Method for preparing high air tightness antibacterial reinforced membrane by using straws

A high-air-tight, reinforced membrane technology, used in textiles and papermaking, fiber processing, raw material separation, etc., can solve problems such as environmental pollution and waste of biological resources, achieve short dissolution time, meet production and living needs, and avoid waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

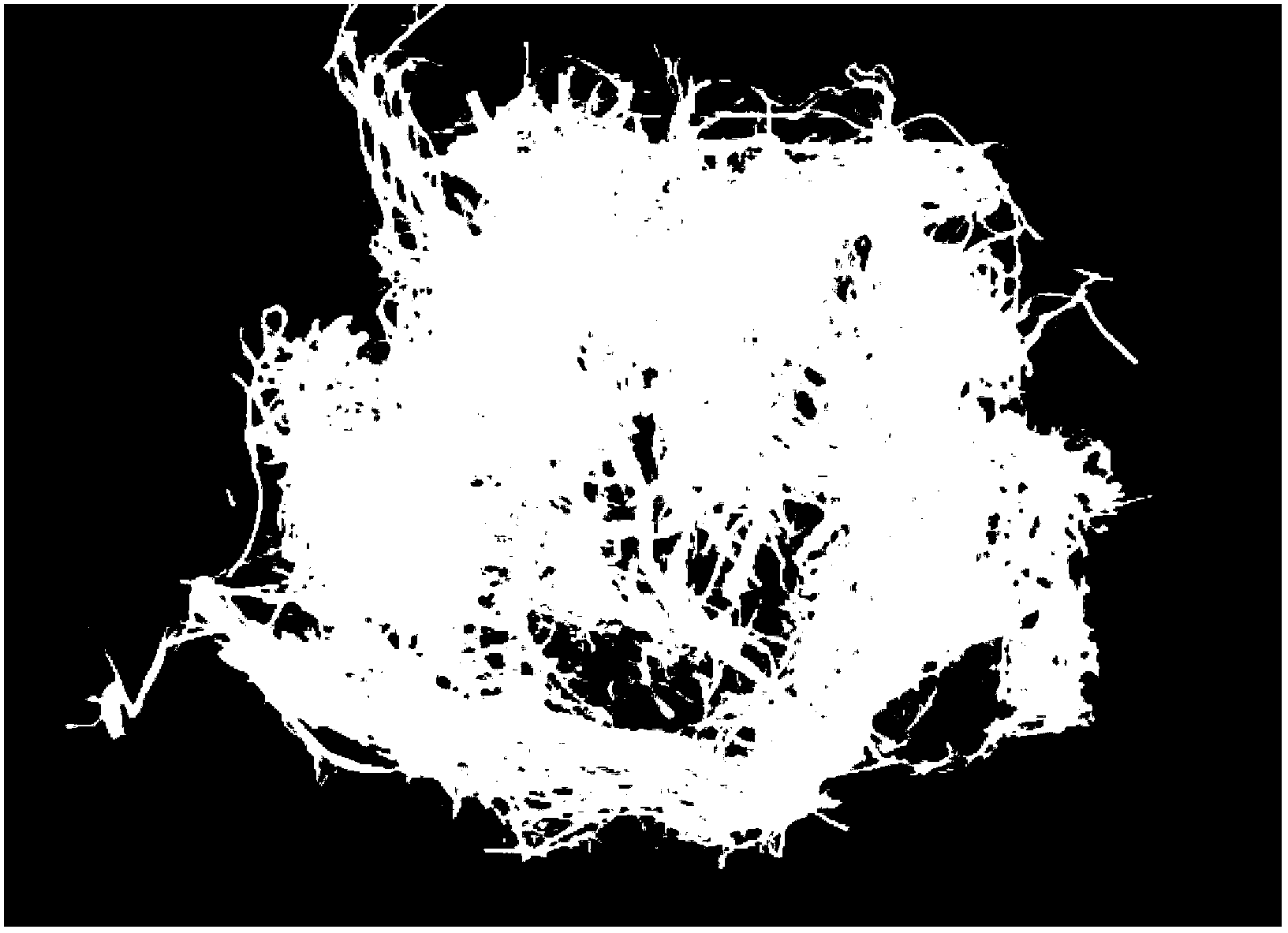

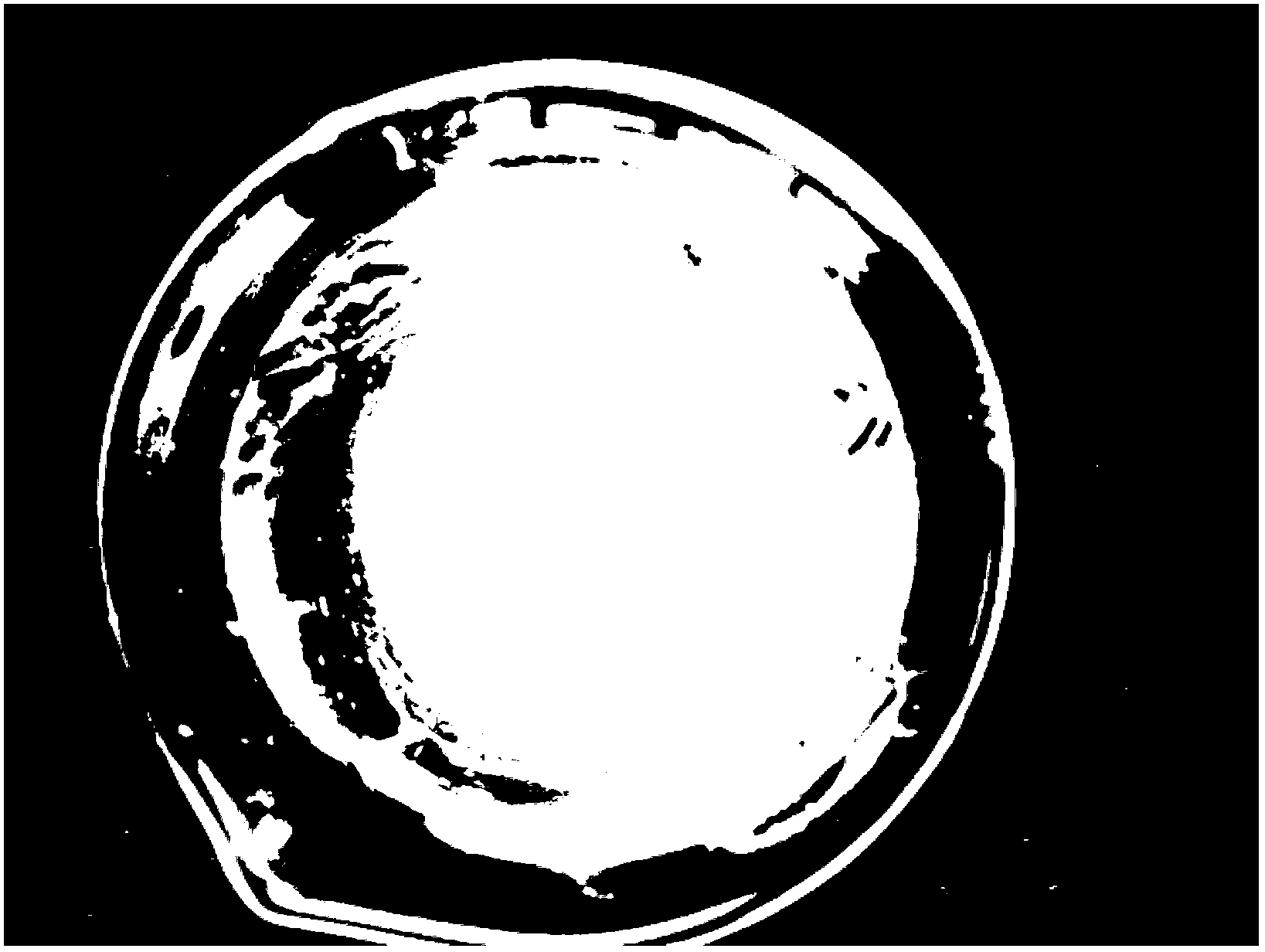

Image

Examples

Embodiment 1

[0033] A method for preparing a highly airtight antibacterial enhanced film with straw, comprising the steps of:

[0034] (1) Prepare straw solution:

[0035] Wash and chop the straw (the straw is rice straw) into short stems with a length of 4-6 mm. Under the pressure of 1.3 MPa and 80 seconds, steam explosion (using steam explosion equipment, or steam explosion equipment) Process to obtain the explosive product;

[0036] Rinse the above crushed product with hydrogen peroxide to make it uniform in color, then dry and pulverize it until it can pass through a 60-mesh sieve to obtain straw powder for use;

[0037] Take the ionic liquid and heat it until it completely melts, add straw powder and mix, and stir at a constant temperature of 100°C for 2-3 hours until the solution becomes transparent to obtain the straw liquid; the mass of the straw powder in the straw liquid (ionic liquid straw solution) The percentage concentration is 10%.

[0038] Add inorganic silver nano-silve...

Embodiment 2

[0052] A method for preparing a highly airtight antibacterial enhanced film with straw, comprising the steps of:

[0053] (1) Prepare straw solution:

[0054] Wash and chop wheat straw into short stems with a length of 4 to 6 mm, and steam-explode (using a steam-explosion device, or steam-explosion equipment) under a pressure of 1.2 MPa for 60 seconds to obtain an explosion-crush product;

