Patents

Literature

80results about How to "Meet the requirements of industrialized mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Conductive plastic and its processing method and apparatus

Owner:BEIJING NASHENGTONG ADVANCED MATERIAL & TECH CO LTD

Method for preparing galacto-oligosaccharide

ActiveCN102676614ASimple production processEasy to operateMicroorganism based processesOn/in organic carrierLactoseGalactooligosaccharide

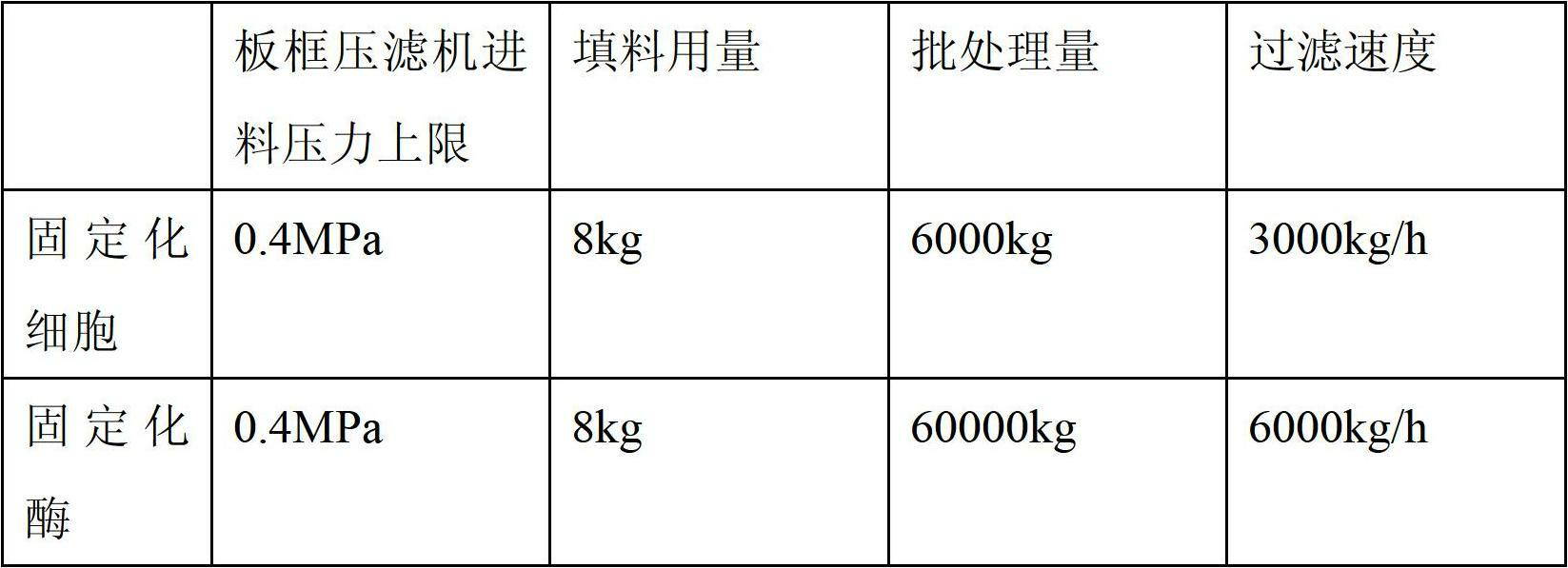

The invention discloses a method for preparing galacto-oligosaccharide. The method comprises the following steps: (1) reacting glutaraldehyde with a macroporous weak basic styrene resin for 16 to 24 hours with stirring at the temperature of between 15 and 35DEG C to activate the resin; (2) reacting liquid beta-galactosidase with the activated macroporous weak basic styrene resin obtained in the step (1) for 16 to 24 hours with stirring at the temperature of between 15 and 35DEG C to obtain cured beta-galactosidase; and (3) adding the cured beta-galactosidase into a lactose solution, and reacting for 24 to 36 hours with stirring at the temperature of between 48 and 52DEG C. By the method for producing the galacto-oligosaccharide, the filter pressure can be kept stable in a syrup filtering process, the yield of the galacto-oligosaccharide is improved, the energy consumption is reduced and the industrial production requirement can be met.

Owner:量子高科(广东)生物有限公司

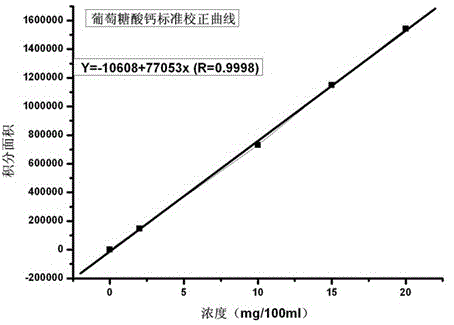

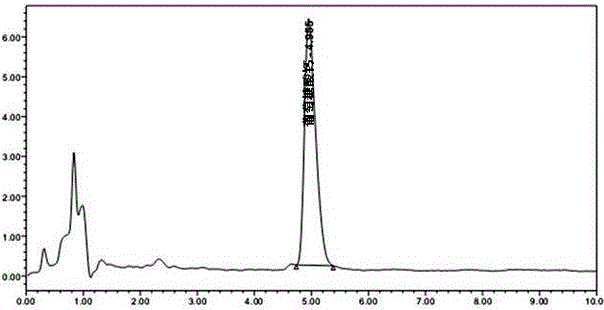

Method of preparing calcium gluconate by composite immobilized enzyme

ActiveCN103602710AHigh reuse rateReduce use costChemical industryOn/in organic carrierChemistryEnzyme method

The invention provides a method of preparing calcium gluconate by a composite immobilized enzyme. Improvement is made on the basis of present methods which produce the calcium gluconate by a free composite enzyme method. Glucose oxidase and catalase are added into a mixed solution of sodium alginate and silica gel, and then are added dropwise into a calcium carbonate solution to be immobilized and moulded. The glucose oxidase and the catalase are immobilized to achieve enzyme liquid separation, thus improving the repeating utilization ratio of the glucose oxidase and the catalase and reducing the using cost of the enzyme. A calcium gluconate product produced by the method provided by the invention is high in purity, and conforms to requirements of the country about energy conservation and environment protection of enterprises at present.

Owner:SHANDONG XIWANG SUGAR

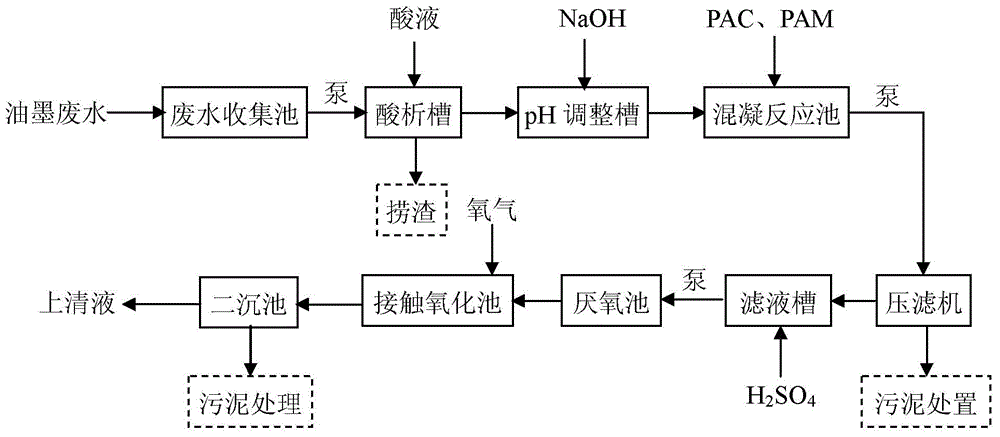

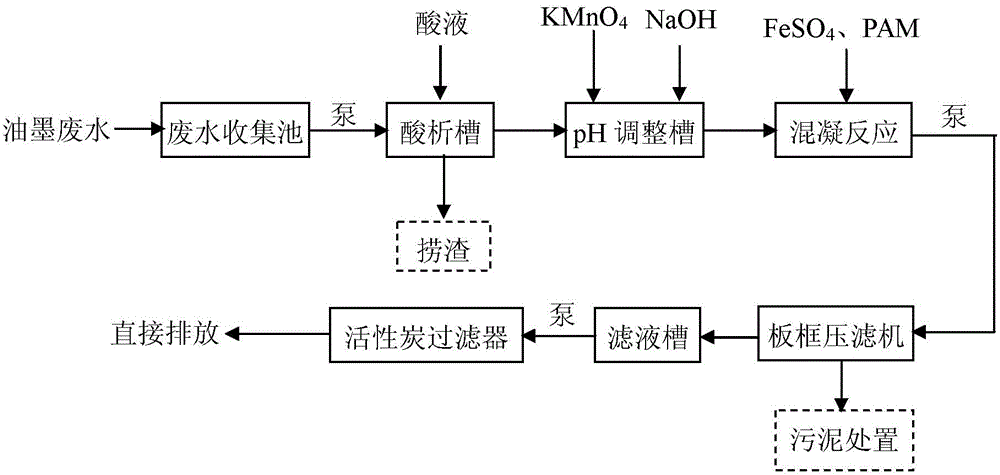

Organic waste liquid treatment method

InactiveCN104556469ATo achieve the goal of "treating waste with waste"Low basic investment costMultistage water/sewage treatmentWater/sewage treatment by neutralisationFilter pressPotassium permanganate

The invention discloses an organic waste liquid treatment method which comprises the following steps: firstly adjusting the pH value of an organic waste liquid to 2-3, aerating and stirring, separating out jellies from the organic waste liquid, and fishing out dross; then adding an alkaline to adjust the pH value to 8-9, inputting 1-2g / L potassium permanganate and reacting for 20-40 minutes; then adding a flocculant FeSO4 and a coagulant aid PAM for coagulating sedimentation and filter pressing by virtue of a filter press; and adsorbing and filtering the filtrate by active carbon to be discharged in a standard manner. The method disclosed by the invention is easy to control the treatment process, is extremely implemented in the existing process, and meets the requirement of industrial production.

