Driving device

A drive device and drive shaft technology, applied in elastic couplings, mechanical equipment, couplings, etc., can solve the problems of easy damage, unreasonable structural design of the drive shaft, not meeting the needs of production, etc., to avoid damage. , Reasonable structure design, prolong service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

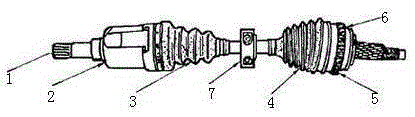

[0011] Such as figure 1 As shown, a driving device includes a drive shaft body 1, and the drive shaft body 1 is provided with an inner constant velocity joint housing 2, an inner coupling shaft 3, a pulse wheel 4 and an outer constant velocity joint housing 5 in sequence. , the inner constant velocity joint housing 2 or the outer constant velocity joint housing 5 is connected with a dust cover 6 . The inline shaft 3 is provided with a damping counterweight 7 .

[0012] The above content is an example and description of the present invention, but it does not mean that the advantages that the present invention can obtain are limited by this, any simple transformation of the structure that may be possible in the practice of the present invention, and / or one of the advantages realized in some embodiments or more are within the protection scope of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com