Patents

Literature

77results about How to "Optimize the production process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Saccharomycete for high-yield production of ethyl acetate under low temperature and application thereof

ActiveCN105349444ALow fermentation temperatureOptimize the production processFungiMicroorganism based processesLaboratory cultureChemistry

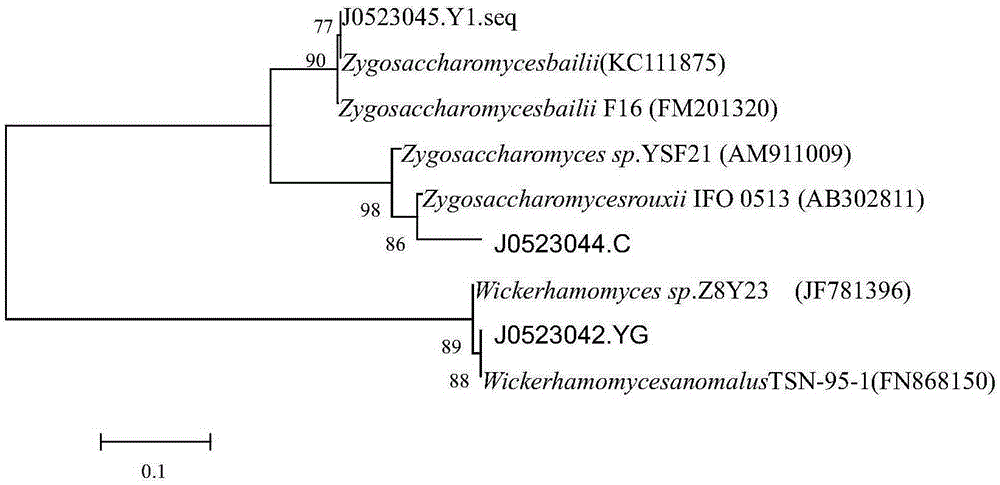

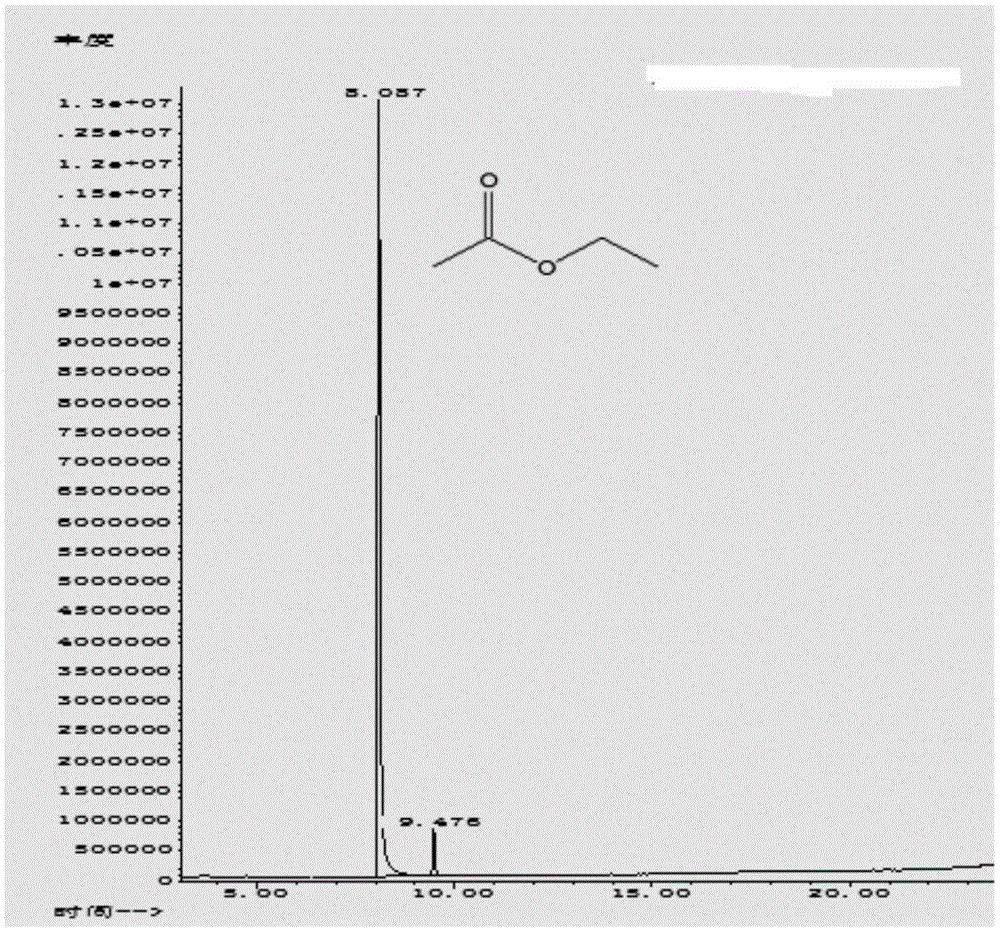

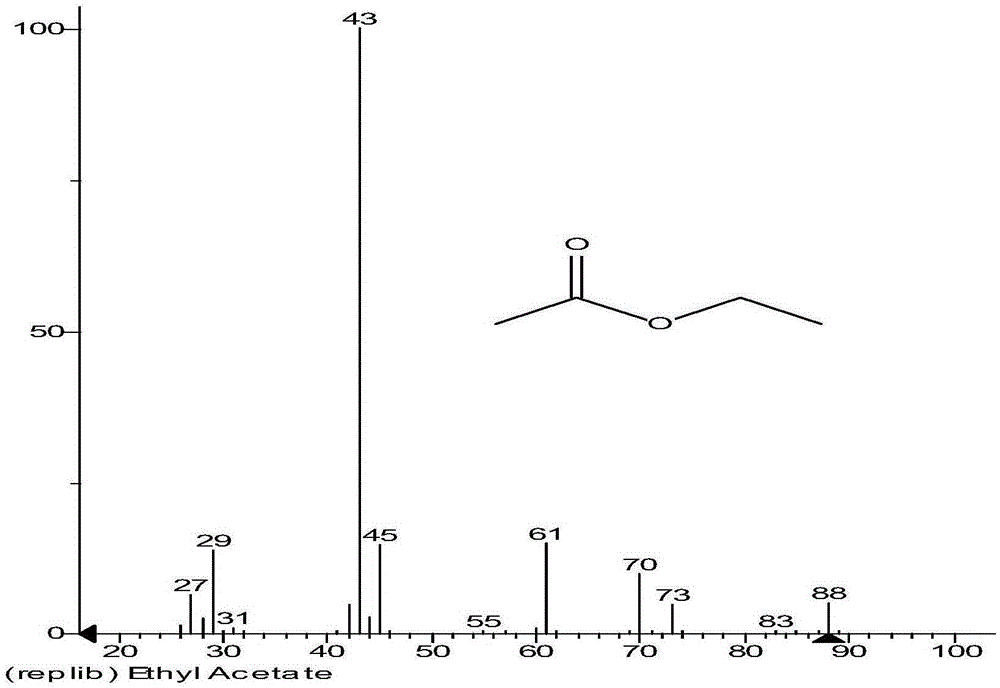

The invention discloses saccharomycete for high-yield production of ethyl acetate under low temperature and belongs to the field of the bioengineering technology. The bacterial strain is Wickerhamomycesanomalus which is preserved in the China General Microbiological Culture Collection Center on Jan 19, 2015 with the preservation number being CGMCC No.10370. The optimum temperature for producing ethyl acetate by means of the strain is 22 DEG C, acid resistance is pH 2.5-7.0, salt tolerance is 0-15% (NaCl%), and ethanol tolerance is 0-10%(v%). Metabolites generated from fermentation are ethyl acetate and a small amount of ethyl alcohol only and do not include fusel oil. The strain can be applied to the traditional fermentation industry for producing table vinegar, soy sauce, fermented soya beans, fermented flour sauce, fermented alcoholic drink, distilled liquor, compound wine and the like, as well as the food industry as an important functional bacterium. Fermentation temperature adopted in traditional production is reduced, the production technology is optimized, production energy consumption and cost are reduced, the content of ethyl acetate is increased, the taste of a product is improved, the quality of the product is improved, and economic benefits are great.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Method for implementing real time altering virtual role appearance in network game

InactiveCN101276475AOptimize the production processImprove implementation efficiencyAnimationSpecial data processing applicationsClient-sideTime changes

