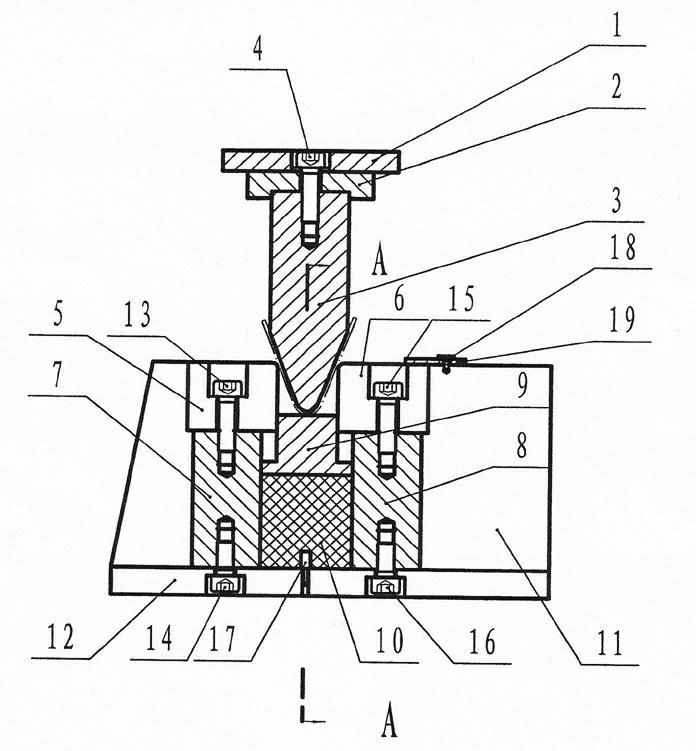

The invention discloses a thin-wall sheet metal part stamping molding method which comprises the following steps: firstly, pre-machining a general outline of an overall thin-wall sheet metal part blank in a front procedure, and performing stamping molding machining on a half finished product of the thin-wall sheet metal part to be machined by using a special overall stamping molding correction mold, thereby obtaining a qualified product, wherein the special overall stamping molding correction mold consists of a concave mold (1), a thin-wall sheet metal part (2), a piston cylinder (13), a lower mold plate (5), a cavity (9) and a step-up piston (10); the cavity (9) for accommodating a viscous medium is formed in the center of the lower mold plate (5); the step-up piston (10) for exerting pressure to the viscous medium is arranged on the cavity (9). By adopting the thin-wall sheet metal part stamping molding method, overall stamping molding is achieved, argon arc welding joints are avoided, the part appearance and surface quality can be improved, and potential safety hazard can be eliminated. The thin-wall sheet metal part stamping molding method has relatively great predictable economic values and social values.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

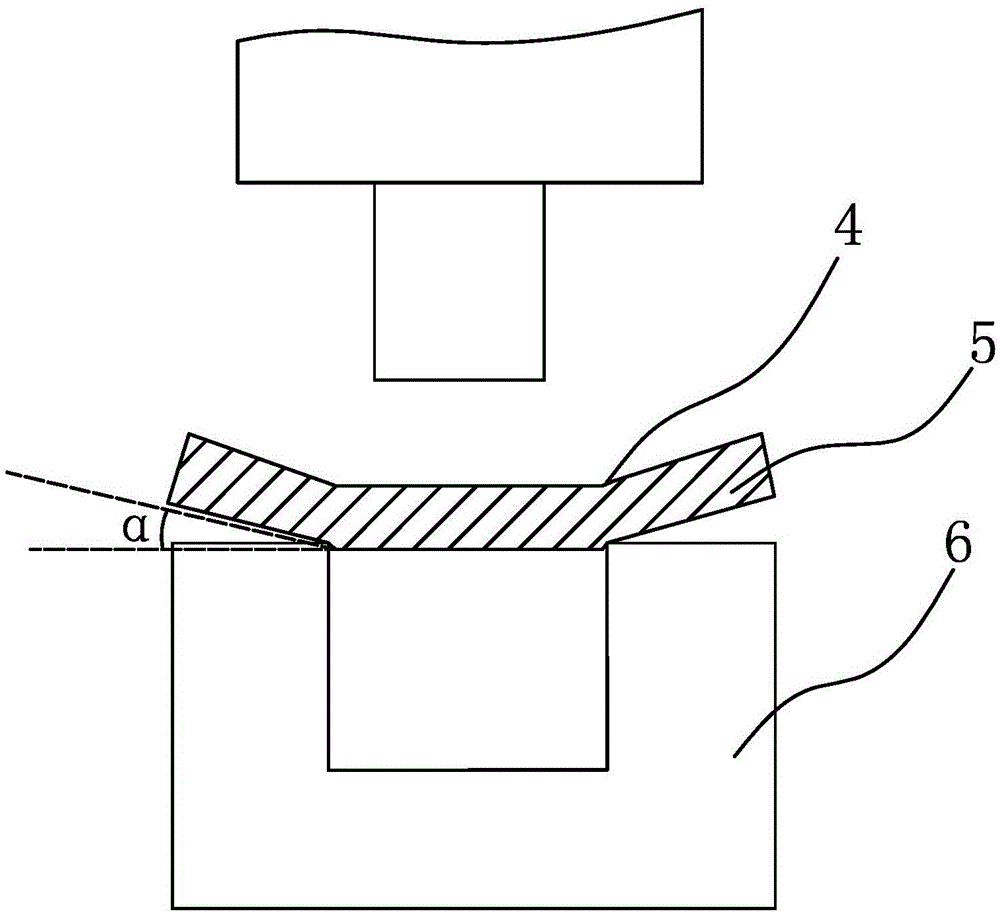

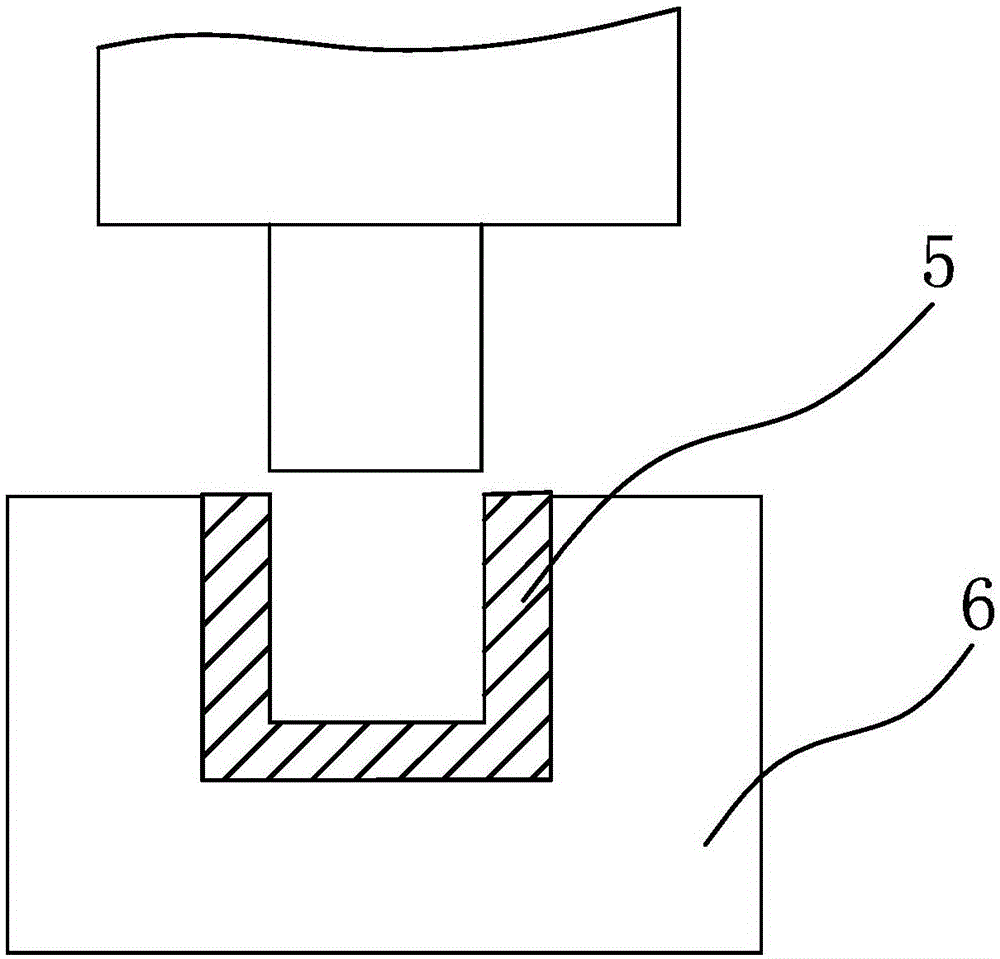

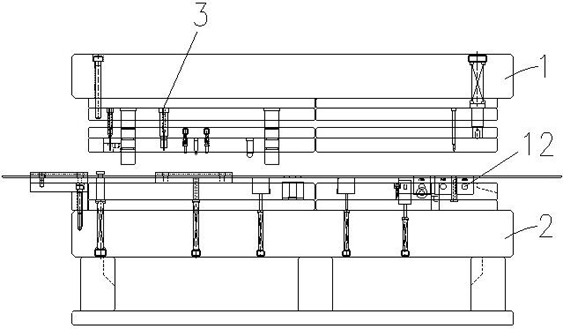

Bending die of multi-angle V-shaped workpiece

The invention discloses a bending die of a multi-angle V-shaped workpiece, which comprises an upper die; the bending die of multi-angle V-shaped workpiece is characterized in that a lower die comprises two upper concave die blocks and two lower concave die blocks, a workpiece propping plate, an elastic cushion, concave die fixing seats and a lower die seat, wherein steps at two sides of the lower part of the reversed T-shaped workpiece propping plate are identical with a step between the inner side surfaces of the upper block and the lower block of the concave dies, so as to ensure that the workpiece propping plate can move up and down; and the elastic cushion is mounted under the workpiece propping plate. When the bending die is used, plates to be processed are arranged on the upper planes of the two upper concave die blocks; an upper die moves downwards; the plate is gradually pushed to downwards move to form through a convex die; after the plate is formed, the upper die moves upwards; the workpiece propping plate moves upwards to prop the formed workpiece out by the effect of elasticity of the elastic cushion; the multi-angle V-shaped workpiece can be punched and formed by adjusting the downward shifting distance of a sliding block of a punch press; and the bending die of the multi-angle V-shaped workpiece has the advantages of good commonality, convenience for operation, and high production efficiency.

Owner:HENGYANG FENGSHUN AXLE CO LTD

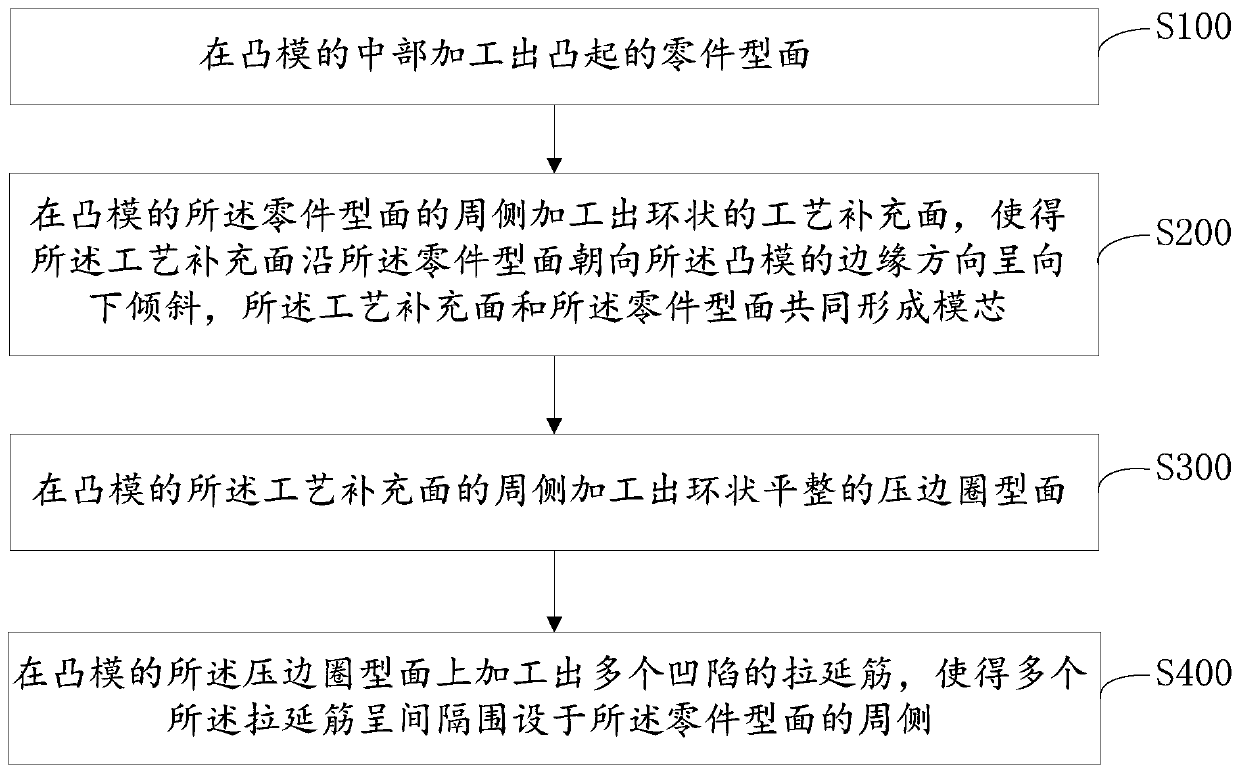

Manufacturing process method of aluminum alloy stamping die surface

ActiveCN111570600AReduce chip outputImprove molding qualityShaping toolsStamping processAluminium alloy

The invention discloses a manufacturing process method of an aluminum alloy stamping die surface. The manufacturing process method includes the following steps that a protruding part profile is machined in the middle of a male die; an annular process supplementing surface is machined on the circumferential side of the part profile of the male die, so that the process supplementing surface inclinesdownwards in the direction towards the edge of the male die along the part profile, and the process supplementing surface and the part profile jointly form a die core; an annular flat edge pressing ring profile is machined on the circumferential side of the process supplementing surface of the male die; and a plurality of concave drawing ribs are machined on the edge pressing ring profile of themale die, so that the drawing ribs are annularly arranged on the circumferential side of the part profile at intervals. By setting a gentle edge pressing ring and the inclined process supplementing surface and formulating a slight drawing process scheme, punch forming of an aluminum alloy is realized; and by adopting the partition type drawing ribs, the portion, between every two adjacent drawingribs, of the edge pressing ring profile is flat, and therefore the output in metal removal in the aluminum alloy stamping process can be effectively reduced, and then the forming quality of the aluminum alloy is improved.

