Patents

Literature

51results about How to "Meet the needs of production and life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil-resistant rubber

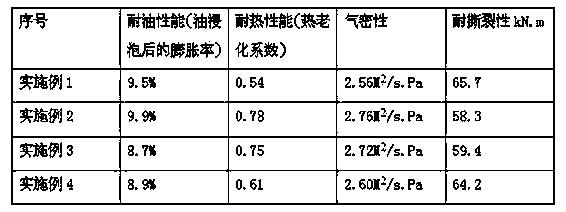

The invention belongs to the field of rubber, and particularly relates to an oil-resistant rubber. The oil-resistant rubber comprises the following components in parts by weight: 80-200 parts of epichlorohydrin rubber, 50-200 parts of fluorinated silicone rubber, 2-10 parts of nano zinc oxide, 1-4 parts of stearic acid, 15-50 parts of carbon black N100, 2-5 parts of paraffin, 4-15 parts of coumarone resin, 2-10 parts of sulfur, 1-5 parts of an antiager, 1-8 parts of calcium carbonate, 1-6 parts of hydroxy silicone oil, 1-5 parts of hydrosilicone oil, 1-5 parts of white carbon black, 1-5 parts of dimethyl silicone oil, 1-4 parts of dibutlyl phthalate, 1-4 parts of zinc diethyl dithiocarbamaate and 1-4 parts of 2-imidazolidinethione. The invention has the benefits that the oil-resistant rubber prepared by the formula has the advantages of good oil resistance, high temperature resistance, corrosion resistance and the like and can effectively meet the requirements in production life.

Owner:山东中一橡胶有限公司

Fire-resistant oil-resistant rubber

The invention relates to fire-resistant oil-resistant rubber which comprises the following raw materials in parts by weight: 10-150 parts of chloroprene rubber, 10-100 parts of fluorosilicone rubber, 1-5 parts of nano-zinc oxide, 1-4 parts of stearic acid, 10-25 parts of magnesium hydroxide, 1-5 parts of aluminum phosphate, 1-10 parts of sulphur, 1-4 parts of N-phenyl-alpha-phenylamine, 1-10 parts of calcium carbonate, 1-6 parts of hydroxyl silicone oil, 1-8 parts of hydrogen silicone oil, 1-5 parts of white carbon black, 1-15 parts of dimethyl silicon oil, 1-10 parts of dibutyl phthalate, 1-8 parts of zinc diethyl dithiocarbamate and 1-8 parts of 2-thiol group imidazoline. The fire-resistant oil-resistant rubber disclosed by the invention has the advantages of good oil-resistant property, high-temperature resistance, fire resistance, corrosion resistance and the like and can effectively meet the requirements of production and living.

Owner:罗云华

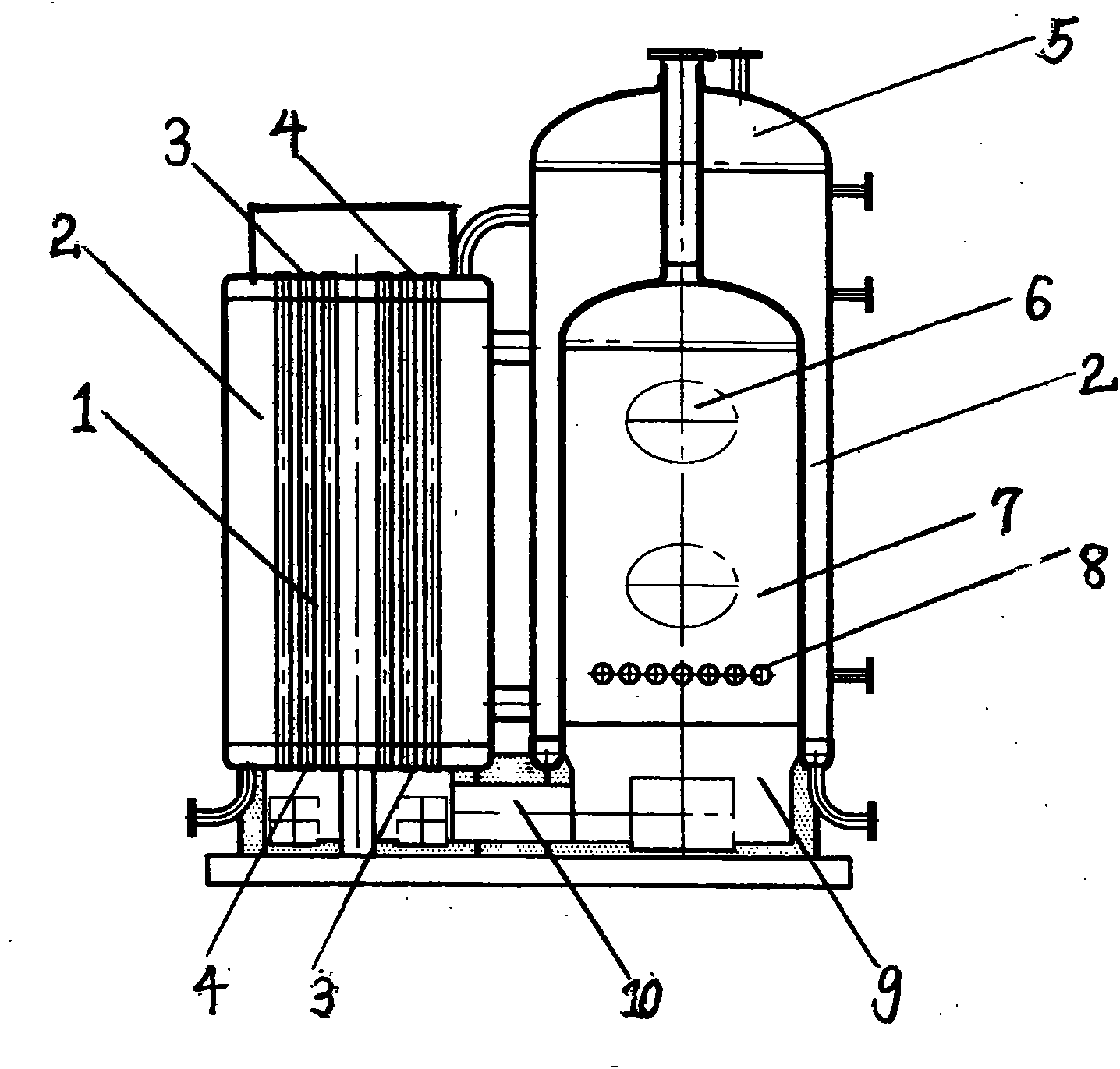

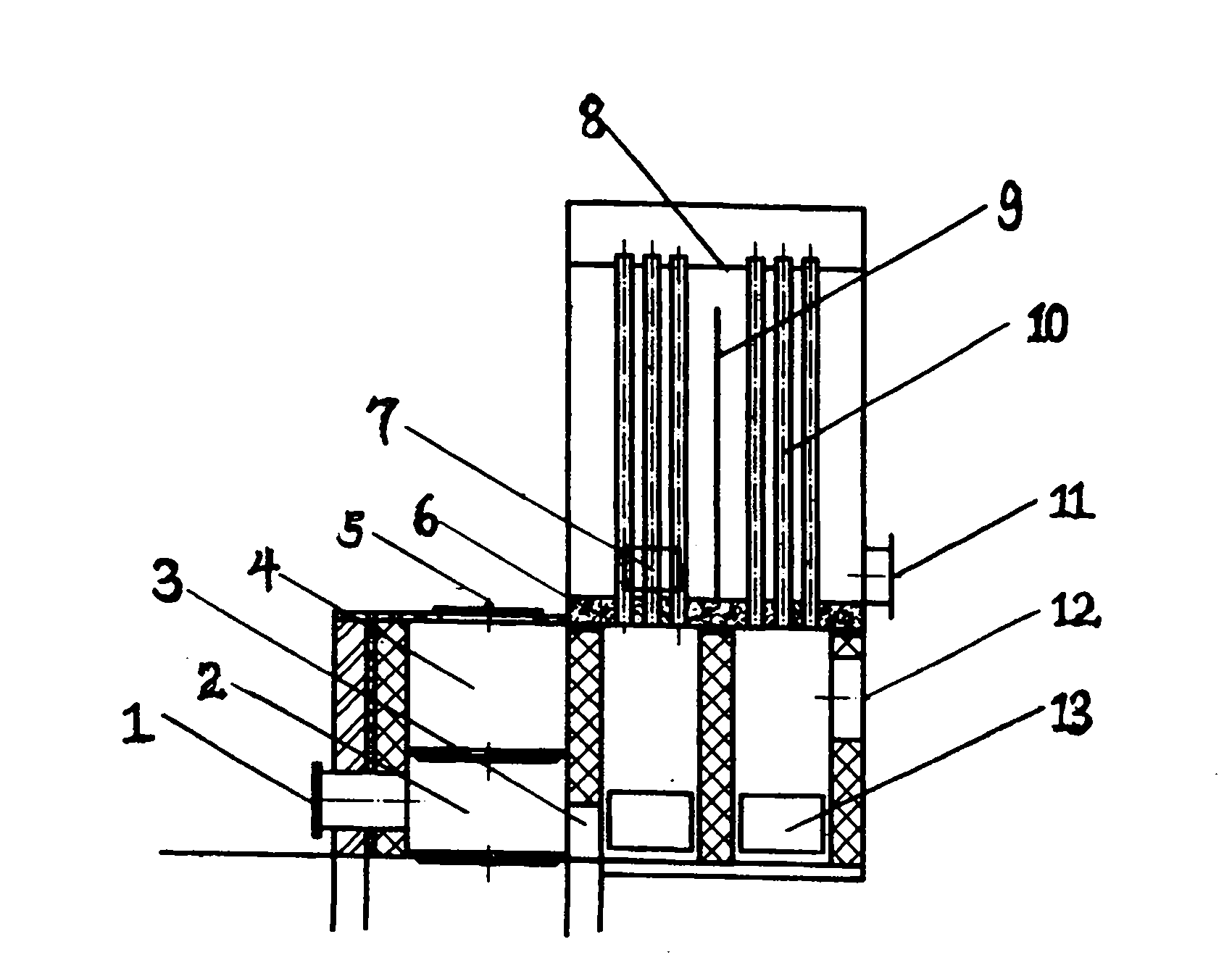

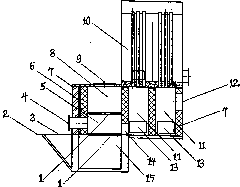

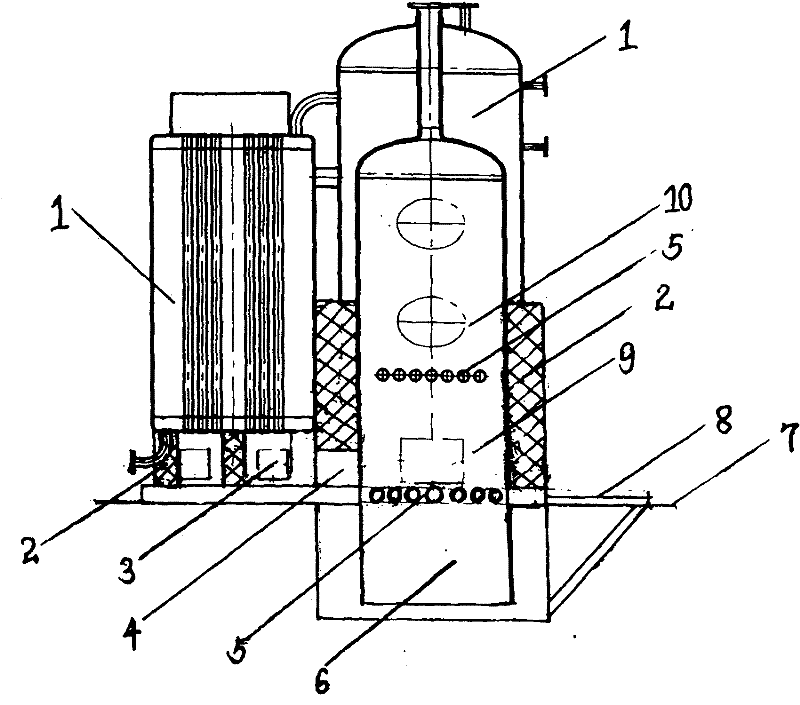

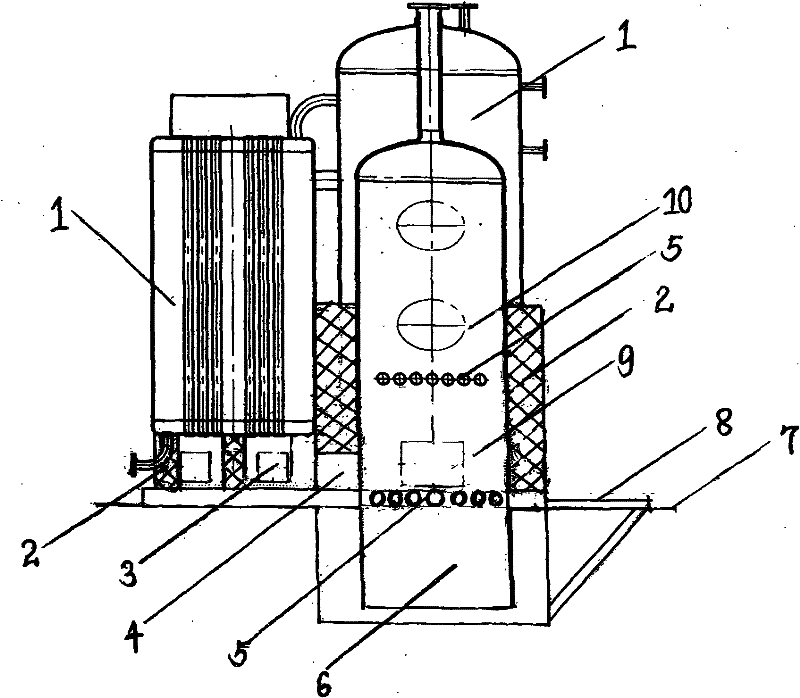

Reverse combustion multi-pass biomass low-carbon energy-saving hot water boiler

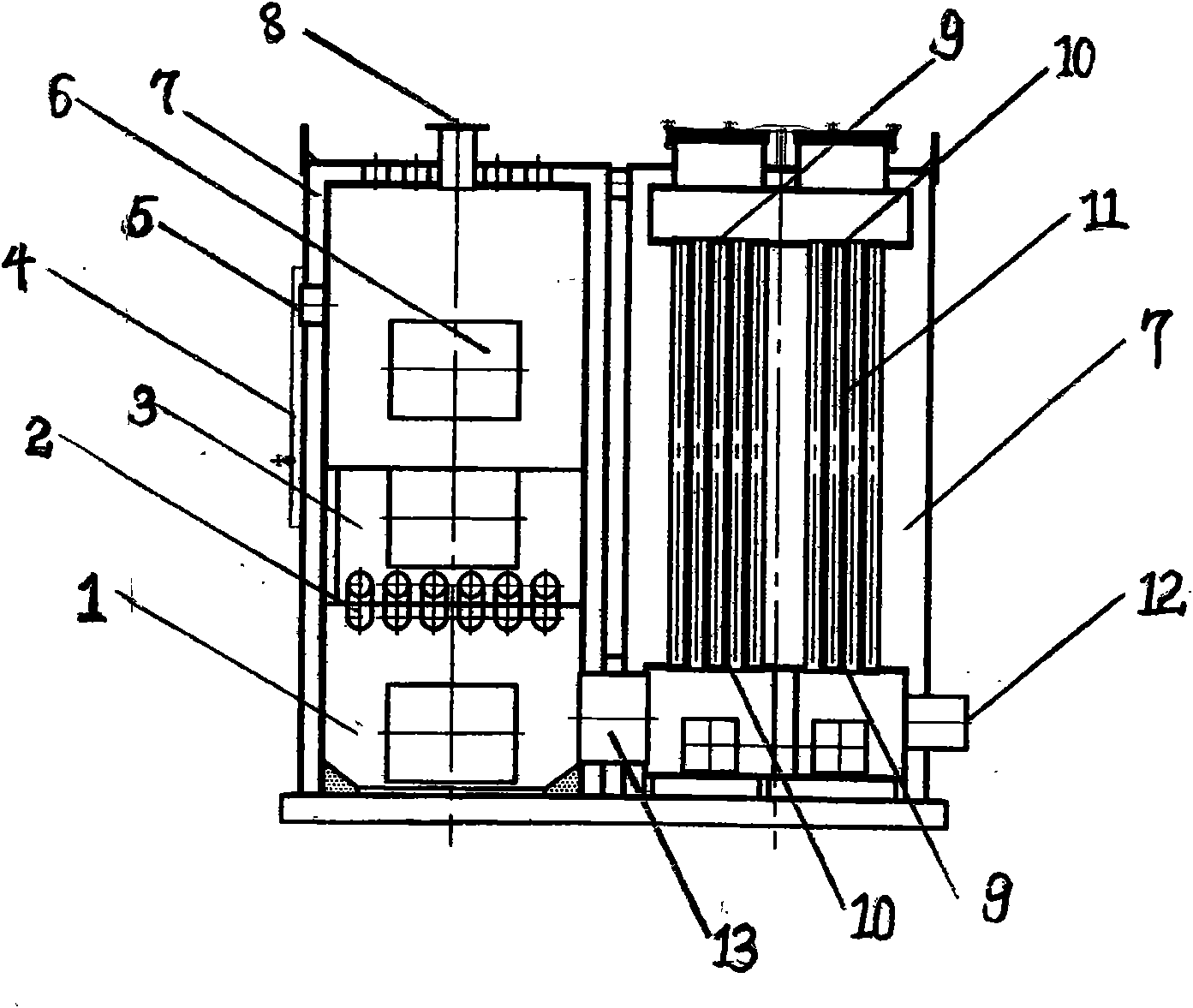

The invention discloses a reverse combustion multi-pass biomass low-carbon energy-saving hot water boiler which comprises a secondary reverse combustion hearth (1), a grate (2), a reverse combustion gasification hearth (3), a secondary air door (4), a high-temperature secondary air inlet (5), a biomass fuel charging opening (6), a water jacket (7), a fire banking and exhaust port (8), a pass fire outlet (9), a pass fire inlet (10), a multi-pass fire tube (11), an induced fan connection port (12) and a reverse combustion port (13). Pipelines of the hot water boiler are vertically arranged, and flames are moved in one of the vertically arranged pipelines from bottom to top and are returned in another pipeline from top to bottom, thus forming multi-pass reverse combustion. The reverse combustion multi-pass biomass low-carbon energy-saving boiler is made of iron plates and iron tubes. The invention has the advantages of complete combustion, low carbon content and energy saving, and can change wastes into valuables, reclaim resources and purify environment, thereby being beneficial to the nation and people.