Owner:PEKING UNIV FOUNDER GRP CO LTD +3

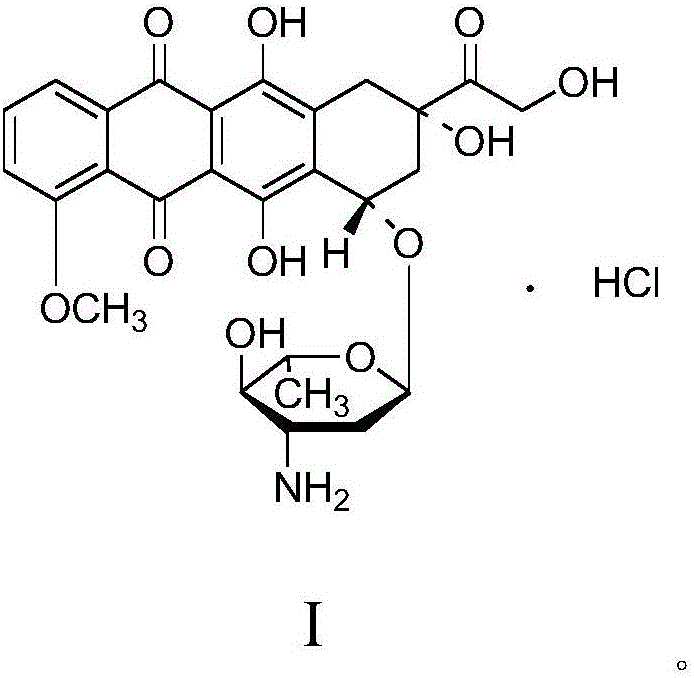

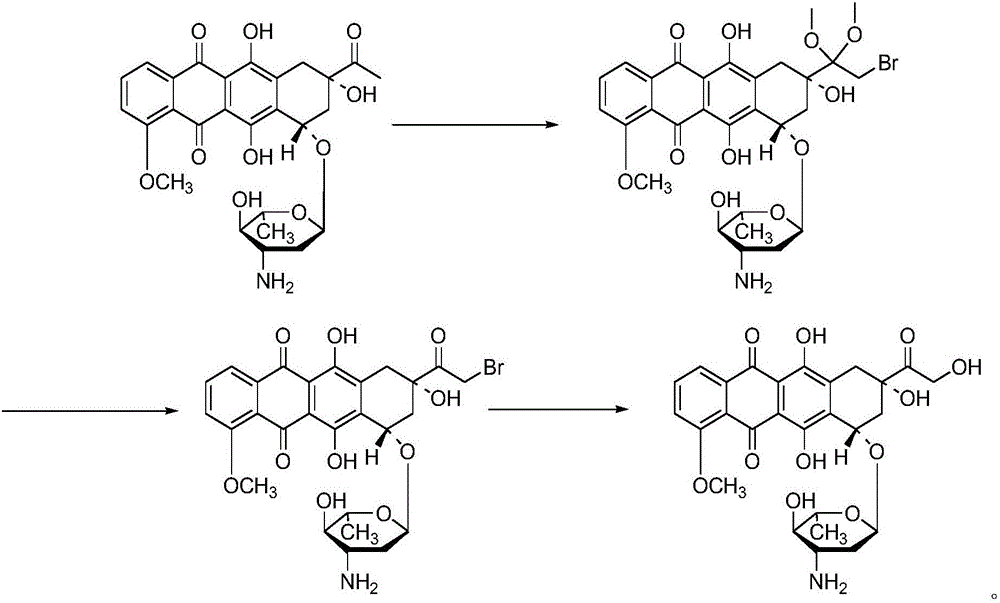

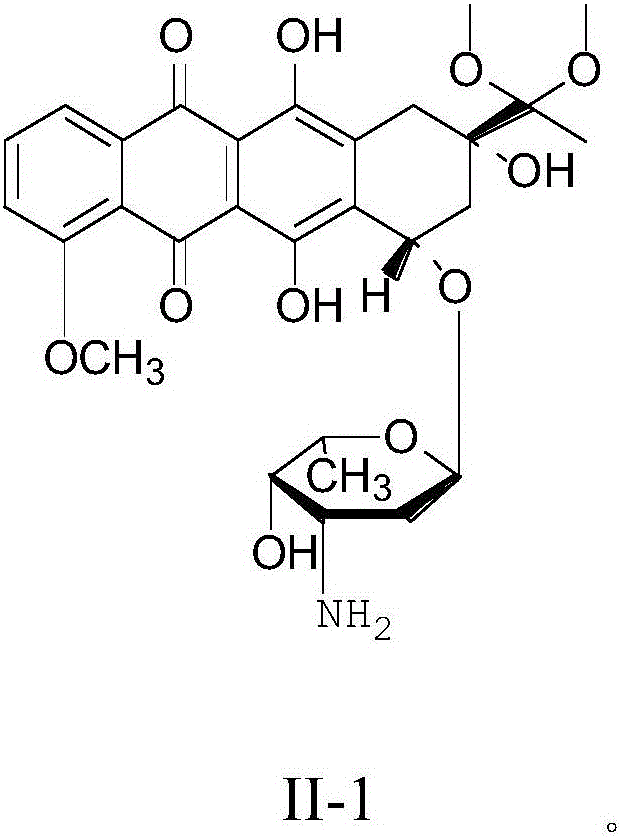

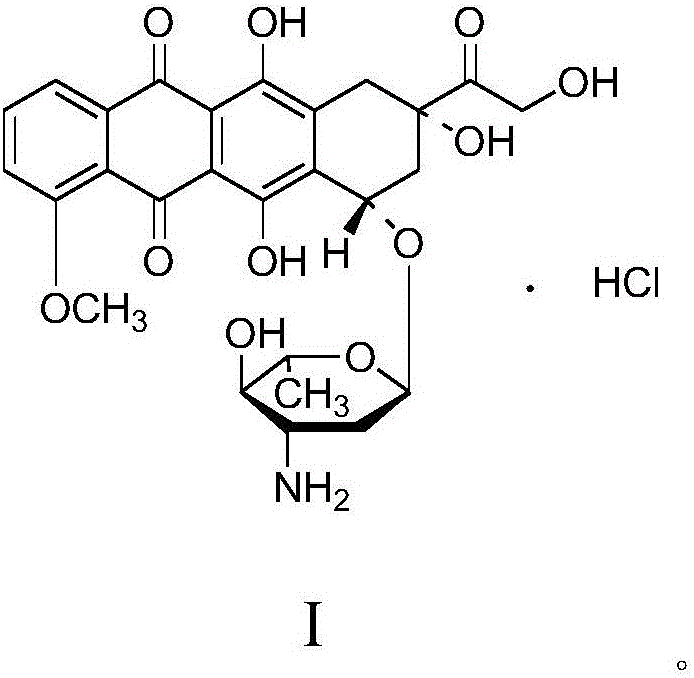

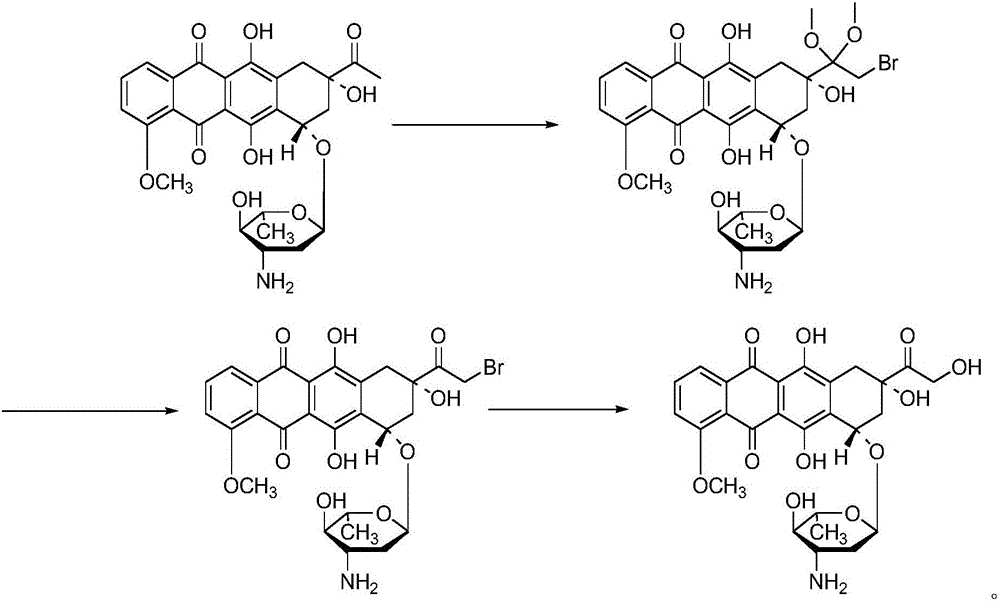

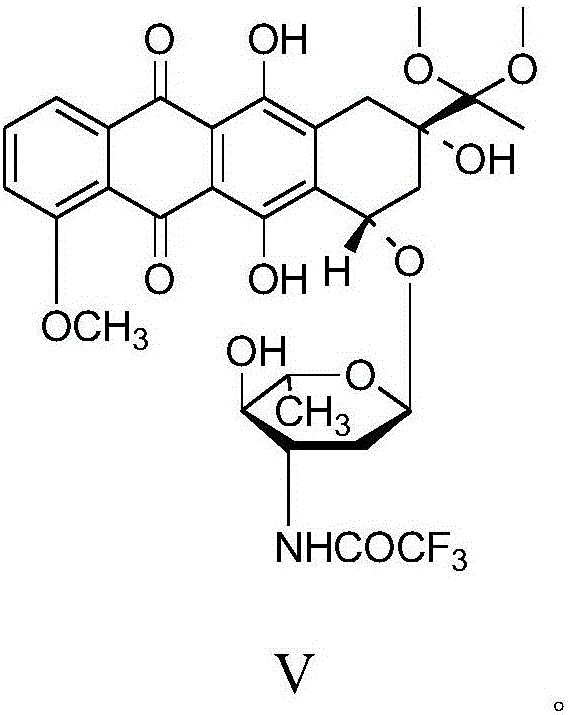

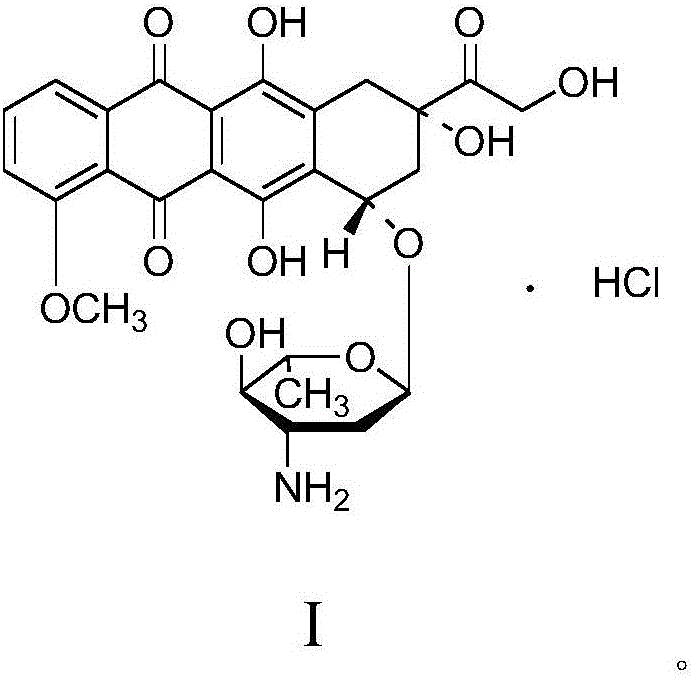

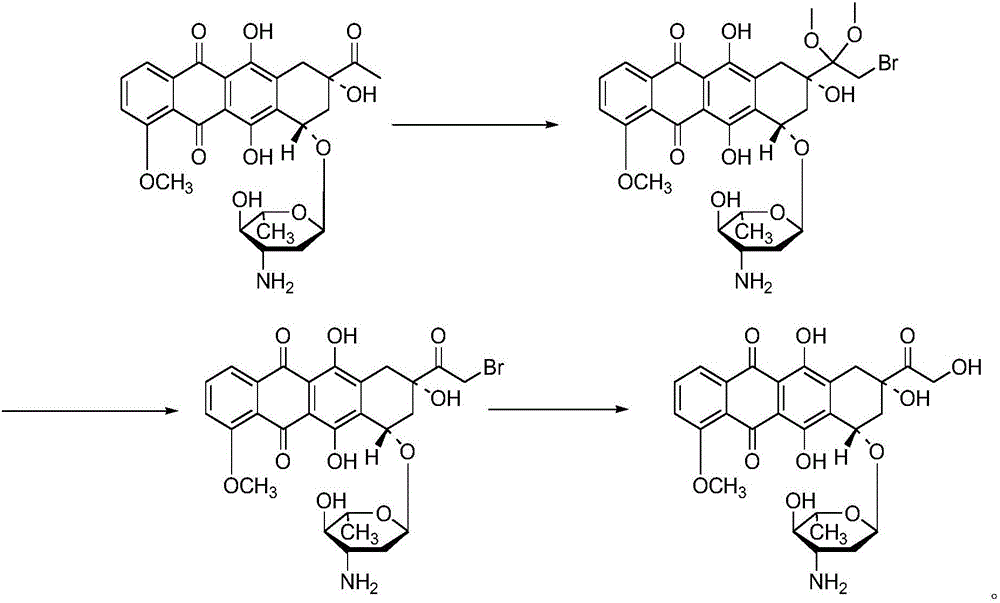

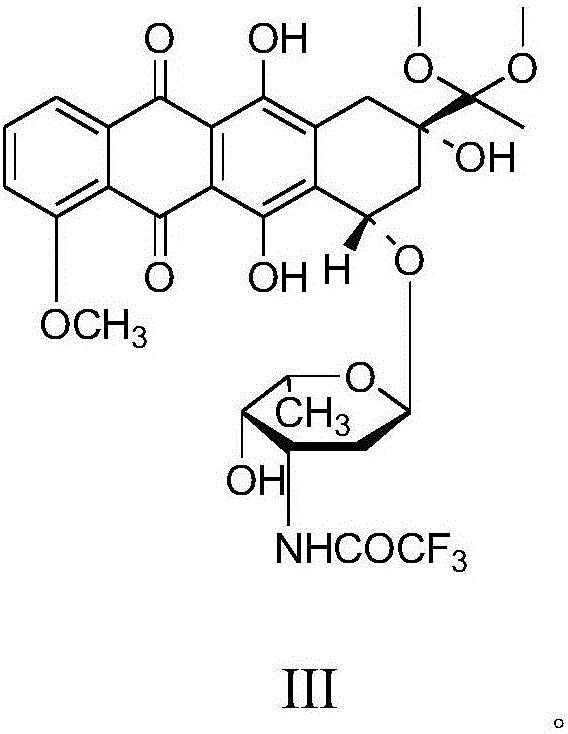

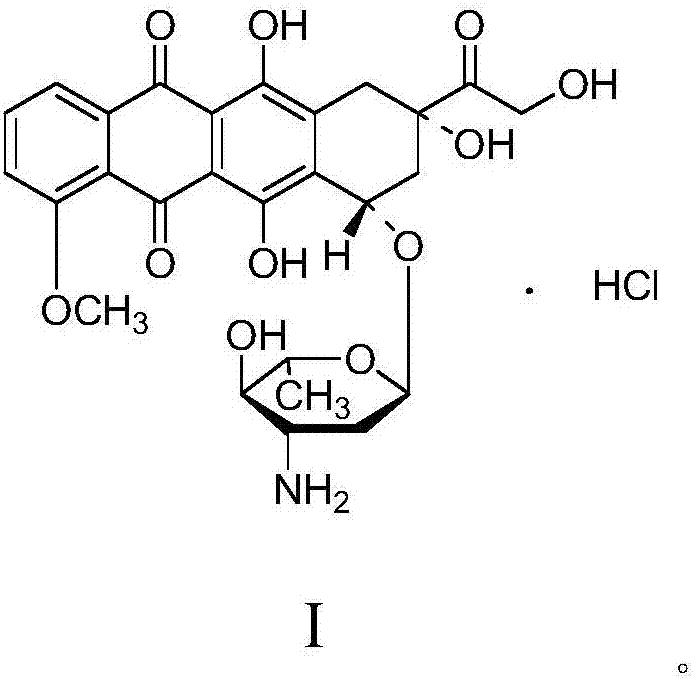

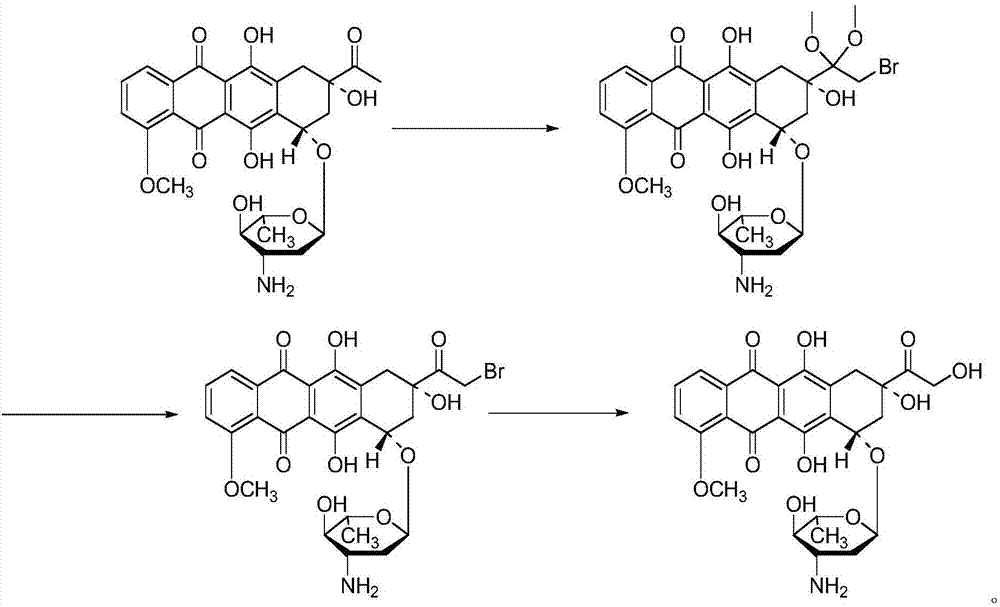

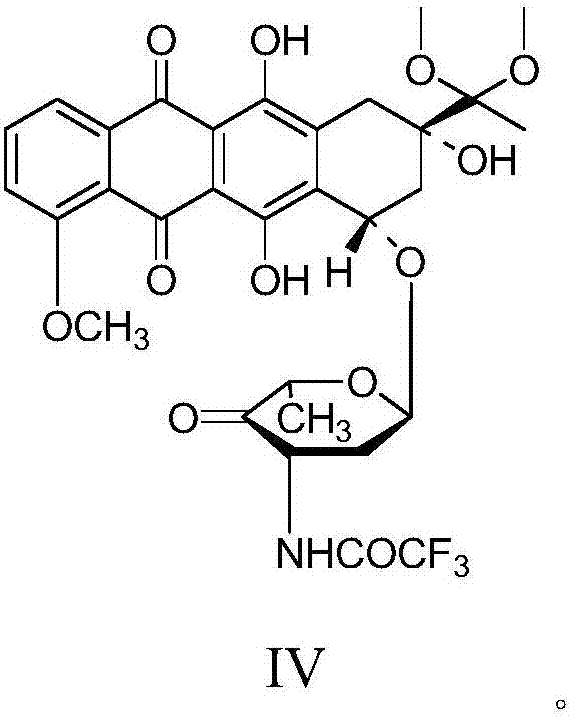

Epirubicin hydrochloride intermediate compound

ActiveCN106749447AReduce pollutionNot technically demandingSugar derivativesSugar derivatives preparationImpurityReagent

The invention provides a novel intermediate and a novel route for synthesizing epirubicin hydrochloride by utilizing the intermediate. The route is simple, cheap and efficient, achieves better energy conservation and emission reduction, and avoids the problems that an intermediate generated by the existing epirubicin hydrochloride synthesis route is water-instable and easy to decompose and a yield of the whole route is low. The route uses a low-cost and easy-to-obtain reagent and adopts a removable selective protection means; generated impurities are few; the purity is high; a yield is high.