[0055]Rinse the above crushed product with hydrogen peroxide to make it uniform in color, then dry and pulverize it until it can pass through a 60-mesh sieve to obtain straw powder for use;

[0056] Take ionic liquid [1-butyl-3-methylimidazole chloride ([bmim]Cl)] and heat until it completely melts, add straw powder and mix, and stir at 100°C for 2-3 hours until the solution becomes transparent, A straw liquid is obtained; the mass percent concentration of straw powder in the straw liquid (ionic liquid straw solution) is 8%.

[0057] Add inorganic silver nano-silver antibacterial powder ...

Embodiment 3

[0063] A method for preparing a highly airtight antibacterial enhanced film with straw, comprising the steps of:

[0064] (1) Prepare straw solution:

[0065] Wash and chop the corn stalks into 4-6 mm long short stems, and process them by steam explosion (using a steam explosion device, or steam explosion equipment) under the pressure of 1.5MPa for 90s to obtain the explosive crushing product;

[0066] Rinse the above crushed product with hydrogen peroxide to make it uniform in color, then dry and pulverize it until it can pass through a 60-mesh sieve to obtain straw powder for use;

[0067] Take the ionic liquid and heat it until it completely melts, add straw powder and mix, and stir at a constant temperature of 100°C for 2-3 hours until the solution becomes transparent to obtain the straw liquid; the mass of the straw powder in the straw liquid (ionic liquid straw solution) The percentage concentration is 6%.

[0068] Add inorganic silver nano-silver antibacterial powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture permeability | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Moisture permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com