Owner:朔州市万申昌新能源研究中心

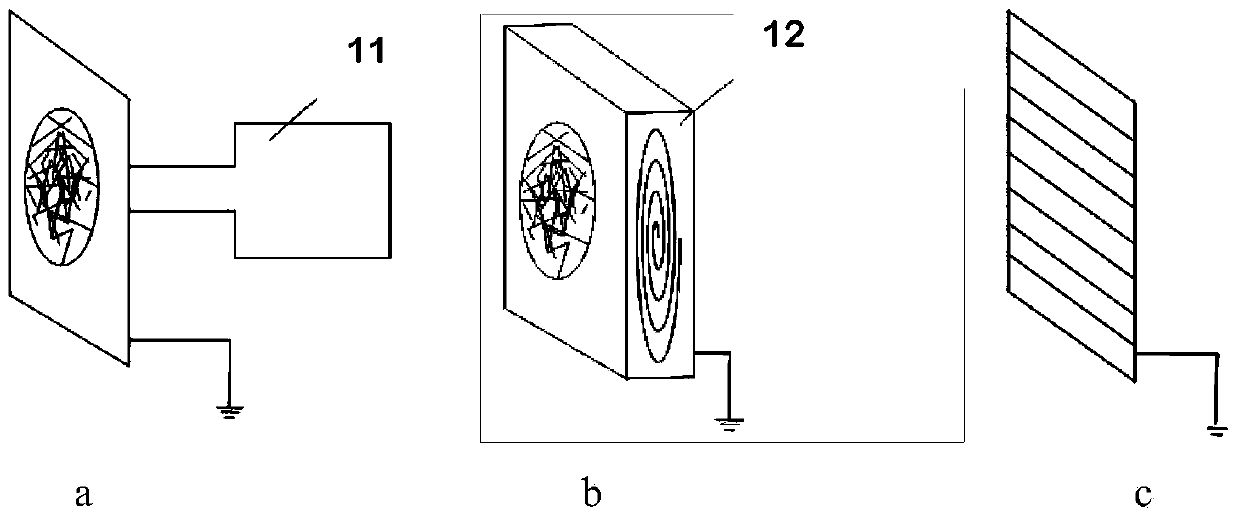

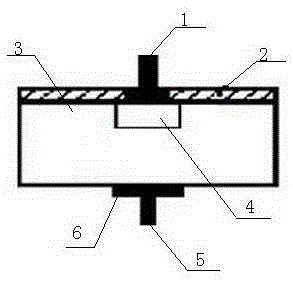

Nano-film spinning device

The invention discloses a nano-film spinning device. The nano-film spinning device comprises a film generator connected with a high-voltage electrostatic generator and a receiving pole plate arranged at the front end of the film generator. An airflow cavity is formed in the rear end of the film generator. A film forming device is arranged on an outlet of the airflow cavity. A gas inlet and a nano-particle inlet are formed in an inlet of the airflow cavity. The gas inlet is connected with an airflow generator. The nano-particle inlet is connected with a nano-particle container. Compared with the prior art, a nano-film is stretched in a high-voltage electrostatic field or an airflow field or a mixed field of the high-voltage electrostatic field and the airflow field, and therefore the diameter of prepared nano-fibers is smaller. Meanwhile, nano-particles are added to the airflow cavity through the nano-particle container, the nano-film and the nano-particles are more uniformly mixed in the spinning process, and uniform protrusion structures on the surfaces of the fibers can be effectively prepared. The appearance and the shape of the fibers can be accurately controlled by controlling the shape, the property and the like of the particles.

Owner:江苏瀚霆环保滤材有限公司

Method for preparing I-type snow melting agent from fly ash of waste

ActiveCN109575880AReduce processing costsImprove snow melting effectCalcium/strontium/barium carbonatesOther chemical processesSulfateWastewater

The invention discloses a method for preparing an I-type snow melting agent from fly ash of waste. The method includes the steps of washing with water, heavy metal removal, decolorization, calcium removal and evaporative crystallization, realizes harmless disposal of fly ash, recycles waste material, produces the I-type snow melting agent has good economic benefit, can also produce calcium carbonate or calcium sulfate, greatly reduces cost of fly ash disposal, causes no emission of waste water in treatment process, and is energysaving and environmentally friendly.

