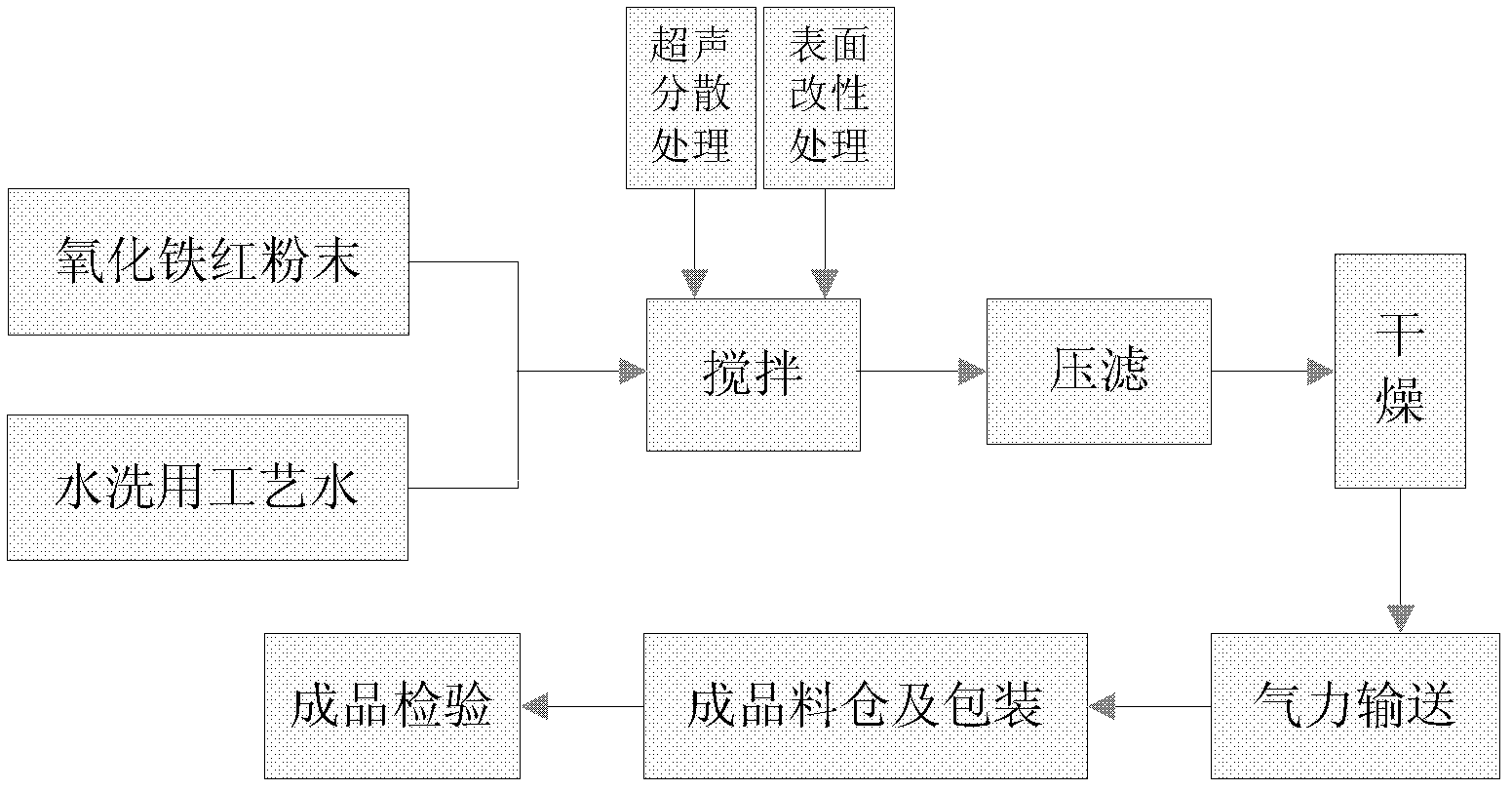

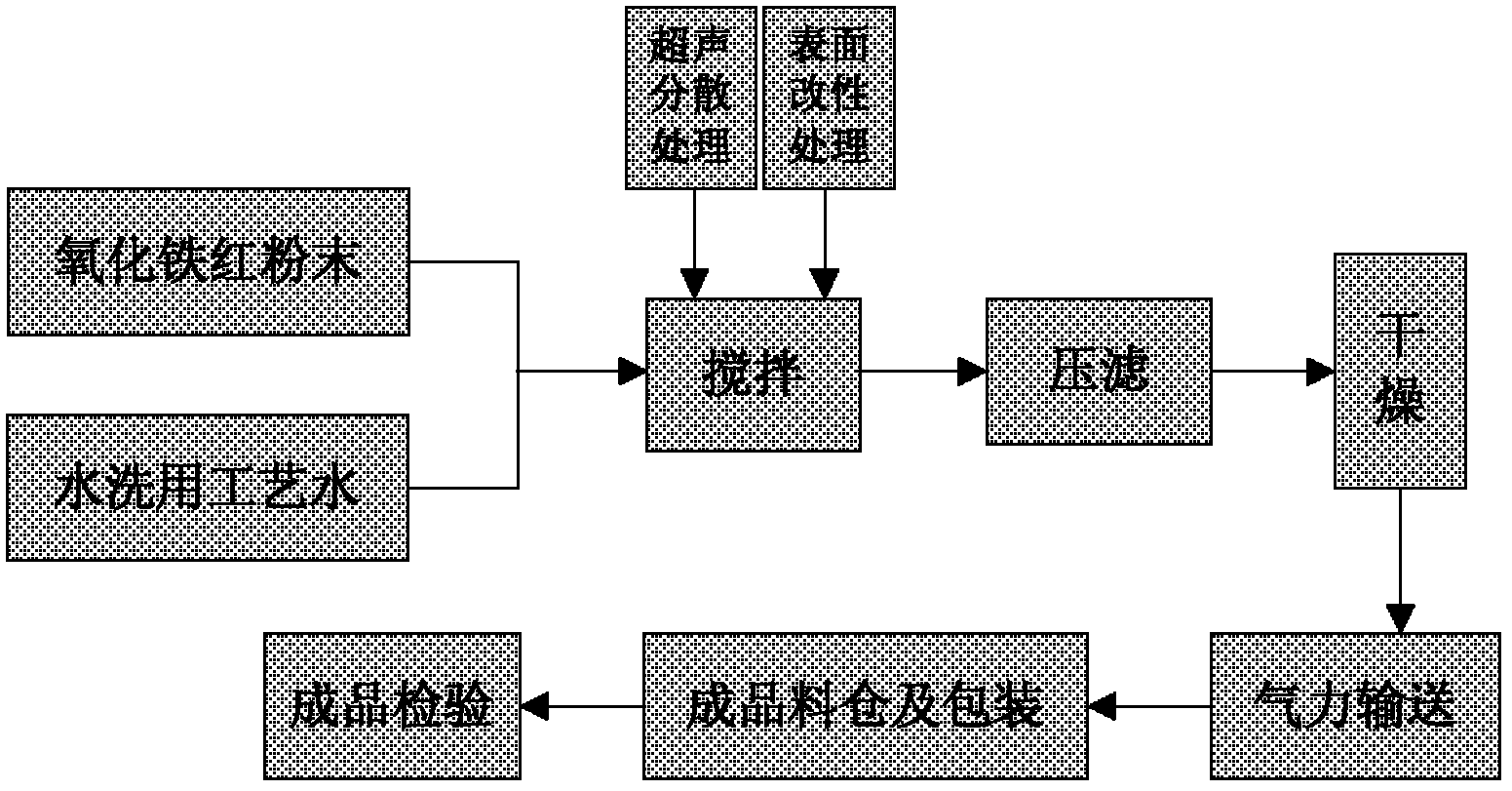

Post-treatment and purification process of iron oxide red for high-property soft magnetic ferrite

A technology of soft magnetic ferrite and iron oxide red, which is applied in the direction of iron oxide, iron oxide/iron hydroxide, etc., can solve the problems of poor product performance stability and consistency, complicated process procedures, and difficult control, etc., and achieve consistency Good, reduce resource and energy consumption, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