Owner:DONGFENG LIUZHOU MOTOR

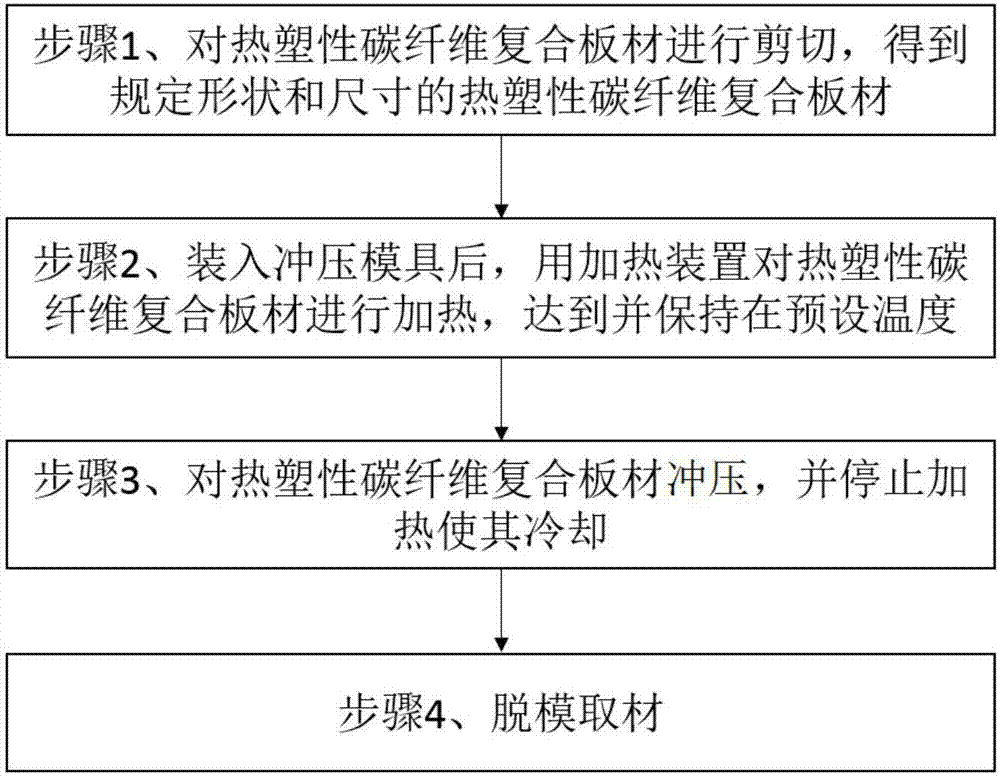

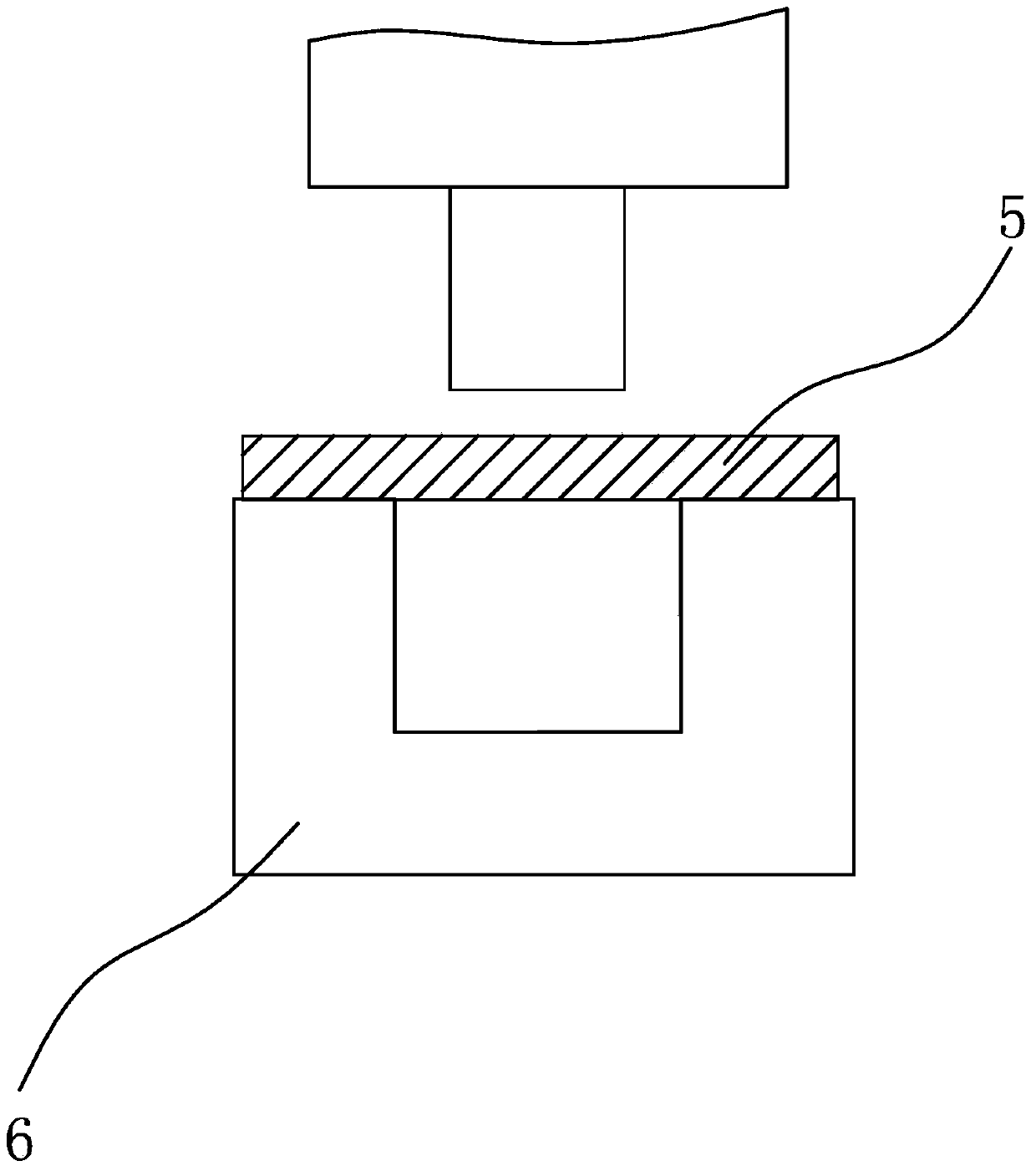

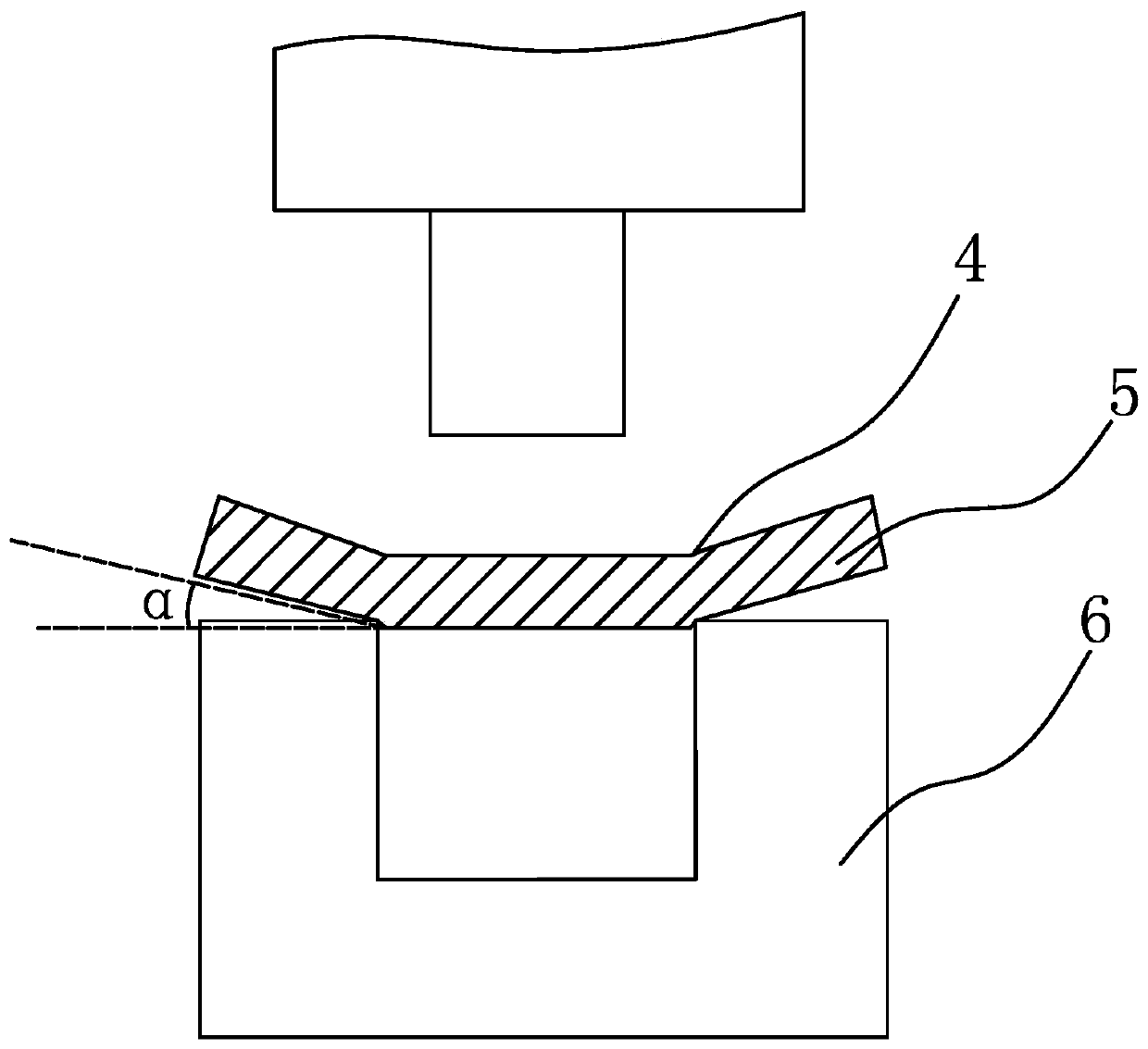

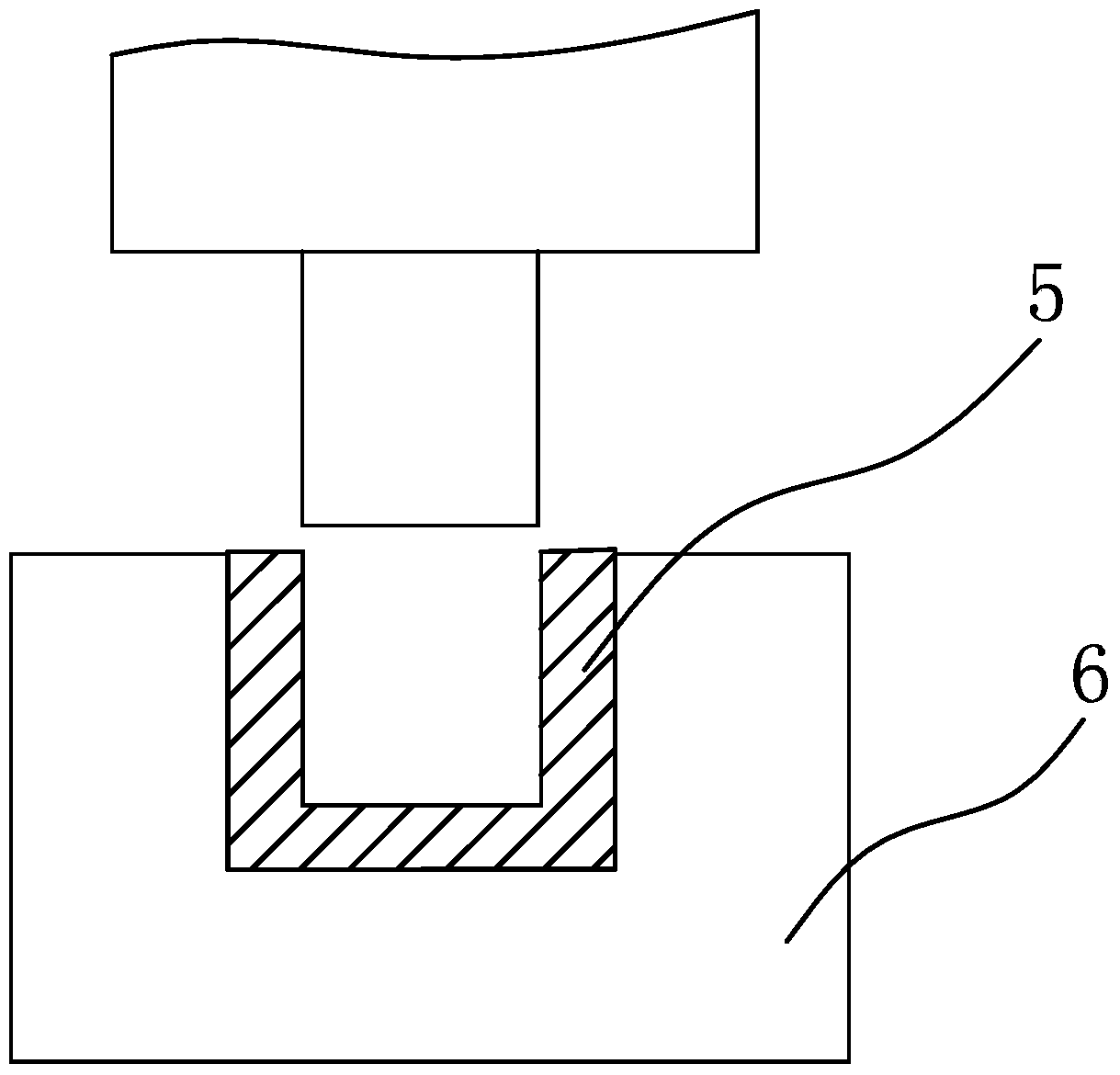

Rapid punch forming process for thermoplastic carbon fiber composite board

The invention discloses a rapid punch forming process for a thermoplastic carbon fiber composite board. The rapid punch forming process for the thermoplastic carbon fiber composite board comprises thefollowing steps that the thermoplastic carbon fiber composite board is put into a punching die at first, then the thermoplastic carbon fiber composite board is heated to reach and be kept at the temperature 10-20 DEG C lower than the viscous state temperature of the thermoplastic carbon fiber composite board, then the punching die is started to punch the thermoplastic carbon fiber composite board, then heating is stopped, and the thermoplastic carbon fiber composite board is cooled to be at the room temperature, demolded and taken out. The rapid punch forming process for the thermoplastic carbon fiber composite board is convenient to operate, simple in process and good in effect, the machined and formed thermoplastic carbon fiber composite board is high in quality, and punch forming of the thermoplastic carbon fiber composite board can be finished easily, conveniently and rapidly.