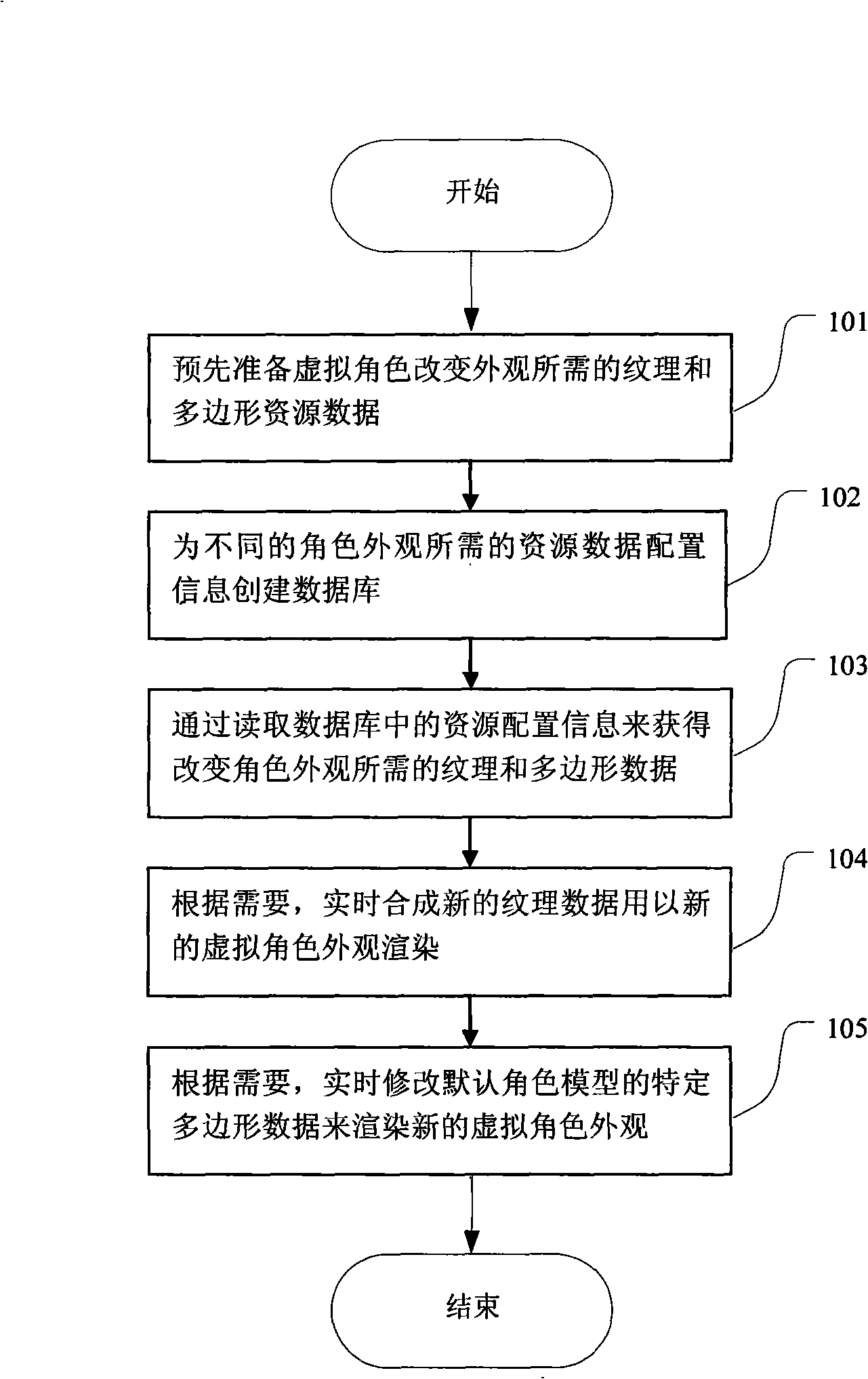

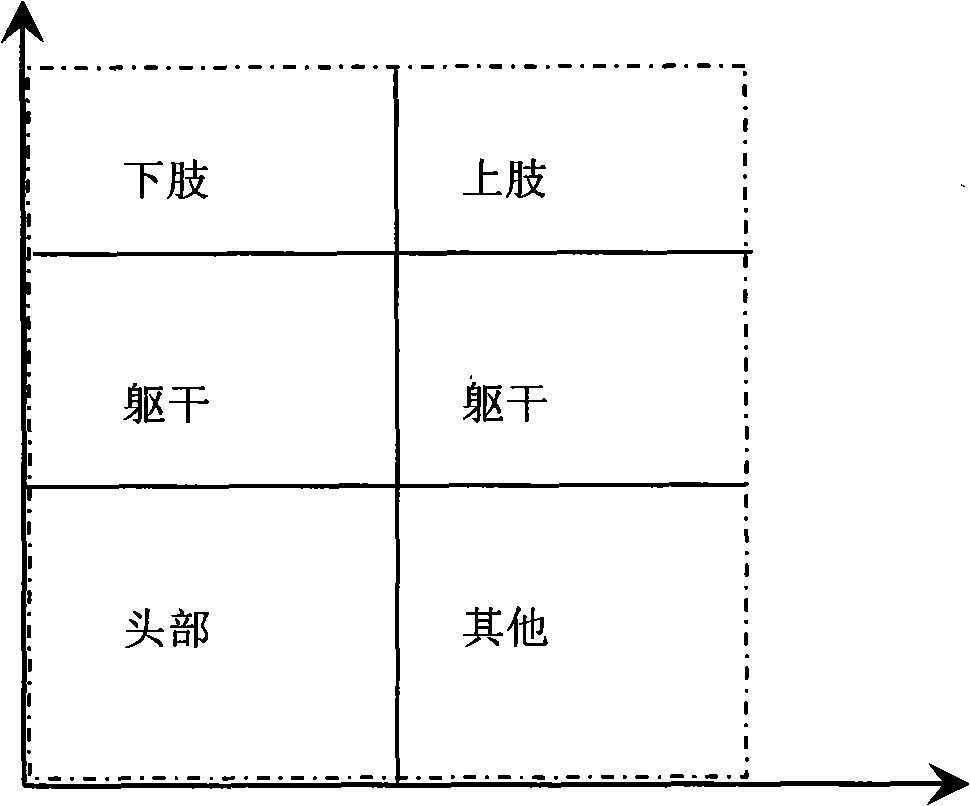

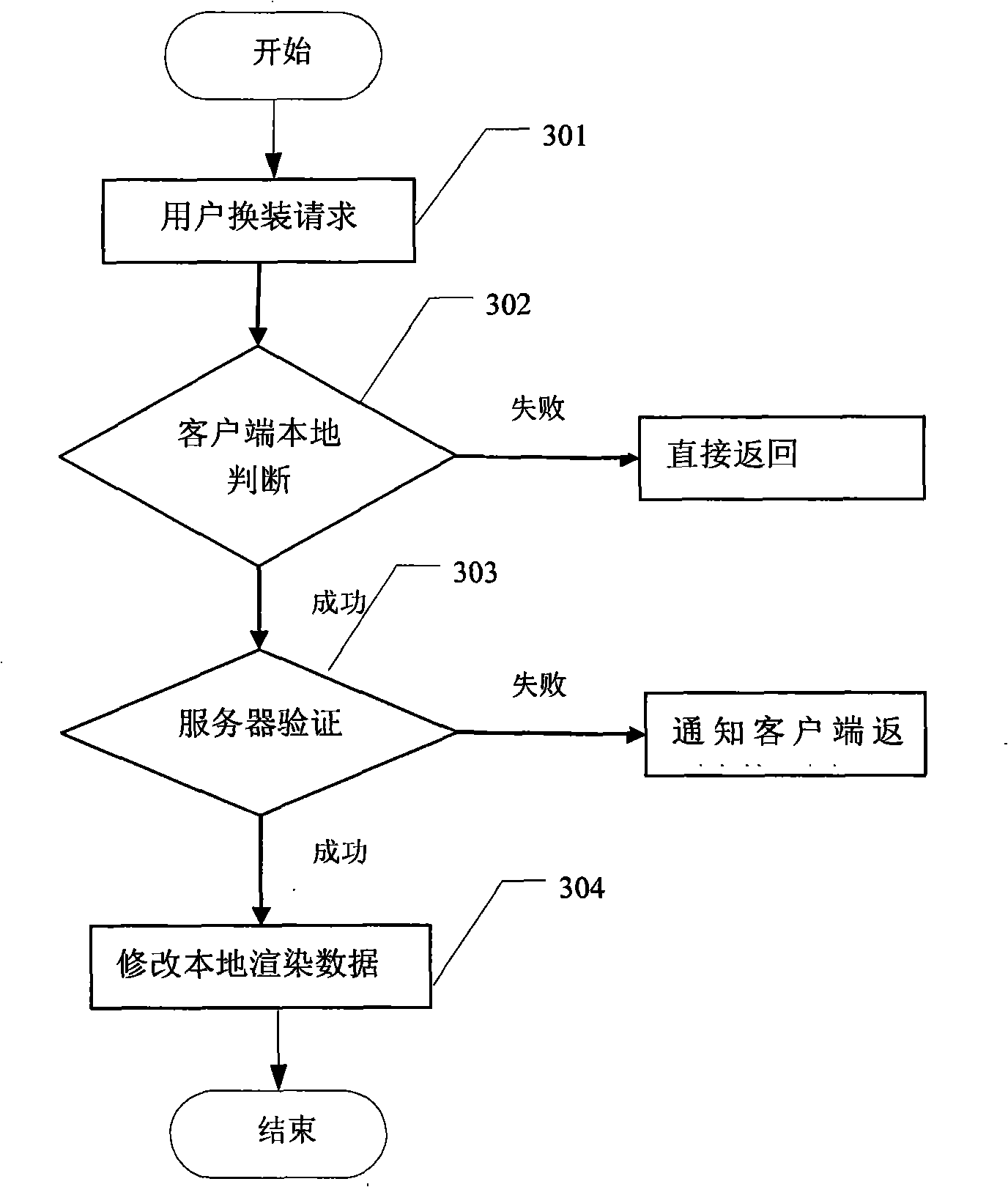

The invention discloses a method for real-time changing appearances of virtual roles in a network game, comprising steps of: a, preparing venation and polygon resource data in advance for changing the appearances of the virtual roles; b, configurating an information creation database for the resource data for changing the appearances of different virtual roles; c, obtaining the venation and polygon resource data for changing the appearances of the virtual roles by reading resource configuration information in the database during the game operation process; and real-time changing the appearances of the virtual roles based on a user request message. According to the invention, the appearances of the virtual roles are changed by real-time changing the venation material and polygon vertex data of the virtual roles in the game based on the prior art, thereby effectively avoiding problems of role design, venation capability, cartoon synchronization, etc., improving the manufacturing process and realizing efficiency, and increasing the operation efficiency of the network game client.

Owner:KONKA GROUP

Single-face metallic waveguide Terahertz quantum cascaded laser and production method thereof

ActiveCN101345393AOptimize the production processReduce pollutionOptical wave guidanceLaser detailsMultiple quantumEtching

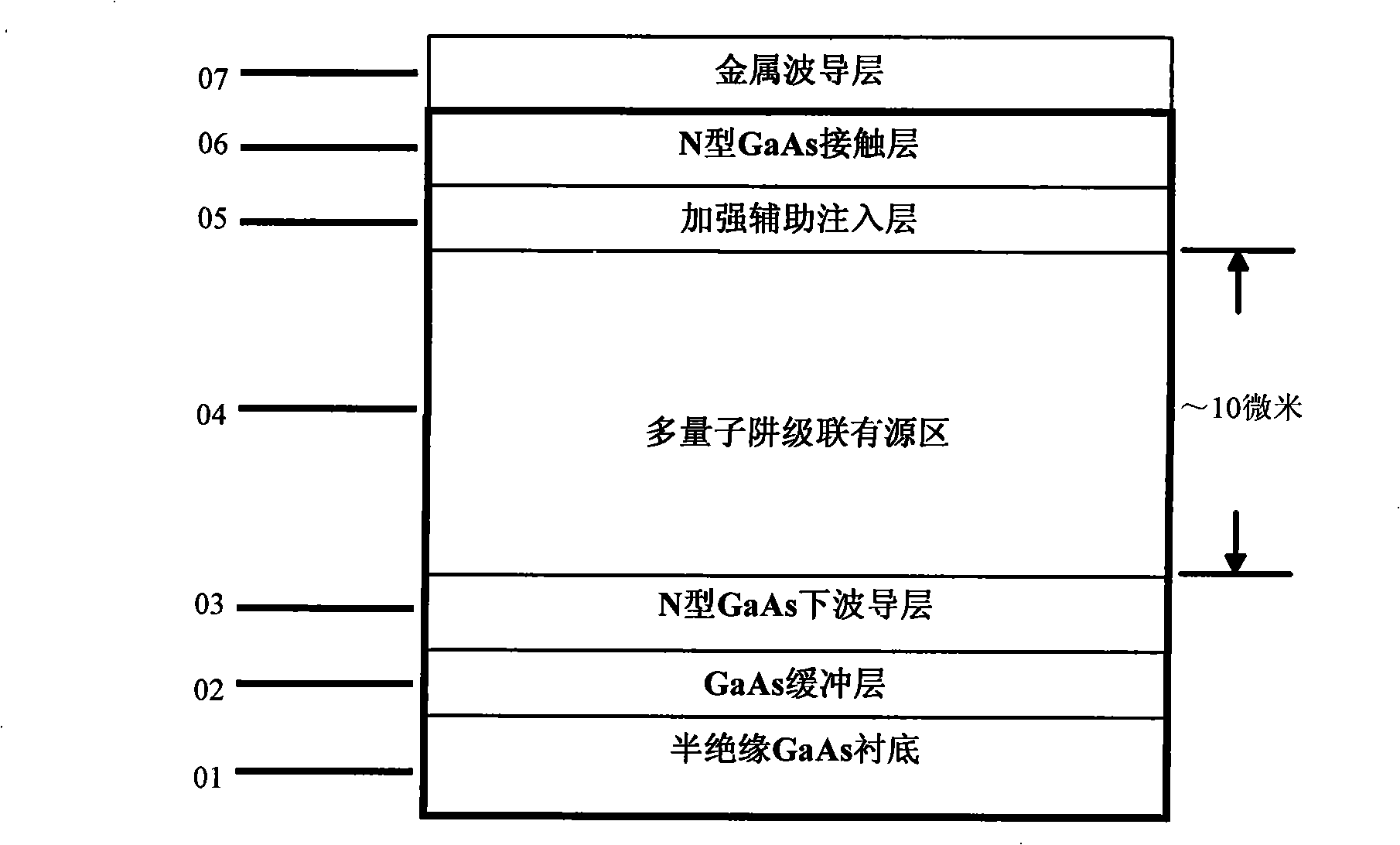

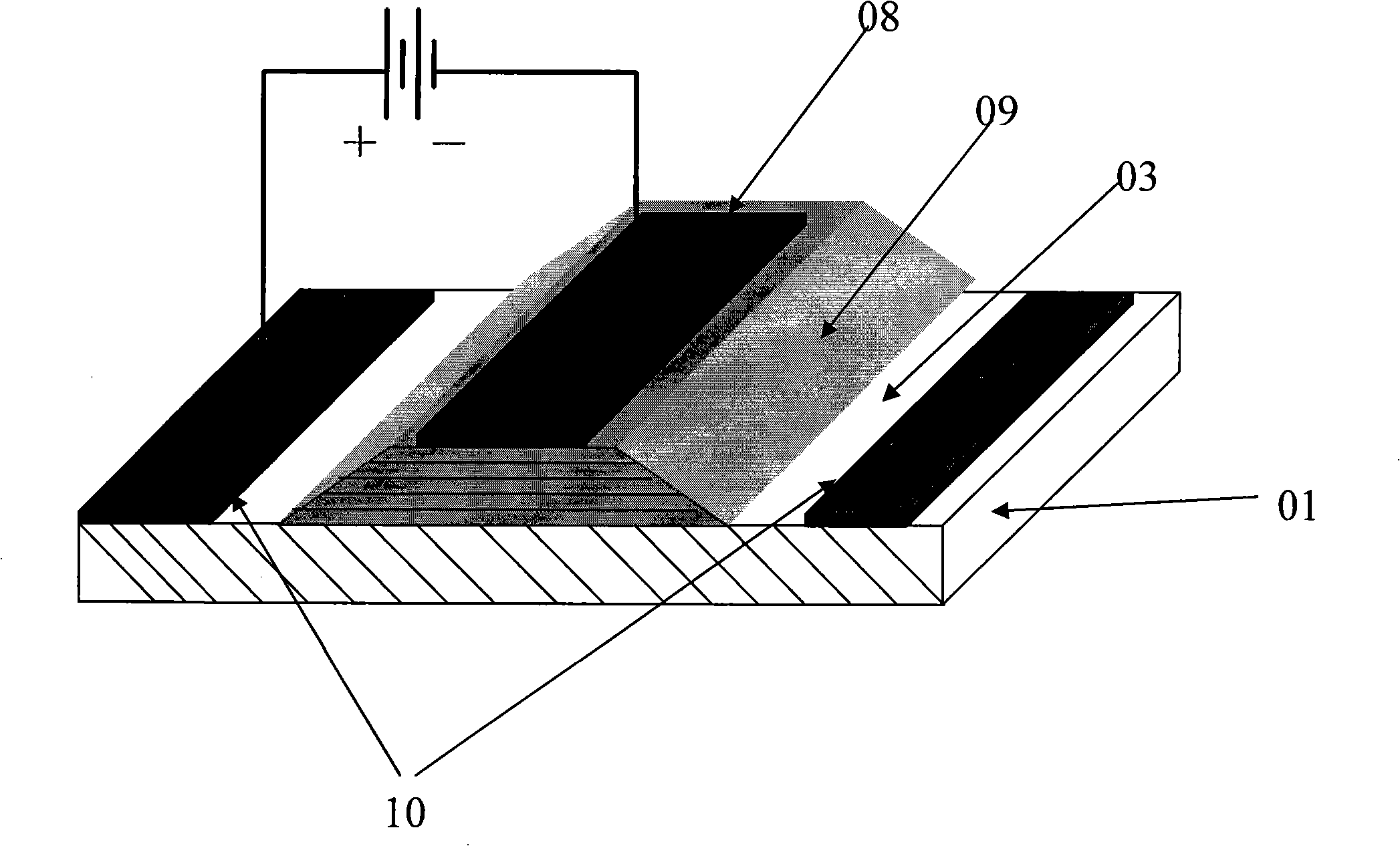

The invention relates to a single-side metal waveguide terahertz quantum cascade laser and a preparation method thereof characterized by growing a GaAs buffer layer, a N type GaAs lower waveguide layer, a multiple quantum well cascade active region, an enhanced auxiliary implanted layer and a N type GaAs upper contact layer on the semiinsulating GaAs substrate by a gas source molecular beam epitaxy device, producing an upper waveguide (electrode) Au layer by means of lithography development and heat evaporation, then producing a ridge structure by means of lithography development and wet etching, furthermore producing an electrode by means of lithography development and heat evaporation, cleavaging a high quality die according to the design specification after rapid thermal anneal, finally finishing the encapsulation of the die.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