Owner:杭州秀澈环保科技有限公司

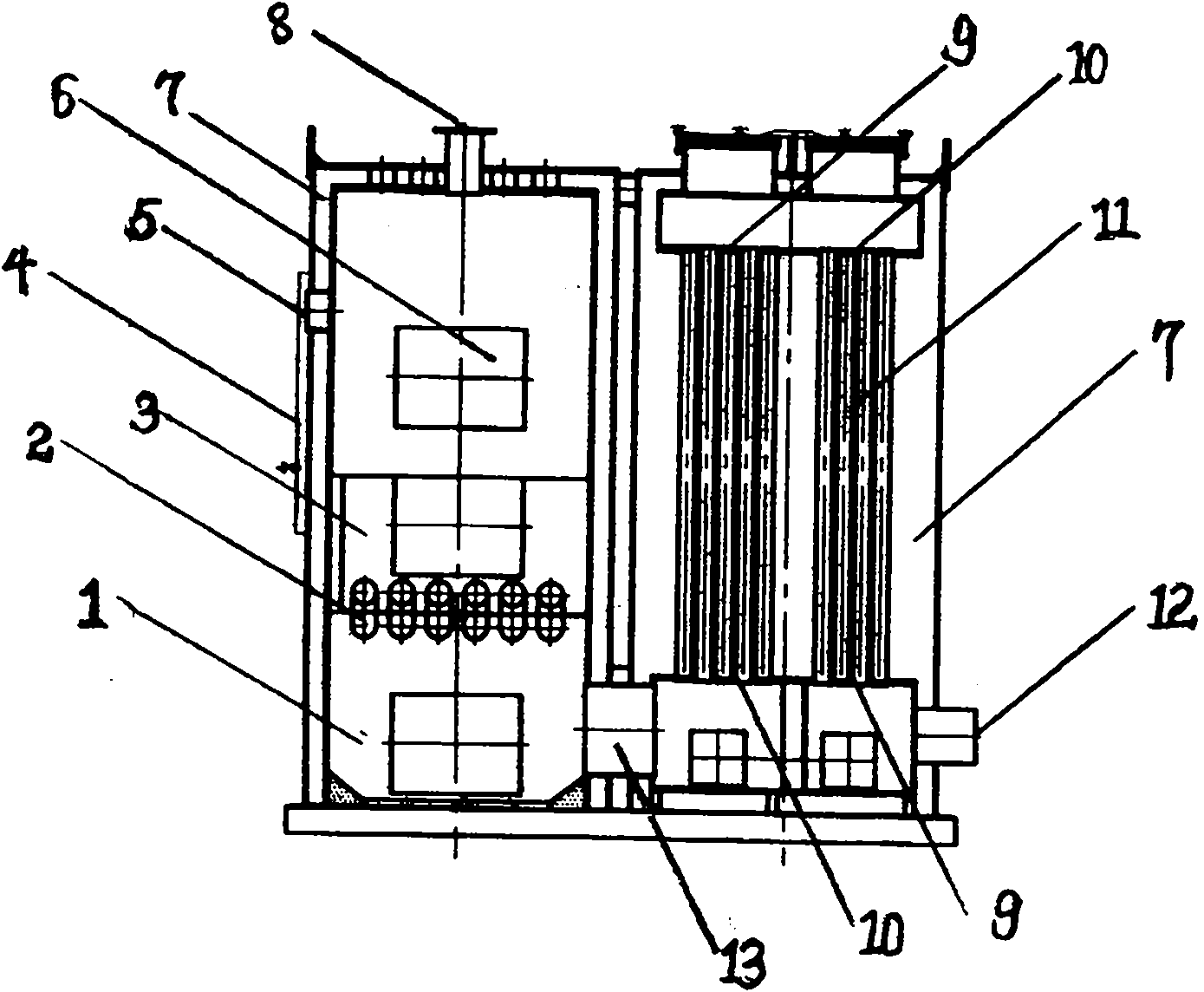

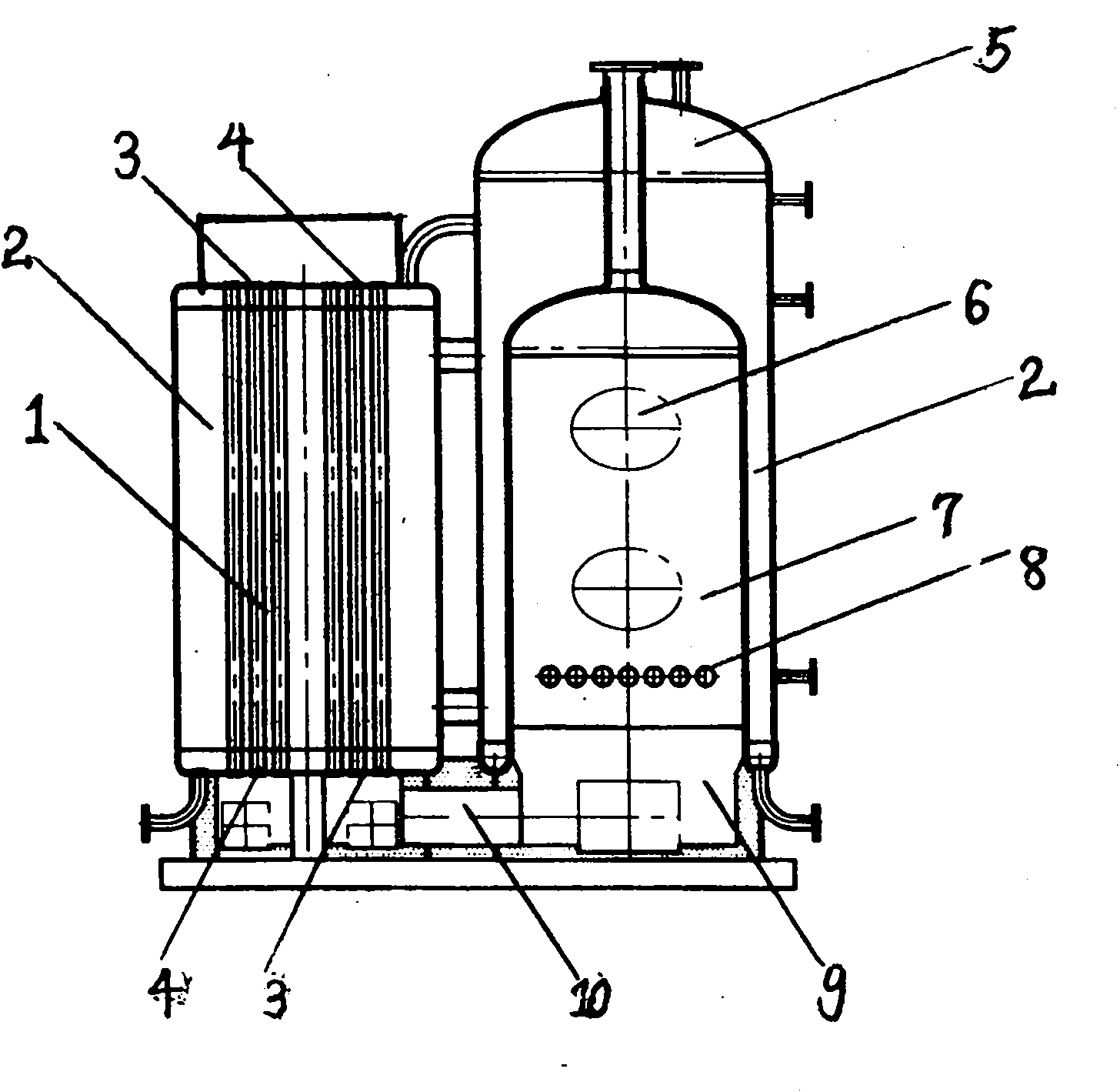

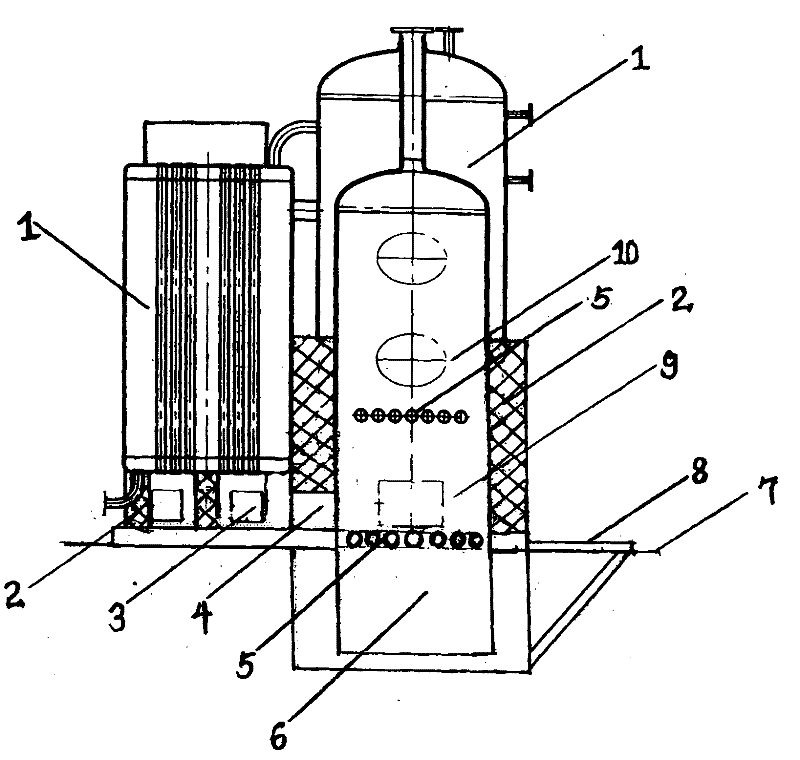

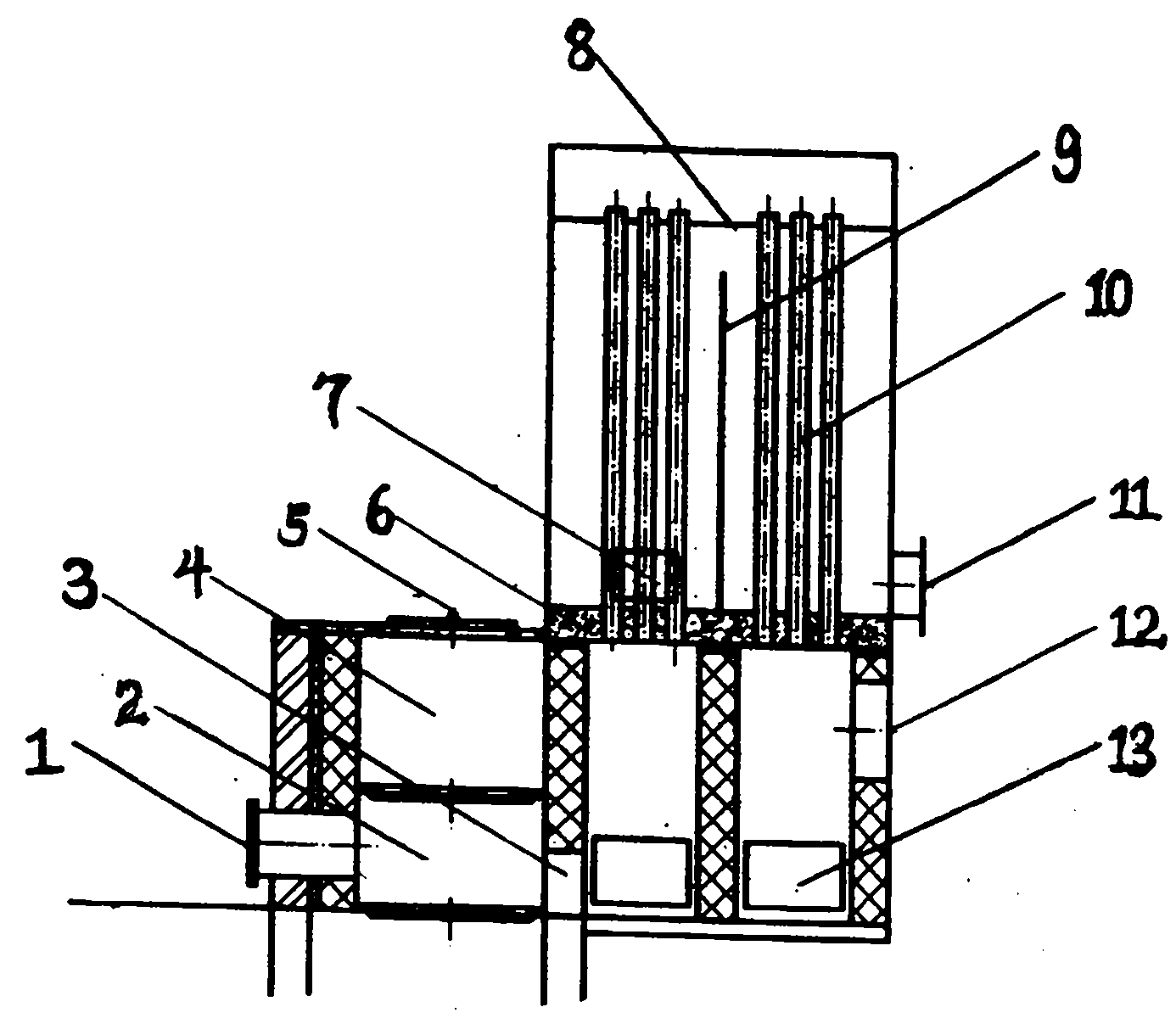

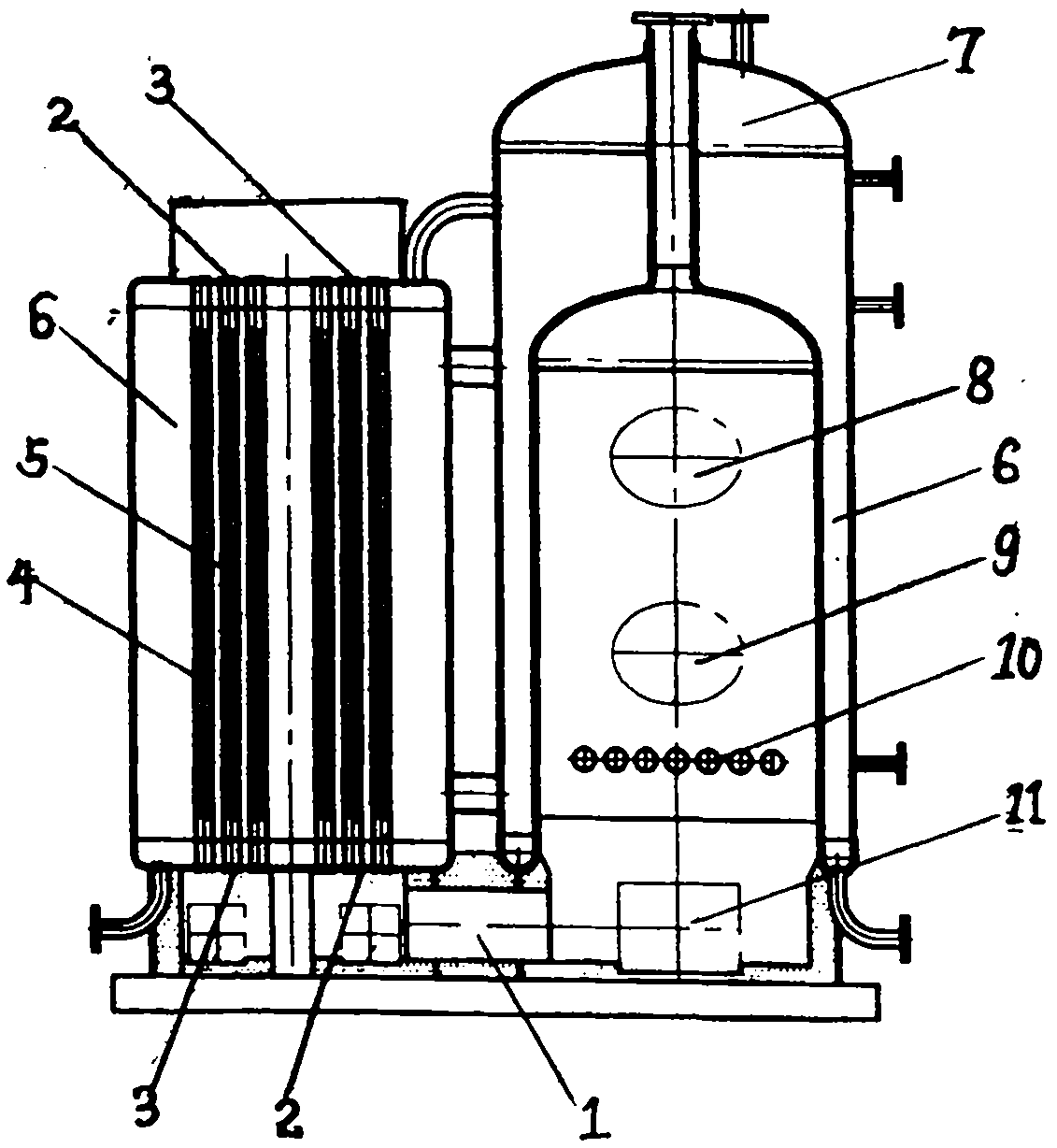

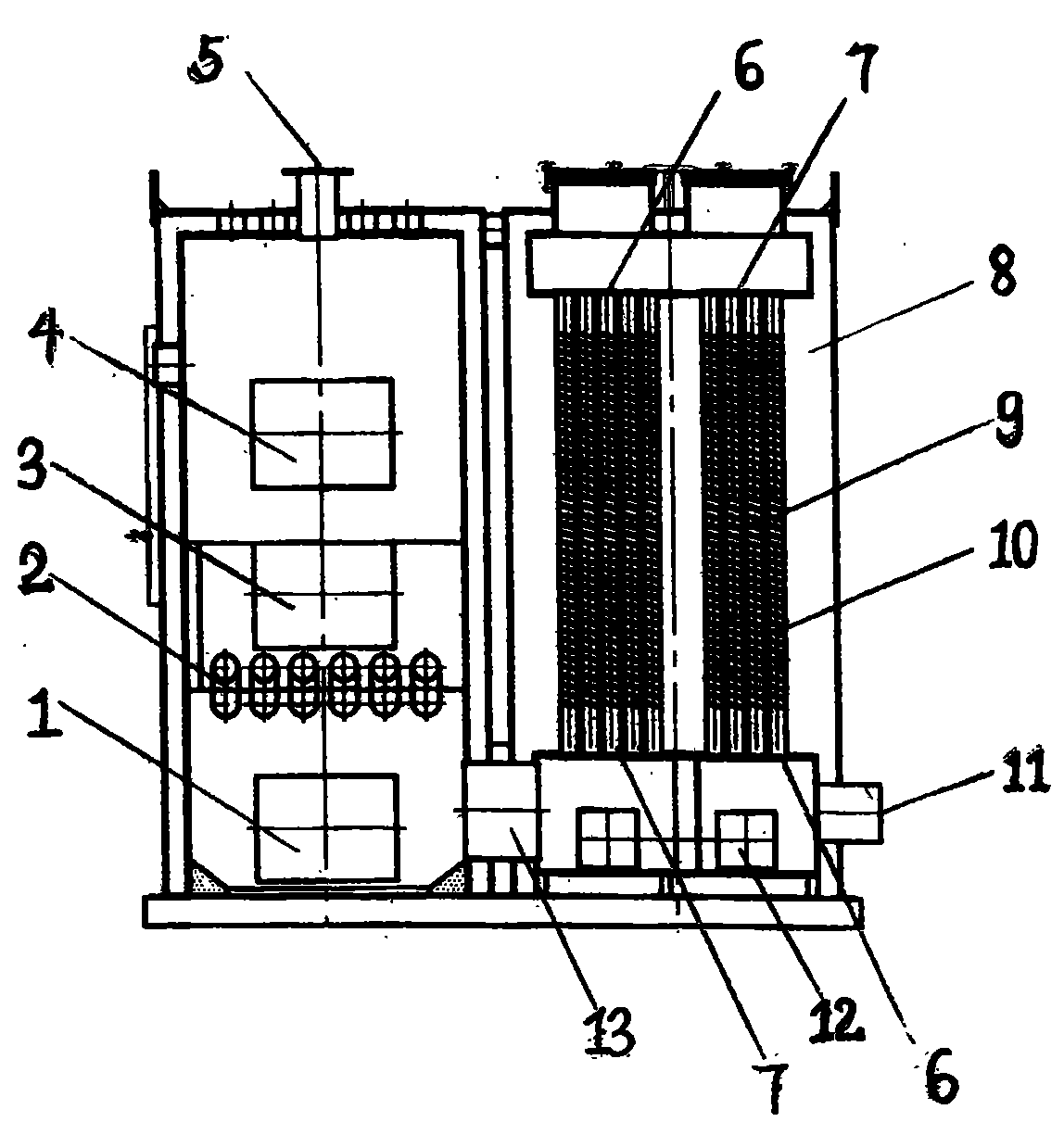

Reverse burning multi-return-stroke biomass low-carbon energy-saving steam boiler

InactiveCN102141242AIncrease temperatureResource regenerationSteam boilersVolatilesCombustion chamber

The invention discloses a reverse burning multi-return-stroke biomass low-carbon energy-saving steam boiler. The steam boiler consists of a multi-return-stroke flame tube (1), a water sleeve (2), a return stroke flame outlet (3), a return stroke flame inlet (4), an ellipsoidal seal head (5), a biomass charging opening (6), a biomass semi-gasification hearth (7), a grate (8), a secondary combustion chamber (9) and a reverse burning channel (10). In the reverse burning multi-return-stroke biomass low-carbon energy-saving steam boiler, fuels are gasified in advance in the biomass semi-gasified hearth under the action of an induced draft fan, and a large number of volatiles are separated out in the gasification process; the fuels are fully combusted under the action of secondary wind; flame enters the flame tube and then the return-stroke flame outlet from bottom to top along the combustion of the fuels; the fuels are returned from the return-stroke flame inlet downwards from top to bottom; therefore, a reverse burning multi-return stroke is formed. The reverse burning multi-return-stroke biomass low-carbon energy-saving steam boiler is made of any one of iron and stainless steel. The boiler makes combustion sufficient, is low-carbon and energy-saving, makes waste profitable, realizes resource regeneration, purifies the environment and is beneficial to the nation and the people.

Owner:朔州诚信锅炉制造有限公司

Brick hearth type hot blast stove

InactiveCN102121753ATake advantage ofRaise the combustion temperatureAir heatersCombustion chamberFire brick

The invention discloses a brick hearth type hot blast stove. The hot blast stove comprises a horizontal plane (1), an ash removing cover (2), an underground ash pit (3), a furnace door (4), a hydrochloric acid silica alumina plate (5), a second combustion chamber (6), refractory bricks (7), a first combustion chamber (8), a feeding hole (9), a heat exchanger (10), a vent hole (11), an access hole (12), a draught fan (13) and a secondary tuyere (14); the hearth of the hot blast stove are all built with the refractory bricks, a layer of the hydrochloric acid silica alumina plate is sandwiched in the middle and used for heat preservation and insulation, and the heat exchanger is arranged on the hot blast stove; materials used by the hot blast stove are the refractory bricks or refractory bricks and common bricks. The hot blast stove has the advantages of no damage to a pipeline by permanent combustion, long service life, high combustion efficiency, easiness for repair, low manufacturing cost and easiness for popularization.

Owner:朔州市朔城区华圣秸秆加工专业合作社

Method for improving hardness of tungsten alloy

The invention discloses a method for improving the hardness of tungsten alloy, which comprises the following steps: Step 1, weighing metal powder; Step 2, mixing materials; Step 3, isostatic pressing; Step 4, sintering; , take an appropriate amount of tungsten powder, nickel powder, iron powder and chromium powder respectively; Mix in the middle to obtain mixed powder; the mass percentage of tungsten powder in the mixed powder is 85%~98%, the mass ratio of nickel powder and iron powder in the described mixed powder is (1.8~3.0): 1, Cr adds The content is in the range of 0.04% to 2.0%. The sintered tungsten alloy of the present invention can increase the hardness of the tungsten alloy by adding the element Cr without further treatment by other methods, so that the hardness of the tungsten alloy can reach above HRC31, which can better meet the needs of people's production and life. .

Owner:XIAN HUASHAN METAL PROD CO LTD

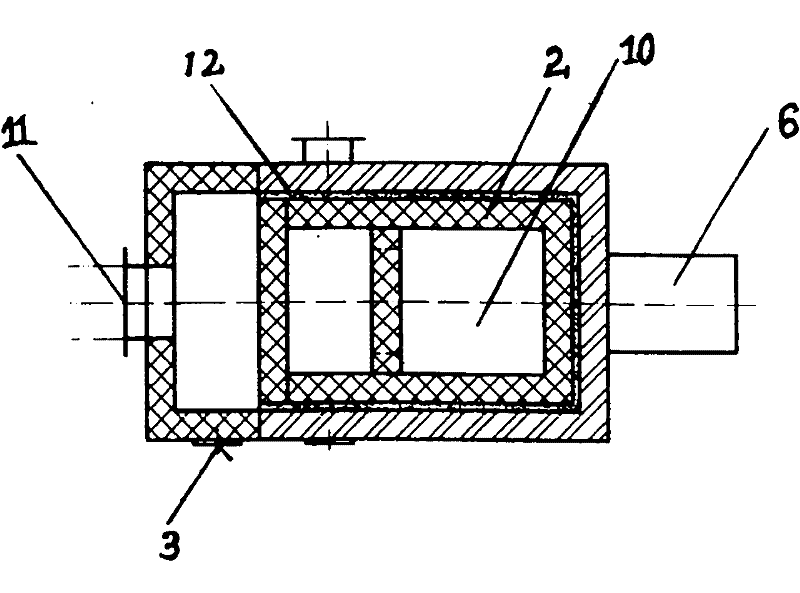

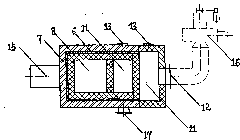

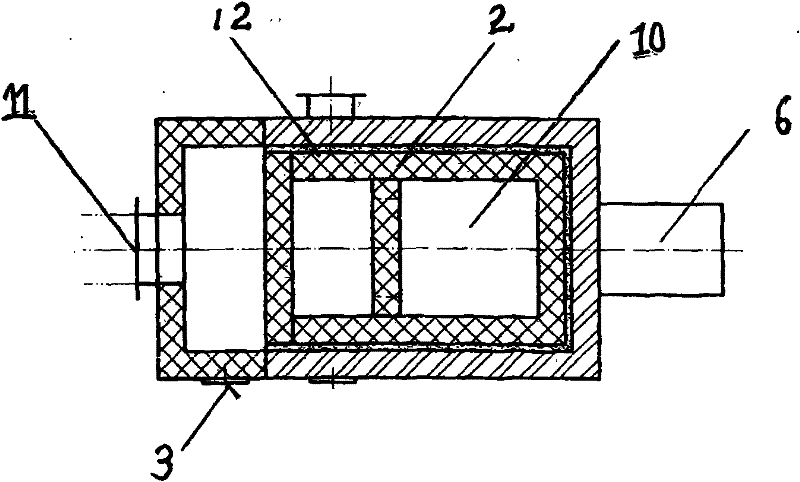

Brick hearth type steam boiler

InactiveCN102183004ATake advantage ofRaise the combustion temperatureSteam boilersSteam boilers componentsRefractoryFire brick

The invention discloses a brick hearth type steam boiler. The steam boiler consists of a steam boiler (1), refractory bricks (2), an ash removal port (3), a counter-burning path (4), a fire grate (5), an underground ash pit (6), a ground plane (7), an ash removal cover (8), a brick counter-burning hearth (9), a brick hearth (10), a smoke receiving tube port (11) and a brick acid aluminum plate (12), wherein the hearth of the steam boiler can be completely built by using the refractory bricks or can be built by combining the refractory bricks and normal bricks; the brick acid aluminum plate (12) is sandwiched in the middle of the two types of bricks and is used for preserving and insulating heat; the biomass boiler (1) is arranged on the hearth; and the underground ash pit (6) is arranged below the ground plane (7). The steam boiler is easy to prepare, overhaul and popularize, has long life, is low in manufacturing cost, and is economical and practical.