Owner:WUHAN UNIV OF TECH

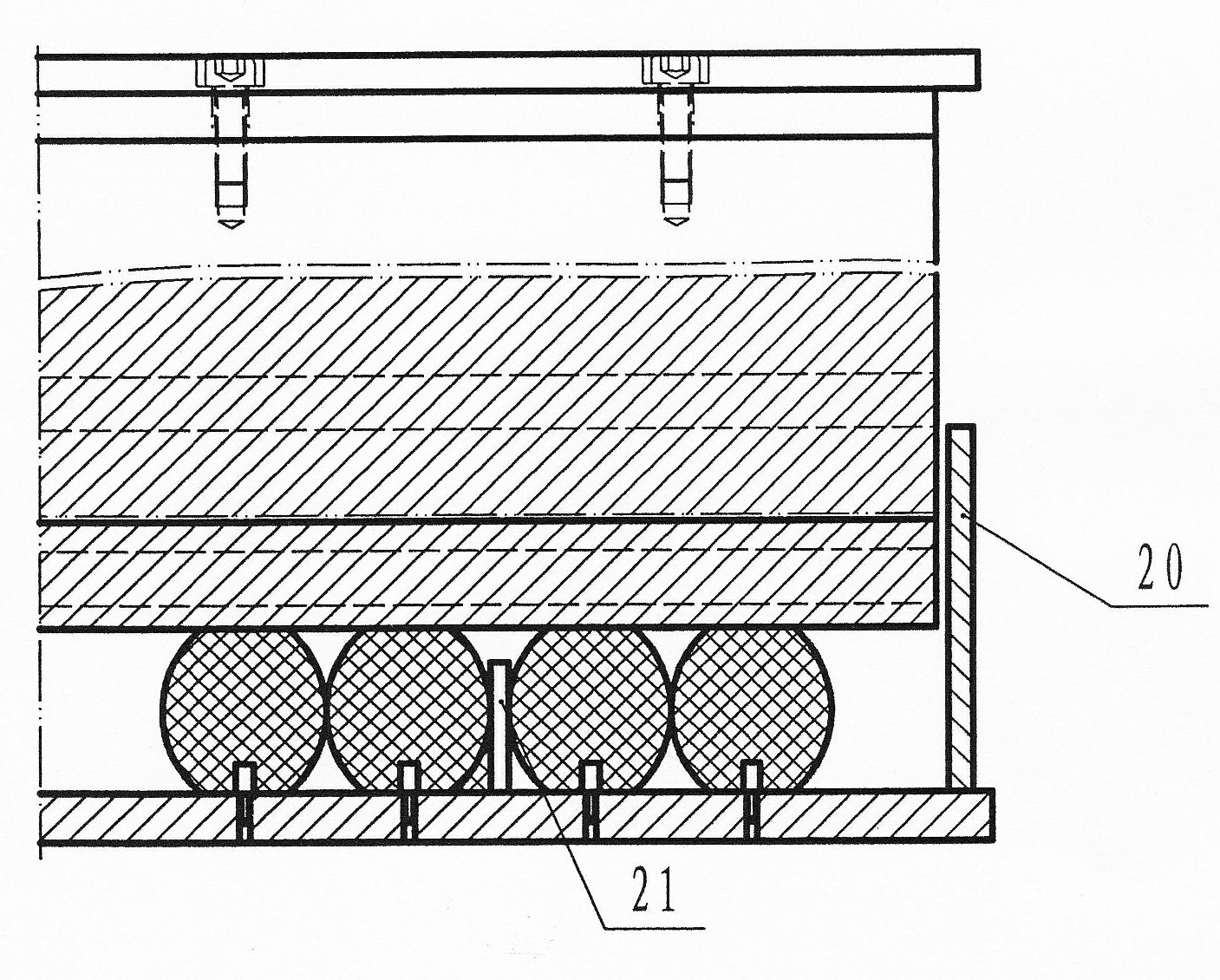

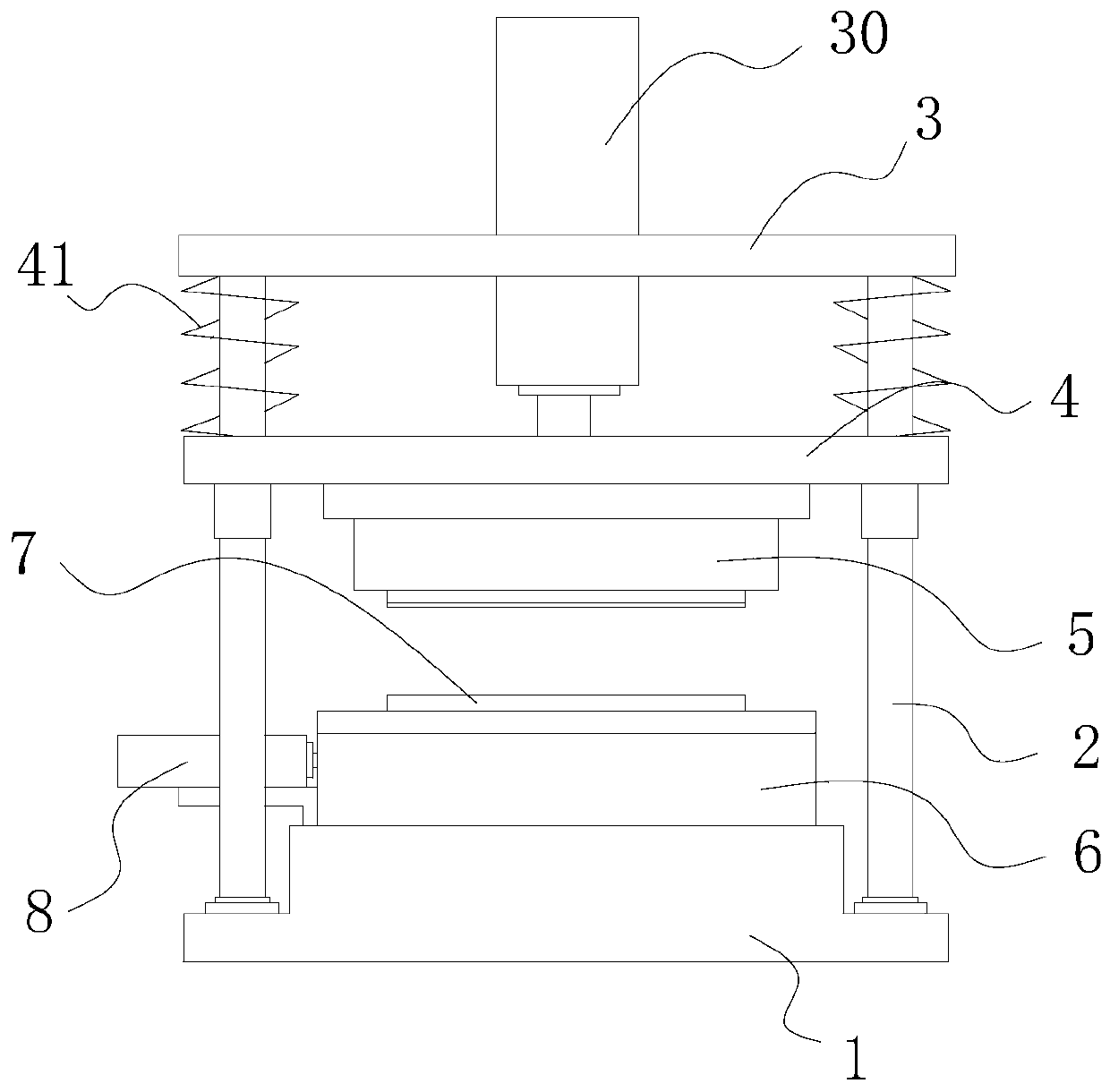

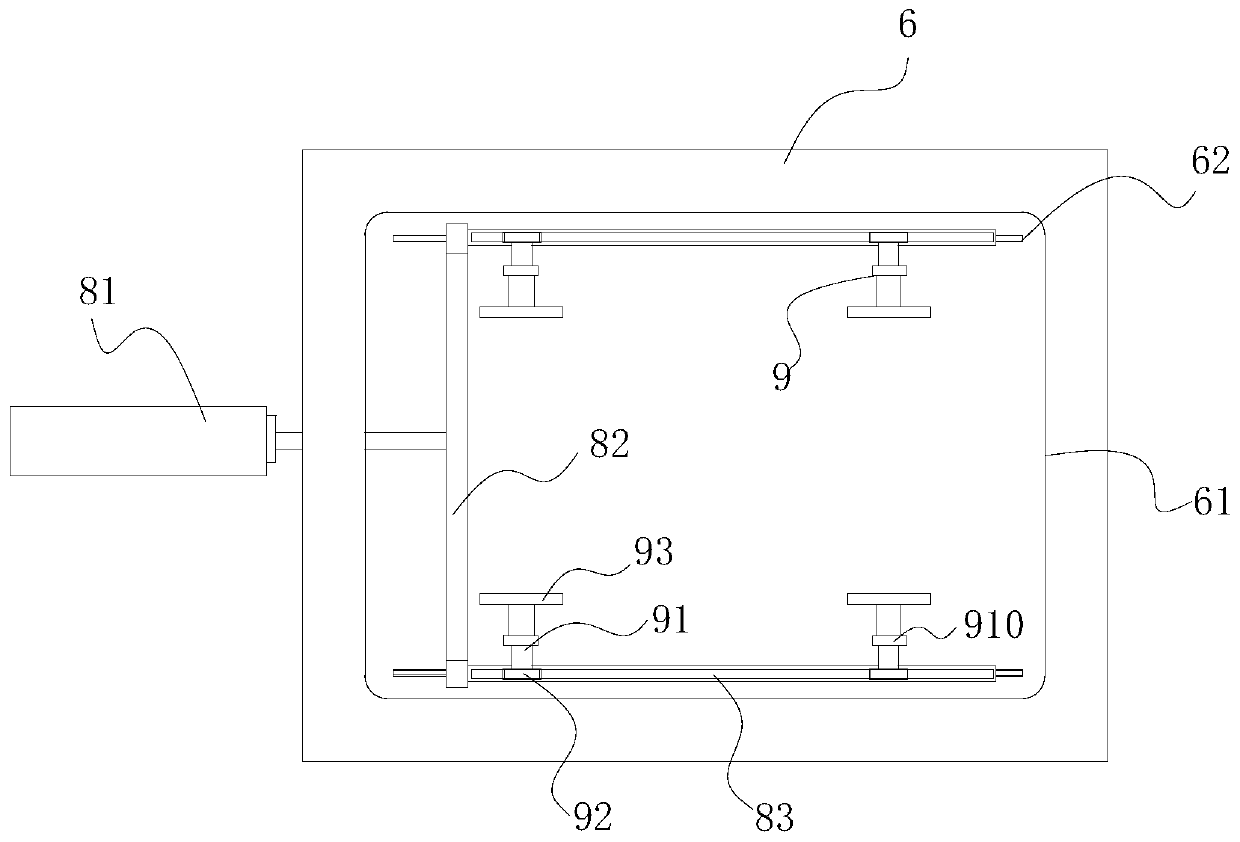

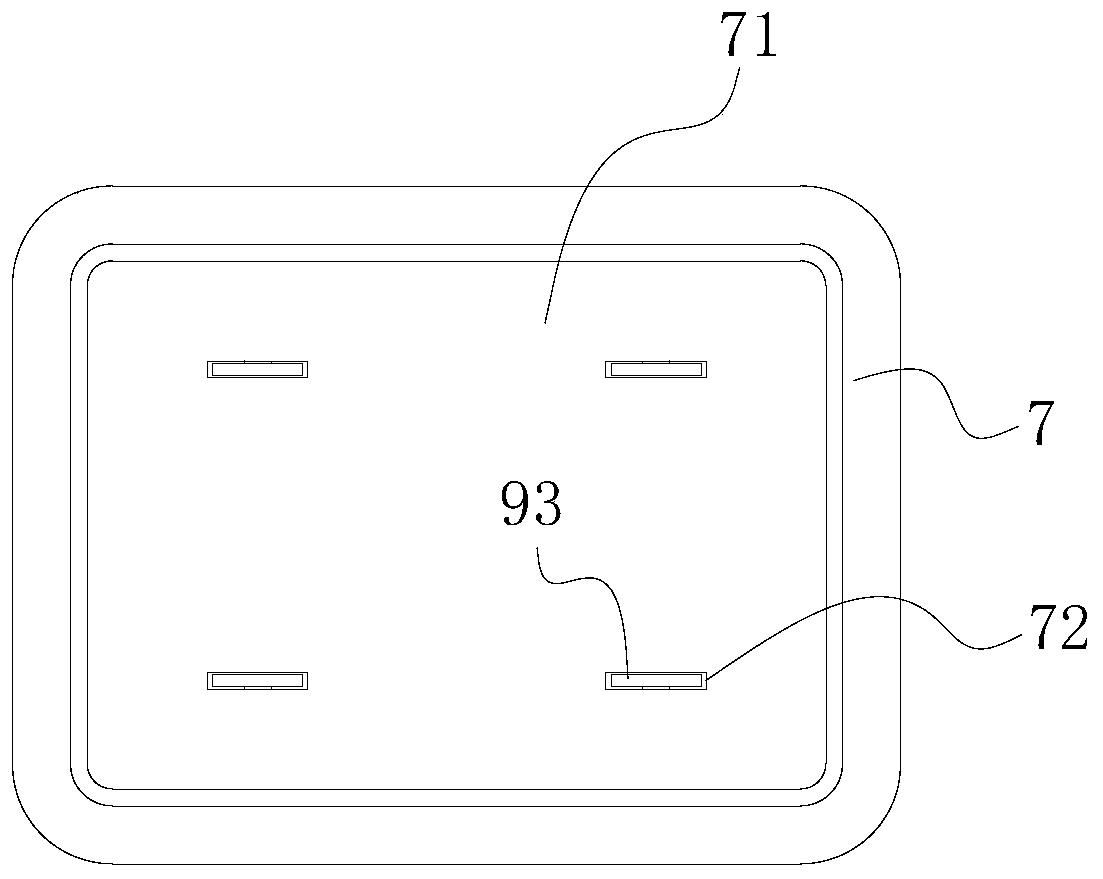

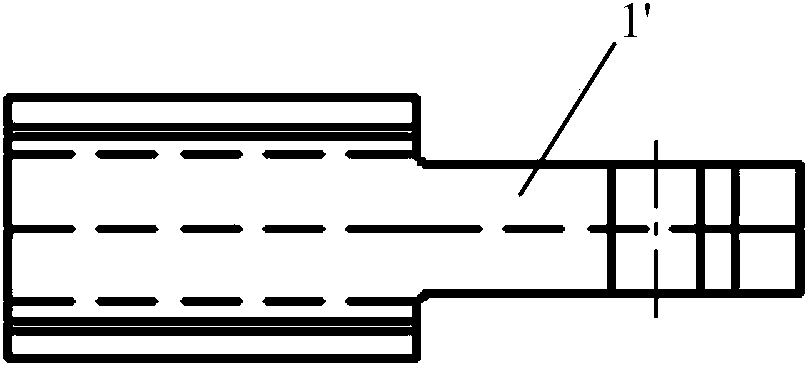

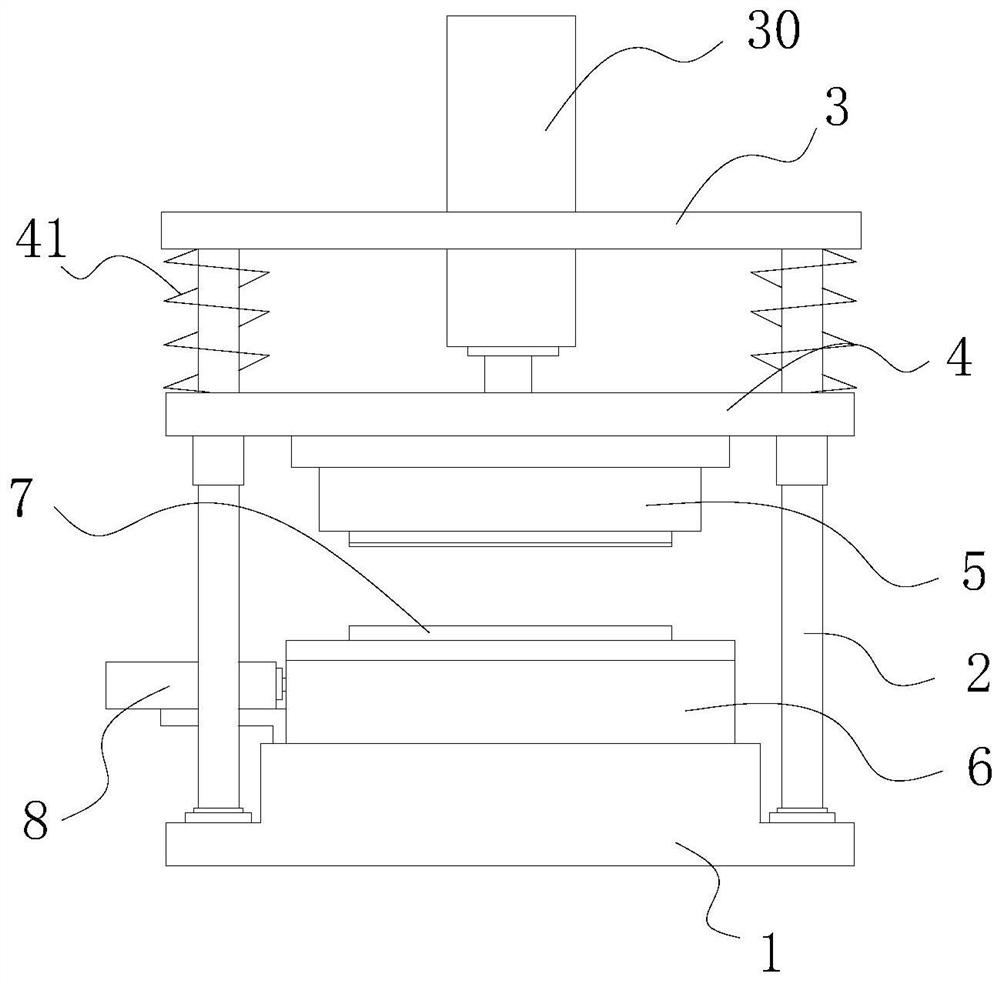

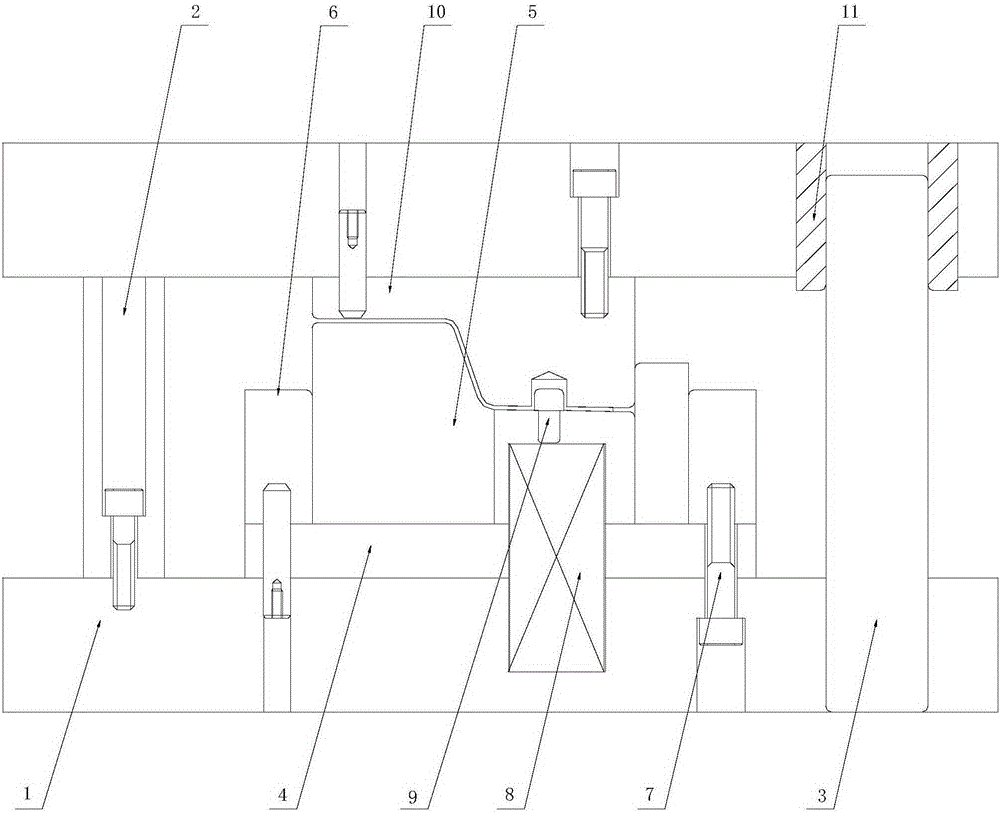

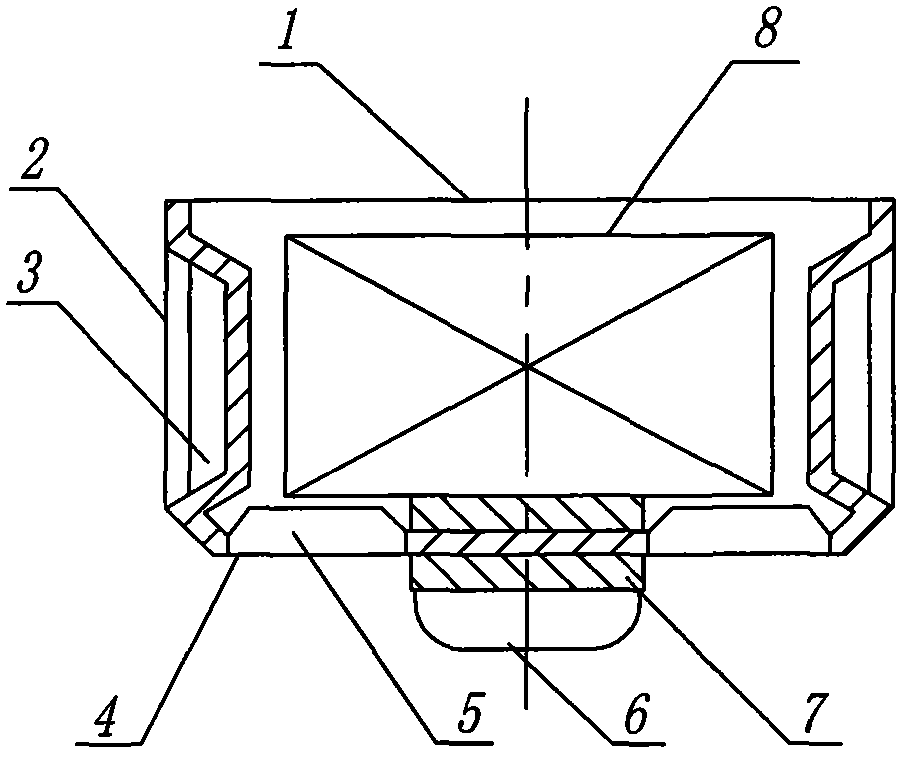

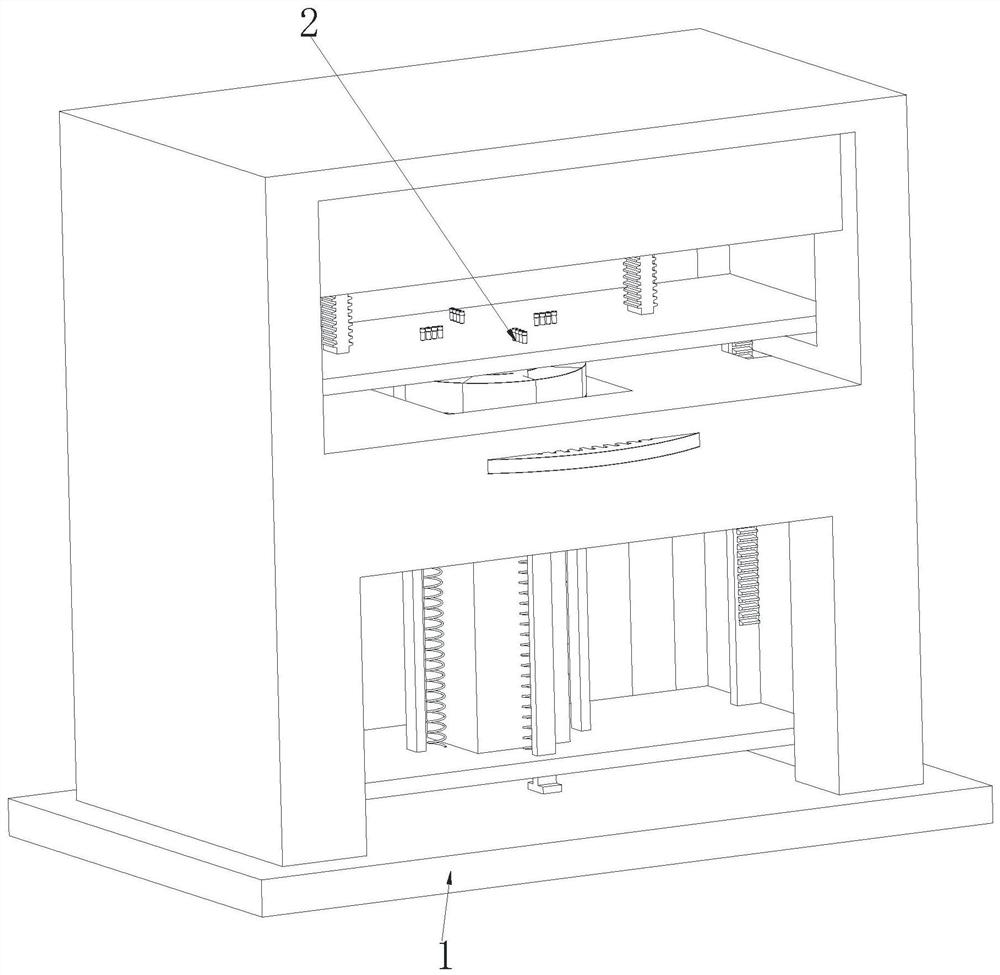

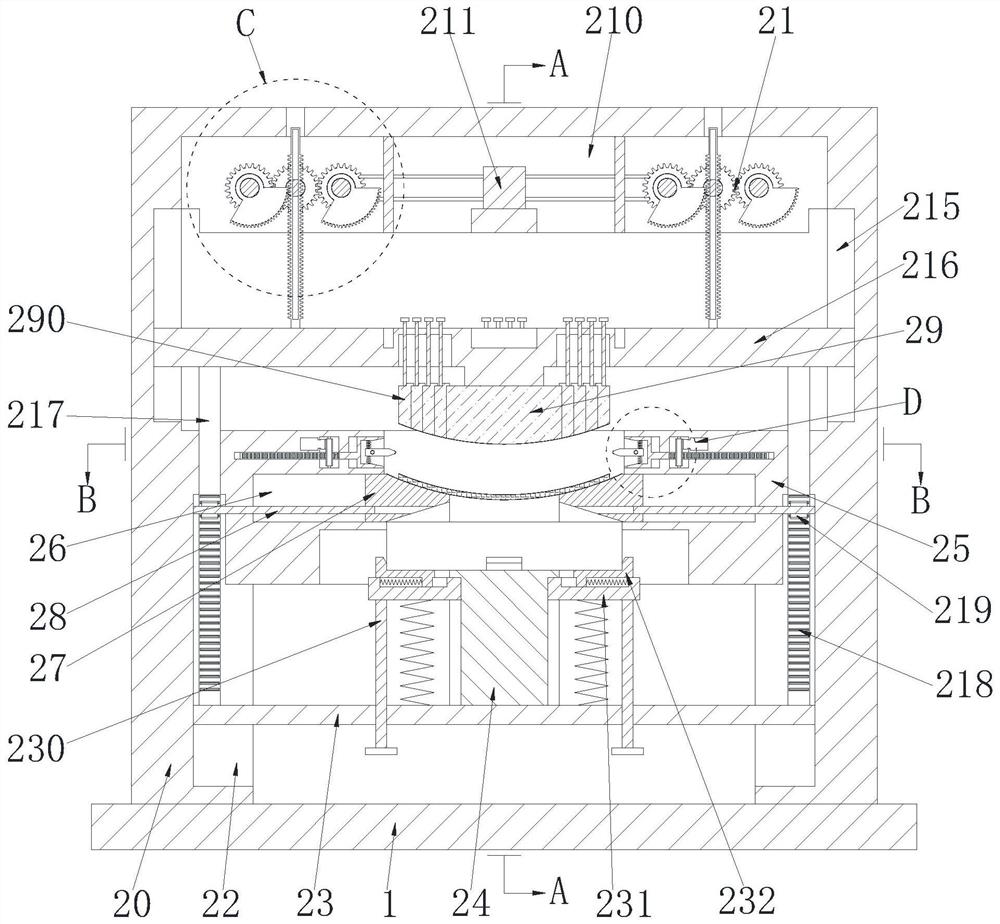

New energy automobile battery shell punch forming device

ActiveCN111036749ARealize stamping and formingEasy to unloadShaping toolsEjection devicesAutomotive batteryNew energy

The invention provides a new energy automobile battery shell punch forming device which comprises a base, guide sliding rods, an upper supporting seat, a punching seat, an upper male die, an auxiliarymounting seat, a lower female die, an unloading driving mechanism and ejection mechanisms. The multiple guide sliding rods are mounted above the base, and the upper supporting seat is fixedly mountedat the tops of the guide sliding rods; and the stamping base is slidably mounted on the guide sliding rods through a plurality of springs, the upper male die is mounted at the bottom of the stampingbase, the lower female die matched with the upper male die is arranged at the top of the auxiliary mounting base, the lower female die is located under the upper male die, a mounting cavity is formedin the auxiliary mounting base, the plurality of ejection mechanisms are installed in the mounting cavity, ejection cams are arranged on the ejection mechanisms, and the unloading driving mechanism used for driving the ejection cams to rotate is further arranged on the auxiliary mounting seat. Automatic ejection and unloading after stamping can be achieved, the production efficiency can be improved, and the labor intensity can be reduced.