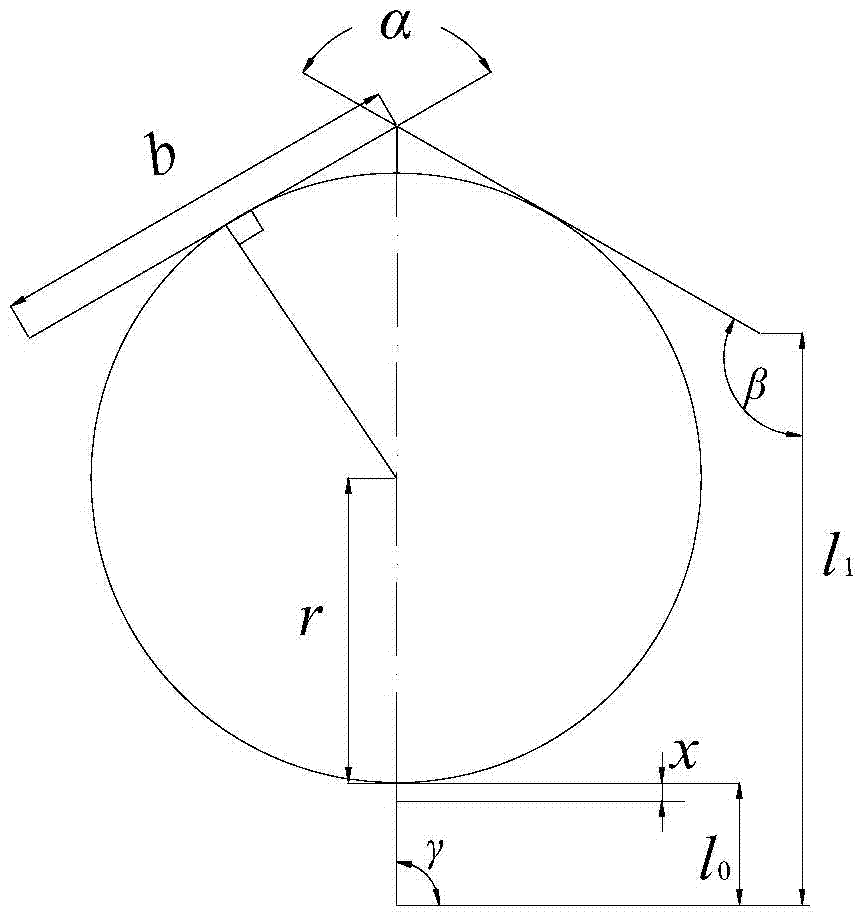

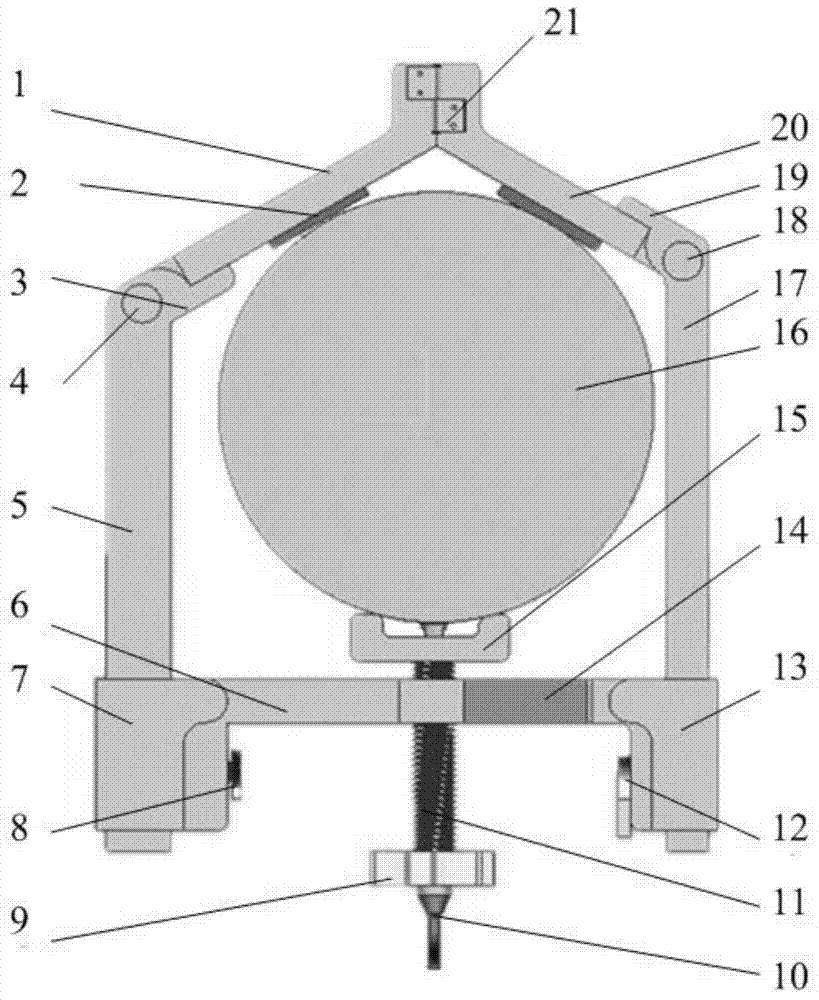

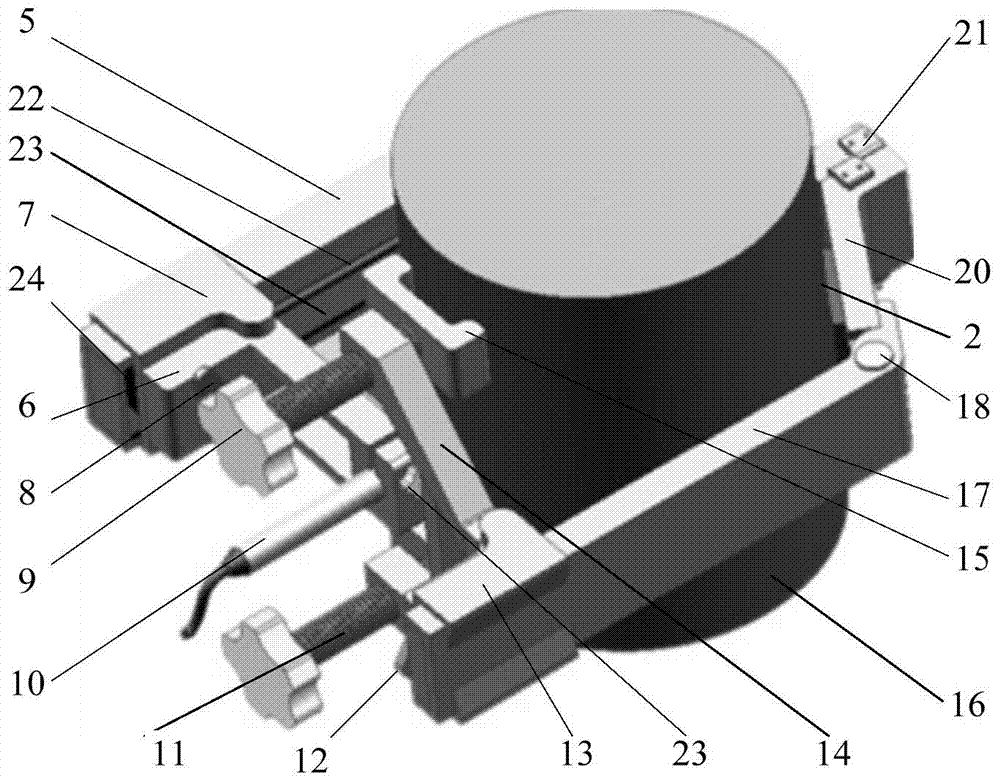

Folding type tree diameter growth real-time precision measurement instrument

ActiveCN104330017AProduction Material OptimizationOptimize the production processElectrical/magnetic diameter measurementsMeasurement deviceEngineering

The invention discloses a folding type tree diameter growth real-time precision measurement instrument. The device can accurately measure tree diameter in real time, the size of the device is small, the device can be folded, and the device is convenient to carry. The measurement device comprises a bracket, a gate ruler, a sensor fixture, a micron displacement sensor and a signal transmission processing circuit. According to the device, the mode of multi-point positioning and three-point measurement of diameter is used, two parts are assembled to form a V-shaped body with an included angel of 90 degrees to 150 degrees, and combined with the micron displacement sensor installed at the diagonal coincide part of a V-shaped angle, the measurement of the tree diameter is realized. The micron displacement sensor and the gate ruler carry out remote data transmission with a host machine through the signal transmission processing circuit. According to the folding type tree diameter growth real-time precision measurement instrument, the tree diameter and the micro change amount can be stably measured in real time at the same time, and a measurement error is reduced. The device can be folded and is convenient to carry, the device is convenient to use, the weight of the device is small, the size of the device is small, and the damage to a trunk by the fixture is small.

Owner:CHINA JILIANG UNIV

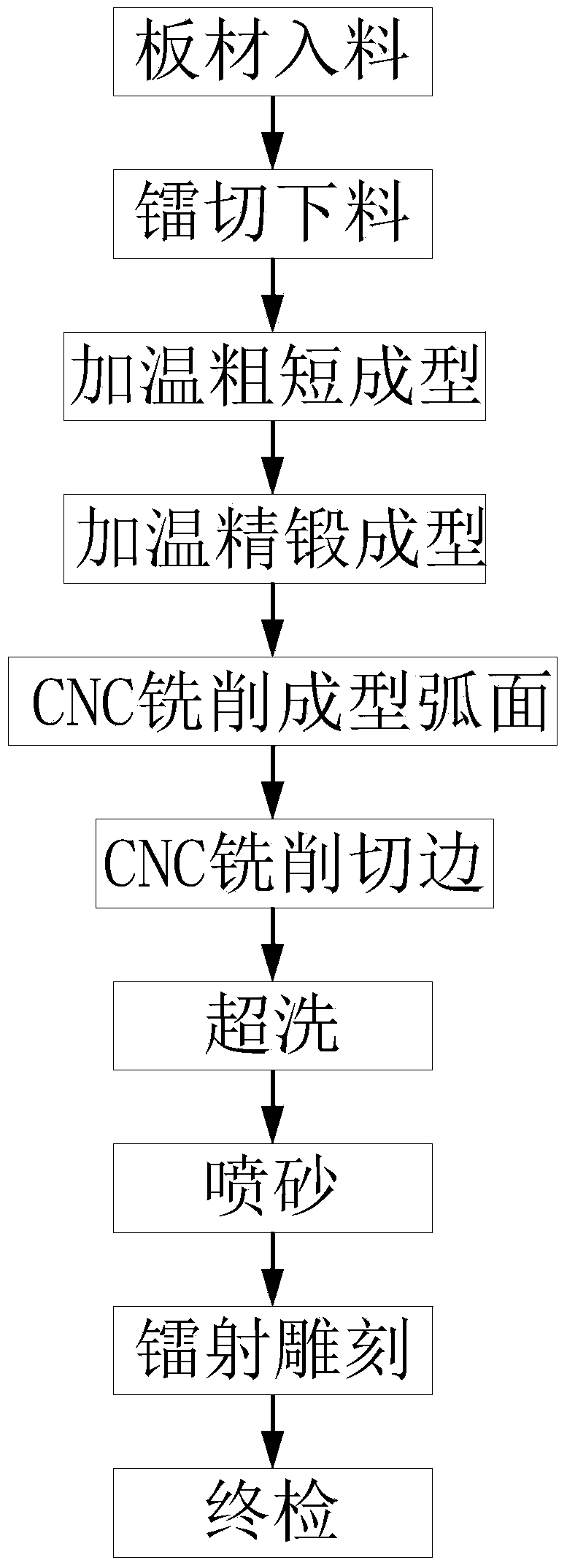

Panel manufacturing method

InactiveCN104175067AOptimize the production processSimple preparation processGolf clubsHeating timeLaser cutting

The invention provides a panel manufacturing method. The method comprises process steps as follows: panel feeding, laser cutting and blanking, heating for rough forge molding, heating for finish forge molding, CNC milling to mold cambered surfaces, CNC milling to mold beveled edges, ultra-washing, sand blasting, laser engraving and check. The heating temperature A of heating for rough forge molding ranges from 750 DEG C to 900 DEG C, and the heating time B of heating for rough forge molding ranges from 5 minutes to 7 minutes; the forging and pressing temperature C of heating for finish forge molding ranges from 750 DEG C to 900 DEG C, and the forging and pressing time D of heating for finish forge molding ranges from 5 minutes to 7 minutes; during CNC milling to mold the cambered surfaces, a to-be-machined panel is firstly fixed on a clamping mold plate on a clamping mold plate base and then milled by a cutter on one side edge of the clamping mold plate. According to the method, manufacturing processes of the panel are optimized with machining methods of heating for rough forge molding, heating for finish forge molding and CNC milling to mold the cambered surfaces, so that the production efficiency of the panel and the product quality of the panel are improved.

Owner:ZHONGSHAN CHANGFU HARDWARE PROD

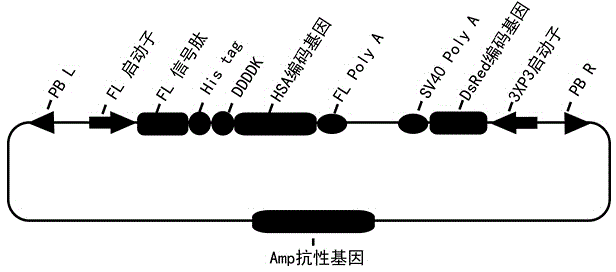

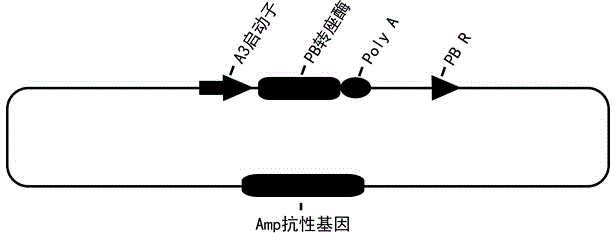

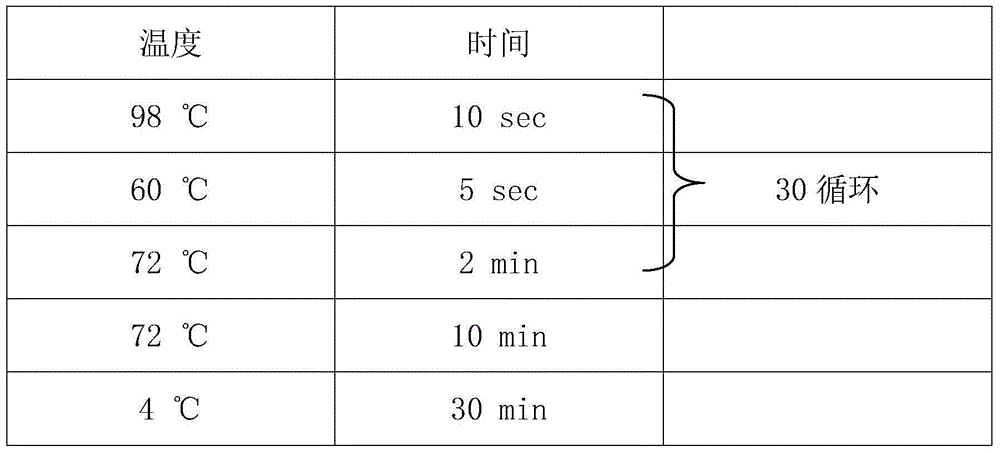

Method for synthesizing secreted human serum albumin employing bombyx mori posterior silk gland

InactiveCN104593413AOptimize the production processThe purification method is simpleSerum albuminFermentationMicro injectionSilk gland

The invention discloses a method for synthesizing secreted human serum albumin employing a bombyx mori posterior silk gland. The method comprises the following steps: firstly, constructing carrier pBHSA plasmids of human serum albumin secreted from bombyx mori, introducing the plasmids and auxiliary plasmids into bombyx mori fertilized ovum by virtue of micro-injection, introducing a red fluorescent protein gene and a human serum albumin gene into a bombyx mori genome by virtue of piggyBac transposons, and carrying out stable inheritance and expression to prepare transgenic bombyx mori; selfing, and carrying out homozygosis on the human serum albumin gene; and breeding the transgenic bombyx mori of secreting the human serum albumin. The transgenic bombyx mori is screened by virtue of a fluorescent marker gene; the secreted human serum albumin is specifically secreted by virtue of bombyx mori posterior silk gland cells; the human serum albumin production process is improved; the purification method is simplified; the production cost is reduced; a foundation is laid for improvement of the production efficiency of the human serum albumin and reduction of the production cost; and the biosecurity of human serum albumin products is ensured.