Owner:LUNAN PHARMA GROUP CORPORATION

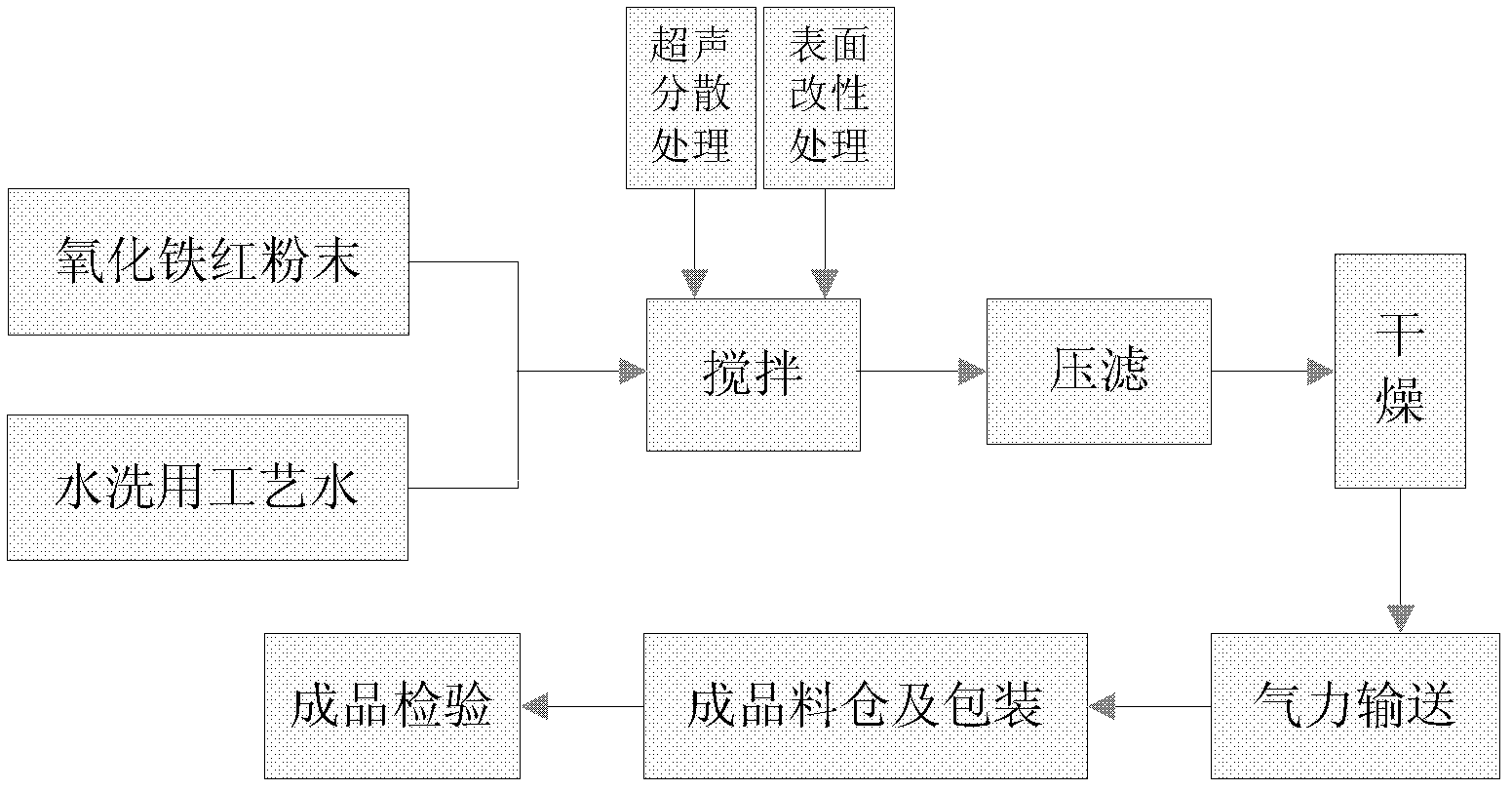

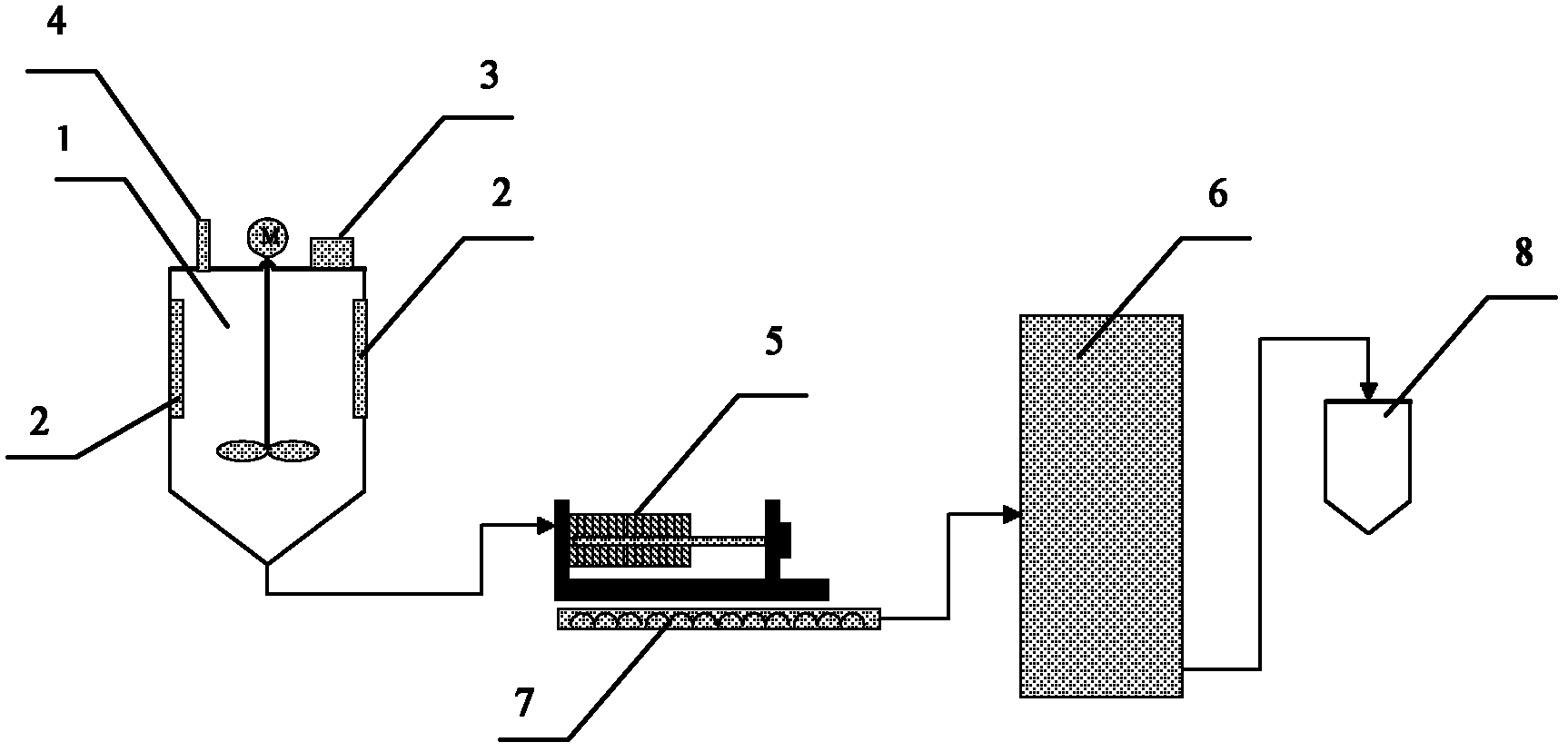

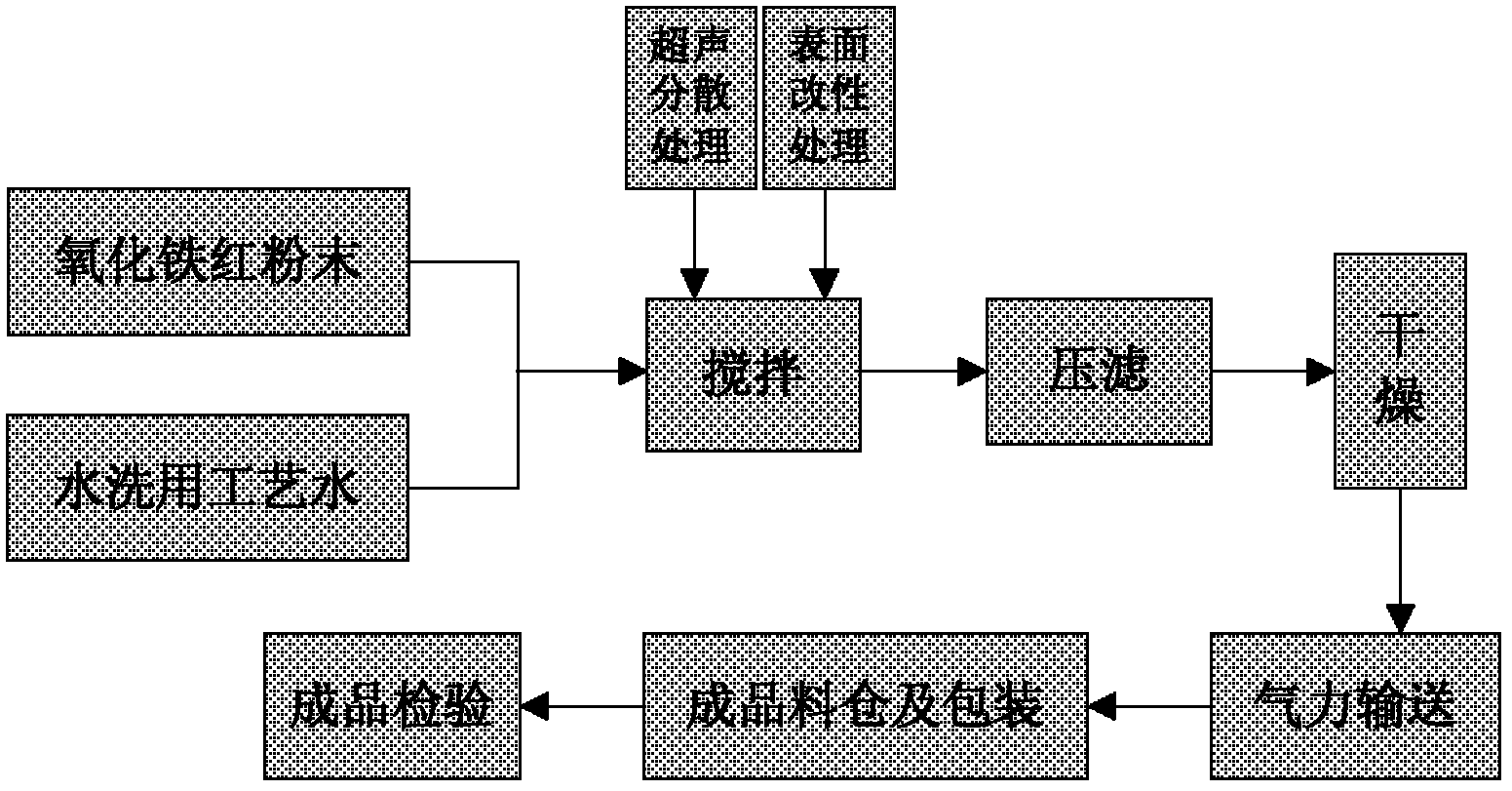

Post-treatment and purification process of iron oxide red for high-property soft magnetic ferrite

ActiveCN102303912AReduced content of water-soluble impuritiesMeet production requirementsFerric oxidesDispersion stabilityWater based

The invention discloses a post-treatment and purification process of iron oxide red for high-property soft magnetic ferrite. The process is characterized by directly water-washing and purifying iron oxide red powder obtained in an acid regeneration process with a Ruthner method, wherein process water is desalted reclaimed water obtained by desalting reclaimed water in a municipal sewage station or is process water obtained by mixing the desalted reclaimed water with production water, and in the water-washing process, the dispersion stability of the iron oxide red particles in a water-based liquid phase is improved by using an ultrasonic dispersion technology and a particle surface modification technology so as to promote the dissolution of soluble impurities in iron oxide red; and then carrying out solid-liquid separation, intensified pneumatic drying and the like. According to the invention, iron oxide red obtained by adopting the post-treatment and purification process disclosed by the invention can meet the production requirement of a high-property soft magnetic ferrite magnetic material. The process has the advantages of short process flow, low energy consumption, no pollution, high yield, stable product property, good consistency of product property and the like, and meets the requirement of industrial mass production.

Owner:SHOUGANG CORPORATION +1

Epirubicin hydrochloride intermediate compound V

ActiveCN106749446AReduce pollutionNot technically demandingSugar derivativesSugar derivatives preparationImpurityEnergy conservation

The invention provides a novel intermediate and a novel route for synthesizing epirubicin hydrochloride by utilizing the intermediate. The route is simple, cheap and efficient, achieves better energy conservation and emission reduction, and avoids the problems that an intermediate generated by the existing epirubicin hydrochloride synthesis route is water-instable and easy to decompose and a yield of the whole route is low. The route uses a low-cost and easy-to-obtain reagent and adopts a removable selective protection means; generated impurities are few; the purity is high; a yield is high.

Owner:LUNAN PHARMA GROUP CORPORATION

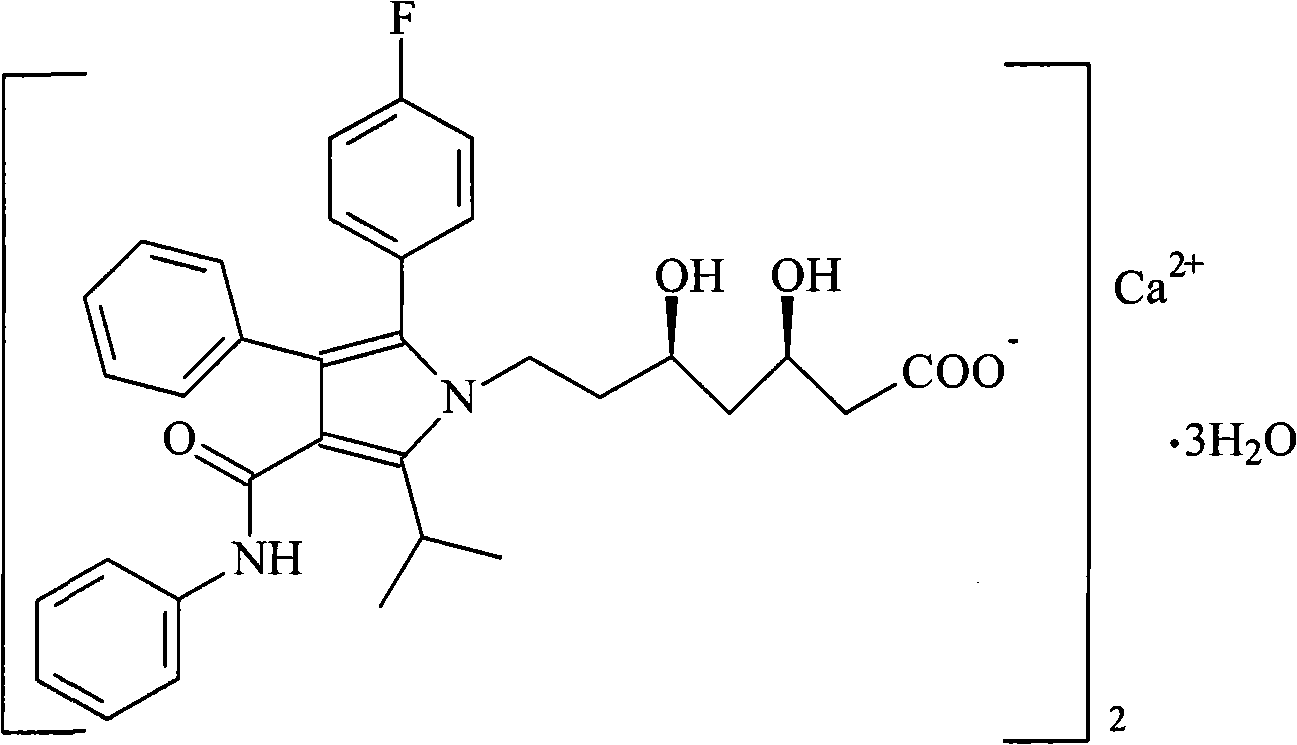

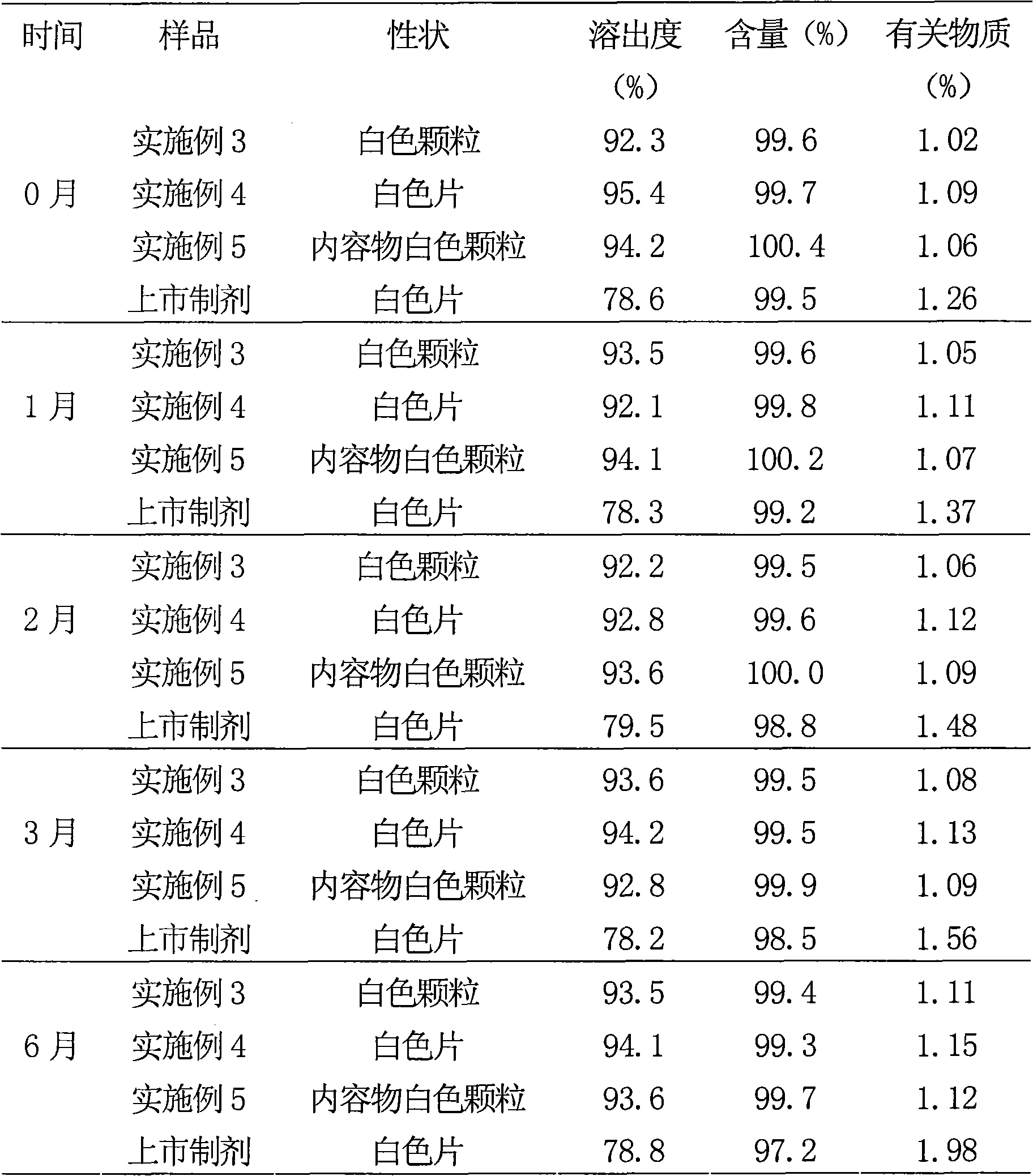

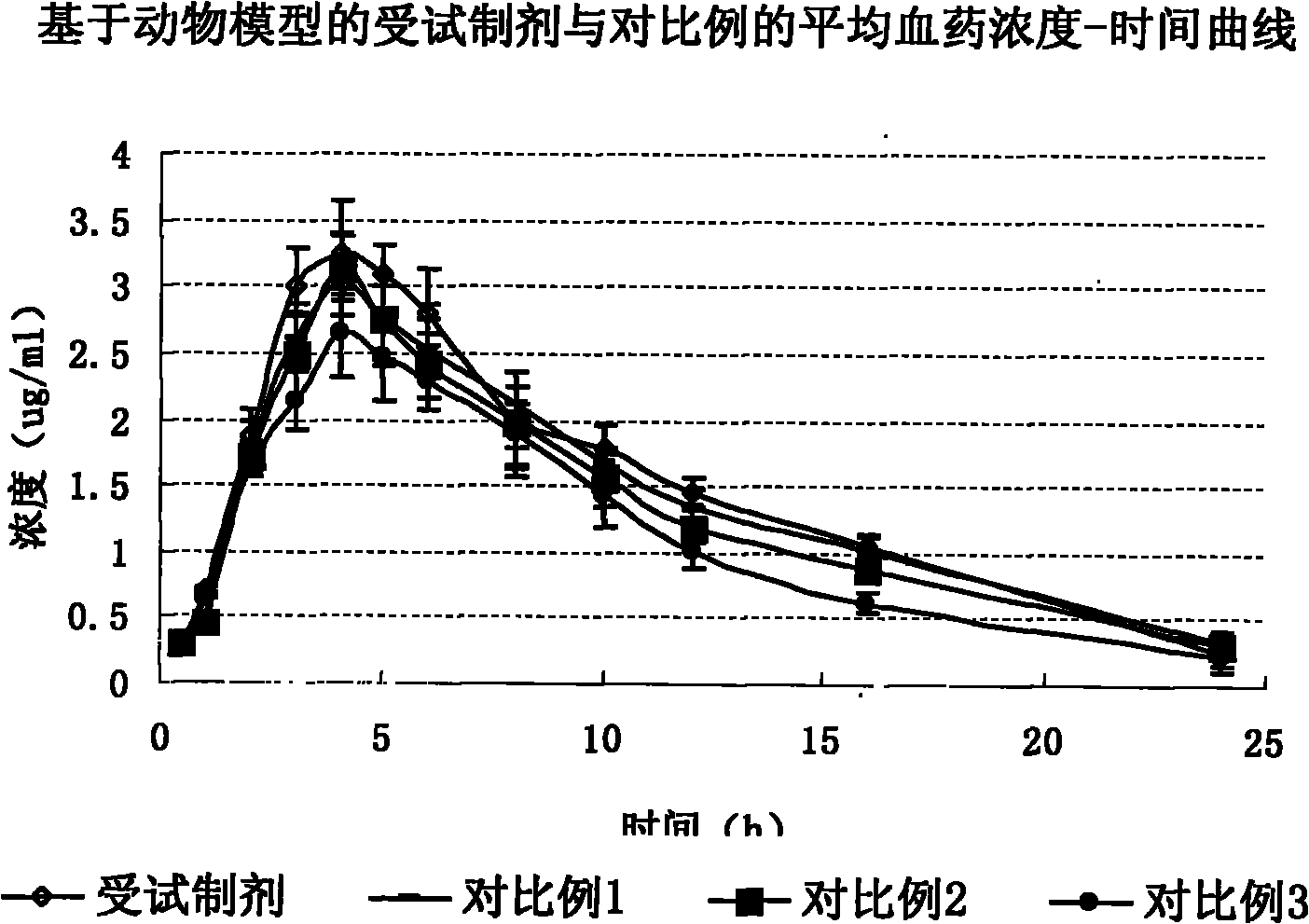

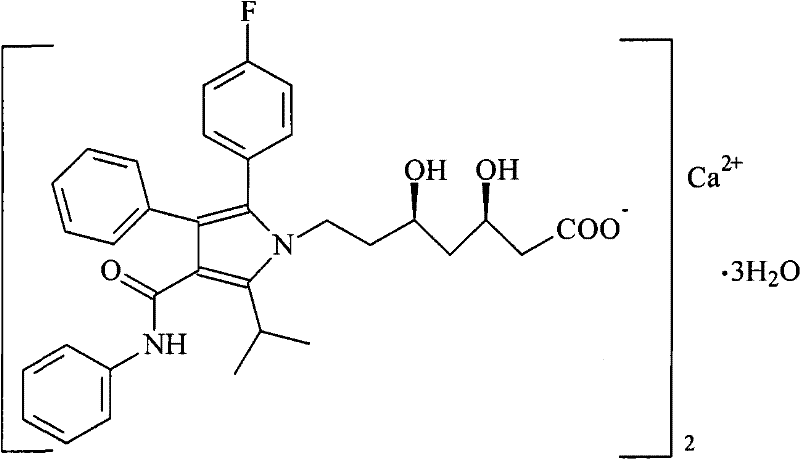

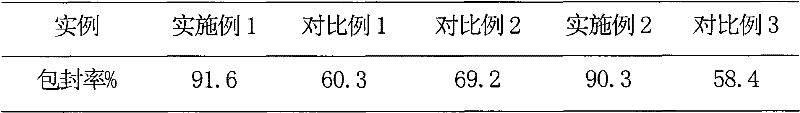

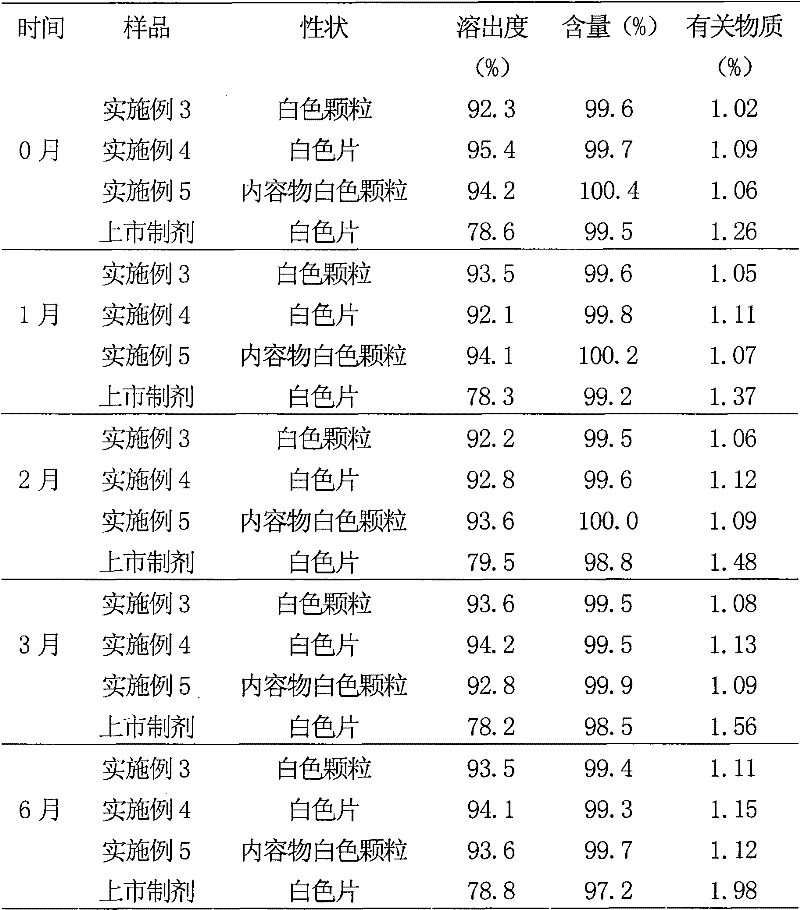

Solid preparation of atorvastatin calcium liposome

InactiveCN102008440AStrong anti-platelet aggregationReduces arrhythmias in reperfused myocardiumMetabolism disorderPharmaceutical non-active ingredientsLiposomeSide effect