Owner:嘉兴晨飞科技有限公司

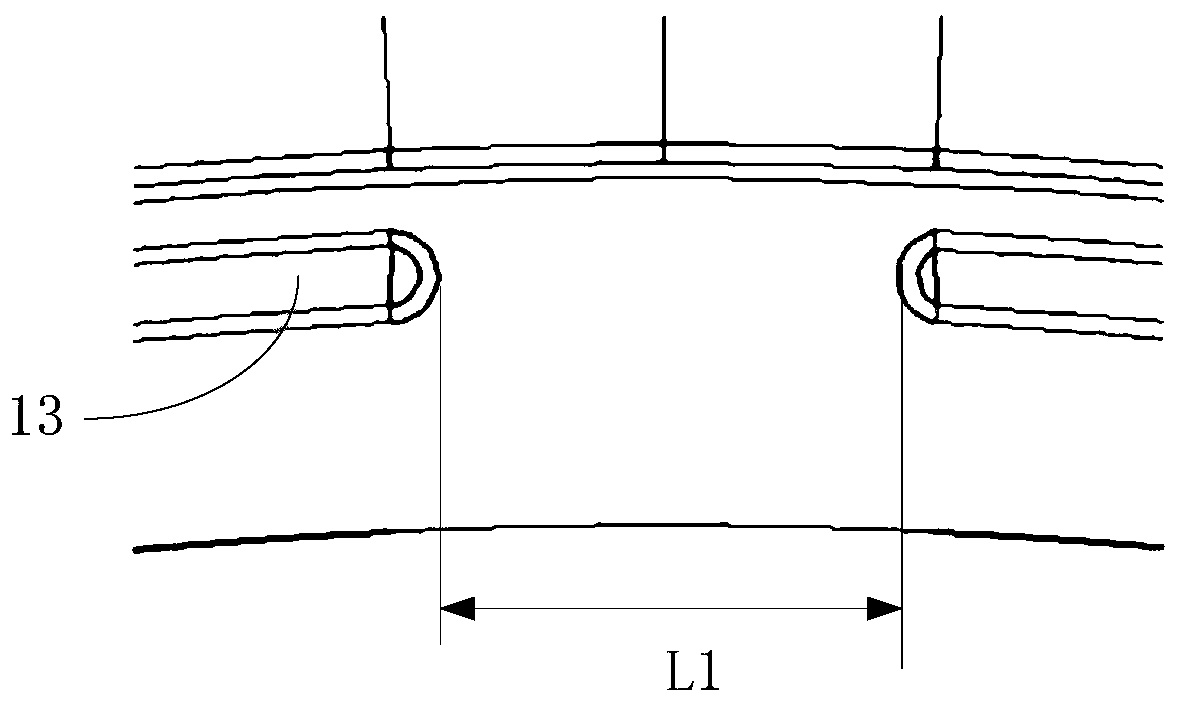

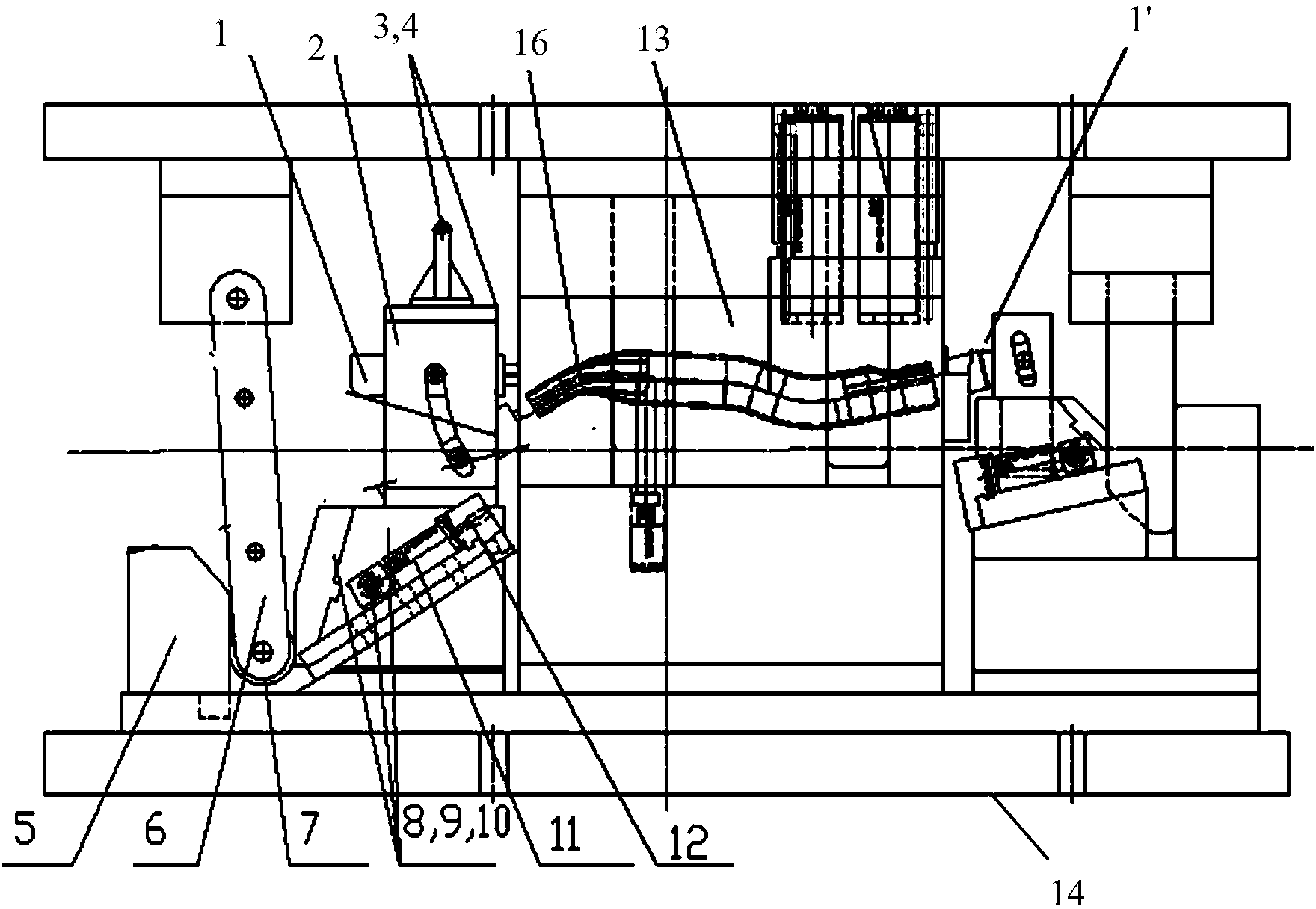

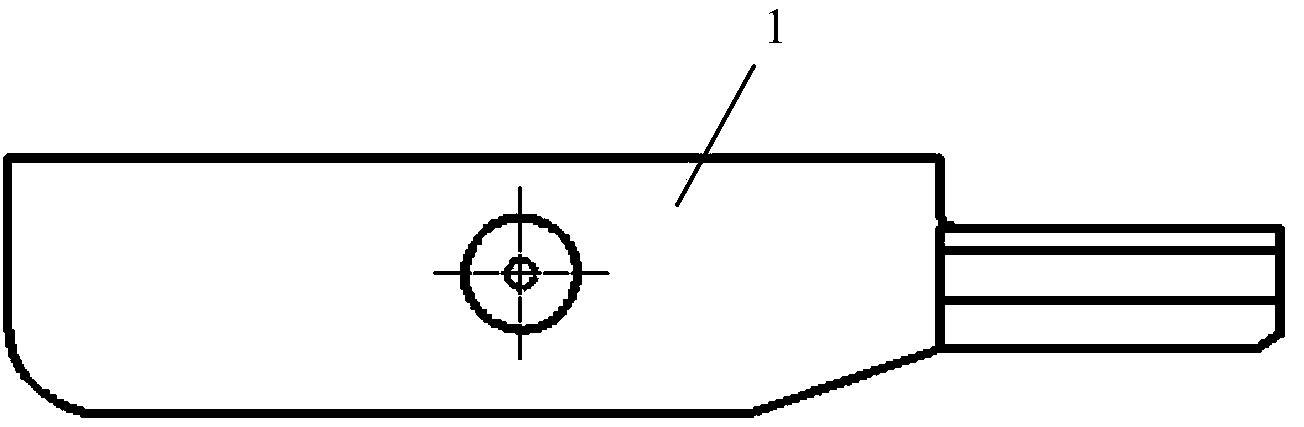

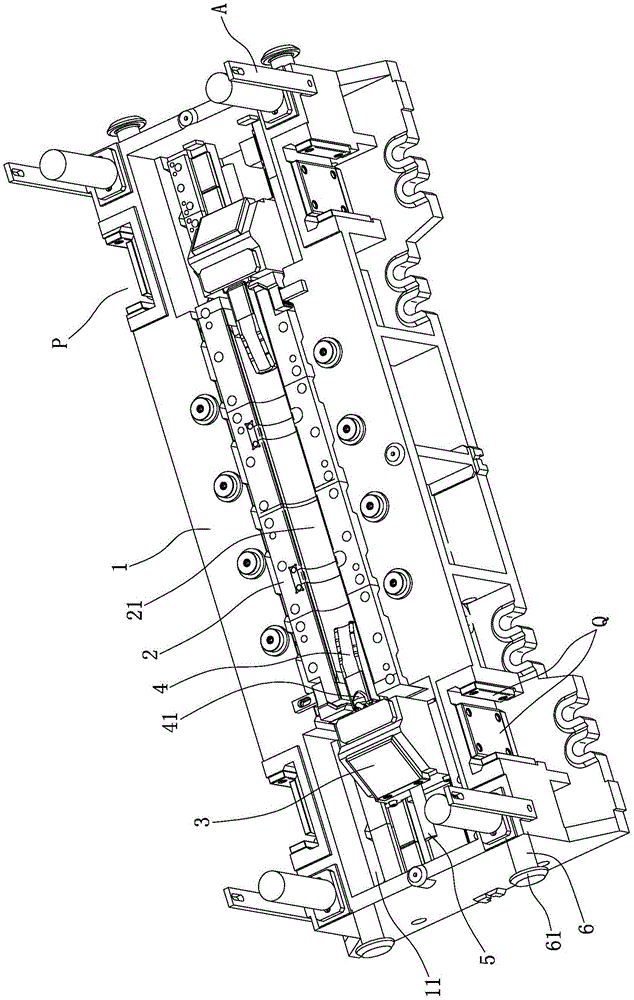

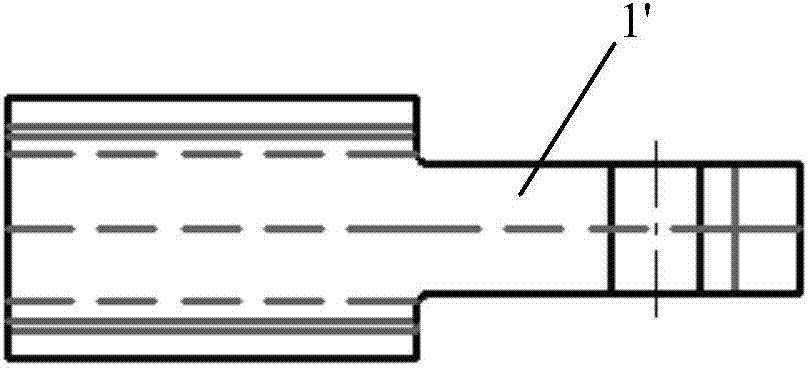

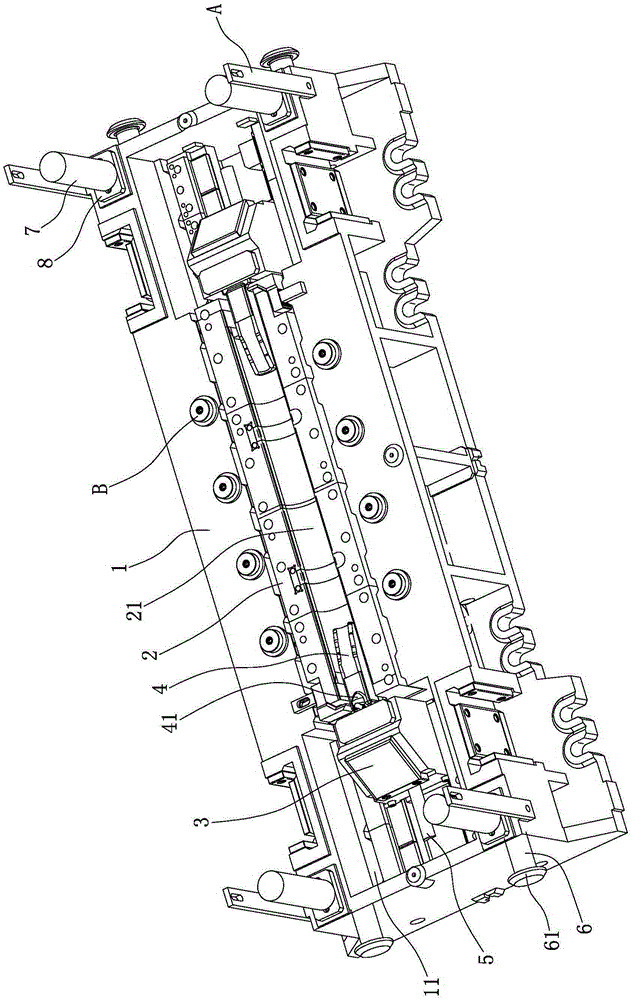

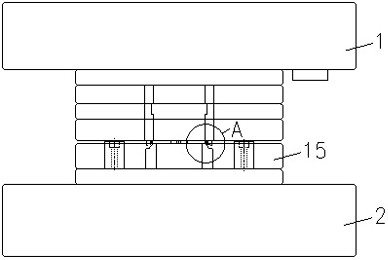

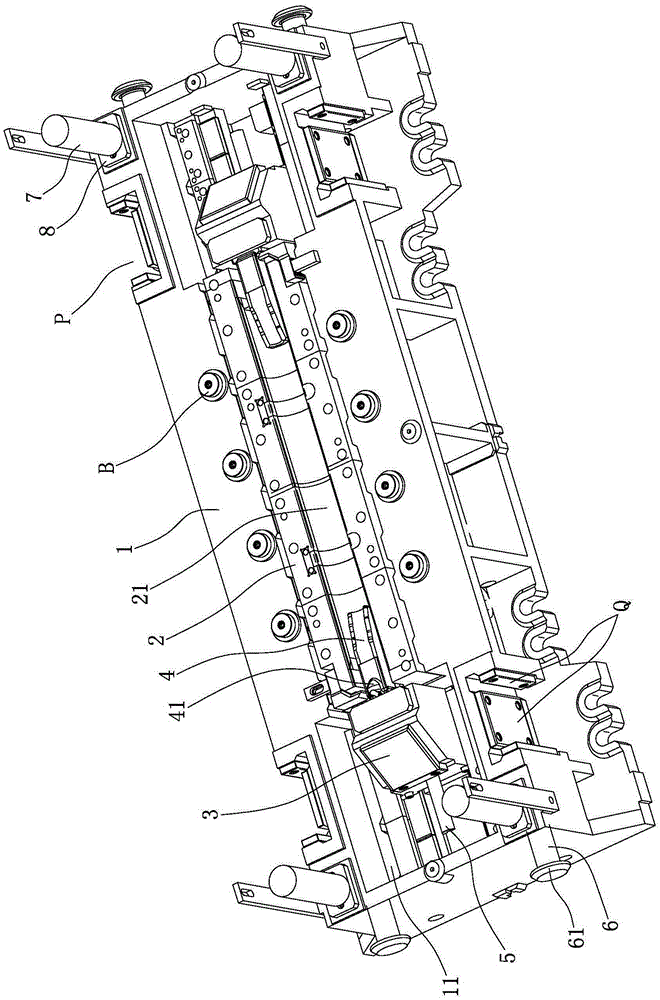

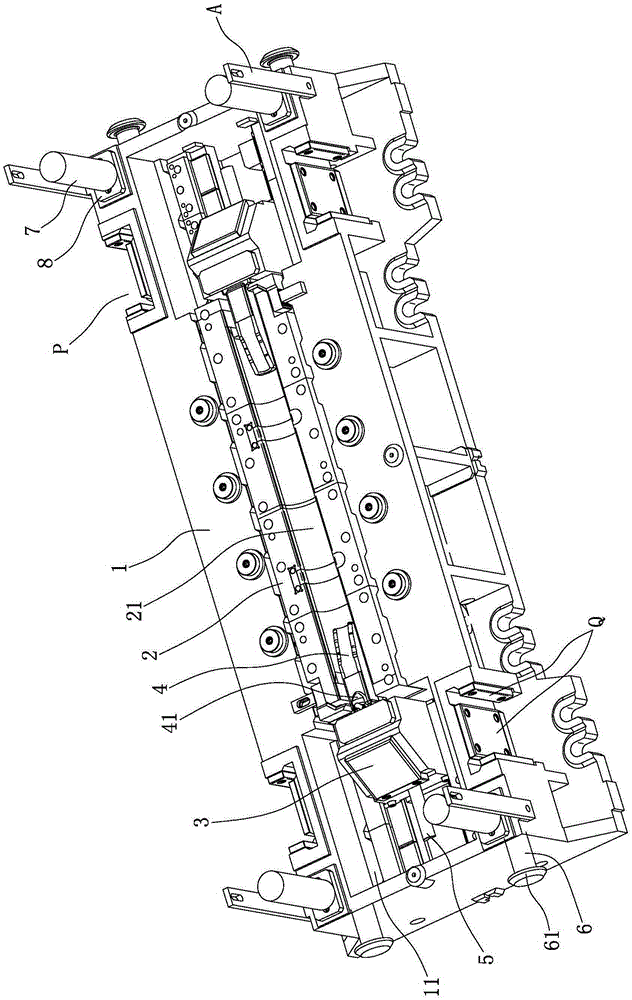

Floating core-pulling mechanism for pipe fitting forming

ActiveCN103521627ARealize stamping and formingShaping toolsStripping-off devicesPipe fittingNatural state

Provided is a floating core-pulling mechanism for pipe fitting forming. The floating core-pulling mechanism for pipe fitting forming can be used for replacing a traditional long-stroke hydraulic core-pulling structure. According to the floating core-pulling mechanism for pipe fitting forming, a guide groove is formed in a guide support, the guide groove and a floating core-pulling portion are in sliding fit through a guide pin, a reset spring is assembled between a base body and the floating core-pulling portion, a sliding wedge supports the guide support, a wedge base is provided with a slope, the sliding wedge and the slope are in sliding fit, a limiting link stopper is arranged corresponding to the sliding wedge, a pinch roller is connected with the lower end of a connecting rod, the upper end of the connecting rod is connected with an upper die, namely a movable die, of a die, when the connecting rod moves downwards, the sliding wedge and the limiting link stopper can be separated through the pinch roller, the connecting rod can enter the position between the sliding wedge and the limiting link stopper to push the sliding wedge, the limiting link stopper and the wedge base are arranged on a lower die, namely a stationary die, of the die, and the nature state of a telescopic device is the state that the size of a gap between the sliding wedge and the limiting link stopper is kept to be smaller than the outer diameter of the pinch roller.

Owner:SHANGHAI HUIZHONG AUTOMOTIVE MFG

A new energy vehicle battery case stamping forming device

ActiveCN111036749BRealize stamping and formingEasy to unloadShaping toolsEjection devicesAutomotive batteryElectrical battery

The invention proposes a stamping and forming device for a battery case of a new energy vehicle, which includes a base, a guide slide bar, an upper support seat, a stamping seat, an upper punch, an auxiliary mounting seat, a lower die, an unloading drive mechanism, and a ejector mechanism. Several guide slide bars are installed on the top of the base, and the top of the guide slide bar is fixedly equipped with an upper support seat, and the stamping seat is slidably installed on the guide slide bar through several springs. The upper punch is installed at the bottom, and the top of the auxiliary mounting seat is provided with a lower die matching the upper punch, the lower die is located directly below the upper punch, and the auxiliary mounting seat is equipped with a There are several ejecting mechanisms installed in the installation chamber, the ejecting mechanism is provided with an ejecting cam, and the auxiliary mounting seat is also provided with an unloading drive mechanism for driving the ejecting cam to rotate. It can realize automatic ejection and unloading after stamping, which can improve production efficiency and reduce labor intensity.