Owner:ZHEJIANG UNIV

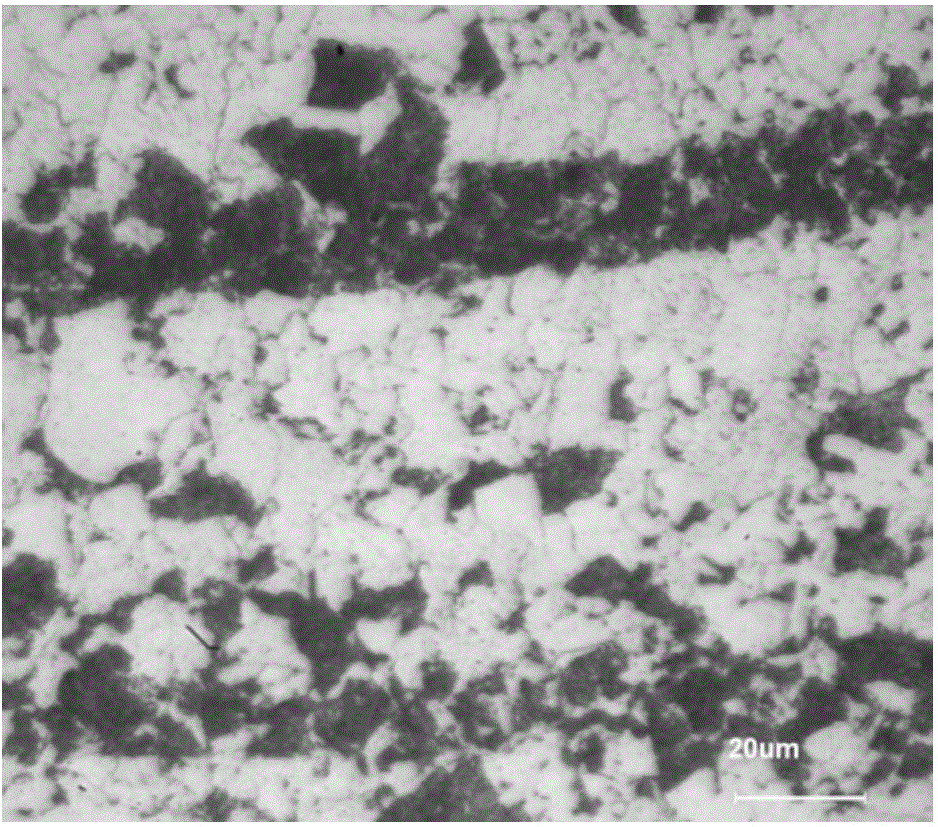

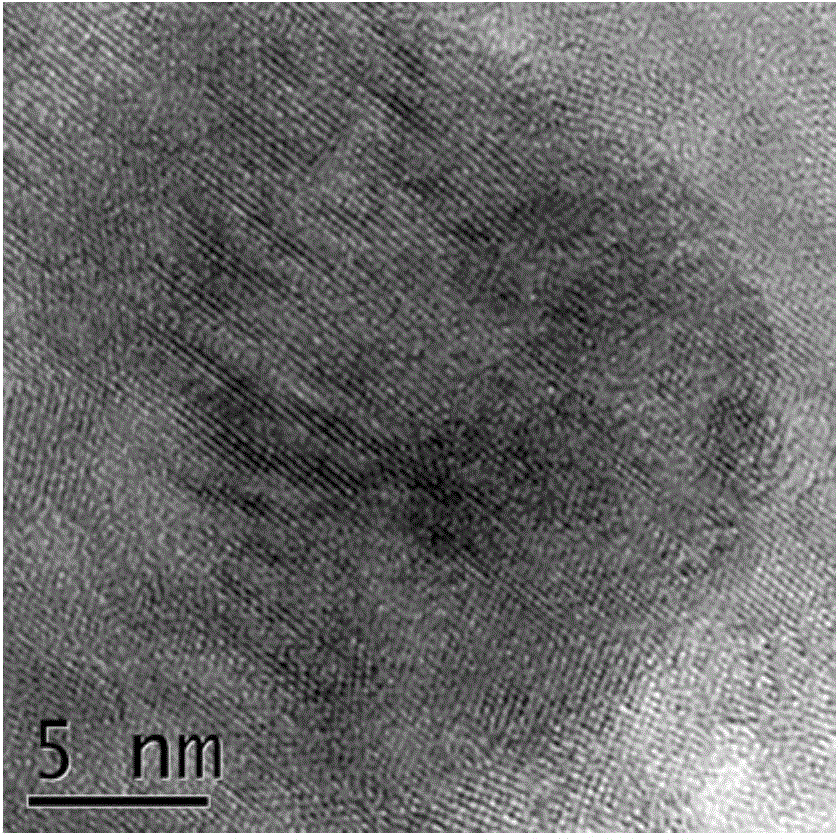

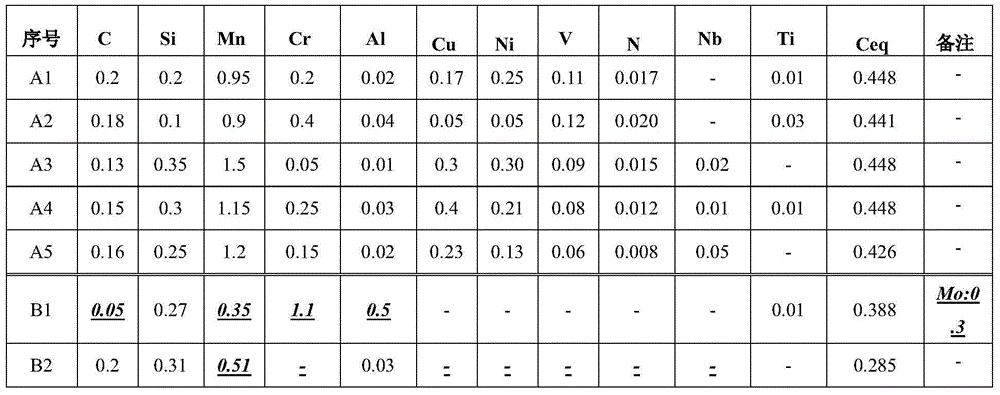

Seawater corrosion-resistant steel pipe and manufacturing method

The invention discloses a seawater corrosion-resistant steel pipe. The seawater corrosion-resistant steel pipe comprises a ferrite-pearlite mixed matrix and contains 0.13-0.20wt% of C, 0.10-0.35wt% of Si, 0.9-1.5wt% of Mn, 0.05-0.4wt% of Cr, 0.01-0.04wt% of Al, 0.05-0.4wt% of Cu, 0.05-0.3wt% of Ni, 0.06-0.12wt% of V, 0.008-0.02wt% of N and the balance Fe and other unavoidable impurities. The invention discloses a manufacturing method of the seawater corrosion-resistant steel pipe. The manufacturing method comprises the following steps of 1, smelting, 2, casting and then rolling for round pipe blank production, 3, heating and soaking, 4, austenite-phase rolling for steel pipe production, and 5, cooling to a room temperature. The seawater corrosion-resistant steel pipe has excellent seawater corrosion resistance, good processing welding performances and excellent low-temperature toughness.

Owner:BAOSHAN IRON & STEEL CO LTD

Multifunctional laundry paper and preparation method thereof

InactiveCN103740490AImprove washing abilityOptimize the production processNon-ionic surface-active compoundsDetergent compounding agentsWater contentIon

The invention discloses multifunctional laundry paper and a preparation method thereof. The paper comprises the following components in percentage by mass: 30-40% of nonionic surfactant, 10-14% of anionic surfactant, 15-20% of emulsifier, 6-10% of dispersant, 12-15% of film-forming agent, 2-5% of compound enzyme, 2-4% of nano-silver antimicrobial and 3-5% of deionized water. The paper disclosed by the invention is formed through the control and the improvement on the preparation process and through the steps of mixing and stirring the components, drying and forming, cutting and packaging and the like. The paper disclosed by the invention has the advantages that the compound enzyme is added in the formula to ensure that the washing capacity is enhanced; the production process of the laundry paper is improved to ensure that the compound enzyme can be well fused into the formula and remain the activity; through regulating and controlling the proportion of the components in the formula, the water content of the laundry paper can be effectively controlled between 3% and 5% to ensure that the laundry paper is highly enriched; the laundry paper is strong in washing capacity, easy in storage and convenient to carry.

Owner:郭向永

Environmentally friendly process for dying textiles

InactiveCN102041677AOptimize the production processLow costBiochemical fibre treatmentDyeing processEnvironmentally friendlyTextile dyeing

The invention provides an environmentally friendly process for dying textiles and relates to the field of textile dying. The process comprises the following steps of: pretreating; dying; and soaping, wherein in the step of pretreating, an all-in-one scouring agent is used, and the kinds of auxiliary agents are reduced, thus the COD (Chemical Oxygen Demand) value is reduced; and in the step of soaping, a composite enzymic preparation is used, so that the sewage chromaticity is reduced; therefore, the sewage can completely reach a discharge standard. The production process not only saves the cost of enterprises, the water and the energy, but also lightens the pressure on sewage discharge through improving the production processes of various links of printing and dying enterprises.

Owner:NANTONG A Z DYEING & TEXTILE

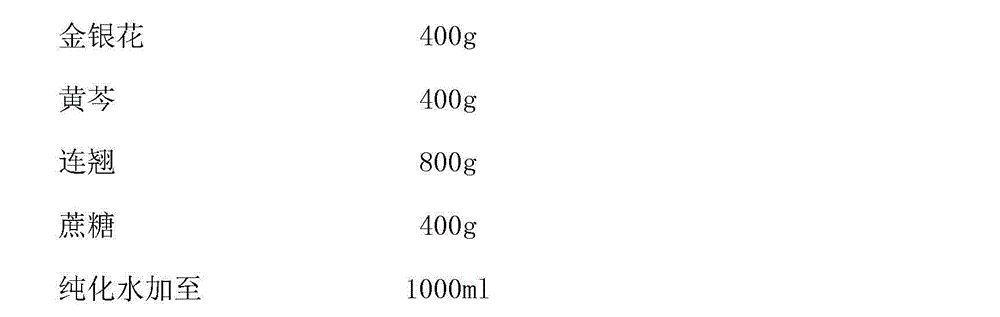

Method for manufacturing Shuanghuanglian oral liquid

ActiveCN102872208AOptimize the production processGood performanceAntibacterial agentsAntipyreticHoneysuckleBalance water

The invention provides a method for manufacturing Shuanghuanglian oral liquid. 1000mL of the oral liquid comprises 350-400g of honeysuckles, 350-400g of radix scutellariae, 700-800g of forsythia and 300-400g of cane sugar. The method includes extracting the honeysuckles and the forsythia via aqueous extraction, ethanol precipitation and aqueous precipitation processes, and extracting the radix scutellariae by an aqueous extraction process; mixing honeysuckle extracts, radix scutellariae extracts and forsythia extracts according to a formula to obtain a mixture; adding the balance water into the extracts; stirring uniformly to obtain a mixture; adjusting a pH (potential of hydrogen) value of the mixture by using sodium hydroxide solution; stirring uniformly; filtering; removing sediments in filtrate by 5% of 101-clarifying agents and auxiliary suspension; adding the cane sugar in the filtrate; stirring so that the cane sugar is dissolved to obtain a mixture; adjusting a pH value of the mixture by using sodium hydroxide solution; adding the balance water to dilute the mixture so as to obtain liquid medicine; stirring uniformly, filtering; bottling; and sterilizing to obtain the oral liquid. Compared with the traditional process, the method has the advantages that extraction rates of various index components are increased to different degrees owing to a novel process, the clarity and the stability of the oral liquid are effectively improved, production cost is lowered, and the method for manufacturing the Shuanghuanglian oral liquid is applicable to industrial production.