Owner:朔州诚信锅炉制造有限公司

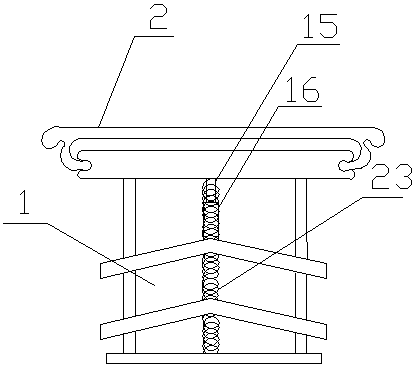

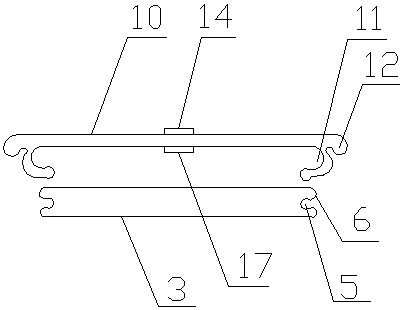

Combined electric appliance fixing seat with wire inlet device

InactiveCN108488570AQuick collapseDoes not take up spaceElectrical apparatusNon-rotating vibration suppressionEngineeringElectric wire

The invention relates to a combined electric appliance fixing seat with a wire inlet device. The combined electric appliance fixing seat comprises a support seat, a base body and the wire inlet device, wherein the support seat comprises a detachable upper support plate, a lower support plate and two groups of support assemblies, chutes are formed in both sides of the upper support plate in a transverse direction, first bulges are arranged on the upper edges of the chutes in the forming direction of the chutes, and the support assemblies comprise four support rods and L-shaped connecting plates; the base body comprises a plurality of bottom plates, first round holes are formed in the middle of the bottom plates, an upper pressing plate is arranged above the first round holes, a sleeve is installed below the first round holes, a first damping spring sleeves the sleeve, and a lower pressing plate which is the same as the inside diameter of the sleeve is arranged in the middle of the uppersupport plate; and the wire inlet device comprises a boss arranged on the lower support plate and a containing cavity formed in the middle of the boss, and a wire and cable clip is arranged in the containing cavity. The combined electric appliance fixing seat has the advantages of the simple structure, easiness in removal and installation and good damping effect and is suitable for electric appliances of different sizes, less space is occupied after retraction, and electric appliance wires are safely arranged.

Owner:瑞普兰德电梯有限公司

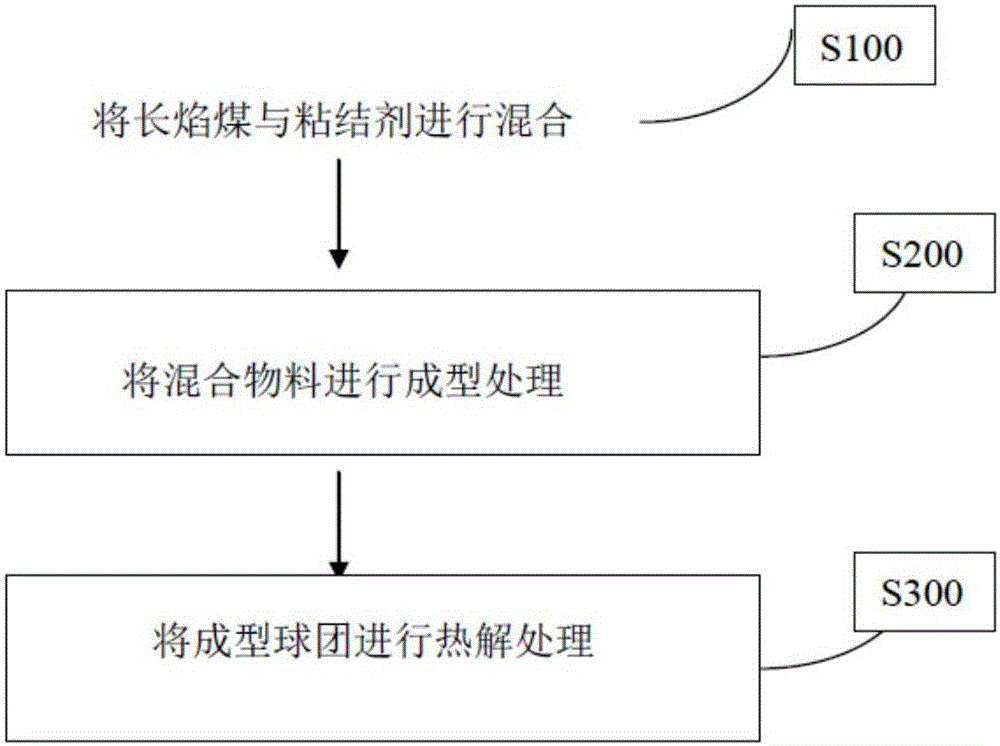

Composite adhesive for molding coal powder and method for preparing molded coal

The invention discloses a composite binder for forming coal powder, which comprises the following components: 20-50wt% of coke powder, 10-50wt% of coal tar, 5-20wt% of quicklime, 2-10wt% of diboron trioxide or boron powder , 5-30wt% caking coal. The invention also discloses a method for preparing molded coal, which includes the following steps: (1) stirring the long-flame coal and the composite binder evenly to obtain a mixture; (2) putting the mixture into a molding device and pressing it into shape; (3) ) Pyrolytic treatment of the compressed mixture. The composite binder disclosed in the present invention has good thermal stability, wide sources of ingredients, low cost, no harmful impurities, and can also realize waste recycling; the method for preparing briquettes disclosed in the present invention is simple and wide in application It is suitable for large-scale production, and the obtained briquettes have high pyrolysis strength, compressive strength and drop strength, which can meet the needs of subsequent production.

Owner:SHENWU TECH GRP CO LTD

Method for in-situ construction of hierarchical pore carbon material and synchronous loading of noble metal nano catalyst in porous mineral

InactiveCN113976109AIncrease the areaAdd channelGas treatmentDispersed particle separationNano catalystPtru catalyst

The invention discloses a method for in-situ construction of a hierarchical porous carbon material and synchronous loading of a noble metal nano catalyst in a porous mineral, and belongs to the technical field of nano catalytic material preparation. The method comprises the following steps: pretreating porous minerals with an acid or alkali solution, preparing an aqueous solution containing a water-soluble polymer by taking noble metal salt as a raw material, mixing and stirring the two aqueous solutions to obtain a precursor solution containing noble metal ions, adding the treated porous minerals into the precursor solution, and performing vacuum impregnation and drying to obtain a metal ion / polymer / porous mineral precursor; and enabling that the precursor is subjected to in-situ carbonization and reduction in the high-temperature heat treatment process, so that the hierarchical porous carbon material is constructed in situ in the porous structure of the porous mineral, the noble metal nano-catalyst is synchronously loaded, and the porous material has excellent catalytic performance, is environment-friendly and has a wide application prospect.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +2

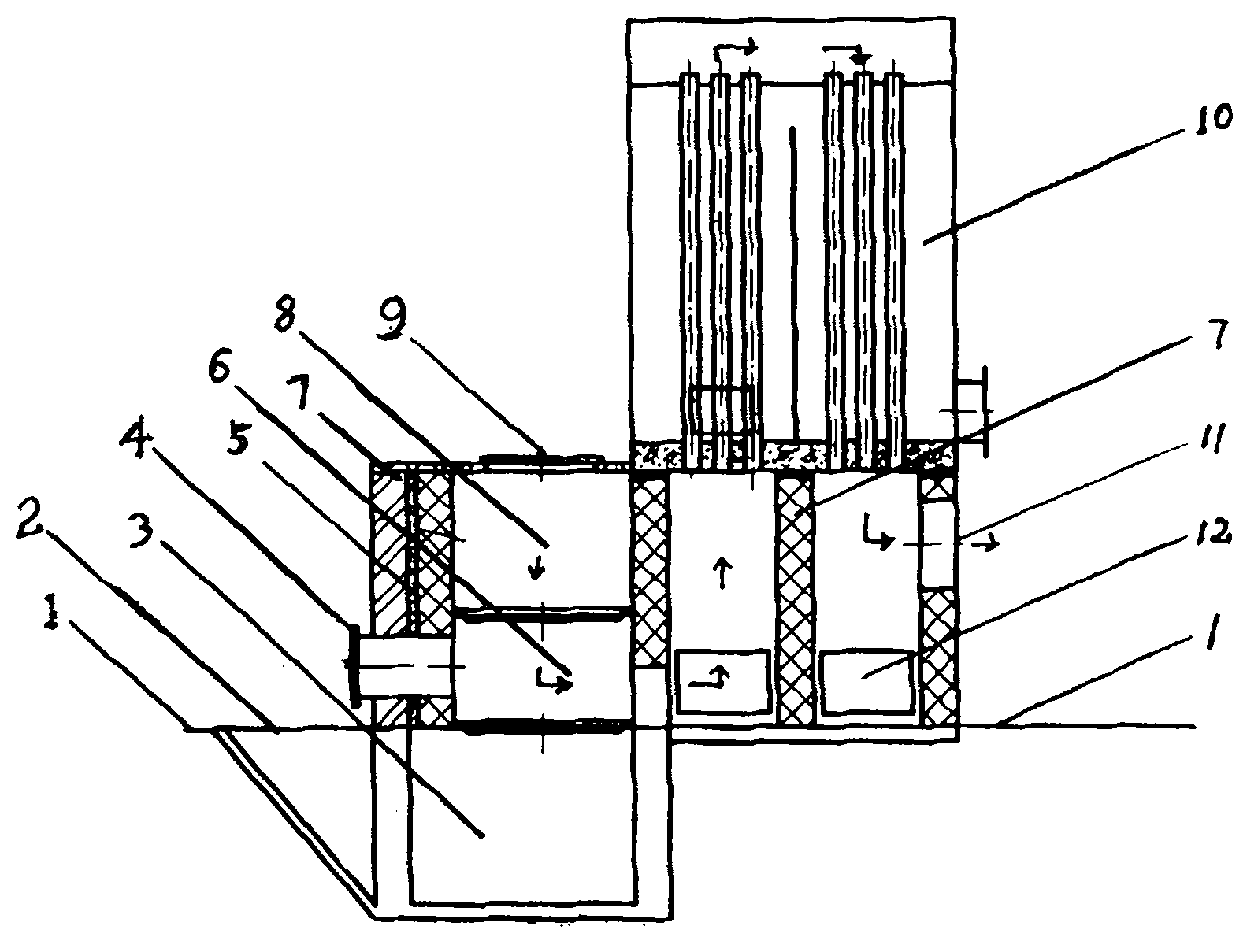

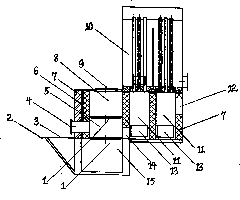

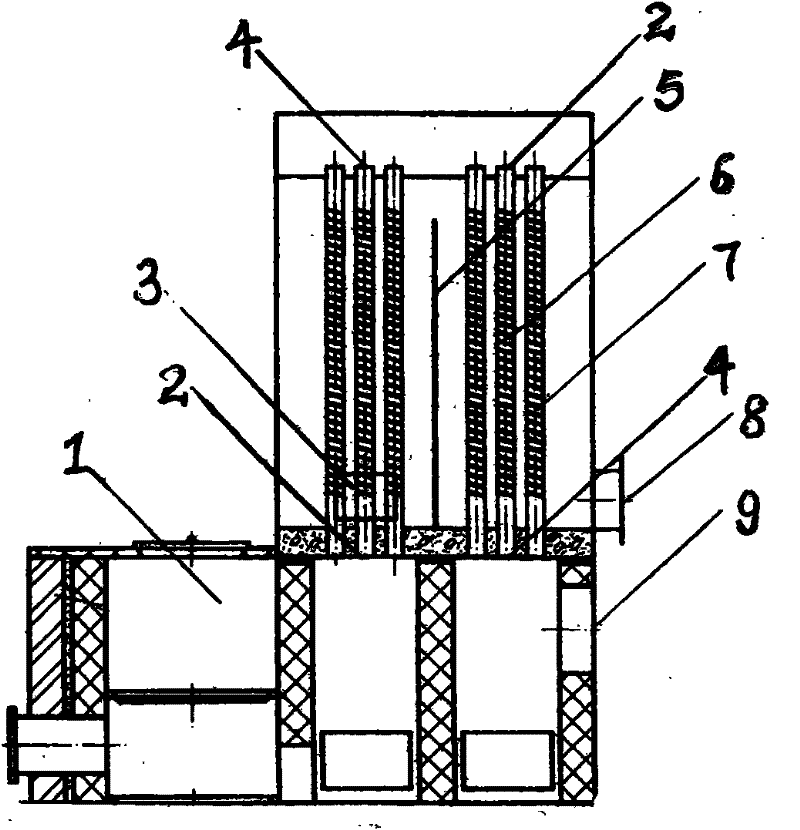

Biomass back-burning multi-return low-carbon energy-saving blast stove

The invention discloses a biomass back-burning multi-return low-carbon energy-saving blast stove, which consists of a stove door (1), a biomass back-burning hearth (2), a biomass back-burning fire hole (3), a biomass hearth (4), a biomass charging hole (5), a refractory material (6), a cold air inlet (7), a sealing plate (8), an air partition board (9), a biomass multi-return fire tube (10), a hot air outlet (11), a smoke receiving pipe hole (12) and an access door (13). The fire tube of the blast stove is vertically welded. A layer of refractory material is filled and compacted below the fire tube. Flame flows bottom up in the vertical tube and then returns top down in another channel to form a plurality of back-burning returns. The blast stove is made from iron plates, iron pipes and the refractory material. The biomass back-burning multi-return low-carbon energy-saving blast stove realizes full burning, has long service life, and is energy-saving and environment-friendly.

Owner:SHANXI RONGSHENDA SCI & TECH

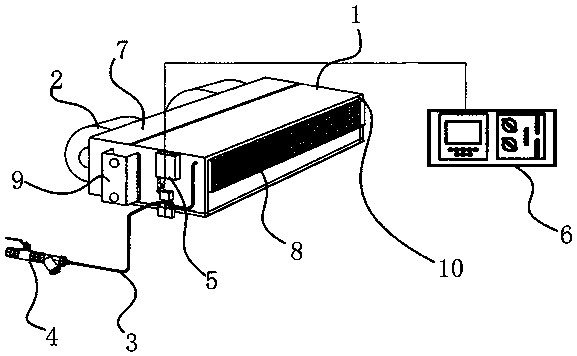

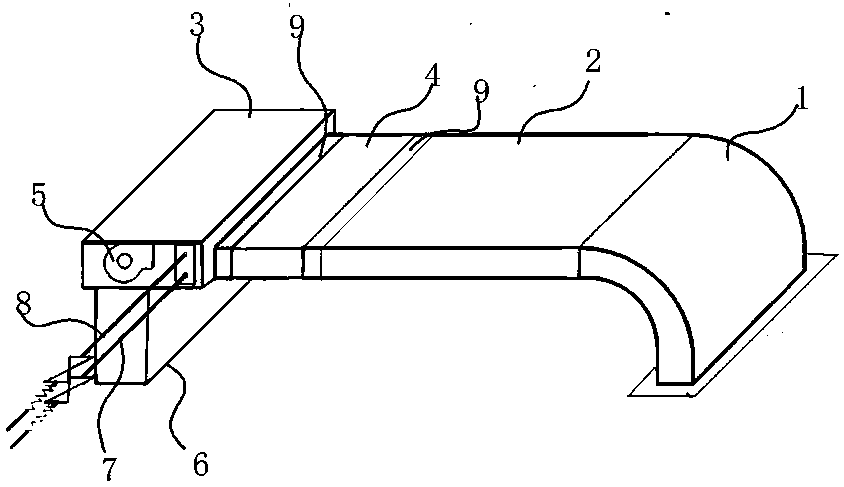

Fresh air device of air conditioner

InactiveCN107781913AThe overall design is simple and reasonableStable installationMechanical apparatusLighting and heating apparatusFresh airEngineering

The invention discloses an air conditioner fresh air device, which comprises a casing (1), a fan (2) arranged on one side of the casing (1), an air outlet arranged on the other side of the casing (1), and the casing ( 1) The connected air inlet pipe (3), the air filter (4) on the air inlet pipe (3), the regulator (5) on the housing (1) and the regulator (5) through The control panel (6) connected by wires; the housing (1) is provided with a heating device (7); the air outlet is provided with a filter plate (8); the fan (2) and the heating device (7) are connected with The regulator (5) is connected in communication; the air outlet of the housing (1) is provided with a temperature sensor matching the regulator (5). The invention adopts the fresh air device of the air conditioner, and the structure design is reasonable.

Owner:朱小平

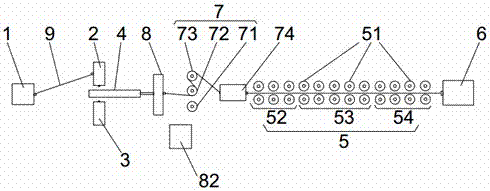

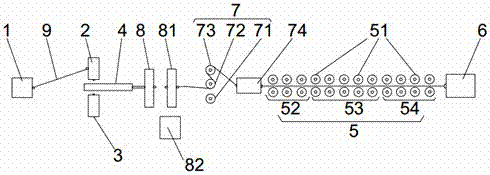

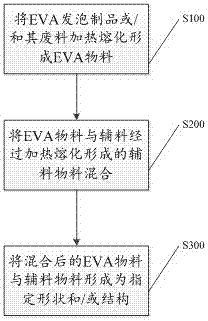

Reprocessing method and device of EVA foamed product and board made through reprocessing method and device of EVA foamed product

PendingCN107199653AEasy to handleReduce pollutionPlastic recyclingFlat articlesPolyesterNew materials

The invention provides a reprocessing method and device of an EVA foamed product and a board made through the reprocessing method and device of the EVA foamed product and relates to the field of recycling of the EVA foamed products. The reprocessing method comprises the steps that the EVA foamed product or / and waste of the EVA foamed product is / are heated and fused into an EVA material; the EVA material and an auxiliary material are heated and fused into an auxiliary material-material mixture; and the mixed EVA material and auxiliary material are made to form a designated shape and / or a structure, wherein the auxiliary material is polyethylene or / and polyester fiber or / and polypropylene fiber. In this way, the ineffective product can be fully used as the raw material of the reprocessing method, on the one hand, the demand for recycling the EVA foamed product and / or the waste of the EVA foamed product can be met, and on the other hand, the produced new material or product can meet production and life demands of people. Hence, environmental protection can be facilitated, and huge commercial value is achieved at the same time.