The invention discloses a solid preparation of atorvastatin calcium liposome. The preparation is prepared from the atorvastatin calcium liposome and other pharmaceutically common auxiliary materials, wherein the atorvastatin liposome is prepared from the following components in parts by weight: 1 part of atorvastatin calcium, 2-5 parts of phospholipid and 0.8-3 parts of additive. The atorvastatin solid preparation prepared from the liposome has the advantages that the dissolution rate is increased, the stability and bioavailability are greatly improved, the product quality of the preparation is improved and the toxic and side effect is reduced.

Owner:HAINAN MEIDA PHARMA

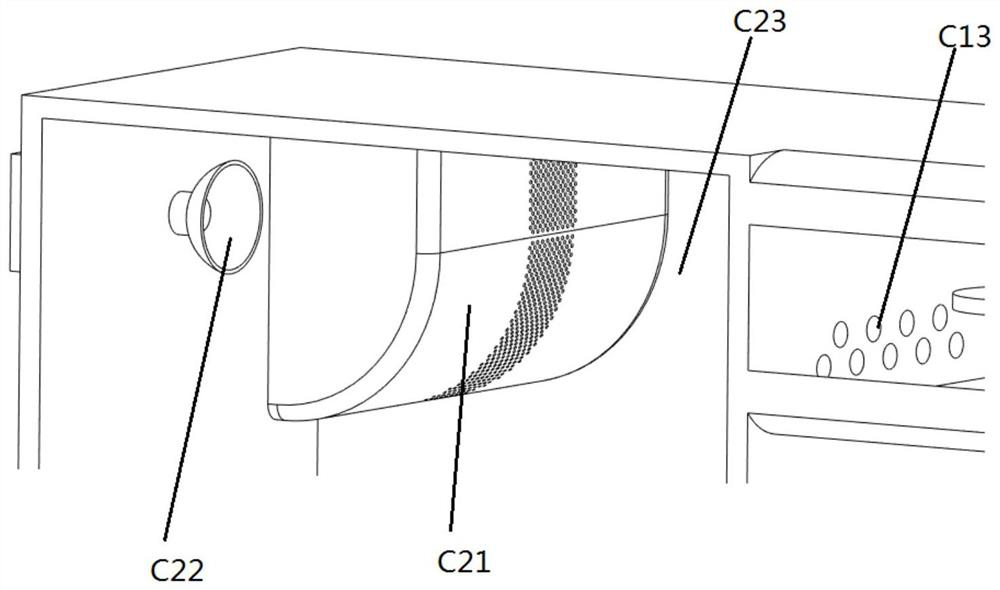

Conductive plastic and its processing method and apparatus

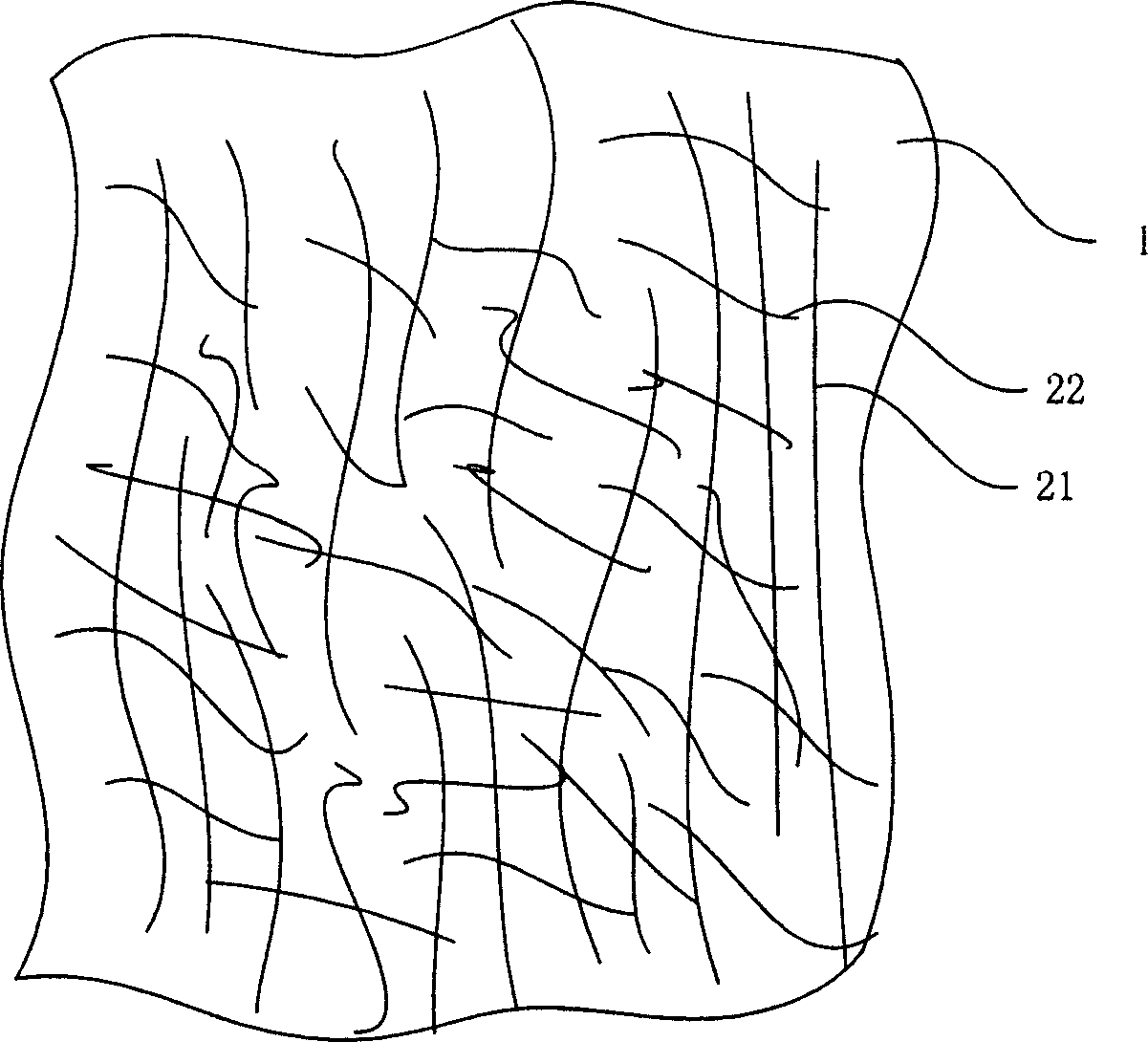

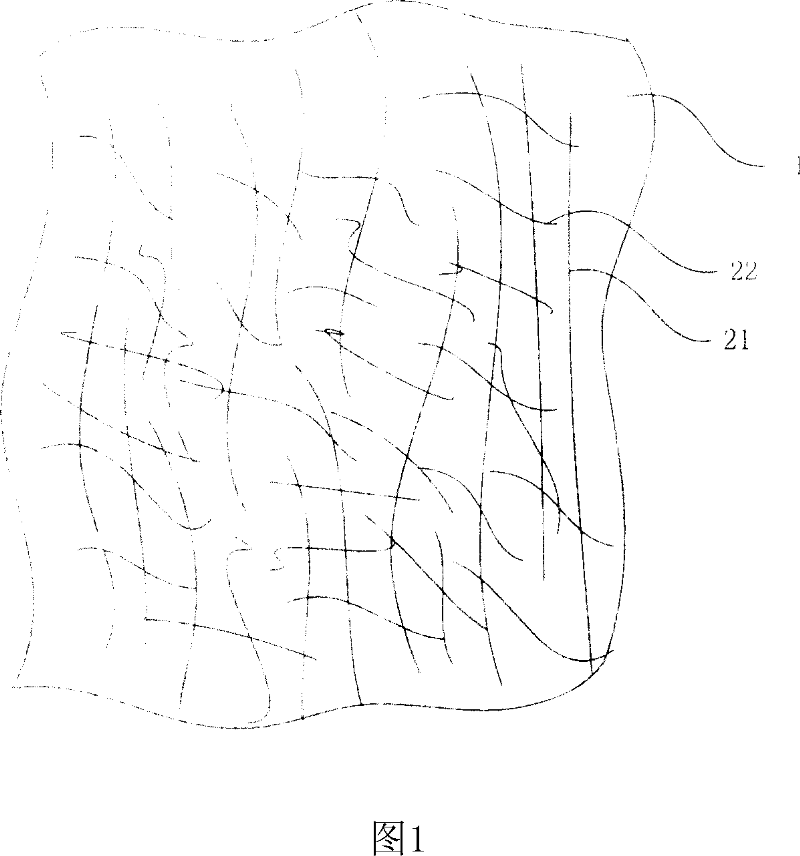

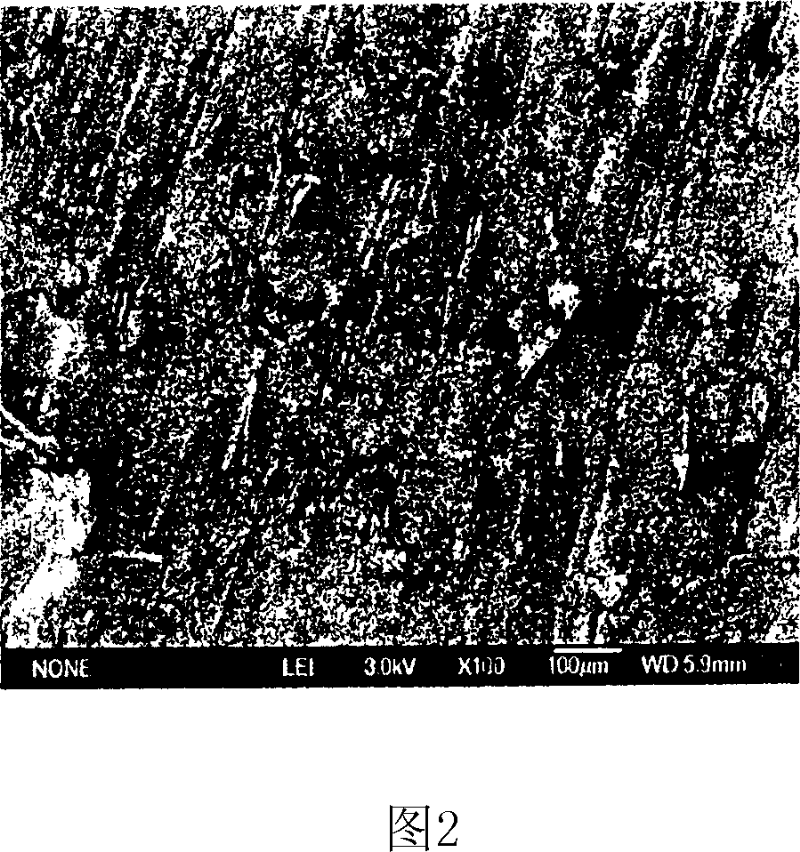

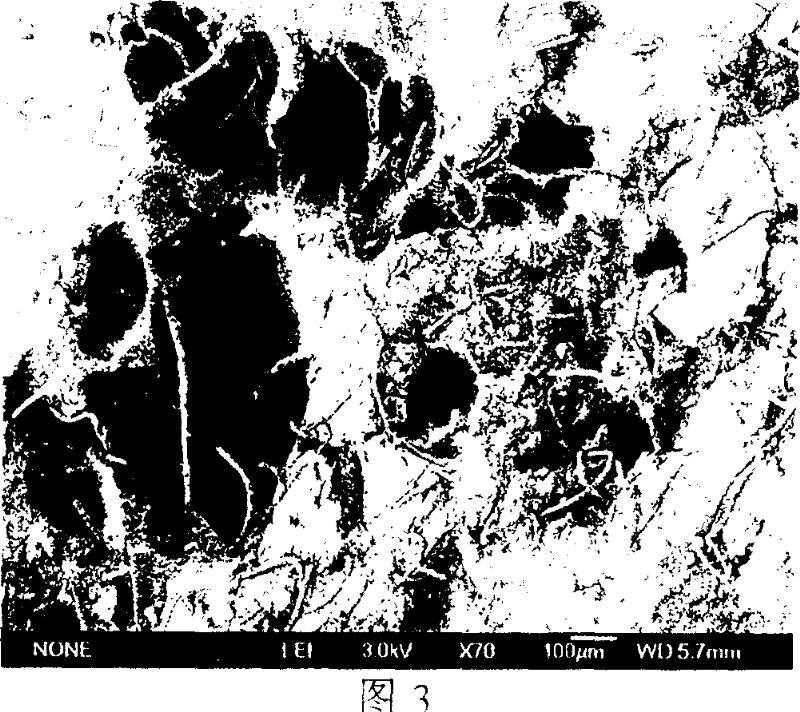

InactiveCN100338130CVolume resistivity is stableImprove antistatic performanceFiberElectrical resistance and conductance

The present invention discloses one kind of conductive plastic and its processing method and apparatus. The conductive plastic includes conductive fiber 0.1-45 vol%, thermoplastic plastic 55-99 vol% and machining assistant 0-3 vol%. The conductive fiber is arranged in 3D netted form homogeneously with multiple joining points, and the conductive plastic has high conductivity, high antistatic and electromagnetic shielding effect, and low surface resistance and volumetric resistivity, and may be injected, extruded and molded like common plastic.

Owner:BEIJING NASHENGTONG ADVANCED MATERIAL & TECH CO LTD

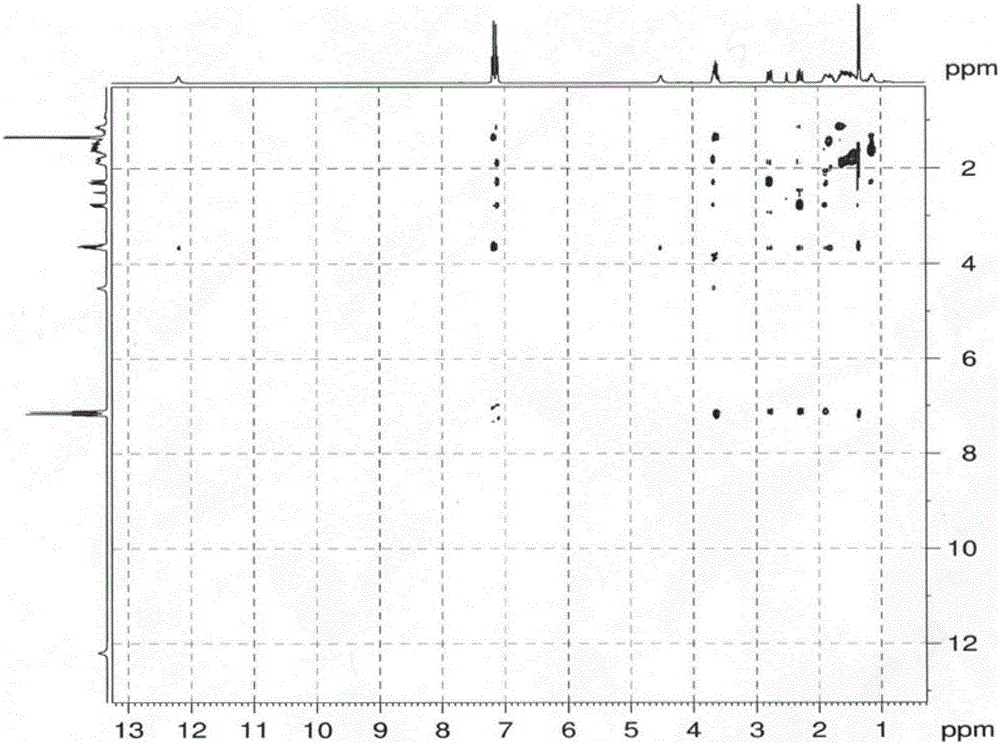

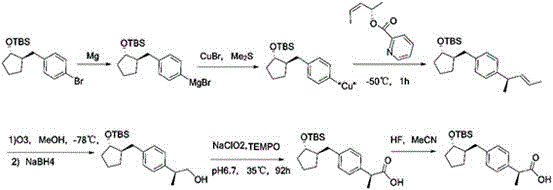

Method for preparing loxoprofen active metabolite

ActiveCN106045842ABeneficial technical effectBeneficial progressCarbamic acid derivatives preparationOrganic compound preparationCompound aPropanoic acid

The invention discloses a method for compounding a trans-hydroxyl active metabolite of loxoprofen. The method comprises the following steps: taking 2-[p(bromomethyl)phenyl]propionic acid as a raw material and carrying out resolution and methyl esterification, thus obtaining an intermediate, namely, a compound as shown in a formula 3; preparing a chiral assistant, namely, a compound as shown in a formula 7, by starting from L-phenylalaninol; firstly forming Schiff base as shown in a formula 9 by cyclopentanone and the chiral assistant, namely, the compound as shown in the formula 7, and then condensing the Schiff base as shown in the formula 9 and the intermediate, namely, the compound as shown in the formula 3, into an intermediate, namely, a compound as shown in a formula 11; carrying out acidic hydrolysis on the intermediate, namely, the compound as shown in the formula 11, and perfroming stereoselective reduction on cyclopentanone carbonyl groups, thus obtaining the trans-hydroxyl active metabolite, namely, a compound as shown in a formula TM. In a compounding path, raw materials can be easily obtained, the operation is convenient, environmental friendliness is realized, a separation means of column chromatography is prevented from being used, and the technical requirements of industrial large-scale production can be completely met.