Owner:嘉兴晨飞科技有限公司

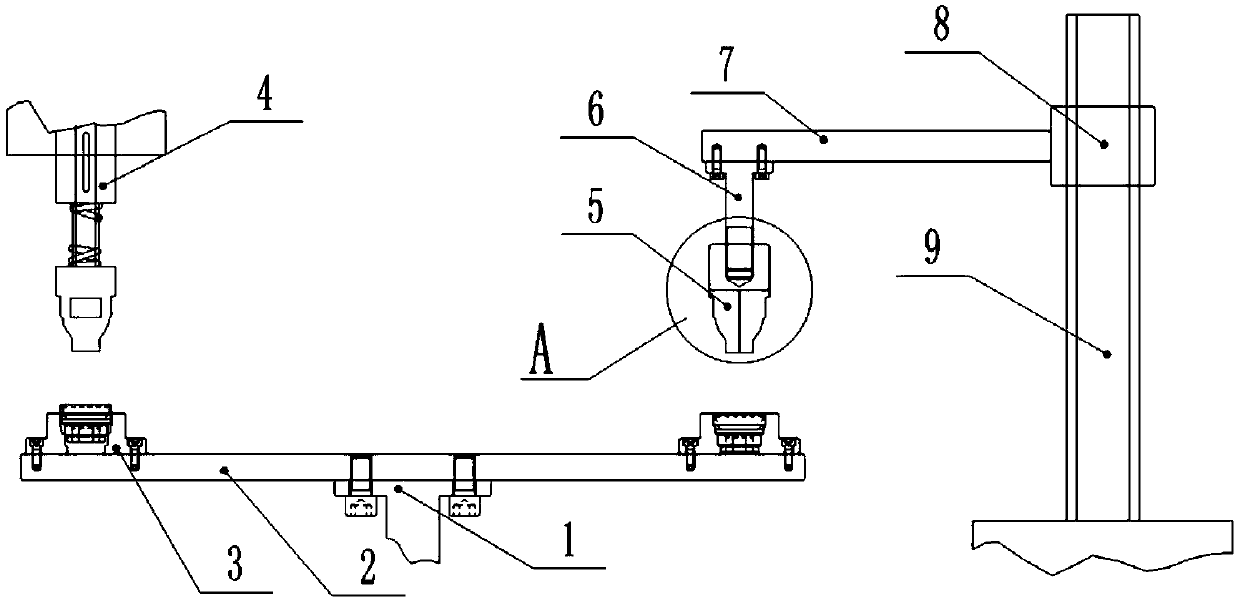

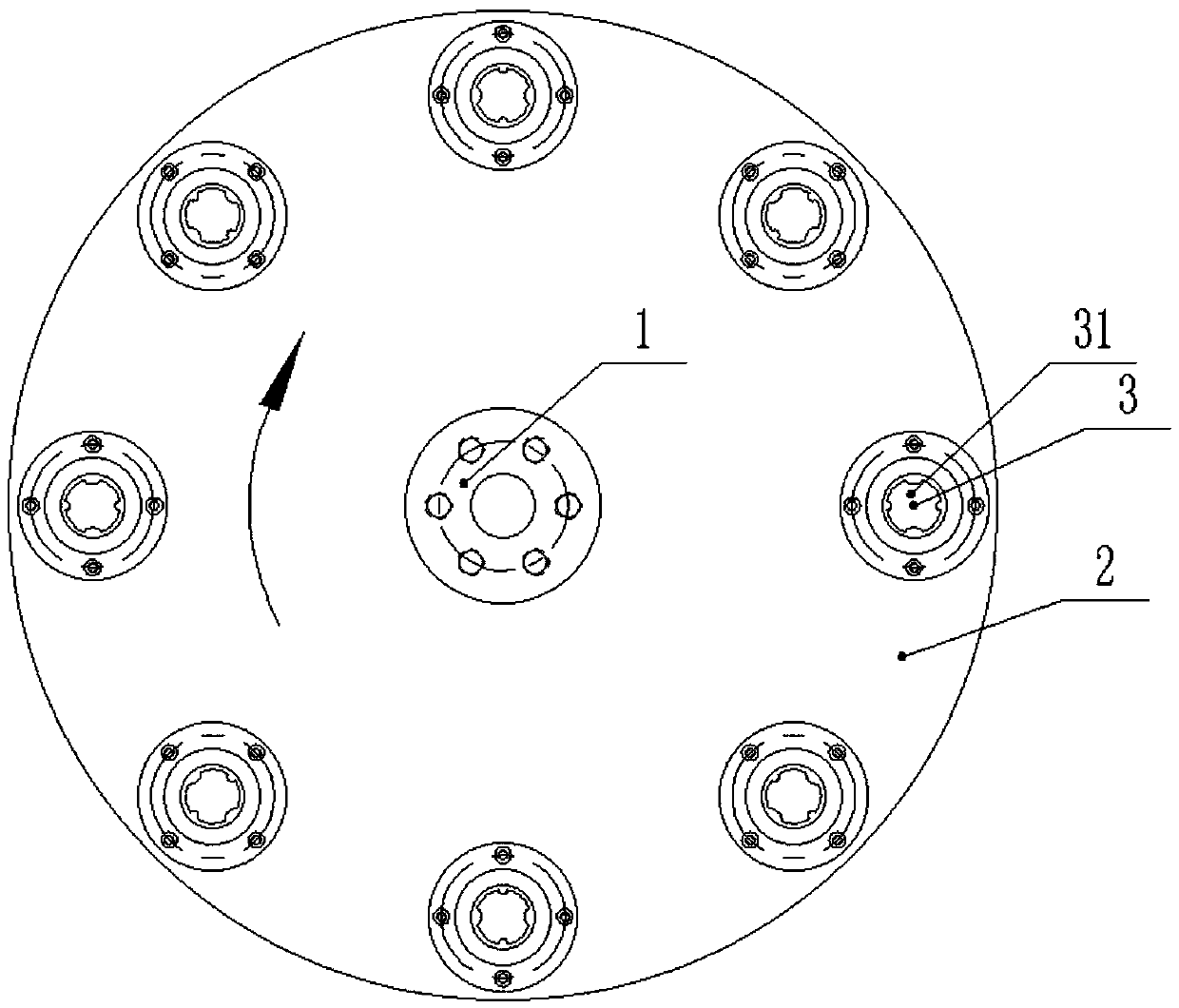

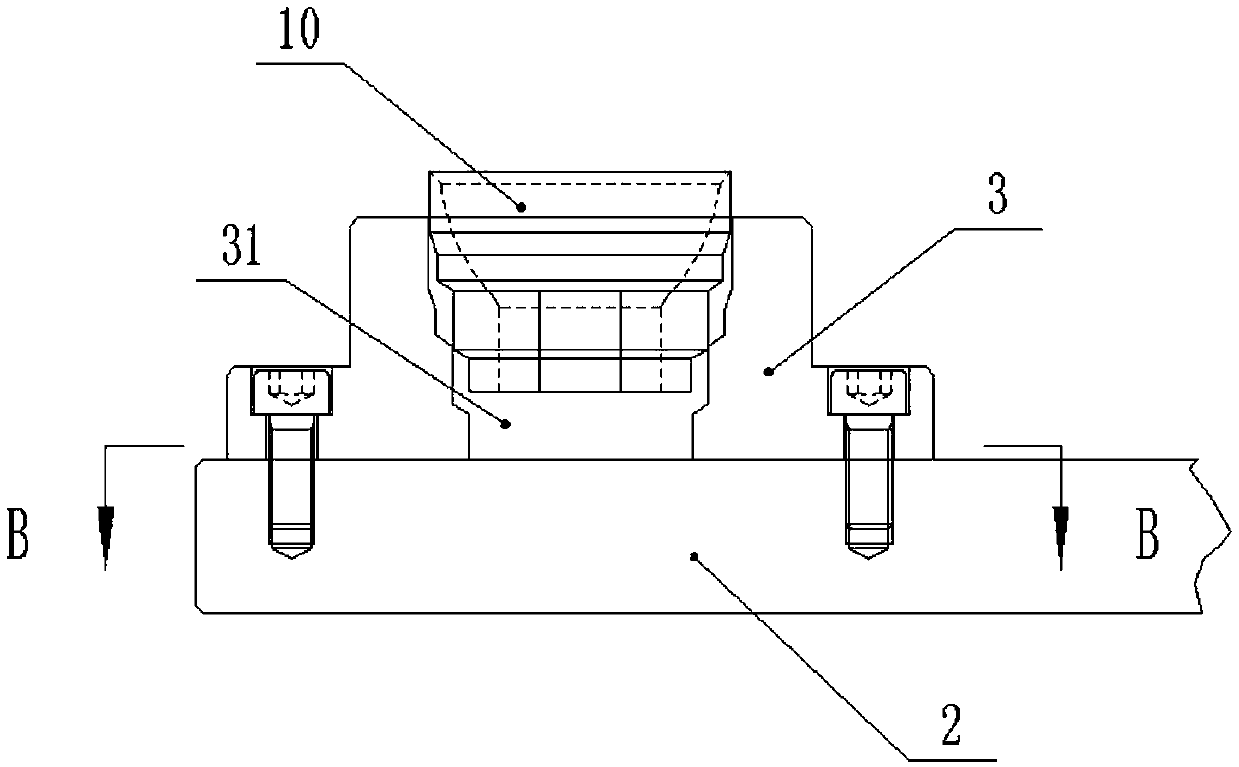

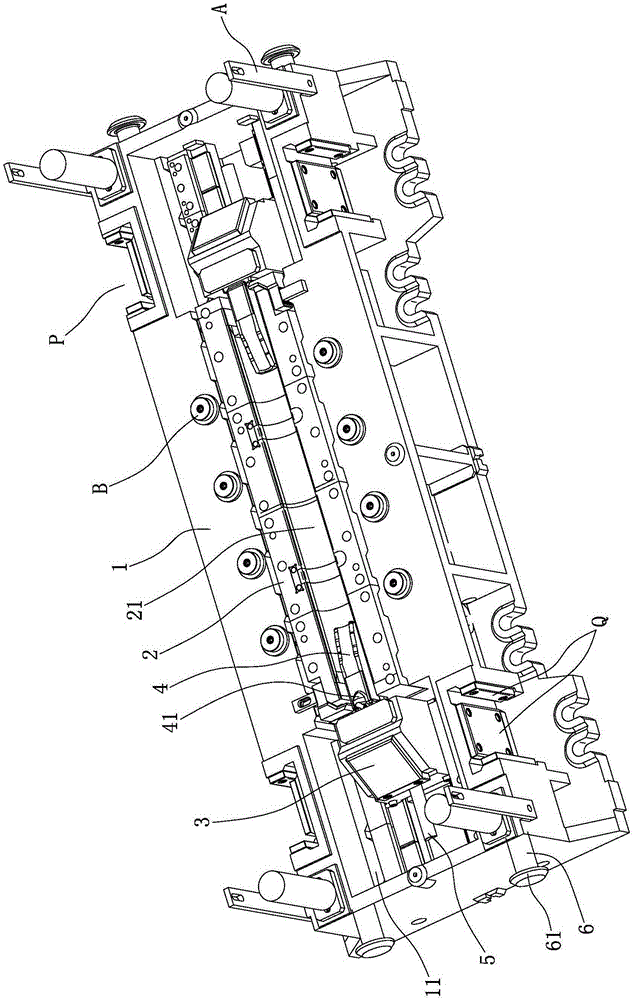

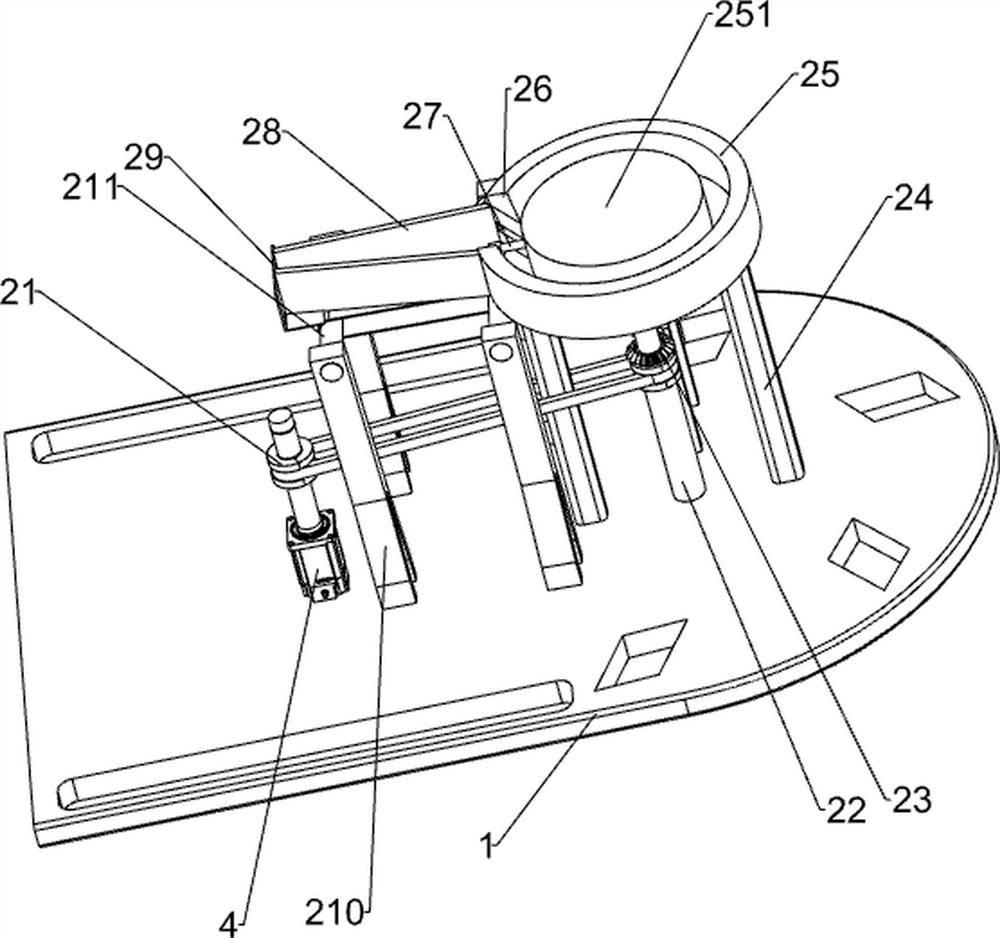

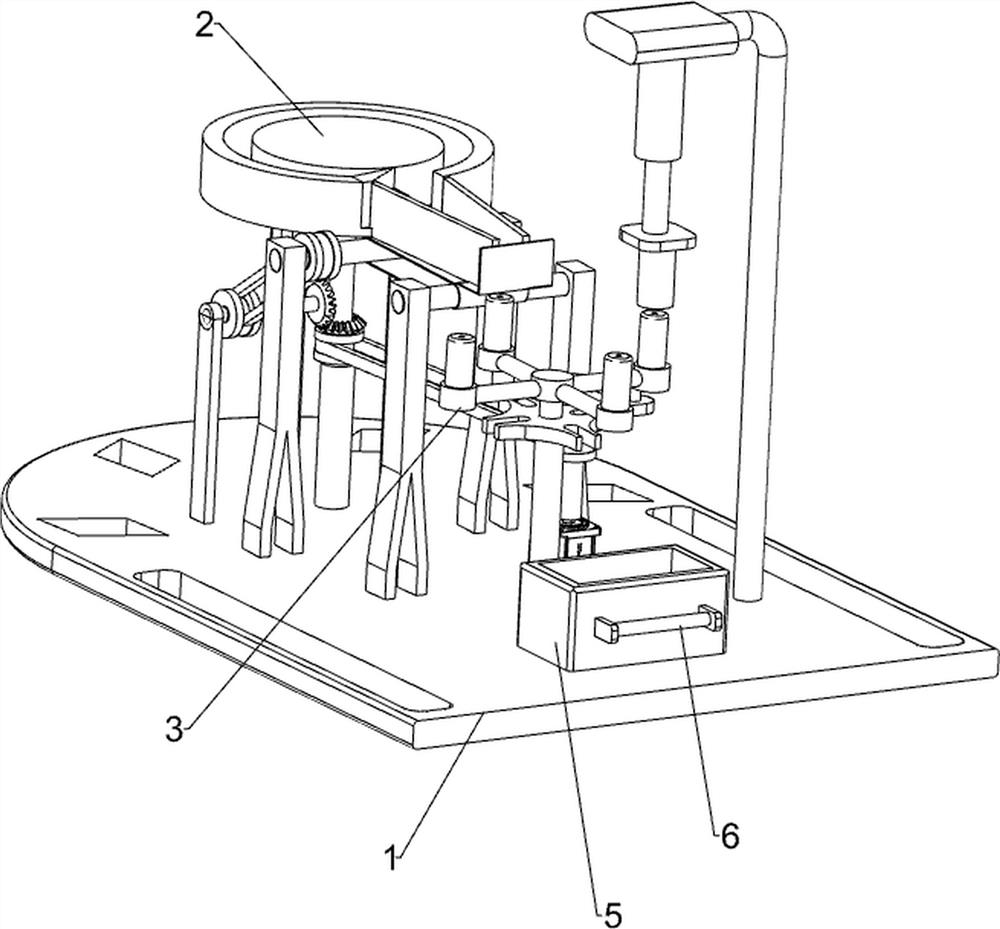

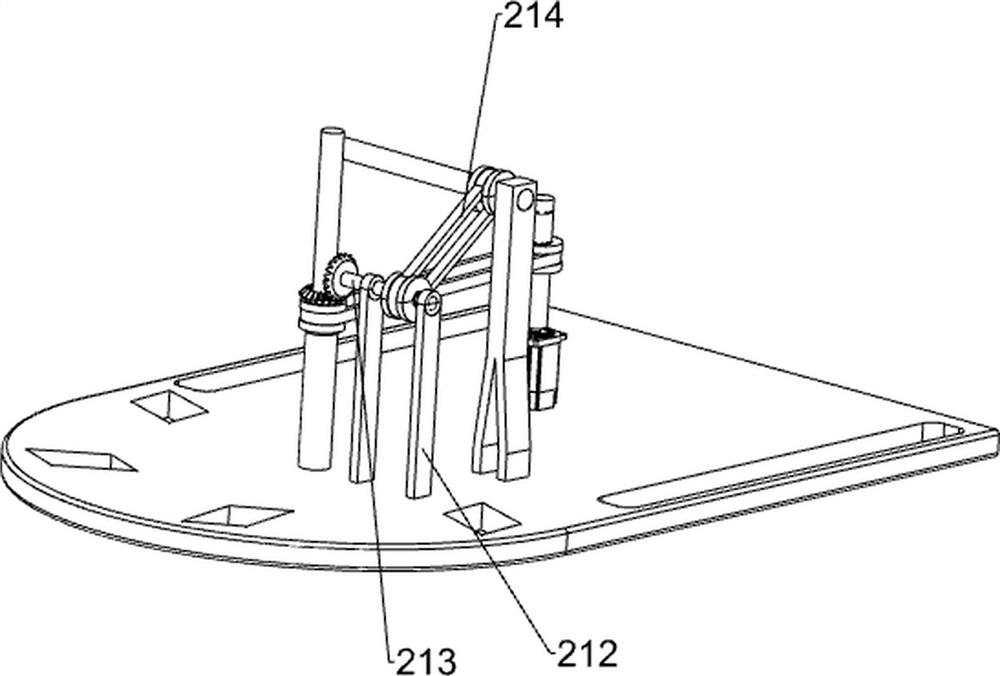

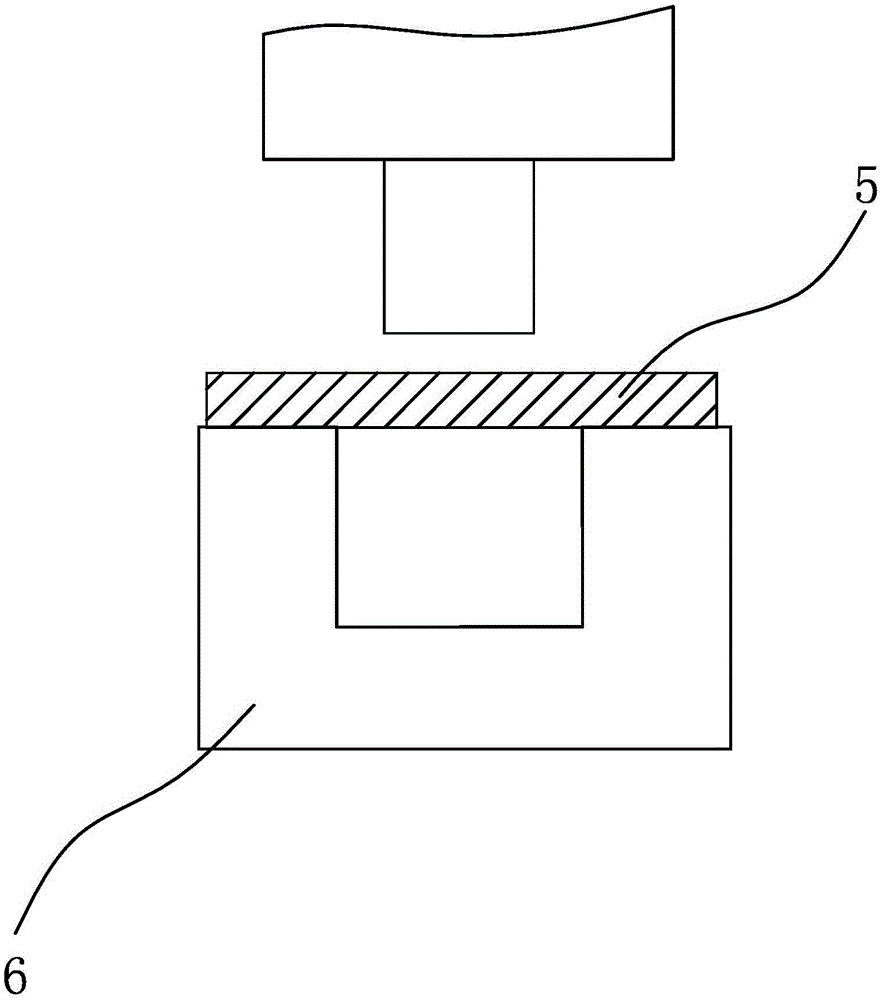

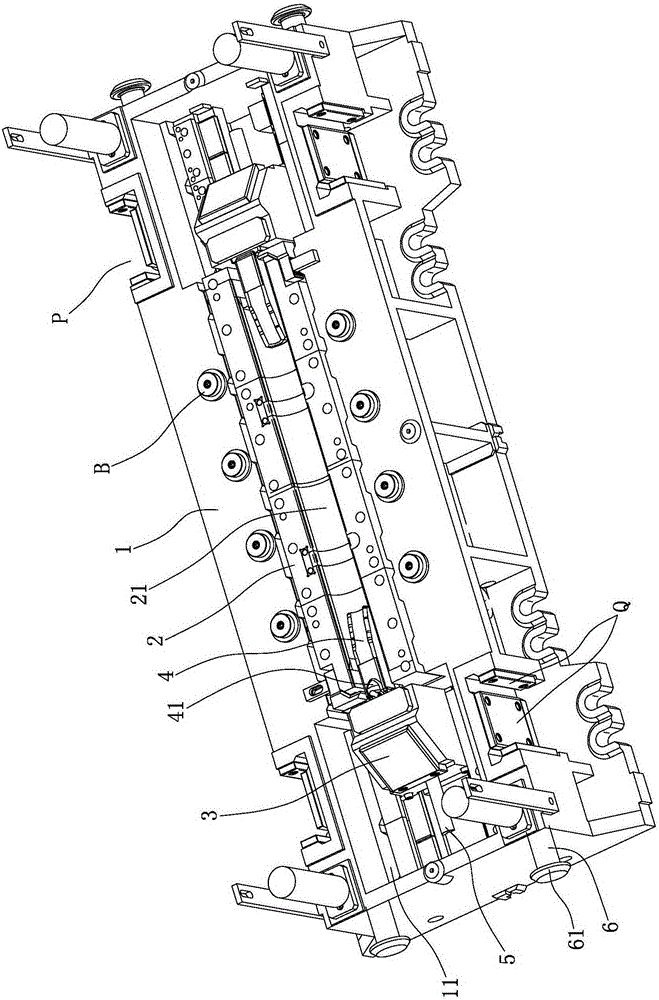

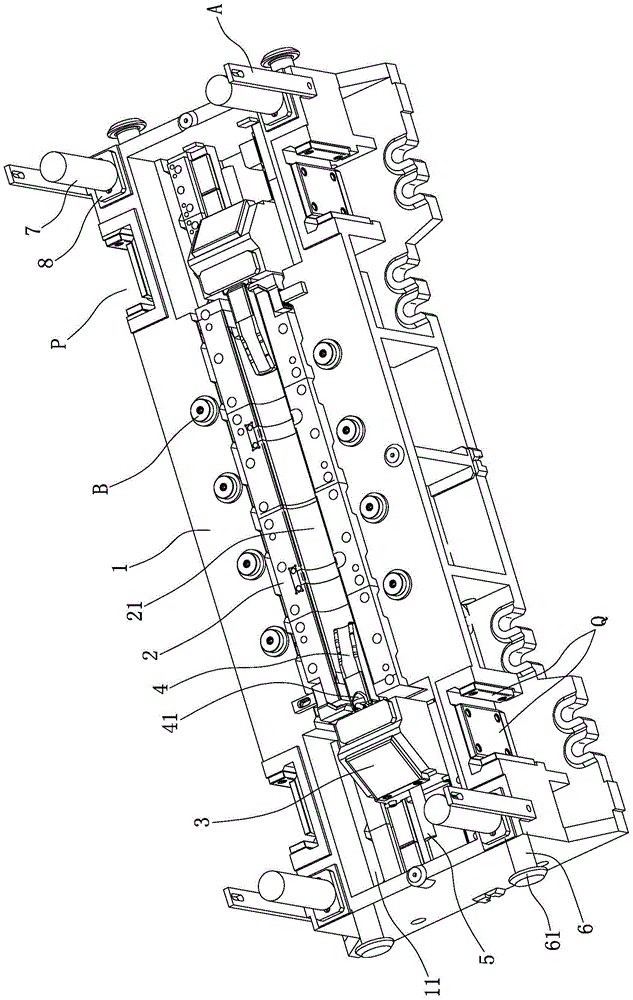

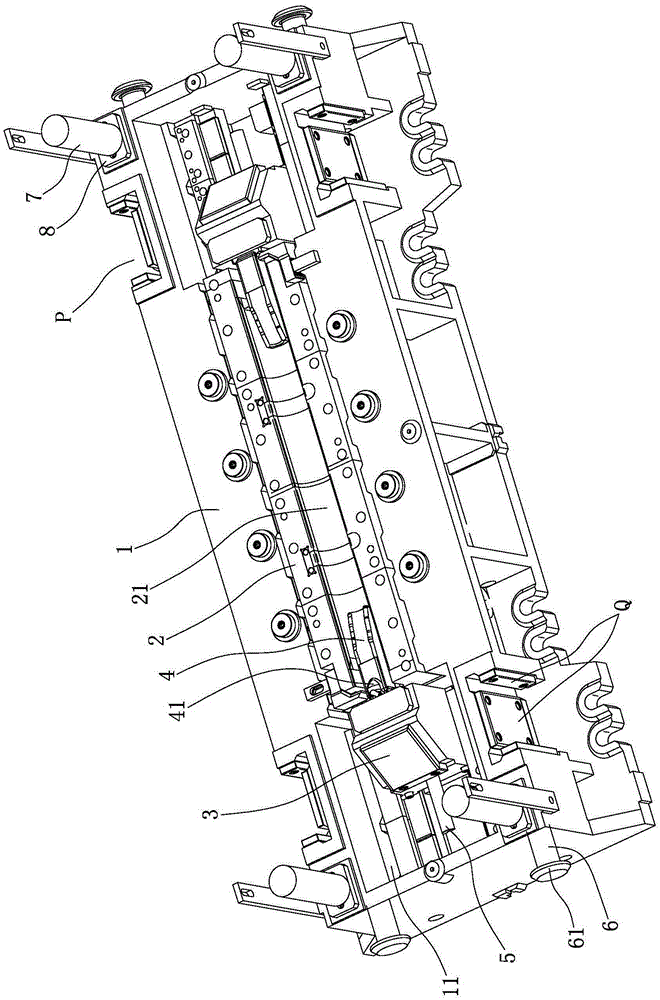

Feeding device for cores of multi-level flywheels

InactiveCN109570375ARealize stamping and formingFree laborMetal-working feeding devicesPositioning devicesEngineeringFlywheel

The invention provides a feeding device for cores of multi-level flywheels. The feeding device comprises a rotating disc, positioning dies are uniformly distributed on the disk surface of the rotatingdisc, positioning cavities for placing the cores are processed in the middles of the positioning dies, a rectifying mechanism is located above the left side of the rotating disc, and comprises a lifting platform moving on a vertical line, a central shaft which is arranged on the lifting platform and can lift and rotate relative to the lifting platform, a positioning head fixed to the lower end ofthe central shaft, and an electromagnet arranged in the positioning head, a pressing spring is further matched with the central shaft, a standing column is fixed to the right side of the rotating disc, a moving table is guided by the standing column to do climbing movement, a swinging rod is installed on the moving table, the swinging rod can swing relative to the moving table, and an expansion head is fixed to the free end of the swinging rod through a connecting rod. The cores are discharged to the rotating disc through a vibrating discharging plate, at the rectifying mechanism, the positions of the cores are adjusted and completely embedded into the positioning cavities, and then the cores are driven by the swinging rod to a stamping position to realize stamping forming. According to the feeding device for the cores of the multi-level flywheels, manual feeding is replaced, safety and reliability are achieved, meanwhile, labor force is released, and the production cost is reduced.

Owner:宁波图耐斯飞轮有限公司

Tubular beam pneumatic molding die

InactiveCN105268856ADoes not affect functionalityEnsure consistencyShaping toolsEngineeringMechanical engineering

The invention discloses a tubular beam pneumatic molding die. A tapered wedge is arranged in each cavity of a die holder, and mandrels are arranged at the opposite ends of the two tapered wedges. The mandrels are fixedly connected with the corresponding tapered wedges, and the mandrels can stretch into a forming groove. A convex hull is integrally formed on the top face of the mandrel on the left side. The left end and the right end of the die holder are each provided with a set of connecting plates which are in a long rectangular strip shape. A front row of limiting blocks and a rear row of limiting blocks are arranged in the middle of the top face of the die holder, and the limiting blocks are big-end-down two-section type hollow short columns. Guide grooves are symmetrically formed in the front side and the rear side of the left end of the die holder, guide grooves are symmetrically formed in the front side and the rear side of the right end of the die holder, and the four guide grooves are distributed in a rectangular mode. Wear-resisting plates are attached to the three inner walls of each guide groove, and are steel plates. The tubular beam pneumatic molding die is easy to apply, and operation of torsion beam molding is simple; the left-right direction of molded torsion beams can be identified easily, and the torsion beams cannot be reversely arranged in subsequent processes.

Owner:CHONGQING SKYMAN AUTOMOBILE BODY MFG

Tubular V-shaped beam forming lower die assembly

InactiveCN105598273AEasy to assemble and disassembleImprove reliabilityShaping toolsVehicle componentsLeft directionShaped beam

The invention discloses a tubular V-shaped beam forming lower die assembly. Cavities are symmetrically formed in the left end and the right end of a die base and communicated with each other through a transverse groove. A plurality of inserts which are sequentially spliced are fixedly arranged in the transverse groove. An inclined wedge block is arranged in each cavity of the die base. The opposite ends of the two inclined wedge blocks are each provided with a core shaft. A protrusion is integrally formed on the top face of the core shaft on the left side. The left end and the right end of the die base are each provided with a set of connecting plates which are each in a long-strip-shaped rectangular shape. Guide grooves are symmetrically formed in the front side and the rear side of the left end of the die base. Guide grooves are symmetrically formed in the front side and the rear side of the right end of the die base. The four guide grooves are distributed in a rectangular shape. Wear-resistant plates are attached to three inner walls of each guide groove and are steel plates. The tubular V-shaped beam forming lower die assembly is ingenious in concept, easy to implement and small in height and size; when a torsion beam is formed through the assembly, operation is easy and convenient, and production efficiency is high; the left direction and the right direction of the formed torsion beam can be easily recognized, and the torsion beam can not be put in the wrong direction in the subsequent procedure.

Owner:CHONGQING SKYMAN AUTOMOBILE BODY MFG

Pipe forming floating core pulling mechanism

ActiveCN103521627BRealize stamping and formingShaping toolsStripping-off devicesPipe fittingNatural state

Provided is a floating core-pulling mechanism for pipe fitting forming. The floating core-pulling mechanism for pipe fitting forming can be used for replacing a traditional long-stroke hydraulic core-pulling structure. According to the floating core-pulling mechanism for pipe fitting forming, a guide groove is formed in a guide support, the guide groove and a floating core-pulling portion are in sliding fit through a guide pin, a reset spring is assembled between a base body and the floating core-pulling portion, a sliding wedge supports the guide support, a wedge base is provided with a slope, the sliding wedge and the slope are in sliding fit, a limiting link stopper is arranged corresponding to the sliding wedge, a pinch roller is connected with the lower end of a connecting rod, the upper end of the connecting rod is connected with an upper die, namely a movable die, of a die, when the connecting rod moves downwards, the sliding wedge and the limiting link stopper can be separated through the pinch roller, the connecting rod can enter the position between the sliding wedge and the limiting link stopper to push the sliding wedge, the limiting link stopper and the wedge base are arranged on a lower die, namely a stationary die, of the die, and the nature state of a telescopic device is the state that the size of a gap between the sliding wedge and the limiting link stopper is kept to be smaller than the outer diameter of the pinch roller.

Owner:SHANGHAI HUIZHONG AUTOMOTIVE MFG

Automobile part molding die

InactiveCN105251875ARealize stamping and formingImprove positioning efficiencyShaping toolsMarine engineeringMaterial resources

The invention discloses an automobile part molding die which comprises a lower die plate. A limiting column is fixed to the left side of the lower die plate. A guide column is installed on the right side of the lower die plate. A cushion board is fixed to the upper end of the lower die plate. A lower die is fixed to the upper end of the cushion board. Anti-tilting fixing boards are arranged at the left end and the right end of the lower die. A discharging screw is installed at the lower portion of the lower die. An elastic body is arranged in the lower die. A locating pin is arranged at the upper end of the lower die. An upper die is arranged above the lower die. An upper die plate is fixed to the upper end of the upper die. A guide sleeve is installed at the right portion of the upper die plate. The automobile part molding die is simple in structural design and low in manufacturing cost, stamping molding of a steel plate is realized, the locating efficiency of the steel plate is improved through the locating pin, production time is shortened, and manpower and material resources are saved.

Owner:无为县鑫发盛汽车零部件有限公司

Stainless steel jacket continuous stamping device

InactiveCN108188238ARealize stamping and formingImprove adaptabilityMetal-working feeding devicesCleaning using liquidsEngineeringProduction effect

The invention discloses a stainless steel jacket continuous stamping device. The stainless steel jacket continuous stamping device comprises a stamping table, supports and an equipment bin. The supports are connected to the two ends of the stamping table correspondingly. The equipment bin is located under the stamping table. A clamping rod is arranged at the upper end of the stamping table. A hydraulic rod is connected with the upper end of the clamping rod. A transverse rod is connected with the upper ends of the supports. A sliding rail is arranged on one side of the transverse rod. The clamping rod is connected with the sliding rail through the hydraulic rod and slidably connected with the transverse rod. By arranging the clamping rod on the upper portion of an extrusion table, the stainless steel jacket continuous stamping device adapts to stainless steel jackets of different specifications for clamping, in addition, damping springs are connected with the lower end of the stampingtable, reset springs are connected with the two ends of the stamping table correspondingly, certain buffer and protection effects on the stainless steel jackets and the stamping table are achieved, and meanwhile, the stainless steel jacket continuous stamping device adapts to the stainless steel jackets of different size specifications for placement; and moreover, a water tank is arranged in the equipment bin for spray washing of the extrusion table, and the machining and production effects are effectively improved.