Owner:HARBIN PHARM GROUP SANJING PHARMACEUTICAL CO LTD

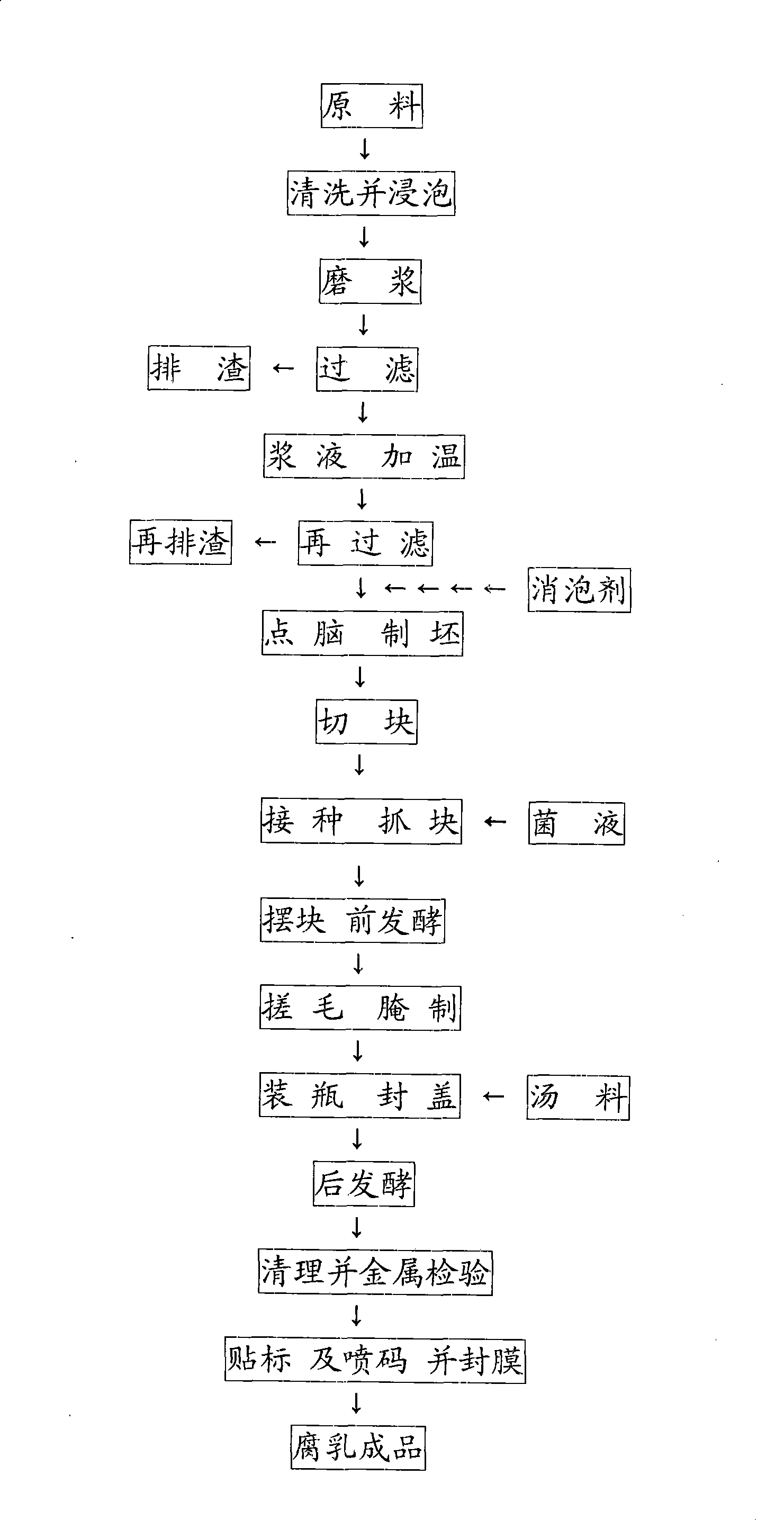

Production method of preserved beancurd

The invention relates to a method for preparing a preserved beancurd product, which belongs to the production field of the preserved beancurds. Primary fermentation and after fermentation are the key steps. The production process of the preserved beancurd comprises the following steps: soybean soaking, jordaning, filtering, warming, refiltration, defoaming, adding coagulant and blank forming, dicing, inoculating, primary fermentation, pickling, bottling, adding soup, covering and after fermentation. The raw materials of GMO free and green food are that protein contained in the soy bean is more than or equal to 38%, slag contained in the soy milk is less than or equal to 15%, crude protein contained in the bean dregs is less than or equal to 28%, and the final temperature of the soy milk in the final siruping tank of overflow tanks is more than or equal to 90 DEG C. When the jellied bean curd is 50%, turning over is carried out slowly and the flow rate of the coagulant is reduced, and when the jellied bean curd is 80%, turning over and the flow of the coagulant are stopped for standing statically; the squeezing is carried out at 8-10Mpa, the moisture content of white blank is 66-73%, the inoculation is carried out at the temperature of 40 DEG C, the primary fermentation is carried out for 36-48 hours and cages are exchanged for three times, and the first exchange, the second exchange and the third exchange are carried out respectively at the temperature of 23-28 DEG C, 22-26 DEG C and 18-22 DEG C. wherein, the relative humidity in the three exchanges are all 60%; pickling is carried out for 3-5 days, then after fermentation is carried out at the temperature of 15-30 DEG C for 45-60 days, and the finished product contains 3.5-18% of salt. The method of the invention can be used for preparing the preserved beancurd.

Owner:北京王致和食品有限公司

Printing technology

InactiveCN102744991AOptimize the production processReduce manufacturing costInksOther printing apparatusPrinting inkEngineering

The invention relates to a printing technology and particularly relates to a six-polychrome printing technology. The printing technology includes the following steps that firstly, a printing ink is printed on a printing stock by a six-color and varnishing printer, secondly, ultraviolet rays emitted by a first group ultraviolet lamp curing lamp are used for illuminating the print ink so that the print ink is subjected to a cross-linking reaction with printed layers, thirdly, ultraviolet rays emitted by a second group ultraviolet lamp curing lamp are used for illuminating the print ink to enable the printed layers to be cured, fourthly, an infrared dryer is arranged to dry the printed layers, and fifthly, and an ultraviolet (UV) polishing device is used for a UV polishing for the dried printed layers. The printing technology has the advantages that by means of the modifications of the printing ink and production process, the problem that the whole printing efficiency is low caused by the slow drying speed of a six-polychrome printing technology in prior art is solved, the production cost is lowered, the production efficiency is improved, and the printing technology has a wide application prospect.

Owner:昆山科望快速印务有限公司

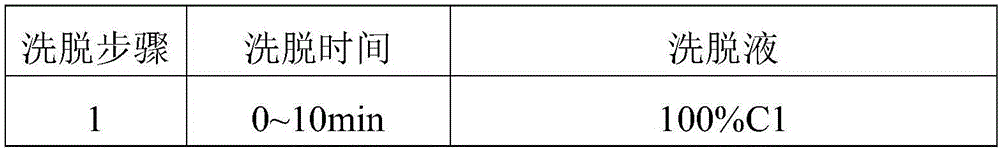

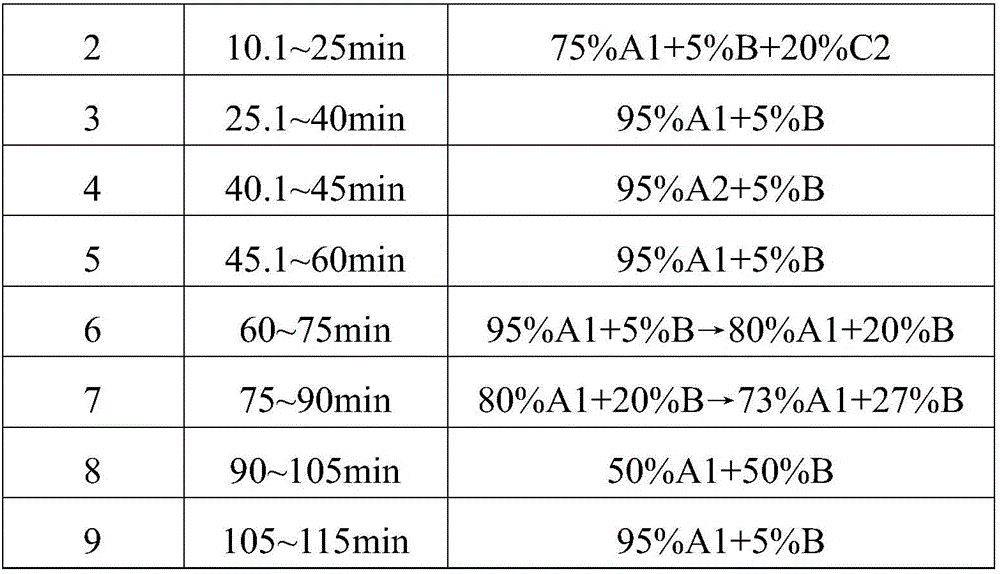

Method for preparing vasopressin deamidization impurities

ActiveCN106699851AOptimize the production processBulkyOxytocins/vasopressinsPeptide preparation methodsChemistryContinuous production

The invention discloses a method for preparing vasopressin deamidization impurities. The preparation method comprises the steps of adopting efficient liquid phase reversed phase chromatography to cause vasopressin deamidization impurity precursor crude product solution to sequentially undergo reverse phase cyclization, reverse phase purification and reverse phase desalting. Filler of the efficient liquid phase reversed phase chromatography is styrene divinylbenzene copolymer. The vasopressin deamidization impurity precursor crude product contains two free sulfhydryl groups. The reverse phase adsorption method cyclization, purification and desalting are applied creatively, the cyclization, purification and desalting problem is solved in one time, the production process is optimized, and the method is suitable for industrial continuous production.

Owner:SPH NO 1 BIOCHEM & PHARMA CO LTD

Plastic mold steel 718 and production process thereof

ActiveCN107794451AOptimize the production processExcellent overall performanceManufacturing convertersProcess efficiency improvementSmeltingImpact resistance

The invention provides plastic mold steel 718 and a production process thereof, and relates to the technical field of steel and iron smelting. The plastic mold steel 718 comprises the following chemical components in percentage by mass: 0.37-0.40% of C, 0.4-0.5 of Si, 1.4-1.5 of Mn, 1.8-2.0 of Cr, 0.4-0.5 of Mo, 1.0-1.1 of Ni, P not more than 0.008, S not more than 0.003, 0.018-0.030 of Als, and the balance of Fe and residual elements; and the thickness is 150 mm. The plastic mold steel 718 is excellent in mechanical performance, high in strength and excellent in impact resistance.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

Normal-temperature instant nutrient chicken soup and method for making same

InactiveCN103141878ASimple ingredientsOptimize the production processFood preparationNutrientZiziphus jujuba

The invention relates to a normal-temperature instant nutrient chicken soup, composed of the following raw materials in parts by weight: 450-1500 parts of chicken, 0-50 parts of fresh ginseng, 0-300 parts of fresh abalone, 0-300 parts of fresh sea cucumber, 15-60 parts of sticky rice, 6-15 parts of jujube, 6-20 parts of garlic, 0-9 parts of gingko, 6-20 parts of Chinese chestnut, 1-3 parts of medlar, 2-6 parts of table salt and 300-1500 parts of water. The nutrient chicken soup provided by the invention is simple in ingredients and optimal in making process; the chicken soup made by the method is complete in nutrition; and the chicken is fresh and tender. The sterilization process provided by the invention is capable of keeping chicken attached to bones, and also capable of keeping the chicken soup for a long time even though no any preservative is added.