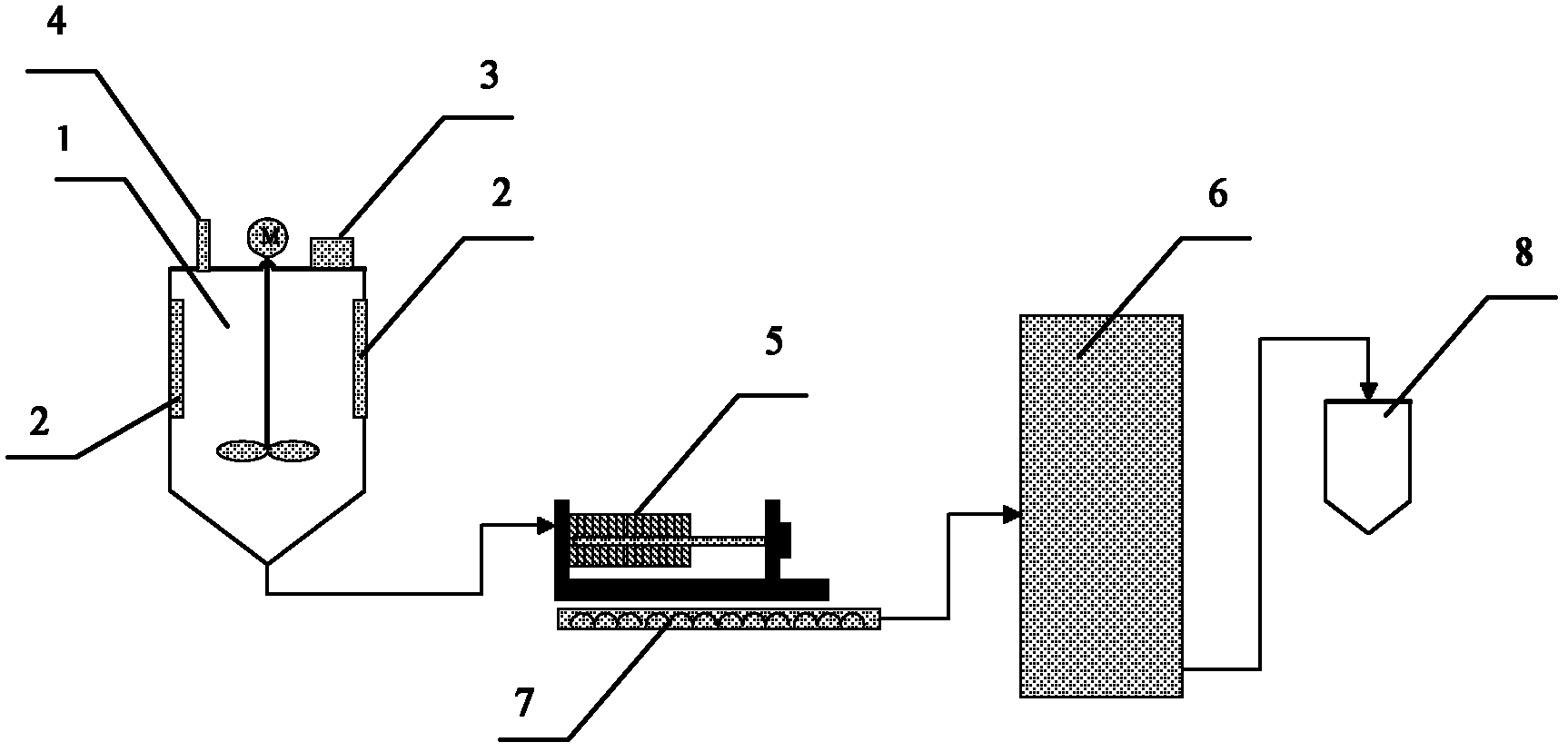

Method used

Image

Examples

Embodiment 1

[0029] (1) The iron oxide red powder produced by Ruthner method acid regeneration is directly put into the mixing tank, and then the process water with 5 times the mass of the iron oxide red powder is added to prepare the iron red water-based suspension.

[0030] (2) The process water is obtained by mixing desalted reclaimed water and production water, with a conductivity of 60μs·cm -1 , the iron red water-based suspension was stirred and washed with water for 1 hour.

[0031] (3) Turn on the ultrasonic generator intermittently during the stirring process, the ultrasonic treatment time is 2 minutes / time, and the interval time is 3 minutes.

[0032] (4) A surface modifier is added during the stirring process, and the dosage is 0.01% of the mass of the iron oxide red powder.

[0033] (5) carry out press filter dehydration treatment through the stirred iron red water-based suspension, control the water content of filter cake to be less than 35%;

[0034] (6) The dehydrated filt...

Embodiment 2

[0038] (1) The iron oxide red powder produced by Ruthner method acid regeneration is directly put into the mixing tank, and then the process water with 8 times the mass of the iron oxide red powder is added to prepare the iron red water-based suspension.

[0039] (2) The process water is obtained by mixing desalted reclaimed water and production water, with a conductivity of 300μs·cm -1 , the iron red water-based suspension was stirred and washed with water for 3 hours.

[0040] (3) Turn on the ultrasonic generator intermittently during the stirring process, the ultrasonic treatment time is 5 minutes / time, and the interval time is 10 minutes.

[0041] (4) adding a surface modifier during the stirring process, the consumption is 0.1% of the mass of iron oxide red powder;

[0042] (5) carry out press filter dehydration treatment through the stirred iron red water-based suspension, control the water content of filter cake to be less than 35%;

[0043] (6) The dehydrated filter ...

Embodiment 3

[0047] (1) The iron oxide red powder produced by Ruthner method acid regeneration is directly put into the mixing tank, and then 10 times the process water of the iron oxide red powder mass is added to prepare the iron red water-based suspension.

[0048] (2) The process water is obtained by mixing desalted reclaimed water and production water, with a conductivity of 600μs·cm -1 , the iron red water-based suspension was stirred and washed with water for 5 hours.

[0049] (3) Turn on the ultrasonic generator intermittently during the stirring process, the ultrasonic treatment time is 10 minutes / time, and the interval time is 10 minutes.

[0050] (4) adding a surface modifier in the stirring process, the consumption is 1% of the mass of iron oxide red powder;

[0051] (5) carry out press filter dehydration treatment through the stirred iron red water-based suspension, control the water content of filter cake to be less than 35%;

[0052] (6) The filter cake after dehydration e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com