Owner:JIANGSU TAI TONG NEW MATERIAL CO LTD

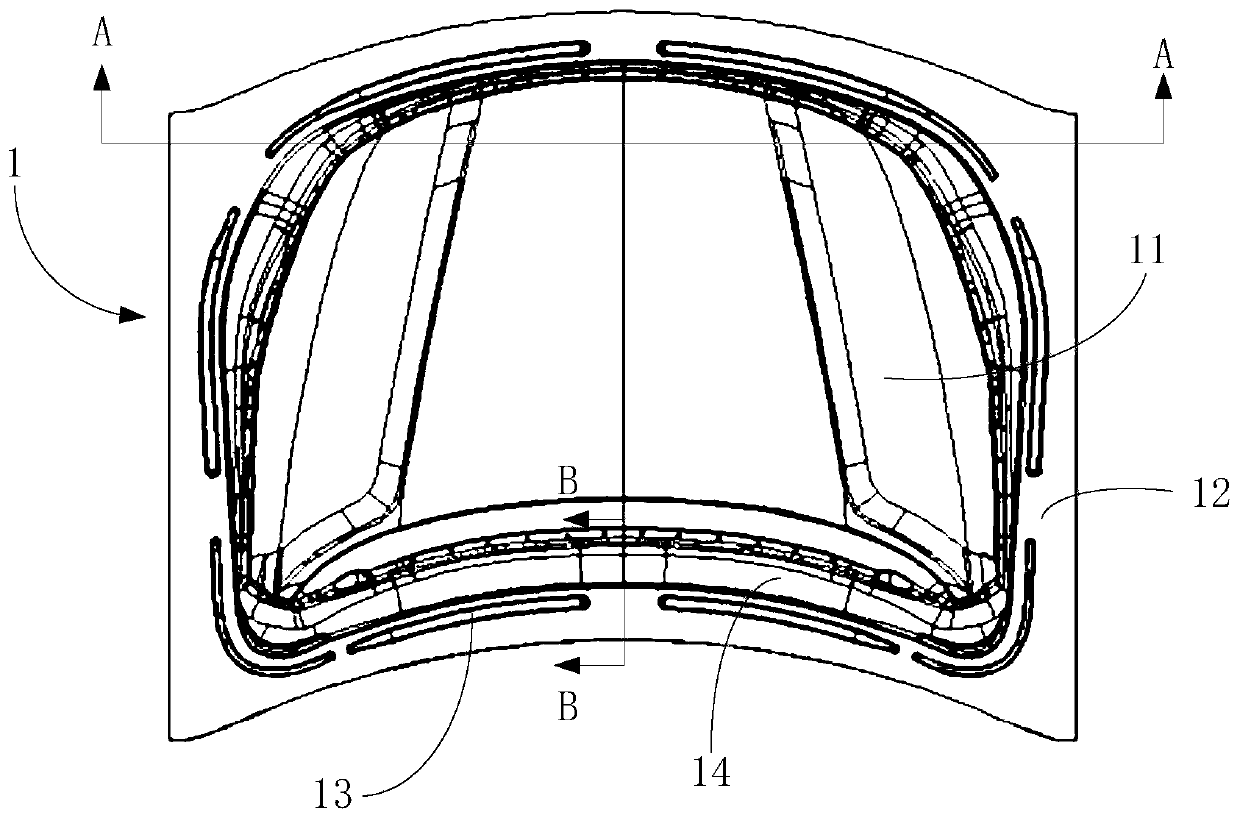

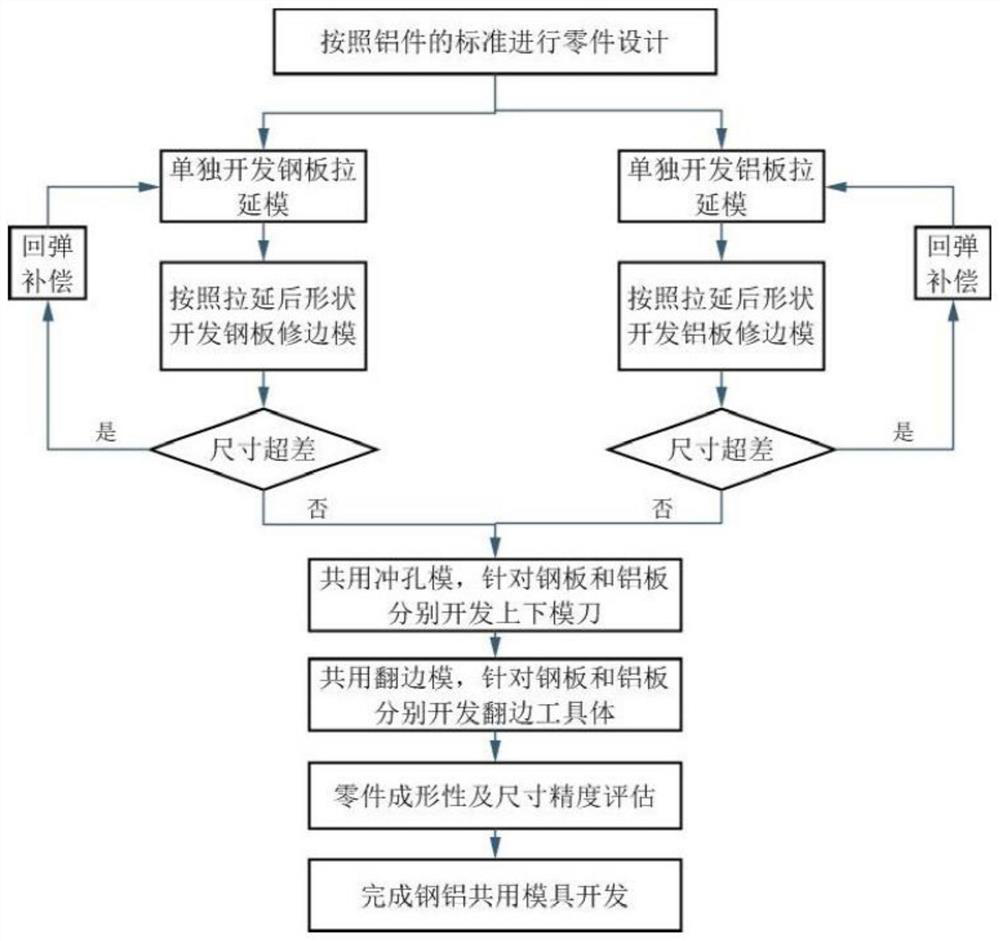

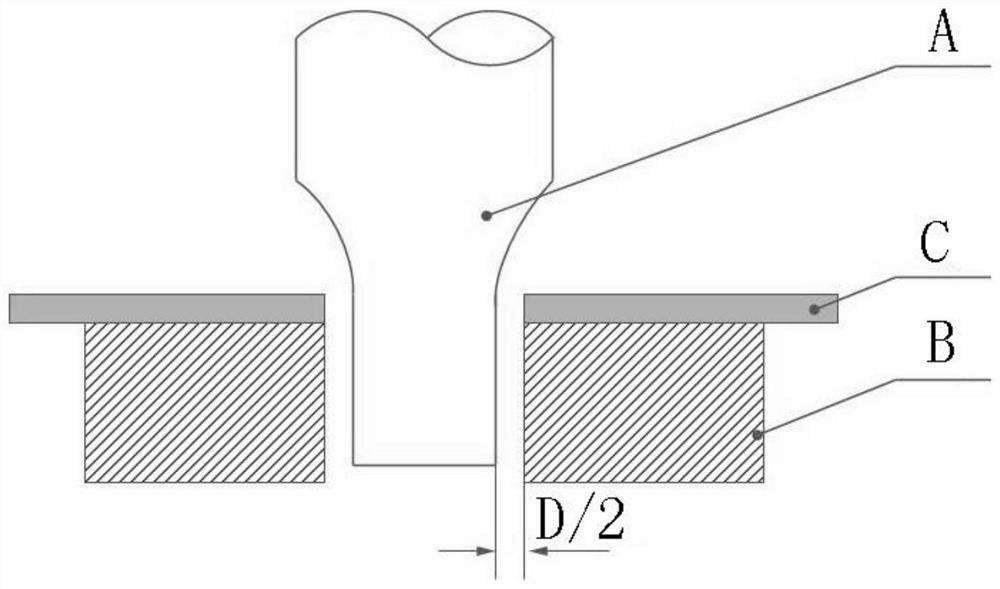

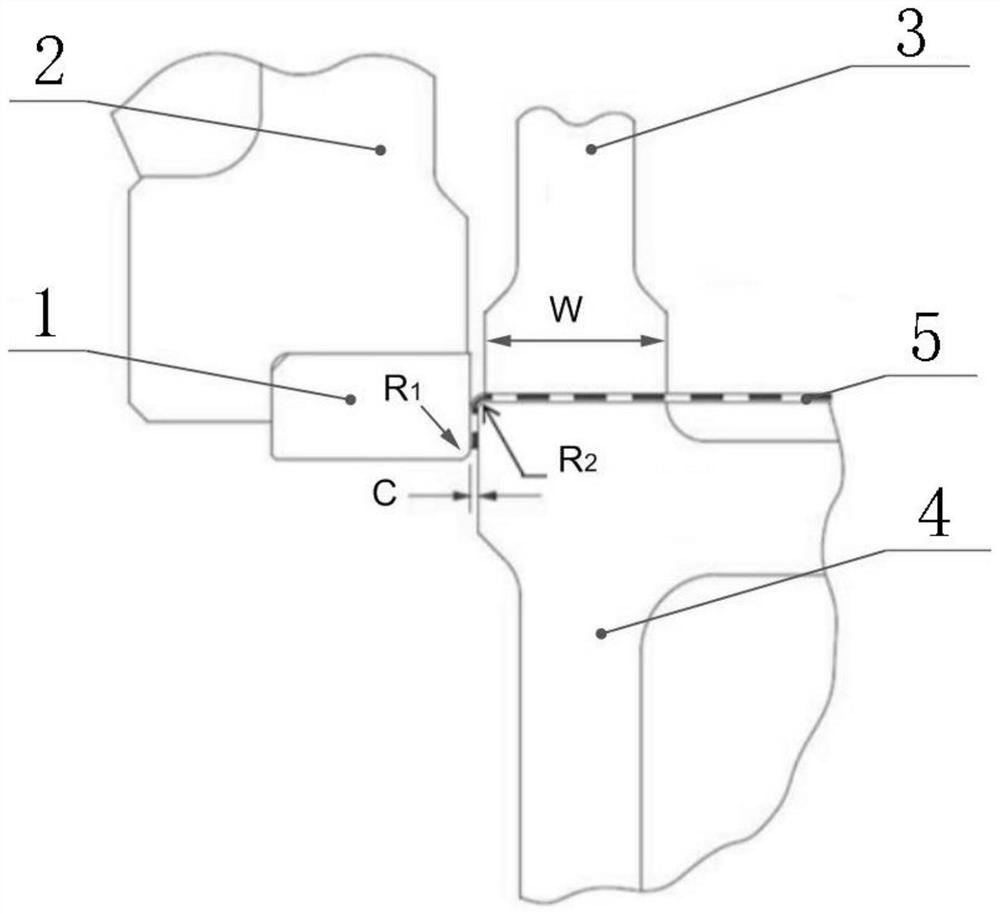

Method for designing stamping die universal for steel and aluminum parts

ActiveCN113857351ARealize stamping and formingReduce development costsShaping toolsFenderMechanical property

The invention discloses a method for designing a stamping die universal for steel and aluminum parts. The method comprises a part basic design procedure, a drawing die design procedure, a trimming die design procedure, a springback compensation procedure, a trimming and punching die design procedure, a flanging die design procedure and formability and size precision evaluation. According to the method for designing the stamping die universal for the steel and aluminum parts, the die designed according to the method can achieve stamping forming of a steel plate and an aluminum plate at the same time on the basis of the mechanical property difference of steel and aluminum, and it can be guaranteed that the stamped parts are free of quality defects such as cracking, wrinkling and size out-of-tolerance; and the method can be effectively applied to development of dies of automobile covering parts such as engine hoods, automobile doors and fenders, the die opening cost of manufacturers is effectively reduced, the method has important significance in pushing lightweight development of automobiles, basic characteristics of steel plate and aluminum plate stamping dies are combined, and therefore the method is easy to master and implement.

Owner:BAOSHAN IRON & STEEL CO LTD

Pneumatic torsion beam stamping die holder assembly

InactiveCN105290222APrevent reverseRapid positioningShaping toolsVehicle componentsEngineeringCushion

The invention discloses a pneumatic torsion beam stamping die holder assembly. An inclined wedge block is arranged in each cavity of a die holder. The opposite ends of the two inclined wedge blocks are each provided with a central spindle. A convex hull is formed integrally on the top face of the left central spindle and is close to the right end face of the corresponding inclined wedge block. The four corners of the top face of the mold holder are provided with stand columns which are cylinders. The four stand columns are distributed in a rectangular manner. The lower ends of the stand columns are fixed to cushion blocks. The left and right ends of the die holder are each provided with a set of connecting plates. The connecting plates are in a long-strip rectangular shape. Front and rear rows of limiting blocks are arranged in the middle of the top face of the die holder. Each limiting block is a big-end-down two-section hollow short column. A screw penetrates the center of each limiting block to be fixed to the die holder. The pneumatic torsion beam stamping die holder assembly is simple and compact in structure, small in height size, easy and convenient to operate and high in production efficiency, the left-right direction of a formed torsion beam can be easily recognized, the torsion beam is conveniently positioned in the follow-up process, and the phenomenon that the torsion beam is placed reversely is avoided.

Owner:CHONGQING SKYMAN AUTOMOBILE BODY MFG

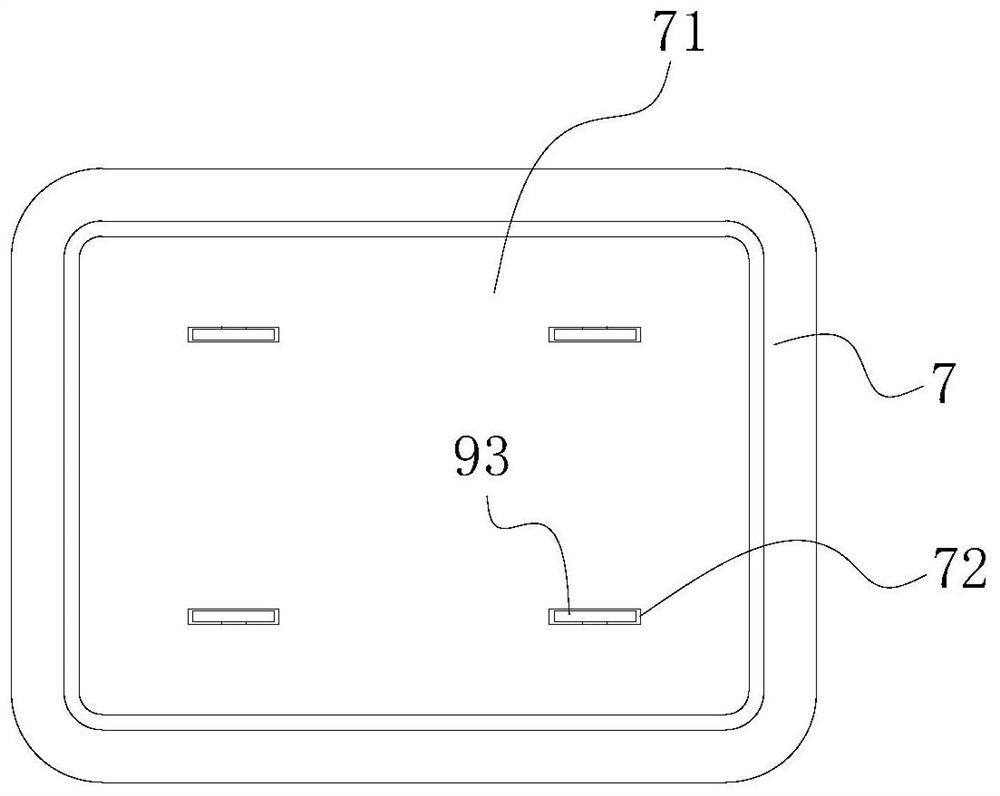

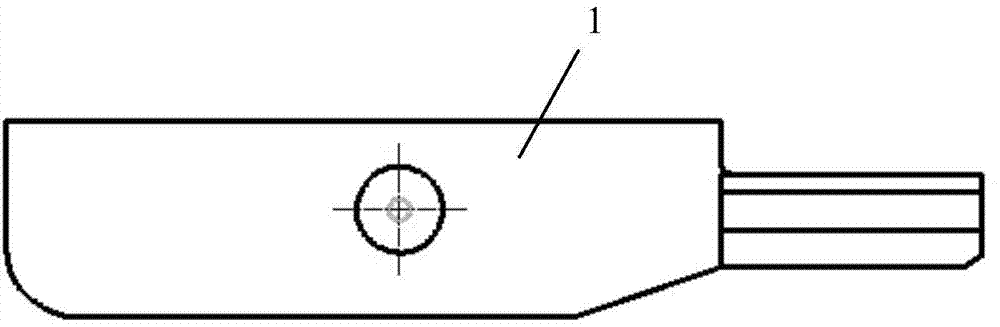

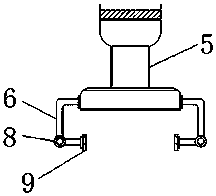

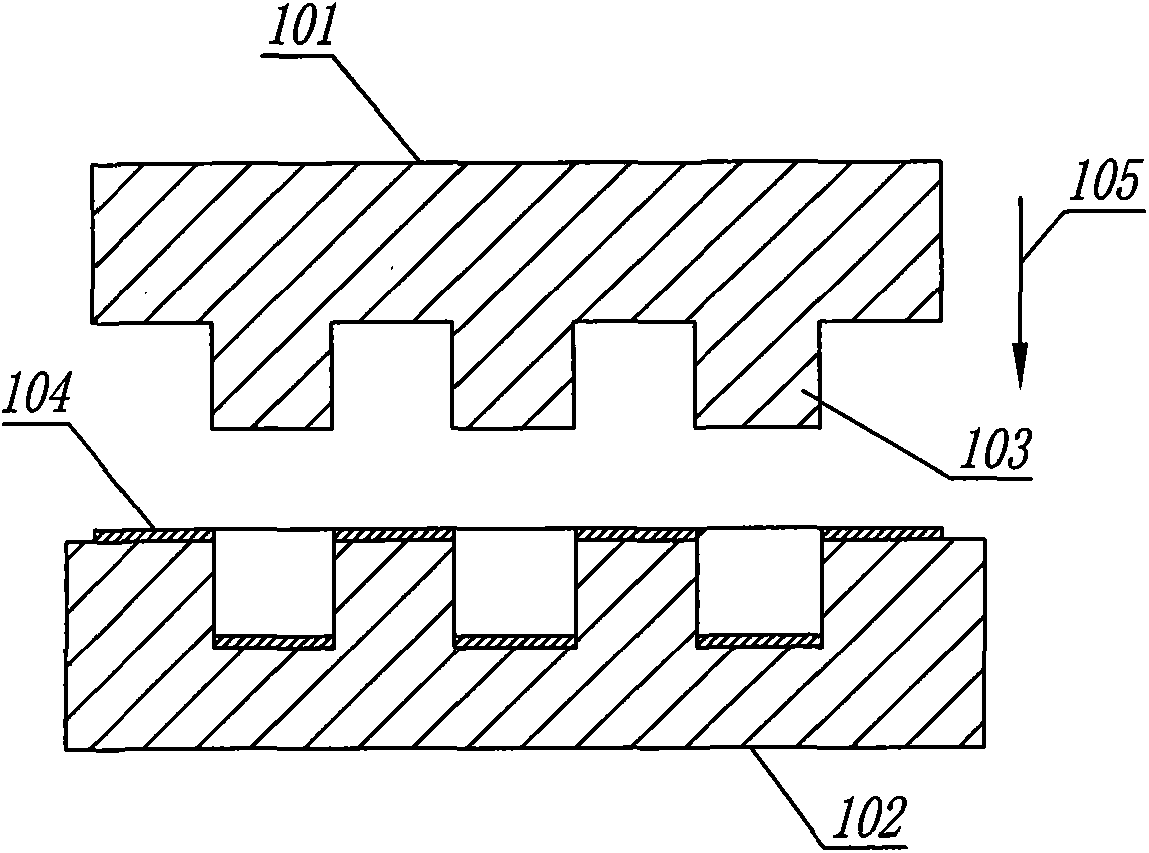

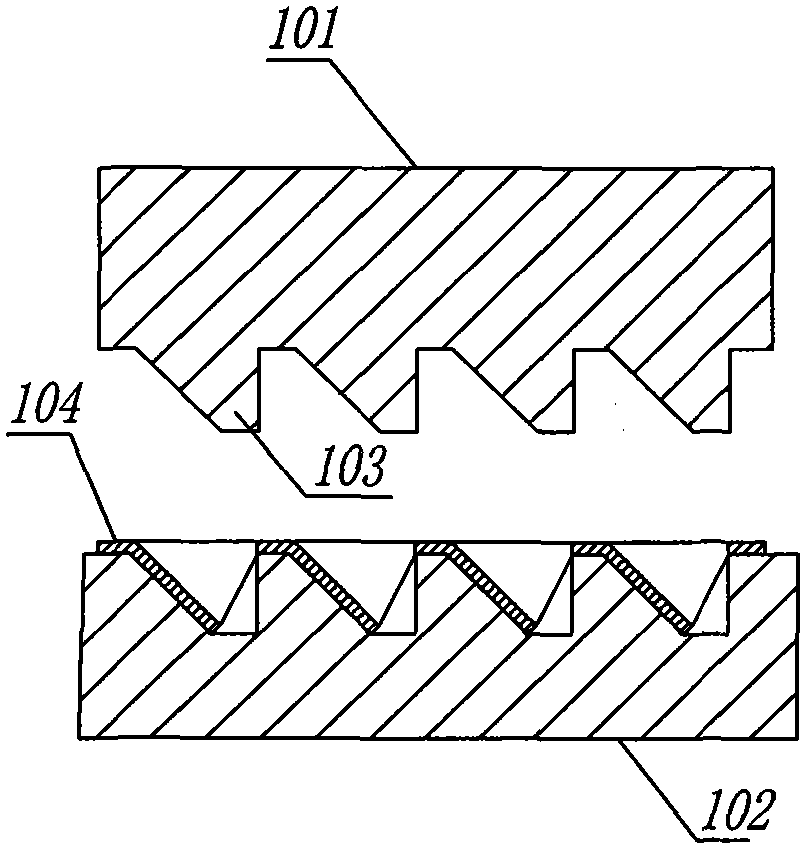

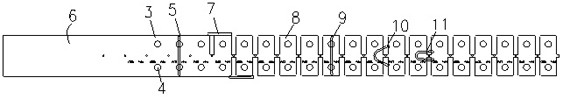

Solid-state light source heat-dissipation metal shell as well as manufacturing method and manufacturing mold thereof

InactiveCN104048277ASimple structureEasy to shapePoint-like light sourceLighting heating/cooling arrangementsEngineeringLouver

The invention provides a solid-state light source heat-dissipation metal shell as well as a manufacturing method and a manufacturing mold thereof. In order to lower the structural member cost and improve the heat-dissipation performance of a solid-state light source, the invention provides a heat-dissipation metal shell (1) as well as a manufacturing method and a manufacturing mold, wherein a metal side wall (2) of the heat-dissipation metal shell (1) is provided with a ventilation window (3); the ventilation window (3) is of a louver-type or staggered structure with formation convex teeth for axial pushing formation; all the formation convex teeth are fixed in a concave mold; a convex mold is provided with a corresponding formation groove; the convex teeth move axially so as to push the metal shell to deform inward, so that an air vent is formed. The used mold is simple in structure, is capable of realizing multi-station continuous mold stamping forming, and is high in production efficiency.