Owner:金世光

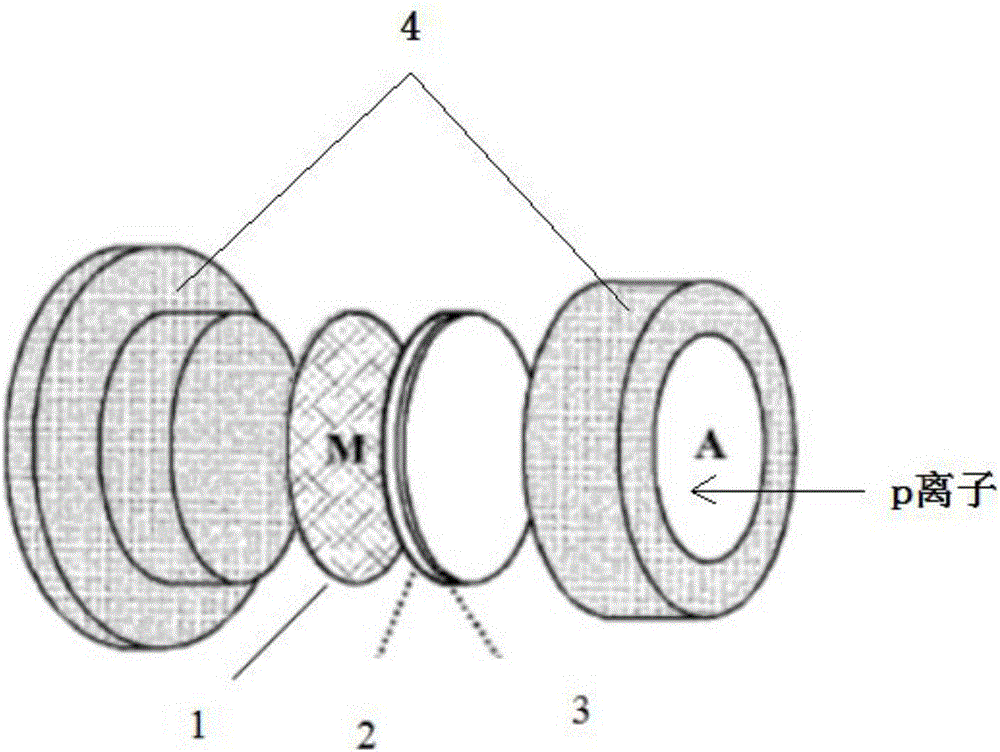

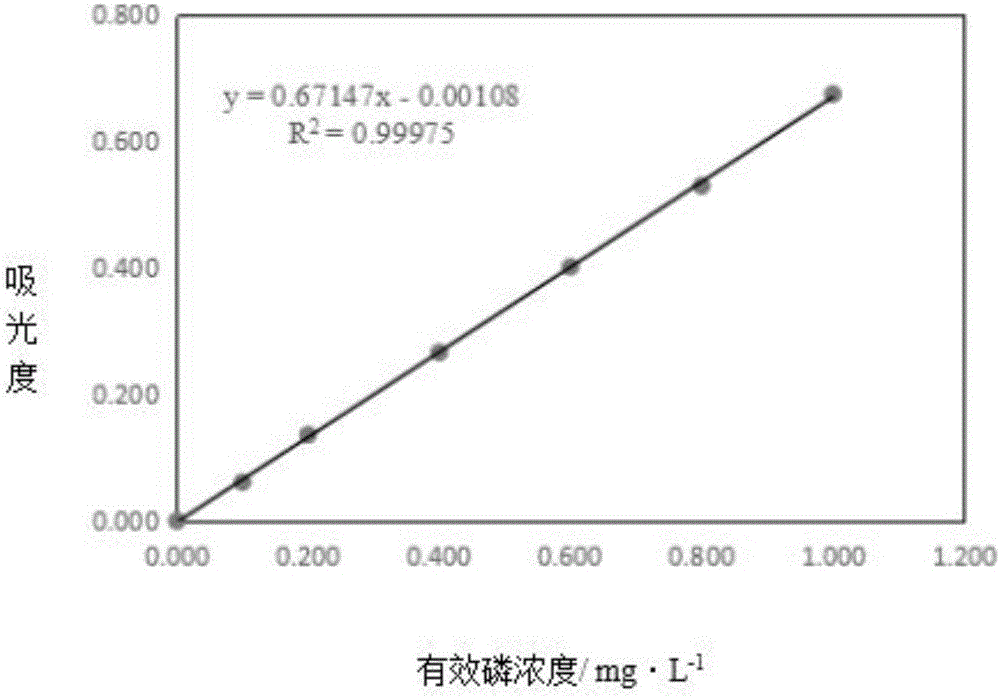

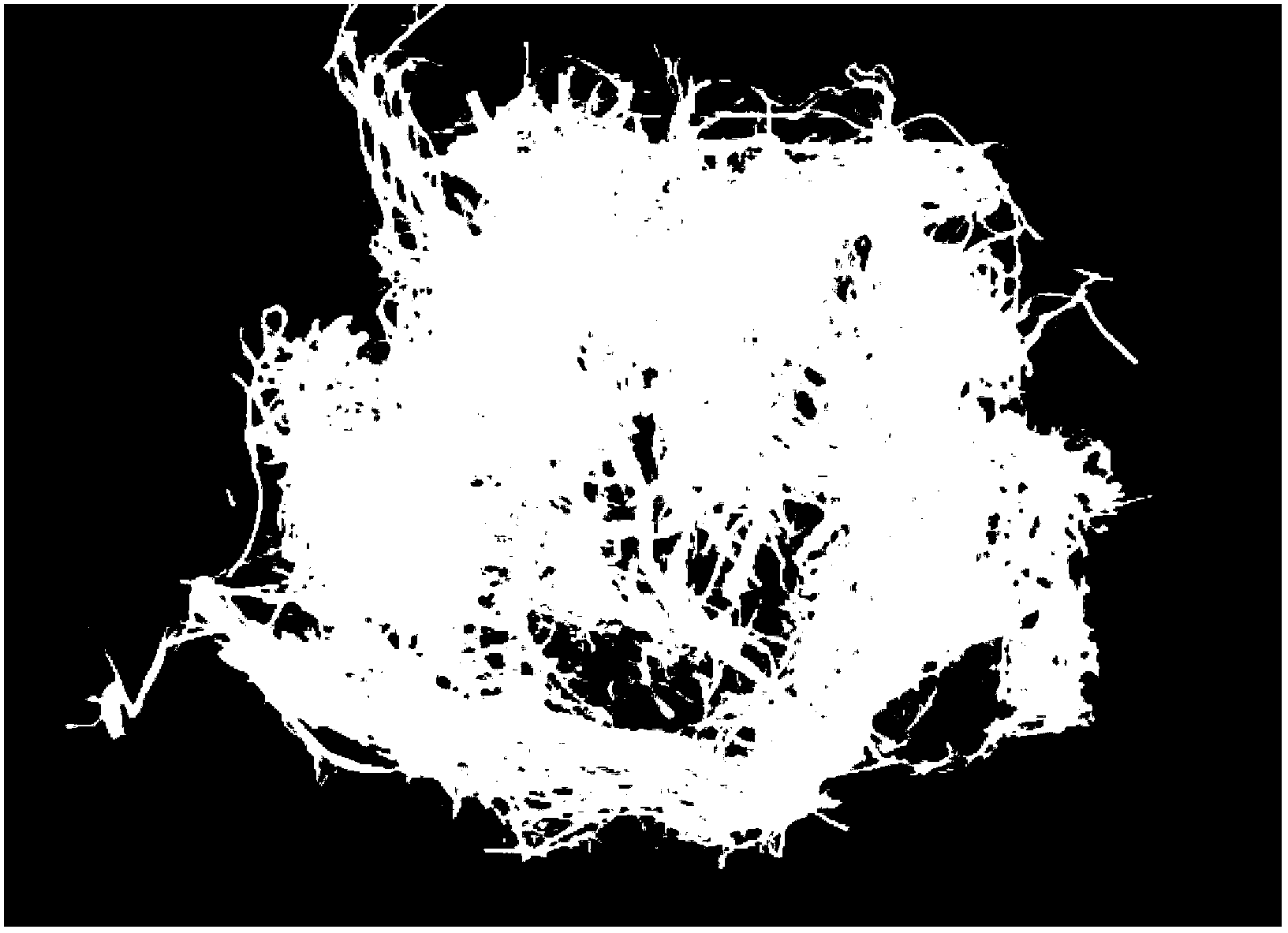

Total-dissociation DGT combined film for determination of soil available phosphorus and preparation method thereof

ActiveCN106568689ALow priceOptimize the production processSurface/boundary effectChemistryFilm material

The invention relates to a total-dissociation DGT combined film for determination of soil available phosphorus and a preparation method thereof. The total-dissociation DGT combined film comprises the material composition: available phosphorus combined material nano Mg-Al-Fe-LDHs, a combined material dispersing agent, an acrylamide gel and the like. The above materials are uniformly mixed through ultrasonic treatment, and the mixture is pumped into a high-silica glass planar groove provided with a certain thickness of gaskets at periphery, after a mouth is sealed, a reaction is carried out for at least 1 h at the temperature of 42 to 46 DEG C, and the DGT combined film is prepared. The combined film material can highly efficiently and rapidly enrich available phosphorus, and can be completely dissociated within 30 min after 8 ml-10 ml of concentrated nitric acid is added; the combined film overcomes the disadvantages that a traditional DGT combined film is slow and incomplete to dissociate, difficult to prepare in laboratory, poor in generality, poor in phosphorus adsorption ability, high in price and the like.

Owner:TIANJIN TIANRUN YIKANG ENVIRONMENTAL PROTECTION TECH CO LTD

Method for preparing high air tightness antibacterial reinforced membrane by using straws

InactiveCN102936353ARaw materials are cheap and easy to getOptimize the production processFibre treatmentCoatingsChemistryComposite material

The present invention relates to a method for preparing a high air tightness antibacterial reinforced membrane by using straws. The method is characterized by comprising the following steps: (1) preparing a straw solution: carrying out a steam decrepitation treatment on straws to obtain a decrepitation product, carrying out hydrogen peroxide rinsing and drying to obtain straw powder, taking an ion liquid and heating until the ion liquid is completely molten, adding the straw powder to mix to obtain a straw liquid, and adding inorganic silver nanometer silver antibacterial powder to the prepared straw liquid to obtain the straw solution; and (2) preparing a high air tightness antibacterial reinforced membrane: taking a cellulose product and flatly fixing on a glass plate, tanking the cellulose product from an oven, uniformly coating the straw solution obtained from the step (1) on the cellulose product, soaking for 2-3 hours by using water after cooling, washing until the ion liquid is completely precipitated, and carrying out open-air drying to obtain the high air tightness antibacterial reinforced membrane. According to the present invention, the method has characteristics of simple process, green property, and no pollution, and the prepared membrane has characteristics of high air tightness, high moisture permeability, and good mechanical property.

Owner:湖北顶新环保新材料有限公司

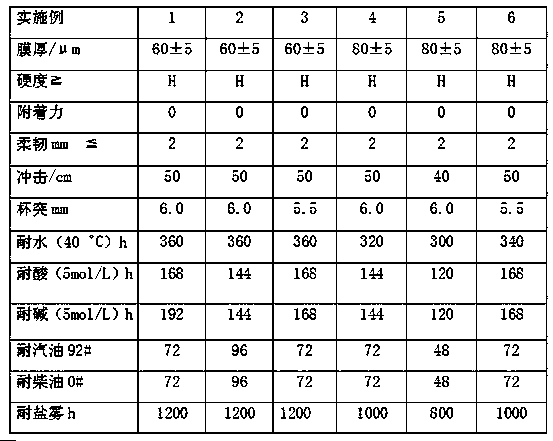

High-performance water-based two-component epoxy primer and preparation method thereof

InactiveCN110655847AOptimize the production processImprove stabilityAnti-corrosive paintsEpoxy resin coatingsEmulsionFirming agent

The invention relates to a water-based high-performance water-based two-component epoxy primer with high salt spray resistance, excellent water resistance and excellent chemical resistance and a preparation method thereof. The primer is composed of a component A and a component B, a mass ratio of the component A to the component B is 3-5: 1, wherein the component A comprises the following components in parts by weight: 30-70 parts of water-borne epoxy resin emulsion, 0.1-5 parts of a surface additive, 1-15 parts of a coalescing agent, 5-15 parts of an antirust filler, 0.1-2 parts of an anti-settling agent, 0.1-1 part of an adhesion promoter, 0.1-1 part of a thickening agent, 5-30 parts of a pigment and 5-10 parts of deionized water; and the component B comprises the following components inparts by weight: 40-70 parts of an aliphatic amine curing agent, 1-5 parts of an anti-flash-rust auxiliary agent and 20-40 parts of deionized water. According to the invention, the emulsion, the antirust pigment and the auxiliary agent are enhanced, and the stability of a finished product and the resistance of a paint film are greatly improved by optimizing a manufacturing process.

Owner:郑州一安水性高分子材料有限公司

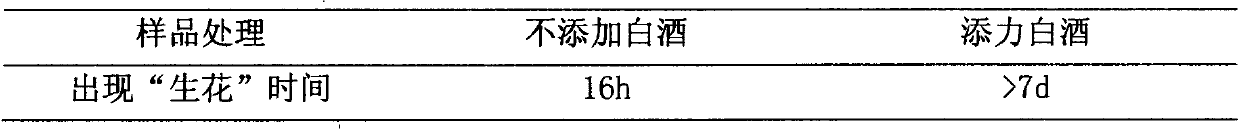

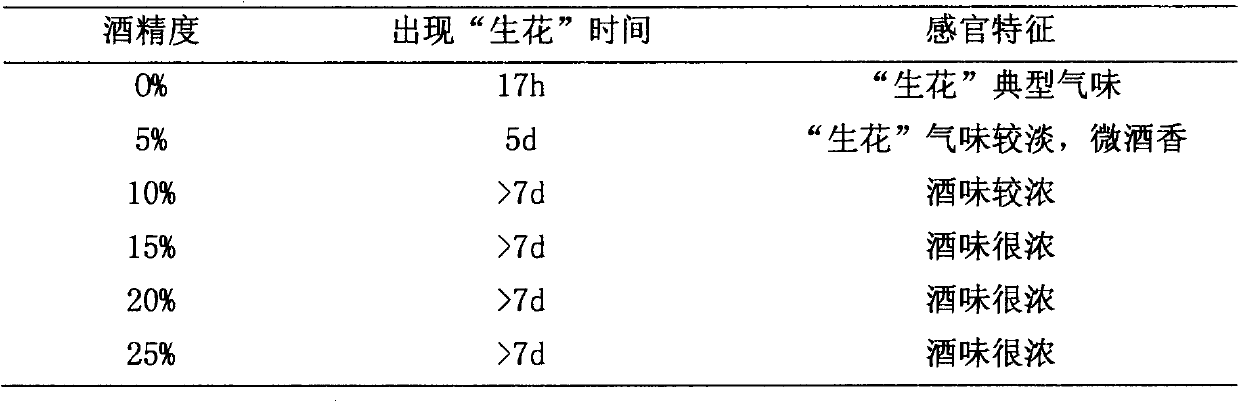

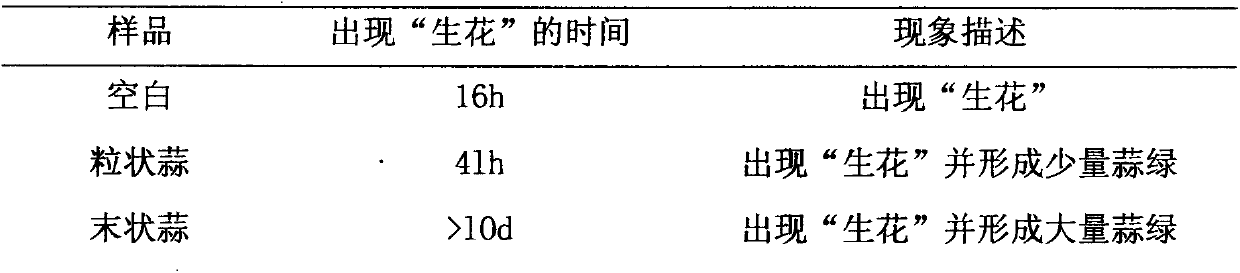

Pickle production method for effectively inhibiting pickle albuginea disease during fermentation process

InactiveCN104172030AOptimize the production processOptimize excipient formulaClimate change adaptationFood preparationChemistryFlavor

The invention discloses a pickle production method for effectively inhibiting pickle albuginea disease during the fermentation process. According to the production method, fresh vegetables are washed and dried; auxiliary materials such as ginger, garlic and the like are processed to obtain a powder; and the powder and the vegetables are put into a jar and fermented for 7-9 days so as to be matured. According to the invention, pickle albuginea can be effectively prevented during the fermentation process, and traditional fermented pickle flavor and taste are not influenced. In addition, the production method accords with production reality of the domestic fermented vegetable processing industry. The technological method is simple and practical, and produced pickles are safe, healthy and nutritive.

Owner:张政

Production method of anti-cracking leather

ActiveCN103484576AExcellent tear resistanceOptimize the production processLeather pressing/rollingLeather surface mechanical treatmentWaxScratching

The invention relates to the technical field of leather production and specifically relates to a production method of anti-cracking leather. The production method comprises the following step of sequentially performing primary coating, tumbling, floating coating, tumbling, scratching, color correction and drum falling treatment on a leather material with a plump leather body and general fur, wherein in the primary coating step, a cationic wax agent and acrylic resin are used for being dissolved in water for spray-coating treatment; in the tumbling step, a tumbling machine is used for tumbling; in the floating coating step, a leather hand feeling agent and waterborne color-changing wax are used for being dissolved in the water for spray-coating treatment; in the top coating step, a hand feeling agent is used for being dissolved in the water for spray-coating treatment. By adopting the method provided by the invention, an obtained leather finished product has the advantages of strong anti-cracking capability and no need of frequent washing, the service life of the leather is prolonged, the original luster of the leather is kept to the greatest extent, strong compressive capacity is achieved, and the leather is less prone to damages during a using process.