Owner:NANJING HERON PHARMA SCI & TECH CO LTD

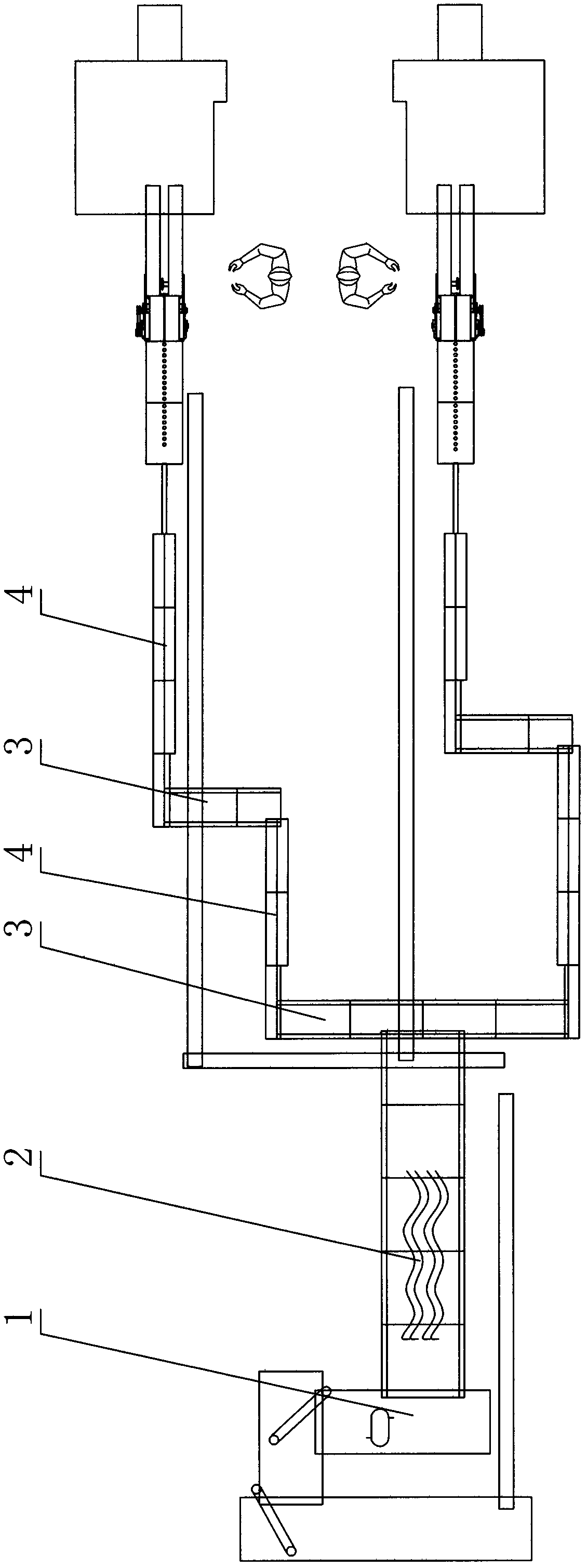

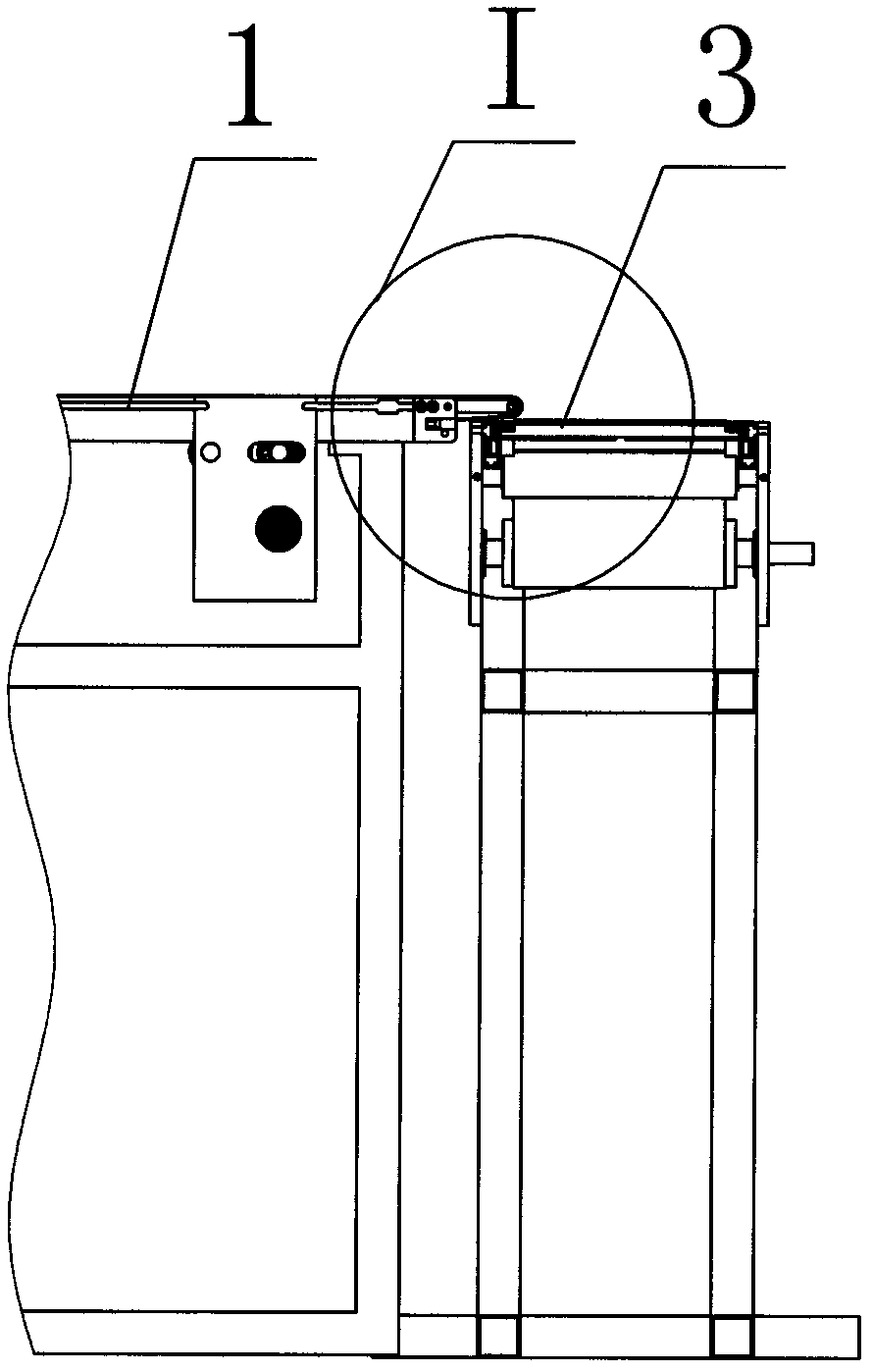

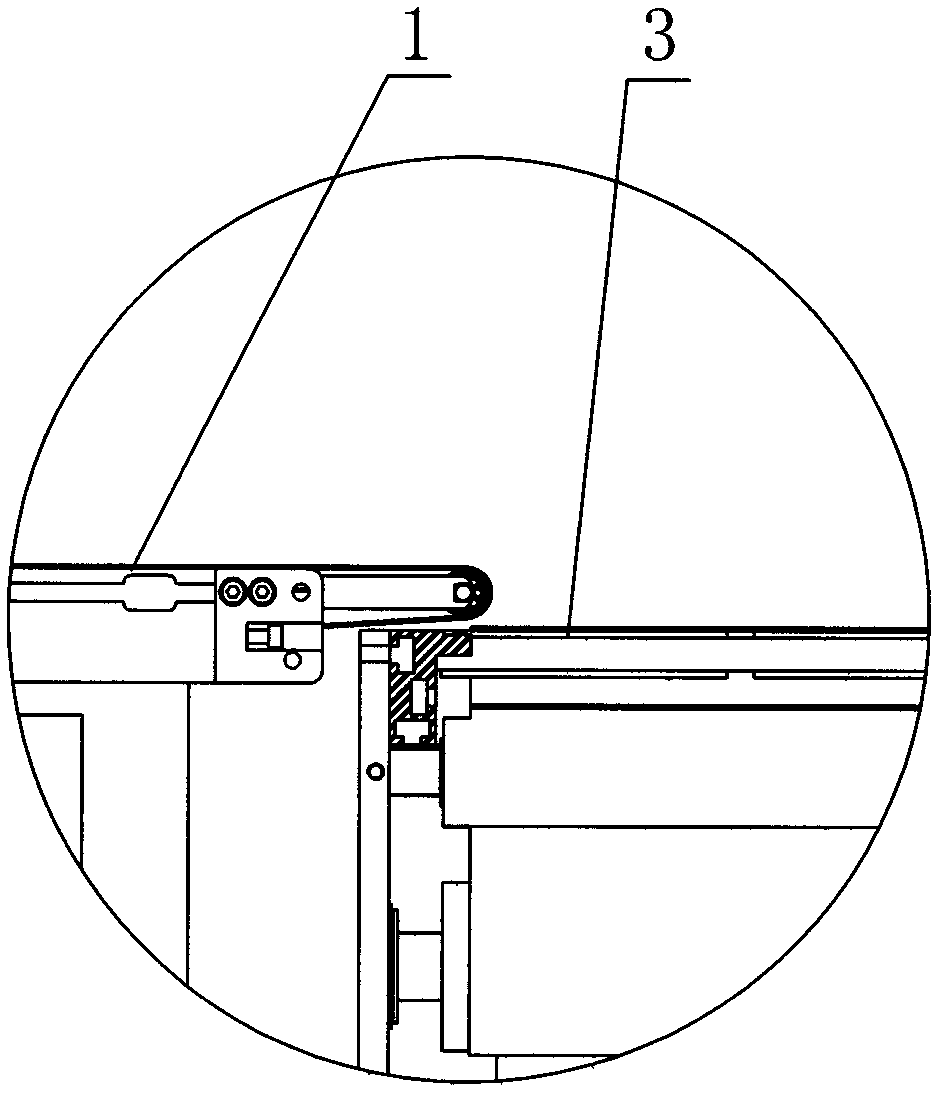

Round bar stock arranging device

ActiveCN102424158ASo as not to damageMeet the requirements of industrialized mass productionPackagingRound barEngineering

The invention discloses a round bar stock arranging device, which comprises a material feeding platform (1) and a conveying unit. The round bar stock arranging device is characterized in that the conveying unit comprises a planar conveying unit (3) and a V-shaped conveying unit (4), both of which are mutually engaged and form a right angle. The bar stock arranging device of the structure, disclosed by the invention, can transversely and vertically convey round bar stocks pre-arranged by the material feeding platform through the conveying unit and then completely arranges the bar stocks, thus the bar stocks are arranged orderly and are convenient for the operation of a subsequent working process.

Owner:WENZHOU RUIDA MACHINERY

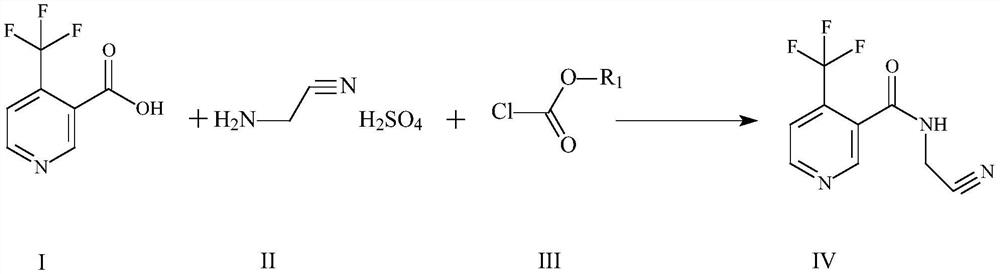

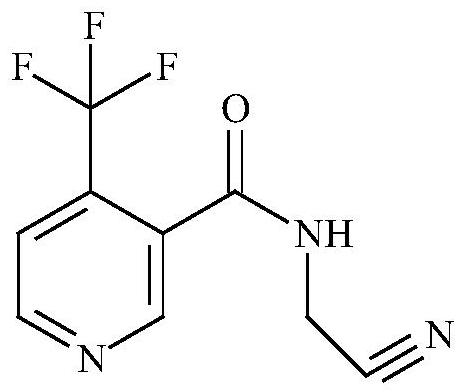

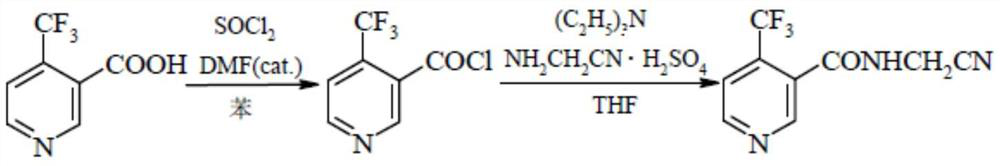

Method for preparing flonicamid

The invention discloses a method for preparing flonicamid. The method comprises the following steps: S1, condensation reaction: in an organic solvent A, carrying out condensation reaction on a compound in a formula I and a compound in a formula III under the action of an acid-binding agent; wherein the organic solvent A is halogenated hydrocarbon or aromatic hydrocarbon; and S2, amidation reaction: after the condensation reaction in the step S1 is completed, directly adding a compound shown in a formula II without separation to carry out amidation reaction so as to obtain a compound shown in aformula IV. The intermediate one-pot method is adopted for continuous reaction to prepare flonicamid, the intermediate does not need to be purified, a target compound can be obtained only through simple operation, the feeding ratio is reduced, raw materials are saved, cost is saved, and operation is simplified. The method has the advantages of mild operation and adjustment, low risk, cheap and easily available raw materials, reduction of the generation and treatment of three wastes, realization of the high-purity flonicamid from the final product, realization of the total yield reaching 90% or above, great significance in the large-scale preparation of flonicamid, and meeting of the requirements of industrial large-scale production.

Owner:厦门优孚利生物医药科技有限公司

Epirubicin hydrochloride intermediate compound III

ActiveCN106749445AReduce pollutionNot technically demandingSugar derivativesSugar derivatives preparationImpurityHydrochloride

The invention provides a novel intermediate and a novel route for synthesizing epirubicin hydrochloride by utilizing the intermediate. The route is simple, cheap and efficient, achieves better energy conservation and emission reduction, and avoids the problems that an intermediate generated by the existing epirubicin hydrochloride synthesis route is water-instable and easy to decompose and a yield of the whole route is low. The route uses a low-cost and easy-to-obtain reagent and adopts a removable selective protection means; generated impurities are few; the purity is high; a yield is high.

Owner:LUNAN PHARMA GROUP CORPORATION

Epirubicin hydrochloride intermediate compound IV

ActiveCN107043362AReduce pollutionNot technically demandingSugar derivativesSugar derivatives preparationImpurityEnergy conservation

The invention provides a novel intermediate and a new route for synthesizing epirubicin hydrochloride by using the intermediate. The route is simple, cheap and efficient, and meanwhile, the problems that the intermediate generated by an existing epirubicin hydrochloride synthesis route is instable in water and easy to decompose and the whole route is low in yield are solved. In order to better achieve energy conservation and emission reduction, a cheap and available reagent is utilized by the route; and meanwhile, removable selective protection means are adopted, so that the generated impurities are few, the purity is high and the yield is high.