Owner:秦彪

Iron cylinder stamping forming equipment

PendingCN112058990ATo achieve the effect of stampingAchieved the effect of automatic stamping and formingMetal-working feeding devicesPositioning devicesServoStructural engineering

The invention relates to stamping forming equipment, in particular to iron cylinder stamping forming equipment. According to the iron cylinder stamping forming equipment, an iron cylinder can be automatically conveyed, and stamping forming can be automatically conducted on the iron cylinder. The iron cylinder stamping forming equipment comprises a bottom plate, a conveying mechanism, a stamping mechanism, a servo motor, a collecting frame and a pull rod. The conveying mechanism is arranged on the rear side of the top of the bottom plate; the stamping mechanism is arranged on the side, away from the conveying mechanism, of the top of the bottom plate; components of the stamping mechanism are connected with components of the conveying mechanism; the servo motor is arranged in the middle of the top of the bottom plate; an output shaft of the servo motor is connected with components of the conveying mechanism; the collecting frame is placed on the side, close to the servo motor, of the topof the bottom plate; and the pull rod is arranged at the end, away from the servo motor, of the collecting frame. Under the cooperation of the servo motor, the conveying mechanism and the stamping mechanism, iron cylinders can be automatically conveyed to a storage table, and the iron cylinders which are not formed are subjected to stamping forming.

Owner:付帅帅

Production technology of winch support

ActiveCN105033042AOptimize the production processHigh strengthShaping toolsCarbon steelMedium frequency

The invention provides a production technology of a winch support and belongs to the technical field of production and manufacturing of winches. The production technology solves the technical problem that the strength of an existing winch support is low. The production technology of the winch support includes the following steps that a, plate materials are prepared, wherein primitive plates made of medium carbon steel materials are taken and shorn into plate materials for manufacturing the winch support, and the plate materials are placed on a stamping platform; b, impressing is performed, wherein two parallel and spaced impressing marks are pressed on the plate materials in a stamping manner; c, medium frequency heating is performed, wherein the plate materials are transferred to a medium frequency furnace and used for performing local medium-frequency heating on the impressing marks; and d, stamping forming is performed, wherein the plate materials are moved back to the stamping platform, and stamping is performed along the impressing marks so that the plate materials can form the U-shaped winch support. The winch support is made from the medium carbon steel materials. The production technology is improved. While the strength of the winch support made from the medium carbon steel is improved, stamping forming is smoothly performed through impressing, integrating, detecting and other procedures, the precision of the support is improved, and the yield of finished products is increased.

Owner:ZHEJIANG TOPSUN LOGISTIC CONTROL CO LTD

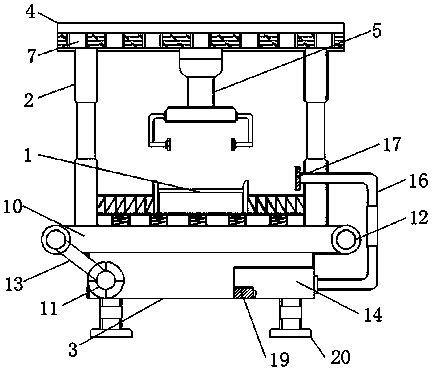

Material taking and stamping device for hot-forging processing

ActiveCN104493062AReduce labor intensityImprove processing efficiencyBoltsForging/hammering/pressing machinesEngineeringUltimate tensile strength

The invention relates to a material taking and stamping device for hot-forging processing. The material taking and stamping device comprises a material taking device and a stamping device, wherein the material taking device is mounted in the middle of the upper end of the stamping device. With the adoption of the material taking device, after external heating equipment finish heating treatment on a rod material, the rod material can be automatically taken out; after the rod material is guided to a determined position, the stamping device can be started; by the utilization of two-time sampling, the rod material can be stamped into a bolt so as to finish the forming processing of the bolt. The material taking and stamping device has the benefits that the material taking and stamping device has the advantages of reasonable structure design, low production and manufacturing cost, high degree of automation, and the like, and can realize automatic material taking and stamping forming in the bolt processing process; a traditional manual handling and clamping way is replaced, so that the labor intensity of workers is reduced, and the bolt forming processing efficiency is improved.

Owner:WUHU YINXING AUTO PARTS

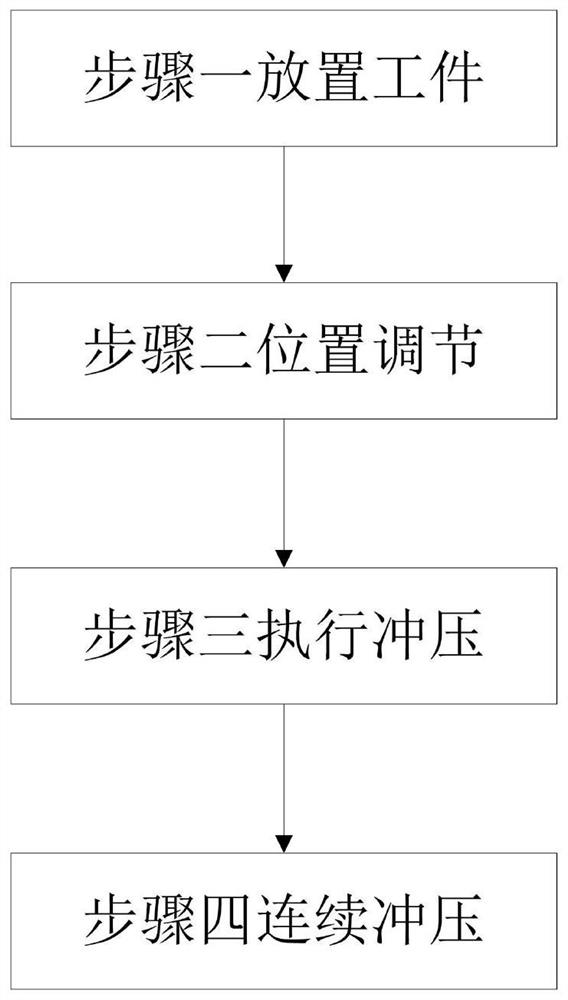

Pressure cooker cover stamping process

InactiveCN112658158AImprove stamping efficiencyRealize stamping and formingShaping toolsMetal-working feeding devicesStamping processMachining

The invention relates to a pressure cooker cover stamping process. According to the pressure cooker cover stamping process, a stamping device is used, and comprises a base and a forming unit, wherein the forming unit is arranged on the upper surface of the base. The pressure cooker cover stamping process can solve the problems that when stamping machining is conducted on a pressure cooker cover at present, a blank piece for manufacturing a rotary table is placed on an existing stamping device in a manual holding mode, and the formed rotary table is still taken down manually after the blank piece is stamped, by means of the taking and placing mode, hands are located in the stamping device many times, workers are in danger all the time, the stamping efficiency of the rotary table can be reduced due to the feeding and discharging mode, dies in the stamping device need to be replaced when an existing stamping device stamps rotary tables of different sizes, the process wastes time and labor, and the overall production progress of the rotary table is influenced.

Owner:朱新科

Pneumatic vehicle V-shaped torsion beam molding device

InactiveCN105328034ADoes not affect functionalityEnsure consistencyShaping toolsVehicle componentsMechanical engineeringSteel plates

The invention discloses a pneumatic vehicle V-shaped torsion beam molding device. Molding cavities are symmetrically formed in the left and right ends of a mold base; inclined wedges are respectively arranged in the two molding cavities; the inclined wedges at the left and right edges are symmetrical; mandrels are respectively arranged at opposite ends of the two inclined wedges, are fixed with the corresponding inclined wedges, and can extend into molding grooves; front and back two rows of limiting blocks are arranged at the middle part of the top surface of the mold base; the limiting blocks are two-section type hollow short columns with small tops and big bottoms; screws are inserted in the centers of the limiting blocks for fixing with the mold base; guide grooves are symmetrically formed in the front and back two edges of the left end of the mold base, and guide grooves are symmetrically formed in the front and back edges of the right end of the mold base; and wear resisting plates are respectively bonded on three inner walls of each guide groove, and are steel plates. The pneumatic vehicle V-shaped torsion beam molding device is skillful in concept, reasonable in design, easy to be implemented, small in height size and low in production cost; and a molded torsion beam is easy to identify a left-right direction, so that the positioning of the torsion beam in subsequent procedures is convenient.

Owner:CHONGQING SKYMAN AUTOMOBILE BODY MFG

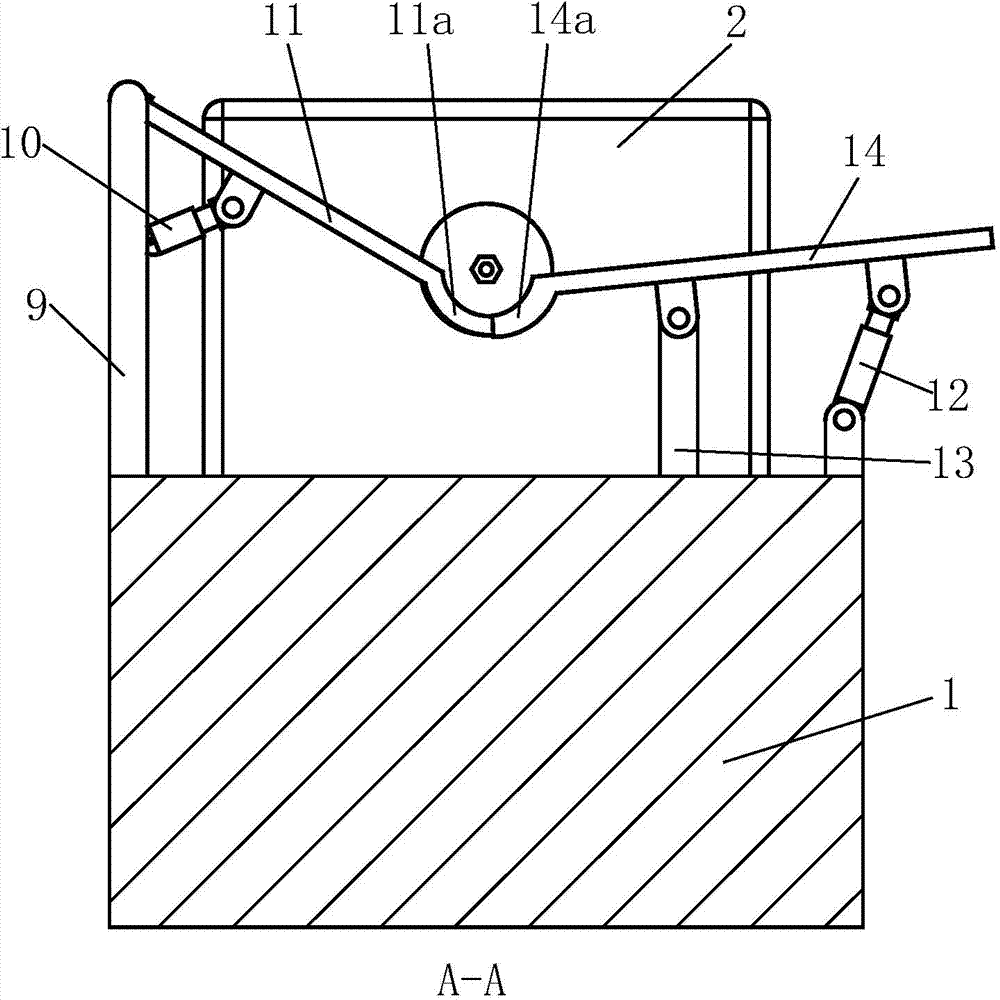

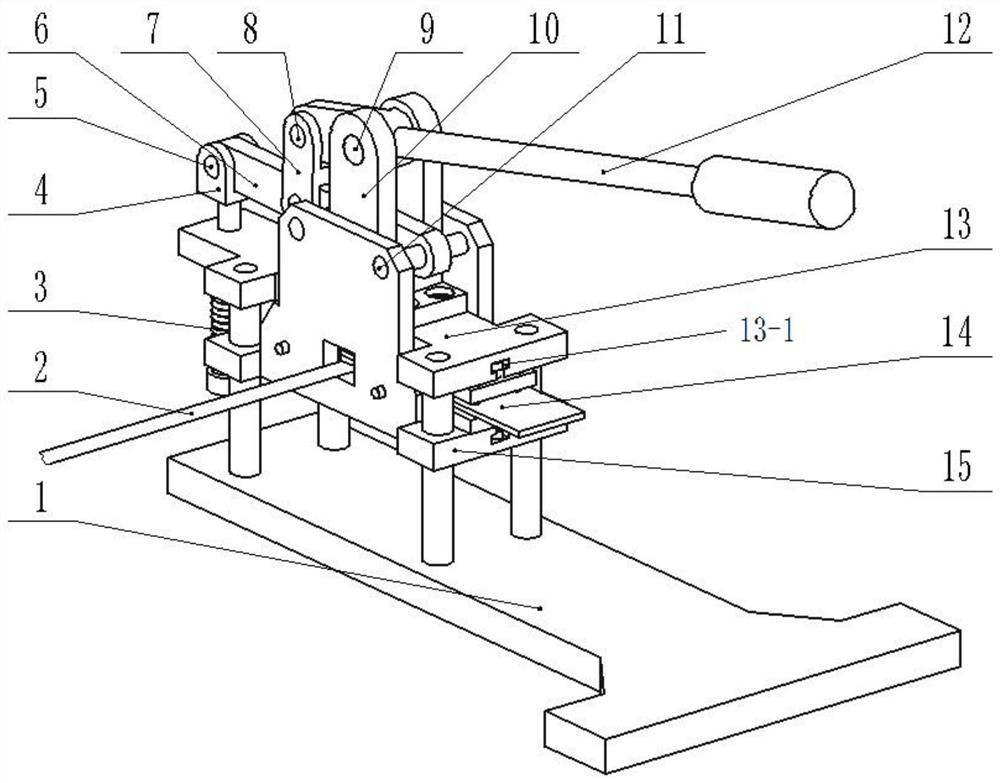

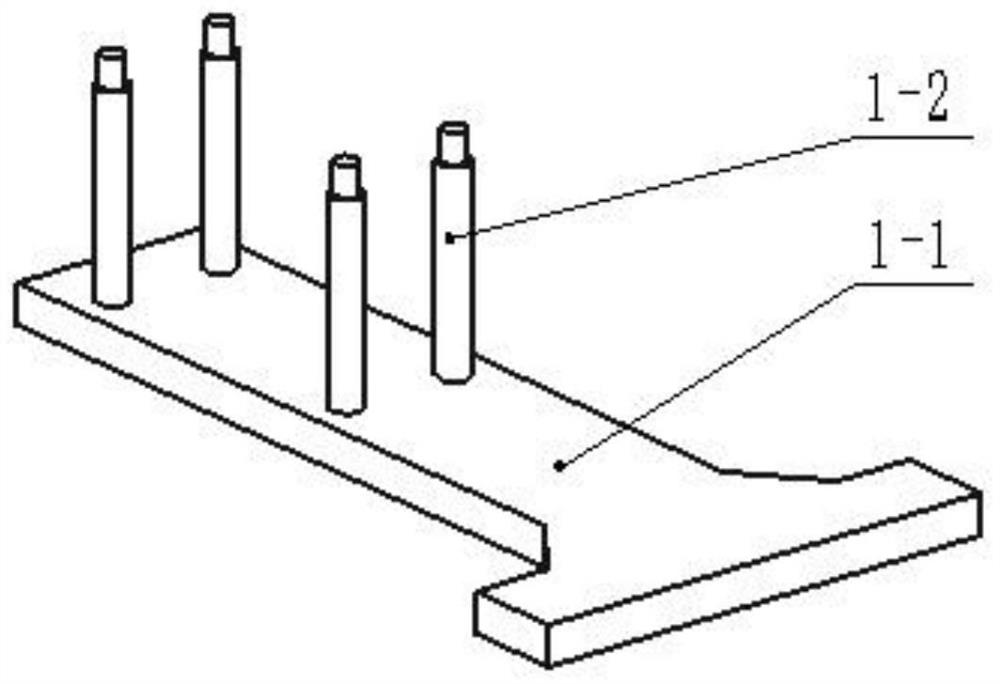

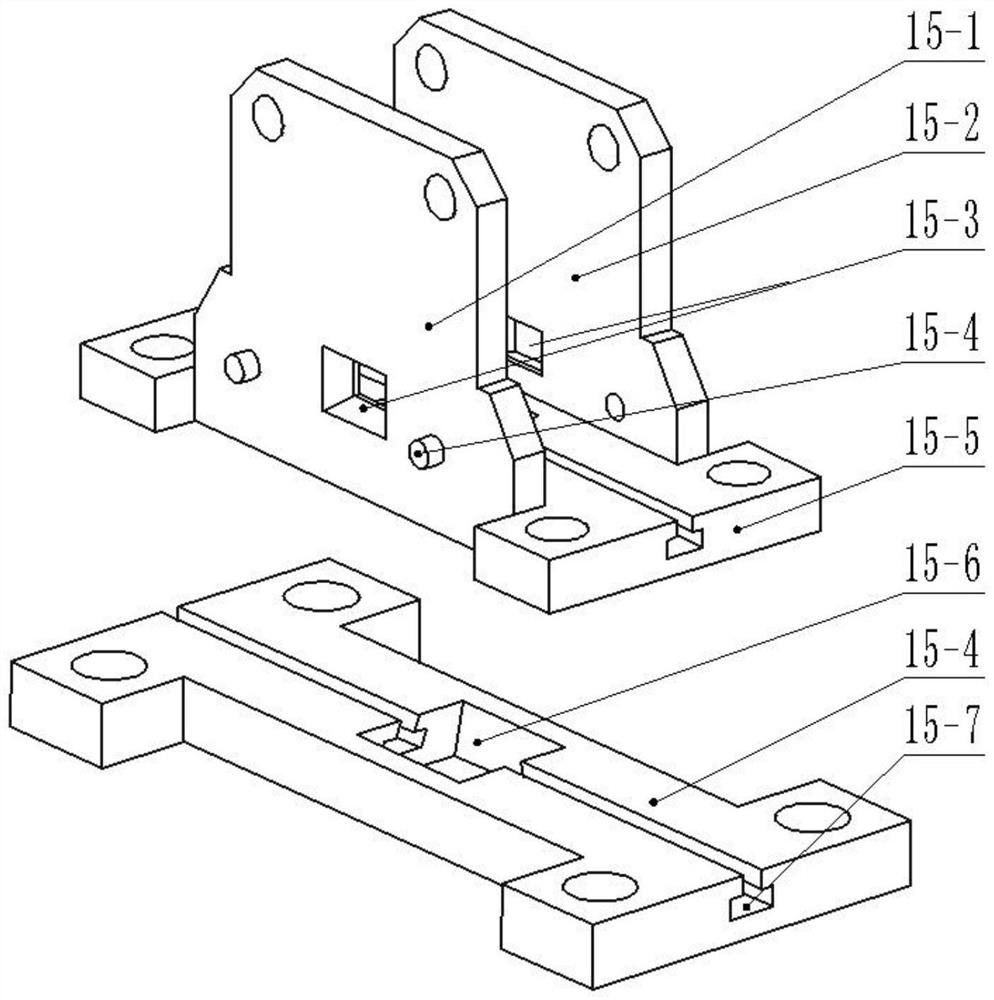

Composite cable clamp stamping tool and stamping method thereof

ActiveCN112045048AAvoid Die Change ProblemsGeneralizationShaping toolsManufacturing engineeringMachine building

The invention relates to a composite cable clamp stamping tool and a stamping method thereof, belongs to the technical field of mechanical manufacturing equipment, and solves problems of time and labor waste in the clamp manufacturing process, poor clamp uniformity and high production cost in the prior art. A composite stamping mold of the composite cable clamp stamping tool is provided with a first mold and a second mold which can move relatively, the first mold and the second mold are provided with multiple sets of stamping units, an outer arc punch and a round hole punch of the first mold are matched with an outer arc punching groove and a round hole punching groove of the second mold to achieve stamping of a cable clamp, the first mold and the second mold of the composite stamping moldare driven by a connecting rod mechanism to perform stamping, and reset is conducted through a reset spring after stamping is completed. According to the composite cable clamp stamping tool, clamps of different models can be manufactured, repeated disassembly and assembly of molds are not needed, raw materials are saved, the uniformity and the quality reliability of the clamps are improved, and the production cost is reduced.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

One-time forming mold for cable clamp body

The invention relates to the field of moulds, in particular to a one-time molding mold for a wire clamp body, comprising: an upper mold, a lower mold, and a punching device located between the upper and lower molds, which is suitable for symmetrically opening a sheet with holes; Corner device, which is suitable for chamfering the two sides of the sheet body; shape cutting device, which is suitable for cutting the sheet body perpendicular to the length direction of the sheet body to form a second sheet body; end bending device, which is suitable for The end of the second sheet is bent; the first bending device is suitable for pre-bending the middle of the second sheet; the second bending device is suitable for bending the middle of the second sheet; the top output device, which is suitable for blanking the second sheet; the process in this scheme is punching-chamfering-cutting-end bending-pre-bending-bending-discharging, 6 processes Realize the one-time stamping and forming of the clamp body.

Owner:中铁建电气化局集团轨道交通器材有限公司

Forming die assembly

InactiveCN105458089ALow costRealize stamping and formingShaping toolsVehicle componentsEngineeringMechanical engineering

The invention discloses a forming die assembly. The forming die assembly is characterized in that an inclined wedge block is arranged in each cavity of a die holder; core shafts are arranged at the opposite ends of the two inclined wedge blocks; a boss is integrally formed on the top surface of the core shaft on the left; the boss is near the right end face of the corresponding inclined wedge block; upright posts are arranged at the four corners of the top surface of the die holder; the lower ends of the upright posts are fixed to cushion blocks; a group of connecting plates is arranged at each of the left end and the right end of the die holder; the connecting plates adopt a long rectangle shape; two front-back rows of limiting blocks are arranged in the middle of the top surface of the die holder; the limiting blocks are hollow two-section short columns which are small in the upper parts and are large in the lower parts; guide grooves are symmetrically formed in the front and back sides of the left end of the die holder, and are symmetrically formed in the front and back sides of the right end of the die holder as well; abrasion resistant plates are pasted on the three inner walls of each guide groove; and the abrasion resistant plates are steel plates. The forming die assembly is easy to implement, simple in structure, and high in production efficiency, and a formed torsion beam easily recognizes the left and right directions.