Owner:杨强

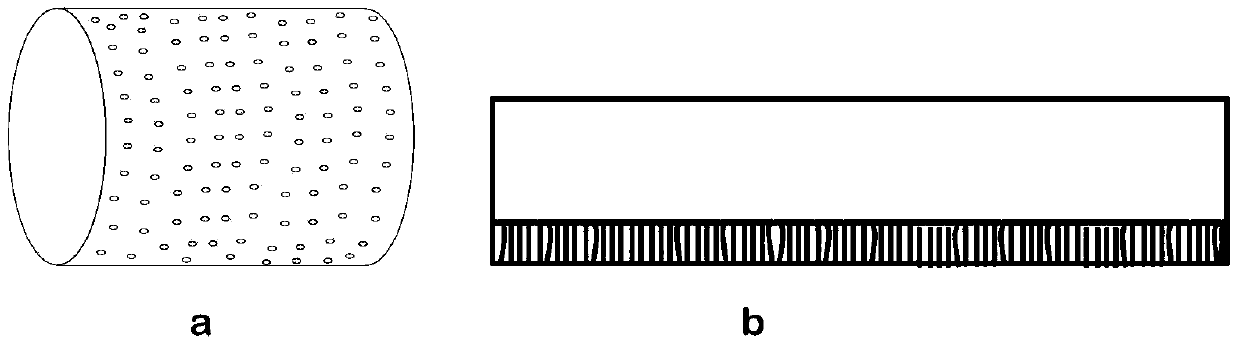

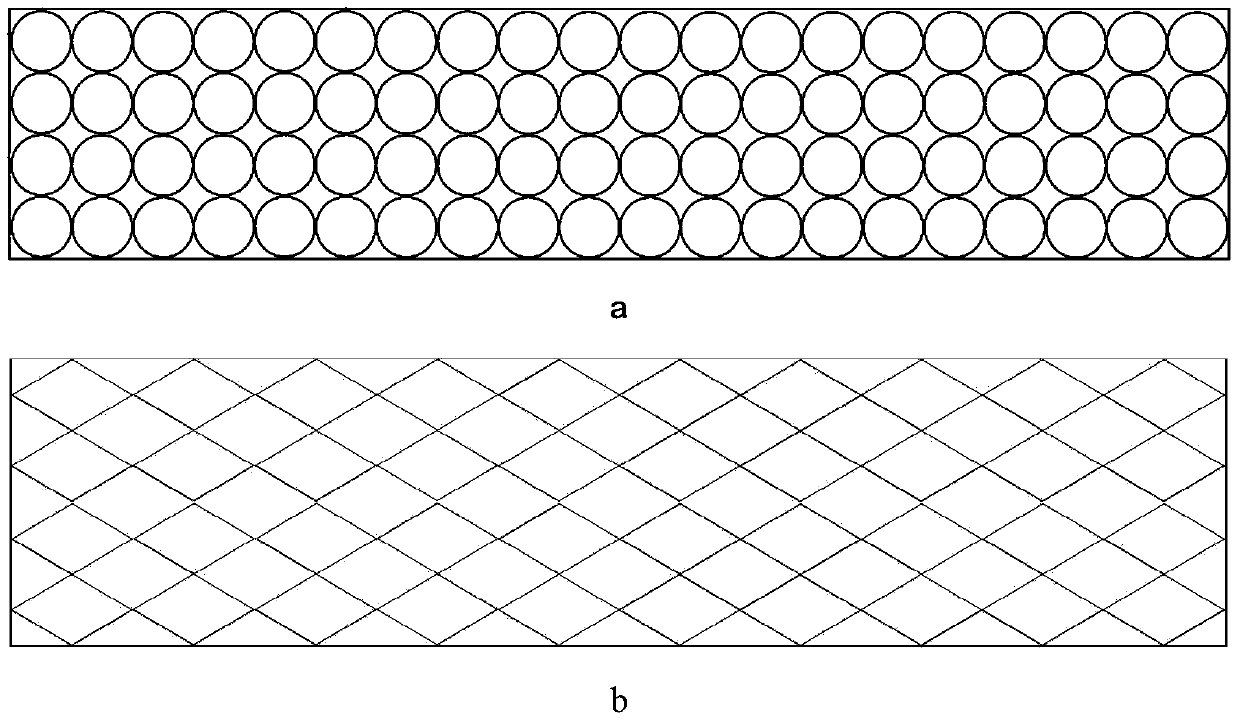

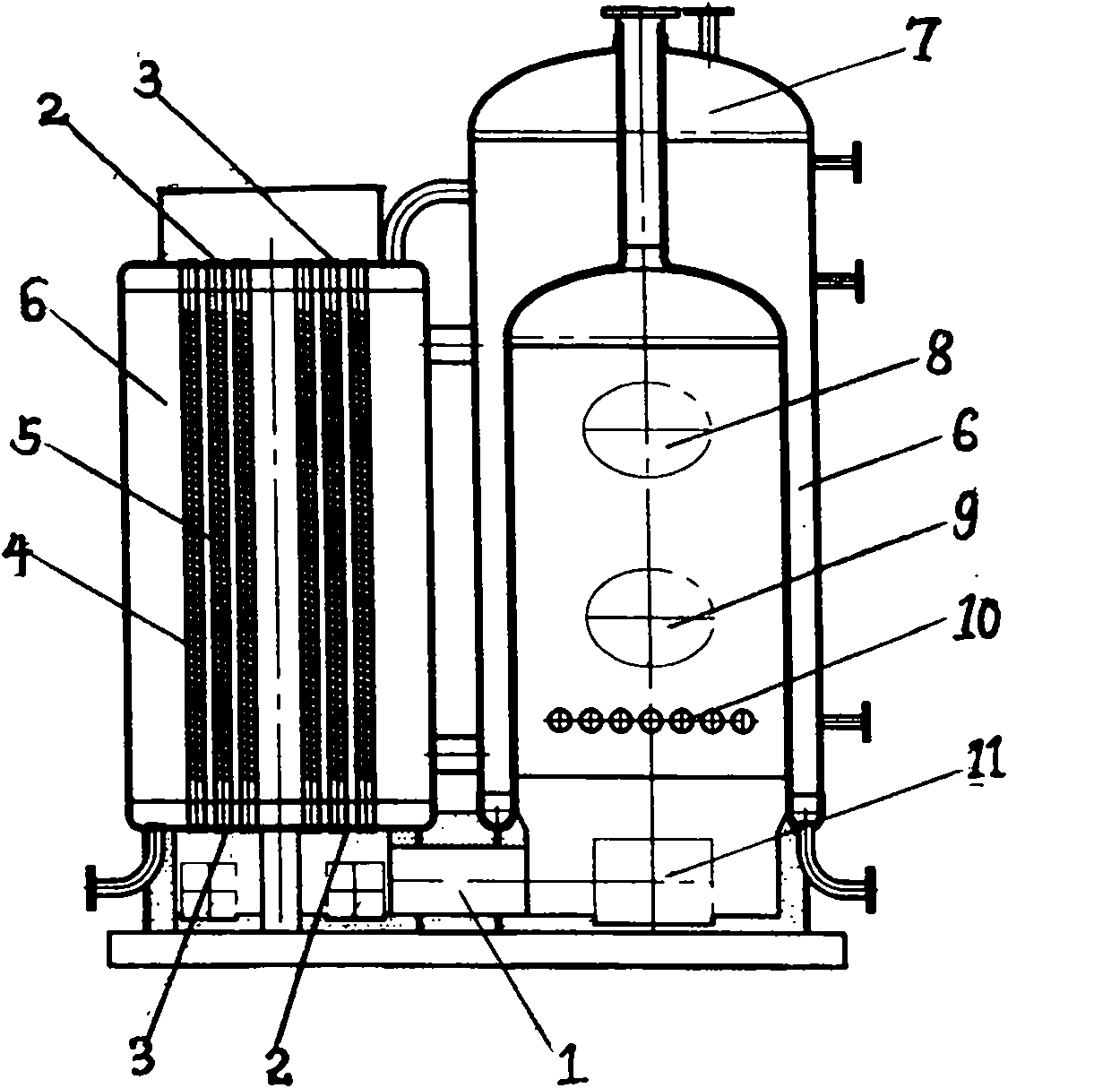

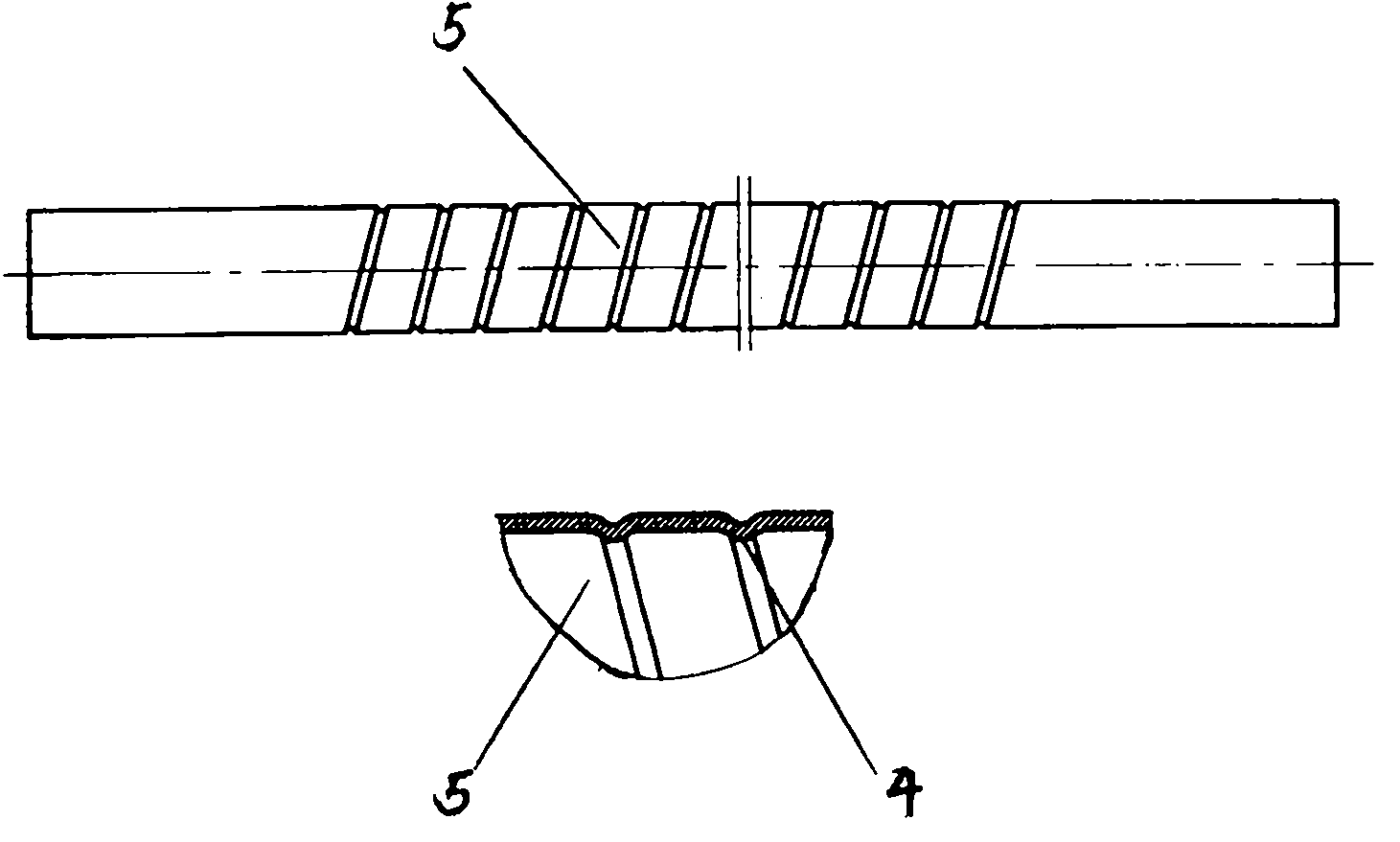

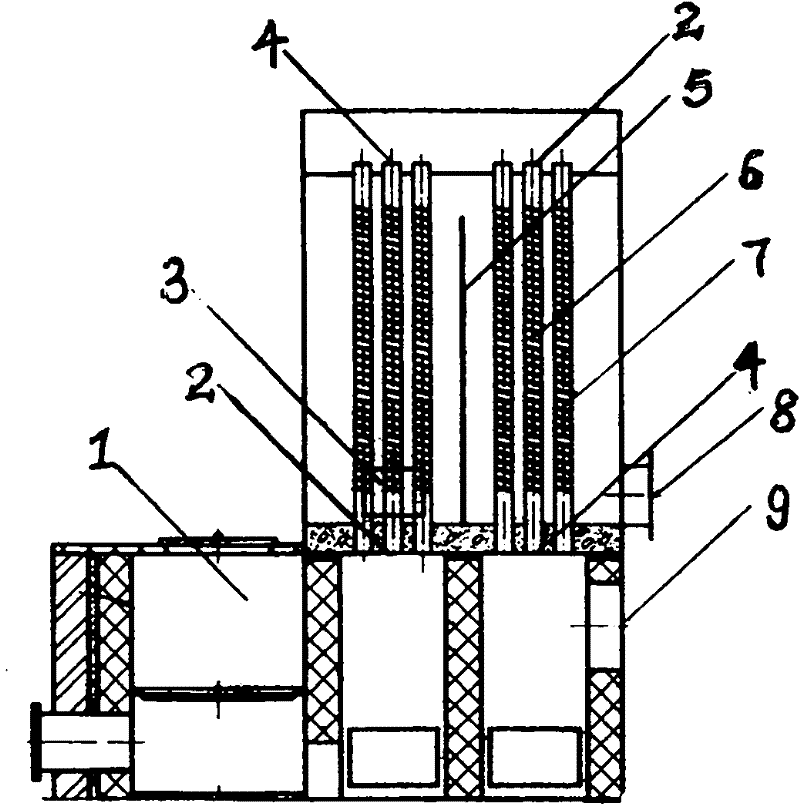

Biomass environmental-friendly energy-saving steam boiler of spiricle fire tube

InactiveCN102155735AImprove heat utilizationSave fuelFire-tube steam boilersBiomassCombustion chamber

The invention discloses a biomass environmental-friendly energy-saving steam boiler of a spiricle fire tube. The steam boilder is composed of a back combustion opening (1), a flame inlet (2), a flame outlet (3), a spiricle fire tube extruded edge (4), a spiricle fire tube (5), a water sleeve (6), an ellipsoidal end (7), a charging opening (8), a semi-gasification furnace chamber (9), a water grate (10) and a secondary combustion chamber (11), wherein the spiricle fire tube is welded in a furnace body vertically or horizontally, and the furnace body is sealed up and down with the flame inlet and the flame outlet remained; when in combusion, the flame enters the fire tube, is not discharged upward directly, but is guided by the extruded edge in the spiricle fire tube. The steam boiler provided by the invention has the advantages of full combustion, high heat utilization ratio, energy-conservation and emmission reduction and favarable economic benefit, and is easy to popularize and implement.

Owner:朔州诚信锅炉制造有限公司

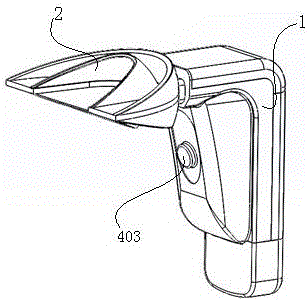

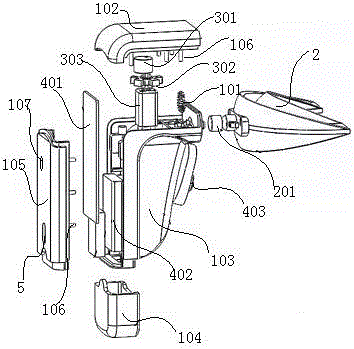

Orthodontics accelerating device

InactiveCN105686889ASpeed up the flowHelps speed up generationOthrodonticsMicrocontrollerMemory chip

The invention discloses an accelerated orthodontic device for teeth, which comprises a housing (1), a tooth bracket arranged on the housing (1), a vibration device adapted to the tooth bracket and arranged in the housing, and a vibration device arranged in the housing and connected to the housing A control device that is compatible with the vibration device, the vibration device includes an eccentric wheel (301), a rotating gear (302) and a micro-motor (303), the rotation shaft of the micro-motor passes through the through hole of the shell and fits the tooth tray; the said The micro-motor is compatible with the control device; the control device includes a circuit control device, a power supply and control buttons. The circuit control device is equipped with a memory chip, a microcontroller chip and a circuit board, and the housing is provided with a circuit control device that is compatible with the circuit control device. the USB connection port (5). The invention loads the vibration force of a specific frequency on the tooth through transmission, and the direction and size change all the time, which can accelerate the flow of blood, and is beneficial to accelerate the formation of osteoclasts and osteoblasts in specific parts of the alveolar bone, thereby reducing positive abnormal time.