Owner:漳州香洲皮革有限公司

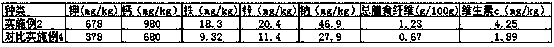

Manufacturing method for potato rice noodles made of fresh potatoes and having low breakage rate

PendingCN108713678AOptimize the production processReduce processing steps and pollutionFood preservationRice flourChemistry

The invention belongs to the technical field of rice noodle processing, and particularly provides a manufacturing method for potato rice noodles made of fresh potatoes and having low breakage rate. The finished product of the potato rice noodles is prepared from the following components: 45 to 60 percent of fresh potatoes, 35 to 40 percent of soaked and drained rice and 5 to 10 percent of starch;the processing steps are as follows: (1), grinding the soaked and drained rice into rice flour; (2), cleaning and peeling potatoes, and then dividing the potatoes into two parts, wherein one part is used for preparing potato slurry, and the other part is steamed and mashed to be mashed potatoes; (3), mixing starch, the rice flour, the potato slurry and the mashed potatoes; (4), pressing the mixture to be semi-finished product rice noodles, wherein the extrusion temperature is 105 to 115 DEG C; (5), putting the semi-finished product rice noodles into a totally-enclosed baking room for baking; (6), molding; (7), drying at a low temperature; (8), packaging. The manufacturing method provided by the invention adopts the fresh potatoes to make potato rice noodles, the manufacturing process is optimized, the nutritional value of the rice noodles is increased, the toughness of the rice noodles is enhanced, the breakage rate is lowered, and the guarantee period of the rice noodles is prolonged.

Owner:广西壮族自治区农业科学院经济作物研究所 +1

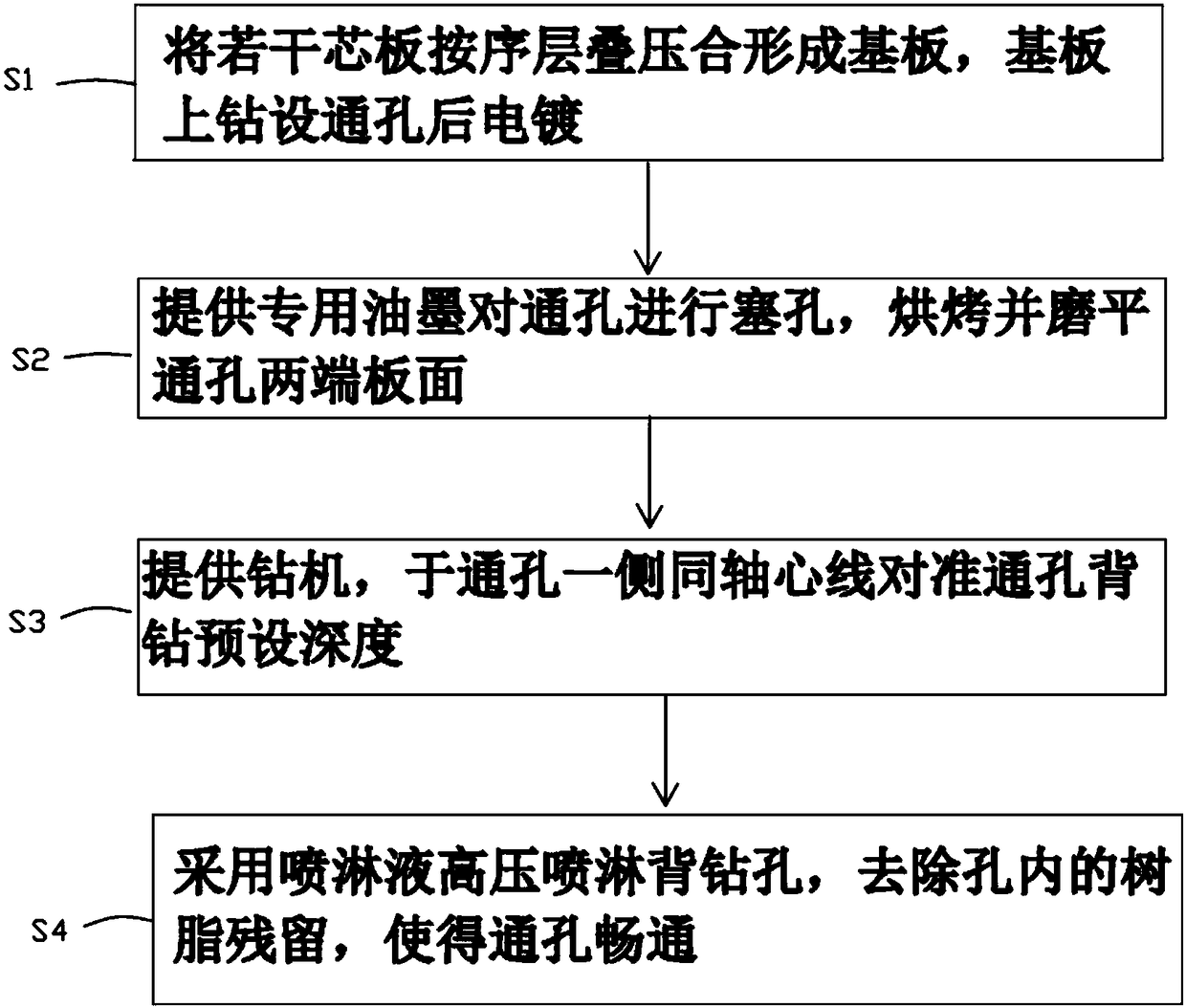

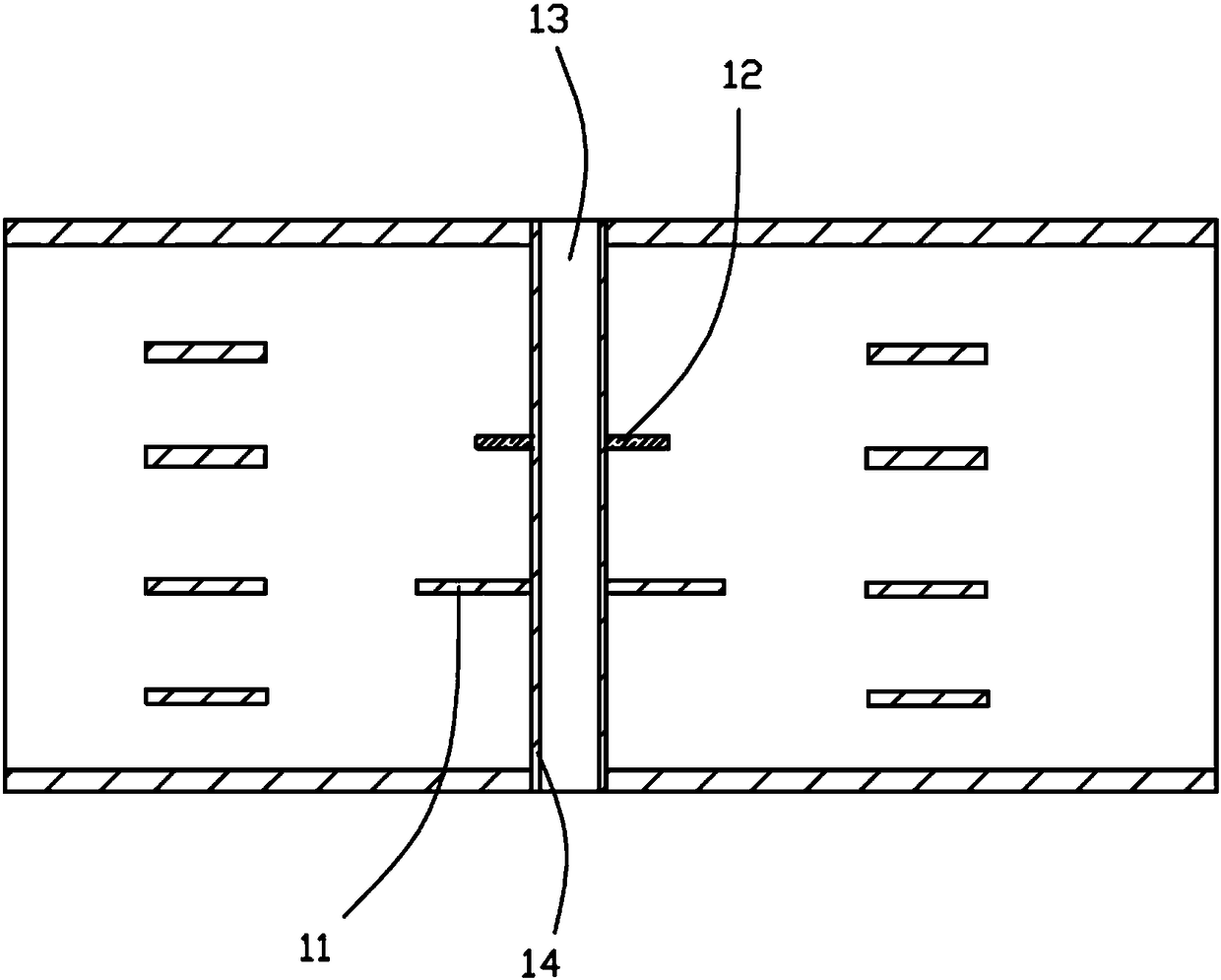

Manufacturing method of HDI plate back drilling hole

InactiveCN111107715AOptimize the production processReduce the problem of draped copper wireConductive material chemical/electrolytical removalCircuit precursor manufactureElectroless platingCopper wire

The invention discloses a manufacturing method of an HDI plate back drilling hole. The method comprises the steps that a production board is drilled, drilled holes comprise a through hole needing backdrilling, and the through hole is metalized through electroless plating copper; a layer of thin copper is flash-plated on the production board through full-board electroplating, wherein the thicknessof a thin copper layer formed during flash-plating is 5 to 8 microns; tin is electroplated on the production board to enable the board surface copper layer and the hole copper to be covered by the tin layer; depth-controlled back drilling is carried out on the through hole needing back drilling according to the design requirement, so that the copper layer at the back drilling part in the throughhole is removed, and a stepped back drilling hole is formed; acid etching treatment is carried out on the production board, and tin is removed; and full-board electroplating treatment is carried out on the production board, and the board surface copper layer and the hole copper are plated to the thickness required by the design. According to the method, by optimizing the production technological process, the problem that a conventional etching process cannot solve the problem of hole blocking of a back drilling burr copper wire is effectively solved; back drilling manufacturing of the HDI plate is achieved; and the percent of pass is high.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

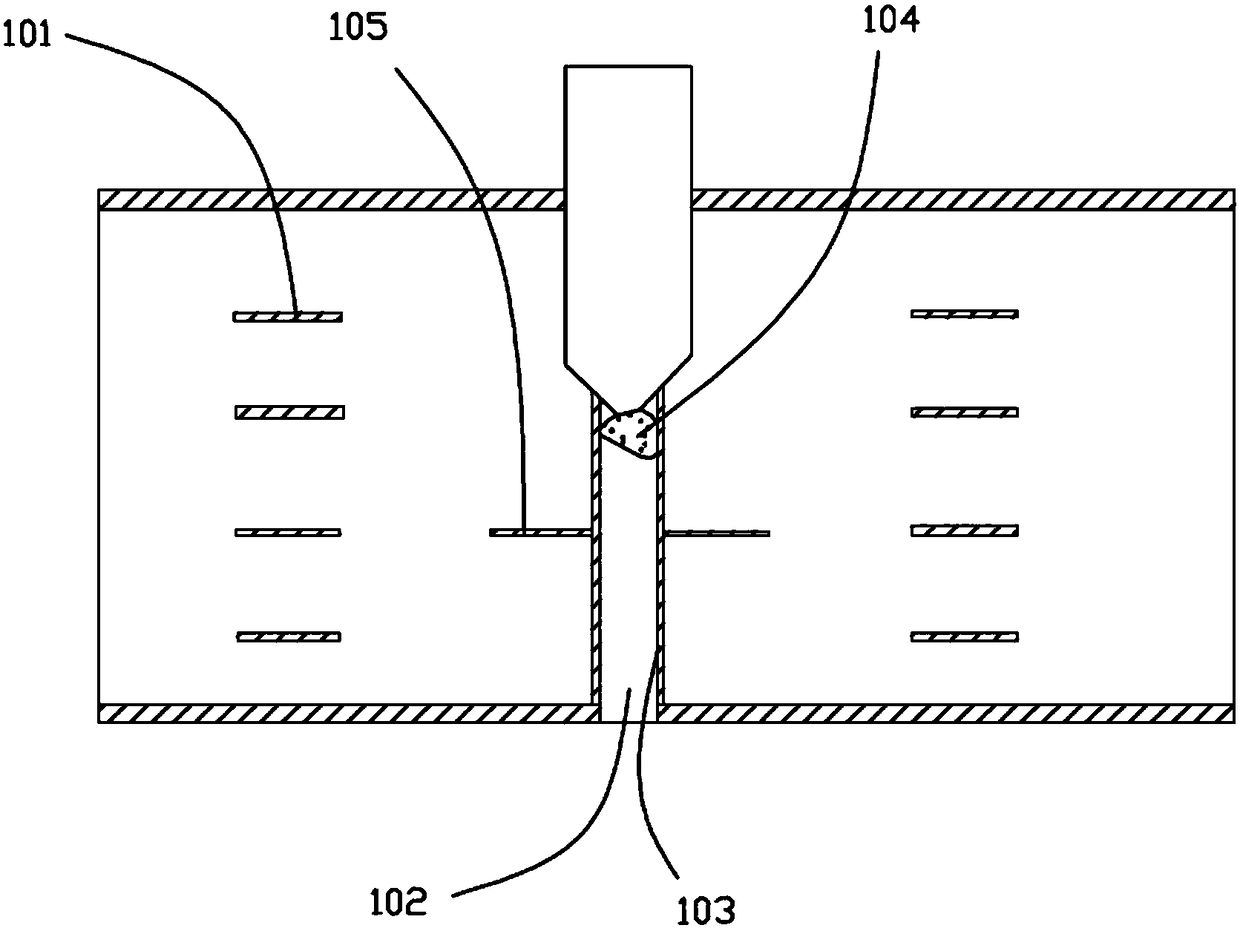

Special ink for assistance in manufacture of backdrill and PCB (printed circuit board) backdrilling method

ActiveCN108410262AOptimize the production processPrecise copper retention height controlInksMetal working apparatusWater solublePrinted circuit board

The invention provides special ink for assistance in the manufacture of a backdrill and a PCB (printed circuit board) backdrilling method. The special ink is mainly made from propylene glycol monomethyl acetate, pumice powder and water-soluble resin, wherein the propylene glycol monomethyl acetate accounts for 20-25% by mass, the pumice powder accounts for 50-60% by mass, and the water-soluble resin accounts for 20-25% by mass. The PCB backdrilling method comprises the steps of 1) stacking a plurality of core plates in order to form a substrate, drilling the substrate to obtain via holes, andplating; 2) providing the special ink to plug the via holes, baking, and grinding the end faces of the via holes; 3) drilling a drill rig, and backdrilling to a preset depth on one side of the via holes, with coaxial alignment to the via holes; 4) subjecting the backdrilled holes to high pressure spraying via a spraying liquid so as to remove resin residue in the holes, so that the via holes are smooth. The problem that large-thickness and -diameter copper wires / fragments block the via holes is successfully solved.