Owner:CHONGQING SKYMAN AUTOMOBILE BODY MFG

Pneumatic type positioning device used for torsion beam punch forming

InactiveCN105251905APrevent reverseRapid positioningShaping toolsMetal-working feeding devicesEngineeringCushion

The invention discloses a pneumatic type positioning device used for torsion beam punch forming. A tapered wedge block is arranged in each mould cavity of a mould base; opposite ends of two tapered wedge blocks are provided with mandrels; the top surface of the left mandrel is integrally formed with a convex hull which is close to the right end surface of the corresponding tapered wedge block; stand columns are arranged on four corners of the top surface of the mould base, and the lower end of each stand column is fixed with a cushion block; a group of connecting plates is arranged at each of left and right ends of the mould base; the connecting plates are in the shapes of long-strip rectangles; front and rear rows of limiting blocks are arranged on the middle part of the top surface of the mould base; the limiting blocks are two-section type hollow short columns which are small in upper parts and large in lower parts; guide slots are symmetrically formed in front and rear sides of the left end of the mould base; guide slots are also symmetrically formed in front and rear sides of the right end of the mould base; and the four guide slots are distributed in the shape of a rectangle. The pneumatic type positioning device is delicate in conception, reasonable in design, easy to implement, simple in structure and high in production efficiency; and the formed torsion beam is easy to identify in a left-right direction.

Owner:CHONGQING SKYMAN AUTOMOBILE BODY MFG

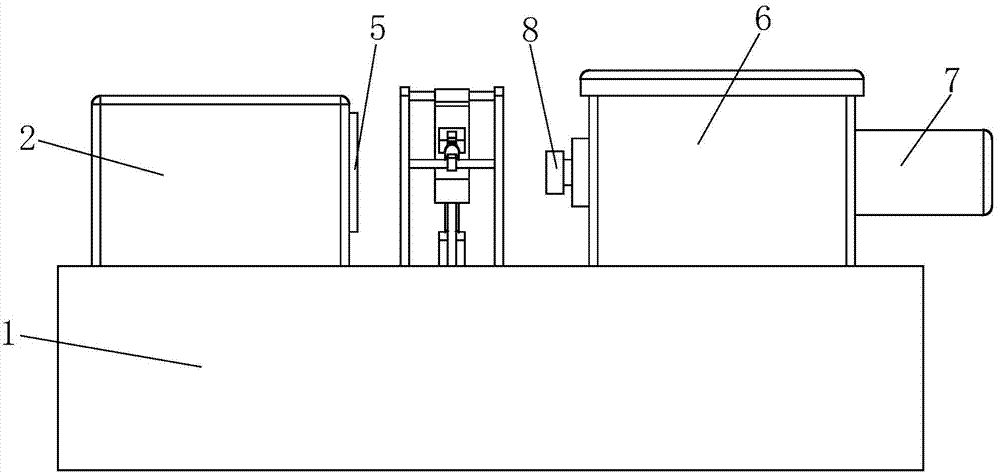

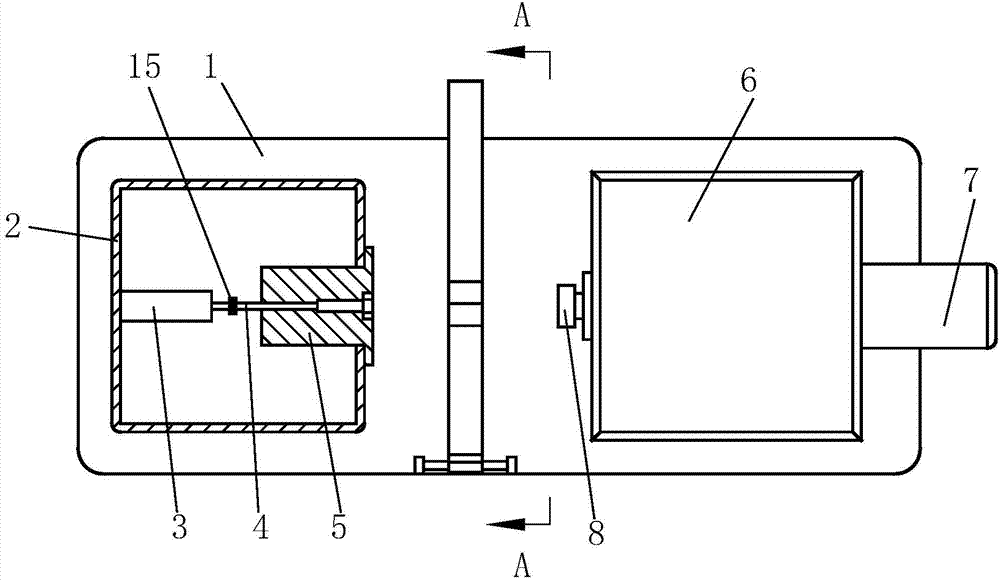

Forming device of microstructure on inner wall of tube

PendingCN109622707AQuick fixRealize stamping and formingMetal-working feeding devicesPositioning devicesInner wall zoneMicrostructure

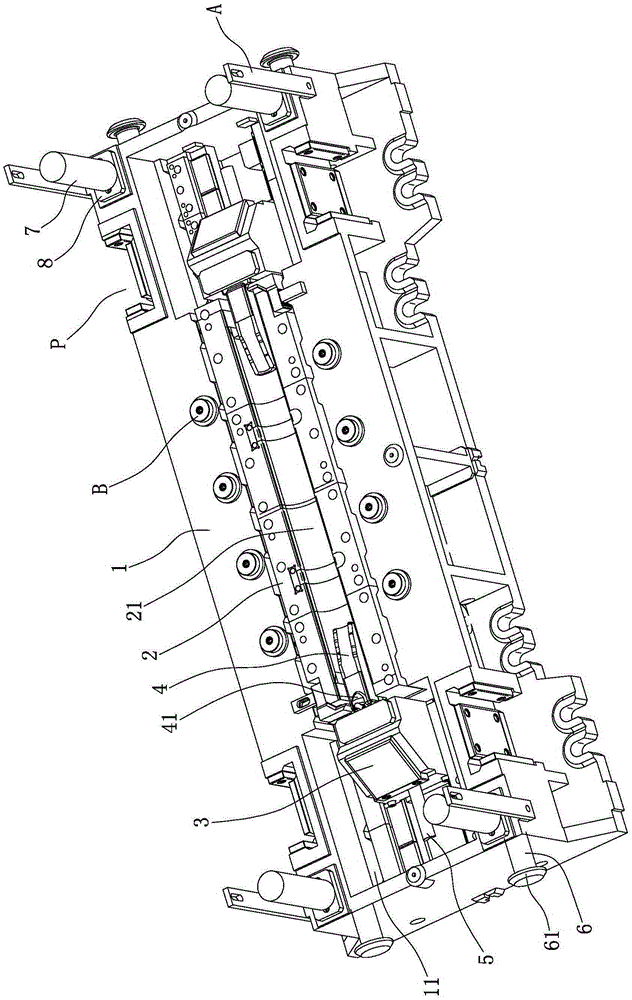

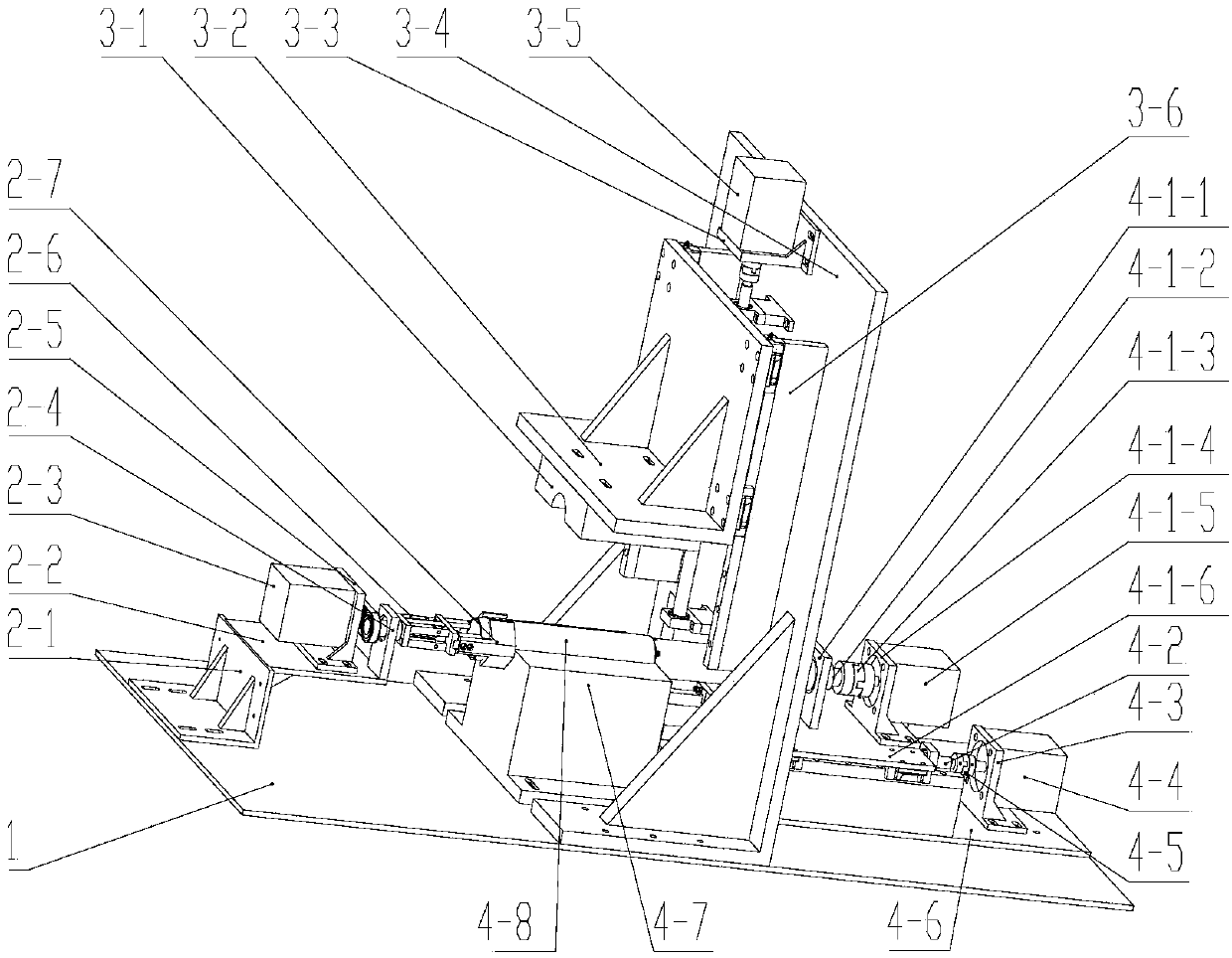

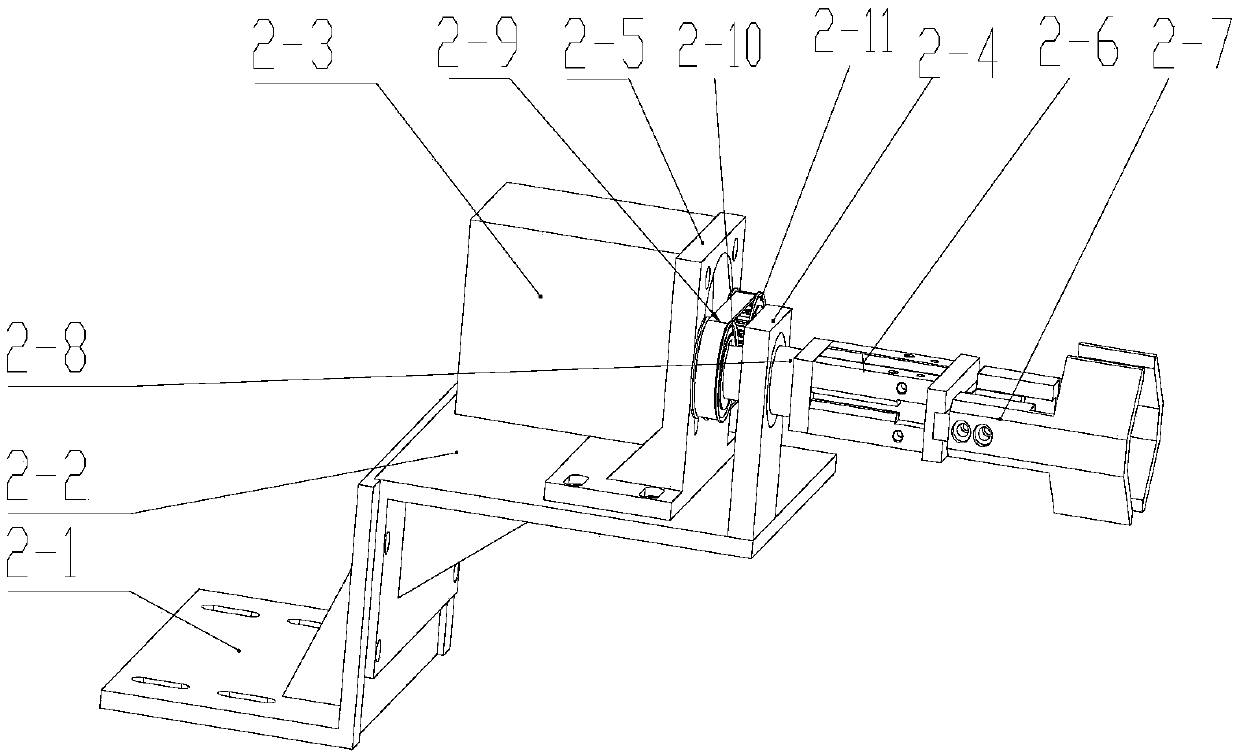

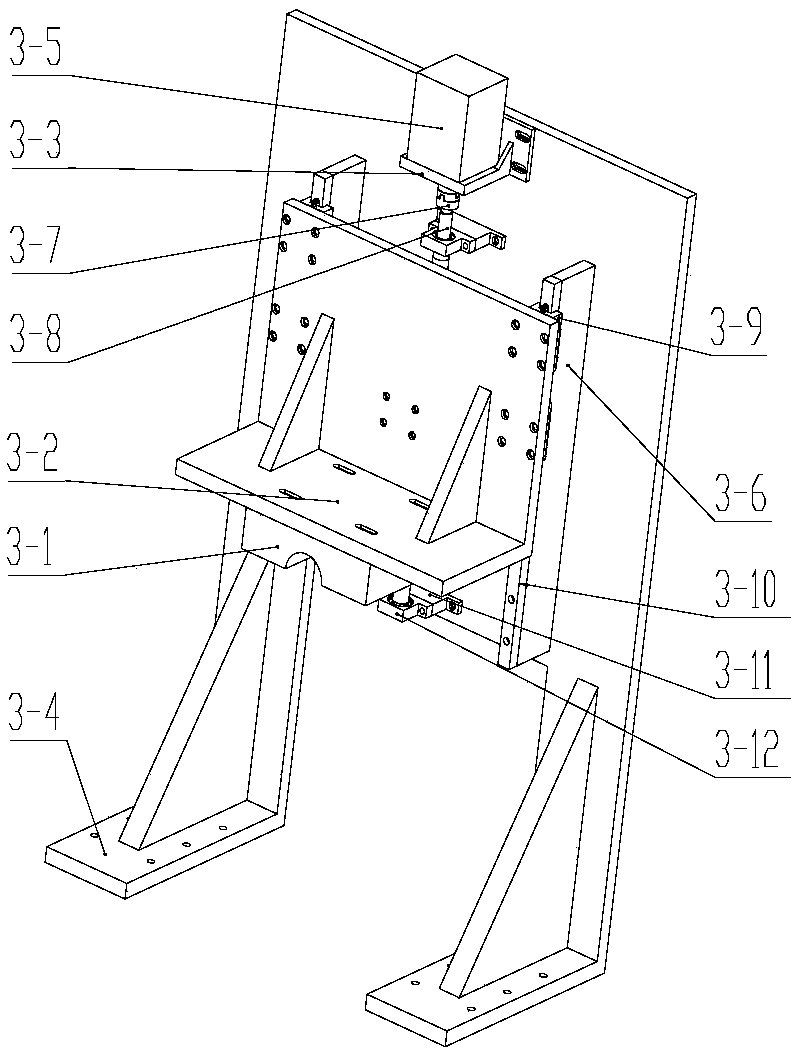

The invention discloses a forming device of a microstructure on the inner wall of a tube, and relates to microstructures on the inner walls of tubes. The forming device is provided a large bottom plate, a clamping and rotating mechanism, a pressing mechanism and a stamping forming assembly, wherein the clamping and rotating mechanism, the pressing mechanism and the stamping forming assembly are fixed on the large bottom plate, the clamping and rotating mechanism is provided with a heightening supporting seat, a first mounting seat, a first servo motor, a first bearing block, a first motor mounting seat, a clamping air cylinder, a pneumatic claw, a cylinder rotating shaft, a belt and belt wheels, the pressing mechanism is provided with a positioning upper cover, an upper cover mounting seat, a second motor mounting seat, a second mounting seat, a second servo motor, a first heightening seat, a first coupler, a first screw rod, first sliding blocks, first sliding rails and a bearing heightening seat, the stamping forming assembly is provided with a stamping forming mechanism, a second screw rod, a fourth motor mounting seat, a fourth servo motor, a third coupler, a mounting plate, apositioning base, a to-be-machined part, second sliding rails, second sliding blocks, a fifth bearing block and a second heightening seat, and the stamping forming mechanism is provided with third bearing blocks, a first transmission shaft, a second coupler, a third motor mounting seat, a third servo motor, a movable plate, a fourth bearing block, a guide sleeve and a rack for stamping.

Owner:XIAMEN UNIV

A production process of winch support

ActiveCN105033042BHigh precisionImprove yieldShaping toolsManufacturing technologyIntermediate frequency

The invention provides a production process of a winch bracket, which belongs to the technical field of winch manufacture. It solves the technical problems such as low strength of the existing winch support. The production process of the winch support includes the following steps: a, sheet material preparation: take the original plate material of medium carbon steel and cut it into a sheet material for manufacturing the winch support, and place it on the stamping table; b, embossing: adopt the stamping method Extrude two parallel and spaced imprints on the sheet; c, intermediate frequency heating: transfer the sheet to an intermediate frequency furnace for local intermediate frequency heating on the imprint; d, stamping: move the sheet back to the stamping table, and Stamping with the imprint makes the sheet into a U-shaped winch bracket. The winch bracket in the present invention is made of medium carbon steel, and the production process is improved. While the winch bracket is made of medium carbon steel to improve its strength, it is smoothly stamped and formed by embossing, shaping, testing and other processes to improve the accuracy of the bracket. degree and yield.

Owner:ZHEJIANG TOPSUN LOGISTIC CONTROL CO LTD

Stamping die assembly for vehicle

InactiveCN105251882AEasy to assemble and disassembleEasy to replaceShaping toolsTransverse grooveFront edge

The invention discloses a stamping die assembly for a vehicle. Cavities are symmetrically formed in the left end and the right end of a die base, and the two cavities are communicated through a transverse groove; a plurality of sequentially-jointed inserts are fixedly arranged in the transverse groove, an inclined wedge block is arranged in each cavity of the die base, and the inclined wedge blocks are connected with a piston rod of an air cylinder; core shafts are arranged at the opposite ends of the two inclined wedge blocks, the core shafts and the corresponding inclined wedge blocks are fixed, and the core shafts can extend into a molding groove; stand columns are arranged at four corners of the top face of the die base and are cylinders, and the four stand columns are distributed in a rectangular shape; guide grooves are symmetrically formed in the front edge and the back edge of the left end of the die base, guide grooves are symmetrically formed in the front edge and the back edge of the right end of the die base, and the four guide grooves are distributed in a rectangular shape; and wear-resisting plates are attached to the three inner walls of each guide groove and are steel plates. The stamping die is ingenious in conception, reasonable in design, easy to implement, small in labor intensity of workers and high in efficiency; and operation for molding a torsion beam is easy and convenient.

Owner:CHONGQING SKYMAN AUTOMOBILE BODY MFG

Torsion beam lower die with opposite air cylinders

InactiveCN105328036APrevent reverseRapid positioningShaping toolsVehicle componentsEngineeringFront edge

The invention discloses a torsion beam lower die with opposite air cylinders. Cavities are symmetrically arranged at the left end and the right end of a die holder, and a wedge block is arranged in each cavity of the die holder; upright posts are arranged at four corners of the top surface of the die holder, the upright posts are cylinders, the four upright posts are in rectangular distribution, the lower ends of the upright posts are fixed to cushion blocks, and the cushion blocks are fixedly connected with the die holder via bolts; a front row of stop blocks and a rear row of stop blocks are arranged in the middle of the top surface of the die holder, each stop block is a two-segment hollow short column with a small top and a large bottom, and screws penetrate the centers of the stop blocks and fixed to the die holder; guide grooves are symmetrically formed in the front edge and the rear edge at the left end of the die holder, guide grooves are also formed in the front edge and the rear edge at the right end of the die holder, and the four guide grooves are in rectangular distribution; and abrasion-resistant plates are mounted on three inner walls of each guide groove, and the abrasion-resistant plates are steel plates. The lower die has the advantages as follows: the design is reasonable, a formed torsion beam is simple and convenient to operate, the labor intensity of workers is low, the production efficiency is high, and the left and right directions of the formed torsion beam are easy to identify.

Owner:CHONGQING SKYMAN AUTOMOBILE BODY MFG

Pipe type V-shaped torsion beam mold for two-way cylinder type vehicle

InactiveCN105251883APrevent reverseRapid positioningShaping toolsVehicle componentsWear resistantEngineering

The invention discloses a pipe type V-shaped torsion beam mold for a two-way cylinder type vehicle. Wedge blocks are respectively arranged in each molding cavity of a mold base; mandrels are respectively arranged at opposite ends of two wedge blocks; a convex hull is integrally formed on the top surface of the mandrel at the left side; stand columns are arranged at four corners of the top surface of the mold base, are cylinders, and are distributed in a rectangular manner; the lower end of each stand column is fixed with cushion blocks; the cushion blocks are fixedly connected with the mold base through bolts; one set of connecting plates is respectively arranged at the left and right ends of the mold base; each set of connecting plates is divided into front and back two parts; four connecting plates are distributed in a rectangular manner; the connecting plates are strip rectangles; guide grooves are symmetrically formed in the front and back edges of the left end of the mold base; guide grooves are symmetrically formed in the front and back edges of the right end of the mold base; four guide grooves are distributed in a rectangular manner; and wear resistant plates are respectively bonded on three inner walls of each guide groove, and are steel plates. The mold is reasonable in design, is convenient for torsion beam molding operation, is low in labor intensity of workers, and is high in production efficiency.

Owner:CHONGQING SKYMAN AUTOMOBILE BODY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com