Owner:LUNAN PHARMA GROUP CORPORATION

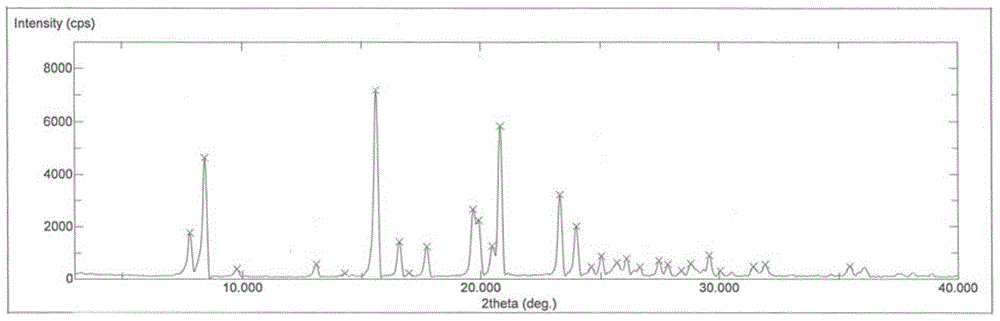

D-ilaprazole sodium compound and pharmaceutical composition thereof

ActiveCN105566294AImprove solubilityImprove liquidityOrganic active ingredientsOrganic chemistrySolubilityDrugs preparations

The present invention provides a D-ilaprazole sodium compound represented by a formula (I), a preparation method and a pharmaceutical composition thereof. According to the present invention, the D-ilaprazole sodium compound has advantages of good solubility and high stability, and meets the medicinal requirements; and the D-ilaprazole sodium compound preparation process has characteristics of stability and good reproducibility, meets the industrial mass production requirements, and has important application values in drug preparation. The formula (I) is defined in the specification.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

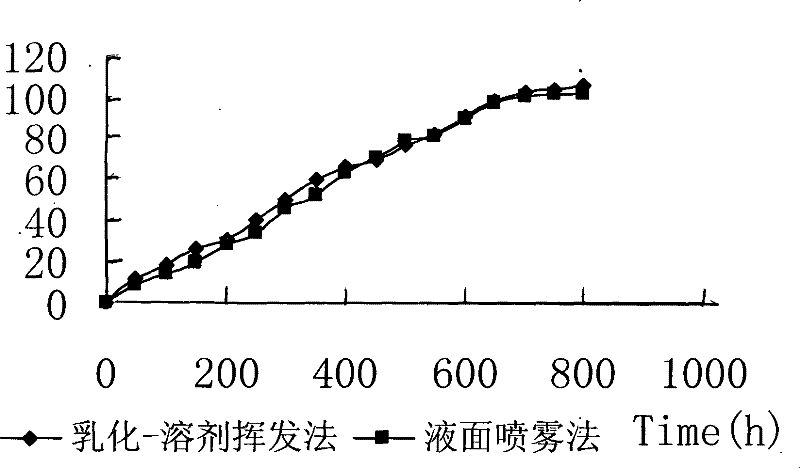

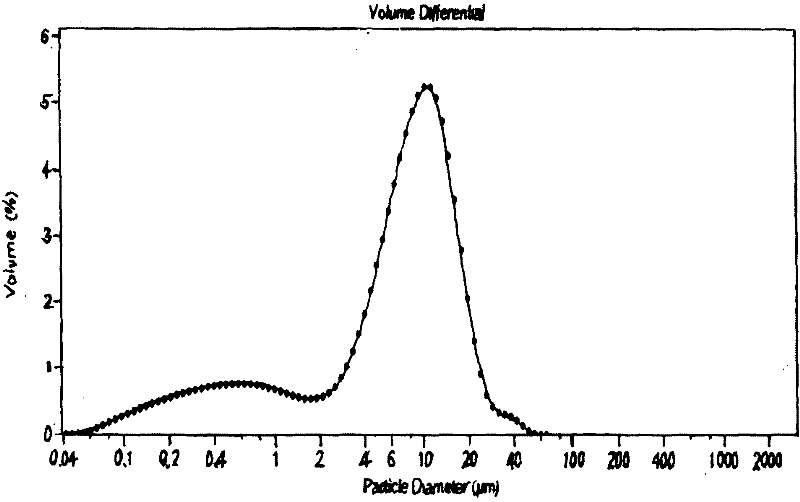

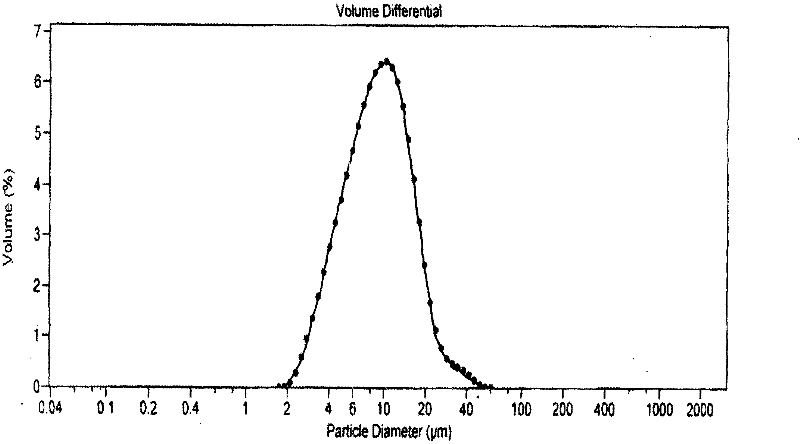

Preparation of new drug delivery system based on liquid surface spray method

InactiveCN1879606BHigh yieldSmall particle sizePowder deliveryPharmaceutical product form changeDrugs solutionEngineering

The invention provides a delivery system for preparing novel drugs based on a liquid surface spraying method, which is a novel microparticle preparation method with great industrialization prospects. The delivery system of the new drug is prepared based on the liquid surface spray method. The solution containing the carrier material is miscible or suspended with the drug or the drug solution, and then atomized, and sprayed into the receiving liquid to form a particle preparation. The flow rate of the atomized liquid is 0.01-100ml / min, spray pressure 0.1-0.5MPa, preparation temperature 5-100°C. The invention has high yield and good method stability, and the whole preparation process of the invention is completed by instruments, which avoids the difference of human factors and greatly improves the yield. The particle size distribution is uniform and reproducible.

Owner:SHENYANG PHARMA UNIVERSITY

Method for removing iron and silicon impurities during regeneration of aluminum scraps

ActiveCN103740947BWon't affect yieldIron and silicon impurity elements are reducedProcess efficiency improvementManganeseBorax

Owner:HUAWEI TEHCHNOLOGIES CO LTD

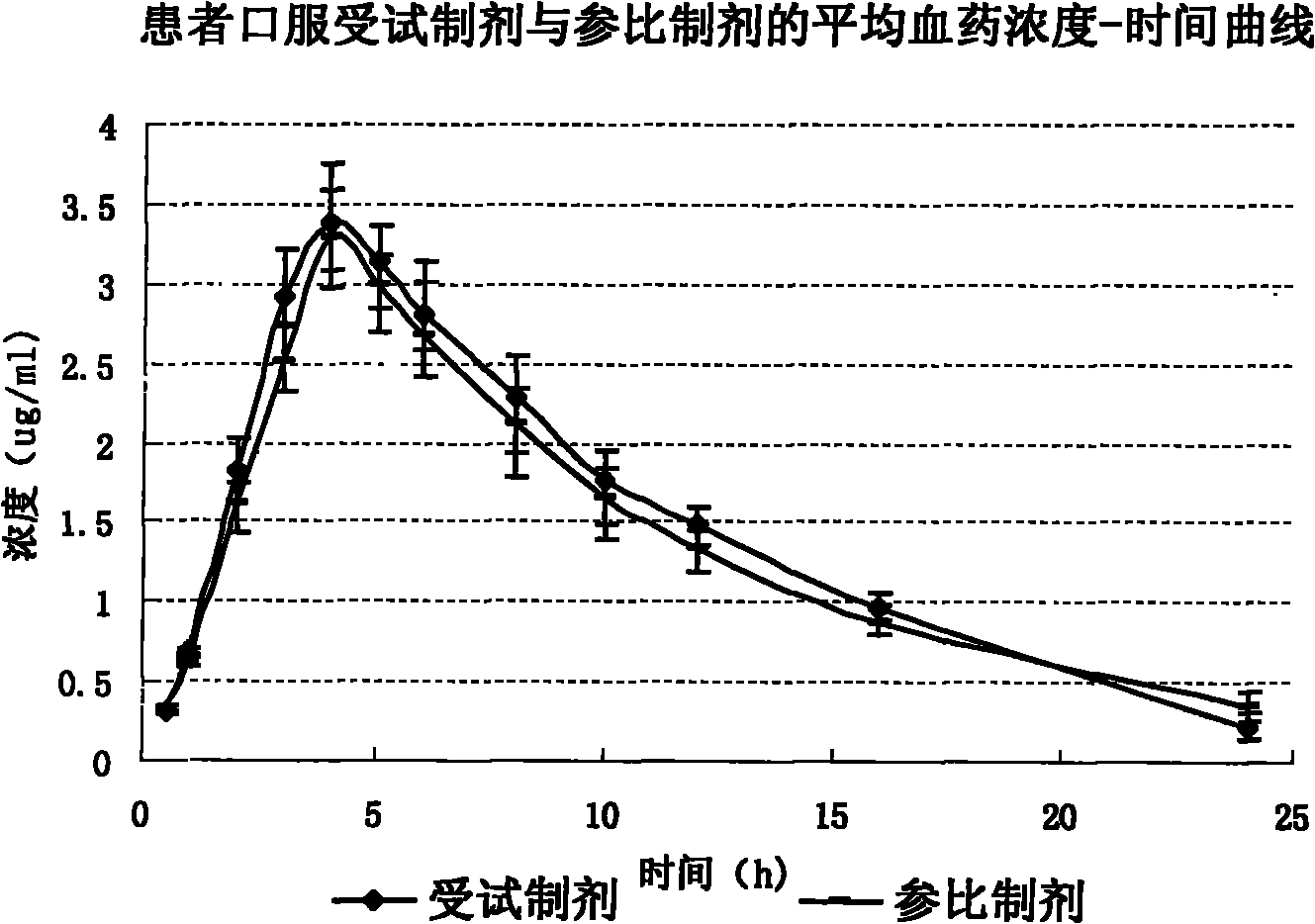

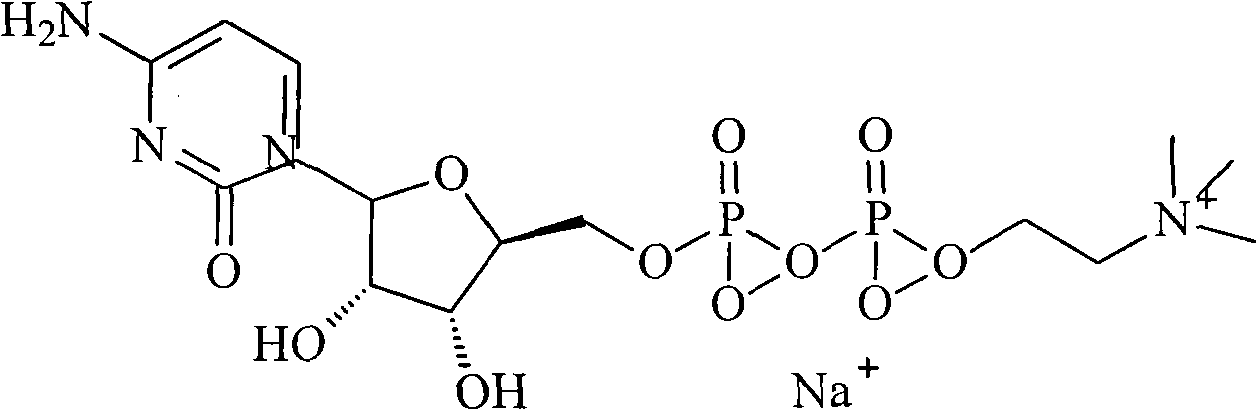

Citicoline sodium liposome solid preparation

InactiveCN102078299AImprove stabilityLong validity periodOrganic active ingredientsNervous disorderLiposomeSide effect

The invention relates to a citicoline sodium liposome solid preparation which is mainly prepared from citicoline sodium, phospholipid, an additive and other pharmaceutic adjuvants, wherein the citicoline sodium accounts for 1 part by weight, the phospholipids accounts for 2-12 parts by weight, and the additive accounts for 0.5-8 parts by weight. The liposome solid preparation prepared by the invention has the advantages that the stability of the active ingredient citicoline sodium is greatly improved, the valid period of product is prolonged, and phospholipid absorption is cooperated with the curative activity of the citicoline sodium, thus the bioavailability is improved, the product quality of the preparation is improved, and toxic and side effects are reduced.

Owner:HAINAN MEIDA PHARMA

Solid preparation of atorvastatin calcium liposome

InactiveCN102008440BImprove stabilityGuaranteed efficacyMetabolism disorderPill deliveryPhospholipidBioavailability

The invention discloses a solid preparation of atorvastatin calcium liposome. The preparation is prepared from the atorvastatin calcium liposome and other pharmaceutically common auxiliary materials, wherein the atorvastatin liposome is prepared from the following components in parts by weight: 1 part of atorvastatin calcium, 2-5 parts of phospholipid and 0.8-3 parts of additive. The atorvastatinsolid preparation prepared from the liposome has the advantages that the dissolution rate is increased, the stability and bioavailability are greatly improved, the product quality of the preparation is improved and the toxic and side effect is reduced.

Owner:HAINAN MEIDA PHARMA

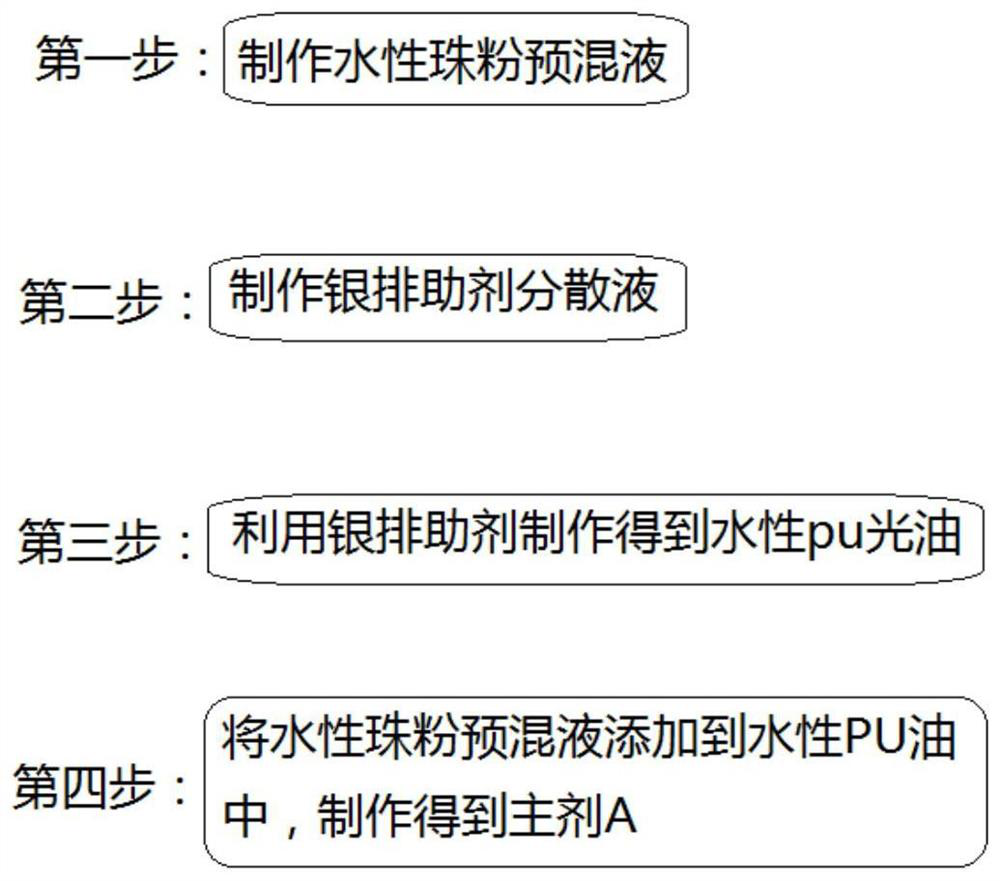

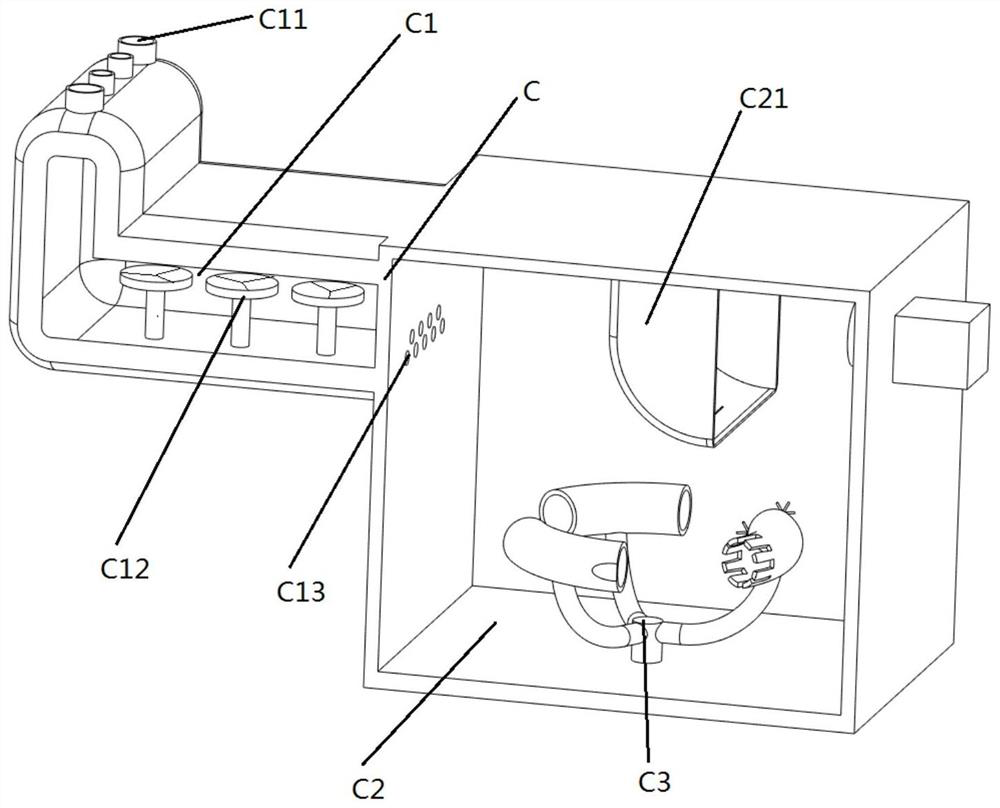

Water-based Low VOC high-metal texture two-component polyurethane low-temperature curing coating and preparation method thereof

PendingCN114085601AStrong adhesionImprove wear resistanceTransportation and packagingMixersSilver pastePolymer science

The invention discloses a water-based Low VOC high-metal texture two-component polyurethane low-temperature curing coating and a preparation method thereof. The coating comprises a main agent A and a curing agent B, the main agent A comprises the following components: 25 to 40 parts of waterborne polyurethane (PU) and acrylic dispersion resin, 0.1 to 0.3 part of a pH regulator, 2 to 5 parts of a waterborne coalescing agent, 0.3 to 1 part of a waterborne wetting agent, 0.2 to 1.0 part of a waterborne flatting agent, 20 to 40 parts of a self-made waterborne silver bar additive, 4 to 12 parts of self-made silver soaking water, 4 to 6 parts of waterborne aluminum silver paste, 0 to 6 parts of pearl powder, 0 to 10 parts of waterborne color paste, 0 to 5 parts of a functional additive, 1 to 5 parts of a thickening thixotropic agent, and 6.5 to 15 parts of deionized water; and the curing agent B comprises the following components in parts by weight: 70-80 parts of a water-based isocyanate curing agent and 20-30 parts of a curing agent diluent; and the method is characterized by mixing the main agent A and the curing agent B into the mixed structure and uniformly stirring. The invention provides the preparation method of a water-based Low VOC high-metal texture two-component polyurethane low-temperature curing coating. The good balance between the high-metal texture appearance and excellent physical and chemical resistance of a two-component polyurethane coating film under the water-based Low VOC condition is realized.

