Method for extracting sucralose-6-ethyl ester from tar

A technology for sucralose and tar, which is applied in chemical instruments and methods, sugar derivatives, sugar derivatives, etc., to achieve the effects of simple and feasible process, cheap and easy-to-obtain raw materials, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

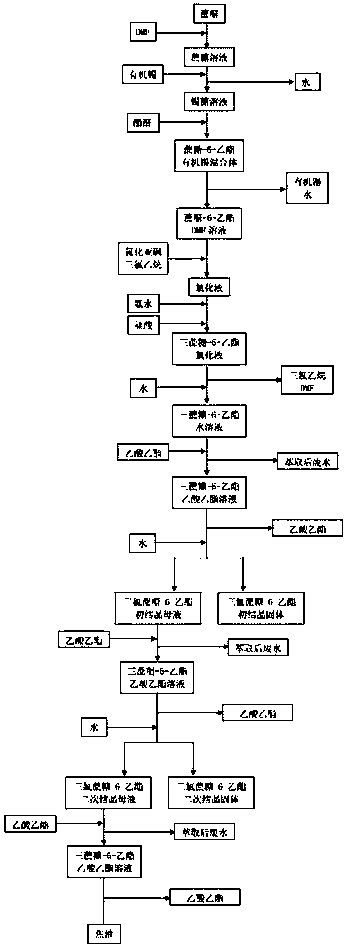

Method used

Image

Examples

Embodiment 1

[0064] S1 gel breaking

[0065] Add 1005.00g tar (sucralose content 12.52g / L, sucralose-6-ethyl ester content 92.48g / L) into a 2000mL four-neck flask, start stirring, and slowly add 33.17g calcium hydroxide powder below room temperature ( Analytical pure), feed liquid pH=9.

[0066] After reacting for 12.5 hours, sampling analysis showed that the content of sucralose was 23.49g / L, and the content of sucralose-6-ethyl ester became 166.55g / L.

[0067] Continue to slowly add 19.78g of calcium hydroxide powder, the pH value of the feed liquid becomes 13, after stirring for 1 hour, add hydrochloric acid dropwise to adjust the pH value of the feed liquid to 7, sampling analysis shows that the content of sucralose is 12.71g / L, sucralose-6- The ethyl ester content became 8.61 g / L. Excessive pH caused the decomposition of sucralose-6-ethyl ester and the experiment failed.

Embodiment 2

[0069] S1 gel breaking

[0070] Add 1501.50g tar (sucralose content 21.04g / L, sucralose-6-ethyl ester content 101.64g / L) into a 2000mL four-neck flask, start stirring, and slowly add 50.50g calcium hydroxide powder below room temperature ( Analytical pure), pH=9, the material liquid is dark brown. After reacting for 24 hours, hydrochloric acid was added dropwise to adjust the pH value of the feed solution to 6.

[0071] Sampling and analysis showed that the content of sucralose was 30.23g / L, and the content of sucralose-6-ethyl ester was 153.89g / L.

[0072] S2 Hydrating Ester

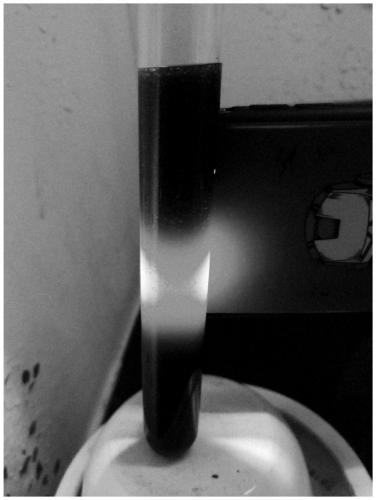

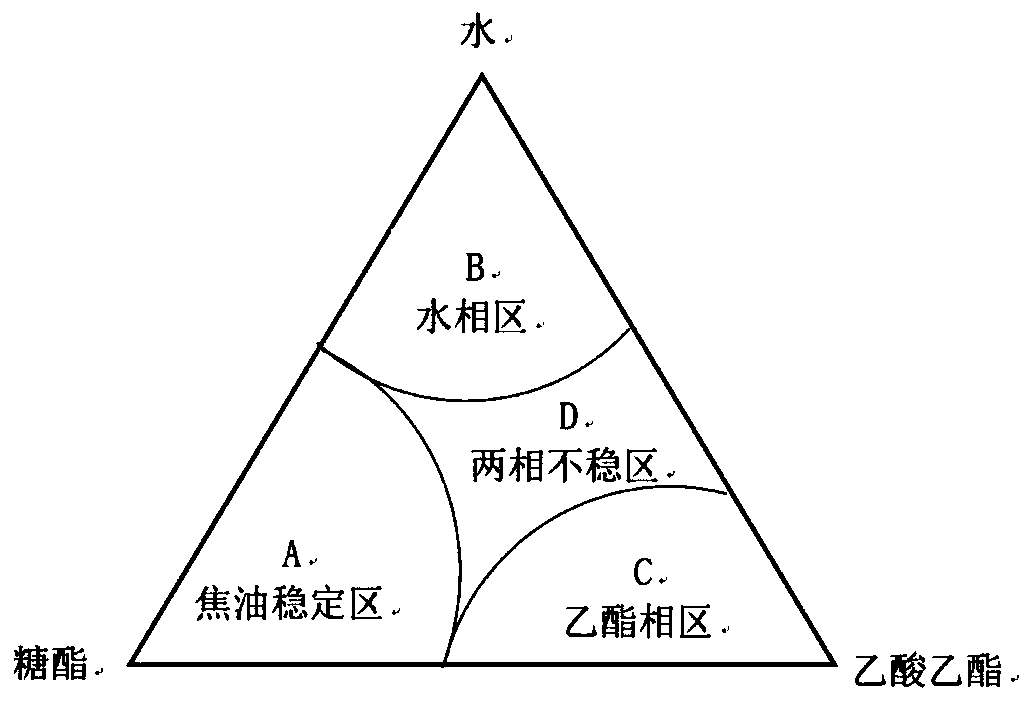

[0073] Transfer the feed liquid after the gel breaking reaction into a 5000mL pear-shaped separatory funnel, add 800g tap water and 800g ethyl acetate, oscillate and let stand to separate layers.

[0074] The lower layer is the ethyl acetate layer, which is the heavy ester phase (ethyl acetate dissolves sugars and has a high density, so it is in the lower layer). The upper layer is the water layer, ...

Embodiment 3

[0086] S1 gel breaking

[0087] Add 1503.0g tar (sucralose content 17.69g / L, sucralose-6-ethyl ester content 109.70g / L) into a 2000mL four-necked flask, start stirring, and slowly add 56.78g ammonia water (analytical pure) below room temperature , pH=9, the feed liquid is dark brown. After reacting for 24 hours, hydrochloric acid was added dropwise to adjust the pH value of the feed solution to 7.

[0088] Sampling and analysis showed that the content of sucralose was 20.14g / L, and the content of sucralose-6-ethyl ester was 138.36g / L.

[0089] S2 Hydrating Ester

[0090] Transfer the material liquid after the gel breaking reaction of S1 into a 5000mL pear-shaped separatory funnel, add 1000g tap water and 1500g ethyl acetate, oscillate evenly and let stand to separate layers.

[0091] The lower layer is the ethyl acetate layer, which is the heavy ester phase (ethyl acetate dissolves sugars and has a relatively high density, so it is in the lower layer). The upper layer is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com