Owner:DONGGUAN SHENGYI ELECTRONICS

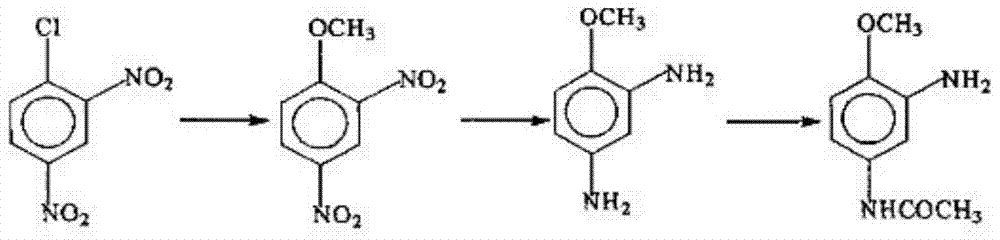

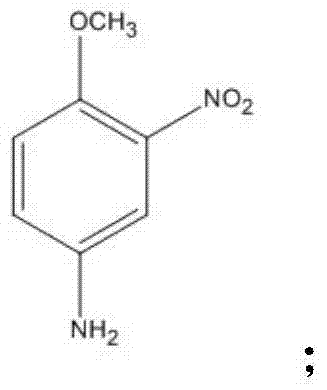

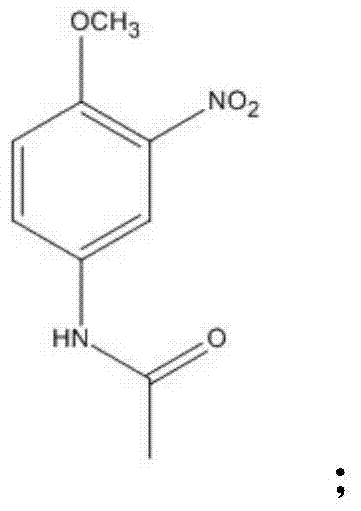

Disperse dye intermediate preparation method

InactiveCN106995383ASimple production methodOptimize the production processOrganic compound preparationCarboxylic acid amides preparationBenzeneMetal

The invention provides a disperse dye intermediate preparation method, which is characterized by utilizing m-dinitrobenzene as a raw material and obtaining a target product through amination, amidation and reduction reaction. In addition, the disperse dye intermediate preparation method disclosed by the invention enables waste residues generated in a reaction process to be recycled through a circular metal reduction method. Furthermore, the disperse dye intermediate preparation method disclosed by the invention has environmental friendliness and no pollution.

Owner:王志训

Fabrication process of blended yarn of wool with rabbit hair

InactiveCN102747476ASimplify production stepsOptimize the production processBiochemical fibre treatmentYarnEnzymeWool

The invention discloses a fabrication process of a blended yarn of wool with rabbit hair. The process comprises steps of matching raw materials, opening, cotton carding, drawing, roving, spinning, enzyme treatment, washing, softening treatment, quality control and packaging. According to the fabrication process, the production process is optimized through simplification of the production steps, the production efficiency is improved while the product quality is guaranteed, the increase of market competitiveness is facilitated, and simultaneously, appearances and handle feels of products are better due to the additional steps such as enzyme treatment and softening treatment.

Owner:TAICANG MINGLIU GARMENT

Method for efficiently producing 2-O-glucose-based ascorbic acid

InactiveCN101914601AReduce manufacturing costOptimize the production processFermentationGlycosyltransferaseDrug biotransformation

The invention discloses a method for efficiently producing 2-O-glucose-based ascorbic acid. The 2-O-glucose-based ascorbic acid is synthesized by using L-ascorbic acid and beta-cyclodextrin as substrates through transformation, wherein the synthesizing conditions are as follows: the temperature is 35-45 DEG C, the pH value is 4.5-5.5, the concentration of the beta-cyclodextrin is 25-100g / L, the concentration of the ascorbic acid is 25-100g / L, and the amount of the glycosyltransferase is 50-200U / mL. The method of the invention has the advantages of simple operation, easy control, low requirements on transformation condition and high output of the 2-O-glucose-based ascorbic acid of 8.5g / L, and provides possibility for massively producing the 2-O-glucose-based ascorbic acid by using a biotransformation method.

Owner:JIANGNAN UNIV

6101B aluminum alloy casting production process

InactiveCN112342414AOptimize the production processGuaranteed mechanical performance requirementsCorrosion resistantMechanical properties of carbon nanotubes

The invention relates to a 6101B aluminum alloy casting production process, and belongs to the field of aluminum alloy casting production. The 6101B aluminum alloy casting production process comprisesthe steps of burdening, furnace charging, smelting, stirring, refining, slagging-off, component adjusting, online refining, online degassing, filtering and casting. Through connection of all processsteps in the production process and control over all process parameters, the 6101B aluminum alloy casting production process is optimized, products meet the mechanical property requirement, the product yield is increased, and the corrosion resistance and oxidation resistance of the products are improved.

Owner:CHINA ZHONGWANG

Production process for aluminum alloy battery boxes

The invention discloses a production process for aluminum alloy battery boxes. The production process comprises the following steps: aluminum blocks are placed in a smelting furnace for smelting underthe condition of 650-690 DEG C to form molten aluminum; tungsten blocks, iron blocks, titanium blocks, zinc blocks, zirconium blocks, magnesium blocks, nickel blocks and manganese blocks are fed in the smelting furnace for smelting in sequence in proportion according to melting points from high to low in the environment of 1300-1500 DEG C; after smelting by 5-9 min, the molten aluminum is uniformly fed inside for smelting by 20-30 min; formed pouring liquid is poured in battery box molds for electric vehicles; the pouring speed is maintained within 30-50 ml / s; the molding is waited; after molding and recovery to the normal temperature, products are placed in a heating furnace for heating to 200-220 DEG C; and the temperature is maintained by 40-60 min under the conditions. Through the production process, the aluminum alloy battery boxes achieve high strength, and the service life of accumulators arranged therein can be effectively prolonged.

Owner:北京诺飞新能源科技有限责任公司

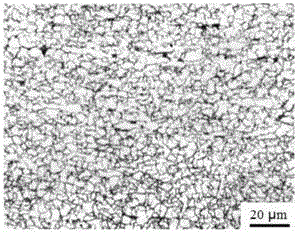

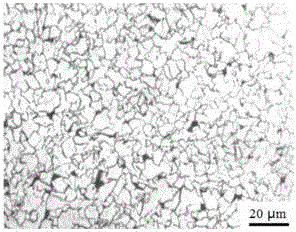

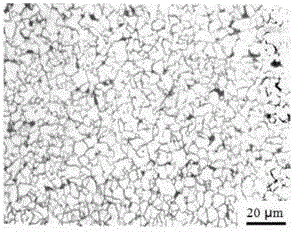

Prediction method and system thereof of lamellar tearing resistance performance of steel used for high-rise building

InactiveCN104899416AUniversalOptimize the production processSpecial data processing applicationsImage analysisCrystallite

The invention belongs to a prediction method and a system thereof of the lamellar tearing resistance performance of steel used for a high-rise building. The prediction method comprises the following steps: reading the base metal information, the rolling technology parameter and the hot rolling metallographic structure of steel materials to be measured from a database; establishing a PLS (Partial Least-Squares Regression) lamellar tearing resistance performance prediction model, and carrying out the checkout and control of prediction precision to obtain the PLS lamellar tearing resistance performance prediction model with the highest precision; calculating to obtain one group of lamellar tearing resistance performance prediction valuea of a specimen; according to an inverse mapping principle, obtaining an optimal rolling technology scheme corresponding to a maximum prediction value by reverse solution; and utilizing dedicated material image analysis software to carry out image analysis on the [Psi]Zmax specimen hot rolling metallographic structure, and measuring and outputting the average grain size, the ferrite volume ratio and the pearlite volume ratio of the [Psi]Zmax specimen hot rolling metallographic structure. The lamellar tearing resistance performance of the common-use steel used for the high-rise building can be predicted, and an ideal prediction result can be obtained so as to guarantee the optimization of the rolling technology and the control precision of the lamellar tearing resistance performance of the steel used for the high-rise building.

Owner:JIANGSU UNIV

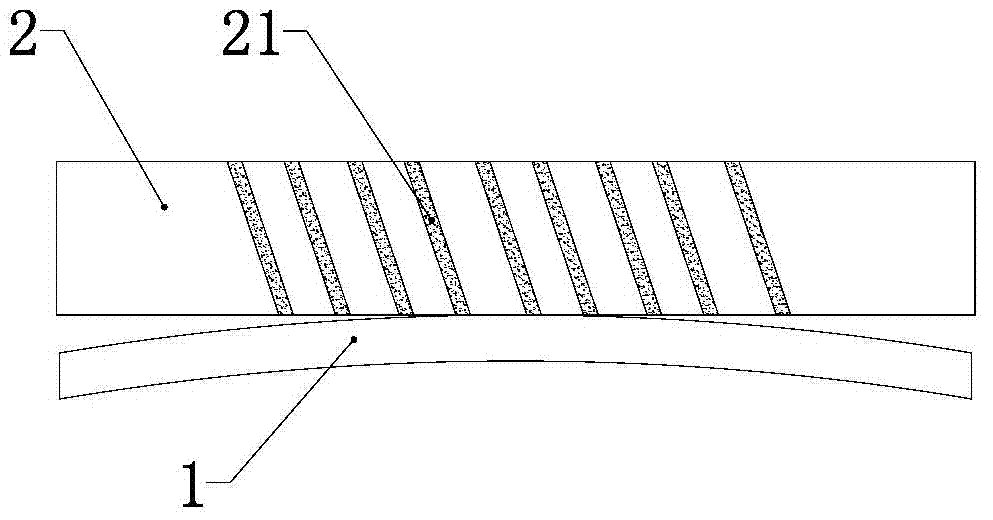

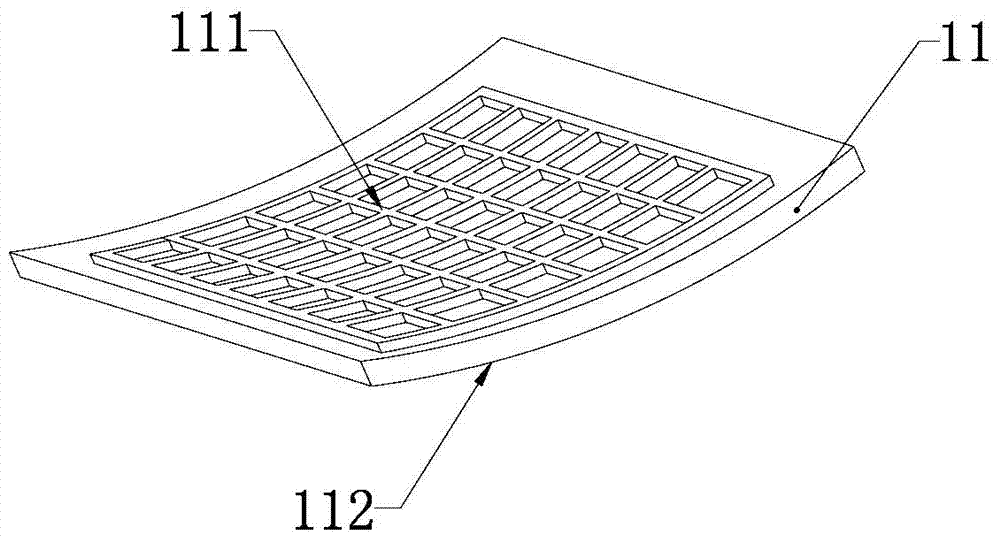

Porcelain tile surface treatment process

InactiveCN104842277AReduce in quantityOptimize the production processImpeller wheelsRotor bladesDeep processingMaterials science

The invention relates to the technical field of deep processing of ceramic wall and floor tiles, and discloses a porcelain tile surface treatment process. The porcelain tile surface treatment process is characterized by adopting a shot blasting process for the treated surfaces of porcelain tiles. Preferentially, the porcelain tiles are porcelain tile blanks treated by a kiln process. Further, the treated surfaces of the porcelain tiles are reverse sides of the porcelain tiles. Further, the reverse sides of the porcelain tiles take the shape of turtle backs with low middles and high peripheries. The porcelain tile surface treatment process can treat the surfaces of the sintered tile blanks and the uneven deformation correction of the surfaces of the tiles caused by different processing procedures, so that the number of scrappers is decreased, the production process of traditional porcelain tiles is optimized, the cost of porcelain tile production equipment is reduced, the processing efficiency of the porcelain tiles is improved, and the quality of the porcelain tile products is guaranteed.

Owner:KEDA INDUSTRIAL GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com