Owner:卡秀万辉(无锡)高新材料有限公司

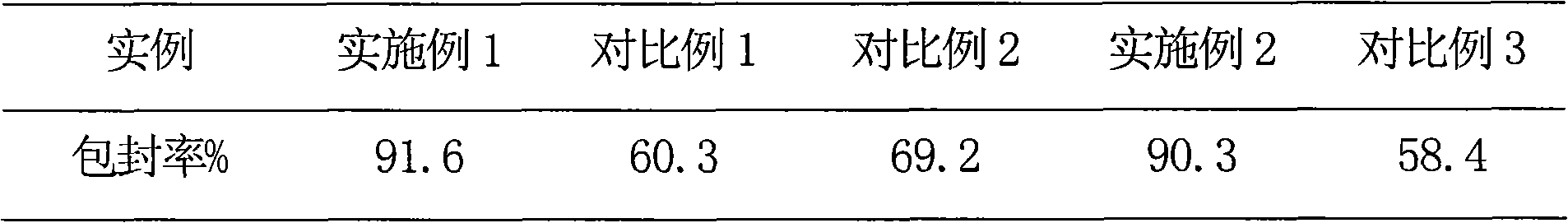

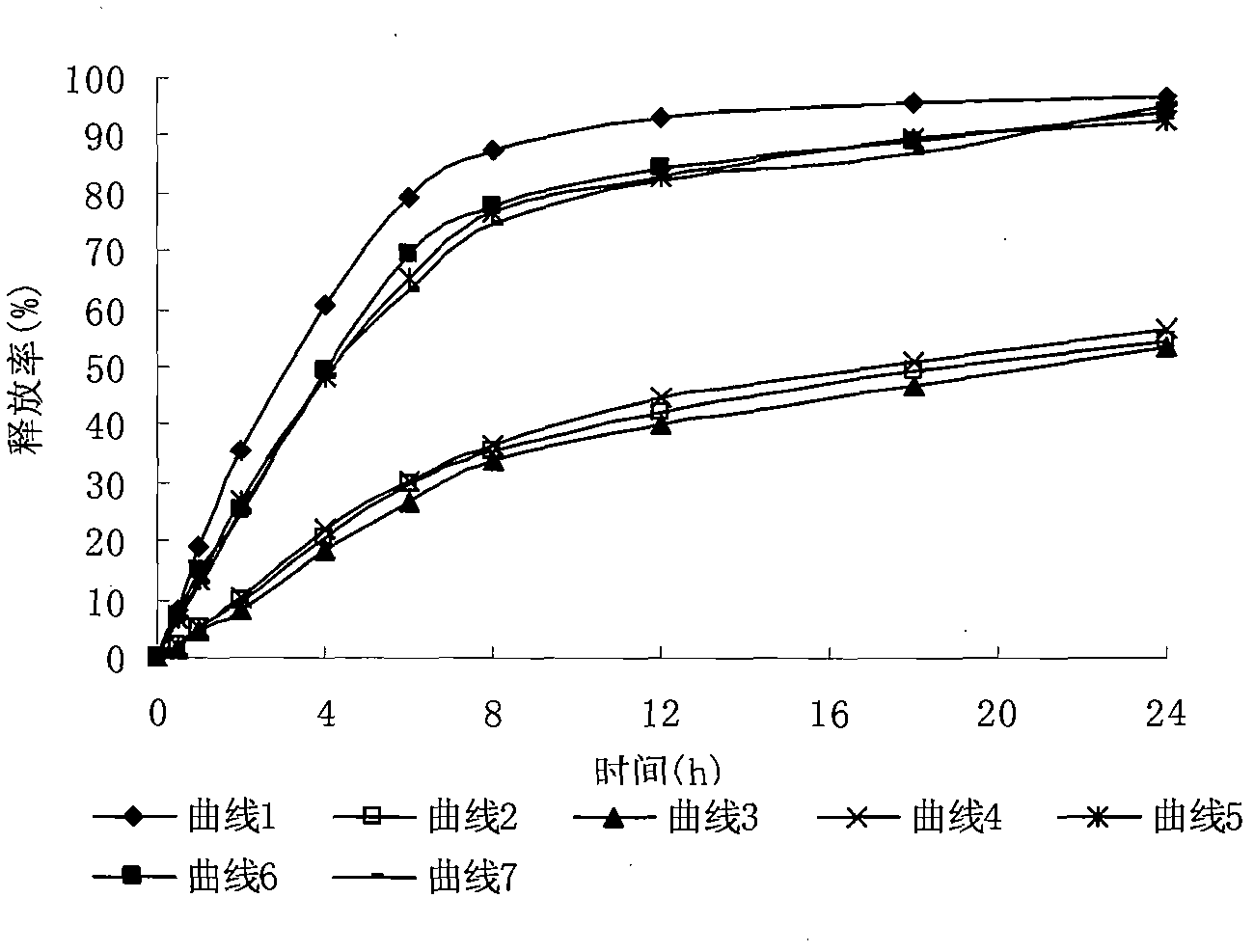

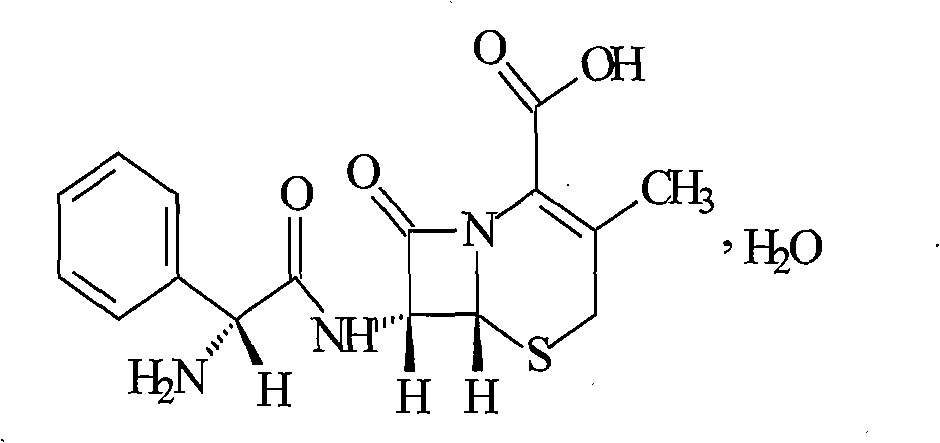

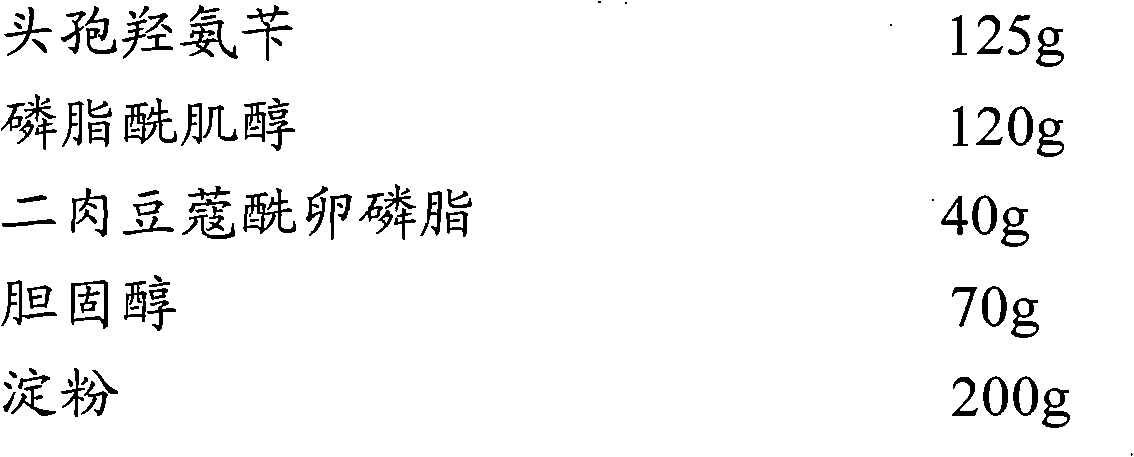

Cefadroxil liposome solid preparation

InactiveCN102327221ALow costHigh encapsulation efficiencyAntibacterial agentsOrganic active ingredientsSide effectMedicine

The invention provides a cefadroxil liposome solid preparation. The cefadroxil liposome solid preparation consists of the following components in part by weight: 125 parts of cefadroxil, 90 to 120 parts of phosphatidylinositol, 30 to 40 parts of dimyristoyl phosphatidylcholine, 50 to 70 parts of cholesterol and 300 to 500 parts of other auxiliary materials which are used commonly and pharmaceutically. The liposome solid preparation is high in entrapment rate, and has uniform grain sizes, and medicines can be kept for a long time in blood circulation; and the quality of the preparation products is improved, the toxic and side effects are reduced, the equipment of a preparation method is simple and is easy to operate, and the cefadroxil liposome solid preparation is suitable for large-scaleindustrial production.

Owner:HAINAN MEIDA PHARMA

Industrial method for continuously extracting high-content marigold flavone

ActiveCN112999252AOptimizing Compression Ratio of Ring Die in GranulatorFully extractedAntipyreticAnalgesicsPhysical chemistryProcess engineering

The invention discloses an industrial method for continuously extracting high-content marigold flavone, wherein the method comprises the following steps: 1) granulating a marigold flower raw material according to a granulator circular mold compression ratio of 1:(1.2-2.2); 2) extracting the marigold flower particles by using 70%-100% acetone as an extracting agent, and filtering to obtain an extracting solution; and 3) down-regulating the volume fraction of acetone to 0-30%, filtering to obtain a filter cake, and drying the filter cake to obtain a marigold flavone product. The method is simple, high in continuity and operability, high in productivity, low in energy consumption and suitable for industrial production.

Owner:CHENGUANG BIOTECH GRP CO LTD

Formula of acrylic lacquer

The invention provides a formula of an acrylic lacquer. The acrylic lacquer comprises the following components in percentage by mass: 55-65% of 801 resin, 25-35% of 582-2 resin, 3-5% of butanol, 2-3% of xylene, 2-4% of cyclohexanone, 0.20-0.40% of 358 auxiliaries and 0.03-0.07% of 331 auxiliaries. According to the invention, acrylic resin is used as the raw material for preparing the lacquer; and the prepared acrylic lacquer can be dried at normal temperature and is favorable in weather, light, heat and mildew resistance and adhesive force, suitable for being sprayed on the surface of an aluminum alloy subjected to anodic oxidation treatment and being used as a sealing agent in wood coating, firm and bright in paint film, capable of being insulated, rapid in drying, better in adhesive force, simple in production process, lower in raw material cost and capable of meeting the requirement of large-scale industrial production.

Owner:DANYANG YONGSHENG PAINT

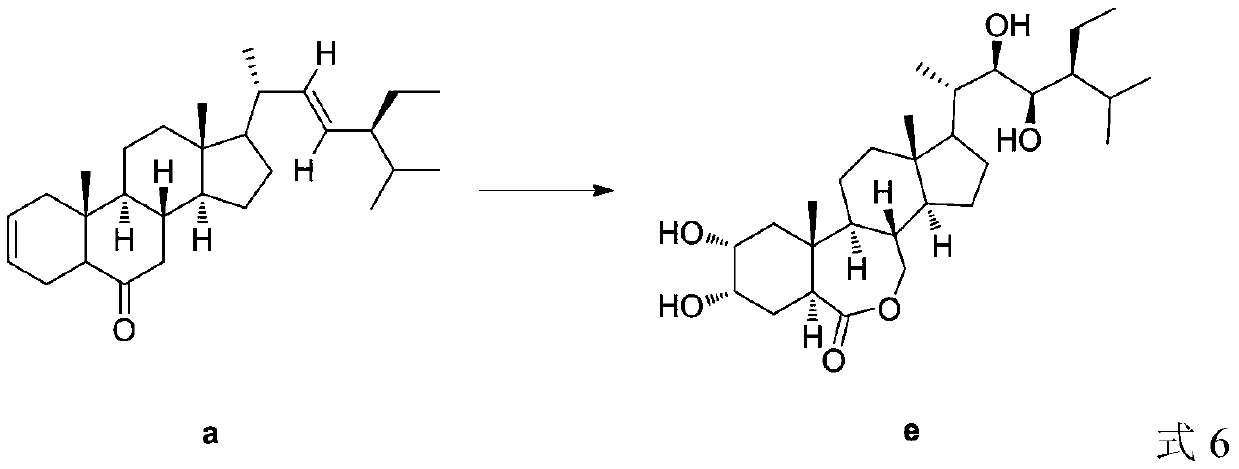

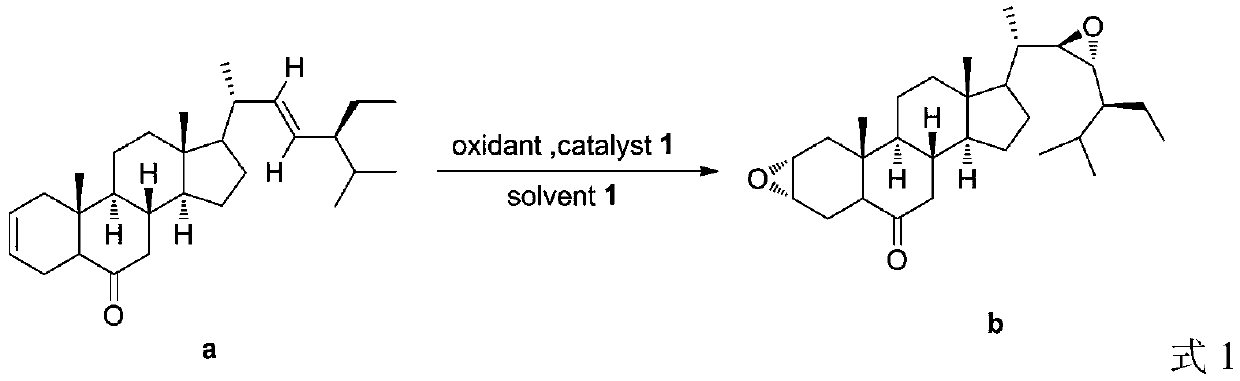

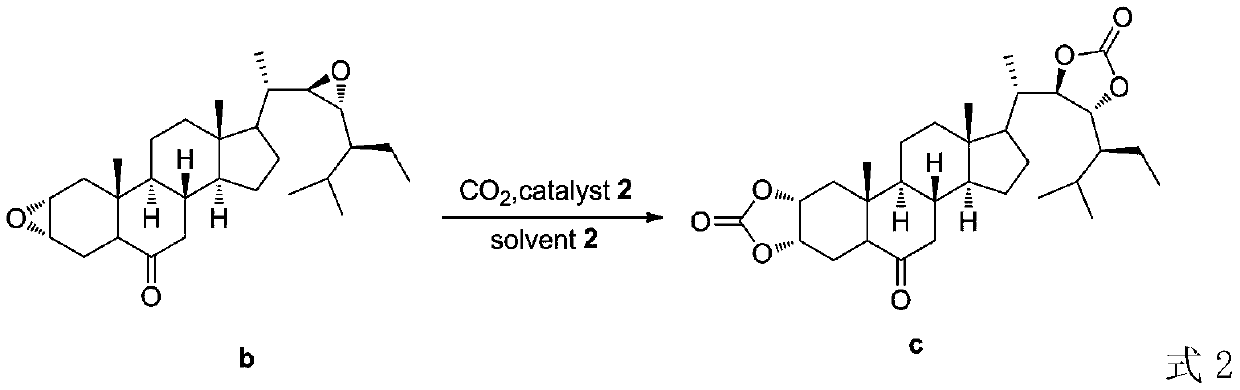

A kind of preparation method of 28-homobrasinolide

Owner:郑州万牛生物技术有限公司

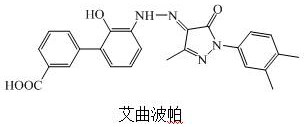

Preparation method of eltrombopag

PendingCN114507186AThe reaction route is simpleEasy to operateOrganic chemistryAcetic acidCombinatorial chemistry

The invention discloses a preparation method of eltrombopag. The preparation method comprises the following steps: 1, sequentially and continuously reacting a starting material I, glacial acetic acid and hydrobromic acid to obtain an intermediate I; 2, reducing the intermediate I through ammonium formate under the catalytic action of palladium to obtain an intermediate II; and 3, carrying out diazotization addition on the intermediate II to obtain eltrombopag. According to the method, on the premise of ensuring the medicine quality, direct reduction of nitryl by hydrogen is avoided, so that safe production amplification can be realized. Meanwhile, on the basis that the single maximum impurity of eltrombopag is controlled not to exceed 0.1% and the total impurity is controlled not to exceed 1.0%, the reaction can be completed more quickly, the time of the preparation process can be further shortened, the preparation speed of eltrombopag is increased, and the market competitiveness of the eltrombopag is enhanced.