Owner:赵格邦

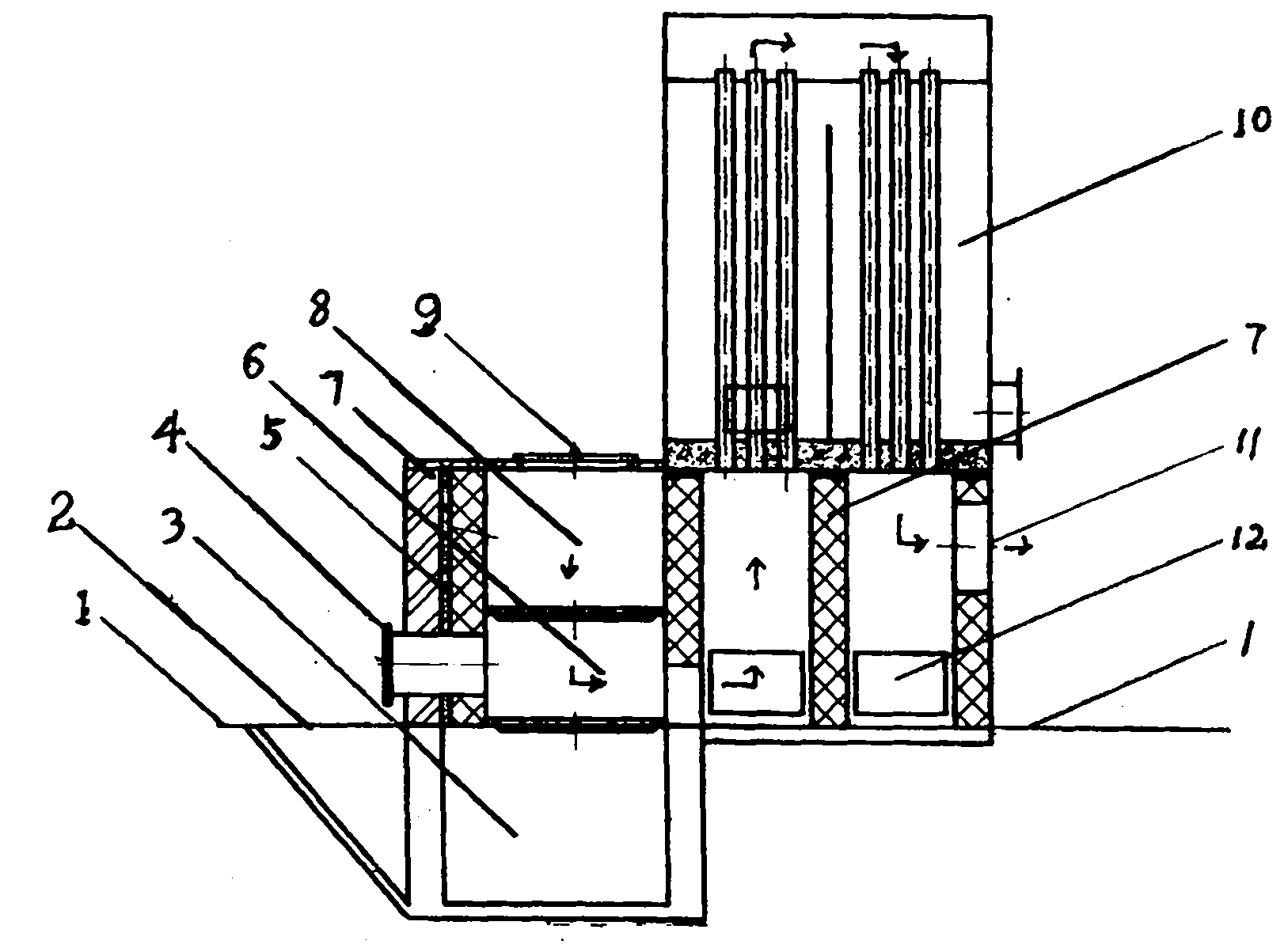

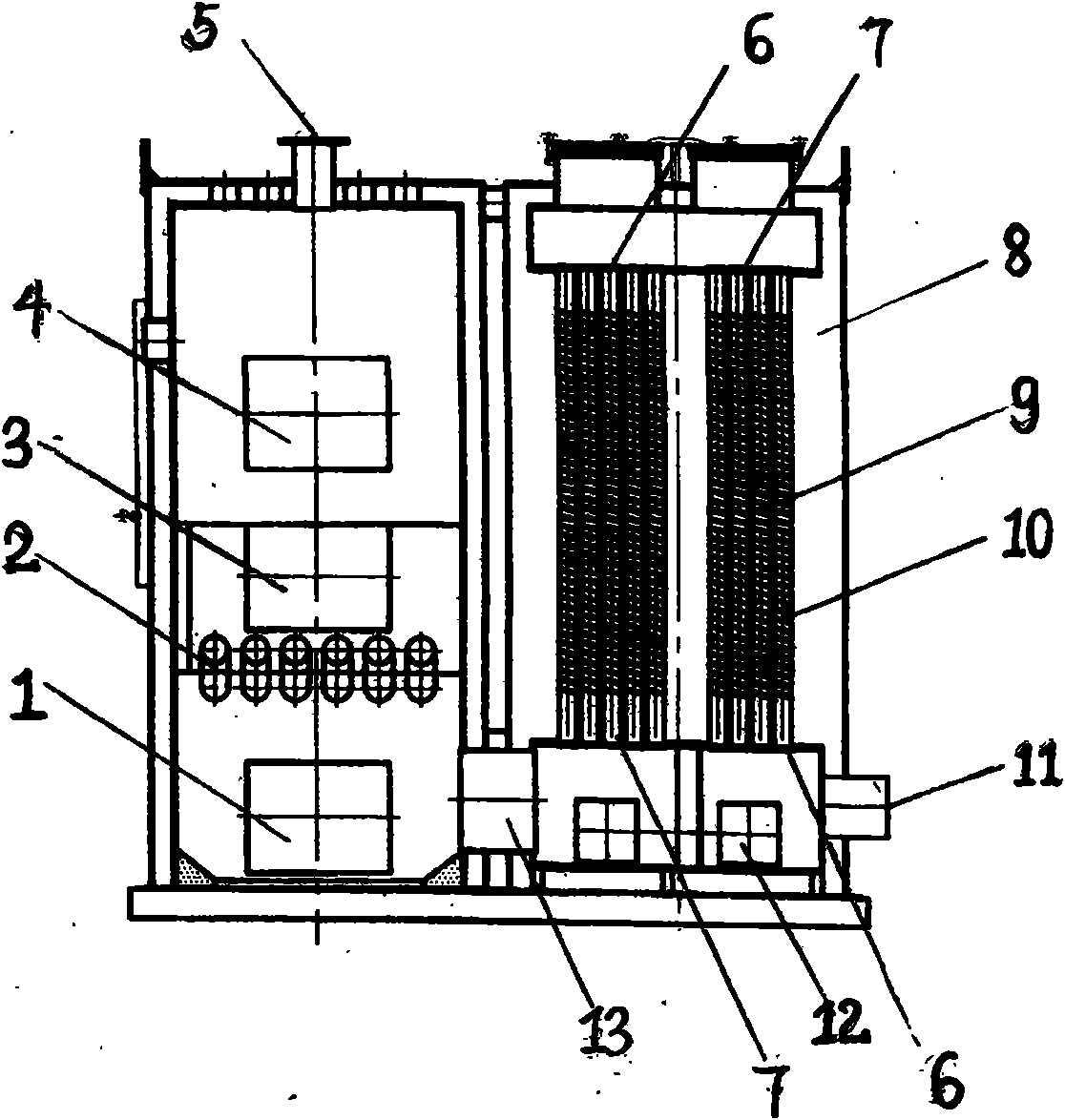

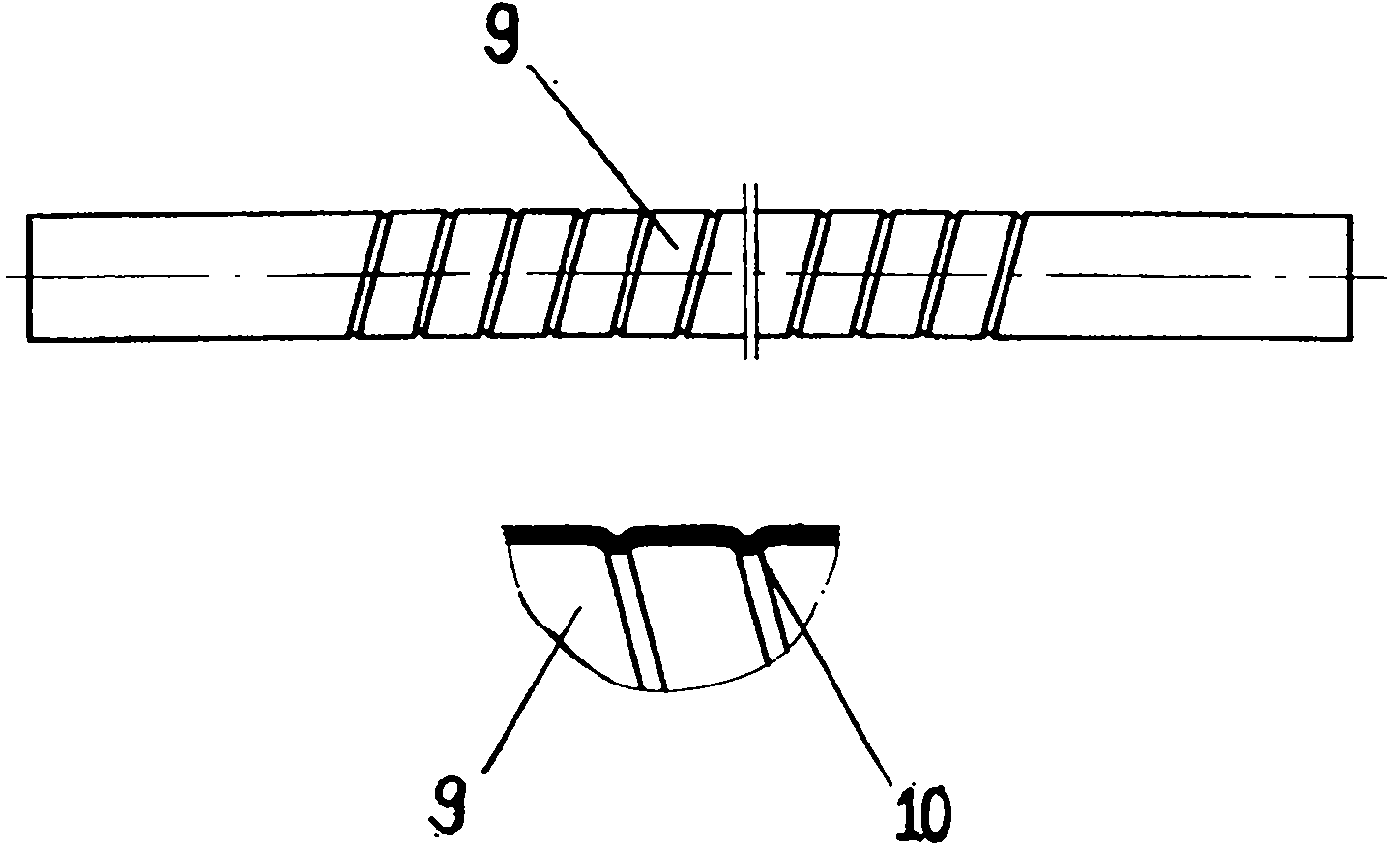

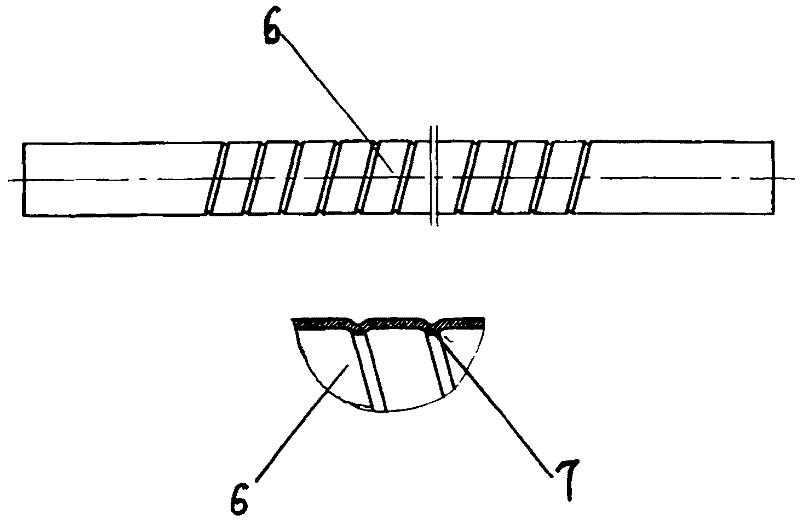

Biomass low-carbon energy-saving boiler with spiral grain fire tube

The invention discloses a biomass low-carbon energy-saving boiler with a spiral grain fire tube, mainly comprising a secondary burning chamber (1), a boiler bridge (2), a semi-gasification burning chamber (3), a feeding door (4), a banking smoke outlet (5), a fire outlet (6), a fire inlet (7), a water jacket (8), a spiral grain fire tube (9), a spiral grain fire tube convex edge (10), a smoke drum joint (11), an ash cleaning door (12) and a back burning port (13), wherein the spiral grain fire tube is vertically welded or welded in a boiler body in a balanced manner, the upper part and the lower part of the spiral grain fire tube are sealed, the fire inlet and the fire outlet are provided, and in burning, the flame enters the fire tube and is directed to move by the convex edge in the spiral grain tube without rising or being discharged directly. The biomass low-carbon energy-saving boiler has the advantages of full burning, high heat utilization ratio, energy conservation, emission reduction, easiness for promotion and implementation and better economic benefit.

Owner:SHANXI RONGSHENDA SCI & TECH

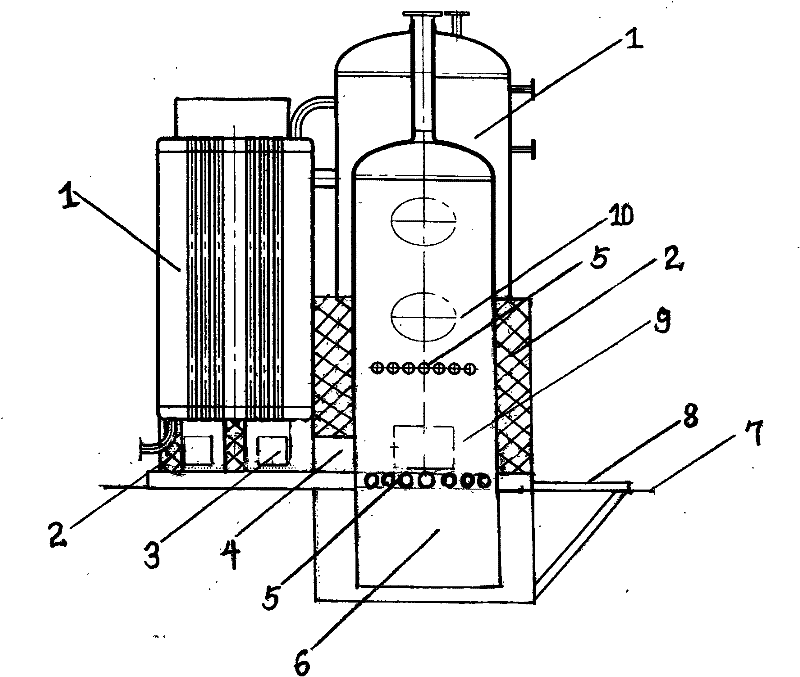

Brick-built furnace-type biomass hot-water boiler

The invention discloses a brick-built furnace-type biomass hot-water boiler which is composed of a fire grate (1), a ground level (2), a deashing opening (3), a boiler door (4), a biomass second furnace (5), a silicic acid aluminum plate (6), firebricks (7), a biomass semi-gasification furnace (8), a biomass feeding port (9); a biomass boiler (10), a back stroke furnace (11), a smoke pipe connecting port (12), a deashing door (13), a backfire port (14), an underground ash pit (15), a draught fan (16) and an air blower port (17); the biomass steam boiler furnace is built with the firebricks or the combination of the firebricks and common bricks, and a layer of silicic acid aluminum plate is sandwiched among the firebricks to play a role of temperature conservation and heat isolation, the upper part of the silicic acid aluminum plate is provided with the biomass boiler (10), and the underground ash pit (15) is arranged below the ground level (2). The boiler provided by the invention has low cost and long service life, and is easy to overhaul.