Owner:TIANJIN LISHENG PHARM CO LTD

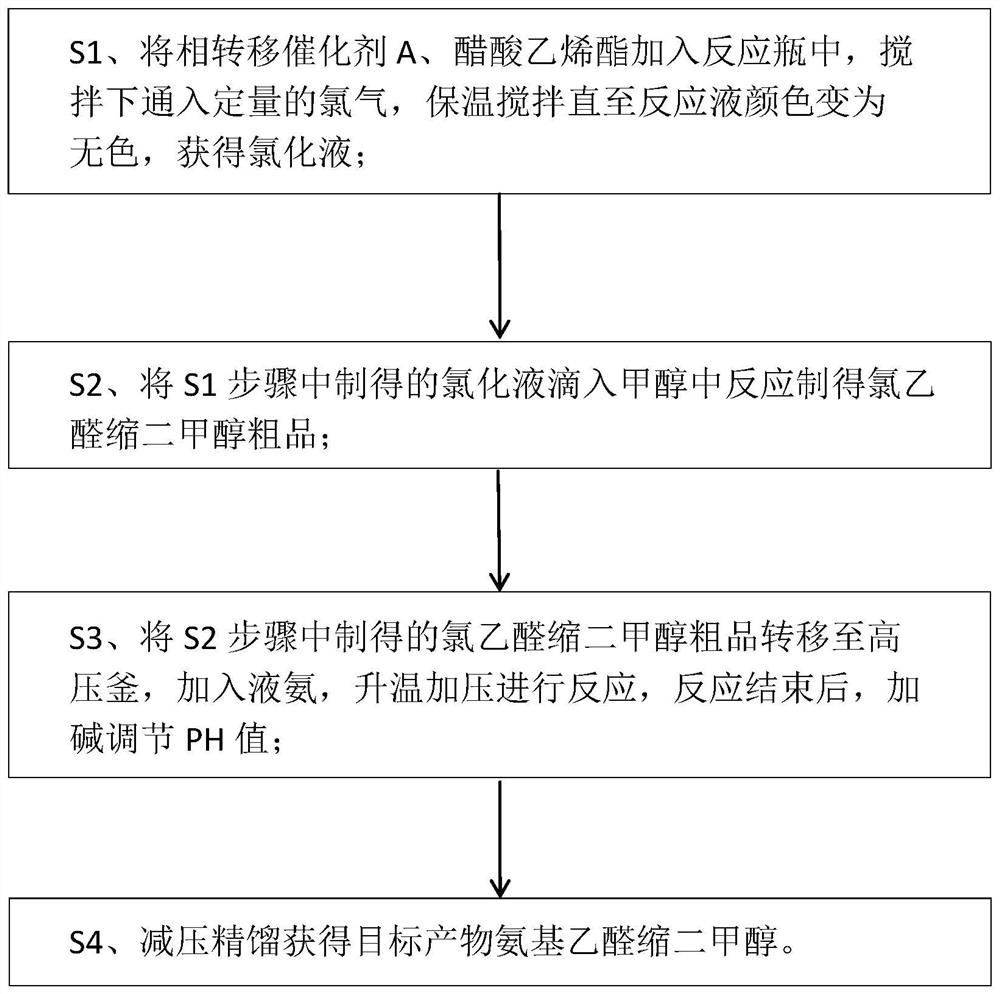

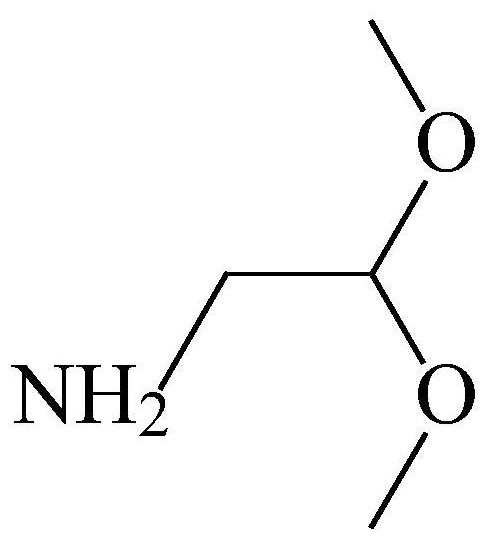

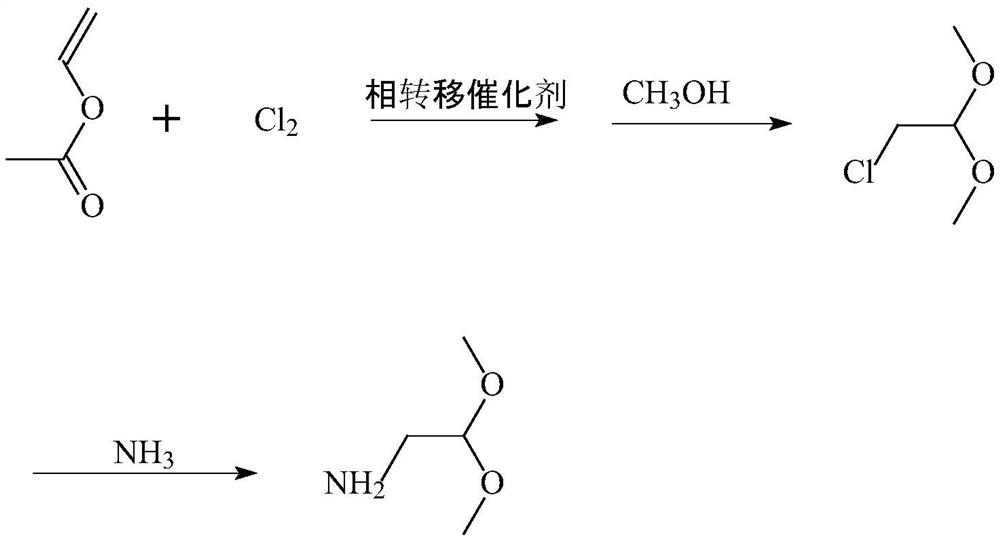

Method for preparing aminoacetaldehyde dimethyl acetal

ActiveCN111875510AHigh purityReduce generationOrganic compound preparationAmino-hyroxy compound preparationPtru catalystDimethyl acetal

The invention discloses a method for preparing aminoacetaldehyde dimethyl acetal, which comprises the following steps: S1, adding a phase transfer catalyst A and vinyl acetate into a reaction flask, introducing a certain amount of chlorine while stirring, and performing heat-insulation stirring until the color of the reaction solution becomes colorless to obtain a chlorination solution; S2, dropwise adding the chlorination liquid prepared in the step S1 into methanol for reaction to prepare a chloroacetaldehyde dimethyl acetal crude product; S3, transferring the chloroacetaldehyde dimethyl acetal crude product prepared in the step S2 to an autoclave, introducing liquid ammonia, carrying out heating and pressurizing reaction, and after the reaction is finished, adding alkali to adjust the pH value; and S4, decompressing and rectifying the reaction product to obtain the target product, aminoacetaldehyde dimethyl acetal. By adopting the method, high-purity aminoacetaldehyde dimethyl acetal can be prepared, and the industrial production requirement of aminoacetaldehyde dimethyl acetal can be met.

Owner:厦门优孚利生物医药科技有限公司

Foot-and-mouth disease virus antigen dilution technology

InactiveCN1225283CReduce manufacturing costReduce production labor intensityAntiviralsViruses/bacteriophagesPhosphateDiluent

A technique for diluting the antigen of foot-and-mouth disease virus uses a diluent prepared from sodium chloride, disodium hydrogen phosphate, potassium chloride, potassium dihydrogen phosphate, magnesium sulfate, glucose and calcium chloride through proportional mixing and concentrating by 10 times. Before it is used, its pH value must be regulated to 7.6 by 7.5% NaHCO3. Its advantages are simple and reliable method and low cost.

Owner:LANZHOU INST OF VETERINARY SCI CHINESE ACAD OF AGRI SCI

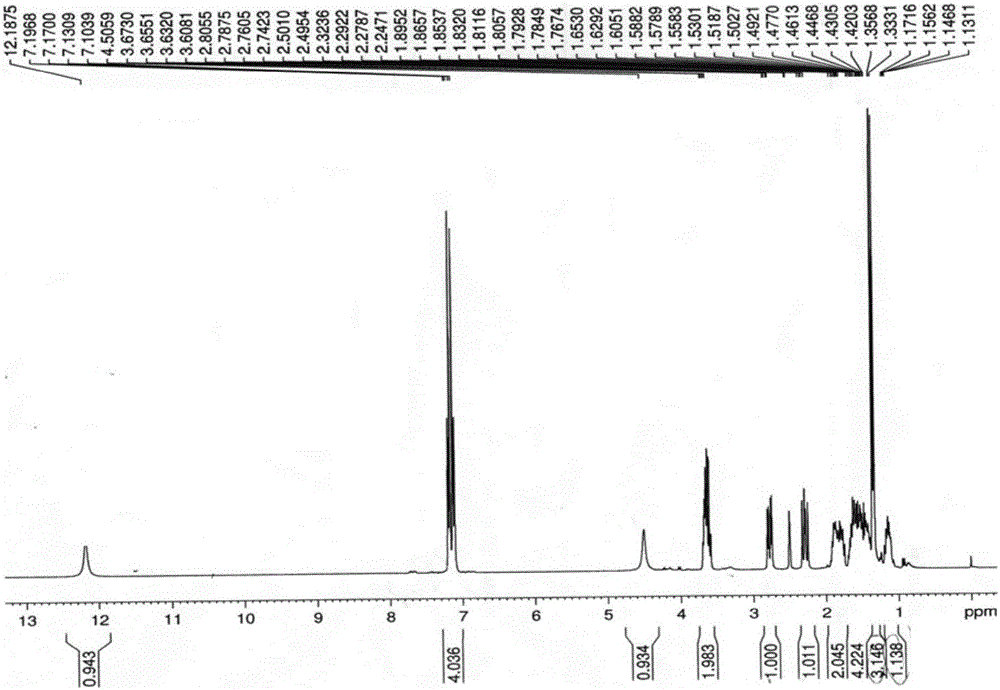

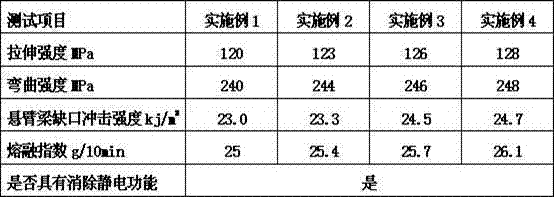

Preparation method of electroconductive polyamide-polyethylene blended alloy material

ActiveCN102746654BReduce process linksMeet the requirements of industrialized mass productionGlass fiberPolyamide

Belonging to the technical field of high polymer material preparation, the invention provides a preparation method of an electroconductive polyamide-polyethylene blended alloy material. The method comprises the steps of: firstly, putting 90-105 parts of nylon 66 resin, 31-38 parts of polyethylene resin, 0.9-1.9 parts of a coupling agent, 32-41 parts of a filling material and 9-14 parts of an electroconductive agent that are weighed by weight into a high-speed mixer for mixing them uniformly, then putting 0.4-0.9 part of an antioxidant, 40-51 parts of a glass fiber and 0.8-1.4 parts of a surface modifier that are weighed by weight into the high-speed mixer for further mixing so as to obtain a granulation material; and putting the granulation material into a twin-screw extruder for melt extrusion, and controlling the temperature of zone one of the screw extruder at 230DEG C, the temperatures of zone two and zone three at 240DEG C respectively, and the temperatures from zone four to zone eight all at 250DEG C, thus obtaining the electroconductive polyamide-polyethylene blended alloy material. The method of the invention has less technological links and can meet the requirements of industrialized mass production. The material prepared by the method of the invention has a good static electricity elimination function, thus being suitable for preparation of components of buildings, electrical appliances and automobiles.

Owner:苏州宇度医疗器械有限责任公司

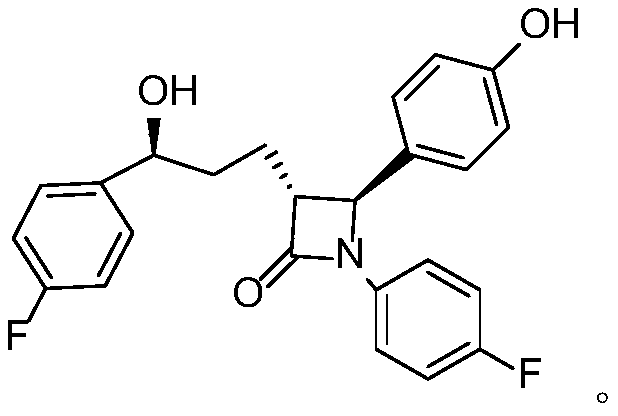

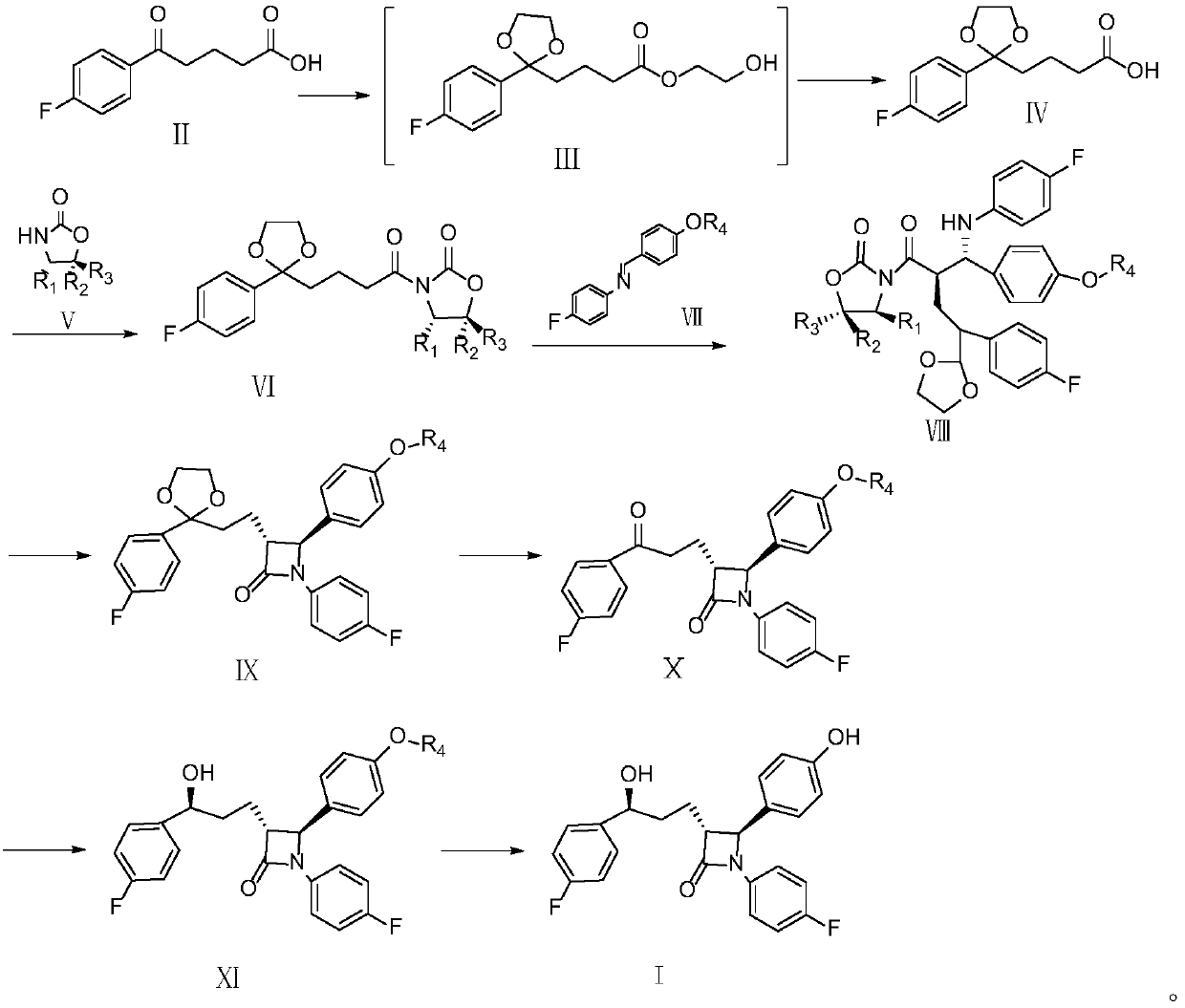

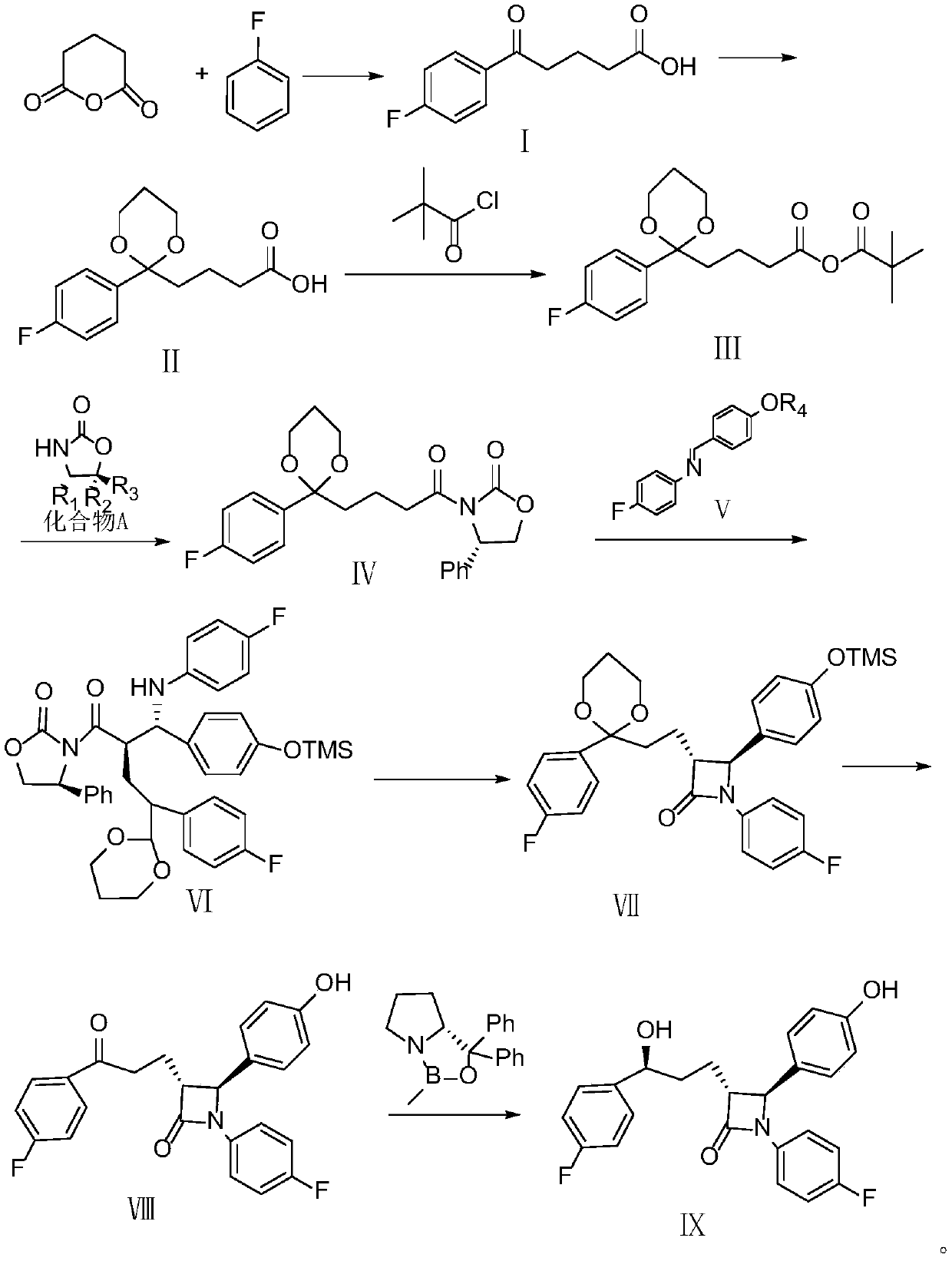

A kind of ezetimibe intermediate compound

ActiveCN107488164BLess impuritiesHigh purityOrganic chemistryBulk chemical productionButyrateCombinatorial chemistry

The invention provides a novel intermediate compound of ezetimibe and a preparation method thereof. The preparation method comprises a step of converting 4-(4-fluoro-benzoyl)-butyric acid into 4-[2-(4-fluoro-phenyl)-[1,3]dithiolan-2-yl]-butyric acid by using an unseparated intermediate compound. The method provided by the invention is simple in route, low in price and high in efficiency; and in order to better protect functional groups, the method employs the selectively removable protective group, so the method has the advantages of few impurities, high product purity and high product yield.

Owner:SHANDONG NEWTIME PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com