Owner:朔州诚信锅炉制造有限公司

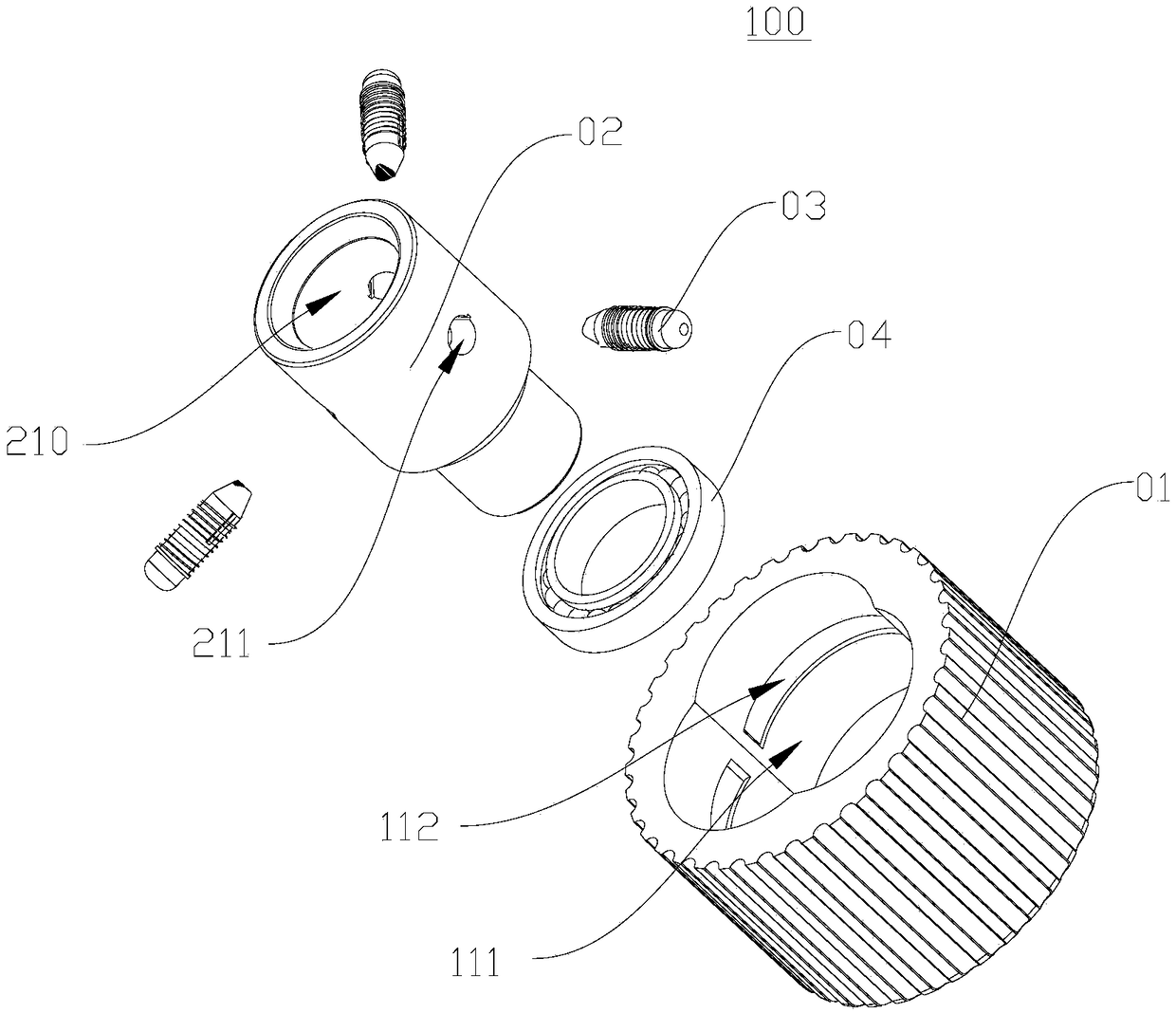

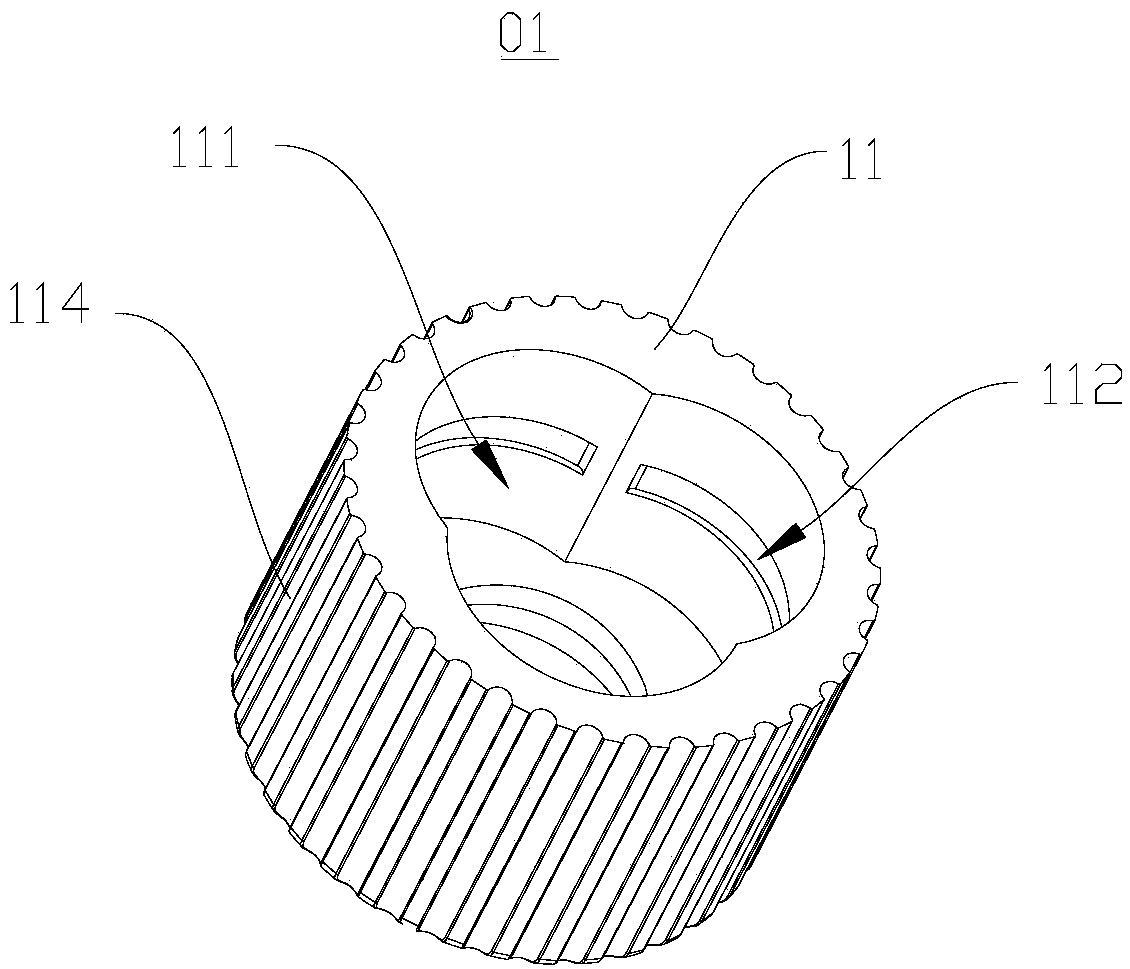

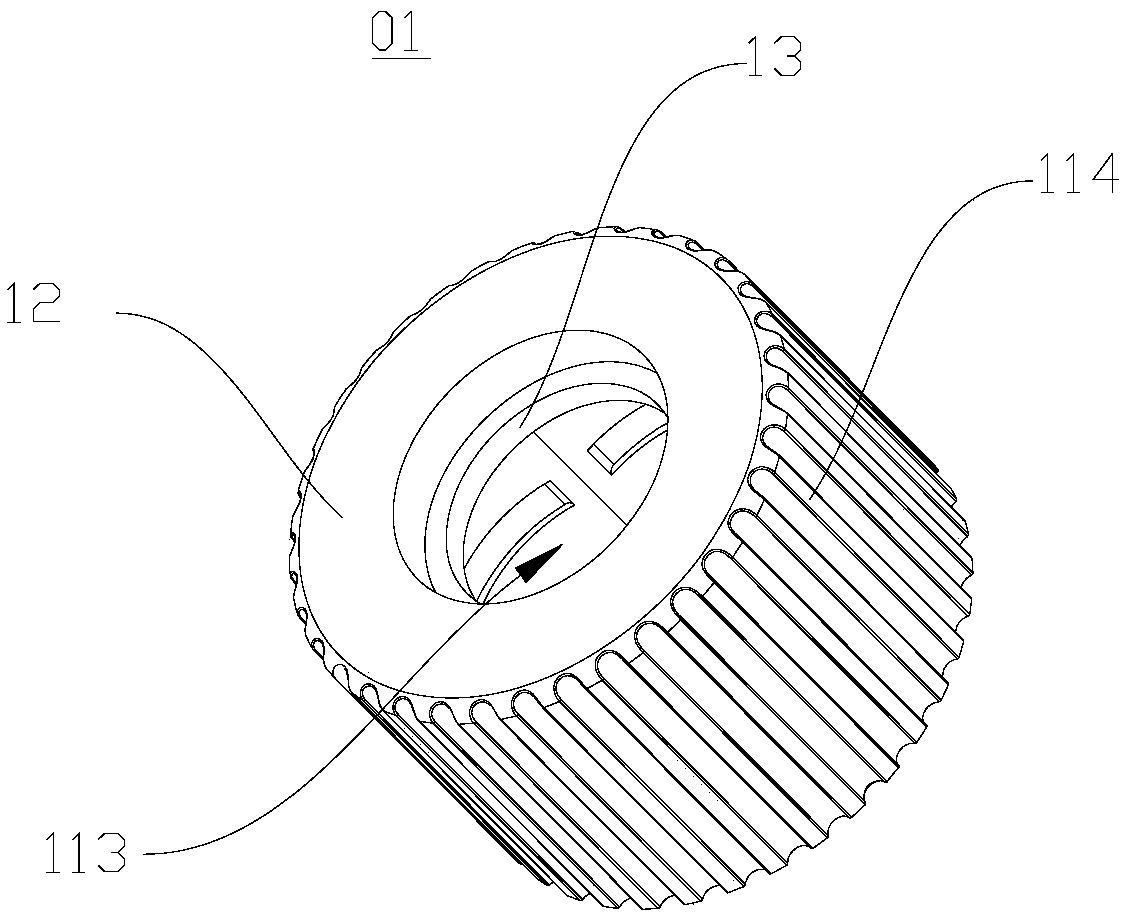

Self-adaption sleeve and spanner

The invention provides a self-adaption sleeve and a spanner and relates to the field of production tools. The self-adaption sleeve comprises a central shaft, a shaft sleeve body and abutting components. A fixing hole is formed in the shaft sleeve body; sliding grooves are formed in the side wall of the fixing hole in the circumferential direction; the central shaft is arranged in the fixing hole;a mounting hole is formed in the central shaft in the axis direction; positioning holes are formed in the central shaft in the radial direction of the mounting hole and communicate with the mounting hole; the abutting components are arranged in the positioning holes correspondingly, one ends of the abutting components abut against the interiors of the sliding grooves correspondingly, and the otherends of the abutting components are used for abutting against a fastener; the abutting components slide in the corresponding sliding grooves so as to change the lengths of the portions, stretching into the mounting hole, of the abutting components, and accordingly, the abutting components can abut against fasteners of different specifications. The self-adaption sleeve can be used for production operation of bolts or nuts of different specifications and models, the production efficiency is improved, and the application cost is also lowered.

Owner:SHIJIAZHUANG ZHONGBO AUTOMOBILE CO LTD +1

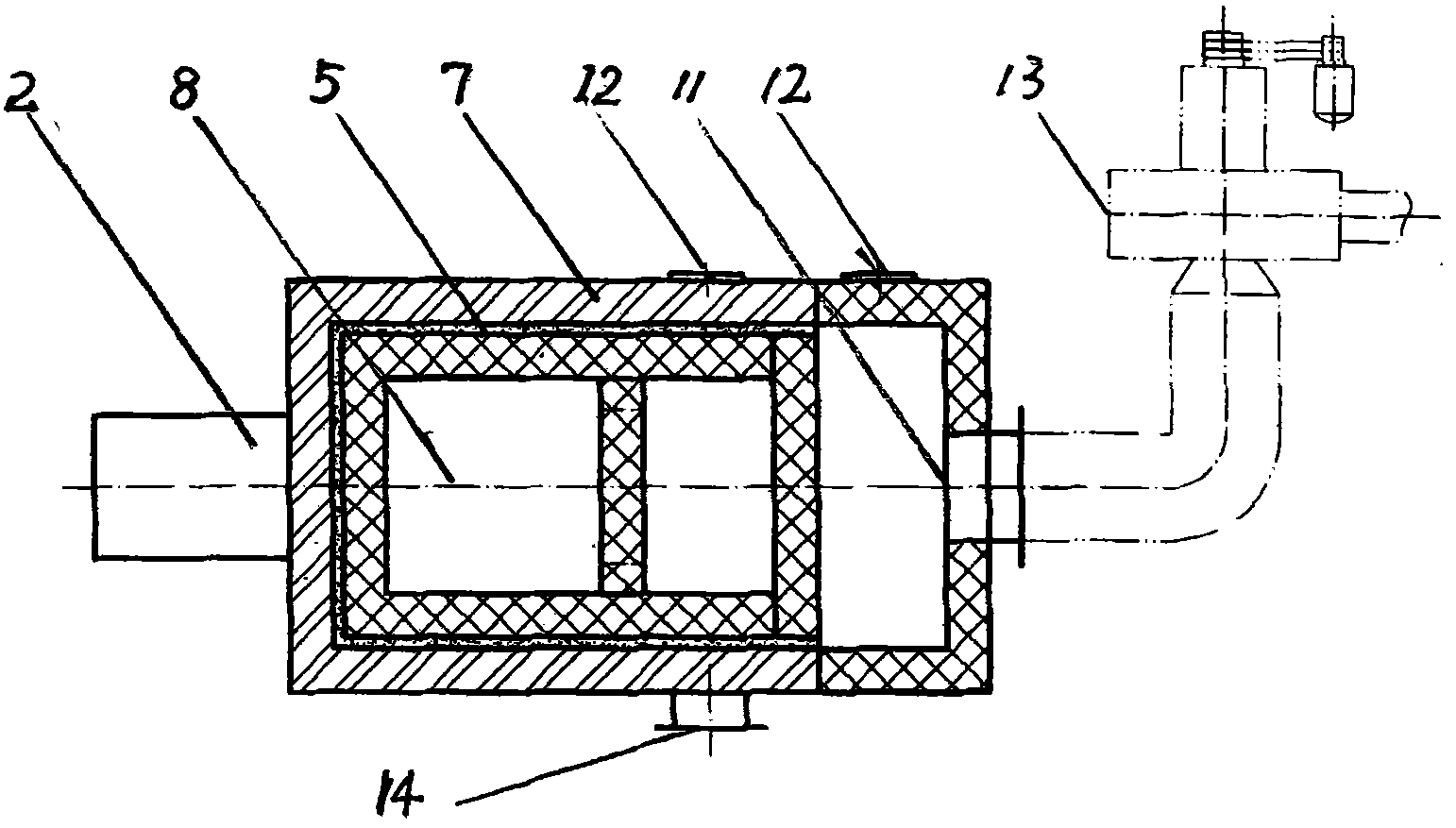

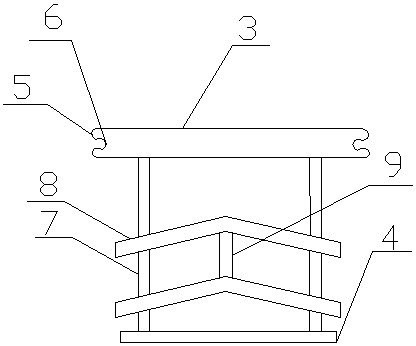

Brick-built hearth-type biomass steam boiler

InactiveCN102183005ASolution to short lifeEasy to makeSteam boilersSteam boilers componentsCombustionThermal insulation

The invention discloses a brick-built hearth-type biomass steam boiler which is composed of a steam boiler (1), firebricks (2), a deashing opening (3), a backfire channel (4), a fire grate (5), an underground ash pit (6), a ground level (7), a deashing cover (8), a biomass brick-built backfire hearth (9), a biomass brick-built gasification hearth (10), a chimney tube connecting opening (11) and a aluminum silicate plate (12). The hearth of the biomass steam boiler is built with the firebricks which can prevent biomass fuels from corroding and corrupting the furnace, and a layer of the aluminum silicate plate is sandwiched between the firebricks to play a role of thermal insulation. According to the invention, a pipeline can never be burnt out, the boiler has long service life and high combustion efficiency, can be easily overhauled, has low manufacturing cost, and is easy to popularize.

Owner:朔州诚信锅炉制造有限公司

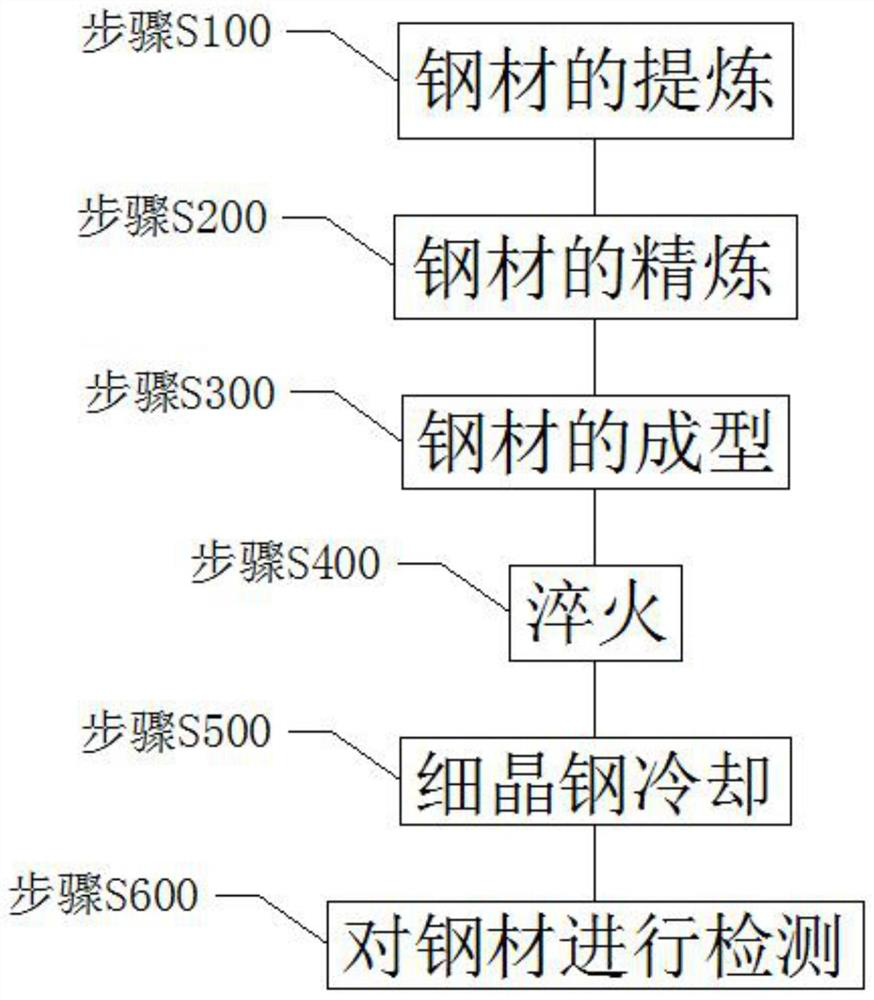

Fine grain steel with tensile strength of 1500 MPa and preparation method thereof

ActiveCN112410661ATensile strength does not affectDoes not affect strengthFurnace typesHeat treatment furnacesToughnessMaterials science

The invention belongs to the technical field of production, research and development of fine grain steel, and provides fine grain steel with the tensile strength of 1500 MPa and a preparation method thereof. The fine grain steel is prepared from the following chemical components in percentage by weight: 0.21-0.26% of C, 0.40-0.54% of Si, 1.48-1.66% of Mn, 0.20-0.25% of Cr, 0.012-0.017% of Nb, 0.095-0.110% of V, less than or equal to 0.040% of S, less than or equal to 0.043% of P, less than or equal to 0.0070% of O, 0.024-0.0265% of N and the balance of Fe and impurities which cannot be purified at the present stage. According to the fine grain steel with the tensile strength of 1500 MPa, the toughness of steel is improved, the steel has the tensile strength of at least 1500 MPa, and the production and living requirements of people are met.

Owner:JIANGSU YONGGANG GROUP CO LTD

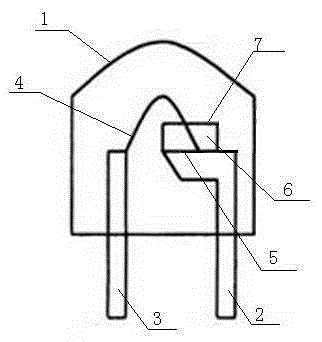

Planar diode

InactiveCN106816475AReasonable structural designProduction costsSemiconductor devicesPlanar diodeP type silicon

The invention discloses a planar diode, which comprises an anode lead (1) and a silicon dioxide layer (2), the N-type silicon layer (3) is compatible with the silicon dioxide (2) layer, and the N-type silicon layer (3) Covered with a P-type silicon chip (4), one side of the P-type silicon chip (4) is adapted to the silicon dioxide layer (2), and one side of the N-type silicon layer (3) is set There is a negative lead (5). The invention has reasonable structural design, low production cost, good use effect and meets the needs of production and life.

Owner:夏振宇

Marine bank-based dual-refrigerant combined type air conditioner

ActiveCN103925666AMeet different refrigeration requirementsReduce energy consumptionAuxillariesLighting and heating apparatusRefrigeration compressorPlate heat exchanger

Owner:JIANGSU JOSUN AIR CONDITIONER

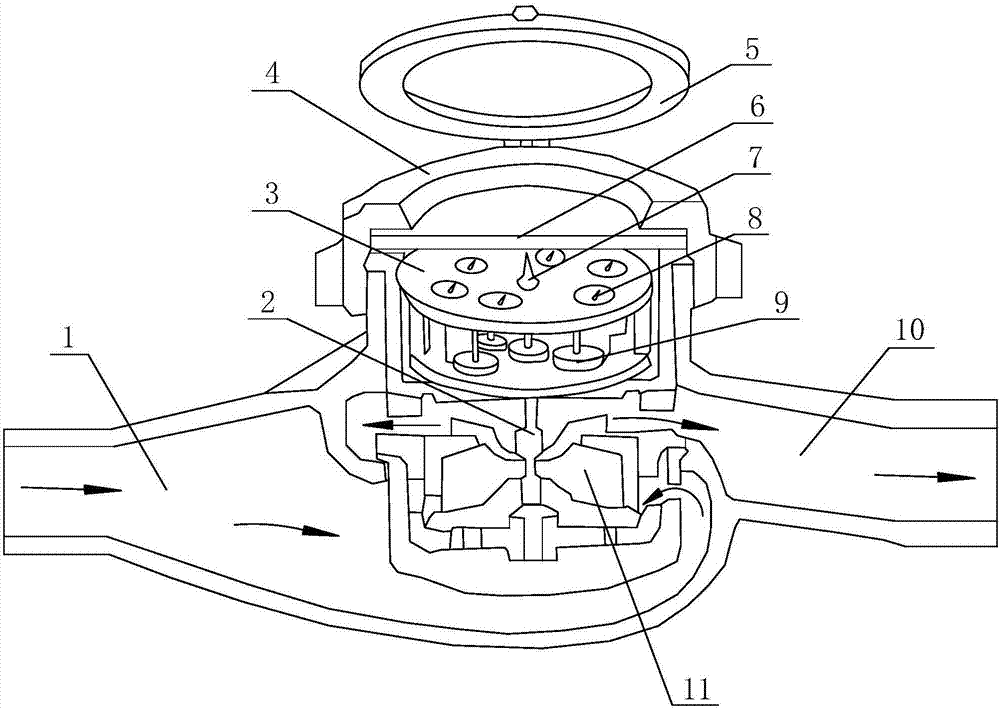

Simple water meter capable of achieving automatic counting

InactiveCN107990944ASimple structureReduce usage errorsVolume meteringVolume/mass flow by dynamic fluid flow effectImpellerEngineering

Owner:罗杰元

Biomass spiral lamination flame tube hot air furnace

The invention discloses a biomass spiral lamination flame tube hot air furnace which is composed of a biomass semi-gasification hearth (1), a flame inlet (2), a cold air inlet (3), a flame outlet (4), an air isolating plate (5), a biomass spiral lamination flame tube (6), an extrusion edge in a spiral lamination tube (7), a hot air outlet (8) and a smoke tube interface (9); the biomass spiral lamination flame tube is welded horizontally or vertically in a furnace body, is sealed up and down, and is provided with the flame inlet and the flame outlet; and during combustion, the flame enters the flame tube, and then is discharged through the guiding of a spiral track in the biomass spiral lamination flame tube but not directly rise to be discharged. The hot air furnace provided by the invention has the advantages of full combustion and high heat utilization ratio. Not only is the pollution reduced, but also the temperature of the flame is improved, the hot air furnace is easy to popularize, and has better economic benefit.

Owner:朔州诚信锅炉制造有限公司

Air outlet channel for central air conditioner

InactiveCN107702304ASimple designEasy to guideDucting arrangementsLighting and heating apparatusAir filterEngineering

The invention discloses an air outlet channel for a central air conditioner, which comprises an air outlet channel body for a central air conditioner arranged between a floor (1) and a ceiling (2). The condenser (4) connected to the air duct (3), the return air duct (5) connected to the condenser (4); the air supply duct (3) or the return air duct (5) is wrapped with an insulation layer (6), The insulation layer (6) is a rock wool layer, glass wool felt layer or rubber-plastic sponge layer; the thickness of the insulation layer (6) is 1-3cm; the condenser (4) is provided with a cold water outlet pipe (7) and a cold water inlet pipe (8) and condensed water drainage pipe (9); the return air duct (5) is provided with a fan (10), the fan (10) is connected to a motor, and the return air outlet of the return air duct (5) is hinged with a louver return air cover ( 11); the air return port is provided with a filter screen (12). The invention adopts the air outlet channel for the central air conditioner, and the structure design is reasonable.

Owner:朱小平

Diode in simple structure

The invention discloses a diode with a simple structure, which comprises a resin shell (1), a cathode lead (2) and an anode lead (3). The anode lead (3) is provided with a metal connecting wire (4), and the cathode The lead wire (2) is provided with a reflector (5), the reflector (5) is provided with an LED chip (6), the LED chip (6) is provided with a phosphor layer (7), and the metal connection The wire (4) is compatible with the LED chip (6). The invention has reasonable structural design, low production cost, good use effect and meets the needs of production and life.

Owner:夏振宇

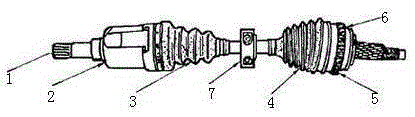

Driving device

InactiveCN106704395AReasonable structural designMeet the needs of production and lifeYielding couplingDrive shaftUniversal joint

The invention discloses a driving device. The driving device comprises a driving shaft body (1). The driving shaft body (1) is sequentially provided with an inner constant velocity universal joint casing (2), an inner coupling (3), a pulse wheel (4) and an outer constant velocity universal joint casing (5). The inner constant velocity universal joint casing (2) or the outer constant velocity universal joint casing (5) is connected with a dust cover (6). The driving device is reasonable in structural design, the production and life needs are met, damage is avoided, the service life is prolonged, and the requirement of industrial production can be met.

Owner:姚素梅

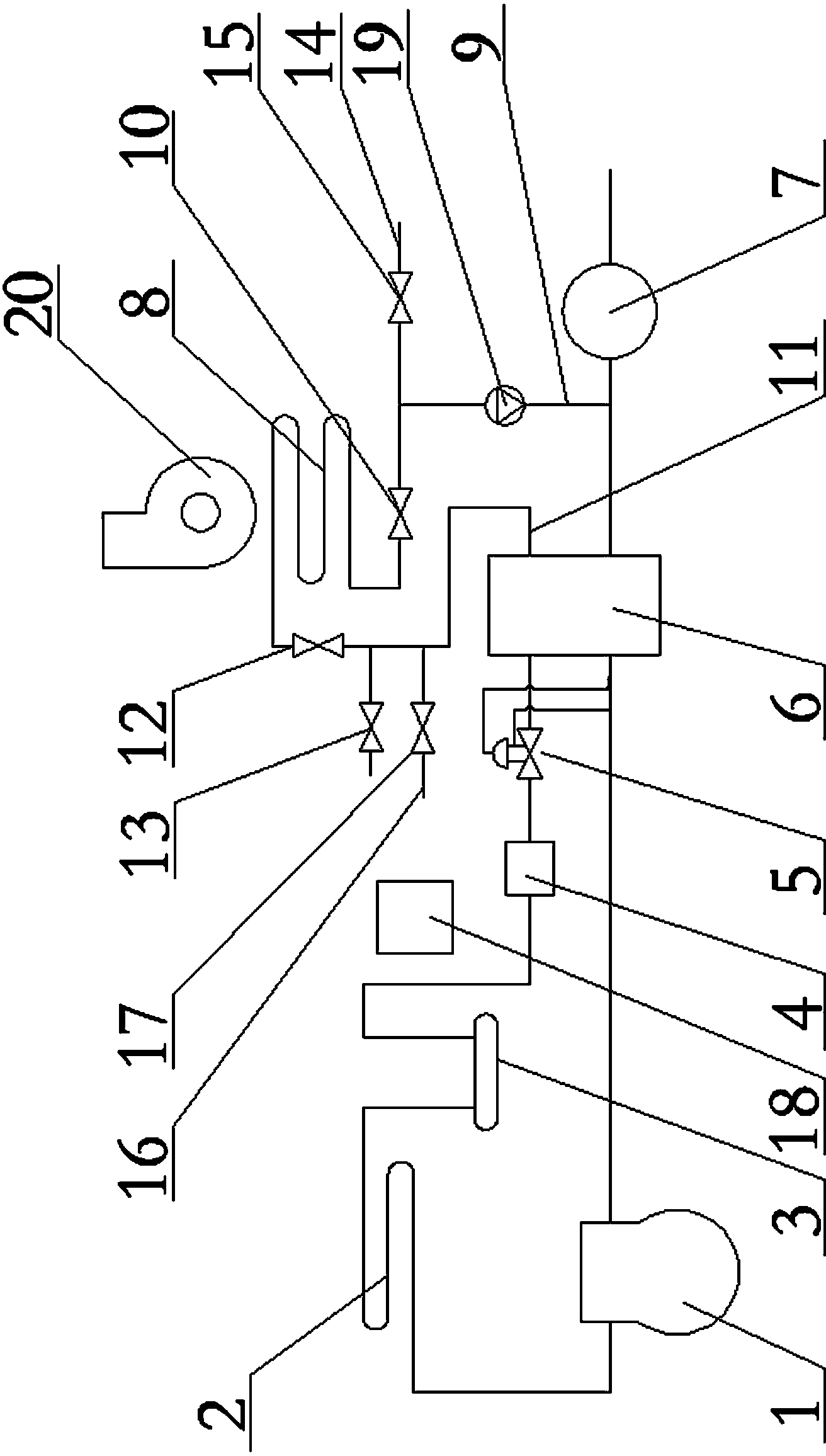

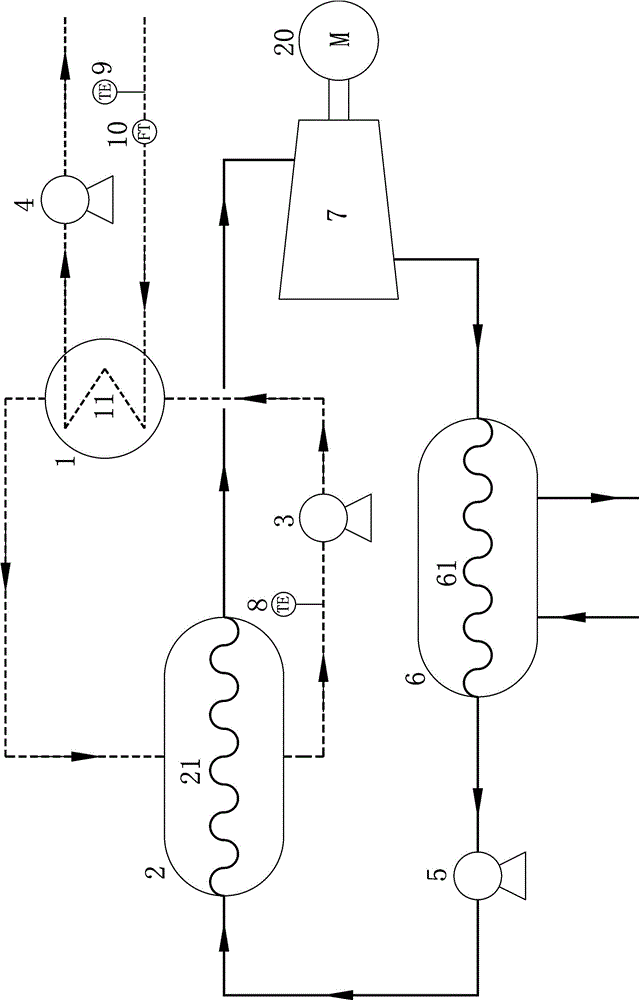

Organic Rankine Cycle generation device for low-pressure diffused steam and use method for same

ActiveCN105604621AReduce wasteReduce heat pollutionSteam engine plantsThermal energyOrganic Rankine cycle

The invention relates to the field of engines driven by fluids and specifically relates to an Organic Rankine Cycle generation device for low-pressure diffused steam and a use method for the same. The Organic Rankine Cycle generation device for the low-pressure diffused steam comprises a heat collector (1), an evaporator (2) and a condenser (6) and is characterized by comprising an energy storage working medium pump (3), a water pump (4), an organic working medium condensation pump (5) and a screw expander (7); and the evaporator (2), the organic working medium condensation pump (5), the condenser (6) and the screw expander (7) compose a generator set system. The use method for the Organic Rankine Cycle generation device for the low-pressure diffused steam is characterized in that the method is implemented at the successive steps that heat exchange is carried out between the low-pressure diffused steam and an energy storage working medium; heat exchange is carried out between the energy storage working medium and an organic working medium; and working medium steam works for the screw expander (7). The device provided by the invention has the advantages of high thermal energy use ratio and high adaptability.

Owner:BAOSTEEL ENG & TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com